Page 1

Instruction Manual 403 and 403VP

LIQ-MAN-ABR-403-403VP February 2015

PURSense

For additional information, please visit our website at www.rosemountanalytical.com.

CAUTION

SENSOR/PROCESS APPLICATION COMPATIBILITY

The wetted sensor materials may not be compatible with process com position and operating conditions.

Application compat ibility is entirely the responsibility of the user.

WARNING

Before removing the sensor, be absolutely certain that the process pressure is reduced to 0 psig and the process

temperature is lowered to a safe level!

™

Conductivity Sensors

Specifications - Sensor

Specifications 403 and 403VP

Wetted Materials titanium, PCTFE, 316 SS, EP

Temperature Range

Maximum Pressure 250 psig (1825 kPa abs)

NOTE

Elastomers and uorocarbon resins are compatible with 21CFR177. Elastomers also meet the requirements of USP

Class VI. Stainless steel contains <5 % delta ferrite. All surfaces in have 16 microinch (0.4 micrometer) Ra nish.

32–221 °F (0–105 °C) Sensors tolerate

steam sterilization to 135 °C

Installation

Depending on the option selected, the sensor can be installed in either a 1 ½-inch or 2-inch Tri-Clamp tee. The gasket,

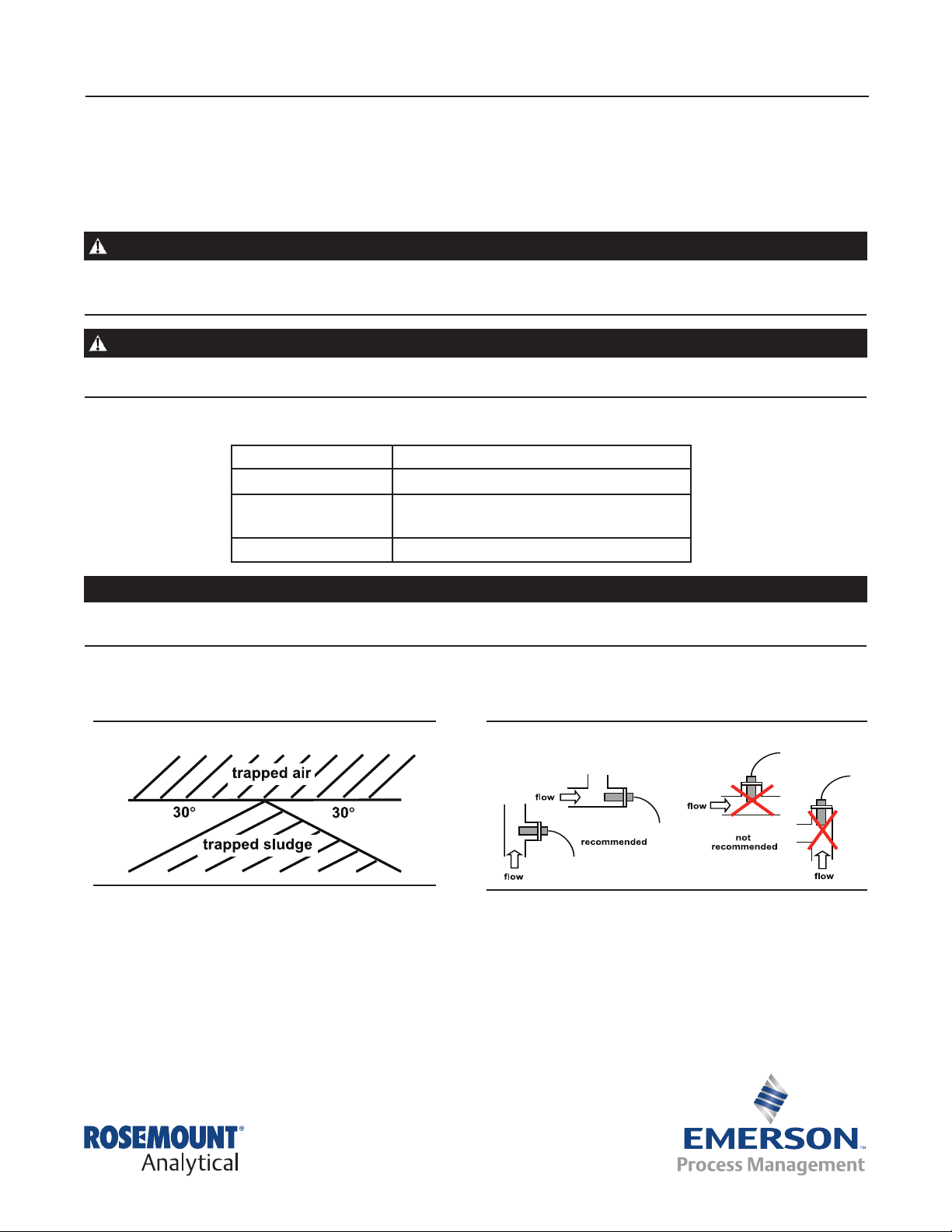

Figure 1. Sensor Orientation

°

clamp, and tee must be supplied by the user. The electrodes must be completely submerged in the process liquid, i.e., up

to the inside surface of the ange.

If the sensor is installed in a side stream with the sample draining to open atmosphere, bubbles may accumulate on the

electrodes. Trapped bubbles will cause errors. Normally, as bubbles accumulate the conductivity reading drifts down. To

control bubble formation, apply a small amount of back pressure to the sensor.

°

Figure 2. Recommended Installation

Page 2

403 and 403VP Instruction Manual

February 2015 LIQ-MAN-ABR-403-403VP

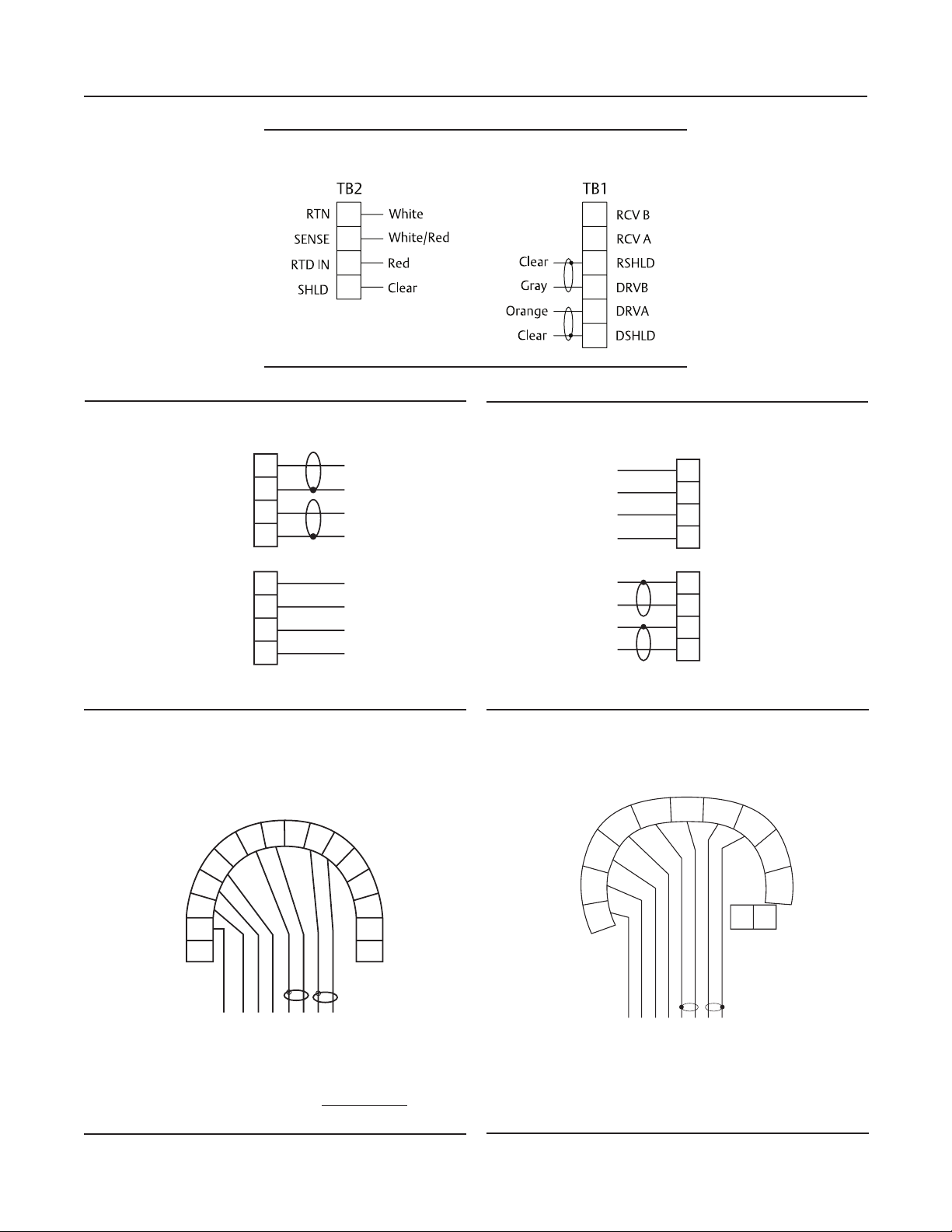

Wiring

NOTE

For additional wiring information on this product, including sensor combinations not shown here, please refer to either

our online wiring programs or the Manual DVD enclosed with each product.

1056, 1057, 56, 5081, 6081, 54e, and XMT : http://www3.emersonprocess.com/raihome/sp/liquid/wiring/XMT/

1066 and sensors with SMART preamps: http://www2.emersonprocess.com/en-US/brands/rosemountanalytical/

Liquid/Sensors/Pages/Wiring_Diagram.aspx

1055: http://www3.emersonprocess.com/raihome/sp/liquid/wiring/1055/

Wire Color and Connections in Sensor

COLOR FUNCTION

Gray Connects to outer electrode

Clear Coaxial shield for gray wire

Orange Connects to inner electrode

Clear Coaxial shield for orange wire

Red

White with red stripe

RTD

White

Clear Shield for all RTD lead wires

RTD in

RTD sense

RTD return

Wiring Diagrams

GROUND

RTD SHIELD

RTD RETURN

RTD SENSE

RTD IN

N/C

RECEIVE COMMON

RECEIVE

N/C

DRIVE COMMON

DRIVE

GROUND

Clear

White

White/Red

Red

Clear

Orange

Clear

Gray

Figure 4. Wiring for 56 and 1056Figure 3. Wiring for 54eC

TB1

White

White/Red

Red

Clear

Clear

Orange

Clear

Gray

1

2

3

4

5

6

7

8

9

10

RTD RTN

RTD SENSE

RTD IN

RTD SHLD

4CT B

4CT A

SHLD 2CT

SEN 2CT B

SHLD 2CT

SEN 2CT A

2

Page 3

Instruction Manual 403 and 403VP

LTR

REVISIONS

DESCRIPTION

DATE

APVD

B

REVISED

12-8-10

J. COVEY

LIQ-MAN-ABR-403-403VP February 2015

Figure 5. Wiring for 1066

Figure 6. Wiring (Panel) for Xmt-C-10

TB1

DRIVE

DRIVE COM

RECEIVE

RECEIVE COM

RTD IN

RTD SENSE

RTD COM

RTD SHIELD

7

6

5

4

3

2

1

Figure 8. Wiring for 5081-C

MODEL 5081C

TRANSMITTER

DRV

RTD SHLD

RTD IN

RTD SENSE

RTD COM

RTD SHLD

RESERVED

RTD

RCV

COM

7

6

5

4

3

2

1

8

SHLD

9

DRV

COM

10

11

Gray8

Clear

Orange

Clear

Red

Red/White

White

Clear

DRV

12

13

14

1516HT/FF (-)

HT/FF (+)

Figure 7. Wiring(Pipe or Wall) for Xmt-C-11

TB1

Clear

White

Red/White

Red

Clear

Orange

Clear

Gray

RTD SHIELD

1

RTD COM

2

RTD SENSE

3

4

RTD IN

5

RECEIVE COM

6

RECEIVE

DRIVE COM

7

DRIVE

8

Figure 9. Wiring for 6081-C

2C T-A

SHIELD

RTD SHIELD

RTD IN

SENSE

RTD RTN

2CT-B

SMART PWR

SHIELD

4C T-A

4CT-B

CLEAR

WHITE

RED

WHITE/RED

CLEAR

CLEAR

ORANGE

SENSOR CABLE

GR AY

WHITE

RED/WHITE

RED

CLEAR

CLEAR

GR AY

CLEAR

ORANGE

3

Page 4

403 and 403VP Instruction Manual

February 2015 LIQ-MAN-ABR-403-403VP

Wiring through a Junction Box

If wiring connections are made through a remote junction box (PN 23550-00), wire point-to-point. Use cable

23747-00 (factory-terminated) or 9200275 (no terminations).

Pin Out Diagram for 400VP

Figure 10. VP pin-out (viewed from connector end of

sensor, looking down)

Cleaning the Sensor

Use a warm detergent solution and a soft brush or pipe cleaner to remove oil and scale. Isopropyl alcohol (rubbing

alcohol) can also be used to remove oily lms. Avoid using strong mineral acids to clean conductivity sensors.

Calibration

PURSense conductivity sensors are calibrated at the factory and do not need calibration when rst placed in service.

Simply enter the cell constant printed on the label into the analyzer.

After a period of service, the sensor may require calibration. The sensor can be calibrated against a solution having

known conductivity or against a referee meter and sensor. If using a standard solution, choose one having conductivity

in the recommended operating for the sensor cell constant. Refer to the analyzer manual or product data sheet

for recommended ranges. Do not use standard solutions having conductivity less than about 100 uS/cm. They are

susceptible to contamination by atmospheric carbon dioxide, which can alter the conductivity by a variable amount as

great as 1.2 uS/cm (at 25°C). Because 0.01/cm sensors must be calibrated in low conductivity solutions, they are best

calibrated against a referee meter and sensor in a closed system.

For more information about calibrating contacting conductivity sensors, refer to application sheet ADS 43-024, available

on the Rosemount Analytical website.

4

Page 5

Instruction Manual 403 and 403VP

LIQ-MAN-ABR-403-403VP February 2015

Troubleshooting

PROBLEM PROBABLE CAUSE SOLUTION

Wiring is wrong. Verify wiring.

RTD is open or shorted. Check RTD for open or short circuits.

See Figure 11.

Off-scale reading

Noisy reading

Reading seems wrong (lower or

higher than expected)

Sluggish response

Sensor is not in process stream. Be sure sensor is completely submerged in

process stream.

Variopol cable is not properly seated. Loosen connector and reseat.

Sensor has failed. Perform isolation checks. See Figure 12.

Sensor is improperly installed in

process stream.

Variopol cable is not properly seated. Loosen connector and reseat.

Bubbles trapped in sensor. Be sure sensor is properly oriented in pipe or

Wrong temperature correction

algorithm.

Wrong cell constant. Verify that the correct cell constant has been

Electrodes are fouled. Clean electrodes.

Sensor is installed in dead area in

piping.

Be sure sensor is completely submerged in

process stream.

ow cell. See Figure 1. Apply back pressure to

ow cell.

Check that temperature correction is

appropriate for the sample. See analyzer

manual for more information.

entered in the analyzer and that the cell

constant is appropriate for the conductivity of

the sample. See analyzer manual.

Move sensor to a location more

representative of the process liquid.

Figure 11. Checking RTD

Disconnect leads and measure resistances shown. The

measured resistance at room temperature should be

close to the value in the table.

red

RTD

red/white

white

Figure 12. Checking Continuity and Leakage

Disconnect electrode leads and measure resistance

and continuity as shown. Sensor must be dry when

checking resistance between electrode leads.

5

Page 6

403 and 403VP Instruction Manual

February 2015 LIQ-MAN-ABR-403-403VP

Notes:

6

Page 7

Instruction Manual 403 and 403VP

LIQ-MAN-ABR-403-403VP February 2015

Notes:

7

Page 8

403 and 403VP Instruction Manual

February 2015 LIQ-MAN-ABR-403-403VP

Rev. P

facebook.com/EmersonRosemountAnalytical

AnalyticExpert.com

twitter.com/RAIhome

youtube.com/user/RosemountAnalytical

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

www.RosemountAnalytical.com

Credit Cards for U.S. Purchases Only.

©2015 Rosemount Analytical, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Brand name is a mark of one

of the Emerson Process Management family of companies. All other marks are the property of their

respective owners.

The contents of this publication are presented for information purposes only, and while effort has been

made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available on request. We reserve the right to modify

or improve the designs or specications of our products at any time without notice.

Loading...

Loading...