Page 1

Epsilon Ei DeviceNet Drive

Reference Manual

P/N 400501-08

Revision A2

Date: March 20,2002

© 2001, 2002 Control Techniques Drives, Inc.

Page 2

Page 3

Epsilon Ei

DeviceNet Drive

Reference Manual

Information furnished by Control Techniques Drives Inc. (Control Techniques) is believed to be

accurate and reliable. However, no responsibility is assumed by Control Techniques for its use.

Control Techniques reserves the right to change the design or operation of the equipment described

herein and any associated motion products without notice. Control Techniques also assumes no

responsibility for any errors that may appear in this document. Information in this document is subject

to change without notice.

P/N 400501-08

Revision A2

Date: March 20, 2002

© 2001, 2002 Control Techniques Drives, Inc.

Page 4

© 2001, 2002 Control Techniques Drives, Inc.

Part Number: 400501-08

Revision A2

Date: March 2002

Printed in United States of America

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose,

without the express written permission of Control Techniques.

The following are trademarks of Control Techniques and may not be reproduced in any fashion

without written approval of Control Techniques: EMERSON Motion Control, EMERSON Motion

Control PowerTools, AXIMA, “Motion Made Easy.”

Control Techniques is a division of EMERSON Co.

Control Techniques Drives, Inc. is not affiliated with Microsoft Corporation, owner of the Microsoft,

Windows, and Windows NT trademarks.

This product contains DeviceNet software that is licensed from SST, a Division of Woodhead Limited,

50 Northland Road, Waterloo, Ontario - Canada - N2V 1N3.

DeviceNet is a trademark of Open DeviceNet Vendor Association.

RS Networx and SLC 500 PLC are trademarks of Allen Bradley. Control Techniques Drives, Inc. is

not affiliated with Allen Bradley.

This document has been prepared to conform to the current released version of the product. Because

of our extensive development efforts and our desire to further improve and enhance the product,

inconsistencies may exist between the product and documentation in some instances. Call your

customer support representative if you encounter an inconsistency.

ii

Page 5

Customer Support

Control Techniques

12005 Technology Drive

Eden Prairie, Minnesota 55344-3620

U.S.A.

Telephone: (952) 995-8000 or (800) 397-3786

It is Control Techniques’ goal to ensure your greatest possible satisfaction with the operation

of our products. We are dedicated to providing fast, friendly, and accurate assistance. That is

why we offer you so many ways to get the support you need. Whether it’s by phone, fax or

modem, you can access Control Techniques support information 24 hours a day, seven days

a week. Our wide range of services include:

FAX (952) 995-8099

You can FAX questions and comments to Control Techniques. Just send a FAX to the number

listed above.

Website and Email www.emersonct.com

Website: www.emersonct.com

Email: info@emersonct.com

If you have Internet capabilities, you also have access to technical support using our website.

The website includes technical notes, frequently asked questions, release notes and other

technical documentation. This direct technical support connection lets you request assistance

and exchange software files electronically.

Technical Support (952) 995-8033 or (800) 397-3786

Email: service@emersonct.com

Control Techniques’ “Motion Made Easy” products are backed by a team of professionals

who will service your installation. Our technical support center in Eden Prairie, Minnesota is

ready to help you solve those occasional problems over the telephone. Our technical support

center is available 24 hours a day for emergency service to help speed any problem solving.

Also, all hardware replacement parts, if needed, are available through our customer service

organization.

When you call, please be at your computer, with your documentation easily available, and be

prepared to provide the following information:

• Product version number, found by choosing About from the Help menu

• The type of controller or product you are using

iii

Page 6

• Exact wording of any messages that appear on your screen

• What you were doing when the problem occurred

• How you tried to solve the problem

Need on-site help? Control Techniques provides service, in most cases, the next day. Just call

Control Techniques’ technical support center when on-site service or maintenance is

required.

Training Services (952) 995-8000 or (800) 397-3786

Email: training@emersonct.com

Control Techniques maintains a highly trained staff of instructors to familiarize customers

with Control Techniques’ “Motion Made Easy” products and their applications. A number of

courses are offered, many of which can be taught in your plant upon request.

Application Engineering (952) 995-8000 or (800) 397-3786

Email: applengr@emersonct.com

An experienced staff of factory application engineers provides complete customer support for

tough or complex applications. Our engineers offer you a broad base of experience and

knowledge of electronic motion control applications.

Customer Service (Sales) (952) 995-8000 or (800) 397-3786

Email: customer.service@emersonct.com

Authorized Control Techniques distributors may place orders directly with our Customer

Service department. Contact the Customer Service department at this number for the

distributor nearest you.

Document Conventions

Manual conventions have been established to help you learn to use this manual quickly and

easily. As much as possible, these conventions correspond to those found in other Microsoft®

Windows® compatible software documentation.

Menu names and options are printed in bold type: the File menu.

Dialog box names begin with uppercase letters: the Axis Limits dialog box.

Dialog box field names are in quotes: “Field Name.”

Button names are in italic: OK button.

Source code is printed in Courier font: Case ERMS.

iv

Page 7

In addition, you will find the following typographic conventions throughout this manual.

This Represents

bold

italic

ALL CAPITALS Directory names, file names, key names, and acronyms.

SMALL CAPS Non-printable ASCII control characters.

KEY1+KEY2

example: (Alt+F)

KEY1,KEY2

example: (Alt,F)

Characters that you must type exactly as they appear. For example, if you are directed to type

a:setup, you should type all the bold characters exactly as they are printed.

Placeholders for information you must provide. For example, if you are directed to type

filename, you should type the actual name for a file instead of the word shown in italic type.

A plus sign (+) between key names means to press and hold down the first key while you press

the second key.

A comma (,) between key names means to press and release the keys one after the other.

Note

For the purpose of this manual and product, “Note” indicates essential information about

the product or the respective part of the manual.

Throughout this manual, the word “drive” refers to an Epsilon drive.

“Warning” indicates a potentially hazardous situation that, if not avoided, could result in

death or serious injury.

“Caution” indicates a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury.

“Caution” used without the safety alert symbol indicates a potentially hazardous situation

that, if not avoided, may result in property damage.

v

Page 8

Safety Instructions

General Warning

Failure to follow safe installation guidelines can cause death or serious injury. The voltages

used in the product can cause severe electric shock and/or burns and could be lethal. Extreme

care is necessary at all times when working with or adjacent to the product. The installation

must comply with all relevant safety legislation in the country of use.

Qualified Person

For the purpose of this manual and product, a “qualified person” is one who is familiar with

the installation, construction and operation of the equipment and the hazards involved. In

addition, this individual has the following qualifications:

• Is trained and authorized to energize, de-energize, clear and ground and tag circuits and

equipment in accordance with established safety practices.

• Is trained in the proper care and use of protective equipment in accordance with

established safety practices.

• Is trained in rendering first aid.

Reference Materials

The following related reference and installation manuals may be useful with your particular

system.

• Epsilon Ei Drive Installation Manual (P/N 400501-06)

• Epsilon Ei and FM-2 Module Indexing Reference Manual (P/N 400507-01)

• FM-3 & FM-4 DeviceNet Module Reference Manual (P/N 400508-03)

• Epsilon and E Series Drive Parameters Reference Manual (P/N 400504-01)

• ODVA Specification Volumes I and II, Release 2.0

vi

Page 9

Safety Considerations

Safety Precautions

This product is intended for professional incorporation into a complete system. If you install

the product incorrectly, it may present a safety hazard. The product and system may use high

voltages and currents, carry a high level of stored electrical energy, or are used to control

mechanical equipment that can cause injury.

You should give close attention to the electrical installation and system design to avoid

hazards either in normal operation or in the event of equipment malfunction. System design,

installation, commissioning and maintenance must be carried out by personnel who have the

necessary training and experience. Read and follow this safety information and instruction

manual carefully.

Enclosure

This product is intended to be mounted in an enclosure that prevents access except by trained

and authorized personnel and prevents the ingress of contamination. This product is designed

for use in an environment classified as pollution degree 2 in accordance with IEC664-1. This

means that only dry, non-conducting contamination is acceptable.

Setup, Commissioning and Maintenance

It is essential that you give careful consideration to changes to drive settings. Depending on

the application, a change could have an impact on safety. You must take appropriate

precautions against inadvertent changes or tampering. Restoring default parameters in certain

applications may cause unpredictable or hazardous operation.

vii

Page 10

Safety of Machinery

Within the European Union all machinery in which this product is used must comply with

Directive 89/392/EEC, Safety of Machinery.

The product has been designed and tested to a high standard. However the level of integrity

offered by the product’s control function – for example stop/start, forward/reverse and

maximum speed – is not sufficient for use in safety-critical applications without additional

independent channels of protection. All applications where malfunction could cause injury or

loss of life must be subject to a risk assessment, and further protection must be provided

where needed.

General warning

Failure to follow safe installation guidelines can cause death or serious injury. The voltages used in

this unit can cause severe electric shock and/or burns, and could be lethal. Extreme care is necessary

at all times when working with or adjacent to this equipment. The installation must comply with all

relevant safety legislation in the country of use.

AC supply isolation device

The AC supply must be removed from the drive using an approved isolation device or disconnect

before any servicing work is performed, other than adjustments to the settings or parameters

specified in the manual. The drive contains capacitors which remain charged to a potentially lethal

voltage after the supply has been removed. Allow at least 6 minutes for the Epsilon 205, 3 minutes

for Epsilon 202/203 and 30 seconds for E Series drives after removing the supply before carrying

out any work which may involve contact with electrical connections to the drive.

Products connected by plug and socket

A special hazard may exist where the drive is incorporated into a product which is connected to the

AC supply by a plug and socket. When unplugged, the pins of the plug may be connected to the

drive input, which is only separated from the charge stored in the bus capacitor by semiconductor

devices. To avoid any possibility of electric shock from the pins, if they are accessible, a means

must be provided for automatically disconnecting the plug from the drive (e.g., a latching

contactor).

viii

Grounding (Earthing, equipotential bonding)

The drive must be grounded by a conductor sufficient to carry all possible fault current in the event

of a fault. The ground connections shown in the manual must be followed.

Fuses

Fuses or over-current protection must be provided at the input in accordance with the instructions

in the manual.

Isolation of control circuits

The installer must ensure that the external control circuits are isolated from human contact by at

least one layer of insulation rated for use at the applied AC supply voltage.

Page 11

Table of Contents

Safety Considerations vii

Introduction 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

DeviceNet Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DeviceNet Communications Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DeviceNet Messaging and Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Master/Slave Relationship . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation 5

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

DeviceNet Hardware Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Physical Connections to the DeviceNet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Configuring the DeviceNet Network 9

Connection Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Software Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DeviceNet Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Data Processing/Order of Operations for Fixed Assembly Blocks . . . . . . . . . . . . . . . . . . . 17

DeviceNet Online Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Input and Output Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DN Allocation Choice (Connections Established) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

DN Allocation Master MacID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

DN Baud Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DN Bus Off Counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DN Bus Off Fault Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DN Bus Off Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DN Comm Time-out Fault Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DN Device Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DN Duplicate MacID Fault Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DN FAB Master Receive Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DN FAB Master Send Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DN Host Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DN MacID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DN Master Receive Bitmap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DN Master Receive FAB Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

ix

Page 12

DN Master Send Bitmap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DN Master Send FAB Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DN Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DN Network Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DN Receive Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DN Status Major Recoverable Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DN Status Major Unrecoverable Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DN Status Minor Recoverable Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DN Status Minor Unrecoverable Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DN Transmit Counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DN Vendor ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Accessing the EDS File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Hardware Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Module Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Network Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setting the Baud Rate and MacID Externally (One Touch) . . . . . . . . . . . . . . . . . . . . . . . . 32

Network Configuration

Quick Start 35

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Epsilon Ei DeviceNet Drive Configuration Quick Start Process . . . . . . . . . . . . . . . . . . . . . . . . 35

Polled I/O Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Master Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Explicit Messaging Quick Start 53

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

How to Send Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Explicit Messaging Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Drive Parameters 61

By Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

By DeviceNet Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Appendix 71

Glossary 75

Index 79

x

Page 13

Epsilon Ei DeviceNet Drive Reference Manual

Introduction

Purpose

This manual describes the Epsilon Ei DeviceNet (Ei-DN) Servo Drive and gives examples for

connecting DeviceNet® with Epsilon Indexing drives. The reader should have knowledge of

basic DeviceNet concepts. In addition, the user should be familiar with the functionality of

the Epsilon Ei drive. The Ei-DN drive is capable of all functions of the Epsilon Ei, as

described in the Epsilon Ei Reference Manual (P/N 400507-01). The Quick Start chapters of

this manual offer specific examples of various messaging types as well as a programming

reference that lists functional requirements for the Epsilon Ei-DN drive. For a list of

definitions, consult the“Glossary” on page 75.

Diagnostic Display

Reset Button

Network Status LED - See page 32

Module Status LED - See page 31

Figure 1: Epsilon Ei DeviceNet Drive - Ei-DN-205 Shown

DeviceNet Connections See page 6

1

Page 14

Epsilon Ei DeviceNet Drive Reference Manual

The Epsilon Ei-DN configuration is easily set within PowerTools FM software. In

PowerTools FM software, the user has the option to select between 8 predefined assembly

blocks to be transferred using polled data (8 bytes input, 8 bytes output polled data length per

drive). The Ei-DN additionally allows the master to set up an explicit messaging connection

to access all user accessible parameters within the Epsilon drive through PLC logic.

The Epsilon Ei-DN drive has passed internal tests for conformance as a group 2 DeviceNet

slave.

DeviceNet Overview

DeviceNet is a low-level network that provides connections between simple industrial

devices (sensors, actuators) and higher level devices (industrial PLC’s). DeviceNet standards

and specifications are managed by the Open DeviceNet Vendors Assoc. (ODVA) which is an

independent supplier organization that manages the DeviceNet specification and supports the

worldwide growth of DeviceNet and Ethernet IP.

DeviceNet Communications Link

DeviceNet has two primary purposes:

1. Transport of control-oriented information associated with low-level devices.

2. Transport of other information that is indirectly related to the system being controlled,

such as configuration parameters.

The list below presents a summary of the Physical/Media specific characteristics of

DeviceNet:

1. Trunk-line/drop-line configuration (See Figure 2, “Master/Slave Relationship” on

page 4.)

2. Support for up to 64 nodes

3. Node removal without severing the network

4. Simultaneous support for both network-powered (sensors) and self-powered (actuators)

devices

5. Use of sealed or open-style connectors

6. Protection from wiring errors

7. Selectable data rates of 125k baud, 250k baud, and 500k baud

8. High current capability (up to 16 amps per supply)

2

Page 15

9. Operation with off-the-shelf power supplies

10. Power taps that allow the connection of several power supplies from multiple vendors

that comply with DeviceNet standards

11. Built-in overload protection

12. Power available along the bus: both signal and power lines contained in the trunk line

DeviceNet Messaging and Communications

Master/Slave Relationship

ODVA defines a DeviceNet Master as:

The device that gathers and distributes I/O data for the process controller. A Master contains

a scan list it uses to poll slave devices.

ODVA defines a DeviceNet Slave as:

The slave returns I/O data to its Master when it is polled. With respect to the network, the

Slave is a Group 2 Server or a Group 2 Only Server.

Introduction

3

Page 16

Epsilon Ei DeviceNet Drive Reference Manual

Configure Master

DeviceNet

RSNetworx

RsLinx

Configure PLC

DeviceNet Master

Scanner Card

Explicit Message Setup

RSLogix

RsLinx

DeviceNet

Trunk Line

Figure 2: Master/Slave Relationship

Drop Line

24VDC

Power Supply

Slaves (Nodes)

Configure Ei-DN

4

Page 17

Epsilon Ei DeviceNet Drive Reference Manual

Installation

Mechanical Installation

Follow the instructions for mechanical installation of an Epsilon Ei Drive as outlined in the

Epsilon Ei Installation Manual (P/N 400501-06).

DeviceNet Hardware Components

The following components are necessary to design a DeviceNet cable system:

•Cables

• Nodes/Devices

• Connectors

• Power Supply

• Terminating Resistors

Cables

These cables can be obtained from the supplier of the DeviceNet Network Master. (For more

details see the ODVA Specification Volumes I and II, Release 2.0.)

Thick Cable

The thick cable consists of two shielded pairs twisted on a common axis with a drain line in

the center covered with an overall braid. The shield is commonly used as a trunk line when

length is important.

Thin Cable

The thin cable is smaller and more flexible than the thick cable. It is commonly used for drop

lines but can be used for shorter distances as a trunk line.

Nodes/Devices

A DeviceNet slave is any device that is addressable through DeviceNet and contains

DeviceNet communications circuitry. DeviceNet Slaves must comply with the following:

A slave must be connected to the network by a tap and drop-line.

Slaves must be DeviceNet-compatible devices.

63 Slaves can be supported on one network.

Each Slave must be assigned a media access control identification number (MacID).

MacID’s on a single network must be unique.

5

Page 18

Epsilon Ei DeviceNet Drive Reference Manual

Connectors

DeviceNet connectors can be either open-style (wires exposed) or sealed. These connectors

can be obtained from the supplier of the DeviceNet Network Master. (For more details see

the ODVA Specification Volumes I and II, Release 2.0.)

Power Supply Requirements

A separate 24 VDC power supply is needed for the DeviceNet network. The Ei-DN slave

interface is powered using this “network power.” Devices may take all of their required power

off of the network per ODVA specifications.

The Ei-DN draws 25 mAmps from the DeviceNet power supply.

The power supply must have its own current limit protection.

Fuse protection must be provided for each segment of the cable system.

The power supply must be correctly sized to provide each device with its required power.

Power supplies should be distributed throughout the DeviceNet network to maintain a

maximum of 4 Amps per trunk branch.

For more details, refer to the ODVA Specification Volumes I and II, Release 2.0.

Terminating Resistors

Terminating resistors are used to reduce the reflection of signals over the network. Each

terminator must be 121 ohms and installed on both ends of the network between CAN_L (pin

2) and CAN_H (pin 3).

Electrical Installation

Physical Connections to the DeviceNet Network

A standard five wire configuration is used to connect the Ei-DN to the DeviceNet Network.

A 24 Volt power supply should be connected between V+ and V-.

When multiple Ei-DN devices are present on the network, connection with all devices can be

accomplished by either daisy chaining or by using a multiple tap box.

Pin Number Name Insulation Color

1 V- Black

2 CAN_L Blue

3DrainNone

4 CAN_H White

5V+Red

6

Page 19

Installation

The connector provided for the DeviceNet connection is keyed: VT (pin 5) and should be

wired to the keyed slot.

Terminating

Resistor

Figure 3: DeviceNet Wiring

7

Page 20

Epsilon Ei DeviceNet Drive Reference Manual

8

Page 21

Epsilon Ei DeviceNet Drive Reference Manual

Configuring the DeviceNet Network

Connection Types

The Epsilon Ei-DN DeviceNet interface was designed to communicate with a DeviceNet

network in two ways. Polled I/O connections and Explicit Messaging connections can be used

to access all read or read/write data from the Epsilon Ei-DN.

Polled I/O Connections (Implicit Messaging)

The Poll Command is an I/O Message that is transmitted by the Master. A Poll Command is

directed towards a single, specific Slave (point-to-point). A Master must transmit a separate

Poll Command Message for each one of its Slaves that is to be polled. The Poll Response is

an I/O Message that a Slave transmits back to the Master.

A Polled Message contains I/O data that can be read by the PLC on every scan. Polled

messages are used for high priority data and are typically used to transmit parameters, such

as index initiates or position feedback.

Explicit Messaging

Explicit Messages are initiated from a user-created program inside a PLC or PC-based

software program. In a PLC, these messages are sent and received using the PLC-specific

explicit message setup. Using Explicit Messaging, all user parameters can be accessed in the

Ei-DN drive. These messages allow parameters to be sent in messages that may take multiple

scans of the PLC. Explicit Messages are lower priority than Polled I/O messaging connections

and work well for transferring recipes or any 32 bit parameters to the drive.

Software Interface

This section discusses how to configure a DeviceNet Network with PowerTools FM software

and discusses the parameters that appear on the tabs related to DeviceNet configuration. Other

tabs are described in the Epsilon Ei Indexing Drive and FM-2 Indexing Module Reference

Manual (P/N 400507-01).

DeviceNet Tab

The DeviceNet tab allows the user to configure DeviceNet parameters and watch the

DeviceNet Parameters while online with the drive through PowerTools FM. The DeviceNet

tab has two sub-tabs: DN Setup and Online.

The DN Setup tab allows the user to set up MacID, Baud Rate, choice of predefined assembly

blocks, and host-mode enable as well as display the fixed assembly block word mapping.

9

Page 22

Epsilon Ei DeviceNet Drive Reference Manual

Figure 4: The DeviceNet Setup Tab

MacID

The MacID is the number assigned to a particular node. Every node on a DeviceNet network

must have a unique MacID. The range is 0-63. The MacID is also read/write accessible with

the one-touch configuration described in “Setting the Baud Rate and MacID Externally (One

Touch)” on page 32.

Baud Rate

Three standard baud rates can be configured for the DeviceNet network: 125K, 250K, and

500K. The baud rate is also read/write accessible with the one touch configuration described

in “Setting the Baud Rate and MacID Externally (One Touch)” on page 32.

Master Receive and Master Send Assembly Block Selections

In PowerTools FM the user is given the option to select from 9 predefined assembly blocks.

Master Receive Assembly Block data translates to 8 bytes of Polled I/O data that will be

transferred from the Ei-DN to the Master via DeviceNet, and Master Receive Assembly

Block data translates to 8 bytes of polled I/O data that will be transferred from the Master to

the Ei-DN.

Index Select Predefined (Index Sel (Predef))

Index Sel (Predef) is a fixed assembly block used for reading and writing basic functions to

and from the Ei-DN. This fixed assembly block is the default selection in PowerTools FM

10

Page 23

Configuring the DeviceNet Network

and has many parameters premapped for quick setup and replacement. Index Sel (Predef) was

created to keep everything simple and standard for the user. Bits that are generally used have

been included in the assembly block for “no-work” access to DeviceNet I/O. The Index Sel

(Predef) is set as default so the user can set Baud Rate, MacID, drive type and then start

communication. The following tables display the data mapping for the Index Sel (PreDef)

Assembly Blocks. See “Appendix” on page 71 for expanded versions of these tables.

Master ReceiveAssembly Block - Index Sel (Predef)

Word Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

End of

End of

0

Index

1 Reserved Reserved Reserved Input Word Select Data Pointer (See page 14)

2 Data Low Word LS Bit

3MS Bit Data High Word

Chaining

Count

Index

Count

Index

Motion

Travel

Limit -

End of

End of

Travel

Limit +

Reg

Limit

Distance

Hit

Brake

Release

Enable

State

Registration

Sensor 1

Status

In - Motion

Registration

Sensor 2

Status

In +

Motion

Home

Sensor

Status

At

Velocity

Absolute

Position

Val i d

End of

Home

Home

Limit

Dist Hit

Torque

Limit

Motion

State Bit

2

Fault

Motion

State Bit

1

Drive

OK

Motion

State Bit

Master Send Assembly Block - Index Sel (Predef)

Word Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Index

Index

Index

Index

Select Bit

3

Select Bit

2

0

1 Reserved Reserved Reset Output Word Select Data Pointer (See page 15) Enable Stop

2 Data Low Word LS Bit

3MS Bit Data High Word

Select Bit 0Jog - Jog +

Select Bit

1

Home

Initiate

Start

DN Bit 7 MSDN Bit 6 MSDN Bit 5 MSDN Bit 4 MSDN Bit 3 MSDN Bit 2 MSDN Bit 1 MSDN Bit 0

Index

Define

Home

Input Word Select Data P ointer (See page 14)

MS

0

Index Select User Defined (Index Sel (UserDef))

Index Sel (UserDef) is the fixed assembly block used when intiating multiples indexes as with

a standard Ei drive. Assignments are made on the same screen as with the Index Sel (Predef).

Index Sel (UserDef) is used for more advanced Ei applications. By allowing the user to set up

his own DN bits, more advanced operations can be controlled right over the DeviceNet

network. In addition to Home and Jog, any of the 16 indexes may be Initiated or changed. The

following tables display the data mapping for the Index Sel (UserDef) Assembly Blocks. See

“Appendix” on page 71 for expanded versions of these tables.

Master Receive Assembly Block - Index Sel (Userdef)

Word Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

0

15 MR

14 MR

13 MR

12 MR

11 MR

10 MR

9 MR

8 MR

7MR

6MR

5 MR

4 MR

3 MR

2 MR

Index

Index

Index

1 Reserved Reserved Reserved Input Word Select Data Pointer (See page 14)

2 Data Low Word LS Bit

3MS Bit Data High Word

Select

Bit 3

Select

Bit 2

Select

Bit 1

Index

Select

Bit 0

Enable

State

Motion

State Bit

2

1 MR

Motion

State Bit

1

DN Bit

0 MR

Motion

State Bit

0

11

Page 24

Epsilon Ei DeviceNet Drive Reference Manual

Master Send Assembly Block - Index Sel (Userdef)

Word Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Index

Index

Index

Index

0

Select

Bit 3

1 Reserved Reserved Reserved Output Word Select Data Pointer (See page15) Reserved Reserved Enable Input Word Select Data Pointer (See page14)

2 Data Low Word LS Bit

3MS Bit Data High Word

Select

Bit 2

Select

Bit 1

Select

Bit 0

DN Bit

11 MS

DN Bit

10 MS

DN Bit

9 MS

DN Bit

8 MS

DN Bit

7 MS

DN Bit

6 MS

DN Bit

5 MS

DN Bit

4 MS

DN Bit

3 MS

DN Bit

2 MS

DN Bit

Index Type

Index Type is the fixed assembly block used for reading and writing parameters when one

index is running different index types (incremental, absolute, etc.). The Index Type Assembly

Block is used to set up and initiate one index as a position controller but also provides the user

with the additional functionality of the Epsilon Ei drive (i.e. home, jog, or most other I/O

parameters). The Index Type Assembly Block gives the user the flexibility of being able to

control the drive position by position but also gives Home and Jog functionality right within

the DeviceNet I/O. See “Appendix” on page 71for expanded versions of these tables

Master Receive Assembly Block - Index Type

Word Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reg

Home

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

DN Bit

0

7 MR

6 MR

5 MR

4 MR

3 MR

2 MR

1 Reserved Reserved Reserved Input Word Select Data Pointer (See page14) Reserved Reserved Reserved

2 Data Low Word LS Bit

3MS Bit Data High Word

1 MR

DN Bit

0 MR

Enable

State

Absolute

Position

Valid

Limit

Distance

Hit

Limit

Distance

Hit

Travel

Limit -

End of

Home

Travel

Limit +

Torq ue

Limit

Motion

State Bit

2

State Bit

1 MS

Fault

Motion

1

DN Bit

0 MS

Drive

OK

Motion

State Bit

0

Master Send Assembly Block - Index Type

Word Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Index

Type Bit

2

Index

Type Bit

0 DN Bit 7 DN Bit 6 DN Bit 5 DN Bit 4 DN Bit 3 DN Bit 2 DN Bit 1 DN Bit 0 Enable Reset Stop

1 Reserved Reserved Reserved Output Word Select Data Pointer (See page 15) Jog Fast Jog - Jog + Input Word Select Data Pointer (See page14)

2 Data Low Word LS Bit

3MS Bit Data High Word

Home

Initiate

Note

“Index Type” bit 1, 2, and 3 in Master Send Block determine the functionality if the

specified index. As noted in the Drives Parameters Reference Manual (400504-01) the

value of these bits reflect the following data: 000 Incremental Index, 001 Absolute Index,

010 Registration Index, 011 Rotary Plus, and 100 Rotary Minus.

Position Control

Position Control is the fixed assembly block designed using the “Position Controller” profile

for DeviceNet as a guide. Parameters are transferred over the polled I/O connection. Using

12

Index

Start

Type Bit

1

Index

0

Page 25

Configuring the DeviceNet Network

the position controller profile positions, velocities, accels, and decels can be written for a

single index. The index can then be initiated. The Position Control object is used heavily

when a central PLC is desired to control all of the Slaves. This type of configuration allows

for quick parameter changes. The following tables display the data mapping for the Position

Control Assembly Blocks. See “Appendix” on page 71 for expanded versions of these tables

Master Receive Assembly Block - Position Control

Word Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Valid

Absolute

Enable

0 Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

1 Reserved Reserved Reserved Response Assembly Code (See page16)

2 Data Low Word LS Bit

3MS Bit Data High Word

State

Command

Error

Data = 1

Ignore

Data = 0

Reserved

Position

Val id

Trajectory

Start Echo

Stop

Input

Reserved Reserved

Fault

End of

Index

Motion

CCW

Hardware

Limit

(Travel

Limit -)

Reserved

CW

Hardware

Limit

(Travel

Limit +)

Trajectory

Started

Drive OK

Master Send Assembly Block - Position Control

Word Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Val i d

Data = 1

0 Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Enable

1 Reserved Reserved Reserved Response Assembly Code (See page16) Reserved Reserved Reserved Command Assembly Code (See page16)

2 Data Low Word LS Bit

3MS Bit Data High Word

Reserved Stop Reserved

Ignore

Data = 0

Absolute=0

Incremental=1

Reserved

Start

Trajectory

No Operation

The No Operation Assembly Block is used when the user only needs to read back data. This

assembly block allows the user to put any data into the corresponding PLC address without

affect from the drive. This type of assembly block is used heavily in applications when the

PLC is explicit messaging.

Master Send Assembly Block - No Operation

Word Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0

1

2

3

13

Page 26

Epsilon Ei DeviceNet Drive Reference Manual

Input Word Select Data Pointer

The Input Word Select Data Pointer may be used when a polled connection is established

between the Ei-DN and the DeviceNet Master. Using the Input Data Pointer Bits, 32-bit

parameters may be read from the Ei-DN by the PLC. Entering the code into the input select

data pointer will place the corresponding parameter value within the two high words of the 4

word polled data packet. The Input Word Data Select Data Pointer is set by the master in word

1 of the Master Send Data.

Code Description

0x00 No Operation

0x01 Position Feedback

0x02 Position Command

0x03 Velocity Feedback

0x04 Command Velocity

0x05 Reserved

0x06 Torque Command

0x07 Index Position

0x08 Index Velocity

0x09 Index Accel

0x0A Index Decel

0x0B - 0x1D Reserved

0x1E Fault Status Bitmap

0x1F Reserved

14

Page 27

Configuring the DeviceNet Network

Output Word Select Data Pointer

The Output Word Select Data Pointer may be used when a polled connection is established

between the Ei-DN and the DeviceNet master. Using the Output Word Select Data Pointer

bits, 32-bit parameters may be read from the Ei-DN by the PLC. Entering the code into the

Output Select Data Pointer will place the corresponding parameter value within the two high

words of the 4 word polled data.

Code Description

0x00 No Operation

0x01 Index Position Registers

0x02 Index Velocity Register

0x03 Index Acceleration Register

0x04 Index Deceleration Register

0x05 Index Dwell Time

0x06 Reserved

0x07 Torque Limit

0x08 Rotary Rollover Value

0x09 Following Error Limit

0x0A Jog Velocity

0x0B Jog Fast Velocity

0x0C Jog Acceleration

0x0D Jog Deceleration

0x0E Home Velocity

0x0F Home Acceleration

0x10 Home Deceleration

0x11 Home Specified Offset

0x12 End of Home Position

0x13 Home Limit Distance

0x14 Chaining Count

0x15 Index Count

0x16 Next Index

0x17 RAM to NVM

0x18 - 0x1F Reserved

15

Page 28

Epsilon Ei DeviceNet Drive Reference Manual

Command Assembly Code

The Command Assembly Code is used only when the position controller object is in use and

the Ei-DN is online and connected. The Command Assembly Code gives the drive a 32-bit

parameter based on the code it is set for. The parameter is placed in words 2 and 3 of the

polled I/O.

Code Description

0x00 No Operation

0x01 Index 0 Position

0x02 Index 0 Velocity

0x03 Index 0 Accel

0x04 Index 0 Decel

0x05 to 0x10 Reserved

0x11 Reserved

0x12 Reserved

0x13 to 0x1D Reserved

0x1E Reset “Set Bit 0 to 1”

0x1F Reserved

Response Assembly Codes

16

The Response Assembly Code is used only when the position controller object is in use and

the Ei-DN is online and connected. The Response Assembly Code gives the drive a 32-bit

parameter based on the code it is set for. The parameter is placed in words 2 and 3 of the

polled I/O.

Code Description

0x00 No Operation

0x01 Actual Position

0x02 Commanded Position

0x03 Actual Velocity

0x04 to 0x1D Reserved

0x1E Fault Status Bitmap

0x1F Reserved

Page 29

Configuring the DeviceNet Network

Data Processing/Order of Operations for Fixed Assembly Blocks

Since the transfer of parameters over the DeviceNet network has the potential to transfer on

the same scan of the PLC, the user needs to take special consideration of the order of bits sent.

When the Master sends two or more bits in the same DeviceNet message, the bits get

implemented in the Ei-DN in the following order:

• Get Master Send Data Pointer

• Process Master Send Data Block (update word information)

• Process Master Send Bits **

• Send Input data to Master Receive FAB

**The following list represents the priority/order of bit data processed (first to last) sent from

the Master.

• Stop Bit (Held until clear)

• Home Bits (Initiate a home)

• Index Bits (Initiate an Index)

• Jog Bits (Held until clear)

** If individual bits are changed simultaneously within each of the above group, the order of

processing shall follow:

1. Home Bits

• Home Initiate

• Define Home

2. Index Bits

• Index Select

• Index Initiate

3. Jog Bits

•Jog +

•Jog-

•Jog Fast

Note

An Implicit Poll initiates motion, and an immediate response is sent. This response does

not wait for motion to complete, i.e., an Index Initiate Command sent before the drive

completes an index will not be acknowledged by the drive.

17

Page 30

Epsilon Ei DeviceNet Drive Reference Manual

Host Mode Enable

Host Mode Enable allows the user to decide where the control will occur from the DeviceNet

network. Host Mode Enable allows the user to ignore hardwire inputs. Conversely, non-host

mode logically OR’s the Inputs with the DeviceNet function.

Enabling the “Host Mode” gives the host (DeviceNet Master) exclusive control of the

following parameters:

Index Select and Index Initiate

Jog +, Jog -, Jog Fast,

Home Initiate

Define Home

Brake Control and Release

All other functions will be logically OR’ed with hardwire and Modbus inputs when in Host

mode.

Host mode is useful when access to the hardwire I/O needs to be switched from “DeviceNet

only” to “DeviceNet I/O or Hardware I/O.”

Ei-DN Input Processing Logic

Host Mode

Host Mode

Modbus Index Select

Hardwire Index Select

DeviceNet Index Select

Modbus Index Initia te

Modbus Index Initia te

Hardwire Index Initiate

Hardwire Index Initiate

DeviceNet Index Initiate

DeviceNet Index Initiate

Modbus Jog+

DeviceNet Jog+

Modbus Jog-

Hardwire Jog-

DeviceNet Jog-

Modbus Jog Fast

Hardwire Jog Fast

DeviceN et Jog F ast

EN

Host Mode

Host Mode

EN

EN

Host Mode

EN

Host Mode

Host Mode

EN

Host Mode

Host Mode

EN

Index Select

Index Initiate

Index Initiate

Index Jog+

Jog-

Jog Fast

DeviceNet Brake Control

DeviceNet Brake Release

Non-Host Mode Modbus In put

Non-Host Mode Hardwire Input

Non-Host Mode DeviceNet Input

Figure 5: Ei-DN Input Processing Logic Diagram

Modbus Home Init iate

Hardwire Home Initiate

DeviceNet Home Initiate

Modbus Define Home

Hardwire Define Home

DeviceNet Define Home

Modbus Brake Control

Hardwire Brake Control

Modbus Brake R elease

Hardwire Brake Release

EN

Host Mode

EN

Host Mode

EN

Host Mode

EN

Home Initiate

Define Home

Brake Control

Brake Release

Non-Host Mode O utput

18

Page 31

DeviceNet Online Tab

The DeviceNet Online Tab is available to the user when PowerTools FM is online with the

Ei-DN. This tab displays DeviceNet specific diagnostics and allows the user to view the

status of the DeviceNet network.

Configuring the DeviceNet Network

Figure 6: DeviceNet Online Tab

Information

Master MacID

The Master MacID is the MacID of the DeviceNet master to the Ei-DN.

Counters

Transmit/Receive Counter

The Transmit and Receive Counters note the successful data packet exchanges between the

Ei-DN and its DeviceNet master.

Bus-Off Counter

The Bus-Off counter counts the number of bus failures in order to safeguard against a network

that goes down. A Buss Off may occur due to errors in wiring, baud rate settings, or MacID

errors on the network. Ten bus-offs in a row initiate the bus-off interrupt (major fault). This

information is used for troubleshooting the Ei-DN

.

19

Page 32

Epsilon Ei DeviceNet Drive Reference Manual

Status

Network Status LED

Network Status vitual LED indicates whether the Ei-DN is communicating properly with the

DeviceNet network. The table below will describe the current condition of this parameter.

Virtual LED

State

Off Not Powered/Not online

Flashing Green Online, Not Connected

Green Link OK Online, Connected

Flashing Red Connection Time-Out One or more I/O Connections are in the Timed-Out state.

Red Critical Link Failure

Drive State Indicates

The device has not completed the Duplicate MacID test yet.

The Device may not be powered, look at Module Status LED.

Device is online but has no connections in the established state. The device has

passed the Duplicate MacID test and is online but has no established connections

The device is online and has connections in the established state. This means the

Failed communication device. The device has detected an error that has rendered it

incapable of communicating on the network (Duplicate MacID or Bus Off).

Device is not online:

to a Master.

device is connected to a Master.

Module Status LED

Module Status virtual LED indicates whether the device is in standby or operational mode.

Coinciding text will describe the current condition of this parameter.

Virtual L ED

State

Off No Power There is no power applied to the device.

Green Device Operational The device is operating in a normal condition.

Flashing Green

Flashing Red Minor Fault Recoverable Fault

Red Unrecoverable Fault The device has an unrecoverable fault, may need replacing

Flashing Red-

Green

Device in Standby (The Device Needs

Drive State Indicates

Commissioning)

Device Self-Testing The device is in self-test.

The device needs commissioning due to configuration missing,

incomplete, or incorrect. The device may be in the standby state.

Established Connections

Polled/Explicit Messaging Virtual LED’s

The virtual LED display for Polled and Explicit Messaging represents the status of these

connections on the DeviceNet Network.

20

Virtual LED State Indicates

Green Connected state

Gray Unconnected state

Page 33

Input and Output Tab

DeviceNet Bits

DeviceNet bits are user-defined bits that are assigned within the inputs and outputs tabs.

These bits are used with specific assembly blocks to transfer data via the polled connection.

DeviceNet bit numbering is the same for all assembly blocks selected; therefore, DN bit 0 MR

(Master Receive) under “Index Sel (User Def)” is the same as DN bit 0 MR (Master Receive)

for “Index Type.”

Configuring the DeviceNet Network

Figure 7: Inputs Tab

Multiple assignments may be made to the same DN bit, and the same I/O function may be

mapped to a DN bit as well as to an I/O assignment. This allows the user to indicate drive

status simultaneously to multiple devices via hardwire and DeviceNet. When multiple

assignments are made, the DN bit is the logical OR condition at he assigned input function.

21

Page 34

Epsilon Ei DeviceNet Drive Reference Manual

Figure 8: Outputs Tab

When an unsupported DN bit assignment is made, a warning message will pop up telling the

user that the selected assembly block does not support that bit. When acknowledged, the

assignment will be mapped to that bit anyway and will not be transferred via DeviceNet.

Faults and Diagnostic Display

PowerTools FM has implemented an extended set of fault and diagnostic parameters to aid in

setup and monitoring of the DeviceNet Network. Figure 9 shows the faults and diagnostic

parameters available to the user through PowerTools FM or using Explicit Messages on the

DeviceNet network.

22

Page 35

Figure 9: Watch Window

Configuring the DeviceNet Network

DN Allocation Choice (Connections Established)

Ei-DN Modbus Address: 34003

Range Units Default Typ e DN Type Group NVM Res. Access

BM16 WORD No RO

This parameter monitors the status of the established connections and displays the corresponding

bitmap. Bit 0 Explicit Message, Bit1 Polled.

DN Allocation Master MacID

Ei-DN Modbus Address: 34004

Range Units Default Typ e DN Type Group NVM Res. Access

0-63 63 US16 UINT No RO

This parameter displays the MacID of the master used to control the Ei-DN. The DN Allocation

Master MacID parameter defaults to 63 when no master is controlling it.

23

Page 36

Epsilon Ei DeviceNet Drive Reference Manual

DN Baud Rate

Ei-DN Modbus Address: 44002

Range Units Default Typ e DN Type Group NVM Res. Access

0-2 Baud ENM WORD Yes RW

Three standard baud rates can be configured for the DeviceNet network: 125K, 250K, and 500K.

The baud rate is also read/write accessible with the one touch configuration located directly on the

drive.

Value Baud

0 125K

1 250K

2 500K

DN Bus Off Counter

Ei-DN Modbus Address: 34206

Range Units Default Typ e DN Type Group NVM Res. Access

0-255 Counts US16 UINT No RO

The Bus Off counter counts the number of bus failures in order to safeguard against a network that

goes down. This information is used for troubleshooting the Ei-DN.

DN Bus Off Fault Count

Ei-DN Modbus Address: 40719

Range Units Default Typ e DN Type Group NVM Res. Access

31

-1 Counts US16 UINT Yes RO

0-2

This parameter indicates the total number of Bus Off Faults that have occurred on the DeviceNet

network.

DN Bus Off Interrupt

Ei-DN Modbus Address: 34205

Range Units Default Typ e DN Type Group NVM Res. Access

0, 1 ENM Word No RO

Ten Bus-Off Faults in a row initiate the Bus-Off Interrupt (Major fault).

24

Page 37

Configuring the DeviceNet Network

DN Comm Time-out Fault Count

Ei-DN Modbus Address: 40717

Range Units Default Typ e DN Type Group NVM Res. Access

15

-1 Counts US16 UINT Yes RO

0-2

This parameter indicates the total # of Communication Time-out Faults that have occurred on the

DeviceNet network.

DN Device Type

Ei-DN Modbus Address: 34002

Range Units Default Typ e DN Type Group NVM Res. Access

US16 UINT No RO

DN Device Type indicates the ODVA (Open DeviceNet Vendors Association) definition for

devices. The Ei-DN is set at a DN Device Type of 0.

DN Duplicate MacID Fault Count

Ei-DN Modbus Address: 40718

Range Units Default Typ e DN Type Group NVM Res. Access

15

0-2

-1 Counts US16 UINT Yes RO

The DN Duplicate MacID Fault Count indicates the total number of duplicate MacID faults that

have occurred on the DeviceNet network.

DN FAB Master Receive Block

Ei-DN Modbus Address: 34011-34014

Range Units Default Typ e DN Type Group NVM Res. Access

US16 UINT No RO

The DN FAB Master Receive Block displays the polled data being transferred from the drive to

the master via the Master Receive fixed assembly block (FAB).

Word Modbus Address

034011

1 34012

2 34013

3 34014

25

Page 38

Epsilon Ei DeviceNet Drive Reference Manual

DN FAB Master Send Block

Ei-DN Modbus Address: 34007-34010

Range Units Default Typ e DN Type Group NVM Res. Access

US16 UINT No RO

The DN FAB Master Send Block displays the polled data being transferred from the master to the

drive via the Master Send fixed assembly block (FAB).

Word Modbus Address

0 34007

1 34008

2 34009

3 34010

DN Host Mode

Ei-DN Modbus Address: 44003

Range Units Default Typ e DN Type Group NVM Res. Access

0,1 ENM Word Yes RW

Enabling the "Host Mode" gives the host (DeviceNet Master) exclusive control of the following

Input functions:

• Index Select and Index Initiate

• Jog +, Jog -, Jog Fast

• Home Initiate

• Define Home

• Brake Control and Release

All other functions will be logically OR'ed with inputs and Modbus 3 when in Host mode.

Host mode is useful when access to the hardwire I/O needs to be switched from "DeviceNet only"

to "DeviceNet I/O or Hardware I/O."

DN MacID

Ei-DN Modbus Address: 44001

Range Units Default Typ e DN Type Group NVM Res. Access

0-63 US16 UINT Yes RW

The DN MacID is the node address of the Ei-DN on the DeviceNet network. The range of this

number is 0-63.

26

Page 39

Configuring the DeviceNet Network

DN Master Receive Bitmap

Ei-DN Modbus Address: 34006

Range Units Default Typ e DN Type Group NVM Res. Access

US16 UINT No RO

This parameter returns the values for the selected master receive bits.

DN Master Receive FAB Type

Ei-DN Modbus Address: 44005

Range Units Default Typ e DN Type Group NVM Res. Access

0-3 ENM Word Yes RW

The DN Master Receive FAB Type displays the chosen fixed assembly block configuration as

shown.

Valu e Master Receive FAB Type

0 Index Select (Predef)

1 Index Select (Userdef)

2 Index Type

3 Position Control

DN Master Send Bitmap

Ei-DN Modbus Address: 34005

Range Units Default Typ e DN Type Group NVM Res. Access

US16 UINT No RO

This parameter returns the values for the selected master send bits.

27

Page 40

Epsilon Ei DeviceNet Drive Reference Manual

DN Master Send FAB Type

Ei-DN Modbus Address: 44004

Range Units Default Type DN Type Group NVM Res. Access

0-4 ENM Word Yes RW

The DN Master Send FAB Type displays the chosen fixed assembly block configuration as

shown.

Val ue Master Receive FAB Type

0 Index Select (Predef)

1 Index Select (Userdef)

2 Index Type

3 Position Control

4 No Operation

DN Module Status

Ei-DN Modbus Address: 34208

Range Units Default Typ e DN Type Group NVM Res. Access

0-31 ENM Word N o RO

The DN Module status indicates the ODVA specific status of the DN device as follows:

Val ue Module Status

1No Power

2 Operational

3 Standby

4 Minor Fault

5 Major Fault

28

Page 41

Configuring the DeviceNet Network

DN Network Status

Ei-DN Modbus Address: 34207

Range Units Default Typ e DN Type Group NVM Res. Access

0-31 ENM Word N o RO

The DN Network status indicates the ODVA specific status of the DeviceNet network as follows:

Val ue Network Status

1No Power

2 Not Connected

3 Connected

4 Time-out

5 Link Failure

DN Receive Counter

Ei-DN Modbus Address: 34203-34204

Range Units Default Typ e DN Type Group NVM Res. Access

31

0-2

-1 Counts US32 UDINT No RO

The DN Receive Counter keeps a running total of all DeviceNet packets successfully received

from the Ei-DN on the DeviceNet network.

DN Status Major Recoverable Fault

Ei-DN Modbus Address: 14003

Range Units Default Typ e DN Type Group NVM Res. Access

True/False BIT BOOL No RO

A Major Recoverable Fault disables the bridge and then re-enables the bridge when the fault

has cleared. At the present, no Major Recoverable Faults are defined in the Ei-DN.

DN Status Major Unrecoverable Fault

Ei-DN Modbus Address: 14004

Range Units Default Typ e DN Type Group NVM Res. Access

True/False BIT BOOL No RO

A Major Unrecoverable Fault is implemented on the Ei-DN

occur: Power Stage Module, Invalid Configuration, Power Up Self Test, NVM Invalid,

Motor Overtemp, Drive Overtemp, Duplicate MacID, and Bus-Off. Major Unrecoverable

Faults disable the bridge and require a cycle of power to reset.

when one of the following faults

29

Page 42

Epsilon Ei DeviceNet Drive Reference Manual

DN Status Minor Recoverable Fault

Ei-DN Modbus Address: 14001

Range Units Default Typ e DN Type Group NVM Res. Access

True/False BIT BOOL No RO

A Minor Recoverable Fault occurs when the drive experiences a connection time-out. This

fault will not disable the bridge and will clear after the fault clears.

DN Status Minor Unrecoverable Fault

Ei-DN Modbus Address: 14002

Range Units Default Typ e DN Type Group NVM Res. Access

True/False BIT BOOL No RO

A Minor Unrecoverable Fault will initiate when any of the following faults occur: Encoder

State, Encoder Hardware, Low DC Bus, High DC Bus, Overspeed, Following Error, Shunt

Power RMS. Minor Unrecoverable Faults can only be reset with a cycle of power to the drive.

DN Transmit Counter

Ei-DN Modbus Address: 34201-34202

Range Units Default Typ e DN Type Group NVM Res. Access

31

-1 Counts US32 UDINT No RO

0-2

The DN Transmit Counter keeps a running total of all DeviceNet packets successfully transmitted

to the Master on the DeviceNet network.

DN Vendor ID

Ei-DN Modbus Address: 34001

Range Units Default Typ e DN Type Group NVM Res. Access

US16 UINT No RO

DN Vendor ID indicates the ODVA (Open DeviceNet Vendors Association) vendor specific

number. The Motion Made Easy Vendor ID is 553.

30

Page 43

Configuring the DeviceNet Network

Accessing the EDS File

The EDS file is used for configuration of the DeviceNet master. This file tells the Master

software how much I/O data is supported for a particular DeviceNet device as well as Control

Techniques’ vendor code, module revision, etc. The EDS file for the Ei-DN also contains the

Class, Instance, and Attribute ID’s for all Ei drive parameters. These class, instance, and

attribute ID’s are used for explicit messaging and can be found in the back of this manual in

the Drive Parameters chapter.

The EDS file is installed with PowerTools FM and can be found in the PTOOLSFM folder.

An icon file is also located in this section for display on the master software configuration

screen. These two files may also be downloaded from our website at www.emersonct.com.

Hardware Interface

Module Status LED

The Module Status LED located on the front of the drive provides device status according to

the following table:

LED State Drive State Indicates

Off No Power There is no power applied to the device.

Green Device Operational The device is operating in a normal condition.

Flashing Green

Flashing Red Minor Fault Recoverable Fault

Red Unrecoverable Fault The device has an unrecoverable fault; may need replacing

Flashing Red-

Green

Device in Standby (The Device Needs

Commissioning)

Device Self Testing The device is in self-test.

The device need commissioning due to configuration missing,

incomplete, or incorrect. The Device may be in the standby state.

31

Page 44

Epsilon Ei DeviceNet Drive Reference Manual

Network Status LED

The Network Status LED located on the front of the drive provides network status according

to the following table:

LED State Drive State Indicates

Off Not Powered/Not online

Flashing Green Online, Not Connected

Green Link OK Online, Connected

Flashing Red Connection Time-Out One or more I/O Connections are in the Timed-Out state.

Red Critical Link Failure

The device is online and has connections in the established state. This means the

Failed communication device. The device has detected an error that has rendered it

The device has not completed the Dup MacID test yet.

The device may not be powered, look at Module Status LED.

Device is online but has no connections in the established state.

The device has passed the Dup MacID test, is online, but has no established

incapable of communicating on the network (Duplicate MacID or Bus Off).

Device is not online:

connections to a Master.

device is connected to a Master.

Setting the Baud Rate and MacID Externally (One Touch)

The Baud Rate and MacID of the Ei-DN may easily be changed using PowerTools FM

programming software or externally on the drive using a one-touch setup with the “Reset”

button. The following is a full description of how to navigate through the DeviceNet edit

mode externally on the Ei-DN.

Viewing and Changing the Baud Rate and MacID

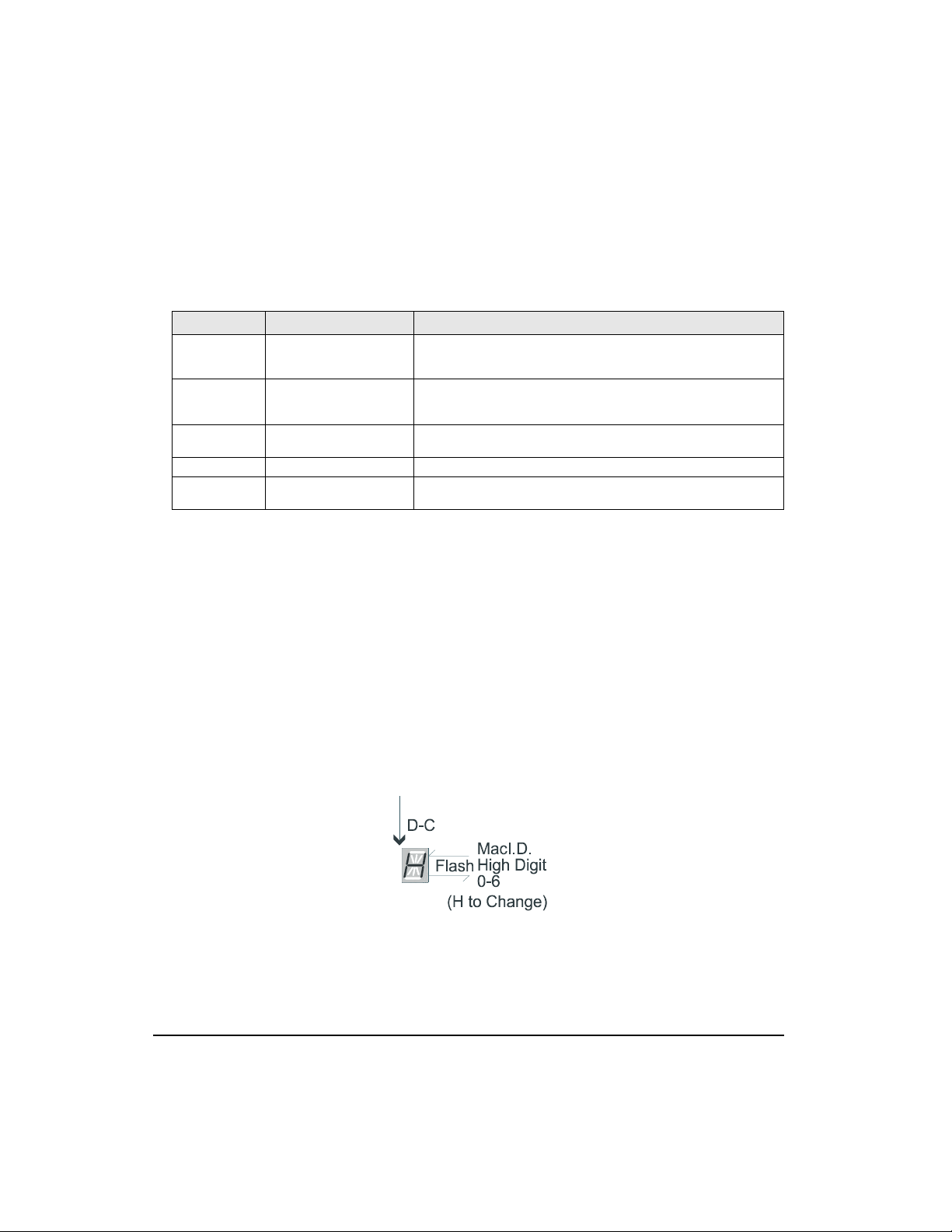

1. Double-click the Reset Button to enter the DeviceNet edit mode. The diagnostic display

located on the front of drive will flash between “H” (high digit) and the high (tens) digit

of the MacID. If the reset button is held in while the “H” is blinking on the diagnostic

display (H to Change), the high digit of the MacID value will scroll. Let the reset button

go when the display shows the correct number for the high digit of the MacID. (The

display will now flash between the letter “H” and the new tens digit for MacID.)

2. Double-click the Reset Button to view the low digit of the MacID. The diagnostic display

located on the front of the drive will flash between an “L” and the low (ones) digit of the

Mac ID. If the reset button is held in while the “L” is flashing on the diagnostic display

(H to Change), the low digit of the MacID value will scroll. Let the reset button go when

32

Page 45

Configuring the DeviceNet Network

the display shows the correct number for the low digit of the MacID. (The display will

now flash between the letter “L” and the new ones digit for MacID.)

3. Double-click the Reset Button to view the Baud Rate selected. The display will flash

between the letter B and the number of the baud rate that is currently configured.

Display Value Baud

1125K

2250K

3500K

To change the baud rate hold the reset button down and scroll through these three options. Let

the “Reset” button go when the displayed value reflects the baud rate for the DeviceNet

network.

(Default Baud Rate is configured to “1” or “125K”)

33

Page 46

Epsilon Ei DeviceNet Drive Reference Manual

4. Double-click the “Reset” button to reveal a flashing “S” on the diagnostic display. If the

parameters entered reflect the proper DeviceNet network settings, the configuration can

be saved by holding the “Reset” button while the “S” is flashing. After the parameters

are saved, the display will flash “O” and then “K” and return the display back to either a

disabled or enabled state. If the user does not want to save the changes, a 30-second timeout will return the drive back to the enabled or disabled display on the drive.

Note

If the user at any time wishes to discontinue the edit mode without saving changes , this

can be accomplished by either allowing the drive a 30 second time-out period without

touching the “Reset” button, or by cycling power to the drive.

34

Note

If the Baud Rate or MacID of the device is changed externally, power to the drive and the

DeviceNet network must be cycled. Changes to the baud rate and Mac ID will not be

reflected until a full power reset has been completed.

Page 47

Epsilon Ei DeviceNet Drive Reference Manual

Network Configuration

Quick Start

This chapter presents sample startups with a Epsilon Ei-DN drive using a 1747-SDN scanner

card as the DeviceNet master in a SLC 500 PLC™. The examples presented are intended as

a tutorial. For greater information about the steps in this chapter, please refer to the

“Configuring the DeviceNet Network” chapter.

Equipment

Epsilon Ei-DN Digital Drive

NT-207 Motor

PowerTools FM Software

Allen Bradley SLC 500 PLC™, 1747-L542 (4 Slot Chassis), P1 Power Supply, 1747 SDN

Scanner Card (inserted in slot #3)

1770 KFD RS 232 to DeviceNet to RS232 Interface module with 96881501 RS232 cable

(included)

DeviceNet thin cable and terminating resistors

RS Logix 500 Industrial Programming Software (PLC)

Epsilon Ei-DN Parameter Tables from the “Drive Parameters” chapter of this manual

Epsilon Ei DeviceNet Drive Configuration Quick Start

Process

1. In PowerTools FM, configure the software for the particular drive and motor (NT-207)

that will be used.

2. Open the DeviceNet tab and configure the DeviceNet Setup.

• Set the MacID and Baud Rate.

• Select the appropriate Predefined Assembly Block for the transmission of polled I/O.

(The tree to the right will display all parameters within the selected assembly block.)

3. Make assignments under the Inputs and Outputs tab for any DN bits that may be

configured in each assembly block.

4. Download the configuration to the Ei-DN.

35

Page 48

Epsilon Ei DeviceNet Drive Reference Manual

5. Install the .eds file in the Master Configuration software (RsNetworx, Wonderware, etc.).

6. Download a configuration for 8 polled input bytes and 8 polled output bytes to be

transferred to/from the Ei-DN.

7. Use ladder logic commands to initiate explicit messaging commands over DeviceNet.

Polled I/O Setup

The following examples assume that the user is familiar with and can set up the Ei using the

Epsilon Ei Reference Manual (P/N 400507-01). This application example will focus on the

DeviceNet setup for the Ei-DN. The setups will demonstrate the Index Sel Predefined, Index

Sel User Defined, and Index Type Position Control assembly blocks to transfer DeviceNet

bits and initiate indexes.

Example #1: Index Sel(Predef)

This sample procedure for the Index Sel(Predef) assembly block will run preconfigured Index

1 and 2 and Jog while reading back Torque Command and Command Velocity respectively.

1. Start a new Ei-DNconfiguration in PowerTools FM and configure the drive for the

particular motor that will be used. (For more information consult the Epsilon Ei Drives

Reference Manual (P/N 400507-01).

2. Configure Index 0 as a Incremental Index, Index Count of 1, Distance of 20 revs at a

Velocity of 1000 RPM, both Acceleration and Deceleration set to 1000 ms/Krevs/m and

a Dwell Time of 0.

36

3. Enter the DeviceNet setup and set the MacID to 1 and the Baud Rate to 125K. Select the

Index Sel (Predef) for both Master Send Assembly Block and Master Receive Assembly

Block.

Page 49

Network Configuration Quick Start

Figure 10: DN Setup / Index Sel (Predef)

4. Download this file to the Ei-DN.

5. Proceed to “Master Configuration” on page 48 before going any farther with this

example. After configuring the master return to this point and continue.

The following will initiate motion.

While Online with both the Ei-DN via PowerTools FM and the PLC via RSLogix 500:

6. Set Output Bit O:1.2/7 high to software enable the drive.

7. Set Output Bit O:1.1/0 high to initiate Index 0.

8. Set Output Bit O:1.1/1 high to initiate Home.

9. Set Output Bit O:1.1/2 high to Jog +.

10. Set Output Bit O:1.1/3 high to Jog -.

11. Set Output Bit O:1.1/4 high to enable Jog Fast.

12. Set Output Bits O:1.1/12 - O:1.1/15 to select the index to initiate or to select the index to

read from or write to using the Input/Output Word Select Data Pointer.

37

Page 50

Epsilon Ei DeviceNet Drive Reference Manual

13. Using Output Word Select Data Pointer 0x0A to set Jog Velocity and Input Select Data

Pointer 0x06 to read back the torque command, use the following table to construct the

proper words for the read and write:

Reserved Reserved Reserved

X X X 01010 X X X 00110

Output Word Select

Data Pointer (See

page 15) = 0x0A

Reserved Jog - Jog +

Input Word Select

Data Pointer (See

page 14) = 0x06

Final Word = XXX01010XXX00110

With zeros in for X’s = 2566 (0xA06)

Write to Words O:1.3 - O:1.4 to write to the selected jog velocity. Data can be obtained from

the online DN view described in the following step.

14. While online with PowerTools FM click the DeviceNet tab and open up the Master

Receive and Master Send Assembly Blocks. Verify that the correct data is moving back

and forth through the assembly blocks and that the data pointers are reading and writing

the data as expected.

Example #2 Index Sel (Userdef)

This sample procedure for the Index Sel (Userdef) assembly block will use the DN bits set up

from Example #1 to initiate indexes and a home. This procedure will also initiate Jog + and

Jog - and select between Jog Fast. Corresponding to these initiates, DeviceNet will read back

End of Index and End of Home bits, indicate in + Motion and in - Motion, Faults, and Drive

OK.

Using the Input and Output Word Select Data Pointer, this procedure will send index

velocities to the drive and receive position feedback from the drive.

38

1. Start a new Ei-DNconfiguration in PowerTools FM and configure the drive for the

particular motor that will be used. For more information consult the Epsilon Ei Drives

Reference Manual (P/N 400507-01.)

2. Enter the DeviceNet setup and set the MacID to 1 and the Baud Rate to 125K. Select the

Index Sel (Userdef) in both Master Send Assembly Block and Master Receive Assembly

Block setups.

Page 51

Network Configuration Quick Start

Figure 11: DN Setup / Index Sel (Userdef)