Page 1

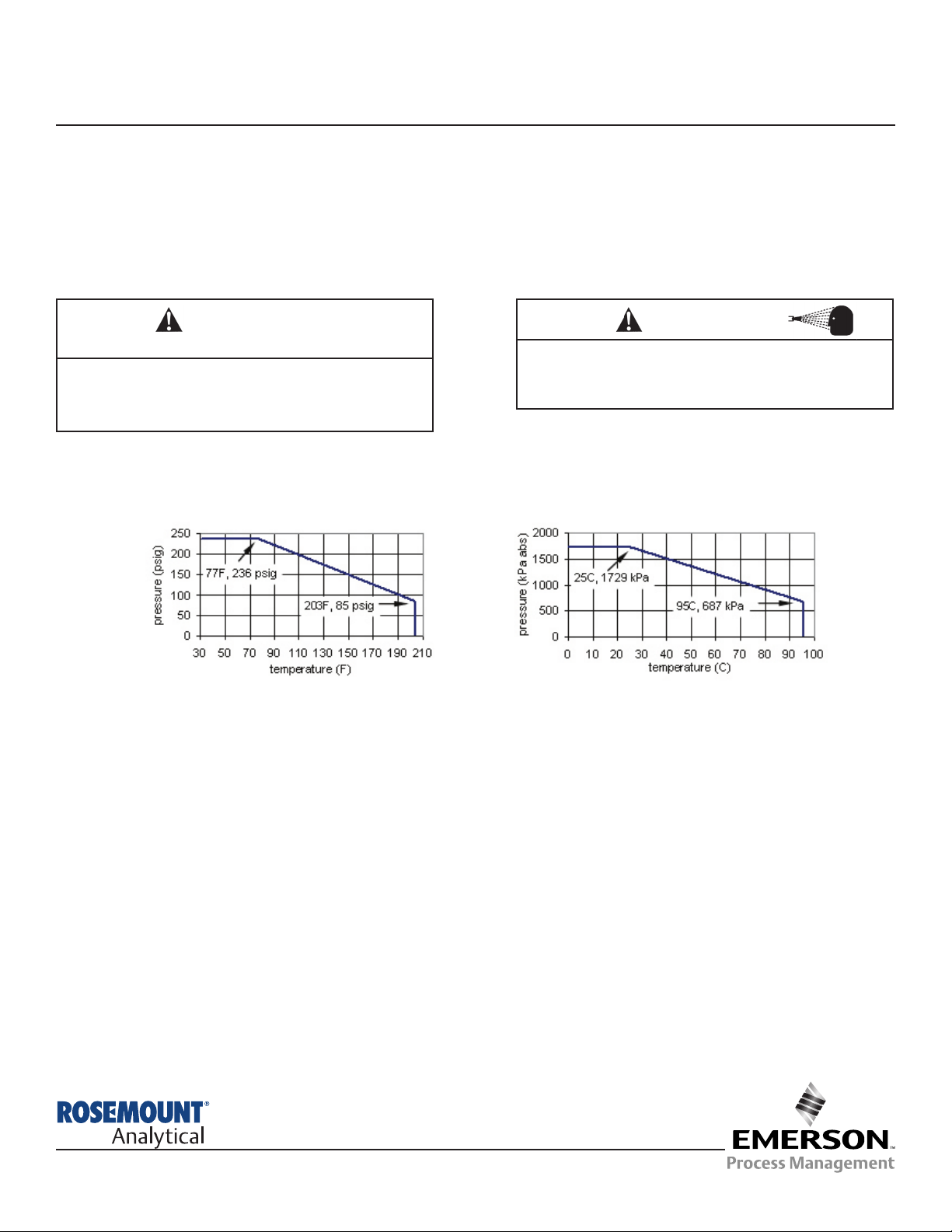

Pressure and Temperature:

Wetted materials: Unfilled PEEK, 316L stainless steel, EP (option 22 only). PEEK meets 21CFR177.2415. EP meets

21CFR177.2600.

Surface finish: 16 microinch (0.4 micron) Ra (except electrode surfaces)

Steam sterilization: tolerates SIP to 284°F (140°C)

Model 410VP

Four-electrode Conductivity Sensor

Instruction Sheet

PN 51A-410VP/rev.D

February 2013

CAUTION

SENSOR/PROCESS APPLICATION COMPATIBILITY

The wetted sensor materials may not be compatible

with process com position and operating conditions.

Application compat ibility is entirely the responsibility

of the user.

INSTALLATION

SENSOR SPECIFICATIONS

The 410VP sensor is available with four process connections: 1½ inch Tri-Clamp1, 2-inch Tri-Clamp, G 1¼, and Varivent N2.

Gaskets and clamps for the Tri-Clamp and Varivent connections must be supplied by the user.

Install the sensor so that the electrodes are completely immersed in the process liquid. Avoid installing the sensor in places

where air bubbles are likely to get trapped or sediment is likely to accumulate on the electrodes. Generally, mounting the

sensor in a vertical pipe run is best. If the sensor must be installed in a horizontal pipe, place the sensor in the 3 o’clock

position. Keep at least 1.0 inch (25 mm) clearance between the end of the sensor and the opposite pipe wall.

To keep response time as fast as possible, do not install the sensor in dead legs or areas where circulation is poor.

1

Tri-Clamp is a registered trademark of Alfa Laval, Inc.

2

Varivent is a registered trademark of Tuchenhagen, GmbH.

WARNING

Before removing the sensor, be absolutely certain

that the process pressure is reduced to 0 psig and

the process temperature is lowered to a safe level!

CAUTION

For additional information, please refer to the Instruction Manuals CD shipped with this

product, or visit our website at www/rosemountanalytical.

Page 2

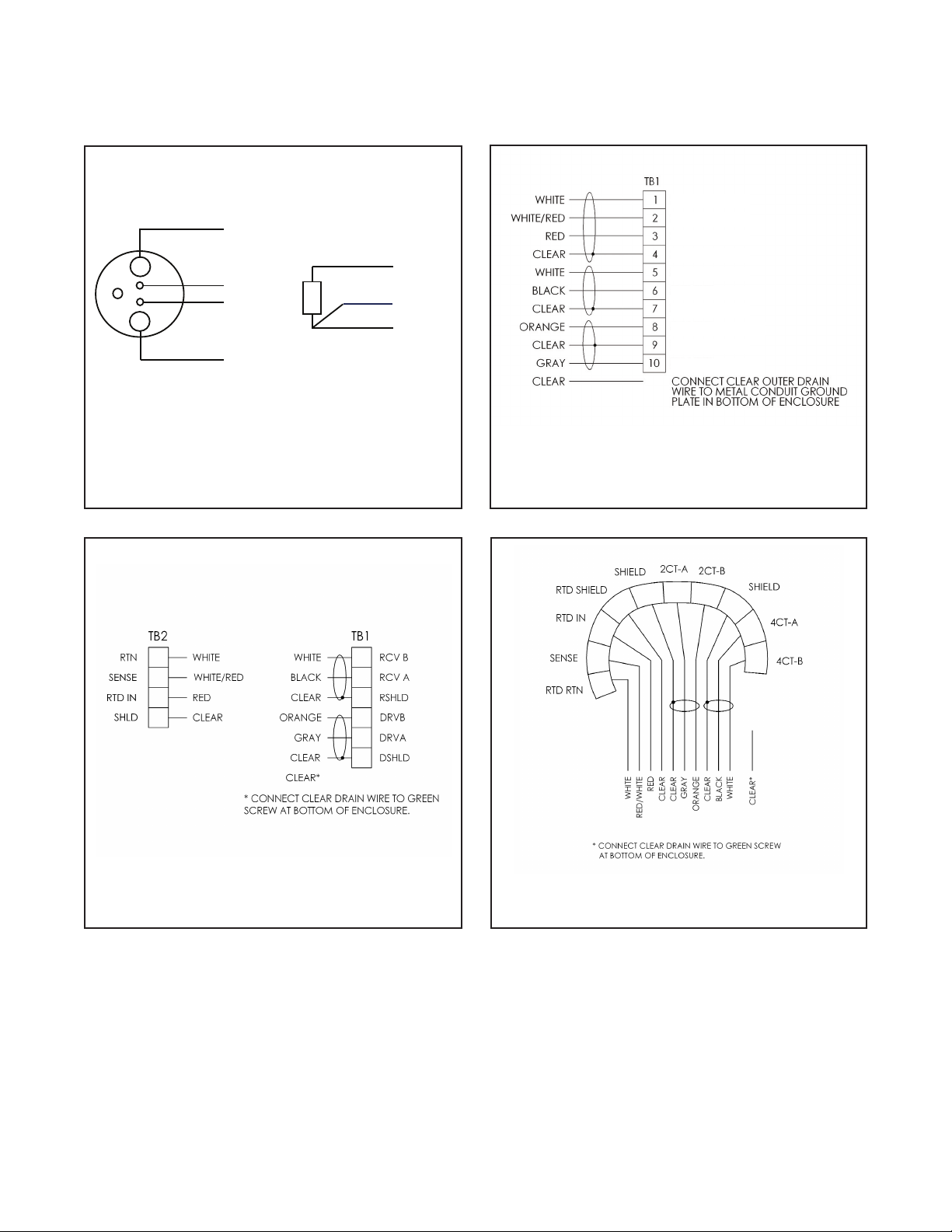

Figure 1. Wire color and functions. Current is

injected through the gray and orange wires. Voltage

is measured across the white and black wires.

Figure 2. Model 1056 and Model 56 wiring.

WIRING

MODEL 410VP WIRING

2

Figure 3.Model 1066 wiring

Figure 4. Model 6081-C wiring

The terminal end of the sensor is keyed to ensure proper mating with the cable receptacle. Once the key has slid

into the mating slot, tighten the connection by turning the knurled ring clockwise.

4CT B

RTD RTN

RTD SENSE

RTD IN

RTD SHLD

4CT A

SHLD 2CT

SHLD 2CT

SEN 2CT B

SEN 2CT A

orange

current

red

RTD

white

black

gray

voltage

voltage

current

white/red

white

RTD in

RTD sense

RTD return

Page 3

3

MODEL 410VP CALIBRATION

The sensor is calibrated at the factory and does not require initial user-calibration. Simply configure the analyzer

to accept a four-electrode sensor and enter the cell constant and calibration factor printed on the label.

After a period of service, the sensor may require calibration. The sensor can be calibrated against a solution

having known conductivity or against a referee meter and sensor. If using a standard solution, choose one

having conductivity greater than 500 uS/cm. Do not use standard solutions having conductivity less than

100 uS/cm. They are susceptible to contamination by atmospheric carbon dioxide, which can alter the

conductivity by a variable amount as great as 1.2 uS/cm (at 25°C). Calibration changes the cell constant

only, not the calibration factor. If you wish to change the calibration factor, consult the factory. For more

information about calibrating contacting conductivity sensors see application sheet ADS 43-024 available

on the Rosemount Analytical website at www.rosemountanalytical.com.

SETUP AND CALIBRATION

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE SOLUTION

Off-scale reading

Wiring is incorrect.

Verify wiring.

RTD is open or shorted.

Check RTD for open connections or

shorts. See Figure 1.

Sensor is not in process stream.

Be sure sensor is completely submerged

in process stream.

Variopol cable is not properly seated. Loosen connector and reseat.

Noisy reading

Sensor is improperly installed in process

stream.

Be sure sensor is completely submerged

in process stream.

Variopol cable is not properly seated. Loosen connector and reseat.

Reading seems wrong (lower

or higher than expected)

Bubbles trapped on sensor.

Be sure sensor is installed so that air

cannot become trapped against it.

Wrong temperature correction algorithm.

Check that temperature correction algorithm is appropriate for the sample. See

the analyzer manual for more information.

Wrong cell constant. Wrong calibration

factor.

Verify that the correct cell constant and

calibration factor have been entered in the

analyzer. See the analyzer manual for

more information.

Bottom of sensor is too close to pipe

wall.

Maintain at least 1.0 in (25 mm) clearance

between bottom of sensor and opposite

pipe wall.

Temperature reading in error

Disconnect red and white RTD wires.

Measure resistance across leads, which

should be about 1100Ω at room

temperature.

Sluggish response

Electrodes are fouled. Clean electrodes.

Sensor is installed in dead area in

process piping

Move sensor to a location more representative of the process liquid.

Page 4

Credit Cards for U.S. Purchases Only.

The right people,

the right answers,

right now.

ON-LINE ORDERING NOW AVAILABLE ON OUR WEB SITE

http://www.rosemountanalytical.com

Specifications subject to change without notice.

8

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.rosemountanalytical.com

© Rosemount Analytical Inc. 2011

Loading...

Loading...