Specifications and Main Features

- It is a VILTER MultiCylinder Compressor 400 VMC series.

- Of said above model/series, the operating voltage is 400V.

- Positive Displacement, specifically developed for superheated vapor pumping, is the type of the compressor.

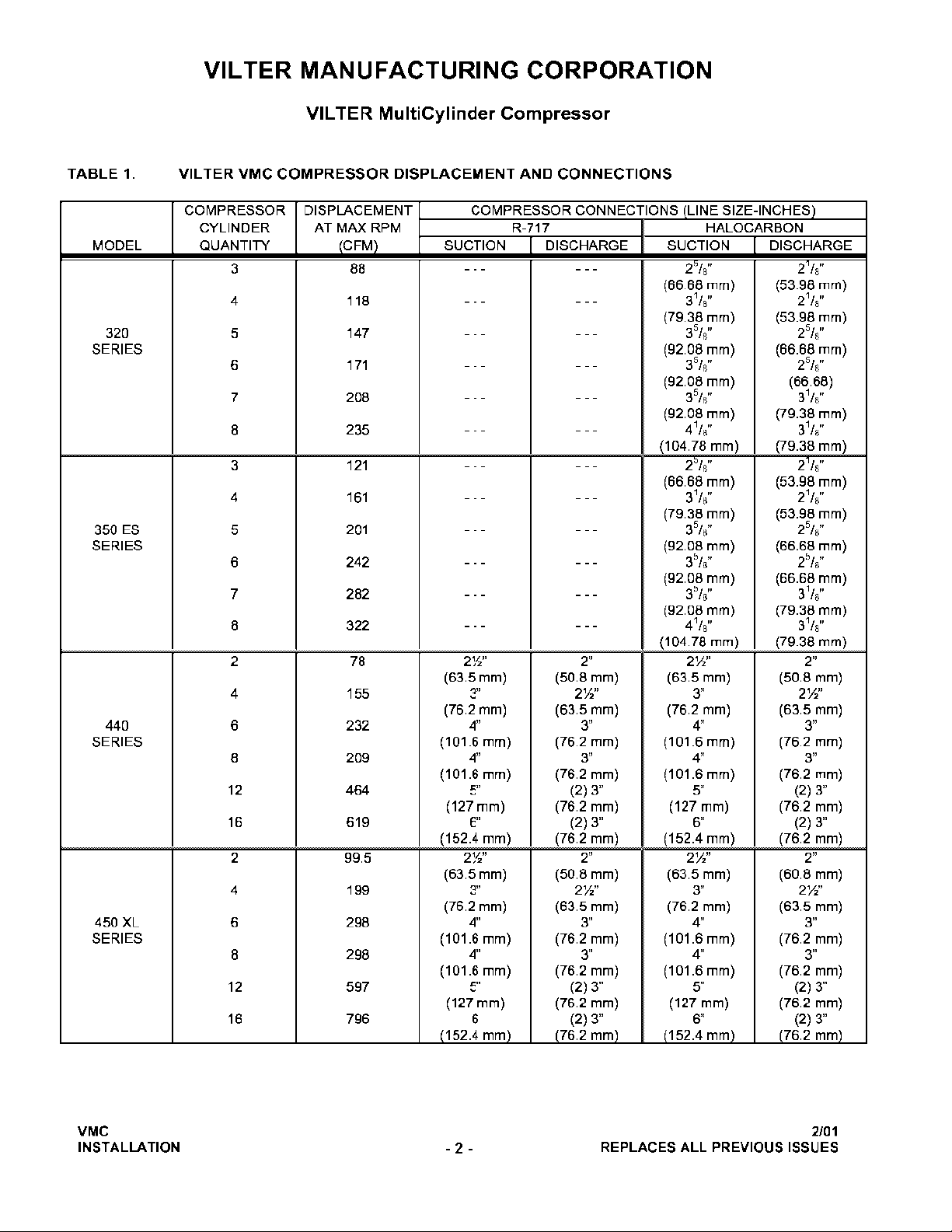

- The range of parameters:

- 88 CFM is the maximum for 3 cylinders.

- 418 CFM is the maximum for 4 cylinders.

- 147 CFM is the maximum for 5 cylinders.

- 171 CFM is the maximum for 6 cylinders.

- 208 CFM is the maximum for 7 cylinders.

- 235 CFM is the maximum for 8 cylinders.

- And further than the above mentioned models with several other capacities

- Sizes of Connection:

- Connection of CIRCULATING water inlet and outlet pipe varies in kind, such as 3’’ up to 4’’ connection for large models.

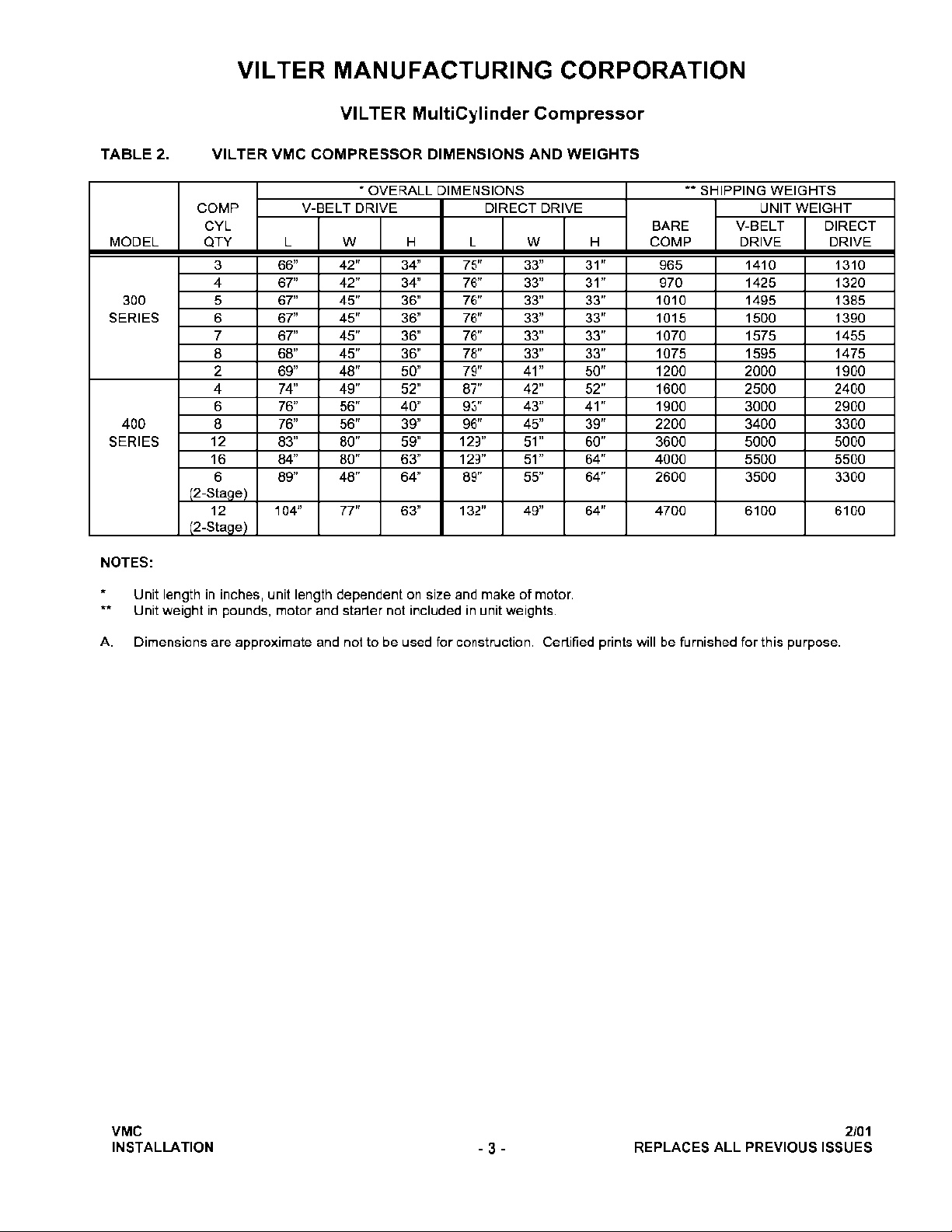

- Weight and Size:

- Sizes are provided in the installation section based on model.

- Depending on the model and configuration it weighs between 965 to 4000 lbs .

- Type of oil system:

- It allows to heat the crankcase.

- It assists in oil cooling for regulating temperature.

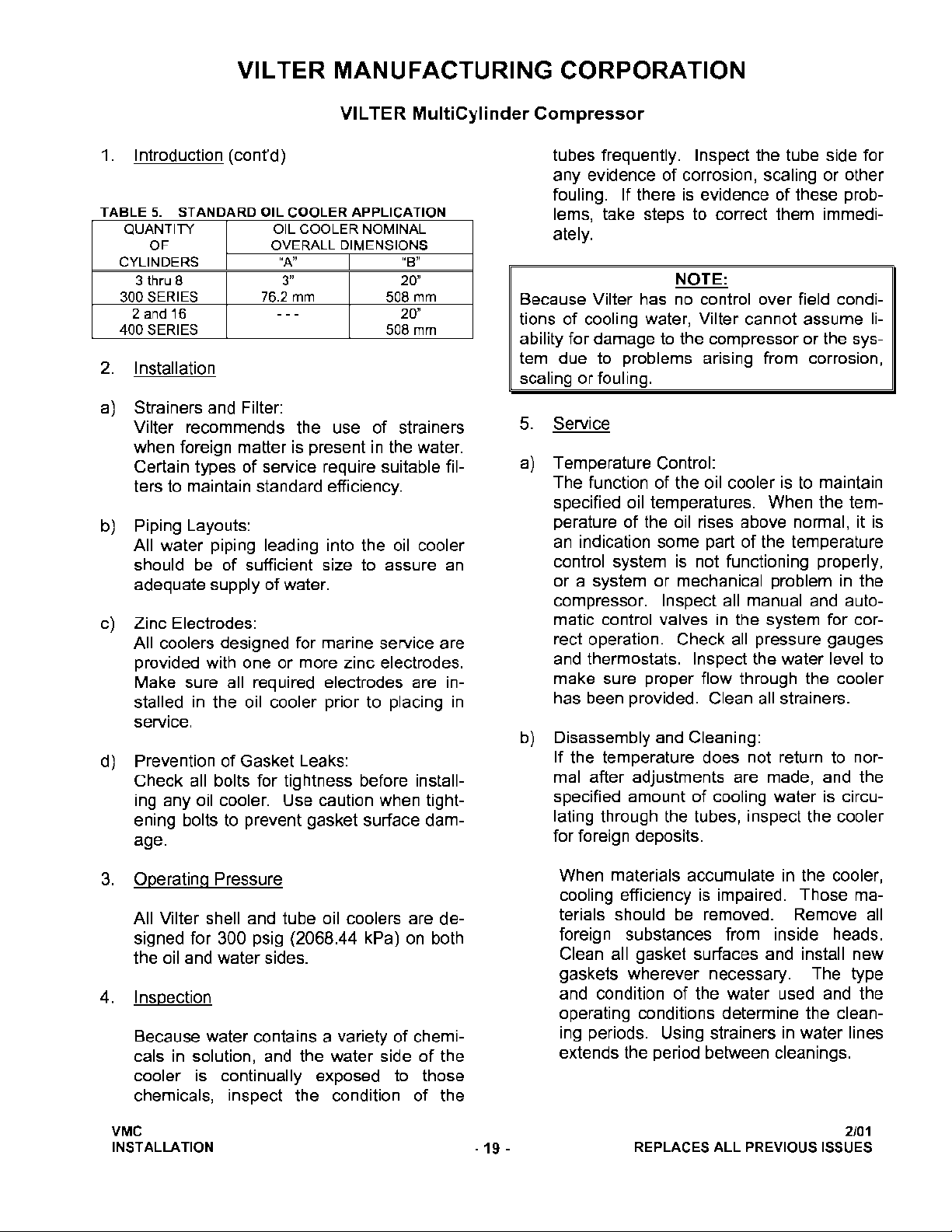

- Safety Devices: Local safety regulations should be followed; It incorporates the above appliances and the electric equipment's safety controls.

- Maintenance Recommendations: In order to allow the model to operate as required, a daily, weekly, monthly and yearly schedule for servicing is set.

Frequently Asked Questions

- Which vapor can the VILTER compressor magnitude withstand?

- The magnitude of the compressor can only withstand vapor which is superheated.

- What is the Capacity of the Compressor?

- The compressor’s maximum capacity depends on the model with the larger configurations rated for a maximum of 619 CFM.

- What electrical specifications are necessary?

- The compressor needs an electrical power supply of 400 volts.

- Does the compressor come with any safety features?

- Yes, Safety devices are designed especially for the locality standards which includes electrical interlocks and full guards for moving parts.

- What Kind of oil Should be Used to the Compressor?

- Vilter recommends using only Vilter-approved lubricants for the VMC Compressors in order to protect warranty coverage.

- How often should a Maintenance be Required?

- Various checks should be done regularly on a daily, weekly, monthly and yearly basis alongside a lubricating program and systematic maintenance for the latter is recommended.

- Is It Possible For the Outdoor Stored VMC to function Outside?

- Although Yes, it can be stored outdoors, but it needs to be in an area with sufficient drainage which helps avoid accumulation of water and also requiring application of suitable rust inhibitors on the metal surfaces.

- Is There a Manual Which Explains the Installation Process?

- There is a manual which roughly outlines the parameters on devoiring details while following the parameters closely is greatly essential.

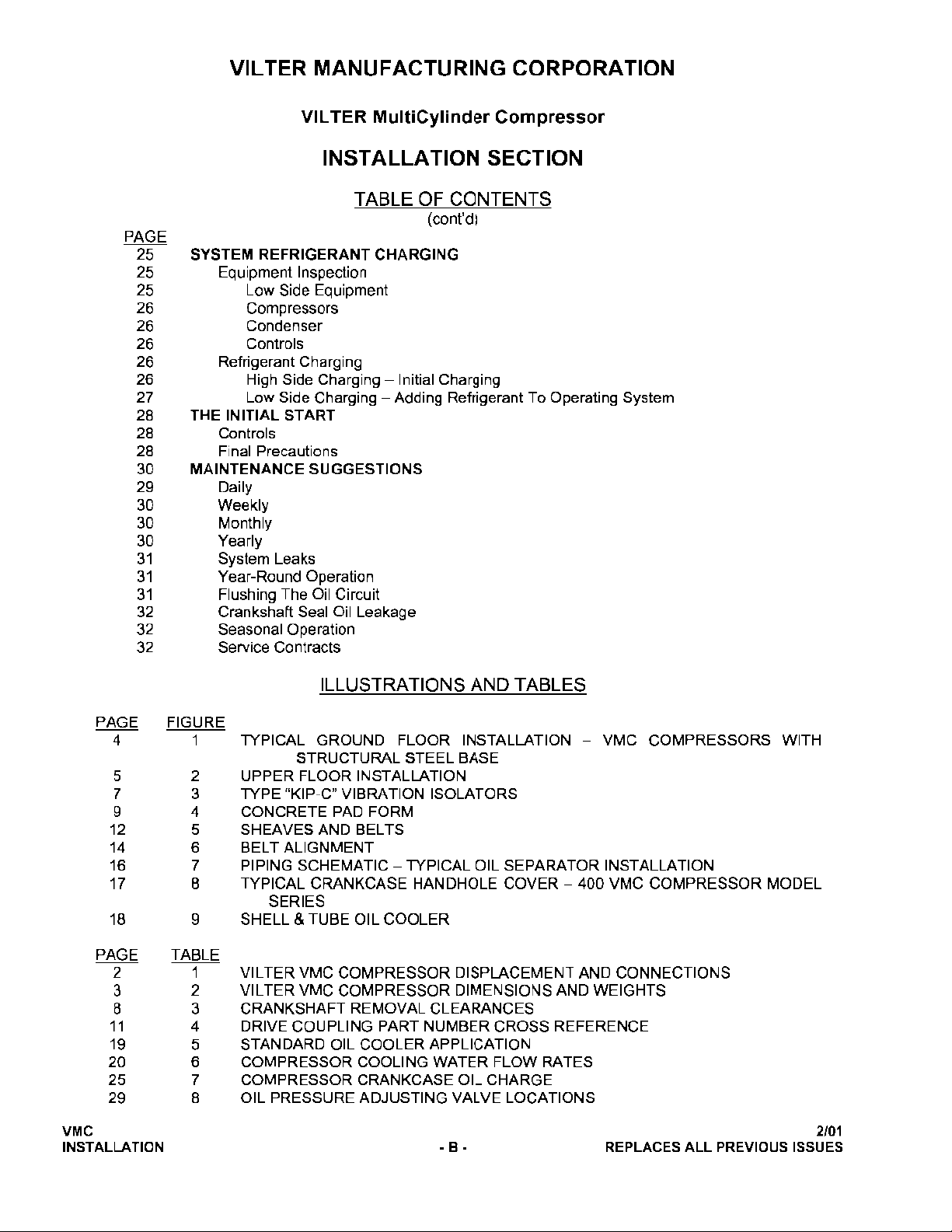

User Manual

Page 1

400 VMC series compressor

Operation and service manual

Page 2

Page 3

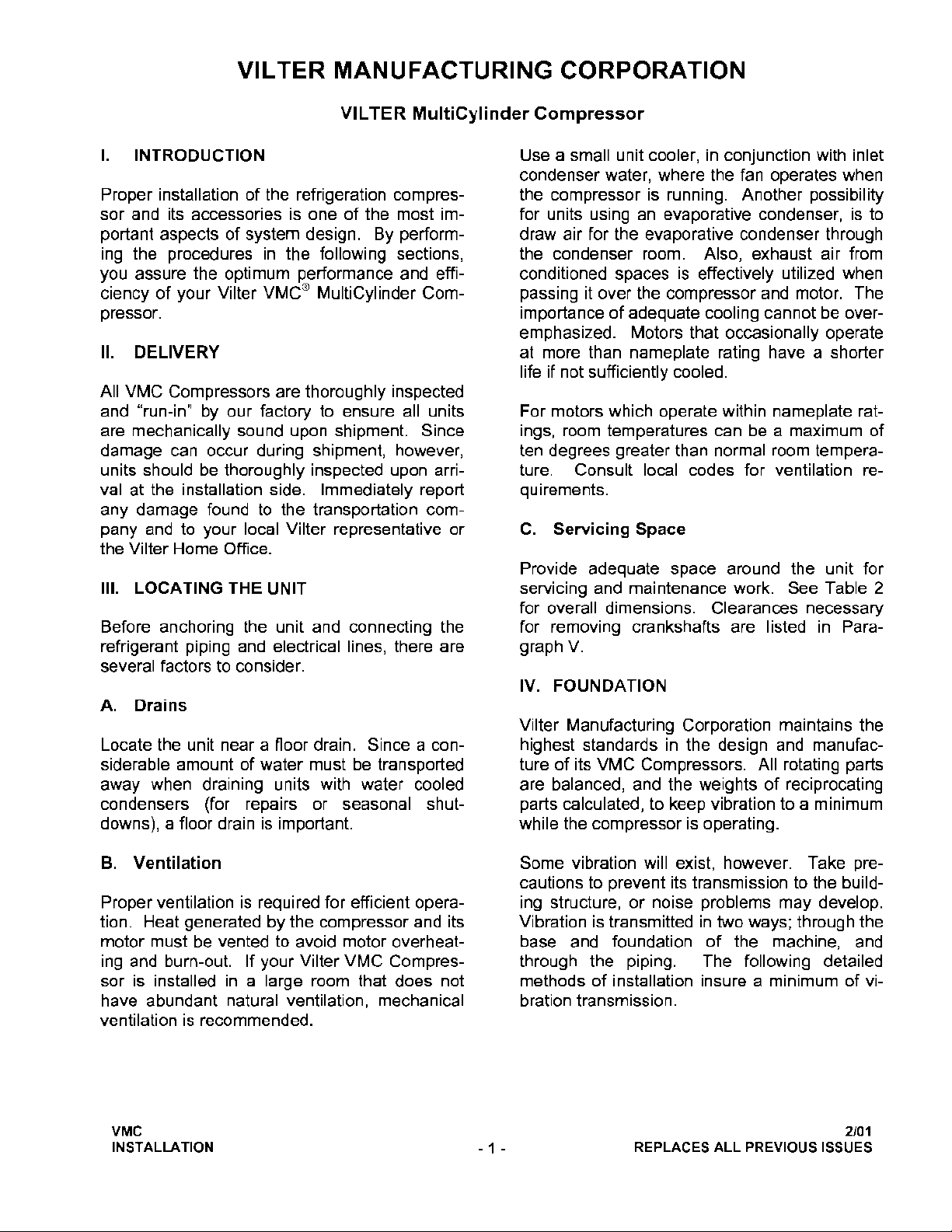

VILTER MANUFACTURING CORPORATION

VILTER Multicylinder Compressor

OPERATING INSTRUCTION MANUAL

400 SERIES COMPRESSORS

READ CAREFULLY BEFORE INSTALLING AND STARTING YOUR COMPRESSOR.

The entire manual should be reviewed before attempting to install, service or repair the compressor.

A refrigeration compressor is a positive displacement machine. It is designed to pump superheated

vapor. The compressor must not be subjected to liquid carry over. Care must be exercised in properly

designing and maintaining the system to prevent conditions that could lead to liquid carry over. Vilter

Manufacturing Corporation is not responsible for the system or the controls needed to prevent liquid

carry over and as such Vilter Manufacturing Corporation cannot warrant equipment damaged by improperly protected or operating systems.

Vilter screw compressor components are thoroughly inspected at the factory, assuring the shipment of a

mechanically perfect piece of equipment. Damage can occur in shipment, however. For this reason, the

units should be thoroughly inspected upon arrival. Any damage noted should be reported immediately to

the Transportation Company. This way , an authorized agent can examine the unit, determine the extent

of damage and take necessary steps to rectify the claim with no serious or costly delays. At the same

time, the local Vilter representative or the home office should be notified of any claim made.

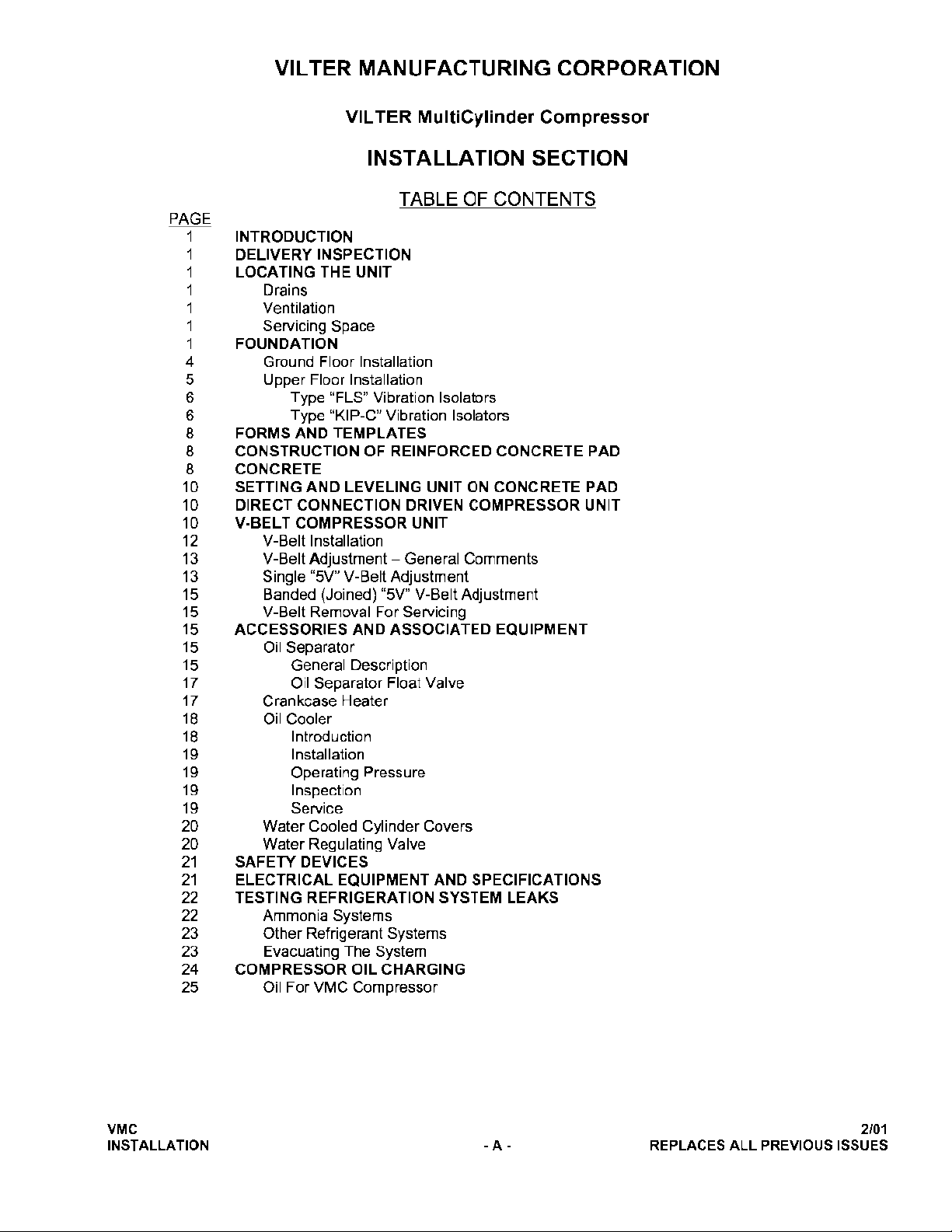

TABLE OF CONTENTS

This manual consists of the following sections:

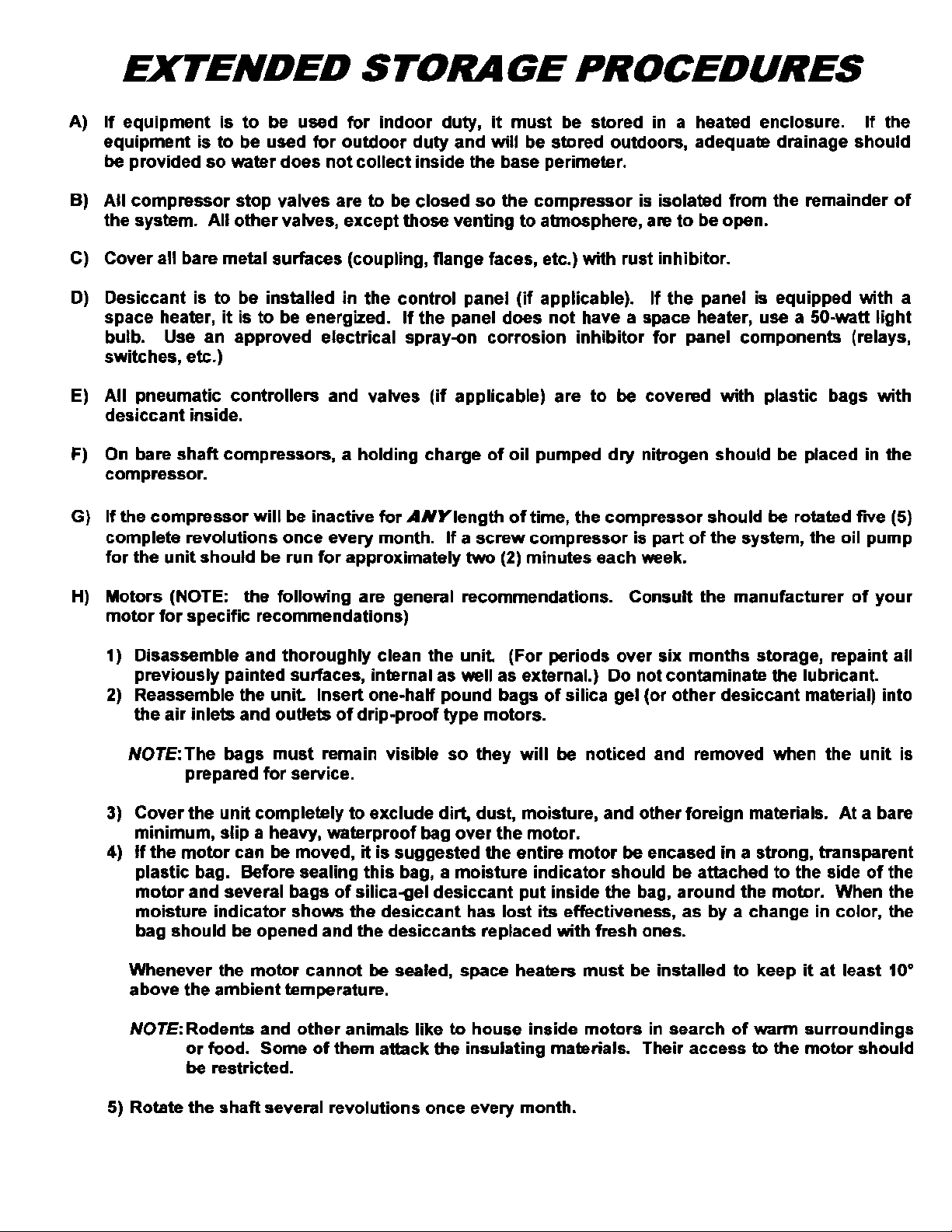

EXTENDED STORAGE PROCEDURES

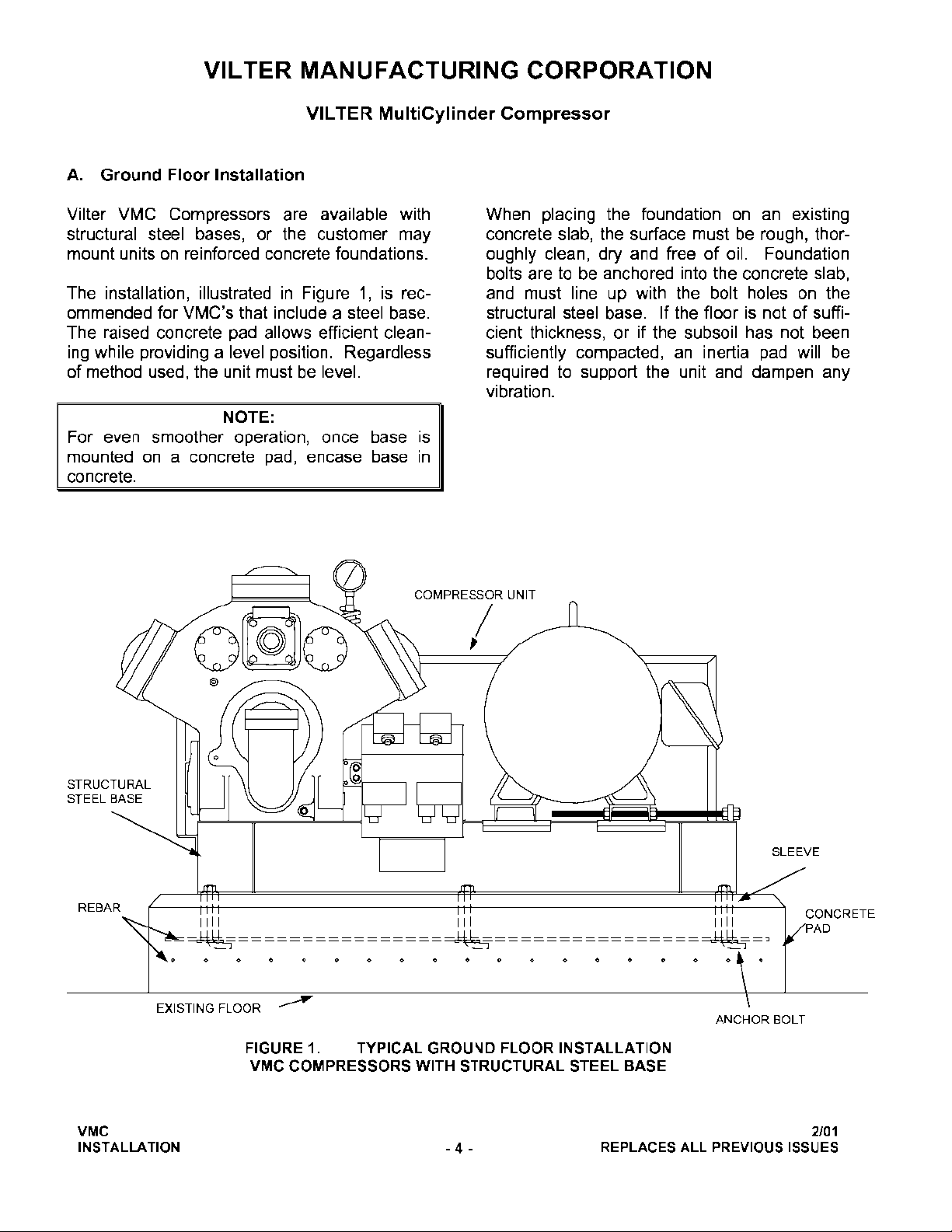

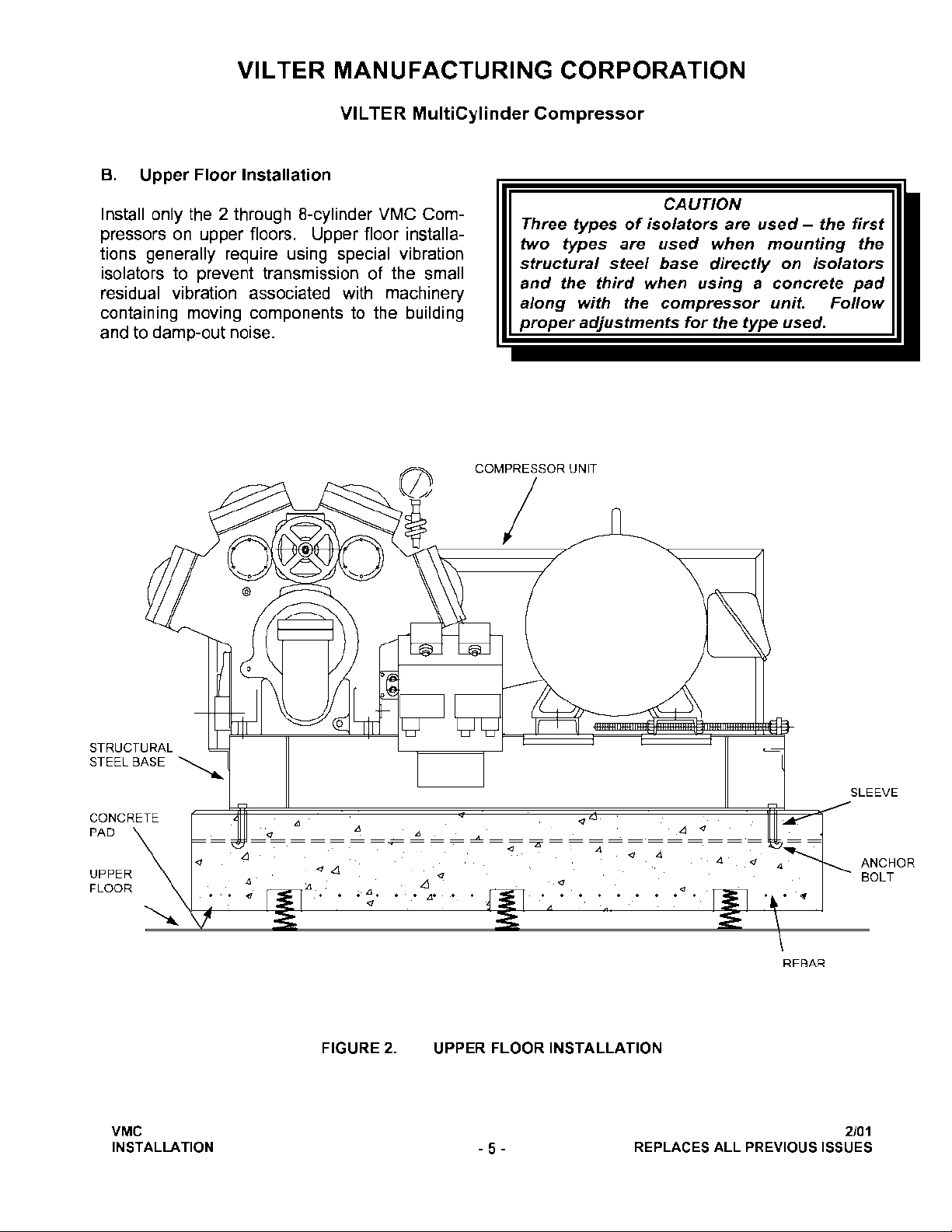

INSTALLATION INSTRUCTION SECTION

This section should be read thoroughly before attempting to install a VMC

Compressor. IMPORTANT: Local codes and ordinances should be

checked beforehand so that violations do not occur, especially concerning

devices for control and safety.

COMPRESSOR OPERATION SECTION

COMPRESSOR SERVICE SECTION

COMPRESSOR REPLACEMENT PARTS SECTION

Section 100R

Section 102R

Section 105R

Section 105X

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Vilter Stop/Check-Valve General Information

AUTO

In the “Auto Position”, the stop valve is operating as a check valve,

allowing flow in the directions of the arrows.

To set the valve to the automatic position, fully close the valve, and

turn the stem out as indicated by the chart below.

CLOSED

In the manually “Closed Postion”, the stop check is operating as a

convientional stop valve, not allowing flow in either direction.

OPEN

In the manually ” Open Position”, with the valve stem fully back seated,

the valve disc is lifted slightly, allowing flow in either direction.

Page 50

Verify the location of Spring and note the direction of the Vilter name

Installation: The new design will apply only to the 2” thru 4” stop valves.

Retrofitting a field installation will require replacing the bonnet

assembly.

The bonnet must be installed with the spring towards the bottom (see

illustrations above). The drill fixture is designed so that the hole for the spring

will always be drilled on the opposite side from the cast in Vilter name on the

bonnet. From the outside of the valve, the casting numbers must always be

towards the top of the valve.

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Page 78

Page 79

Page 80

Page 81

Page 82

Page 83

Page 84

Page 85

Page 86

Page 87

P28 and P128 Series Lube Oil Controls

with Built-in Time Delay Relay

The P28 and P128 Series Lube Oil Controls provide

dependable and economical oil pressure cut-out for

pressure-lubricated refrigeration compressors. The

field-adjustable pressure differential of these controls

provides compressor operation according to the

manufacturer’s specifications. The P28 and P128

controls operate by measuring the net lube oil pressure

and de-energizing the compressor if the pressure falls

below the differential setpoint.

Manual or automatic reset models are available with

factory set and sealed time delays of 30, 45, 60, 90,

or 120 seconds (all time delays may not be available

on all models). The P128 is the same control as the

P28 but with 1/4 inch male flare pressure connections.

Master Catalog 125

Pressure Controls Section P

Product/Technical Bulletin P28

Issue Date 0498

Figure 1: P128AA

Features and Benefits

Built-in Time Delay Relay

with Ambient Compensation

Trip-free Manual Reset Provides manual reset that cannot be overridden

Replaceable Time Delay

Relay Assembly

Available with Runlight and

Alarm Terminals

Minimizes timing fluctuations due to temperature

variations

by pressing and holding the reset button

Allows easy field replacement of the time delay

relay and terminal board

Allows the control to be wired for normal oil

pressure runlight signals and shutdown alarm

circuits for remote monitoring of oil pressure

status

© 1998 Johnson Controls, Inc.

Part No. 24-7664-605, Rev. A

Code No. LIT-125420

1

Page 88

ntroduction

I

!

WARNING: Personal injury hazard. All

P28 and P128 controls are

designed as lubrication

protection controls. Failure of

the P28 or P128 could allow

the refrigeration compressor

to be damaged in a way that

may not be apparent upon

visual inspection. Follow

proper procedures and the

compressor manufacturer’s

instructions, as well as any

warning signs on or around

the equipment, when

discharging and

disassembling the

compressor.

Environmental damage

hazard. If leakage of sensed

media (such as refrigerant or

oil) can be harmful to the

environment, or hazardous in

any way, user must provide

for proper containment.

The P28 and P128 controls measure the net oil

pressure available to circulate oil throughout a

pressure-lubricated refrigeration system. The net oil

pressure is the difference between the oil pressure at

the pump discharge and the refrigerant pressure in

the compressor crankcase.

Example: If the oil pressure pump discharge reading

is 90 psi (621 kPa) and the crankcase

pressure is 70 psi (483 kPa), the net oil

pressure is 20 psi (138 kPa).

The P28 and P128 have a built-in time delay relay.

This relay allows the oil pressure to build up for the

time delay period before the compressor trips. This

also prevents nuisance lockouts due to intermittent

loss of oil pressure. The time delay relay is a

“trip free” device. The manual reset cannot be

overridden by pressing and holding the reset button.

Manual reset models are available with time delays

of 30, 45, 60, 90, or 120 seconds. Automatic reset

models are available with a 90-second time delay.

The time delay relay is compensated to minimize the

effect of ambient temperature variations. However,

the time delay relay will be affected by voltage

variations.

Dimensions

Figure 2: P28 or P128 Dimensions (in./mm)

peration

O

When the compressor starts, the timer is energized

because the ne t oil pressure of the system is zero.

During normal operation, the net oil pressure should

build up to the pressure switch’s cut-out setting

(scale setting) plus the switch differential (3 to 5 psi

[21 to 34 kPa]) within the required time delay,

causing the time delay relay to de-energize.

If the net oil pressure does not rise to the cut-out

pressure setting plus the switch differential within the

required time delay, the time delay relay trips and

stops the compressor.

If the net oil pressure drops below the cut-out

pressure setting during the compressor’s run cycle,

the time delay relay energizes. If the net oil pressure

returns within the time delay, the time delay relay deenergizes and the compressor continues to operate

normally. If the net oil pressure does not return

within the time delay, the control shuts down and

locks out the compressor.

2 P—P28 and P128 Series Lube Oil Controls with Built-in Time Delay Relay Product/Technical Bulletin

Page 89

Example: Net oil pressure (oil pump pressure minus

crankcase pressure) required to the

bearings is 9 psi (62 kPa). The control

scale setting should be 9 psi (62 kPa).

The switch differential is 5 psi (34 kPa).

Upon initial start of the compressor, the

time delay relay energizes. If the net oil

pressure does not build up to 14 psi

(97 kPa), or the scale setting (9 psi) plus

the switch differential (5 psi), during the

time delay, the control breaks the circuit to

the compressor. If the pressure of 14 psi

(97 kPa) is reached during the time delay,

the time delay relay de-energizes and the

compressor continues to operate normally.

nstallation

I

Mounting

Pressure Connections

!

CAUTION: Equipment damage hazard.

●

Avoid sharp bends or kinks in the

capillary or tubing to avoid damage to

the capillary.

●

Coil and secure excess capillary or

tubing. Because harmonic vibration

can break the capillary or tubing, some

slack must be provided.

●

Do not allow the capillary or tubing to

rub against metal surfaces where

friction can cause damage.

●

When using a control with

1/4 in. / 6.4 mm tubing, a pulsation

damper must be used. Pulsation can

cause excessive wear and damage

the control.

!

CAUTION: Equipment damage hazard.

●

A P28AN or P28DN control used for

ammonia service must be mounted

separately from the electrical cabinet.

An ammonia leak could damage the

electrical circuitry.

●

Do not use Johnson Controls/Penn

Ecosafe® hose tubing in applications

with ammonia or other corrosive

refrigerants. Corrosion could cause

tube breakage and refrigerant

leakage.

●

Use only the mounting screws

supplied with the control. Damage to

internal components may occur if

other screws are used.

The P28 and P128 controls are not position sensitive

and can be mounted in any position.

Use the two mounting screw holes located on the

back of the control case to mount the control directly

to a wall or panel board. Mount the control so that

the pressure connections on the bellows are above

the crankcase liquid level of the equipment being

controlled.

Note: When mounting the control to a

compressor is required, a mounting bracket

(Part No. 271-51) is available.

1. Purge all tubing and lines before connecting the

pressure control.

2. Connect the oil pressure line pump discharge to

the pressure connector labeled “OIL.”

3. Connect the crankcase pressure line to the

pressure connector labeled “LOW.”

4. Coil and secure excess capillary or tubing to

avoid vibration.

Wiring

!

WARNING:

●

Make all wiring connections using copper

conductors only.

●

Wire in accordance with National Electric Code

and local regulations. For maximum electrical

rating of the control, see the label inside the

control cover.

●

Use the terminal screws furnished (8-32 x 1/4 in.

binder head). Substitution of other screws may

cause faulty connections.

Shock hazard.

Disconnect all

power supplies before making

wiring connections to avoid

electrical shock or damage to

the equipment.

P—P28 and P128 Series Lube Oil Controls with Built-in Time Delay Relay Product/Technical Bulletin 3

Page 90

See Figures 3 through 10 for typical wiring diagrams

y

y

y

g

y

g

g

y

g

or refer to the compressor manufacturer’s

specifications.

When the P28 or P128 control is supplied with a

Terminal 3, it may be wired to operate a runlight for

indicating when there is sufficient net oil pressure.

When the control is supplied with a Terminal A, it can

be wired to operate a shutdown alarm or signal for

indicating when the compressor has tripped.

For applications using a 208V control circuit, it is

suggested that one leg of the 208V circuit and a

neutral or ground wire be used as a 120V source to

power the time delay relay.

When a P28 or P128 is installed on a 440 or 550

VAC system, use an external step-down transformer

to provide either 120 or 240V to the pilot and time

delay relay circuits. The transformer must be of

sufficient volt ampere capacity to operate the motor

starter and the time delay relay. Table 1 presents

the power requirements for the P28 or P128 time

delay relay. Table 2 presents the electrical ratings.

Table 1: Electrical Power Required for

Time Delay Relay

Voltage

Timing in Se conds 12, 24, or 120V 240V

30, 45, 60, 90, or 120

Table 2: Electrical Ratings--Pilot Duty

Time Delay Relay

Circuit

120/240 VAC 750 VA, 120/240 VAC 10W Tungsten, 120/240 VAC 10 Ampere, 120 VAC

24 VAC/VDC

12 VAC/VDC

* Must be the same voltage as the pilot circuit.

** Must be the same voltage as the time delay relay circuit.

Low

Pilot Circuit Alarm Circuit* Crankcase Heater**

(Terminal 1)

5 Ampere, 240 VAC

125 VA, 24 VAC

57.5 VA, 24 VDC

PC

2

Oil

120/240 M odels

240

3

1

PC

TD

1

2

2

H

120

DR

L

TD

M

A

125 VA, 24 VAC

57.5 VA, 24 VDC

1

Low

Oil

Low Volta

3

1

PC

PC

2

1

2

H

*12 volt also available.

e Models

TD

2

24*

L

TD

M

A

15 VA 30 VA

Runlight**

(Terminal 3)

10W Tungsten

-- 10W Tungsten

1

-

Pressure actuated contacts. Open on increase in pressure difference between oil and low pressure conntectors. Makes

PC

1

and breaks tim e dela

-

Contacts close simultaneousl

PC

2

-

Time dela

TD

1

is not established or maintained.

-

TD

Contacts close simultaneousl

2

DR--Volta

-

H

H eater f o r time dela

Connect Terminals L and M as a sin

Connect Terminals 2 and 240 or 120 to ener

relay. Conta c t s o pe n afte r time d e l ay interval if pressure dfference between oil and low pressure connectors

e dropping resistor used in dual voltage models.

heater circuit.

when PC contacts open (runlight circuit).

when TD contacts open (alarm circuit).

relay.

le p ole s witch.

1

1

ize circuit only when motor starter is closed.

Figure 3: P28 or P128 Internal Wiring Circuit, Showing Alarm Circuit and Runlight Terminals

4 P—P28 and P128 Series Lube Oil Controls with Built-in Time Delay Relay Product/Technical Bulletin

Page 91

y

g

Crankcase

g

g

y

y

g

g

g

y

g

Heater

When Used*

Add itional c ont ro l s in th is lin e onl

Operatin

Control

240

1

L

2

M

A

120

P28 or P 12 8

240V 3-phase

.

L

1L2L3

T1T

Motor

2T3

Ground

120 or 24 0V

Suppl

Hot

Crankcase

Heater

When Used*

Alarm

if Used

Runli

if Used

240

3

L

1

M

2

*

A

120

P28 or P12 8

ht

240 or

120V

Operatin

Control

Any Voltage

C

2

L1L2L

C

4

C

3

T

1T2T3

Motor

Additional controls

in this line o nl

3

.

*Crankc ase heater cannot be cycled with this hookup. See Figure 5.

Figure 4: P28 or P128 Used on a 240V System with

240V Magnetic Starter Coil

Add itional c ont ro l s in th is lin e only.

Crankcase

Heater

When Used*

Runli

if Used

ht

Operatin

Control

240

3

L

1

2

*

Alarm

if Used

M

A

120

P28 or P 12 8

*When crankcase heater is used, disconnect jumper fr o m 2 to M

and reconnect from 2 to L.

240V 3-phase

L1L2L

T

1T2T3

Motor

3

Figure 5: P28 or P128 Wired for 3-wire Control

(Jumper between 2 and M [or L] must be field

installed.)

*Wh e n crank cas e heater is use d, disconnec t jump er from 2 to M

and reconnect from 2 to L.

Figure 6: P28 or P128 Where Separate Supply is

Provided for Control Circuit (Jumper between

2 and M [or L] must be field installed.)

440V

3-phase

Crankcase

Heater

When Used*

240V 440V

Runli

ht

if Used

C

C

L1L2L

2

3

240

3

T

1T2T3

Motor

Additional controls

in this line onl

.

Alarm

if Used

L

1

M

2

*

A

120

P28 or P 12 8

Operatin

Control

*When crankcase heater is used, disconnect jumper 2 to M

and reco nn ect 2 to L . Also, m ake su re that control circuit

transformer has sufficient output for addition al load.

Figure 7: P28 or P128 Wired for 440V Supply

and 240V Magnetic Start Coil (Also for 550V

Using Proper Transformer) (Jumper between

2 and M [or L] must be field installed.)

3

P—P28 and P128 Series Lube Oil Controls with Built-in Time Delay Relay Product/Technical Bulletin 5

Page 92

240V

g

y

g

y

y

g

3-phase

L1L2L

2

3

Crankcase

Heater

When Used*

Runli

if Used

ht

Start

C

C

Stop

240

3

Alarm

if Used

L

1

2

*

M

A

T1T2T

Motor

Additional controls

120

in this line o nl

.

P28 or P12 8

*When crankcase heater is used, disconnect jumper from 2 to M

and reconnect 2 to L.

Compressor

3

Low

Oil

3

P74AA

Motor

Low

P28/P128

Oil

Junction Box

Operatin

Control

1

240

L

2

M

240 V

L

1

T

1

L

2

L

3

T

2

T

3

Note:This system would provide shutdown on low

lube oil pressure in either of two com pres sors

operated b

the common motor.

Figure 10: P28 or P128 and P74AA Wired for an

Oil Pressure Control System Where One Motor

Operates Two Compressors

Figure 8: P28 or P128 Where Manual “Start-Stop”

Pushbutton Station is Used (Jumper between

2 and M [or L] must be field installed.)

240V

3-phase

L

1L2L3

T1T2T

Motor

.

3

Alarm

if Used

3

L

1

2

M

A

24*

P28 or P 12 8

Transform er

Starter Coil

Operatin

Control

Additional controls

in this line onl

*12 volt also available.

Figure 9: P28 or P128 Where 24V Control Circuit

Power is from a Step-down Transformer (Jumper

between 2 and M must be field installed.)

Adjustments

The P28 and P128 controls are shipped with a cut-out

pressure differential of 9 psi (62 kPa). However, the

controls can be adjusted according to the compressor

manufacturer’s specifications.

Note: When the controls are shipped as an

accessory to the compressor unit, time delay

and cut-out pressure are set to manufacturer’s

specifications. Replacement controls should

duplicate the manufacturer’s specifications.

!

CAUTION: Equipment damage hazard.

To avoid damage to the

compressor, obtain the

compressor manufacturer’s net

oil bearing pressure

specifications as soon as

possible. If necessary, reset the

cut-out pressure difference to the

manufacturer’s specifications.

When the manufacturer’s specifications are not known,

proceed as follows to set the cut-out pressure

differential:

1. With the compressor running, read the oil pressure

and the crankcase pressure.

2. Subtract the crankcase pressure reading from the

oil pressure pump discharge reading. This is the

net oil pressure to the bearings.

6 P—P28 and P128 Series Lube Oil Controls with Built-in Time Delay Relay Product/Technical Bulletin

Page 93

3. Set the cut-out pointer 6 to 8 psi (41 to 55 kPa)

below the established running net oil pressure with

the Adjusting Disk using a standard screwdriver.

3. Apply power to start the compressor. The time

delay relay should trip after the time interval and

stop the compressor.

To increase the cut-out pressure, turn the

Adjusting Disk counterclockwise. To decrease,

turn clockwise.

To raise the pressure differential, turn the

Adjusting Disk (see Figure 2) to the left when

viewing the front of the control. Turn the adjusting

disk to the right to lower the pressure differential.

est for Shutdown

T

Immediately after installing, and at regular intervals

thereafter, the time delay relay should be tested to

verify that all circuits are operating correctly.

!

WARNING: Shock hazard. Disconnect

power from the control before

testing for shutdown to avoid

electrical shock or damage to

the equipment.

To test for shutdown:

1. Remove power from the control and remove the

control cover.

2. Connect a jumper between Terminals 1 and 2.

See Figure 3 for terminal locations.

4. Remove power from the control and remove the

jumper between Terminals 1 and 2.

5. Replace the cover on the control and apply power.

6. Manually reset the time delay relay if required.

heckout Procedure

C

Before leaving the installation, observe at least

three complete operating cycles to be sure that all

components are functioning correctly.

ungus Proofing

F

Fungus proofing can be supplied at extra cost when

specified. Conforms to government specifications

MIL-V-173A.

epairs and Replacement

R

Field repairs must not be made, except for

replacement of the time delay relay assembly. For a

replacement control or time delay relay assembly,

contact the nearest Johnson Controls representative or

Refrigeration Application Engineering at 414-274-5535.

Note: If the control is mounted on a condensing

unit where air from auxiliary equipment

(blowers or fans) may strike the control,

the control cover should be replaced

before proceeding to Step 3.

Table 3: Replacement Time Delay Relay Assemblies

Part Number Voltage Reset Type Timing in Seconds Alarm Circuit

RLY13A-600R

RLY13A-602R

RLY13A-603R

RLY13A-608R

RLY13A-609R

RLY13A-610R

RLY13A-616R

RLY13A-617R

P—P28 and P128 Series Lube Oil Controls with Built-in Time Delay Relay Product/Technical Bulletin 7

120/240 VAC Manual 60 No

120/240 VAC Manual 90 No

120/240 VAC Manual 90 Yes

120/240 VAC Automatic 90 No

24 VAC/VDC Manual 120 No

120/240 VAC Manual 30 No

120/240 VAC Manual 120 No

120/240 VAC Manual 45 No

Page 94

rdering Information

O

Table 4: Ordering Information

Series Part

Number

P28AA

P128AA

P28AN

P28DA

P28DN

P28GA

P28NA

P28PA

* Style 5 connections are 1/4 in. / 6.4 mm SAE male flare connectors (no capillary tubing). Style 13 connections are 36 in. / 914 mm

capillary tubing and 1/4 in. / 6.4 mm flare nut. Style 15 connections are 1/4 in. / 6.4 mm female National Pipe Thread connectors.

pecifications

S

Power Requirements

Pressure Specifications

Pressure Switch Units

Ambient Operating Conditions

Dimensions (H x W x D)

The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these specifications,

consult the local Johnson Controls Refrigeration Application Engineering at (414) 274-5535. Johnson Controls, Inc. shall not be liable for damages

resulting from misapplication or misuse of its products.

Pressure

Connections*

Style 13, Style 5,

or Style 15

Style 5 Manual Non-corrosive

Style 15 Manual Ammonia 120/240 VAC No No

Style 13 Manual Non-corrosive

Style 15 Manual Ammonia 120/240 VAC Yes Yes

Style 13 Automatic Non-corrosive

Style 13 or Style 5 Manual Non-corrosive

Style 5 Manual Non-corrosive

Product

Material

Mounting

Wiring Terminal

Agency Listings

Shipping Weight

Reset Type Refrigerant Time Delay

Relay Voltage

Manual Non-corrosive

All-range

All-range

All-range

All-range

All-range

All-range

P28 and P128 Series Lube Oil Controls with Built-in Time Delay Relay

See Tables 1 and 2.

Adjustable Cut-out Pressure Difference: 8 to 70 psi (55 to 483 kPa)*

Maximum Differential: 70 psi (483 kPa)

Maximum Working Pressure: 250 psig (1724 kPa) on the high side

Maximum Overpressure: 325 psi (2240 kPa) oil and low side pressure

*The time delay relay is de-energized 3 to 5 psi (21 to 34 kPa) above the cut-out scale setting.

Enclosed Dust-protected Pennswitch

32 to 104°F / 0 to 40°C

Case: 0.062 in. / 1.6 mm Galvanized Steel

Cover: 0.028 in. / 0.7 mm Cold Rolled Steel (plated and painted)

Flat Surface or with a Universal Mounting Bracket (Part No. 271-51)

Large 8-32 x 1/4 in. Binder Head Screws

UL Guide No. SDFY; File SA516**

CSA Class No. 1222 01; File LR948**

*

*Most models. Contact Johnson Controls for a complete listing.

5.66 x 5.32 x 2.09 in. / 144 x 135 x 53 mm

3.0 lb / 1.36 kg

120/240 VAC No No

120/240 VAC No No

120/240 VAC Yes Yes

120/240 VAC No No

24 VAC/VDC No No

24 VAC/VDC No No

Alarm

Terminal

Runlight

Terminal

Controls Group FAN 125

507 E. Michigan Street Master Catalog

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53201

8 P—P28 and P128 Series Lube Oil Controls with Built-in Time Delay Relay Product/Technical Bulletin

Page 95

Master Catalog 125

Temperature Controls Section A

Product Bulletin A70, A72

A70, A72 Series Temperature Controls

for Refrigeration and Heating

Issue Date 0996

Applic ation

The A70 single-pole and A72

two-pole controls are supplied in a

wide selection of ranges to meet

most application needs. See

“Temperature Ranges.”

Models may be supplied to open

a circuit on temperature increase

or close a circuit on temperature

increase as required. An A70

single-pole control may optionally

include a separate reverse-acting

auxiliary contact. Models are

available with a SPDT enclosed

Pennswitch.

All Series A70, A72 controls are

designed for use

operating controls. Where an

operating control failure would

result in personal injury and/or

loss of property, it is the

responsibility of the installer to

add devices (safety, limit

controls) or systems (alarm,

supervisory systems) that

protect against, or warn of,

control failure.

only

as

Specifications

Features

•

Long life contact structure with

high contact force right up to

break -- no bounce on make.

•

Make reset models are

“trip-free”.

•

Ranges available to cover

most applications.

•

Auxiliary contact can be used

to actuate an alarm circuit

when the main contact opens.

•

Two-pole construction

provides a number of

application advantages (see

“General Description”).

•

Heavy gauge “low profile”

stainless steel element cup to

protect against mechanical

damage.

Fig. 1 -- Single function

temperature control, Style 1.

General Description

The A70 controls provide

dependability and quality at

attractive prices. The A72 DPST

controls provide a number of

application advantages such as:

• Control of polyphase motors

without use of magnetic

starters where protection

against overloading and single

phasing is otherwise provided.

• Provides two separate control

circuits necessary for the

control of multiple systems.

• One set of contacts breaks the

“hot” line when wired as a twopole switch in single-phase

circuits.

• Permits control of two

separate load circuits.

• Automatic control of heavy

electrical loads.

• All A70, A72 controls have a

single calibrated scale which

shows directly both cut-in and

cutout settings. Adjustments

can be made readily without

removing the cover.

© 1996 Johnson Controls, Inc.

Code No. LIT-125155

1

Page 96

Optional Constructions

Adjusting Knobs

May be supplied on differential or

range adjusting screw for limited

adjustment within specified limits.

Adjustment Cutout Stops

Cutout stops, factory set as

specified.

Bulb and Capillary

Standard bulb and capillary are

copper. Stainless steel, monel

and steel bulbs are available, if

required. Bulb and capillary with

neoprene coating to military

specifications MIL-R-3065, Grade

SB-515-ABFF may be supplied at

additional cost. Capillary length

6 ft (1.8 m) only.

Covers

Standard finish is gray enamel.

Stainless steel covers available at

slight additional cost for exposed

installations.

Fungus Proofing

Supplied at extra cost, when

specified. Conforms to

government specifications

MIL-V-173A.

Manual Reset

Provides lockout which requires

manual reset before a restart is

possible. Manual reset is “tripfree” and cannot be blocked or

tied down. Button must be

pressed and released before

operation will resume.

Metric Scale Plates

Temperature models are available

with Celsius plates.

Mounting Brackets

Controls are supplied less bracket

unless specified. Controls may

be supplied with mounting

brackets at additional cost. Part

No. 271-350 is standard.

Fig. 2 -- Standard mounting

bracket

Bulb Wells

Supplied at extra cost, when

specified.

Capillary Tubing

Standard temperature elements

supplied with 6 ft (1.8 m) capillary.

Extra length tube available at

additional cost. Longer capillary

tube supplied up to 10 feet (3 m)

in 2 foot (0.6 m) increments; over

10 feet (3 m) in 5 foot (1.5 m)

increments.

Contact Action

Open on rise or close on rise as

specified.

Type

Number

Single-Pole

A70AA

A70AQ

A70BA

A70DA

A70GA

A70HA

A70JA

A70KA

Two-Pole

A72AA

A72AC

A72AE

A72AP

A72CA

A72CE

Temperature Elements

Standard temperature element

styles are shown on Page 5. For

styles other than shown, please

check with the nearest Johnson

Controls district office or

Customer Service.

Type Number Selection

Main

Contact

Action

Open Low 1 No No 1/2 in.

Open Low 1 No Yes 1/2 in. Manual Start

Open Low 1 Yes No 1/2 in.

Open High 1 Yes No 1/2 in.

Open Low 1 No No 1/2 in. Reverse Acting

Open Low 1 Yes No 1/2 in. Reverse Acting

Open High 1 No No 1/2 in. Reverse Acting

Open High 1 Yes No 1/2 in. Reverse Acting

Open Low 2 No No 3/4 in.

Open Low 2 No No 3/4 in. No Cover

Open Low 2 No No 3/4 in. Outdoor Case

Open Low 2 No No 3/4 in. Manual Start

Open High 2 No No 3/4 in.

Open High 2 No No 3/4 in. Outdoor Case

No.

of

Poles

Lockout

with

Manual

Reset

Knob Conduit

Opening

Misc.

Aux. Contact

Aux. Contact

Aux. Contact

Aux. Contact

2 A70, A72 Product Bulletin

Page 97

Master Catalog 125

Pressure Controls Section P

Product Bulletin P74

Issue Date 0204

P74 Series

Differential Pressure Controls

Application

These differential pressure

controls are for use as operating

controls and/or indicating system

functions through display lights or

panels. They measure the

difference in pressure exerted

upon its two sensing elements.

The controls are available for

applications sensing air, oil or

liquid. Typical applications are

proof of flow across a chiller or

water cooled condenser, proof of

flow in a heating or cooling coil

and lube oil pressure sensing on

refrigeration compressors. On a

proof of flow application the

control measures pressure drop

across two different points in

either a closed water circulating

system or a city water to supply

system.

Specifications

Fig. 1: P74 Differential Pressure

Control with

Style 13 elements.

On a proof of flow application in a

water chiller system the control

activates a light or signal to

indicate a loss of water.

The control may also be applied

as a lube oil pressure sensing

control on refrigeration

compressors. They may be used

in combination with P28 and/or

P45 oil pressure cutout controls

on two compressor, single motor

units to reduce the oil system

cost. (See Fig. 4.) Special low

pressure models are available for

variable speed and screw

compressor oil pressure

applications.

All Series P74 differential

pressure controls are designed

for use only as operating

controls. Where an operating

control failure would result in

personal injury and/or loss of

property, it is the responsibility

of the installer to add devices

(safety, limit controls) or

systems (alarm, supervisory

systems) that protect against,

or warn of, control failure.

© 2004 Johnson Controls, Inc. 1

Part No. 997-545, Rev. C

Code No. LIT-125490

Page 98

Features

• Heavy duty, low profile

elements withstand unduly

high overrun pressures that

may be encountered in

shipment or in some machine

rooms.

• Lockout models have a

“trip-free” manual reset.

• Long life contact structure with

high contact force -- no

contact bounce.

• Single unit mounting and

wiring -- saves installation time

and material.

Range and Differential Specifications

Electrical Ratings

General Description

Single and double pole models

are available with contacts that

open on a pressure differential

increase or close on a pressure

differential increase. Also

available are models with singlepole, double-throw enclosed

contacts or with main and

separate reverse-acting auxiliary

contacts. Controls with lockout

feature require manual reset to

reclose circuit after lockout. The

“trip-free” reset will not permit

restart until reset button is pushed

and released.

The operation point of the control

is readily adjusted by rotating the

adjusting disk. The control set

points are easily read on a

calibrated scale.

2 P74 Product Bulletin

Page 99

Optional Constructions

Pressure Elements

Regularly supplied for noncorrosive refrigerants (fluorinated

hydrocarbons). Available for

ammonia service with 1/4 in. -

18 FNPT connector (See Style

Chart, Fig. 2.)

Pressure Connectors

Standard controls supplied with 36

in. capillary tubing with 1/4 in. flare

nut (Style 13). Controls with 1/4

in. SAE male flare connector (no

capillary tubing, Style 5),

36 in. capillary tubing with 1/4 in.

sweat section (Style 34), or 1/4 in.

FNPT connector (Style 15) may

be supplied on quantity orders

(see Pressure Element Styles).

Repairs and Replacement

Field repairs must not be made.

For a replacement control, contact

the nearest Johnson Controls

distributor.

Ordering Information

To order, specify:

1. Quantity required.

Fig. 3: Typical proof of flow hookup.

2. Complete Product Number, if

available.

3. If complete Product Number

is not available, specify Type

Number (see Specifications

table) and the following.

4. Type of refrigerant or fluid.

a. Non-corrosive.

b. Ammonia.

5. Style of pressure connector.

6. Optional constructions.

7. Setting -- contacts close at

____ and open at ____.

Fig. 2: Pressure element styles

available on the P74. Style 13 is

standard. Other styles shown above

can be supplied on quantity orders.

Fig. 4: Typical wiring diagram showing the P74AA and a P28

on a motor operating two compressors.

P74 Product Bulletin 3

Page 100

Performance specifications appearing herein are nominal and are subject to

accepted manufacturing tolerances and application variables.

Controls Group

507 E. Michigan Street

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53202

4 P74 Product Bulletin

Loading...

Loading...