Emerson Anderson Greenwood 9300, Anderson Greenwood 9390P, Anderson Greenwood 9340C, Anderson Greenwood 9309V, Anderson Greenwood 9304V Installation And Maintenance Instructions Manual

...Page 1

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

Before installation these instructions must be fully read and understood

TABLE OF CONTENTS

1 Introduction .................................................. 2

2 Main valve .................................................... 3

3 Pilot maintenance ...................................... 14

4 Functional testing of complete

assemblyofmain valve and pilot .............. 27

5 Storage and handling ................................ 29

6 Trouble shooting ........................................ 30

7 Main valve spare parts and repair kits ..... 30

8 Pilot spare parts and repair kits ............... 31

9 Accessories, options, and

accessoryrepairkit ................................... 32

10 Lubricants and sealants for Series 9300.. 32

Installation and Maintenance Instructions

for Anderson Greenwood Series 9300 Pilot

Operated Safety Relief Valves (POSRV).

The intent of these instructions is to acquaint

the user with the storage, installation and

operation of this product. Please read these

instructions carefully before installation.

SAFETY PRECAUTIONS

When the safety valve is under pressure

neverplace any part of your body near

the outlet/exhaust of the valve.

The valve outlet and any separate drains should

be piped or vented to a safe location.

Always wear proper safety gear to protect hands,

head, eyes, ears, etc. anytime you are near

pressurized valves.

Never attempt to remove the safety valve from

asystem that is pressurized.

Never make adjustments to or perform

maintenance on the safety valve while in service

unless the valve is isolated from the system

pressure. If not properly isolated from the system

pressure, the safety valve may inadvertently open

resulting in serious injury.

Remove the safety valve prior to performing any

pressure testing of the system.

The safety of lives and property often depends on

the proper operation of the safety valve. The valve

must be maintained according to appropriate

instructions and must be periodically tested and

reconditioned to ensure correct function.

WARNING

The protection and safety of equipment, property

and personnel depends on the proper operation

of the safety valves described in this manual.

AllEmerson safety valves should be kept in proper

working condition in accordance with the

manufacturer’s written instructions. Periodic

testing and maintenance by the user of this

equipment is essential for reliable and safe valve

operation.

All installation, maintenance, adjustment,

repair and testing performed on safety valves

should be done by qualified technicians having

the necessary skills and training adequate to

perform such work. All applicable Codes and

Standards, governing regulations and authorities

should be adhered to when performing safety

valve repair. No repair, assembly, adjustment or

testing performed by other than Emerson or its

authorized assemblers and representatives shall

be covered by the warranty extended by Emerson

to its customers. The user should use only original,

factory supplied OEM parts in any maintenance or

repair activity involving this product.

This Maintenance Manual is provided as a general

guide for the repair and maintenance of the safety

valves described herein. It is not possible to

describe all configurations or variations with such

equipment. The user is advised to contact Emerson

or its authorized assemblers and representatives

for assistance in situations that are not adequately

covered or described in this manual.

Before removing a safety valve for maintenance,

ensure that the system pressure has been fully

depressurized. If an isolation block valve is used

ensure that any trapped fluid between the block

valve and the safety valve is safely vented.

Before disassembling the safety valve ensure that the

valve has been decontaminated from any harmful

gasses or fluids and that it is at a safe temperature

range for handling. Fluids can be trapped in

thedome space of pilot operated safety valves.

installation, the Installation and Operational Safety

Instructions should be fully read and understood.

These Instructions may

be requested from the factory or are available at

www.valves.emerson.com.

Before

STORAGE AND HANDLING

Pressure/vacuum relief valve performance may

be adversely affected if the valve is stored for

an extended period without proper protection.

Rough handling and dirt may damage, deform,

or cause misalignment of valve parts and

may alter the pressure setting and adversely

affect valve performance and seat tightness.

It is recommended that the valve be stored in

theoriginal shipping container in a warehouse

or at a minimum on a dry surface with a

protective covering until installation. Inlet and

outlet protectors should remain in place until

the valve is ready to be installed in the system.

Emerson.com/FinalControl

© 2017 Emerson. All rights reserved.

Engineering Doc. #05.9040.275 Rev.D

VCIOM-06024-US 15/01

Page 2

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

1 INTRODUCTION

1.1 Description of valve

The Series 9300 employs the highly successful

pressurized PTFE film seat, as well as

protected FEP diaphragms. The design allows

these valves to be used in the pilot operated

pressure relief mode and simultaneously

provide vacuum relief, either via weight loads

of the internals, or with a specific pilot control

of the vacuum opening. The Series 9300

was designed with a special studded inlet

connection to reduce the inlet profile, and

coupled with larger orifice areas, these valves

provide flow capacities as much as 45% greater

than the Series 90 valves. The Series 9300 is

a full body valve to pipe away the discharge if

required.

1.1.1 Pilot operated safety relief valve with

non-flowing modulating pilot

• 9340P - Positive pressure relief valve

• 9340C - Positive and negative pressure relief

valve

• 9304V - Negative pressure relief valve

Pilot operated valves use a pilot to control

pressure over a large unbalanced member in

the main valve, such as a diaphragm piston.

Thelarge overbalance means a much larger

force on top of the seat compared to process

forces pushing up on the seat. At set pressure,

the pilot relieves the pressure quickly,

permitting the main valve seat to open rapidly.

All of the pilots have the same construction,

except for the location of the connections

to the main valve diaphragm actuators, or

theconnections for the pressure sense.

Foreither the 9340P or the 9340C, thepilot

controls only the positive pressure relief.

Thenegative pressure relief is controlled by

theweight of the parts that move in the main

valve when it opens. In the 9304V, the pilot

controls thenegative pressure relief.

1.1.2 Pilot operated safety relief valve with flowing

modulating or snap action pilot

• 9390P - Positive pressure relief valve

• 9390C - Positive and negative pressure relief

valve

• 9309V - Negative pressure relief valve

Weighted-loaded and spring operated valves

open as process forces overcome downward

forces, with little flexibility to overcome

problem applications. Anderson Greenwood

pilot operated valves can be adjusted to open

with a rapid ‘snap’ action or modulating action.

Most applications are well served by the snap

action mode, with full opening at set pressure

and full reseating after a short blowdown.

However, some systems might best be served

by a proportional opening, whereby the valve

opens just enough to satisfy small upsets

and maintain constant system pressure, yet

still have the capability to reach full capacity

within 10% overpressure. The 9390C and 9309V

pilots have the same construction except for

thelocation of the connections for the pressure

sense. For either the 9390P or 9390C, thepilot

controls only the positive pressure relief.

Inthe9309V, pressure relief is controlled

by theweight of the parts that move in the

main valve when it opens. The pilot controls

the negative pressure relief on the negative

pressure relief valve. The Anderson Greenwood

9390 Series can be set for a snap acting or

modulating mode with a simple adjustment of

the external blowdown screw. No part changes

are necessary to change the operating mode.

1.2 Service applicability

Refrigerated or cryogenic storage tanks

(accurate low-pressure protection), natural

gas transmission and distribution, blanketed

vessels in the petrochemical, food and

electronics industries, ammonia, air blowers in

the waste water treatment plants and marine

(LNG and LPG).

1.3 Code applicability

The Series 9300 are designed to meet

therequirements of ASME UV Code Stamp, NB

certified capacity 15 psig and above, and API 2000.

1.4 Conversion

Valve conversions are defined as any change

w

hich affects critical parts and/or valve

nameplate data, from that which was originally

supplied by the manufacturer such as a change

in set pressure. Conversions, when required

by the owner/user, shall only be performed

the manufacturer, their appointed/authorized

assembler or repair center in strict

accordance with written instructions provided

by themanufacturer. Communication with

themanufacturer is critical when making

any conversion to ensure the converted

valve(s) provides the same safe, reliable

performance as the original valve supplied by

the manufacturer.

For conversion information on the Series 9300

Pressure Relief Valves:

www.valves.emerson.com

by

2

Page 3

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

1.5 SIZE/PRESSURE RANGES OF SERIES 9300 PRESSURE/VACUUM RELIEF VALVES

Materials AL, CS, SS

Main valve soft goods PTFE Diaphragm seat and seals

Pilot soft goods Elastomer or all PTFE Soft goods

Set pressure range 4” wc to 50 psig (9.9 mbarg to 3.45 barg)

Vacuum range -1.73” wc to -14.7 psig (-4.3 mbarg to -1.01 barg)

Process temperature -320°F to 200°F (-196°C to 93°C)

Size 2” to 12”

Blowdown - (fixed or variable)

1.6 Basic pilot series for the 9300 main valve

1.6.1 Series 91 Pilot

The Series 91 was designed for specific

applications where FEP diaphragms alone were

not rugged enough and premium sealing

required for super cryogenic fluids. Series9

was

1

design includes stainless steel (SS), and PTFE

diaphragms which provide extraordinary

performance for hard to hold cryogenic fluids.

1.6.2 Series 93 Pilot

The Series 93 is a pilot operated pressure

relief valve designed with elastomer seats

and seals, and construction materials in

aluminum (AL), carbon steel (CS), and stainless

steel(SS). These construction materials satisfy

the majority of gas piping and chemical tank

applications. The Series 93 pilot can be used

on any Series 9000 valve except a combination

9000 larger than 6”.

1.6.3 Series 93T Pilot

The Series 93T was an offshoot of the Series

93, designed specifically for cryogenic and

chemical applications where an elastomer seal

is not satisfactory.

1.6.4 Series 400B

The Series 400B is used with 8”, 10”, and

12” combination weight-loaded vacuum and

pressure valves where quick relieving of dual

chamber diaphragms is required to open

themain valve.

2 MAIN VALVE

2.1 General main valve maintenance

Since the Series 9300 valve can be either a

pressure only, vacuum only, or pressure/

vacuum relieving device, it is built in a modular

fashion. The standard single diaphragm unit

will function on pressure and vacuum, however,

opening under very low vacuum requires use of

the auxiliary diaphragm chamber. The valve can

also be repaired in a modular fashion. The seat

can be replaced without complete disassembly

of the diaphragm cases. Selective repair can be

performed as required.

Prior to disassembly of the main valve

or pilot, it is recommended to stamp or

mark the location of the pilot, and the

orientation of thediaphragm cases, studs,

and column supports to the main valve body.

Thispracticewill ensure proper alignment and

location of parts during reassembly.

To prevent mixing up parts it is recommended

to repair the main valve and pilot in stages.

Forthis reason, the diaphragm, nozzle, and seat

maintenance and/or replacement instructions

are separate from the pilot instructions.

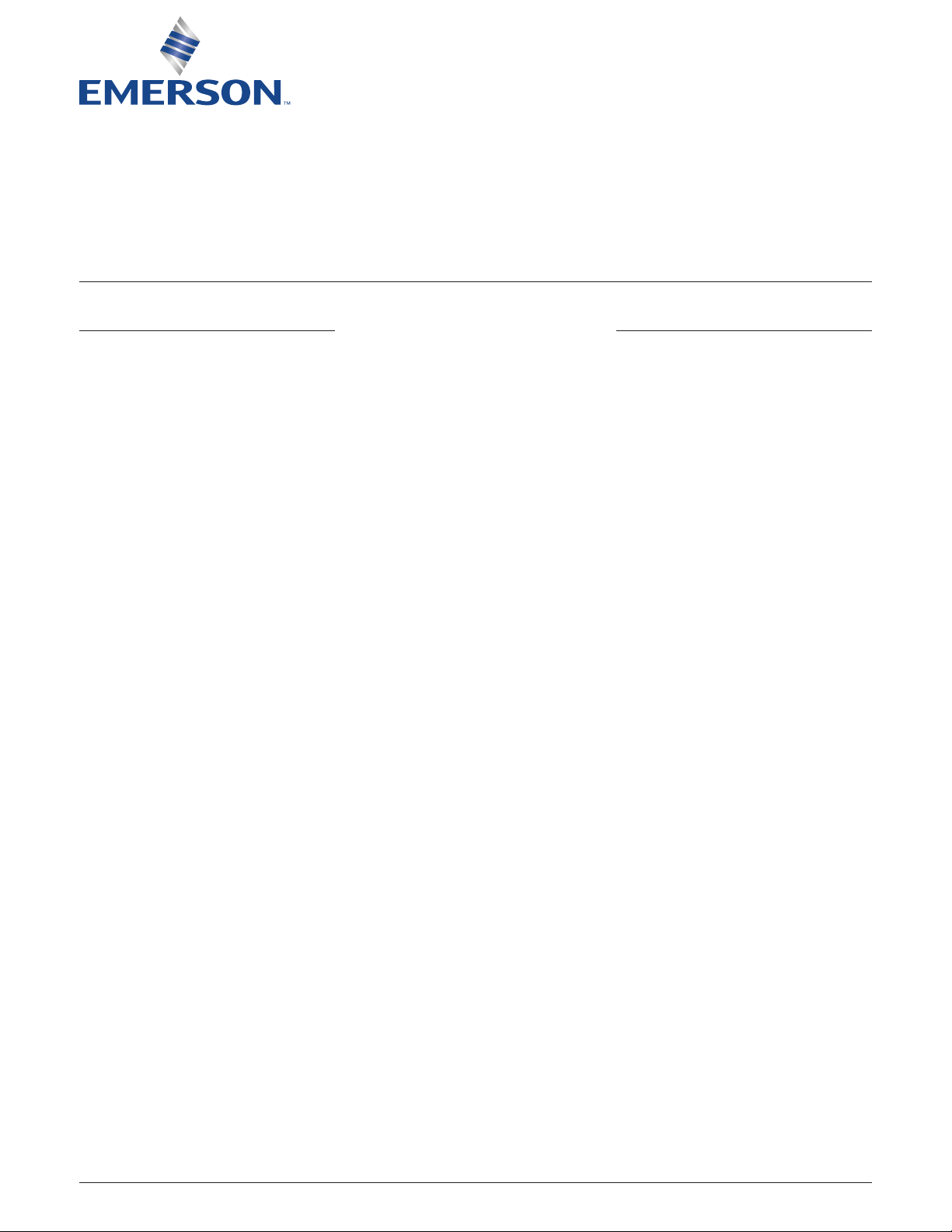

2.2 Main valve single chamber diaphragm

disassembly (Refer to figure 1)

1. Remove the pilot (as a unit) and the tubing

from the diaphragm case. Set them aside.

Note: match mark orientation of tubing and

case assembly to the body. This will assist in

reassembly.

2. Unscrew the case bolts (700/710) and

remove the upper diaphragm case (210).

3. On valve sizes 2” through 4”, remove the

diaphragm assembly, lower case (280), shaft

(320) and seat plate assembly from the main

valve body (100).

4. On valve sizes 6” and larger, remove seat

plate assembly from shaft (320) prior to

removing diaphragm assembly, lower

case (280), and shaft (320). To remove, spin

diaphragm plate assembly counterclockwise

while holding seat plate assembly stationary

until shaft (320) is free of seat hub (420).

Theseat plate assembly should then rest on

nozzle (460).

5. On valve sizes 6” and larger, remove

diaphragm assembly and shaft (320) from

lower case (280). Then remove lower case

from the body (100).

6. On valve sizes 6” and larger, lift seat plate

assembly from the body (100).

CAUTION

When removing seat plate assembly, be careful

not to damage thenozzle (460).

7. Unscrew counterclockwise the seat plate

assembly from the main shaft (320). This is

9

normally a hand operation, however, a

/

16”

(14.3 mm) wrenching flat is provided on the

seat hub (420). The connecting thread will

run free, then tighten, and run free again as

it disengages from a locking helicoil (330)

in the vertical shaft (320). This will allow the

seat plate assembly, diaphragm assembly

and lower case (280) to be separated.

8. Holding the shaft (320) stationary, remove

the jam nut (520) from the diaphragm

assembly. Remove the diaphragms

(170,175, 950, 960), washers (580, 590, 600),

gaskets (620), plates (150, 160), and lower

case (280) (as a unit) from the shaft (320).

3

Page 4

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

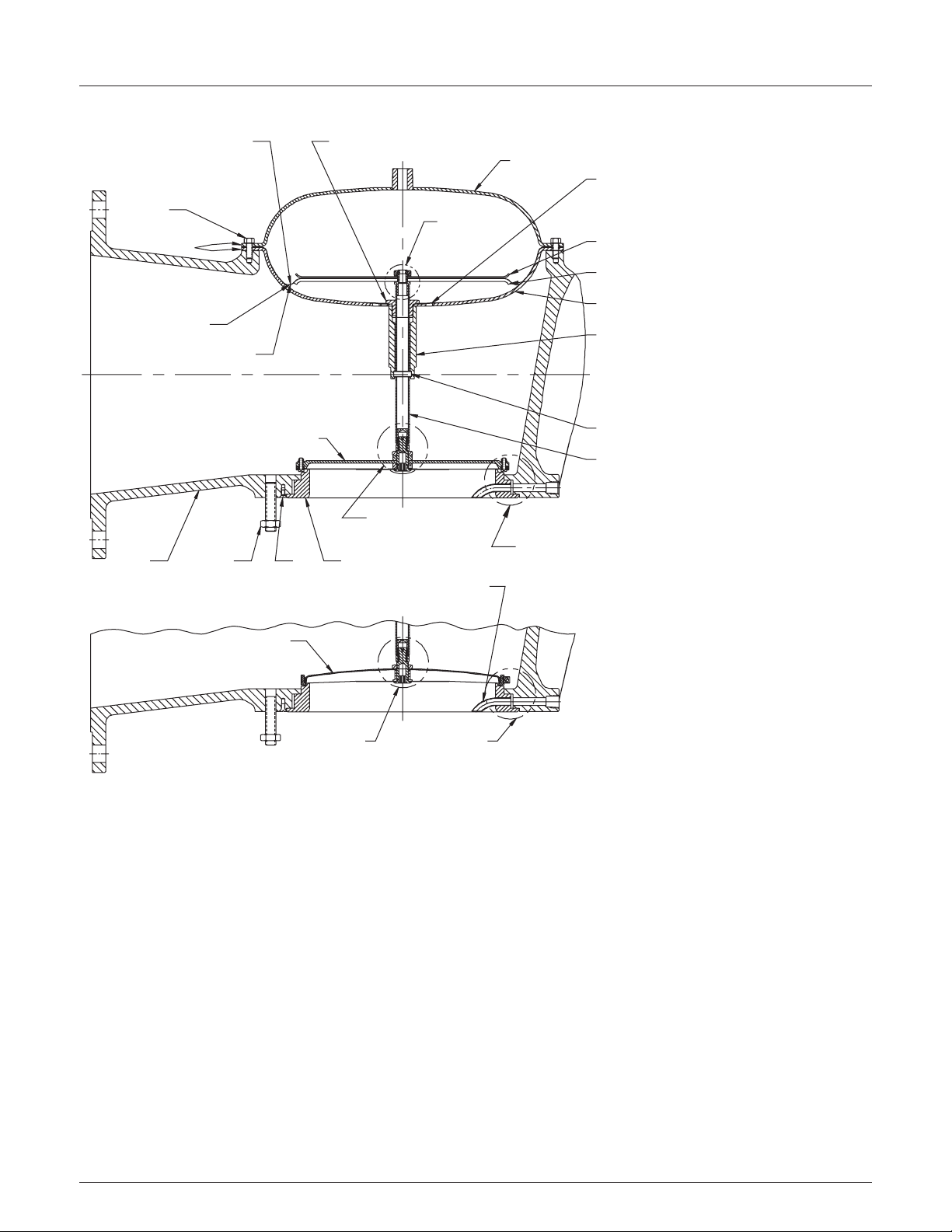

2.3 Main valve dual chamber diaphragm

disassembly (refer to figure 2)

1. Remove the pilot and tubing from

theauxiliary diaphragm case.

Note: match mark orientation of tubing and

case assembly with the body. This will assist

in reassembly.

2. Unscrew the upper auxiliary case bolts

(700) and nuts (730), and remove the upper

auxiliary diaphragm case (210B).

3. Install a 6” to 8” long braided wire through

the hole at the top of the lift rod (250) to retain

the lift rod (250). (See Figure 3, detail C)

4. Lift the auxiliary (160B, 170B, 290) and main

diaphragm (150, 160A, 170A) assemblies

to the full open position using the auxiliary

vacuum plate (160B). The open dome port

can be temporarily capped to hold the main

diaphragm assembly open.

5. Remove nuts (530 and 520B) and PTFE

O-ring (670). (See Figure 3, detail A).

6. The lift rod (250) is attached to the auxiliary

plate bushing (240) with threads. Unscrew

the lift rod (250) from the bushing (240) by

turning the rod (250) clockwise until it drops

down into the main valve shaft bore (320).

7. Remove the main diaphragm case bolts

(700, 710). Remove the studs (810) from

the body (100). Remove the lower auxiliary

diaphragm case (280B) and the upper main

diaphragm case (220) as a unit, which is

assembled to the diaphragm case adapter

(230). Allow the lift rod (250) to slip from

the center hole and lift the lower auxiliary

diaphragm case (280B), upper main

diaphragm case (220), and adapter (230)

upwards as one unit.

10. On valve sizes 6” and larger, remove

diaphragm assembly (150, 160A, 170A) and

shaft (320) from lower case (280A). Then

remove lower (280A) case from the body (100).

11. On valve sizes 6” and larger, lift seat plate

(910, 920) assembly from the body (100).

CAUTION

When removing seat plate assembly (910, 920),

becareful not to damage the nozzle (460).

12. Unscrew counterclockwise the seat

plate (910, 920) assembly from the main

shaft (320). This is normally a hand

9

operation, however, a

/

16” (14.3 mm)

wrenching flat is provided on the seat

hub (420). Theconnecting thread will

run free, thentighten, and run free again

as it disengages from a locking helicoil

(330) in the vertical shaft (320). This will

allow theseat plate assembly (910, 920),

diaphragm (150,160A,170A) assembly and

lower case (280A) to be separated.

13. Holding the shaft (320) stationary,

remove the jam nut (520A) from the

diaphragm (150, 160A, 170A) assembly.

Removethediaphragms (170A, 175A, 950,

960), washers (580, 590, 600), gaskets

(620A), plates (150A, 160A), and lower

case (280A) (as a unit) from the shaft (320).

(Seefigure 3, detail C).

With the main valve disassembled, you are now

ready to disassemble, inspect, and replace soft

goods starting with the seat plate (910, 920)

assembly.

CAUTION

Be careful not to bend the lift rod (250) during

case assembly removal.

8. On valve sizes 2” through 4”, remove

thediaphragm assembly (150, 160A, 170A),

lower case (280), shaft (320) and seat plate

assembly (910, 920) from the main valve

body (100).

9. On valve sizes 6” and larger, remove seat

plate assembly (910, 920) from shaft (320)

prior to removing diaphragm assembly

(150, 160A, 170A), lower case (280) and

shaft (320). To remove, spin diaphragm

plates (150, 160A, 170A) assembly

counterclockwise while holding seat plate

(910, 920) assembly stationary until shaft

(320) is free of seat hub (420). The seat plate

(910, 920) assembly should then rest on

nozzle (460).

4

Page 5

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

MAIN VALVE PARTS

Item Description

100 Body

110 Screw - nozzle retainer

120 Screw - seat (used with Item 130 seat plate assembly option 1)

125 Clamp band - seat (used in place of item 120 and 130 seat plate assembly option 2)

130 Nut, lock (used with item 120 seat plate assembly option 1)

140 Retainer seat

150 Plate - main pressure

160 Plate - main vacuum

170 Diaphragm - main

175 Diaphragm reinforcement (used on 2” and 3” low pressure only)

210 Case, upper diaphragm

215 Cap spacer (6” only, not used on dual chamber diaphragm)

220 Case, upper main (used on dual chamber diaphragm only)

230 Adapter (used on dual chamber diaphragm only)

240 Bushing (used on dual chamber diaphragm only)

250 Rod (used on dual chamber diaphragm only)

260 Bushing - rod (used on dual chamber diaphragm only)

270 Washer (used on dual chamber diaphragm only)

280 Case, lower diaphragm

290 Plate - aux pressure (used on dual chamber diaphragm only)

300 Washers (used under 700/710 on aluminum cases only)

320 Shaft - assembly (includes item 330 as part of assy)

330 Helicoil

340 Sleeve guide

360 Bushing split (not used on 2” and 3” or high pressure)

420 Hub seat

430 Spacer seat

440 Bushing seat

450 Nut - seat jam

460 Nozzle (assembly)

500 Bushing guide

520 Nut - jam

530 Nut (used on dual chamber diaphragm only)

570 Secondary seat (high pressure only)

580 Washer

590 Washer

600 Gasket - clamp plate

610 Seat - film

620 Gasket - case

630 Nozzle gasket

640 Spacer (O-ring/-018)

660 Gasket - adapter (used on dual chamber diaphragm only)

670 Seal - adapter (used on dual chamber diaphragm only)

680 Retaining - ring (used on dual chamber diaphragm only)

690 Seal - rod (used on dual chamber diaphragm only)

700 Cap bolt - hex

710 Cap bolt - eye (not shown used on 4” and above)

730 Nuts (used on dual chamber diaphragm only)

810 Stud

820 Nut

840 Stud - 2nd chamber support (used on dual chamber diaphragm only)

850 Nuts (used on dual chamber diaphragm only)

890 Screen - lower case

900 Screen - upper case (used on dual chamber diaphragm only)

910 Plate - seat

920 Plate - seat protector

930 Nameplate (not shown)

940 Rivets (not shown)

950 Diaphragm slipper outer

960 Diaphragm slipper inner

970 Washer seat (used prior to 1990)

NOTE

Suffix A and B are used after Item #s to denote parts

for main and auxiliary chambers in the dual chamber

design.

5

Page 6

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

170/175

700/710

620

950

960

Seat plate assembly

(lowandhighpressure aluminum)

(highpressurestainless steel)

100

810/820 110 460

500

See detail C

See detail D

Internal pressure pickup not included with

remote pressure sense

210

890

160

150

280

340

360

320

See detail E

Seat plate assembly

(lowpressure stainless steel)

See detail D

FIGURE 1

9390P Single chamber diaphragm assembly

See detail E

6

Page 7

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

700

730

280B

290

250

170A/170B

700/710

See detail D

Seat plate assembly

See detail C

160B

See detail A

See detail B

Dome port

170B/175B

210B

730

620B

730

840

220

500A

890

620A

160A

150

280A

340

360

320

810/820

FIGURE 2

9390C Dual chamber diaphragm assembly

Remote pressure sense shown

100

See detail E

7

Page 8

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

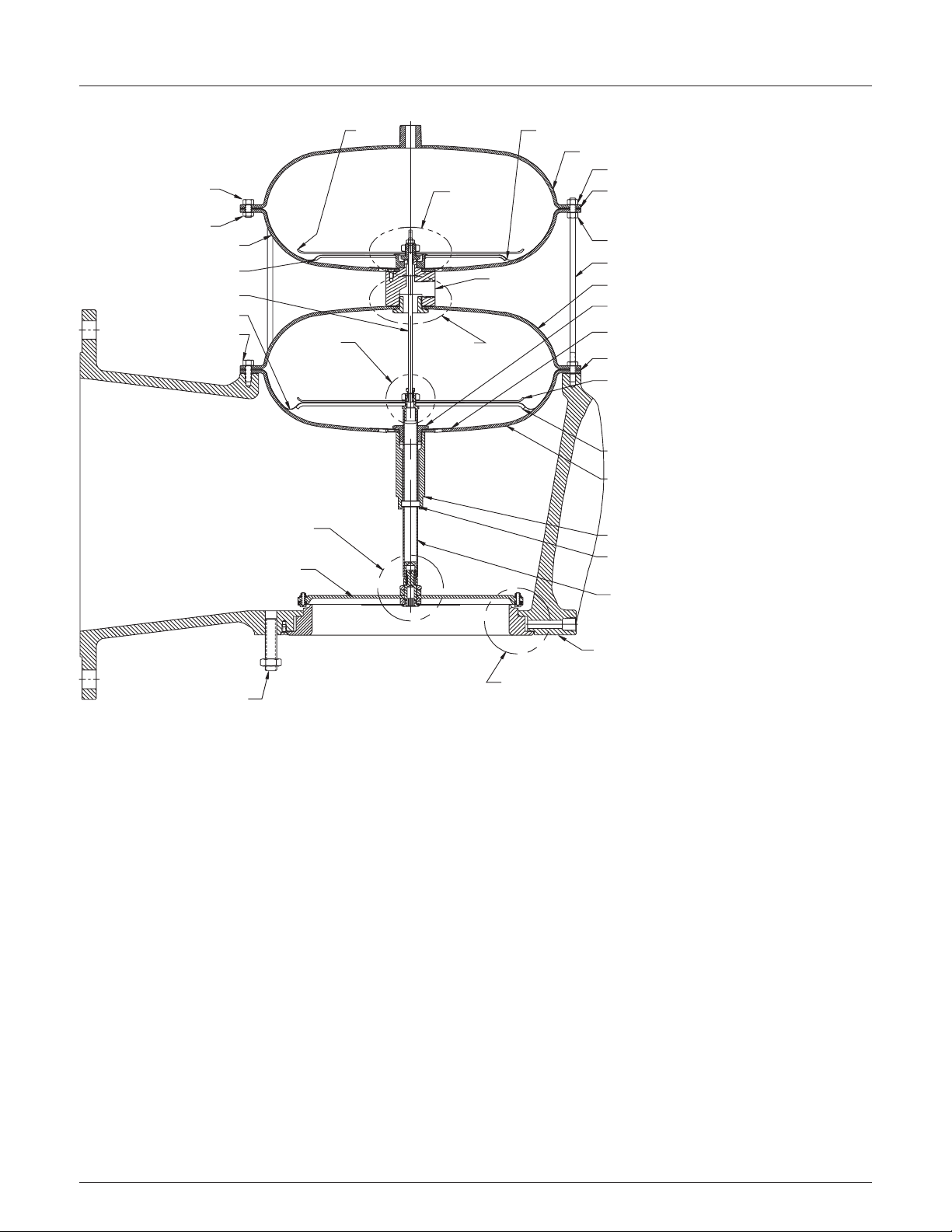

175B

590B

530

670

160

150

Single chamber diaphragm

600

580

320

600

520

590

520B

580

160B

170B

270

690

110

230

Detail “A” and “B” assembledDetail “D”

Retaining wire for assembly

and disassembly

680

900

500B

250*

220

500B

FIGURE 3

240

Detail “A”

Auxiliary diaphragm chamber assembly

230

Detail “B”

690

660

160A

170A

150A

580

590

320

Detail “C”

* Used only with dual chamber diaphragm model

520A

260*

175A

600

8

Page 9

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

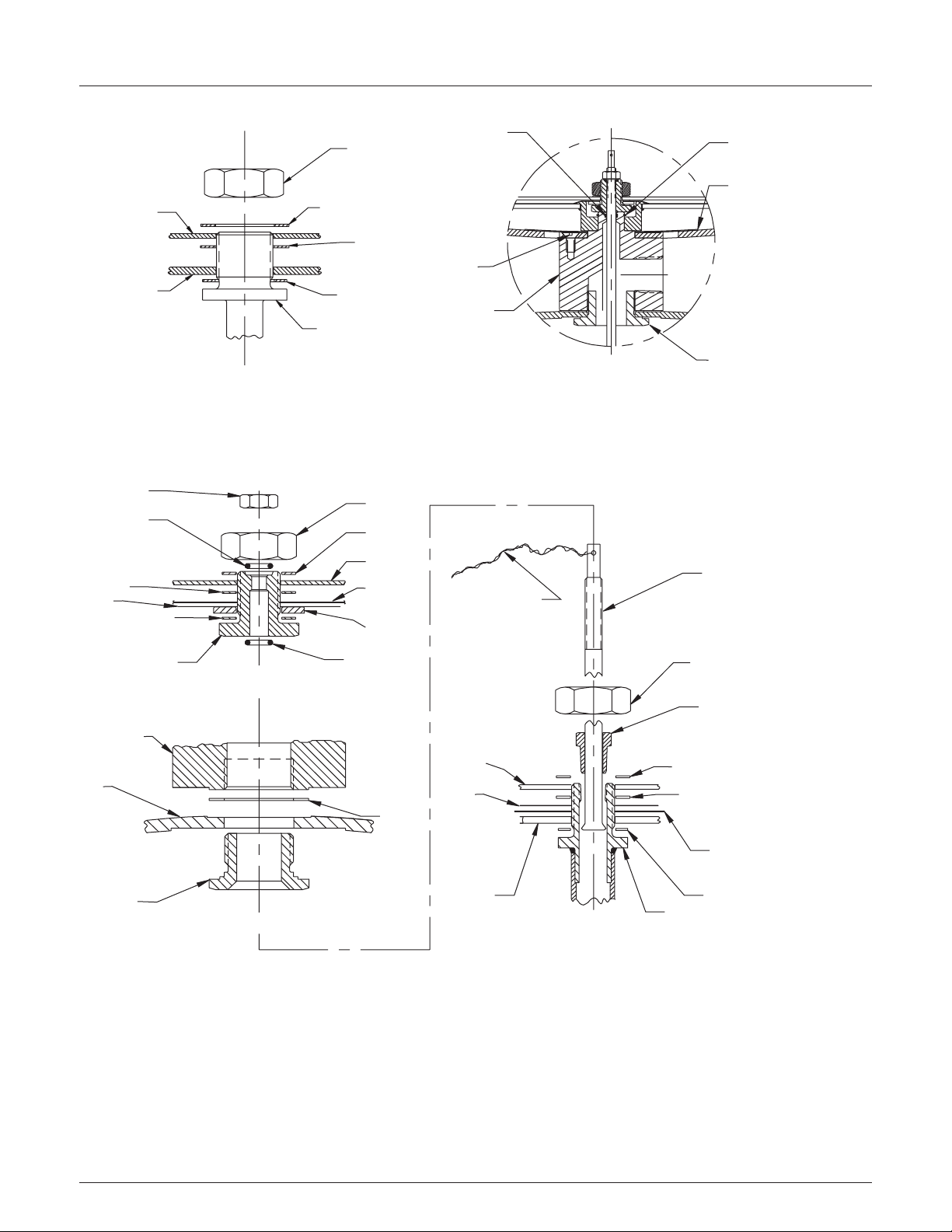

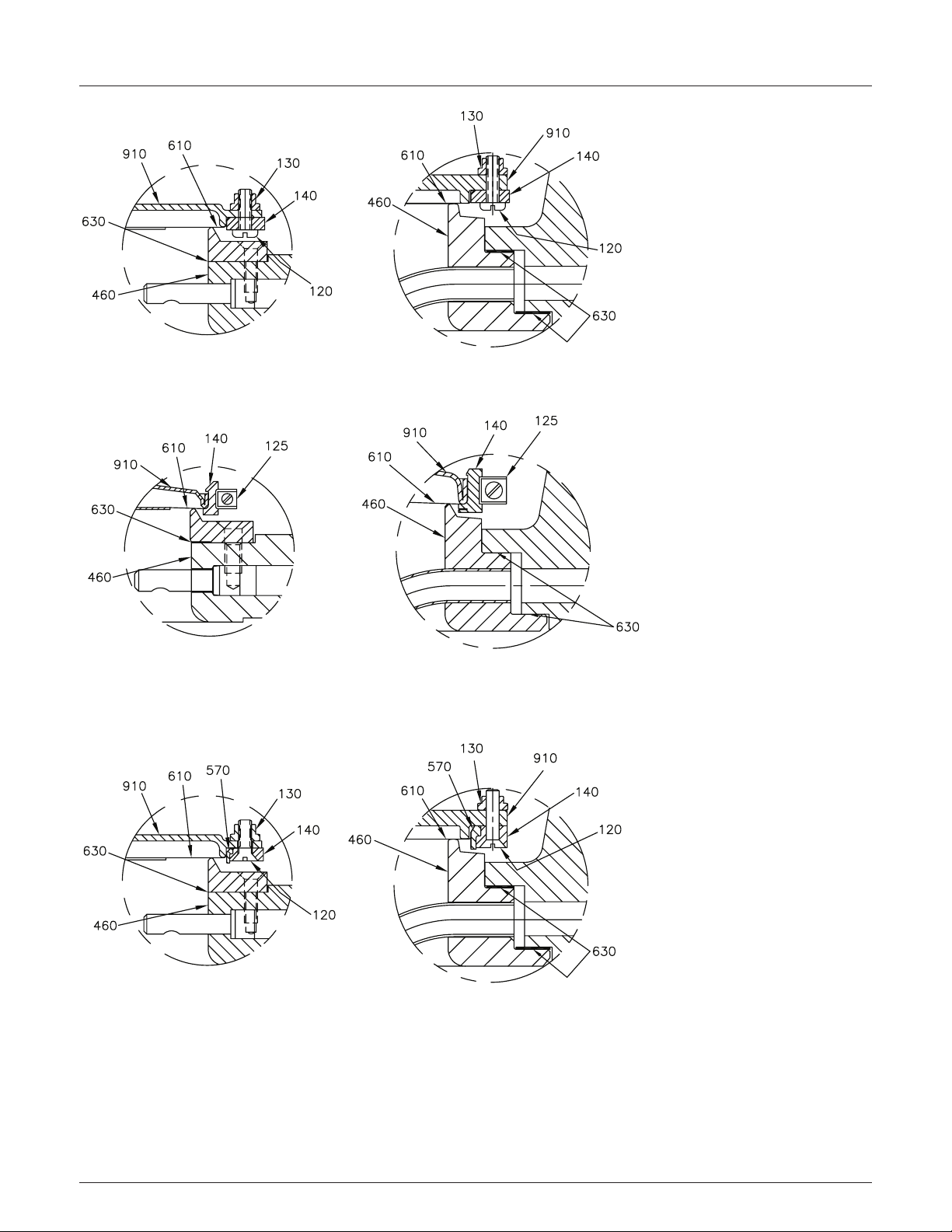

2.4 Main valve seat disassembly and

replacement (bolted) (refer to Figure 4, detail

D, and Figure 5, detail E)

1. To assist in seat plate disassembly, partially

thread the seat plate assembly into the

fixture which consists of a 6” long hexagon

bar with a ½” x 13 x 1” deep threaded hole in

5

one end, and a

/

16” x 18 x 1” deep threaded

hole in the other end.

5

Note: the

/

16

” hole is for valves sizes

2” through 6” and the ½” hole is for 8”

through12”.

2. With the seat plate assembly threaded into

the fixture, secure the fixture into a vise and

remove the seat screws (120) by holding

thelock nut (130) and turning the screws

(120) counterclockwise. Then remove

theseat plate (910).

9

3. Holding the

⁄

16” wrench flat (located at

the top end of the seat hub (420)) secure,

loosenthe seat plate jam nut (450) by

turning it clockwise. Then remove the seat

hub (420) from the fixture and disassemble

the remaining parts of the seat plate

assembly.

Note: secondary PTFE seat (570) used only

in high pressure stainless steel options.

4. Inspect seat plate (910) radius for damage.

Minor nicks and scratches may be removed

by polishing radius with 320 grit or finer

sand paper, maintaining seat shape.

WARNING

No lapping or machining of seat plate allowed.

5. Inspect threaded parts and sealing surfaces

and if damaged replace. Otherwise, clean all

metal parts with oil free solvent and dry with

lint free towel.

6. The new seat film (610) is supplied as a

square sheet of PTFE without holes for

thescrews. To install, secure the larger end

9

of the seat hub with the

/

16” wrenching flat

into a vise and install in this order: protector

plate (920), PTFE seat film (610), seat

bushing (430), spacer (640) (on outside of

seat plate (910), on 6” size seat plates), seat

plate (910) (radius side down) and jam nut

(450). Then tighten by turning the jam nut

(450) clockwise.

7. Remove the seat hub (420) from the vise and

install it into the fixture. To complete the

assembly, install the secondary seat (570)

(high pressure stainless steel only) and then

the seat retainer (140) (bevel side down)

onto the seat film (610). Then using a scribe

punch out a hole in the film starting with the

four threaded indicator holes (only threaded

holes in seat retainer (140)). Then install

the

4 long retainer screws (120) through those

holes and tighten in a criss cross pattern.

Note: lubricate retainer screws (120) with

Fluorolube to reduce the chances of galling.

8. Punch out the remaining seat screw holes

and install the screws (120) and nuts (130)

and tighten.

CAUTION

Be careful not to puncture or scratch the seat

(610) during this operation.

9. Trim off the excess film from the outside

diameter of the seat plate (910) to complete

the replacement process.

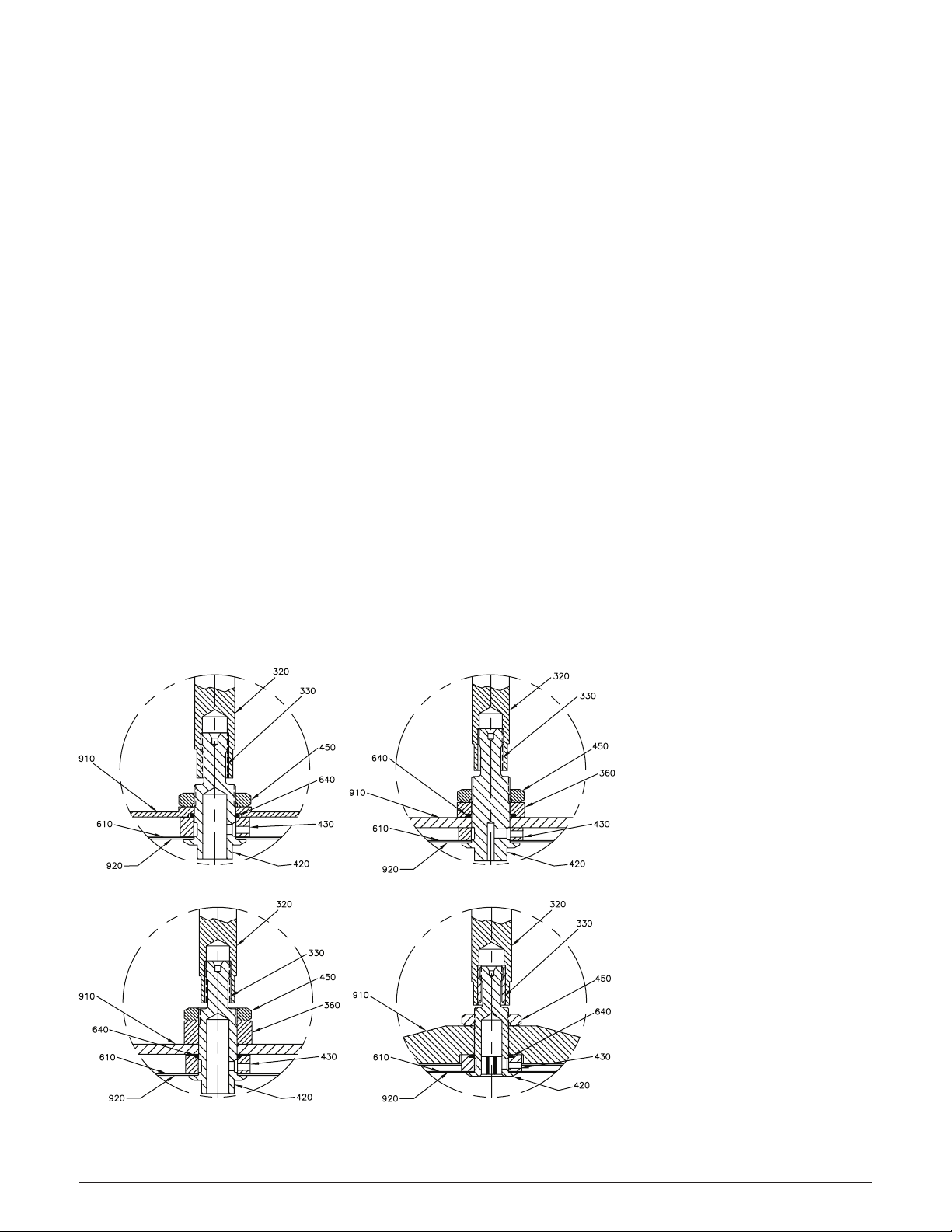

FIGURE 4, DETAIL D

Main valve seat plate hub assembly

9

Page 10

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

2” Inlet size 3” thru 12” inlet size

Aluminum internals

2” Inlet size 3” thru 12” inlet size

Low pressure stainless steel internals

2” Inlet size 3” thru 12” Inlet size

High pressure stainless steel internals

FIGURE 5, DETAIL E

Main valve seat plate assembly (internal pressure sense shown)

10

Page 11

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

2.5 Main valve seat disassembly and

replacement (banded) (Refer to Figure 4,

detail D and Figure 5, detail E)

1.

To assist in seat plate disassembly, partially

thread the seat plate assembly into the fixture

which consists of a 6” long hexagon bar with

a ½” x 13 x 1” deep threaded hole in one end,

5

/

and a

16” x 18 x 1” deep threaded hole in the

other end.

5

Note: the

/

16” hole is for valves sizes

2” through 6” and the ½” hole is for 8”

through12”.

2. With the seat plate assembly threaded into

the fixture and secured in a vise, remove

9

the band clamp (125). Then holding the

/

16

wrench flat on the seat hub (420) stationery

remove the seat plate jam nut (450).

3. Remove the seat hub (420) from the fixture

and disassemble the remaining parts from

the seat plate assembly.

4. Inspect seat plate (910) radius for damage.

Minor nicks and scratches may be removed

by polishing radius with 320 grit or finer

sand paper maintaining seat shape.

WARNING

No lapping or machining of seat plate allowed.

5. Inspect threaded parts and sealing surfaces

and if damaged replace. Otherwise, clean all

metal parts with oil free solvent and dry with

lint free towel.

6. The new seat film (610) is pre-molded.

Toinstall, secure the wrenching flat of

theseat hub (420) into a vise and install

the protector plate (920), PTFE seat film

(610) (radius side down), seat bushing (430),

spacer (640), seat plate (910) (radius side up),

and install the jam nut (450) HAND TIGHT.

CAUTION

Tightening the jam nut (450) prior to stretching

the film (610) will cause ripples in the film.

(SeeFigure 5, Detail E)

7. Remove the seat hub (420) from the vise

and install it into the fixture. Then install

the seat retainer (140) (beveled side down)

onto the seat film (610), and then install

theclamp band (125) and tighten.

8.

Using a heat gun, apply heat to the seat film

(610) in a circular motion approximately 2” to

3” above surface until all ripples and

creases

are gone. This usually takes less than 1minute.

Now tighten jam nut (450) wrench tight.

9. Trim excess film (610) from back side of seat

plate (910) to complete reassembly process.

2.6 Diaphragm replacement

2.6.1 Single chamber diaphragm replacement

(See Figure 3, detail D)

1. Secure the main valve shaft (320) wrenching

surface in a soft jaw vise. Caution should be

taken when securing aluminum shaft (320)

to prevent destroying the part.

2. Remove jam nut (520) by turning it

counterclockwise.

3. Note: mark plates as top (vacuum) and

bottom (pressure) prior to disassembly.

Remove the following parts in thisorder:

washer (580), vacuum plate (160),

washer (590), diaphragm (170), *slipper/

reinforcement diaphragm (950,960/175)

(seenotes for configuration variances),

pressure plate (150), and PTFE washer (600).

Note: on single chamber valves with high

pressure stainless steel internals, an outer

(950) and inner (960) diaphragm slipper is

used to protect the diaphragm (170) from

wear. The outer slipper (950) is between

the diaphragm (170) and lower case (280).

Theinner slipper (960) is between the

diaphragm (170) and the pressure plate(150).

Note: on 2” and 3” single and dual chamber

valves with low pressure aluminum or low

pressure stainless steel internals, use a

reinforcement diaphragm (175) between

the main diaphragm (170) and lower case

(280). The reinforcement diaphragm (175)

is recognized by a small offset hole at

thecenter of the diaphragm.

CAUTION

Installing the reinforcement diaphragm (175)

in the wrong location will cause damage to

thediaphragm assembly.

4. Inspect plates (150, 160) for cracks,

warpage. Clean all metal parts with oil free

solvent, and dry with lint free towel.

5.

Proceed with this step only on disassembly of

main valve dual diaphragms. Inspect lift rod

(250) straightness and ensure small diameter

tip is not damaged. Also raise the lift rod(250)

up and check the surface for damage.

6. Proceed with this step only on disassembly

of main valve dual diaphragms. Install 6” to

8” of braided stiff wire through the hole at

the top of the lift rod (250). This will aid in

reassembly of auxiliary diaphragm.

7. Install new PTFE washer (600), pressure

plate (150), *slipper/reinforcement

diaphragm (950,960/175) (radius side down)

(see notes for configuration variances),

diaphragm (170), flat washer (590), vacuum

plate (160), flat washer (580), and jam nut (520).

Note: on single chamber valves with high

pressure stainless steel internals, an outer

(950) and inner (960) diaphragm slipper is

used to protect the diaphragm (170) from

wear. The outer slipper (950) is between

thediaphragm (170) and lower case (280).

The inner slipper (960) is between the

diaphragm (170) and the pressure plate (150).

Note: on 2” and 3” single and dual chamber

valves with low pressure aluminum or low

pressure stainless steel internals, use a

reinforcement diaphragm (175) between

the main diaphragm (170) and lower case

(280). The reinforcement diaphragm (175)

is recognized by a small offset hole at

thecenter of the diaphragm.

CAUTION

Installing the reinforcement diaphragm (175)

in the wrong location will cause damage to

thediaphragm assembly.

8. Tighten jam nut (520), wrench tight.

11

Page 12

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

2.6.2 Dual chamber diaphragm replacement

(SeeFigure 3, detail A, B, C)

1.

Secure auxiliary diaphragm bushing(240) into

CAUTION

When tightening jam nut be careful not to damage

diaphragm.

soft jaw vise, and remove nut(530) and jam

nut (520B) by turning it counterclockwise.

2. Remove washer (580), auxiliary plate (160B),

washer (590A), reinforcement diaphragm

(175), washer (270), and PTFE washer (600).

3. Inspect threads on bushing (240) and general

condition of metal washers (270, 580, 590B)

including sealing surface where PTFE

washers (600) seat. Clean metal parts with

Note: on 2” and 3” single and dual chamber

valves with low pressure aluminum or low

pressure stainless steel internals, use

areinforcement diaphragm (175B) between

the main diaphragm (170B) and lower

case (280B). The reinforcement diaphragm

(175B) is recognized by a small offset hole at

thecenter of the diaphragm. (See detail A)

oil free solvent, and dry with lint free towel.

4. Install PTFE washer (600), washer (smooth

side up) (270), auxiliary diaphragm (radius

side down) (170), washer (smooth sidedown)

(590B), auxiliary plate (bevel side down) (160B),

washer (580), jam nut (520B), and tighten by

turning the jam nut (520B) clockwise.

2.7 Main valve nozzle replacement

1. Remove nozzle retaining screws (110) and

gently tap nozzle (460) with soft face mallet.

2. Inspect nozzle seating surface for nicks or

scratches. If they cannot be removed with a

crocus cloth or finer sandpaper, the nozzle

(460) must be replaced.

1. The contact surfaces must be clean, free from grease, and dry.

2. Remove the protective strip on the adhesive tape.

3. Lightly press in place as shown below.

UPPER CASE(S) AND TOP OF BODY

3. If the upper and lower nozzle gaskets (630)

are to be replaced, install PTFE gasketing.

(See Figure 6, Section A-A, the nozzle part only)

4. Reattach nozzle (460) and retaining

screws(110).

Put tape just inside of bolt holes, overlapping ends at a bolt hole. Put tape on top case only.

Puttape on top surface of body. Do not put on lower case of mating pair.

Nozzle

A

Section A - A

A

Place tape toward outer edge of each gasket ledge. Put overlaps on opposite sides.

3

Use ⅛” tape on 3” and 4” nozzles.

/

16” tape on all cases and larger nozzles.

FIGURE 6

PTFE Tape gasket mounting instructions

12

Page 13

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

2.8 Reassembly of main valve single chamber

diaphragm

1. Ensure nozzle (460) maintenance is

complete and nozzle (460) is reinstalled.

2. Secure seat hub (420) into soft jaw vise.

3. Install lower case (280) on top of seat plate.

4. Lower shaft (320) and diaphragm assembly

through center hole of case (280).

5. Holding shaft (320) stationary, screw the

seat plate assembly (910, 920) onto the main

valve shaft (320). The connecting thread

will run free, tighten, and free again as it

engages with the locking helicoil (330).

CAUTION

Do not tighten the seat hub against the shoulder

of the shaft.

6. Apply PTFE gasketing (620) to top of the

main valve body (100). (See Figure 6)

7. Lower seat plate (910, 920), shaft assembly,

(320) and lower diaphragm case (280) into

main valve body (100). Align bolt holes with

diaphragm (170), case (280), and body (100).

8. Install PTFE gasket (620) material to upper

case (280). (See Figure 6)

9. Reattach the upper diaphragm case (210)

and seat plate assembly (910, 920) to

thebody (100).

10. Align match marks of case (210) with body

(100), and install cap bolts (700, 710) and

tighten in a crisscross pattern.

11. Reattach the pilot and tubing.

2.9 Reassembly of main valve dual chamber

diaphragm

1. Ensure nozzle (460) maintenance is

complete and nozzle (460) is reinstalled.

2. Secure seat hub (420) into soft jaw vise.

3. Install lower case (280A) on top of seat

plate(910).

4. Lower shaft (320) and diaphragm assembly

through center hole of case (280A).

5. Holding shaft (320) stationary, screw the

seat plate assembly onto the main valve

shaft (320). The connecting thread will run

free, tighten, and free again as it engages

with the locking helicoil (330).

CAUTION

Do not tighten the seat hub against the shoulder

of the shaft.

6. Apply PTFE gasketing (620) to top of

themain valve body (100). (See Figure 6)

7. Lower seat plate (910, 920), shaft assembly

(320), and lower diaphragm case (280A) into

main valve body (100). Align bolt hole with

diaphragm (170A), case (280A), and body (100).

8. Replace the Seal Rod (690) in the upper end

of the adapter bore (230) lubricating it with

Dow Corning FS3451 or equivalent when the

new one is installed. (See Figure 3, Detail A)

9. Install PTFE gasket material to upper main

case (220) (See Figure 6) and lower auxiliary

case assembly spool (see Figure 6).

10. Lubricate threads and shaft of lift rod (250)

and lower spool assembly onto the main

valve (100) while lifting rod wire through

thecenter hole of the adapter (230).

11. Align match marks of case (220, 280A) with

body (100), and install cap bolts (700, 710)

and tighten in a crisscross pattern.

12. Lower auxiliary diaphragm assembly onto

lower auxiliary case (280B) lifting rod wire

through the center of diaphragm bushing

(240). Holding the wire, spin diaphragm

assembly 2 full turns clockwise.

13

. Now bend the wire in half and spin the liftrod

(250) counterclockwise approximately 20turns.

This is the starting position for setting the

lift of the auxiliary diaphragm (170B).

14. To set lift position, position the edge of a

ruler at the top edge of the auxiliary vacuum

plate (160B) and lift the rod (250) up. Normal

3

lift is ⅛” to

/

16”. To increase lift, spin rod

(250) clockwise. To decrease lift, turn rod

counterclockwise.

15. To lock setting insert PTFE seal rod O-ring

(690) onto rod (250) and install jam nut

(520B). To tighten, hold jam nut (520B) and

lift rod (250) stationery and turn rod jam nut

(530) clockwise until wrench tight.

Note: re-check Lift to ensure adjustment

did not change during tightening.

16. Uncap the dome port and close the auxiliary

and main diaphragm assemblies.

17.

Apply PTFE Gasket (620B) to upper auxiliary

diaphragm case. (See Figure 6) Replace the

upper auxiliary diaphragm case (620B). Install

case bolts (700) and nuts (730) and tighten.

18. Replace the pilot and tubing.

3 PILOT MAINTENANCE

3.1 Pilot disassembly for non-flowing

modulating pilots (Series 400B)

(RefertoFigures 7 and 8)

1. Remove bonnet cap (5), loosen adjustment

screw lock nut (7), back out adjusting screw

(6) to relieve spring (9) tension. Removebonnet

nuts (11), bonnet washers (10and 53), bonnet

assembly (4, 29, 51), bonnet gasket (12), spring

washer (8), and spring (9).

2. Push down on spool retaining nut (30)

with a Phillips screw driver engaging the

spool anti-rotation pin (21), and remove

nut (30) with a ½” open end wrench turning

counterclockwise.

3.

Remove spindle spring (31), case bolts (13and

48), nuts (17 and 49), washers (16and 50) and

upper case (3). Remove the bonnet studs (43).

Note: internals are now accessible for removal.

4. Remove -014 O-ring (32), plate sense gasket

(18), sense plate (33), sense diaphragm (34),

gasket (15), ring lantern (35), diaphragm

(19), feedback diaphragm (38), gasket (15),

feedback diaphragm plate (14) and gasket (15).

5. Remove spool (36) and spindle (24) assembly.

6. Remove the lower spindle, -013 O-ring

(23), outlet seat (22), -014 O-ring (32) from

the spindle (24). Now the spindle (24) may

be removed from the spool (36). Remove

thetop inlet seat O-ring from the spindle.

7. Remove the lower diaphragm case (2)

from the body by removing the 4 inner case

bolts(20).

8. Remove the inlet connector (27) and inlet

screen (41) by removing the 2 bolts (28) on

the side of the pilot body (1).

9. Clean all metal parts, and throw away all

gaskets, diaphragms, and seals.

Note: pay particular attention to all port

holes and polished areas.

13

Page 14

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

FIGURE 7

Detail A

2

43

18

19

20

Auxiliary dome

connection ½ NPT

Exhaust ports (frontand back)

withventscreen item 29

54/10

5

53

8

11

12

3

21

22

42

32

23 24

Pressure

actuator

connection

1

6

7

32

29

Detail C

9

4

30

51

31

32

33

34

35

36

Detail B

25 26 27 283741

48

50

49

38

¾ NPT

Pilot inlet pressure

Inlet ½ NPT

Detail D

PARTS

Item Description Item Description Item Description

1 Body 20 Bolt 35 Ring - lantern

2 Case - diaphragm, lower 21 Pin - groove 36 Spool

3 Case - diaphragm, upper 22 Bushing - guide 37 Gasket - body

4 Bonnet assembly 23 O-ring (-013) 38 Slipper - feedback diaphragm

5 Cap - bonnet 24 Spindle 41 Screen - inlet

6 Screw - pressure adjustment 25 Ferrule - tubing 42 Plug - pipe

7 Nut - lock 26 Retainer - inlet connection 43 Stud - bonnet

8 Washer - spring 27 Connector - inlet 48 Case bolt

9 Spring 28 Bolt 49 Nut

10 Washer - plain 30 Nut - spool retainer 50 Washer

11 Nut 31 Spring - spindle 51 Plug

12 Gasket - bonnet 32 O-ring (-014) 52 Insert

18 O-ring (-022) 33 Plate - sense 53 O-ring

19 Diaphragm - feedback 34 Diaphragm - sense 54 Seal - thread

14

Page 15

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

13

34

19

16

Detail A

28

40

39

Vacuum actuator connection

Detail B

15

14

15

17

Remote vacuum

sense ⅜” NPT

1

27

26

Detail C

PARTS

Item Description

13 Bolt

14 Plate, diaphragm support

15 Gasket, diaphragm case

16 Washer, lock

17 Nut

19 Diaphragm, feedback

29 Vent

34 Diaphragm, sense

39 Ferrule, tubing

40 Retainer, dome tubing

44 Bushing

FIGURE 8

3.2 Pilot assembly for non-flowing modulating

pilots (Series 400B)

Assembly is done in the reverse order of

disassembly.

1. Lubricate all O-rings, sliding surfaces,

screw threads and spring washer pivot

points with Dow Corning No. 33 silicone

grease or equivalent.

Note: for oxygen service valves use only

lubricants suitable for this service, such as

Krytox 240AC.

2. The spindle O-ring and bearing surface should

be lubricated with Dow Corning FS 3451 or

equivalent.

Note: do not lubricate inlet or outlet seat

O-rings

3. Assemble the diaphragm lower case (2) to

the body (1).

Note: for Pilots with Kalrez

®

O-rings, use

two PTFE gaskets (37) between the lower

diaphragm case (2) and the body (1).

44

29

Detail D

4. Assemble the inlet screen (41) to the inlet

connector (26) and the inlet connector (26)

to the body (1).

5. Assemble the inlet seat (upper O-ring [-014])

(UPPER 32) and the spindle O-ring (23) to

the spindle (24).

6. Assemble the spindle (24) to the spool (36)

and install the outlet seat (lower O-ring

[-014]) (LOWER 32) to the spindle (24).

NOTE

Kalrez® is a registered trademark of DuPont Dow

Elastomers.

15

Page 16

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

7. Install the spool (36) with spindle (24) in

thebody (1). Position the spool (36) to

engage the anti-rotation groove pin (21).

8. Install a diaphragm case gasket (15) on

thelower diaphragm case (2) and the

feedback diaphragm support plate (14).

Note: install the support plate (14) with

the rounded edge up towards the feedback

diaphragm (38).

9. Install the following parts in the order listed

on the spool (36):

a. Feedback diaphragm support plate (14)

b. Gasket (15)

c. Feedback diaphragm (38)

d. Diaphragm (19)

e. Lantern ring (35)

f. Gasket (15)

g. Sense diaphragm (34)

h. Sense plate (33)

Note: install the sense plate (33) with the round

edge towards the sense diaphragm (34).

i. Install -022 O-ring (18) around

thespindle. On the sense, add plenty of

lubricant to the O-ring.

10. Install bonnet studs (43) thru upper

diaphragm case (3). Install the upper

diaphragm case (3), case bolts (13, 48),

washers (16, 50), and nuts (17, 49).

11. Install the spindle spring (3) and spool

retainer nut (30). Lube nut with Dow

Corning 33 on bevel and use Fluorolube

on the threads. Push down on the spool

retainer nut (30) with a Phillips screw driver

engaging the anti-rotation pin (21) and

tighten the nut to 10 foot pounds using ½”

open end wrench.

Note: do not over tighten, the diaphragms

may be damaged.

12. Pretest pilot function by depressing

spindle/diaphragm assembly stack

downward. The spindle spring should return

the stack assembly to the upward position.

If it doesn’t return to upward position,

disassemble pilot and re-check assembly.

13. Install spring (9), spring washer (8), bonnet

gasket (12) and bonnet (4) onto upper

diaphragm case (3). Install bonnet washers

(10,53) and nuts (11) and tighten.

14. Install pressure adjustment screw (6),

locknut (7) and cap (5).

This pilot is now ready for testing.

3.3 Pilot disassembly for flowing modulating

or snap action pilots (Series 91, 93, and 93T)

refer to Figures 9 thru 13

The pilot disassembly instructions and soft

goods vary between pilot series. Pay particular

attention to orientation of parts and materials.

The 93T pilot has all PTFE soft goods including

diaphragms, and its maximum set pressure

is 15 psig. The 91 pilot has PTFE soft goods

with stainless steel (SS), Hastelloy

diaphragms, and its set pressure ranges from

16 psig to 50 psig. The 93 pilot is different from

®

, and PTFE

the 93T and 91 pilot in that it uses elastomer

seat, seals and diaphragms.

1. Remove cap (760) and adjusting screw (790)

and adjusting screw seal (720) for vacuum

pilot. Remove bonnet bolts (770), seals (700)

for vacuum pilot, bonnet (200), spring (840)

and spring washer (820).

2. On Series 91 and 93T pilots, loosen boost

tube fitting (310) on boost tube (320) at boost

tube connector bolt (270). Refer to detailB.

Remove boost tube connector nut (300),

washer (290), lover boost tube seal (590),

seal retainer (280). Let these three parts

slide down boost tube. Remove boost tube

connector bolt (270), upper boost tube seal

(590) and seal retainer (280).

3. On Series 93 pilot, loosen boost tube fitting

(310) on boost tube (320) at boost tube

connector bolt (270). Refer to detail B.

Remove boost tube connector nut (300),

washer (290), lover boost tube seal (600)

Letthese three parts slide down boost tube.

Remove boost tube connector bolt (270) and

upper boost tube seal (590).

4. Remove case bolt nuts (260), washer (250)

and bolts (240). Remove upper case (210).

5. On Series 91 and 93T pilot. Hold hex spacer

(120) with a shortwell ¾” socket that has

theratchet area bored out and inserting

another socket into the bored out hole, loosen.

6. Remove parts in the following order: hex

spacer (120), sense plate (150), upper gasket

(650), sense diaphragm case gasket

spindle gasket (680), sense spacer (140),

plate (160), spacer ring (230), diaphragm

gasket (620), boost diaphragm gasket (680)

(See Figure 12, detail A)

7. On Series 93 pilot. Hold hex spacer (120)

with a shortwell ¾” socket that has the

ratchet area bored out and inserting another

socket into the bored out hole, loosen.

8. Remove parts in the following order: hex

spacer (120), sense plate (150),sense

diaphragm (510), upper gasket (650), sense

spacer (140), boost plate (160), spacer

ring (230), diaphragm gasket (620), boost

diaphragm gasket (510), boost spacer (130),

check plate (560) and spindle seal (660).

(See figure 12, detail A)

9. Remove boost tube (320) from body (100)

and lower boost tube seal (590/600(93T))

from boost tube (320).

10. Remove spindle diaphragm (500) and gasket

(690) for 93T pilot and spindle/disc assembly

(550) from body (100).

11. Remove spindle diaphragm plate (170) and

shim washer(s) (490) from spindle/seat

assembly (550).

Note: shim washer(s) may not always be

used in assembly (550).

12. Refer to detail A. For the 93T pilot seat

assembly, remove the retainer ring (430)

and seat retainer (420) from the spindle/disc

assembly (550). Remove the seat (570).

(650),

boost

16

Page 17

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

13. Remove blowdown bushing (390) and

blowdown seal (630) from body (100).

Note: the blowdown screw retainer (380)

is a loose fit on the blowdown adjustment

screw (350). Be prepared to catch it

when the bushing (390) is removed from

thebody(100).

14. Loosen the blowdown screw locknut (370)

and remove the blowdown adjusting screw

(350) and seal (630) from the bushing (390).

15. Remove the vent (800) from the body (100).

Note: it is not necessary to remove

thefilter screen (400) or nozzle (110) from

thebody(100).

16. Clean all parts and replace all soft goods.

The spindle/seat assembly (550) is factory

assembled and must be replaced as a unit.

If the nozzle (110) is nicked or scratched,

it should be replaced. To remove it, use a

deepsocket.

3.4 Pilot assembly for flowing modulating or

snap action pilots (Series 91, 93, and 93T)

1. On Series 93 and PTFE seat Series 91

and93T pilots, if you removed the nozzle

(110), reattach the nozzle (110) to the body

(100), and replace the spindle seat assembly

(550).

2. If you removed the filter screen (400),

reattach the filter screen (400), and reattach

the vent (800) to the body (100).

3. Reattach the blowdown seal (620), and

blowdown adjusting screw (350) to

theblowdown bushing (390), and tighten

theblowdown nut (370).

Note: make sure the blowdown screw

retainer (380) is on the blowdown

adjustment screw (350).

4. Attach the bushing seal (630) and the

blowdown bushing (390) to the body (100).

5. Place the shim washer(s) (490), if applicable,

and spindle spacer (170) on the spindle seat

assembly (550). Then place the spindle seat

assembly (550) in the body (100).

6. Lay a straight edge across the body (100)

and check the gap between the straight

edge and the spindle spacer (170). Add or

remove shim(s) (490) as required to make

the top of the spindle spacer (170) even with

the top of the body (100).

7. Align the small hole in the lower diaphragm

case (220) with the hole in the spindle

diaphragm (500). Then align the spindle

diaphragm hole (500) with the hole in the

body (100). Install the lower case (220), body

bolts (340) and bolt seals (610) onto the body

(100) and tighten together.

Note: on the 91 and 93T pilots, there are

gaskets (690) on each side of the spindle

diaphragm (500) and a diaphragm case plate

(180) that must be installed onto the lower

case (220) using the spiral pin (410).

8. On Series 91 and 93T pilots, slide the hex

nut (300), flat washer (290), seal retainer

(280), and seal boost tube (590) on to the

boost tube (320).

On Series 93 pilots, slide the hex nut (300),

flat washer (290), and thread seal (600)

on to the boost tube (320). Then attach

the boost tube (320) to the body (100) with

theconnector (330).

9. On Series 91 and 93T pilots, install parts in

the following order: spindle seal (660), boost

spacer (130), diaphragm case gasket (640),

boost diaphragm (510/520), diaphragm

case gasket (larger I. D. hole) (640),

spacer ring (230), boost plate (160),

spacer (140), diaphragm case gasket (640),

sensediaphragm (510), diaphragm gasket

(smaller I.D. hole)(640), sense gasket (670),

sense plate (150), hex spacer (120), springdisc

(830), lock washer (780) and jam nut (750).

Note: be sure to align large hole in

diaphragm(s) (510/520) and gaskets

(ALL640) with the boost tube hole (270).

10.

On Series 93 pilot, install parts in

thefollowing order: spindle seal (660),

checkplate (rubber side down) (560),

boost spacer (130), boost diaphragm (510),

diaphragm gasket (650), spacer ring (230),

boost plate (160), sense spacer (140),

diaphragm gasket (650), sense diaphragm

(510), sense plate (150), hex washer (120),

spring disc (830),

nut (750).

Note: be sure to align large hole in

diaphragm(s) (510) and gaskets (ALL 650)

with the boost tube (270) hole.

11. To tighten spindle (550) and diaphragm

assembly, hold ¾” socket tool onto hex

washer (120) stationary, and tighten the jam

nut (750).

12. Install upper diaphragm case (210), case

bolts (240), washers (250) and nuts (260),

and tighten.

13. Install the upper boost tube seal (590)

(Series93 pilot), PTFE seal (590) and seal

retainer (280) (Series 91 and 93T pilot),

andboost tube connector/bolt (270) into

thelarge hole of the diaphragm cases

(210,220). Slide

(600) (Series93 pilot),

seal retainer (280) (Series 91 and 93T pilot),

washer (290), nut (300), and boost tube

connector nut (310/480) up the boost tube

(320) attach to the boost tube connector/

bolt (270). Tighten boost tube fitting (310)

on the boost tube (320) at the boost tube

connector/bolt (270).

14. Install the spring (840), spring washer (820),

bonnet assembly (200), and bonnet bolts

(770), adjusting screw (790), locknut (190),

and cap (760).

Note: for the vacuum pilot remember to

replace bonnet bolt (700), bonnet gasket

(580) and adjusting screw seal (720).

lock washer (780), and jam

the lower boost tube seal

PTFE seal (590) and

sense

17

Page 18

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

PILOT PARTS (FIGURES 9, 10, 11)

Item Description

100 Body

110 Nozzle

120 Spacer - hex

130 Spacer - boost

140 Spacer sense

150 Sense plate

160 Plate - boost

170 Spacer - spindle

180 Plate - diaphragm case (93T only)

190 Pressure adjustment lock nut

200 Bonnet assembly (items 450 - 710 part of assembly)

210 Diaphragm case upper

220 Diaphragm case lower

230 Ring - spacer

240 Case - bolt

250 Case washer - lock

260 Case nut - hex

270 Connector - boost tube

280 Seal - retainer (93T only)

290 Washer - flat

300 Nut - hex

310 Nut - connector

320 Tube - boost

330 Connector - straight

340 Bolt - body

350 Needle - blowdown adjustment

370 Blowdown nut

380 Blowdown retainer

390 Blowdown bushing

400 Screen filter

410 Pin - spiral (93T only)

430 Ring - retainer (93T only)

440 Nut - swage (93T only)

450 Insert - bonnet (part of item 200 assembly)

460 Wire

470 Seal - ½” dia

480 Ferrule (not shown)

Item Description

490 Washer - shim (for stack height only)

500 Diaphragm - spindle

510 Diaphragm - sense/boost

520 Diaphragm - sense (93T only)

550 Spindle

560 Plate - check

570 Seat

580 Gasket - bonnet

590 Seal - boost tube

600 Seal - thread

610 Seal - body bolt

620 Seal - blowdown

630 Seal - bushing

640 Gasket - case

650 Gasket - diaphragm

660 Seal - spindle

670 Gasket - sense (93T only)

680 Gasket - spindle (93T only)

690 Gasket - spindle diaphragm used if item 500 is PTFE)

700 Seal - bonnet bolt (93T only)

710 Seal - bonnet insert (part of item 200 assembly vacuum only)

720 Seal adjustment screw (93T only)

730 Base - seat (93T only)

740 Ball

750 Nut - hex

760 Cap

770 Bolt - bonnet

780 Washer - lock

790 Pressure adjustment screw

800 Vent - body (dependent on configuration of assembly)

810 Vent - bonnet

820 Washer - spring

830 Disc spring

840 Spring

910 Name plate (not shown)

920 Screw - drive (not shown)

18

Page 19

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

450

460

See detail B

Figure 13

230

150 210 470

160

320

220

440

770

A

180

See detail A

Figure 13

580

500

690

520

510

240

250

260

640

410

A

Exhaust

See Figure 7 or 8

800

630

380

390

100

To main valve dome

350

620

340 610

370

FIGURE 9

Series 93 and 93T pressure pilot (below 15 psig)

330

400

To process

View A - A

19

Page 20

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

820 790

840

750

780

830

470

150

520

240

250

260

640

680

A

460

760

190

450

200

120

770

810

140

580

160

210

230

220

510

690

See detail A

Figure 13

380

330

320

620

400

350

340610

800

A

100

370

390

630

View A - A

FIGURE 10

Series 91 and 93 pressure pilot (Above 15 psig)

20

Page 21

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

To process

To process

See detail B

See detail A

Main valve dome

FIGURE 11

Series 93 vacuum pilot

21

Page 22

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

Detail A

Series 93 - pressure

above 15 psig

Detail A

Series 91 - pressure

above 15 psig

FIGURE 12

Detail A

Series 93 - pressure

below 15 psig and vacuum

Detail A

Series 93T - pressure

below15psig

22

Page 23

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

270 270

210

650

230

650

220

600

290

300

310

480

590

510

520

210

640

220

280

280

590

670

510

520

590

290

300

310

480

FIGURE 13

Detail B

Series 93 pilot - pressure

below 15 psig and vacuum

Detail B

Series 93 pilot - pressure

below 15 psig

23

Page 24

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

3.5 Pilot adjustment for non-flowing

modulating pilots (Series 400B)

The pilot may be set separate from the main

valve provided there is access to a pilot test

system similar to the one shown in Figure 14.

3.5.1 Adjustment of set pressure

1. Install the pilot valve onto the pilot test

system and attach gage sensing lines to

thesupply and dome connections.

2. Remove cap.

3. Screw the set pressure adjustment screw

clockwise until it is screwed IN 80% to 90%.

4. Increase the supply pressure to nameplate

setting and slowly back out the adjustment

screw until flow through the pilot exhaust

begins.

5. Continue to back the set pressure

adjustment screw out until the dome

pressure is 70% of the supply pressure.

When the dome pressure reaches 70% of

the supply pressure read the supply gage

pressure. If it is below set pressure, youwill

need to tighten down on the pressure screw,

or back off it if you are high. Tighten the locknut

once the desired set pressure is achieved.

Note: adjust the set pressure for 101% ± 1%

of the nameplate set pressure.

6. Cycle the pilot valve a minimum of 5times

to assure that the dome pressure reduction

at set pressure is consistent. Increase

thepressure very slowly in order to obtain

an accurate reading of thecracking

pressure and to expose any erratic

performance.

Note: cracking pressure on vacuum pilots

is that pressure at which the initial dome

pressure change is noted.

7. Hold the pilot valve at set pressure to obtain

the dome pressure reading.

Note: the first 6 steps should be

completed before this step is undertaken.

Inmodulating 400B pilots, the dome

pressure decreases proportional to increase

in inlet pressure.

Full dome reduction (dome pressure)

occurs ≤ 6% over pressure.

8. Check the pilot exhaust for leakage when

the pilot is in null position between crack

and reseat.

Note: maximum leakage allowed is

60bubbles per minute.

3.5.2 Reseat pressure

Reseat is defined as that supply pressure when

the dome pressure is 75% of the supply pressure.

Note: blowdown adjustment is not required on

Series 400B pilots.

3.5.3 ADJUSTMENT TOLERANCES

Pressure Tolerance

Set pressure ± 3%

Crack pressure 98% of set

Reseat pressure 96% of set

24

Page 25

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

Set pressure adjustment

Supply pressure gauge

Supply

pressure

Supply vacuum gauge

½” Pipe (min)

Vent

Accumulator .25 ft

Supply port (½” NPT)

Positive pressure pilot

Vacuum set adjustment

⅜” Pipe (min)

3

[.007 m3]

Test pilot

Reseat pressure adjustment

Dome pressure gauge

Test pilot

Supply vacuum

FIGURE 14

Vent

Accumulator .25 ft

Supply port (⅜” NPT)

Negative pressure pilot

3

[.007 m3]

Reseat vacuum

adjustment on back side

Dome vacuum gauge

25

Page 26

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

3.6 Pilot adjustment for flowing modulating or

snap action pilots (Series 91, 93, and 93T pilots)

The pilot may be set separate from the main

valve provided there is access to a pilot test

system similar to the one shown in Figure 14.

3.6.1 Adjustment of set pressure

1. Install the pilot valve onto the pilot test

system, and attach gage sensing lines to

thesupply and dome connections.

2. Remove the cap.

3. Screw the set pressure adjustment screw

clockwise until it is screwed in 80% to 90%.

4. Increase the supply pressure to nameplate

setting and slowly back out the set pressure

adjustment screw until flow through the pilot

exhaust begins.

5.

Continue to back the set pressure adjustment

screw out until the dome pressure is 70%

of the supply pressure.

When the dome

pressure reaches 70% of the supply

pressure read the supply gage pressure.

If it is below set pressure, you will need to

tighten down on the pressure screw, or back

off it if you are high. Tighten the locknut

once the desired set pressure is achieved.

Note: set pressure on a vacuum pilot is

evidenced by a rapid change of the dome

pressure (0 gage) to the supply pressure.

Aslow ramp speed is recommended on low

set valves in order to obtain true reading of

set pressure.

6. Check the pilot exhaust vent for leakage.

The pilot shall be bubble tight up to crack

pressure shown in 3.6.3. Also, check upper

pilot vent for leakage. There should be

0leakage from the upper vent.

3.6.2 Reseat pressure

1. Turn the blowdown adjusting screw

clockwise to decrease the reseat pressure

or counterclockwise to increase the reseat

pressure.

2.

A small interaction between set pressure

and reseat pressure adjustments will occur;

therefore, it may be necessary to readjust

theset pressure after setting reseat

pressure.

Note: if the blowdown adjusting screw has

been removed or turned to either extreme,

positioning it midway will aid in obtaining

the correct reseat pressure. There are

approximately 7 to 8 turns to obtain full travel

of the adjustment. Midway from either end

should produce a blowdown for snap action.

For modulating pilot action, back the

adjustment screw out counterclockwise.

3. Cycle the pilot valve a minimum of 5

times to assure that dome pressure

reduction at set pressure is consistent.

Increasethepressure very slowly in order to

obtain an accurate reading of thecracking

pressure and to expose any erratic

performance.

Note: cracking pressure on vacuum pilots

is that pressure at which the initial dome

pressure change is noted.

4. Hold the pilot valve at set pressure to obtain

the dome pressure reading. For modulating

pilots, dome pressure shall be read with

theinlet at 105% of set pressure.

Note: the first 4 steps should be completed

before this step is undertaken.

On snap action pilots, the dome pressure

decreases rapidly with a “snap” to

15% ± 10% of set pressure.

On modulating action pilots (Series 90),

the dome pressure decreases slowly to

30% ± 5% of set pressure and recovers to

60% ± 10% of set pressure at set pressure.

5. After desired pilot action is set, verify pilot

seat tightness. This is accomplished by

checking the pilot exhaust vent for leakage.

The pilot should be bubble tight up to crack

pressure as shown in 3.6.3. Be aware

of crack pressure changes between set

pressure ranges.

3.6.3 ADJUSTMENT TOLERANCES

Set press.

Pilot action Set press.

Snap 4” WC to 7” WC ± .2” WC 75% 90% ± 1

Snap 7” WC to 1.0 psig ± 3% 90% 90% ± 1

Snap Above 1 psig ± 3% 95% 92% ± 1

Snap -4” WC to -7” WC ± .2” WC 75% 90% ± 1

Snap -7” WC to -1.0 psig ± 3% 90% 90% ± 1

Snap -1 PSI to -14.7 psig ± 3% 95% 92% ± 1

Modulating action 4” WC to 7” WC ± .2” WC 75% 100%

Modulating action 7” WC to 1.0 psig ± 3% 90% 100%

Modulating action Above 1.0 psig ± 3% 95% 100%

Modulating action -4” WC to -7” WC ± .2” WC 75% 100%

Modulating action -7” WC to -1.0 psig ± 3% 90% 100%

Modulating action -1.0 PSI to -14.7 psig ± 3% 95% 100%

tolerances

Crack press.

% set

Reseat press.

% set

26

Page 27

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

4 FUNCTIONAL TESTING OF COMPLETE

ASSEMBLY OF MAIN VALVE AND PILOT

4.1 General

Assemble the pilot to the main valve, and

install remaining tubing and accessories.

Thecomplete valve assembly should be leak

tested for internal and external leaks using

apressure equal to 30% and 90% of set.

4.1.1 Leakage check - pressure relief valves

Apply pressure to the inlet equal to 30% of

theset pressure. Check for leakage at the

main valve seat, no visible leakage shall occur.

Holdtime is 1 minute.

Increase the inlet pressure to 90% of the set

pressure. Check for leakage at the cap seal,

casting, pilot support pipe and supply tube and

other applicable connections using leak test

solution and at the main valve seat. No visible

leakage shall occur for a hold time of 1 minute.

4.1.2 Leakage check - vacuum relief valves

Valves equipped with vacuum pilots shall be

leak tested per 4.1.1 on positive pressure with

the set pressure equal to the reciprocal of

thevacuum set pressure. Valves with weighted

diaphragms shall be tested for leakage at 50%

of their weighted set.

4.1.3 Back flow preventers and/or field test

The use of some field test connection or

back flow preventers necessitates the use of

check valves. These valves shall be installed

per theapplicable assembly drawings and in

thefree flow direction shall open at less than

.5” W.C. The check valves may be tested for

forward flow either before or after assembly

at the shops option. The output check valve of

back flow preventers shall be checked for zero

leakage per 4.1.1 paragraph 2.

4.2 Leakage check - pressure relief valves

pressure pilot (Series 400B pilot)

1. Connect gas bottle as shown in Figure 15.

2. Close valve “C”.

3. Open block valve “B” to supply regulator.

Note: regulator pressure should be set at 0.

4. Connect bubble tester bottle to pilot exhaust

vent and block the second pilot vent if

thepilot is equipped with one.

5. Increase pressure at field test port to

slightly above tank pressure by slowly

increasing regulated pressure.

6. Open field test valve “A” and slowly increase

regulator pressure until bubbles are seen in

the bottle. That pressure will be within 3% of

the set pressure.

7. To remove the test set-up, close valves “A”

and “B” and open valve “C”.

27

Page 28

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

Pressure regulator w/

test gauge or manometer

Field test valve “A”

Vent valve “C”

Block valve “B”

Compressed nitrogen

FIGURE 15

4.3 Field test instructions for flowing

modulating or snap action pilots

4.3.1 General

An optional field test accessory is available

for checking the positive set pressure without

removing the valve from service. The field test

accessory consists of a 3-way ball valve to allow

the pilot to sense pressure from either the

process or from the test gas source.

A standard bottle of nitrogen equipped with

a pressure regulator, block valve, pressure

gage, and convenient length of high pressure

flexible hose is recommended for testing. A set

up similar to that shown in Figure 13 should be

used. Such a test kit is available from Anderson

Greenwood under the part number 04.4812.001

plus additional dash numbers for the pressure

gages required.

Remote sense connection

(to tank)

5. Increase pressure at field test port to

slightly above tank pressure by slowly

increasing regulated pressure.

6. Open field test valve “A” and slowly increase

regulator pressure until bubbles are seen in

the bottle. That pressure will be within 10%

of the set pressure.

Note: for pilots adjusted for snap action, the

main valve seat will open at set pressure

if the tank pressure is present. If it is not,

asudden increase in pilot exhaust flow will

be observed at set pressure.

7. To remove the test set-up, close valves “A”

and “B” and open valve “C”.

4.3.2 Field test procedure for flowing modulating

or snap action pilots

1.

Connect the gas bottle as shown in Figure 16.

2. Close vent valve “C”.

3. Open block valve “B” to supply regulator.

Note: regulator pressure should be set at 0.

4. Connect bubble tester bottle to pilot exhaust

vent.

28

Page 29

ANDERSON GREENWOOD SERIES 9300 PILOT OPERATED SAFETY RELIEF VALVES

InstallatIon and MaIntenance InstructIons

5 STORAGE AND HANDLING

Because cleanliness is essential to

thesatisfactory operation and tightness of

a Series 9000 pilot operated relief valve,

precautions should be taken to keep out all

foreign particles and materials. Valves should

be closed off properly at both the valve inlet