Page 1

ANDERSON GREENWOOD M4TL LIQUID LEVEL MANIFOLDS

A single-flanged, two-valve manifold consisting of two block valves with no

equalizer passage suitable for pressures up to 6000 psig (414 barg)

GENERAL APPLICATION

The manifold is designed for direct mounting to

P-style differential pressure transmitters in

liquid level service on pressurized vessels.

TECHNICAL DATA

Materials: CS, SS, Hastelloy

Seats: Metal or soft

Connections: ½” NPT

Pressure (max.): 6000 psig (414 barg)

Temperature (max.): 1000°F (538°C)

FEATURES

• Cost savings of 20-30% when manifolding

instruments by eliminating several parts used

in conventional methods of ‘piping up’.

• Compact design requires minimum space for

operation and installation.

• Free-swivelling ball end stems ensure

bubble-tight valve closure without seat

galling.

• Easy instrument removal due to direct bolting

to the manifold. Signal lines, purge lines,

etc. are left undisturbed, facilitating repairs,

service and calibration.

• Immediate installation with AGCO Mount as

the manifold, steam block, bracket and all

associated piping can be installed without the

instrument at the time of plant construction.

• Secure mounting ensured by the AGCO

Mount. Instrument piping stability is

enhanced when supported directly by the pipe

stand through the manifold.

• All packing is below stem threads,

body-to-bonnet seal is below the threads

minimizing process fluid corrosion.

• Reduced chance of instrument damage.

With the AGCO Mount, the instrument can be

warehoused safely until final ‘loop’ checkout.

www.valves.emerson.com © 2017 Emerson. All rights reserved.

VCTDS-01139-EN 16/02

Page 2

ANDERSON GREENWOOD M4TL LIQUID LEVEL MANIFOLDS

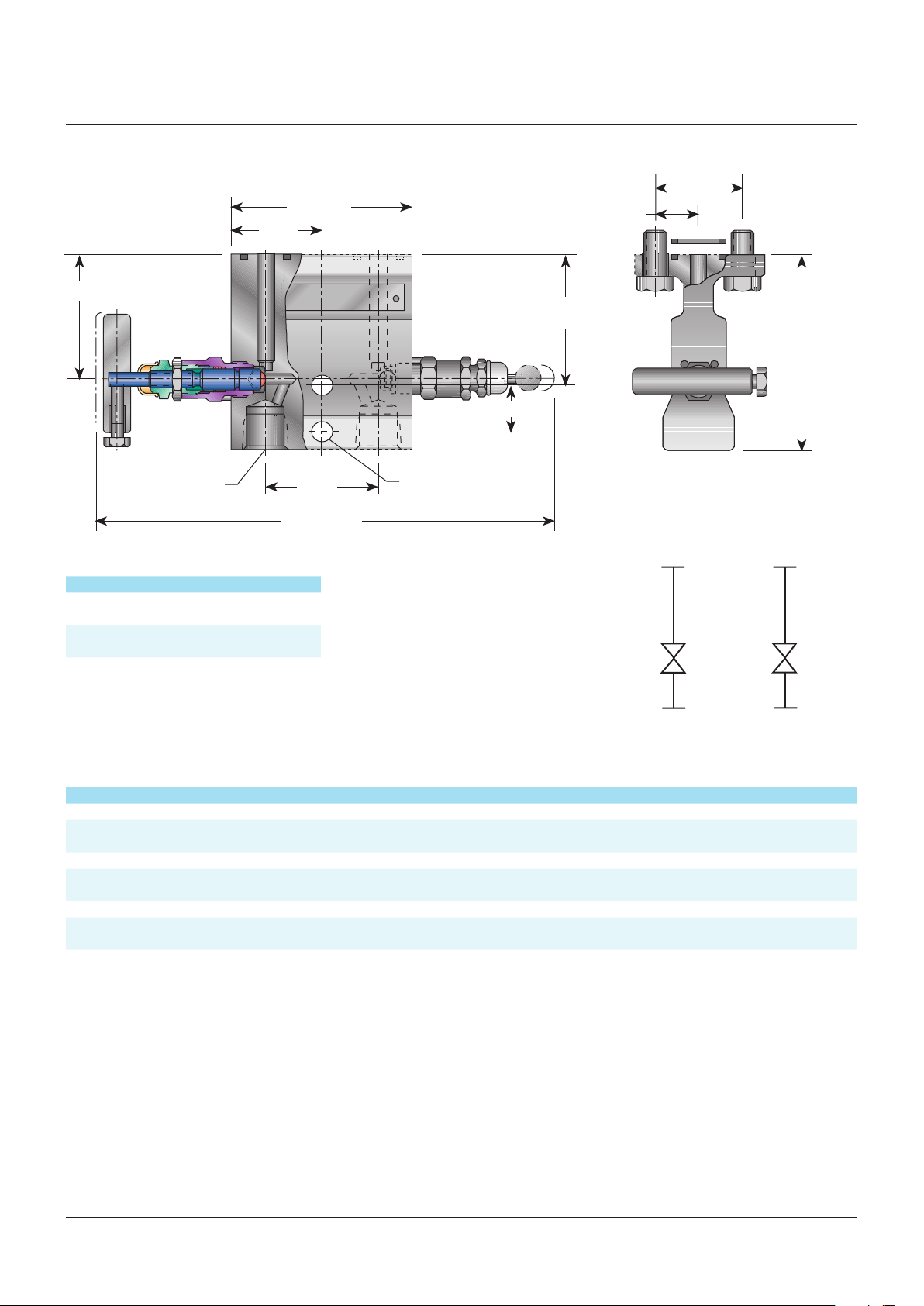

METAL SEAT (SOFT SEAT AVAILABLE) DIMENSIONS, INCHES (mm)

3.40 [86.4]

1.70

[43.2]

2.38 [60.5]

0.94 [23.9]

2.41

[61.2]

1.62

[41.1]

0.81 [20.6]

Instrument side

3.70

[94.0]

½ - 14 NPT

process connection

2 places

DIMENSIONS, INCHES (mm)

Packing A

PTFE 8.60

(218.4)

(251.5)

GRAFOIL

®

9.90

2.12

[53.8]

A Max. open

Ø 0.38 (9.6)

Mounting holes

2 places

Instrument

Block/

isolate

Process

STANDARD MATERIALS

Valve Packing Body Bonnet Stem Ball Bolts

[2]

CS

[2]

CS

SS PTFE A479-316 A479- 316 A276-316 316 A193-B7

SS GRAFOIL®/ A479-316 A479- 316 A276-316 316 A193-B7

[3]

SG

[3]

SG

[4]

SG3

PTFE A576 10L18 A108 A581-303 17-4 PH A193-B7

GRAFOIL®/ A576 10L18 A105 A581-303 17-4 PH A193-B7

Low emissions graphite

Low emissions graphite

PTFE A479-316 Monel® 400 Monel® K500 A193-B7 PTFE

GRAFOIL®/ A479-316 A479-316 Monel® 400 Monel® K500 A193-B7

Low emissions graphite

PTFE Hastelloy® C-276 Hastelloy® C-276 Hastelloy® C-276 Elgiloy

®

A193-B7

Block/

isolate

NOTES

1. Approximate valve weight: 5.0lb (2.3kg).

Metal seat: 0.156-inch (4.0mm) diameter orifice.

Valve Cv0.36 maximum.

Soft seat: 0.187-inch (4.8mm) diameter orifice.

Valve Cv0.83 maximum.

2. CS is zinc chromate plated to prevent corrosion.

3. SG (Sour Gas) meets the requirements of NACE MR0175/ISO 15156 (for chloride conditions ≤ 50 mg/l (ppm)) and NACE MR0103-2005.

4.

SG3 (Sour Gas) meets the requirements of NACE MR0175/ISO 15156 (for chloride conditions > 50 mg/l (ppm)).

5. 316 SS bolts lower pressure ratings to a maximum of 4500 psig (310 barg). Consult factory for full ratings.

2

Page 3

ANDERSON GREENWOOD M4TL LIQUID LEVEL MANIFOLDS

BONNET ASSEMBLY OPTIONS

The 4TL has metal seats as standard with the

option of soft seated designs.

All stem threads are rolled and lubricated to

prevent galling and reduce operating torque.

The stem seal is a patented PTFE packing

gland which is adjustable in service. All bonnets

are assembled with a bonnet locking pin to

prevent accidental removal while in service

and a protective dust cap is fitted to contain

stem lubricant and prevent the influx of

contaminants.

Metal-seated bonnet assemblies

The metal-seated bonnet assemblies have a

rotating stem with free swivel ball-type seat for

long service life. The specially hardened ball

seat is ideal for both gas and liquid service.

Soft-seated bonnet assemblies

The soft-seated bonnet assemblies have a

one-piece rotating stem and plug. In addition to

the adjustable PTFE packing gland, the bonnets

are available with a FKM O-ring and PTFE

back-up ring.

PRESSURE AND TEMPERATURE RATINGS

Valve Packing Ratings

[1]

CS

[1]

CS

SS PTFE 6000psig at 200°F (414barg at 93°C)

SS GRAFOIL

[2]

SG

, SG3

[2]

SG

), SG3

NOTES

1. CS is zinc chromate plated to prevent corrosion.

2. SG (Sour Gas) meets the requirements of NACE MR0175/ISO 15156 (for chloride conditions ≤ 50 mg/l (ppm))

and NACE MR0103-2005.

3.

SG3 (Sour Gas) meets the requirements of NACE MR0175/ISO 15156 (for chloride conditions > 50 mg/l (ppm)).

4. 316 SS bolts lower pressure ratings to a maximum of 4500 psig (310 barg). Consult factory for full ratings.

5. Minimum temperature: -70°F (-57°C).

PTFE 6000psig at 200°F (414barg at 93°C)

4000psig at 500°F (276barg at 260°C)

GRAFOIL®/ 6000psig at 200°F (414barg at 93°C)

Low emissions graphite 4000psig at 600°F (276barg at 316°C)

®

/ 6000psig at 200°F (414barg at 93°C)

Low emissions graphite 1500psig at 1000°F (103barg at 538°C)

[3]

PTFE 6000psig at 200°F (414barg at 93°C)

[3]

GRAFOIL®/ 6000psig at 200°F (414barg at 93°C)

Low emissions graphite 1500psig at 1000°F (103barg at 538°C)

4000psig at 500°F (276barg at 260°C)

4000psig at 500°F (276barg at 260°C)

PRESSURE VS. TEMPERATURE

M4TLHIS-4

6000

[414]

5000

[345]

4000

[276]

M4TLEIS-4

M4TLHIC-4

M4TLEIC-4

M4TLVIC-4

M4TLVIS-4

Denotes

intersecting

data

3000

Pressure psig (barg)

[207]

2000

[138]

1500

[103]

1000

[69]

0

0

[-18]

100

[38]

200

[93]

300

[149]

400

500

[260]

600

[316]

[204]

Temperature °F (°C)

700

[371]

800

[427]

900

[482]

1000

[538]

3

Page 4

ANDERSON GREENWOOD M4TL LIQUID LEVEL MANIFOLDS

AGCO MOUNT KITS

Flow

5.0

[126.0]

4.5

[114.0]

[76.0]

AGCO Mount kits are available for all manifolds

where they apply. See AM option for each

manifold.

AGCO MOUNT KITS FOR LIQUID LEVEL MANIFOLD

Manifold style Description Material

M4TL Standard kit CS, zinc chromate plated

For bottom test ports

With steam block

M4TL Standard kit SS

For bottom test ports

With CS steam block

3.0

4

Page 5

ANDERSON GREENWOOD M4TL LIQUID LEVEL MANIFOLDS

SELECTION GUIDE

Example: M4TL V I C - 4 - AM

Packing

V PTFE

H Grafoil

Seat material

I Integral (body material)

Body material

C CS, A576-10L18

S SS, A479-31

W 316L SS

J Hastelloy

Connections

4 Flange outlet x ½-inch FNPT (inlet)

Connection style

B Female socket weld

Options

AM AGCO mount

AMMS AGCO mount kit -multi mount-stainless

AMV AGCO mount kit (vertical)

AMVS AGCO mount kit (vertical stainless steel)

AMW AGCO mount kit (wall mounting)

BL Bonnet lock device

CL00 Chlorine cleaning (CL)

HD Hydrostatic testing (100%) (MSS-SP-61)

OC00 Oxygen clean (OC)

PMI00 PMI body only

PT Top purge port ¼"

R3V Add for use with Rosemount model 305C (SS 18-8 Bolts)

SB Steam block

SG (Sour Gas) NACE edition 2003 /MR0103

SG3 (Sour Gas) NACE MR0175/ISO 15156-3 (latest edition)

SS All 316 SS construction

SSB 316 SS flange bolt (B8M Class 2) - will provide full pressure rating

SSC 316 flange bolt (B8M) - maximum pressure rating 4500 psi [310 barg]

SSD 696 material bolt

T Large diameter gasket groove

TB Bottom test port ¼"

TF Top test ports ¼" FNPT

XP ASME B31.1 (with Grafoil bonnets only)

OR O-ring gasket

®

®

NOTE

1. 316 SS bolts lower pressure ratings to a maximum of 4500 psig (310 barg). Consult factory for full ratings.

5

Page 6

© 2017 Emerson. All rights reserved.

6

Loading...

Loading...