Page 1

ANDERSON GREENWOOD SERIES 95 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

Before installation these instructions must be fully read and understood

The safety of lives and property often depends

on the proper operation of the pressure relief

valve. The valve must be maintained according to

appropriate instructions and must be periodically

tested and reconditioned to ensure correct function.

WARNING

Removal of the seal wires in an attempt to adjust

and/or repair this product by unauthorized or

unqualified persons voids the product warranty

and may cause damage to equipment and serious

injury or death to persons.

The product is a safety related component

intended for use in critical applications. The

improper application, installation or maintenance

of the product or the use of parts or components

not manufactured by Anderson Greenwood may

result in a failure of the product.

Any installation, maintenance, adjustment, test,

etc. performed on the Product must be done

in accordance with the requirements of all

applicable Anderson Greenwood Procedures and

Installation and Maintenance Instructions for

Anderson Greenwood Series 95 Pilot Operated

Safety Relief Valves (POSRV).

The intent of these instructions is to acquaint

the user with the storage, installation and

operation of this product. Please read these

instructions carefully before installation.

SAFETY PRECAUTIONS

When the pressure relief valve is under pressure

never place any part of your body near the pilot

exhaust nor the outlet of the main valve.

The main valve outlet should be piped or vented to

a safe location.

Always wear proper safety gear to protect head,

eyes, ears, etc. anytime you are near pressurized

valves.

Never attempt to remove the pressure relief valve

from a system that is pressurized.

Never make adjustments to or perform

maintenance on the pressure relief valve while

in service unless the valve is isolated from the

system pressure. If not properly isolated from the

system pressure, the pressure relief valve may

inadvertently open resulting in serious injury.

Remove the pressure relief valve prior to

performing any pressure testing of the system.

Instructions as well as applicable National and

International Codes and Standards.

STORAGE AND HANDLING

Pressure relief valve performance may be

adversely affected if the valve is stored for an

extended period without proper protection.

Rough handling and dirt may damage, deform,

or cause misalignment of valve parts and may

alter the pressure setting and adversely affect

valve performance and seat tightness. It is

recommended that the valve be stored in the

original shipping container in a warehouse

or as a minimum on a dry surface with a

protective covering until installation. Inlet and

outlet protectors should remain in place until

the valve is ready to be installed in the system.

Emerson.com/FinalControl

© 2017 Emerson. All rights reserved.

Engineering Doc. #05.9040.083 Rev. E

VCIOM-06026-US 14/12

Page 2

ANDERSON GREENWOOD SERIES 95 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

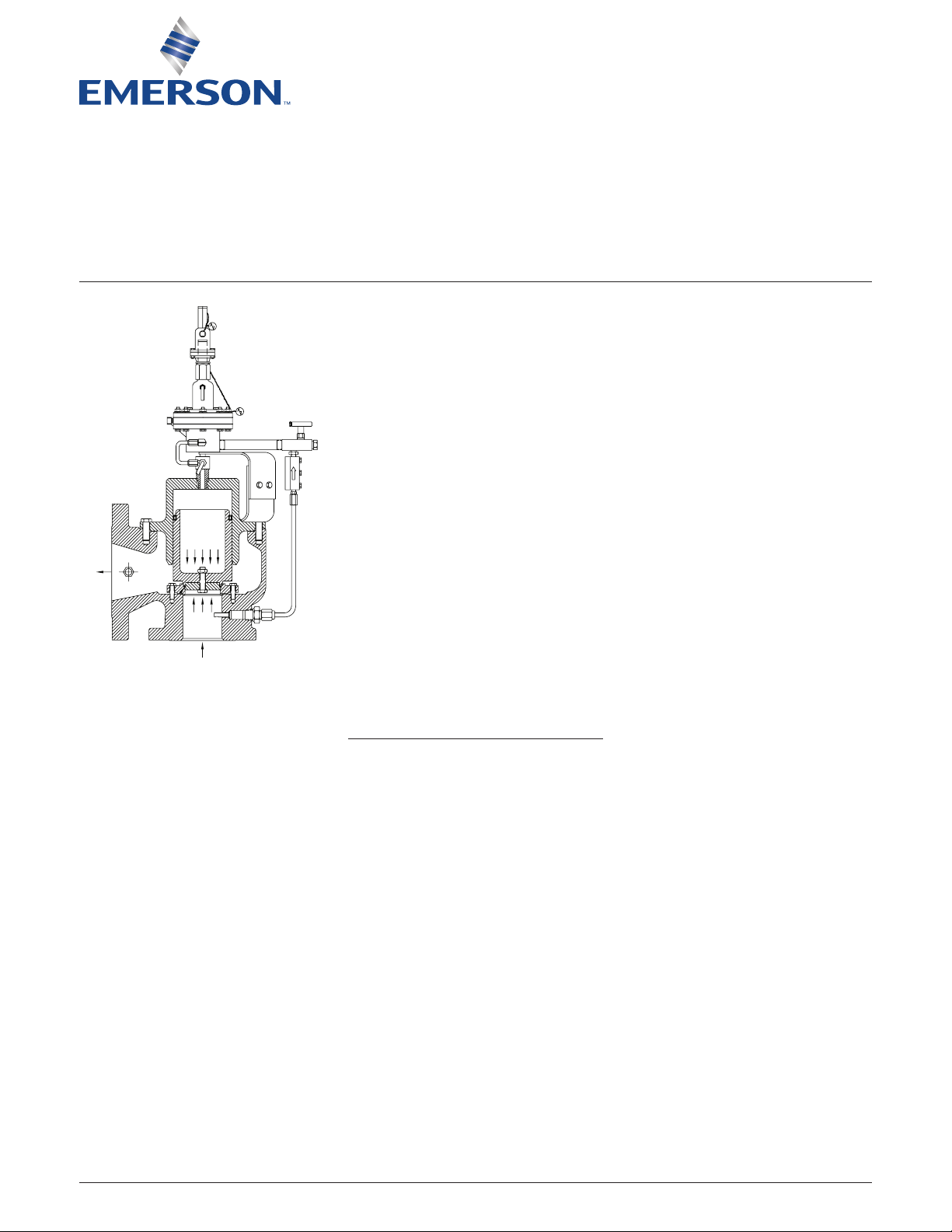

FIGURE 1

Pilot vent

Dome (top of the piston)

Pilot

Auxiliary setting device

Bonnet vent

Field test

Check

valve

1 GENERAL VALVE DESCRIPTION

Refer to Figure 1

The Anderson Greenwood Series 95 Valve

consists of a main valve and pilot. The main

valve has an unbalanced piston with O-ring

seat. Tank pressure is applied to the top of the

piston by means of the pilot. The area of the top

of the piston is larger than the bottom and the

valve remains closed.

When the tank pressure increases to the

set pressure of the pilot, the pilot opens and

vents the pressure from the top of the piston.

Theforce acting on the bottom of the piston is

now greater than that acting on the top and the

valve opens.

When the tank pressure decreases to the

closing pressure of the pilot, the pilot closes

and tank pressure is directed to the top of the

piston. The force acting on the top of the piston

is now greater than the force on the bottom and

the valve closes.

Outlet

O-ring seat

P (Tank)

P (Tank)

Inlet (tank pressure)

Tank pressure

sense line

Main valve

Unbalanced

piston

2

Page 3

ANDERSON GREENWOOD SERIES 95 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

FIGURE 2

Item Description

1 Auxiliary setting device

2 Supply tubing

3 Pilot exhaust tubing

4 Pilot bracket bolt

5 * Pilot

6 Pipe nipple

7 Field test hand valve

8 Field test plug

9 Connector

10 Check valve

11 Connector

12 Connector

13 Close tee

15 Check valve

16 Connector

17 Connector

18 Pipe plug

19 Body bolt

20 Lock washer

21 Upper body

22 * Diaphragm

23 * Washer

24 Spring pin

25 Lower body

26 Body

27 Spring

28 Ball

29 O-ring

[1]

30

Gasket

Auxiliary setter, with field test and backflow preventer

Indexed in order of disassembly

2 ACCESSORY MAINTENANCE

Refer to Figure 2

The accessories used on the Series 95 are

the auxiliary setter, field test and backflow

preventer. The field test and backflow preventer

are always used; the auxiliary setter is optional.

Only the backflow preventer, which consists of

[2]

one

diaphragm type check valve and a ball

check valve requires maintenance. Normal

maintenance is to clean the check valves and

replace the diaphragm, washer, gasket

[1]

and

O-ring.

When replacing the diaphragm, care should

be taken not to damage the diaphragm. To

assemble the diaphragm type valve, uniformly

tighten the body bolts, first one side, then the

opposite side. Do not overtighten the bolts as this

will distort the diaphragm and cause leakage.

NOTES

1. Gasket used on some check valves. If check valve

has gasket, use gasket supplied in repair kit otherwise discard kit gasket.

2. Some earlier model valves use two diaphragm

check valves and no ball check valve.

* Recommended spare parts for repairs

3

Page 4

ANDERSON GREENWOOD SERIES 95 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

FIGURE 3

Item Description

10 Lower bracket

20 Upper bracket

30 Bracket bolt

40 Washer

50 Hex nut

100 Body

110 Screw

140 Piston

150 Seat retainer

200 Washer (used on 6 x 8 only)

210 Cap/liner

420 Bolt

460 Nozzle

520 Nut

550 Washer

560 * Guide seal

610 * O-ring seat

620 * Cap gasket

630 * Nozzle gasket

640 * Washer

700 Cap bolt - hex

710 Cap bolt - eye

NOTES

1. Recommended spare parts for repairs

* Not shown - used on ≥ 4”

Refer to Section 8 for Soft goods repair kits part

numbers.

[1]

Indexed in order of disassembly

3 MAIN VALVE MAINTENANCE

Refer to Figure 3

Normal valve maintenance will be to only clean

the parts. It may also be necessary to replace

the seat. The piston seal should not need to be

replaced. If the piston seal is removed, a new

seal must be installed.

The piston can be removed from the cap/liner

by pulling the piston out or by pushing it out

with a rod through the hole in the top of the

cap/liner.

No lubricant is required on the piston seal.

A small amount of thread sealant should be

used on the pipe threads to prevent leakage.

PTFEtape is recommended.

The piston should be assembled to the cap/

liner and the two parts should then be

assembled to the valve body. The piston can

be prevented from sliding out of the cap/liner

during assembly by covering or plugging the

hole in the top of the cap/liner.

For marine service, the bolts in the main valve

and pilot exposed to the environment should

be replaced during routine maintenance every

five years.

4

Page 5

ANDERSON GREENWOOD SERIES 95 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

4 PILOT MAINTENANCE

Refer to Figure 4A

Anderson Greenwood recommends the pilot

be returned to the factory for repair or to be

repaired by a factory serviceman in the field.

Normal maintenance is to completely

disassemble the pilot and replace all the

diaphragms, seals and seat. To facilitate

assembly, place all parts removed in an

orderly arrangement so that the correct

parts are assembled in the proper sequence.

Nolubricants are required in the pilot. A small

amount of thread sealant should be used on the

pipe threads to prevent leakage. PTFE tape is

recommended.

Assembly is done in the reverse order of the

disassembly. The following items should be

observed when assembling the pilot:

• The round metal diaphragm is the sense

diaphragm. The clear PTFE diaphragm is the

boost diaphragm.

• The holes in the spindle diaphragm must be

aligned with all the holes in the body. The

small hole in the lower case must be aligned

with the hole in the body.

• Two of the six case bolts must be assembled

through the holes in the lower case before

it is attached to the body. After attachment

there is insufficient clearance to do so.

• Tighten the spindle nut snugly but not

excessively. Three diaphragms are

sandwiched in the spindle/stack assembly

and excessive tightening will damage them.

Hold the hex spacer when torquing the

spindle nut to prevent the stack from rotating.

After the pilot is assembled the set pressure

must be adjusted. Refer to Section 5

forinstructions.

FOR FIGURES 4A AND 4B

Item Description

100 Body

110 Nozzle

120 Hex spacer

130 Boost spacer

140 Sense spacer

150 Sense plate

160 Boost plate

170 Spindle spacer

190, 190A Pressure adjuster lock nut

200, 200A Bonnet assembly

210 Upper diaphragm case

220 Lower diaphragm case

230 Spacer ring

235A Adapter

240 Case bolt

250 Lock washer

260 Hex nut

320 Boost tube

330 Connector elbow

340 Body bolt

350 Blowdown needle

370 Hex jam nut

380 Retainer plug

390 Blowdown bushing

400 Filter screen (not shown)

420 Retainer seat

430 Retainer ring

440A Hex nut

450 Bonnet insert

460 Wire (not shown)

470 Seal - ½” diameter (not shown)

[1]

[1]

Item Description

490 Washer shim (for stack height)

500 Spindle diaphragm*

510 Sense/boost diaphragm*

520 Sense diaphragm*

550 Spindle

555A Extension rod

560 Check plate

570 Seat

580, 580A Bonnet gasket*

610 Body bolt seal*

620 Blowdown seal*

630 Bushing seal*

640 Case gasket*

660 Spindle seal*

680 Spindle gasket*

690 Spindle diaphragm gasket*

730 Seat base - type 95

740 Ball

750 Hex nut

760, 760A Cap

770, 770A Bonnet bolt

780 Lock washer

790, 790A Pressure adjustment screw

800 Vent - body (not shown)

805A Vent - plug

810 Vent - connector

815 Vent - tube

820, 820A Spring washer

830, 830A Spring disc

840, 840A Spring

NOTES

A = used in auxiliary setter

* Recommended spare parts for repairs

1. Part of Item 200 assembly

Refer to Section 8 for Soft goods repair kits part

numbers.

Refer to Section 8 for Soft goods repair kits part

numbers.

5

Page 6

ANDERSON GREENWOOD SERIES 95 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

FIGURE 4A

Series 95 pilot with auxiliary setter

6

Page 7

ANDERSON GREENWOOD SERIES 95 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

FIGURE 4B

7

Page 8

ANDERSON GREENWOOD SERIES 95 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

5 PILOT SET PRESSURE ADJUSTMENT

Refer to Figure 5

To adjust the opening and closing pressure of

the pilot after the pilot has been completely

disassembled and reassembled, a test set-up

similar to that shown in Figure 5 should be used.

5.1 Check the position of the blowdown

adjustment screw. It should be turned half

way in (approximately 5 turns).

5.2 With the pressure adjustment screw turned

most of the way in, increase the supply

pressure to the desired set pressure.

Backthe pressure adjustment screw out

until the pilot “snaps” open. The dome

pressure should decrease to 25% or less

of the supply pressure. When the pilot

opens and flows, the supply pressure will

decrease due to the pressure drop in the

lines to the accumulator. The set pressure

is the highest pressure recorded on the

supply pressure gauge.

5.3 Decrease the supply pressure to the

correct reseat pressure and back the

blowdown adjustment screw out until the

dome pressure “snaps” back. The supply

pressure at which this occurs is the reseat

pressure and it should be about 90% of

the set pressure. When the pilot reseats,

the supply pressure will increase due to

reduced flow through the supply line. The

reseat pressure will be the lowest pressure

read on the supply gauge. Tighten the

jam nut after each setting for accurate

readings. Recycle the pilot valve to verify

the settings. A small interaction between

the blowdown adjustment and the pressure

adjustment will occur.

Auxiliary set pressure

adjustment under cap

Supply pressure

Vent

Accumulator (¼ cubic ft.)

Supply

Supply port

½” (1.5 mm) pipe

Primary set pressure

adjustment under cap

Blowdown

adjustment

½” (1.5 mm) pipe

6” to 12” long

FIGURE 5

Series 95 pilot test set-up

Dome pressure

gauge

8

Page 9

ANDERSON GREENWOOD SERIES 95 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

6 PILOT SET PRESSURE FIELD TEST

PROCEDURE

Refer to Figure 6

This procedure is for measuring the pressure

where the valve will open. It will not measure

where the valve closes. To measure the closing

pressure, use the procedure in Section 5.

6.1 Remove the pilot discharge tube from the

pilot and replace with a cap that has a

.06”diameter (1.5 mm) hole in it.

6.2 Connect the test equipment to the field test

valve.

6.3 With the metering and vent valve closed,

open the gas bottle and adjust the regulator

pressure to about 200 psi (14 kp/cm

2

).

6.4 Open the field test valve. Slowly open the

metering valve and observe the test gauge.

Increase the pressure until gas flow at the

pilot discharge fitting increases rapidly.

The pressure at which this occurs is the set

pressure of the valve.

6.5 To adjust the opening pressure turn

the spring adjusting screw under the

cap/adapter “in” to increase pressure or

“out” to decrease pressure.

6.6

The IMO (International Maritime Organization)

Rule set pressure tolerances are:

+ 10% 0 - 21.3 psi (0 - 1.5 kp/cm

+ 6% 21.3 - 42.7 psi (1.5 - 3.0 kp/cm

+ 3% 42.7 psi or 3.0 kp/cm

Auxiliary set pressure

adjustment under cap

2

)

2

and above

2

)

Auxiliary setter

Unscrew here for removal

(install hand-tight only lubricate threads)

Pilot discharge fitting

Pilot discharge tube

Main valve

Primary set pressure

adjustment under cap

Bonnet vent

Pilot

Field test

valve

Test gauge

Metering valve

High

pressure

Vent valve

Adapter fitting to ½” NPT port

on field test valve

hose

FIGURE 6

Series 95 pilot recommended field test

Nitrogen

bottle with

shutoff valve

and regulator

set-up

9

Page 10

ANDERSON GREENWOOD SERIES 95 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

7 VALVE DIAGNOSIS GUIDE

Problem Causes

Valve does not close on start-up with

littleor nocargo tank pressure

Valve opens at a pressure below

nameplateset pressure

Valve opens at correct pressure but

doesnot close

(Refer to Figure 1)

Main valve piston in lift position, pressurize domethrough

Fieldtest handvalve (0.5 to 1.0 kp/cm2) to close piston.

Set pressure incorrect

Auxiliary setter device incorrect one for valve.

Auxiliary setter device not screwed down all the way.

Pilot sense diaphragm leaks. Check for gas flow

throughpilot spring bonnet vent.

Backflow preventer check valve leaks. (Item 15, Figure2)

Checkfor gas flow at discharge tube to main valve outlet.

Nogas flow should be detected.

Pilot not sensing correct tank pressure

Check valve in tank pressure sense line (Figure 1) restricted.

Filter screen in pilot or small orifices in pilot restricted.

IMPORTANT

In an emergency, main valve can be closed by pressurizing dome

(top of piston) through close tee (Item 13, Figure 2) remove plug

(item 18) and apply pressure equal to tank pressure.

8 REPAIR KITS

Main valve size Soft goods kit part number Bolt kit part number

2 x 3 04.4744.810 04.4744.330

3 x 4 04.4744.804 04.4744.331

4 x 6 04.4744.834 04.4744.332

6 x 8 04.4744.835 04.4744.333

Pilot 04.4744.025 04.4744.333

Backflow preventer (diaphragm) 04.4744.781 04.4744.335

Check valve (ball check) 04.4744.782 None

© 2017 Emerson. All rights reserved.

10

Loading...

Loading...