Page 1

00825-0100-4530, Rev EC

Superior Performance

Guided Wave Radar

Level and Interface Transmitter

Quick Installation Guide

March 2013

Page 2

Quick Installation Guide

March 2013

About this guide

This installation guide provides basic guidelines for Rosemount 5300 Series

transmitters. It does not provide instructions for configuration, diagnostics,

maintenance, service, troubleshooting, Explosion-proof, Flameproof, or

intrinsically safe (I.S.) installations. Refer to the Rosemount 5300 Series Reference

Manual (Document No. 00809-0100-4530) for more instruction. The manual and

this Quick Installation Guide (QIG) are also available electronically on

www.rosemount.com.

Failure to follow safe installation and service guidelines could result in death or serious

injury

Make sure the transmitter is installed by qualified personnel and in accordance with

applicable code of practice.

Use the equipment only as specified in this QIG and the Reference Manual. Failure to do so

may impair the protection provided by the equipment.

Do not perform any services other than those contained in this manual unless you are

qualified.

Explosions could result in death or serious injury

Verify that the operating environment of the transmitter is consistent with the appropriate

hazardous locations specifications. See Product Certifications on page 25 in this Quick

Installation Guide.

To prevent ignition of flammable or combustible atmospheres, disconnect power before

servicing.

Before connecting a HART

explosive atmosphere, make sure the instruments in the loop are installed in accordance

with intrinsically safe or non-incendive field wiring practices.

To avoid process leaks, only use O-rings designed to seal with the corresponding flange

adapter.

Electrical shock can result in death or serious injury

Avoid contact with the leads and terminals. High voltage that may be present on leads can

cause electrical shock.

Make sure the main power to the Rosemount 5300 Series transmitter is off and the lines to

any other external power source are disconnected or not powered while wiring the

transmitter.

Probes with non-conducting surfaces

Probes covered with plastic and/or with plastic discs may generate an ignition-capable level of

electrostatic charge under certain extreme conditions. Therefore, when the probe is used in a

potentially explosive atmosphere, appropriate measures must be taken to prevent

electrostatic discharge.

®

, FOUNDATION™ fieldbus, or Modbus based communicator in an

2

Page 3

March 2013

Any substitution of non-authorized parts or repair, other than exchanging the complete

transmitter head or probe assembly, may jeopardize safety and is prohibited.

Unauthorized changes to the product are strictly prohibited as they may unintentionally and

unpredictably alter performance and jeopardize safety. Unauthorized changes that interfere

with the integrity of the welds or flanges, such as making additional perforations, compromise

product integrity and safety. Equipment ratings and certifications are no longer valid on any

products that have been damaged or modified without the prior written permission of

Emerson Process Management. Any continued use of product that has been damaged or

modified without prior written authorization is at the customer's sole risk and expense.

Eliminate the risk of ESD discharge prior to dismounting the transmitter head from the probe.

Probes may generate an ignition- capable level of electrostatic charge under extreme

conditions.

During any type of installation or maintenance in a potentially explosive atmosphere the

responsible person should make sure that any ESD risks are eliminated before attempting to

separate the probe from the transmitter head.

Quick Installation Guide

Contents

Confirm system readiness . . . . . . . . . . . . . . . . . 4

Mount the transmitter head/probe . . . . . . . . . 5

Connect the wiring . . . . . . . . . . . . . . . . . . . . . . . 8

Configure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Safety Instrumented Systems (4-20 mA only) 21

Product certifications . . . . . . . . . . . . . . . . . . . . 25

3

Page 4

Quick Installation Guide

Step 1: Confirm system readiness

Confirm HART revision capability

If using HART-based control or asset management systems, confirm the HART

capability of those systems prior to transmitter installation. Not all systems

are capable of communicating with the HART Revision 7 protocol.

This transmitter can be configured for either HART Revision 5 or 7.

For instructions on how to change the HART revision of your transmitter, see

“Switch HART revision mode” on page 4.

Confirm correct Device Driver

Verify that the latest Device Driver (DD/DTM) is loaded on your systems to

ensure proper communication.

Download the latest Device Driver from www.rosemount.com/LevelSoftware.

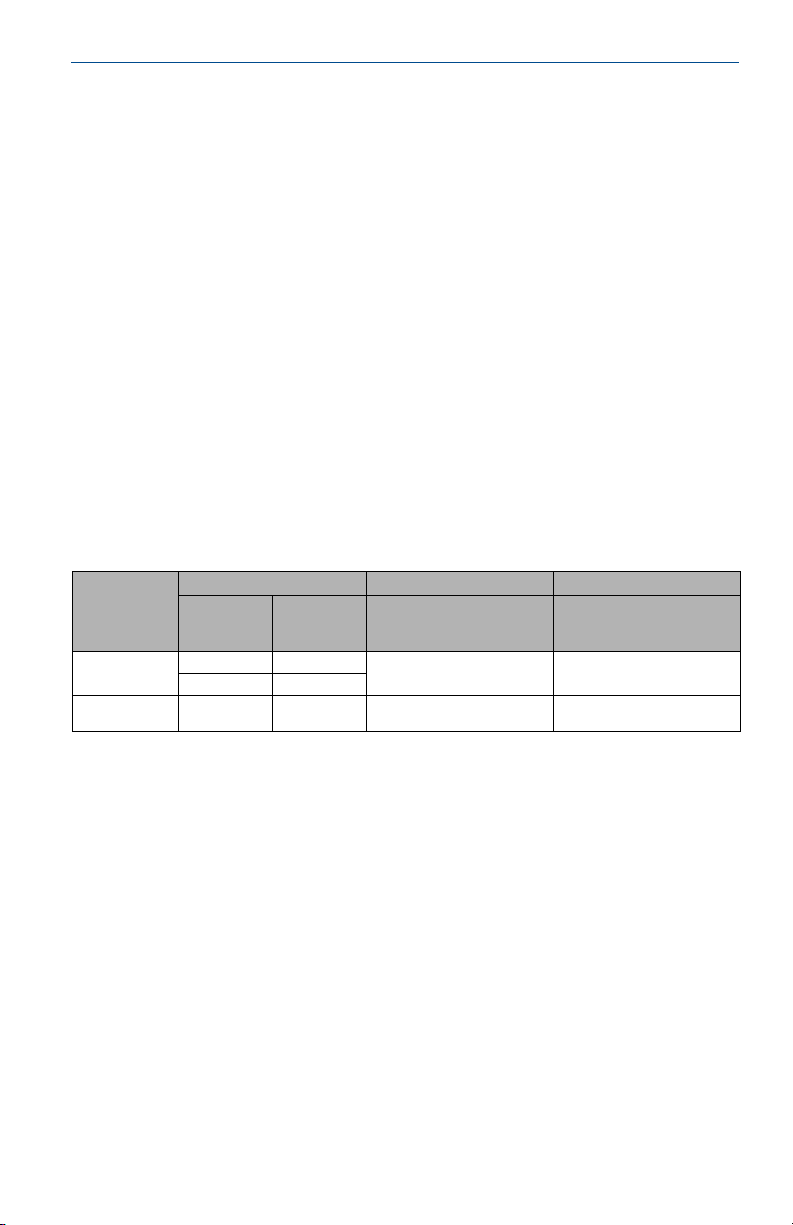

Rosemount 5300 device revisions and drivers

Tab l e 1 provides the information necessary to ensure that you have the correct

Device Driver and documentation for your device.

Table 1. Rosemount 5300 device revisions and files

March 2013

Firmware

1

Vers ion

2F0 and later

2A2 - 2D2 5 3

1. Firmware version is printed on the transmitter head label, e.g. SW 2E0.

2. Device revision is printed on the transmitter head label, e.g. HART Dev Rev 4.

3. HART Revision 5 and 7 are selectable.

Find Device Driver Review Inst ructions Review Functionality

HART

Universal

Revision

74

53

Device

Revision

Manual Document Number Changes to Sof tware

2

00809-0100-4530

Rev EA

00809-0100-4530

Rev DA

See footnote 3 for list of

changes.

Switch HART revision mode

If the HART configuration tool is not capable of communicating with HART

Revision 7, the Rosemount 5300 Series will load a Generic Menu with limited

capability. The following procedures will switch the HART revision mode from the

Generic Menu:

1. Manual Setup > Device Information > Identification > Message

To change to HART Revision 5, Enter: “HART5” in the Message field

To change to HART Revision 7, Enter: “HART7” in the Message field

3

N/A

4

Page 5

March 2013

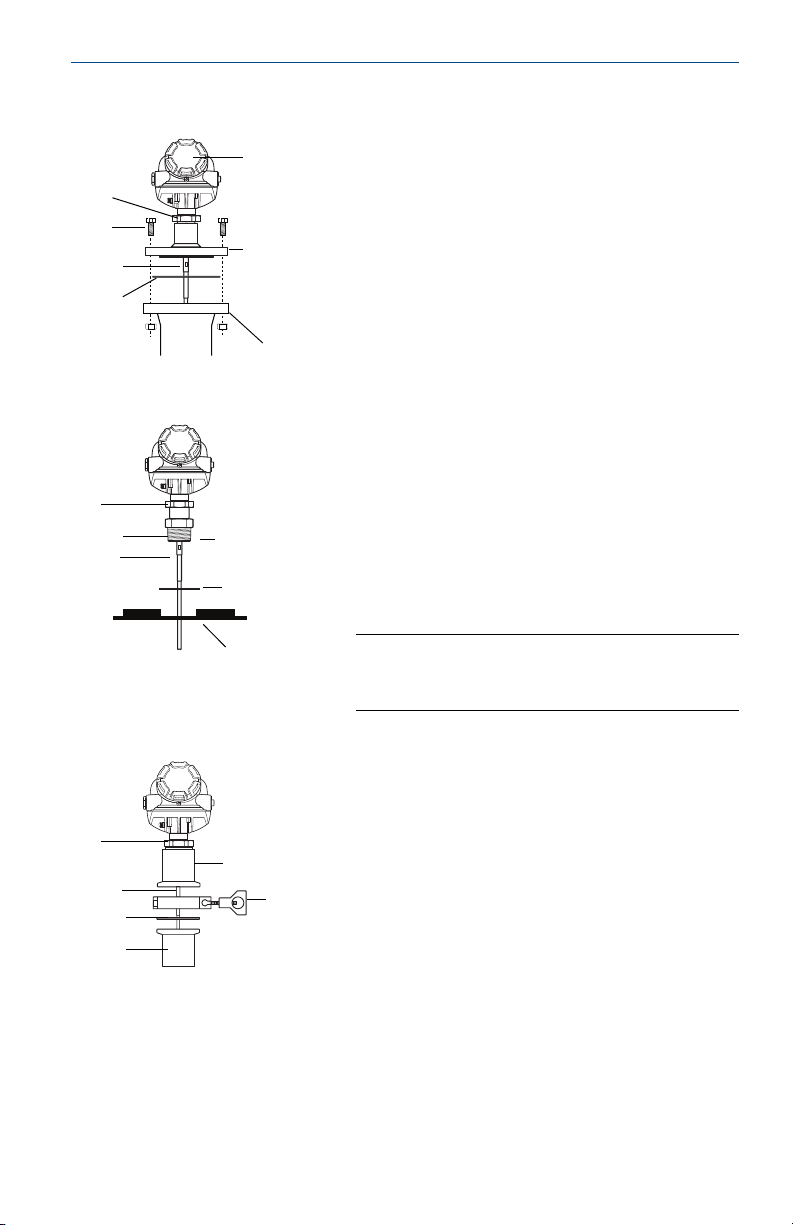

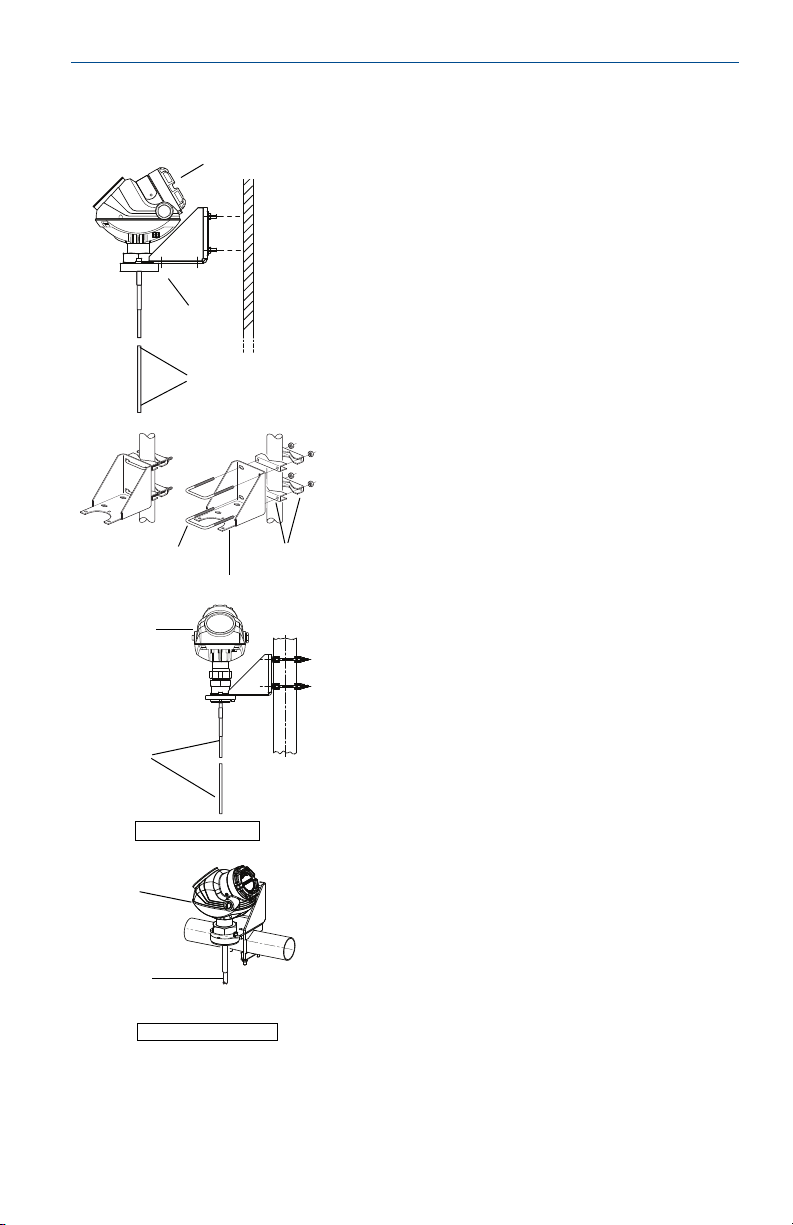

Flange

Probe

Gasket

Tan k

Flange

Tra ns mi tt er

Housing

Nut

Bolt

Adapter

Probe

Tan k Fl ang e/

Process

Connection

Nut

Sealant on

threads (NPT)

or

Gasket (BSP/G)

NOTE:

For adapters with NPT threads, pressure-tight joints

require a sealant.

Gasket

Probe

Nut

Tan k

Tri -Cl am p

Clamp

Quick Installation Guide

Step 2: Mount the transmitter head/probe

Tank connection with flange

1. Place a gasket on top of the tank flange.

2. Lower the probe with flange into the tank.

3. Tighten the bolts and nuts with sufficient torque

regarding flange and gasket choice.

4. Loosen the nut that connects the housing to the

probe and rotate the housing to the desired

direction.

5. Tighten the nut.

Threaded tank connection

1. For adapters with BSP/G threads, place a gasket

on top of the tank flange.

2. Lower the probe into the tank.

3. Mount the adapter into the process connection.

4. Loosen the nut that connects the housing to the

probe and rotate the housing to the desired

direction.

5. Tighten the nut.

Refer to the Rosemount 5300 Series Reference Manual (Document No.

00809-0100-4530) for details regarding the mounting of transmitter head/probe.

Tri-Clamp tank connection

1. Place a gasket on top of the tank flange.

2. Lower the transmitter and probe into the tank.

3. Fasten the Tri-Clamp to the tank with a clamp.

4. Loosen the nut that connects the transmitter

housing to the probe slightly.

5. Rotate the transmitter housing so the cable

entries/display face the desired direction.

6. Tighten the nut.

5

Page 6

Quick Installation Guide

Step 2 continued...

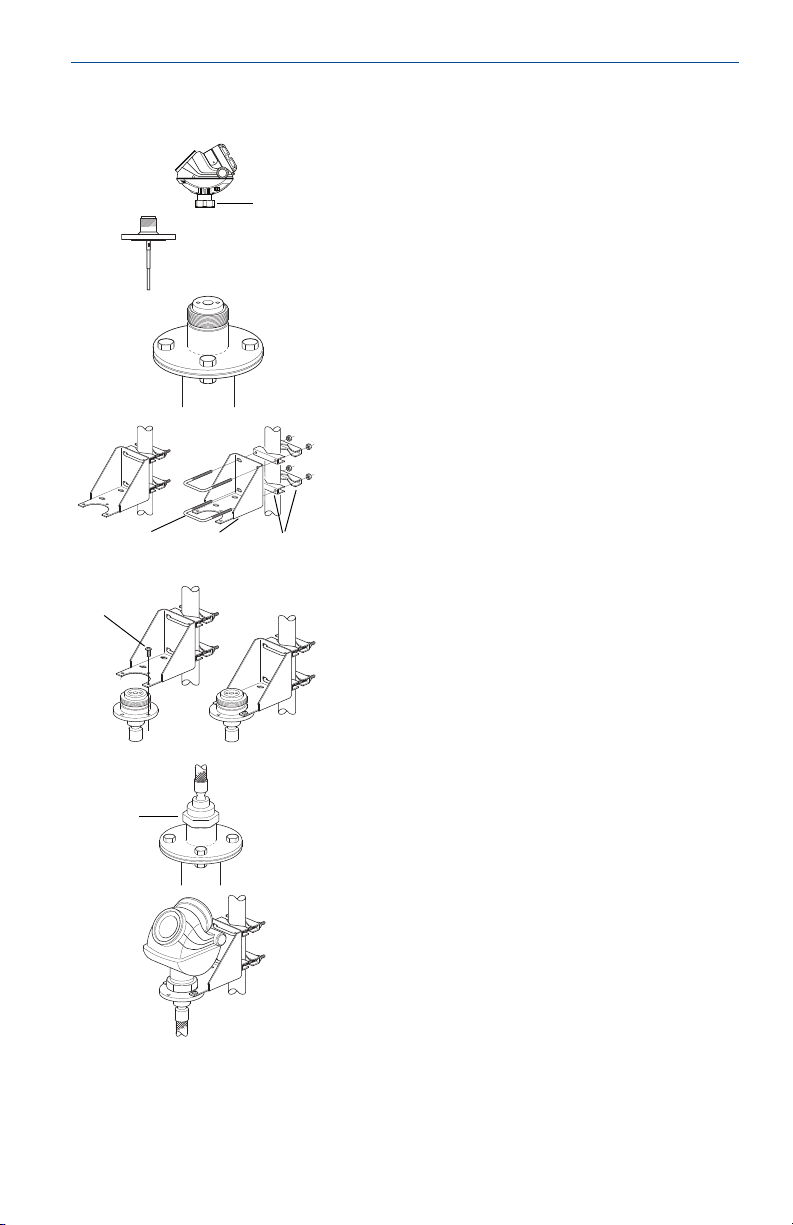

U-bolts

Bracket

Clamping

brackets

Transmitter

housing

Bracket

Probe

Vertical mounting

Transmitter

housing

Probe

Horizontal mounting

Transmitter

housing

Probe

March 2013

Bracket mounting, on wall

1. Mount the bracket directly to the wall with

screws suitable for the purpose.

2. Mount the transmitter with probe to the bracket

and secure the installation with the three

supplied screws.

Bracket mounting, on pipe

1. Put the two U-bolts through the holes of the

bracket. Holes are available for both vertical and

horizontal pipe mounting.

2. Put the clamping brackets on the U-bolts and

around the pipe.

3. Fasten the bracket to the pipe using the four

supplied nuts.

4. Mount the transmitter with probe to the bracket

and secure with the three supplied screws.

6

See the Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530) for more

installation details.

Page 7

March 2013

Step 2 continued...

M50 nut

U-bolt Bracket Clamping

brackets

M6 screw

M50 nut

Quick Installation Guide

Remote housing

1. Remove the transmitter head from the probe by

unscrewing the M50 nut.

For safety information regarding ESD discharge,

see the applicable warning on

2. Mount the probe in the tank.

3. Mount the bracket to the pole, making sure the

distance between the probe and bracket does

not exceed the length of the remote connection.

Put the two U-bolts through the holes of the

bracket. Several holes are available for

vertical/horizontal pipe mounting.

Put the clamping brackets on the U-bolts and

around the pipe.

Use the supplied nuts to fasten the bracket to

the pipe.

page 3.

4. Fasten the housing support to the bracket using

the M6 screws. The screws are threaded through

the top of the mounting bracket and into the

housing support.

5. Mount the probe housing on the probe, making

sure that the M50 nut is properly tightened.

6. Connect the transmitter head on the housing

support, making sure that the M50 nut is

properly tightened.

7

Page 8

Quick Installation Guide

Step 3: Connect the wiring

Wiring and power supply requirements can be dependent upon the approval

certification. As with all F

supply and terminating resistors are required for proper operation.

It is recommended that shielded twisted pair wiring (18-12 AWG) suitable for the

supply voltage be used and, if applicable, approved for use in hazardous areas.

For electrical information, such as power supply, see diagrams and drawings for

HART, Modbus, and F

NOTE:

Avoid running instrument cable next to power cables in cable trays or near heavy electrical

equipment.

It is important that the instrument cable shield be:

- trimmed close and insulated from touching the transmitter housing

- continuously connected throughout the segment

- connected to a good earth ground at the power supply end

Grounding

When wiring the transmitters, the grounding should be completed such that:

The loop is grounded at the power supply.

When transmitters are installed on metal tanks, ensure there is a

metal-to-metal connection between the device and the tank.

If the tank is non-metallic, the housing must be grounded to an earth ground

that is separate from the power supply. The external ground terminal may be

used for this purpose.

If the tank is cathodically protected, the housing must be grounded to an

earth ground that is outside of the cathodic protection system ground. Use

the external terminal for this purpose.

When transient protection terminal block is used, the ground wire should be

separate from the signal wire. Use the external ground terminal.

Make sure grounding is done (including IS ground inside Terminal compartment)

according to Hazardous Locations Certifications, national and local electrical

codes.

The most effective transmitter housing grounding method is a direct connection

to earth ground with minimal (< 1 ) impedance.

OUNDATION fieldbus requirements, a conditioned power

OUNDATION fieldbus on the following pages.

March 2013

NOTE:

Grounding the transmitter housing using the threaded conduit connection may not provide

a sufficient ground. The transient protection terminal block will not provide transient

protection unless the transmitter housing is properly grounded. Use the above guidelines to

ground the transmitter housing. Do not run transient protection ground wire with signal

wiring; the ground wire may carry excessive current if a lightning strike occurs.

8

Page 9

March 2013

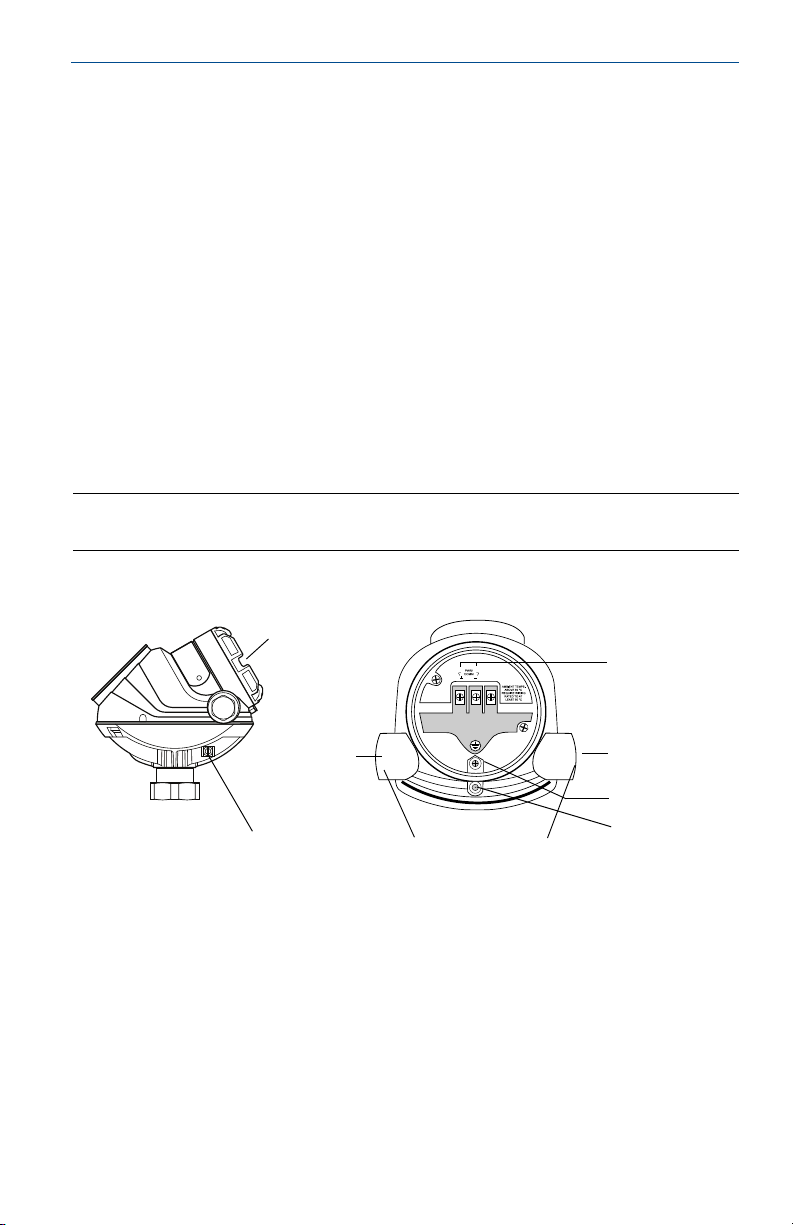

Cable Entry, ½

in. NPT - 14 or

M20x1.5

adapter

Internal Ground

Screw

Ter min als for

signal and

power supply

External Ground Screw

Ter mi na l

Block

Cover

Cable Entry, ½

in. NPT - 14 or

M20x1.5

adapter

Remove the orange, protective,

plastic plugs, used for

transportation.

Seal any unused port with the

enclosed metal plug.

Locking screw

Quick Installation Guide

To connect the transmitter

1. Verify that the power supply is disconnected.

2. Remove the terminal block cover (see picture below).

3. Pull the cable through the cable gland/conduit. For Explosion-proof /

Flameproof installations, only use cable glands or conduit entry devices

certified Explosion-proof or Flameproof. Install wiring with a drip loop where

the bottom of the loop must be lower than the cable/conduit entry.

4. To connect the wires, see the illustrations on the following pages.

5. Use the enclosed metal plug to seal any unused port.

6. Tighten the cable gland.

7. Mount the cover and make sure it is fully engaged to meet Explosion-proof

requirements (adapters are required if M20 glands are used).

For ATEX, IECEx, NEPSI, INMETRO, and TIIS installations, lock the cover with the

locking screw.

8. Connect the power supply.

NOTE:

Use PTFE tape or other sealant at the NPT threads in the Cable Entries.

Terminal block

9

Page 10

Quick Installation Guide

Load Resistance

250

Power

Supply

HART

Modem

Field

Communicator

PC

Rosemount 5300 Series

Tra nsm it ter

Power

Supply

RL250

Approved IS

Barrier

Field

Communicator

PC

For IS Parameters, see the

Product certifications ch apter.

HART

Modem

Rosemount 5300 Series

Transmitter

Step 3 continued...

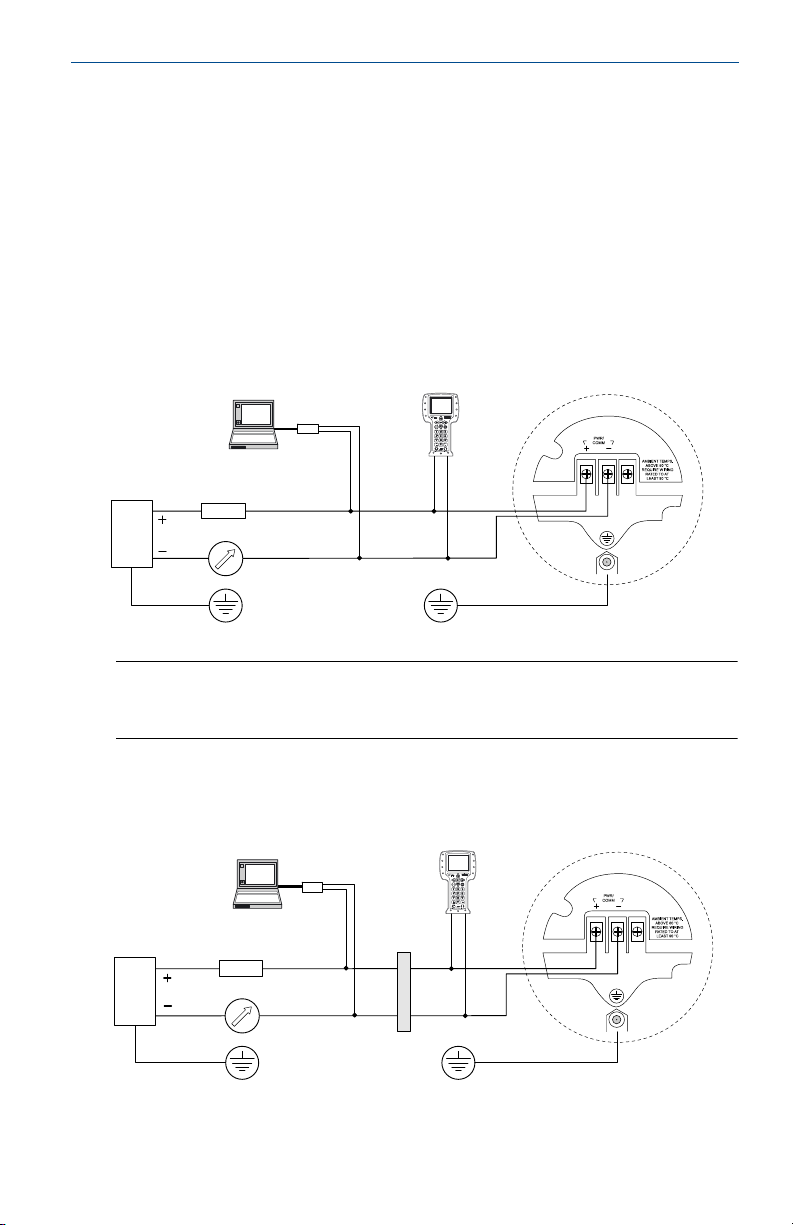

HART communication

The Rosemount 5300 Series transmitter operates with a power supply ranging

from 16 - 42.4 Vdc (16 - 30 Vdc in IS applications, 20-42.4 Vdc in Explosion-proof /

Flameproof applications and in Non-Sparking / Energy Limited applications).

All configuration tools for HART communication, such as the Field Communicator

and Rosemount Radar Master, require a minimum load resistance (R

within the loop in order to function properly, see diagrams below.

Non-intrinsically safe power supply

March 2013

) of 250

L

NOTE:

Rosemount 5300 Series Transmitters with Flameproof/Explosion-proof output have a

built-in barrier; no external barrier needed.

Intrinsically safe power supply

10

Page 11

March 2013

Step 3 continued...

Load Resistance

250

Power

Supply

HART

Modem

Field

Communicator

PC

Rosemount 5300 Series

Tra nsm it ter

HART: U

n

= 42.4 V

Power

Supply

Load Resistance

250

PC

HART

Modem

Field

Communicator

Rosemount 5300 Series

Tra ns mi tt er

Tra nsi en t

Protection

Symbol

HART: Un = 42.4 V

Quick Installation Guide

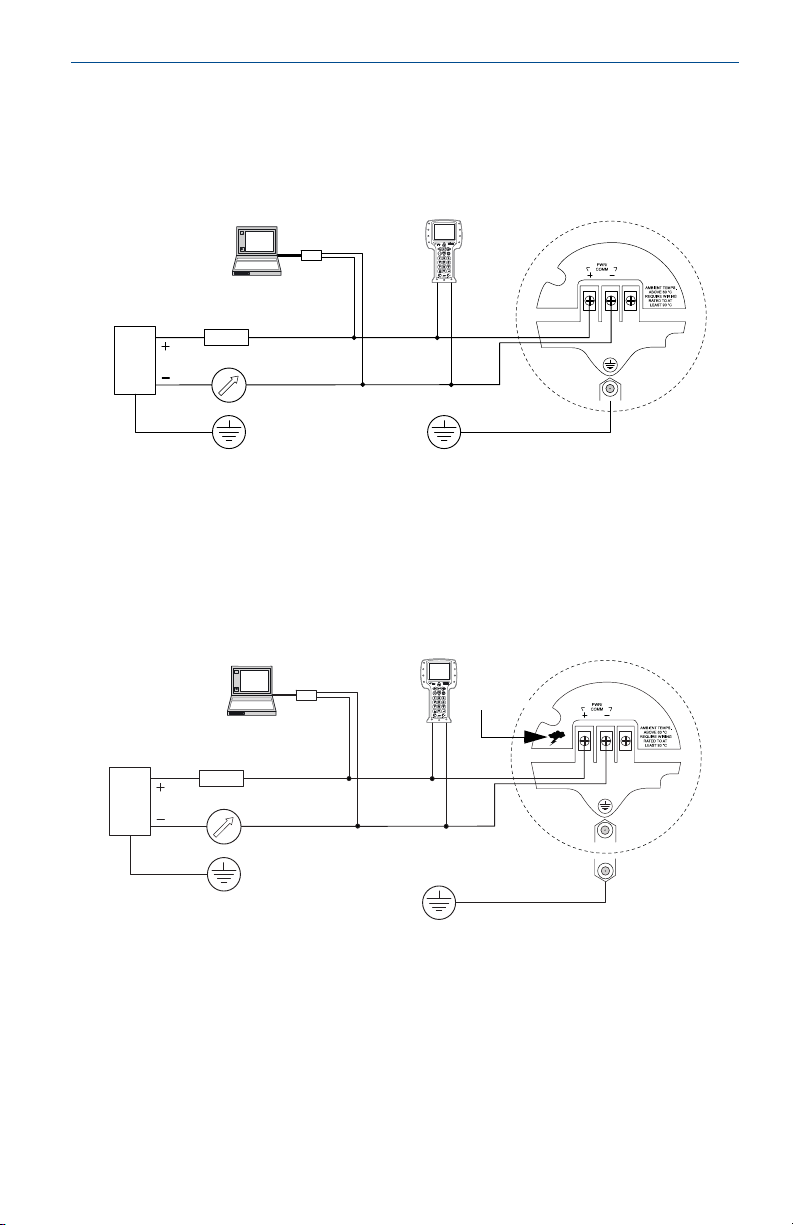

Type n approvals : non-sparking / energy limited power supply

Transient protection terminal block

11

Page 12

Quick Installation Guide

Step 3 continued...

R(): Maximum Load Resistance

UE(V): External Power Supply Voltage

Explosion-proof/Flameproof (Ex d)

Installations

Non-Hazardous Installations,

and Non-Sparking / Energy

Limited Power Supply

R(): Maximum Load Resistance

UE(V): External Power Supply Voltage

Operating

region

Operating

region

Intrinsically Safe Installations

R(): Maximum Load Resistance

UE(V): External Power Supply Voltage

Load limitations

The Field Communicator requires a minimum load resistance of 250 within the

loop to function properly. The maximum load resistance can be obtained from

the following diagrams.

March 2013

NOTE:

For Flameproof / Explosion-proof installations, the diagram is only valid if the HART load resistance

is at the + side and if the - side is grounded. Otherwise, the load resistance value is limited to

435 .

NOTE:

Rosemount 5300 Series Transmitters with Flameproof/Explosion-proof output have a built-in

barrier; no external barrier needed.

12

Page 13

March 2013

Step 3 continued...

Power

Supply

Field Communicator

PC

Rosemount 5300 Series

Tra nsm it ter

Fieldbus

Modem

Power

Supply

Approved IS Barrier

Field Communicator

PC

For IS Parameters, see the

Product certifications chapter.

Rosemount 5300 Series

Tra ns mi tt er

Fieldbus

Modem

Quick Installation Guide

FOUNDATION fieldbus

The Rosemount 5300 Series transmitter, FOUNDATION fieldbus version, operates

with a power supply ranging from 9 - 32 Vdc (9 - 30 Vdc in IS applications and 16 32 Vdc in Explosion-proof / Flameproof and in Non-Sparking / Energy Limited

applications).

FISCO, IS applications: 9 - 17.5 Vdc.

Non-intrinsically safe power supply

NOTE:

Rosemount 5300 Series Transmitters with Flameproof/Explosion-proof output have a built-in

barrier; no external barrier needed.

Intrinsically safe power supply

13

Page 14

Quick Installation Guide

Step 3 continued...

Power

Supply

Field Communicator

PC

Rosemount 5300 Series

Transmitter

Fieldbus

Modem

If it is the last

transmitter on the

bus, connect the

120

termination

resistor.

120

Power

Supply

120

RS-485 Bus

120

A

B

HART HART +

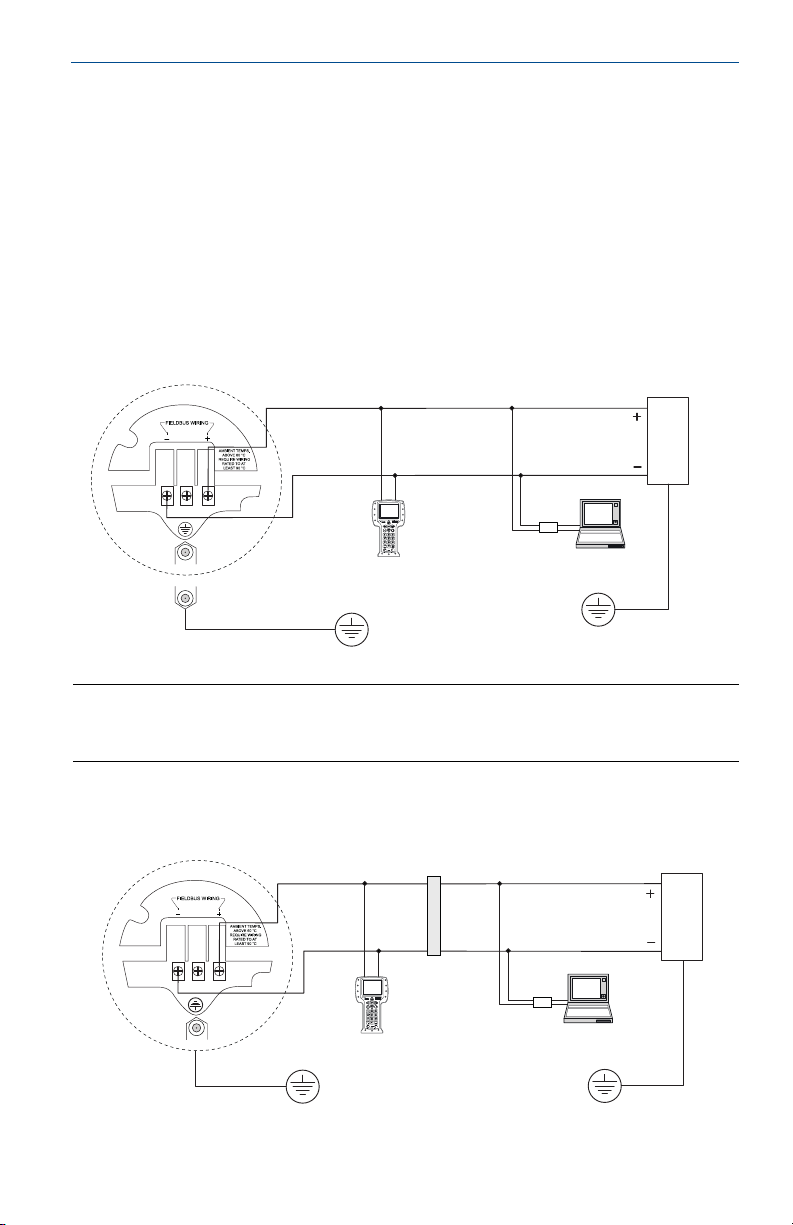

Type n approvals : non-sparking / energy limited power supply

RS-485 with Modbus communication

The 5300 Series RS-485 with Modbus communication transmitter version

operates using a power supply ranging from 8 - 30 Vdc (max. rating). See the

Rosemount 5300/5400 Series with HART to Modbus Converter Manual

supplement (Document No. 00809-0500-4530) for details.

Power Consumption:

< 0.5 W (with HART address = 1)

< 1.2 W (incl. four HART slaves)

March 2013

NOTE:

Rosemount 5300 Series Transmitters with Flameproof/Explosion-proof output have a built-in

barrier; no external barrier needed.

14

HART to Modbus Converter

-

+

MB

MODBUS

(RS-485)

POWER

Ambients > 60 ºC

HART

Use wiring rated

for min 90 ºC

erter

MB

MODBUS

MA

-

+

(RS-485)

MA

-

Page 15

March 2013

Quick Installation Guide

Step 4: Configure

NOTE:

If the transmitter is pre-configured at the factory, it is only necessary to proceed with the

following steps if you need to verify or change the settings.

Basic configuration can easily be done either with Rosemount Radar Master, a

Field Communicator, the AMS™ Suite, DeltaV®, or any other DD (Device

Description) compatible host system. For advanced configuration features,

Rosemount Radar Master is recommended.

Rosemount Radar Master Guided Setup includes a Wizard for Basic Configuration

and a Device Specific Setup which are sufficient for most cases. Further

configuration options are available using the Setup Functions, as described in the

Rosemount 5300 Series Reference Manual (Document No. 00809-0100-4530).

Configuration with Rosemount Radar Master Guided Setup is described on the

following pages and the corresponding Field Communicator fast key sequence

OUNDATION fieldbus parameters are given.

and F

Help is accessed by selecting the Contents option from the Help menu. Help is

also available through a Help button in most windows.

The configuration instructions in this Quick Installation Guide cover standard

installations. For more complicated situations, such as interface applications or

for installations that have disturbing objects within the radar beam etc, see the

Rosemount 5300 Series Reference Manual (Document No. 00809-0100-4530).

Installing the Rosemount Radar Master software

To install Rosemount Radar Master:

1. Insert the installation CD into the CD-ROM drive.

2. Follow the instructions. If the installation program does not start

automatically, run Setup.exe from the CD.

15

Page 16

Quick Installation Guide

Run Wizard

March 2013

Configuration using the Rosemount Radar Master software

1. Start Rosemount Radar Master (Programs > Rosemount > Rosemount Radar

Master).

2. Connect to the desired transmitter. Once the transmitter is connected, the

Guided Setup window appears automatically.

3. Click the Run Wizard for guided setup button. Follow the instructions for a

Basic Configuration and you will be guided through a short transmitter

installation procedure.

4. The first window in the Configuration Wizard presents general information

such as Device Model (5301 / 5302 / 5303), serial number, Probe Type,

Probe Length, communication protocol, and device address. Check that the

information complies with the ordering information. Click Next.

1

5. The General window lets you enter Tag, Message

This information is not required for operation of the transmitter and can be

left out if desired.

, Descriptor1, and Date1.

Handheld HART Communicator: Fast Key Sequence [2, 2, 1].

Click Next and the following window appears (Probe).

6. Verify that the parameters in the Probe window are correct. The parameters

1) Only for HART communication.

16

Page 17

March 2013

Quick Installation Guide

are normally configured at the factory, but can be changed if, for example, the

probe is cut in the field, or if disturbing objects in the near zone need to be

blocked out (Hold Off Distance/Upper Null Zone (UNZ)).

Handheld HART Communicator: Fast Key Sequence [2, 1, 2].

OUNDATION fieldbus parameters:

F

TRANSDUCER_1100 > PROBE_TYPE

TRANSDUCER_1100

TRANSDUCER_1100

> PROBE_LENGTH

> GEOM_HOLD_OFF_DIST

Click Next and the following window appears (Geometry).

7. Enter Tank Height, the distance from the Upper Reference Point to the Lower

Reference Point (which is the tank bottom in the screenshot above), making

sure it is as accurate as possible. See Configuration in the Rosemount 5300

Series Reference Manual (Document No. 00809-0100-4530) for details.

Set Mounting Type. Set Diameter if Mounting Type is Nozzle or

Pipe/Chamber. Set Nozzle Height if Mounting Type is Nozzle.

Handheld HART Communicator: Fast Key Sequence [2, 1, 3]

OUNDATION fieldbus parameters:

F

TRANSDUCER_1100 > GEOM_TANK_HEIGHT

TRANSDUCER_1100 > MOUNTING_TYPE

TRANSDUCER_1100 > PIPE_DIAMETER

TRANSDUCER_1100 > NOZZLE_HEIGHT

17

Page 18

Quick Installation Guide

Click Next and the following window appears (Tank Environment).

8. In the Environment window, select Measurement Mode. If the surface is

moving up or d own at rates over 4 0 mm/s (1.5 in./s), the Rapid Level Changes

box should also be selected. Enter the Upper Product Dielectric Constant

(icons for help functions are available to the right). For Interface Level with

Submerged Probe and Product and Interface measurement modes, it is

important that the dielectric constant value is exact.

See the Rosemount 5300 Series Reference Manual (Document No.

00809-0100-4530) for details.

Handheld HART Communicator: Fast Key Sequence [2, 1, 4]

March 2013

OUNDATION fieldbus parameters:

F

TRANSDUCER_1100 > MEAS_MODE

TRANSDUCER_1100

TRANSDUCER_1100

TRANSDUCER_1100

> PRODUCT_DIELEC_RANGE

> UPPER_PRODUCT_DC

> ENV_ENVIRONMENT

Click Next and the following window appears (Volume).

9. If volume calculation is desired, choose a pre-defined Volume Calculation

Method and tank dimensions based on a tank shape that corresponds to the

actual tank. Choose Strapping Table if the actual tank does not match any of

18

Page 19

March 2013

NOTE:

The 4-20 mA range must not include the

upper transition zone, the lower transition

zone, or the upper null zone. See the

Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530) for

details.

Quick Installation Guide

the available pre-defined tank options, or if high volume accuracy is desired.

Choose None if volume calculation is not desired.

Handheld HART Communicator: Fast Key Sequence [2, 1, 5]

OUNDATION fieldbus parameters:

F

TRANSDUCER_1300 > VOL_VOLU ME_CA LC_METHO D

TRANSDUCER_1300 > VOL_IDEAL_DIAMETER

TRANSDUCER_1300 > VOL_IDEAL_LENGTH

TRANSDUCER_1300 > VOL_VOLUME_OFFSET

Click Next and the following window appears (Analog Output).

10. This step is not applicable for F

OUNDATION fieldbus, the parameters are entered

in the AI-block instead.

Handheld HART Communicator: Fast Key Sequence [2, 1, 6]

For HART communication, choose Primary Variable, PV.

Specify the analog output range by setting the Upper Range Value (20 mA)

and the Lower Range Value (4 mA) to the desired corresponding level values.

The Alarm Mode specifies the output state when a measurement error

occurs. Choose between the following:

High: 21.75 mA (standard) or 22.5 mA (Namur)

Low: 3.75 mA (standard) or 3.6 mA (Namur)

Freeze: the output current is set to the last valid value at the time when the

error occurs.

Click Next.

11. Continue with Steps 2 to 5 in the Guided Setup window:

Step 2: Device specific setup might advise you to make further configurations.

Handheld HART Communicator: Fast Key Sequence [2, 1, 7, 2].

Step 3: Restart the device to make sure all configuration changes are properly

activated.

Step 4: View live values from the device to verify that the transmitter works

correctly.

Step 5: Make a complete backup of the device.

19

Page 20

Quick Installation Guide

Step 1: Run Wizard

Step 3: Restart the device

Step 4: View live values from the device

Step 5: Make a complete backup of the device

Step 2: Device specific setup

12. The Basic Configuration with the Radar Master Wizard is now finished.

Proceed with the Device Specific Setup to see which additional configuration

is needed.

You may be required to calibrate Vapor Compensation, to set up

Probe End Projection, or to perform a Trim Near Zone depending on type of

the device, application, and functions available.

For further information, see the Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530).

For Signal Quality Metrics information and further configuration, see the

Rosemount 5300 Series Reference Manual (Document No. 00809-0100-4530).

Setup - Modbus communication parameters

For transmitters with the Modbus option, do the following to configure the

communication parameters:

1. In the Setup menu select General. The following window appears.

March 2013

2. Choose the Communication tab.

3. Click Modbus Setup.

4. Enter the desired Modbus communication settings.

20

Page 21

March 2013

Quick Installation Guide

Safety Instrumented Systems (4-20 mA only)

The following section is applicable to the Rosemount 5300 Prior-Use option

(Special certification: QS). Additional Safety Instrumented Systems information is

available in the Rosemount 5300 Series Reference Manual (Document No.

00809-0100-4530). The manual is available electronically at

www.rosemount.com or by contacting an Emerson Process Management

representative.

To identify a 5300 Prior-Use option transmitter:

Verify the QS option code in the model code, on the label affixed to the

outside of the transmitter head or

Handheld HART Communicator: Fast Key Sequence [1, 7, 8].

Verify that the Prior-Use safety device is ON or

Open Rosemount Radar Master, right click on the device, and select

Properties. Verify that the Safety Device (QS Option) is present

Installation

The device should be installed and configured as a level sensing device per

manufacturer’s instructions. The materials must be compatible with process

conditions and process fluids. No special installation is required in addition to the

standard installation practices outlined in this document.

Environmental limits are available in the Rosemount 5300 Series Reference

Manual (Document No. 00809-0100-4530), Appendix A: Reference Data.

The loop must be designed so the terminal voltage does not drop below the

minimum input voltage, see values in

22.5 mA.

Tab l e 2 , when the transmitter output is

Table 2. Minimum input voltage (U

Hazardous approval

Non-Hazardous Installations and

Intrinsically Safe Installations

Explosion-proof / Flameproof

Installations

) at different currents

i

Current

3.60 mA 3.75 mA 21.75 mA 22.50 mA

Minimum input voltage (UI)

16 Vdc 16 Vdc 11 Vdc 11 Vdc

20 Vdc 20 Vdc 15.5 Vdc 15.5 Vdc

Configuration

Use a HART-compliant master, such as Rosemount Radar Master or a Field

Communicator, to communicate with and verify configuration of the Rosemount

5300 Series. A full review of configuration methods is available in the Rosemount

5300 Series Reference Manual (Document No. 00809-0100-4530).

NOTE:

The Rosemount 5300 Series transmitter is not safety-rated during maintenance work,

configuration changes, multidrop, loop test, or other activity that affects the Safety Function.

Alternative means should be used to ensure process safety during such activities.

21

Page 22

Quick Installation Guide

Table 3. Alarm levels and operation values

Rosemount Alarm Level

Normal Operation

3.75 mA

1

1. Transmitter Failure, hardware or software alarm in Low position.

4 mA 21.75 mA

2

3.9 mA

low saturation

20.8 mA

high saturation

Namur Alarm Level

Normal Operation

3.6 mA

1

4 mA 22.5 mA

2

3.8 mA

low saturation

20.5 mA

high saturation

2. Transmitter Failure, hardware or software alarm in High position.

20 mA

20 mA

Damping

User adjusted damping affects the transmitter’s ability to respond to process

changes. Therefore, the damping values + response time should not exceed the

Safety loop requirements.

Alarm and saturation levels

DCS or safety logic solver should be configured to handle both High alarm and

Low alarm.

Ta bl e 3 identifies the alarm levels available and their operation values.

March 2013

1

It is assumed that the current output signal is fed to a Safety Integrity Level 2

(SIL2) -compliant analog input board of a safety logic solver. For instructions on

alarm level settings, see the Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530), “Analog Output (HART)” section.

NOTE:

Only the High or Low Alarm Mode can be used for the Safety Function. Do not choose Freeze

Current as an error will not be announced in the current loop.

Write protection

A Rosemount 5300 transmitter can be protected from unintentional

configuration changes by a password protected function. It is recommended to

use write protection described in the Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530), “Write Protecting a Transmitter” section.

1) In certain cases, the transmitter does not go into the user defined alarm state. For example, in case of a short circuit,

the transmitter goes into High Alarm state even if Low Alarm has been configured.

22

Page 23

March 2013

Quick Installation Guide

Site acceptance

After the installation and configuration, proper operation of the transmitter

should be verified. A site acceptance test is therefore recommended. The proof

test outlined in this section can be used for this.

Operation and maintenance

The Rosemount 5300 Series Prior-Use option must be tested at regular intervals

to confirm that the overfill and empty tank protection function result in the

desired system response. The following proof test is recommended. If an error is

found in the safety functionality, the measuring system must be switched out of

service and the process held in a safe state by means of other measures.

Proof test results and corrective actions taken must be documented at

www.emersonprocess.com/rosemount/safety.

The required proof test intervals depend on the transmitter configuration and

process environment. Refer to the reference manual and the Failure Modes,

Effects, and Diagnostic Analysis (FMEDA) report for further information.

Proof test

This test detects approximately 95% of the possible Dangerous Undetected (DU)

failures of the transmitter including the sensor element, not detected by the

transmitter’s automatic diagnostics. See the Rosemount 5300 Reference Manual

(Document No. 00809-0100-4530) for additional details and instructions. Prior to

this test, the echo curve should be inspected to ensure that no disturbing echoes

affecting the measurement performance are present in the tank.

Required tools: Field Communicator and mA meter.

1. Bypass the logic solver or take other appropriate actions to avoid false trip.

2. Disable write protection if the function is enabled.

3. Using Loop Test, enter the mA value representing a high alarm current output.

Verify that the analog current reaches that value using the reference meter.

This step tests for compliance voltage problems, such as a low loop power supply

voltage or increased wiring resistance.

NOTE:

Use the Handheld HART Communicator: Fast Key Sequence [2, 4, 1, 4] to perform a Loop

Test. See the Rosemount 5300 Series Reference Manual (Document No. 00809-0100-4530)

for additional information.

4. Using Loop Test, enter the mA value representing a low alarm current output.

Verify that the analog current reaches that value using the reference meter.

This step tests for possible quiescent current related failures.

5. Perform a two-point calibration check of the transmitter by applying level to

two points on the probe within the measuring range1. Verify that the current

output corresponds to the level input values using a known reference

measurement.

This step verifies that the analog output is correct in the operating range and that

the Primary Variable is properly configured.

1) For best performance, use the 4 - 20 mA range points as calibration points.

23

Page 24

Quick Installation Guide

6. Enable write protection.

7. Restore the loop to full operation.

8. Remove the bypass from the safety logic solver or otherwise restore normal

operation.

9. Document the test result for future reference.

Inspection

Visual inspection

It is recommended to inspect the probe for possible build up or clogging.

Special tools

Not required.

Product repair

All failures detected by the transmitter diagnostics or by the proof test must be

reported. Feedback can be submitted electronically at

www.emersonprocess.com/rosemount/safety (Contact Us).

The Rosemount 5300 Series is repairable by complete transmitter head

replacement. Contact your local Emerson Process Management representative to

perform the replacement. Additional information is available in the Rosemount

5300 Series Reference Manual (Document No. 00809-0100-4530).

March 2013

References

Specifications

The Rosemount 5300 must be operated in accordance with the functional and

performance specifications provided in the Rosemount 5300 Series Reference

Manual (Document No. 00809-0100-4530), Appendix A: Reference Data.

Failure rate data

The FMEDA report includes failure rates and common cause Beta factor

estimates. The full report is accessible at

www.emersonprocess.com/rosemount/safety/PriorUse.htm.

Useful lifetime

The established failure rates of electrical components apply within the useful

lifetime, which should be based on experience. According to IEC 61508-2,

7.4.7.4, note 3, the useful lifetime often lies within a range of 8 to 12 years for

transmitters.

24

Page 25

March 2013

Quick Installation Guide

Product certifications

EU conformity

The EC declaration of conformity can be found on page 33. The most recent

revision of the EC declaration of conformity can be found at

www.rosemount.com.

Safety Instrumented Systems (SIS)

The Rosemount 5300 Series has been evaluated by a third party, Exida, against

hardware requirements according to IEC 61508. With a FMEDA (Failure Modes,

Effects and Diagnostics Analysis) report with a Safe Failure Fraction (SFF) above

90%, 5300 is suitable in SIS according to the Prior Use methodology. For more

information, go to: http://emersonprocess.com/rosemount/safety/. To order the

certificate of FMEDA data, use option code QS.

Hazardous Locations certifications

North-American certifications

Factory Mutual (FM) approvals

Project ID: 3020497

Specific conditions of use:

WARNING: Potential Electrostatic Charging Hazard - The enclosure is constructed from

plastic. To prevent the risk of electrostatic sparking, the plastic surface should only be

cleaned with a damp cloth.

WARNING: The apparatus enclosure contains aluminum and is considered to constitute a

potential risk of ignition by impact or friction. Care must be taken into account during

installation and use to prevent impact or friction.

1

Explosion-proof:

E5

Explosion-proof for Class I, Div. 1,

Groups B, C, and D;

Dust-ignition-proof for Class II/III, Div. 1, Groups E, F, and G;

With Intrinsically Safe connections to

Class I, II, III, Div. 1, Groups B, C, D, E, F, and G.

Tem p. C ode T4

Ambient temperature limits: -50 °C to +70 °C

Seal not required.

Approval valid for HART, F

1) Ordering information code for Product Certifications, see the Rosemount 5300 Series Product Data Sheet

(Document No. 00813-0100-4530) or the Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530).

2) +60 °C with F

OUNDATION fieldbus or FISCO option.

OUNDATION fieldbus, and Modbus options.

2

.

25

Page 26

Quick Installation Guide

1

Intrinsically safe and FISCO model:

I5, IE

Intrinsically Safe for Class I, II, III, Div. 1, Groups A, B, C, D, E, F, and G,

Class I, Zone 0, AEx ia IIC T4 when installed per Control Drawing: 9240 030-936.

Non-Incendive Class I, Div. 2, Groups A, B, C, D, F, and G;

Suitable for Class II, III, Div. 2, Groups F and G;

4-20 mA/HART model: U

= 30 Vdc, Ii = 130 mA, Pi = 1.0 W, Ci = 7.26 nF, Li = 0 H.

i

Max. operation: 42.4 V, 25 mA

OUNDATION fieldbus model: U

F

= 30 Vdc, Ii = 300 mA, Pi = 1.3 W, Ci = 0 nF, Li = 0 H.

i

Max. operation: 32 V, 25 mA

FISCO model: U

Tem p. Code T4

Ambient temperature limits: -50 °C to +70 °C

= 17.5 Vdc, Ii = 380 mA, Pi = 5.32 W, Li = Ci = 0.

i

2

Approval valid for HART, FOUNDATION fieldbus, and FISCO options.

Canadian Standards Association (CSA) approvals

Certificate: 1514653

Product options bearing the Dual Seal marking meets the Dual Seal Requirements of

ANSI/ISA12.27.01-2003.

Dual seal annunciation

The breach of the secondary seal is annunciated via product leakage from the antenna’s

vents. The leakage will be visible and/or audible from the transmitter

head’s threads.

Dual seal maintenance

No maintenance required. Verify proper operation by keeping leak path free from ice or

contamination.

WARNING: The substitution of components may impair intrinsic safety.

1

Explosion-proof with internal intrinsically safe circuits [Exia]

E6

Class I, Div. 1, Groups B, C, and D;

Class II, Div. 1 and 2, Groups E, F, and G;

Class III, Div. 1

Tem p Co de T 4.

Ambient temperature limits -50 °C to +70 °C

Approval valid for HART, FOUNDATION fieldbus, and Modbus options.

1

Intrinsically Safe Exia:

I6, IF

Class I, Div. 1, Groups A, B, C, and D.

Tem p Co de T 4.

4-20 mA/HART model: U

OUNDATION fieldbus model: U

F

FISCO model: U

= 17.5 Vdc, Ii = 380 mA, Pi = 5.32 W, Li = Ci = 0.

i

= 30 Vdc, Ii = 130 mA, Pi = 1.0 W, Ci = 7.26 nF, Li = 0 H.

i

= 30 Vdc, Ii = 300 mA, Pi = 1.3 W, Ci = 0 nF, Li = 0 H.

i

Installation Drawing: 9240 030-937

Ambient temperature limits -50 °C to +70 °C

Approval valid for HART, F

OUNDATION fieldbus, and FISCO options.

2

2

.

March 2013

1) Ordering information code for Product Certifications, see the Rosemount 5300 Series Product Data Sheet

(Document No. 00813-0100-4530) or the Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530).

2) +60 °C with F

OUNDATION fieldbus or FISCO option.

26

Page 27

March 2013

Quick Installation Guide

European certifications

ATEX approvals

Special conditions for safe use (X)

The intrinsically safe circuits do not withstand the 500 V AC test as specified in IEC 60079-11

clause 6.4.12.

Impact and friction hazards need to be considered according to EN 60079-0 clause 8.1.2

when the transmitter and part of antennas exposed to the exterior atmosphere of the tank is

made with light metal alloys and of category II 1G EPL Ga.

The Ex ia version of model 5300 FISCO field device may be supplied by an [Ex ib] FISCO power

supply when the power supply is certified with three separate safety current limiting devices

and voltage limitation which meets the requirements for type Ex ia.

1

Flameproof:

E1

Nemko 04ATEX1073X

II 1/2 G T4

II 1D T79 °C

Ex ia/db ia IIC T4 Ga/Gb (-40 °C < Ta < +70 °C3)

Ex ta IIIC T79 °C

m = 250 V

U

Approval valid for HART, F

1

Intrinsically safe and FISCO model:

I1, IA

Nemko 04ATEX1073X

II 1 G T4 or

II 1/2 G T4

II 1 D T79 °C

Ex ia IIC T4 (-50 °C < Ta < +70 °C3)

Ex ia/ib IIC T4 Ga/Gb (-50 °C <

Ex ta IIIC T79 °C

4-20 mA/HART model: U

= 7.26 nF, Li = 0 H.

C

i

F

OUNDATION fieldbus model: U

= 4.95 nF, Li = 0 H.

C

i

FISCO model: U

Installation Drawing: 9240 030-938

Approval valid for HART, F

1

Type n:

N1

II 3G Ex nAnL IIC T4 Gc (-50 °C < T

II 3G Ex nL IIC T4 Gc (-50 °C < T

Nemko 10ATEX1072

4-20 mA/HART model: U

F

OUNDATION fieldbus model: U

Approval valid for HART and F

2

2

(-40 °C < Ta < +70 °C3)

OUNDATION fieldbus, and Modbus options.

2

2

(-50 °C < Ta < +70 °C3)

= 17.5 Vdc, Ii = 380 mA, Pi = 5.32 W, Ci = 4.95 nF, Li < 1 μH.

i

Ta < +60 °C)

= 30 Vdc, Ii = 130 mA, Pi = 1.0 W,

i

= 30 Vdc, Ii = 300 mA, Pi = 1.5 W,

i

OUNDATION fieldbus, and FISCO options.

< +70 °C3)

a

< +70 °C3)

a

= 42.4 V

n

= 32 V

n

OUNDATION fieldbus options.

1) Ordering information code for Product Certifications, see the Rosemount 5300 Series Product Data Sheet

(Document No. 00813-0100-4530) or the Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530).

2) +69 °C with F

3) +60 °C with F

OUNDATION fieldbus or FISCO option.

OUNDATION fieldbus or FISCO option.

27

Page 28

Quick Installation Guide

Brazilian certifications

INMETRO approvals

Special conditions for safe use (X)

Letter X in the number of the certificate indicates the following special condition(s) for safe

use:

For models 530xFxxxxxxxxxE1..., 530xFxxxxxxxxxKA..., 530xFxxxxxxxxxKB... or

530xFxxxxxxxxxKC... and when the sensor area requires an EPL Ga, the installation of the

transmitter on the process wall must be done in a way that ensures the minimum

degree of protection IP67 in the connection, in compliance with regulation ABNT NBR

IEC 60529.

The intrinsically safe circuit did not withstand the dielectric rigidit y tests with 500 Vca as

specified in clause 6.4.12 of regulation IEC 60079-11.

Probes covered with plastic or plastic discs should have a non-conductive area not

exceeding the maximum permitted area for the MC group, which is 4 cm

when an antenna is used in a potentially explosive atmosphere, appropriate measures

should be taken by the user to prevent electrostatic discharge.

This equipment contains light metals. The equipment must be installed in a way that

the risk of impact or friction with other metal surfaces is eliminated.

The Ex ia version of the field device of model FISCO 5300 can be provided with a FISCO

[Ex ib] power supply when the power supply is certified with three current limiter safety

devices separately and with limitation of voltage, complying with the requirements of

the Ex ia model.

Certificate: NCC 4205/07X

Standards:

ABNT NBR IEC: 60079-0:2008/2010, 60079-1:2009, 60079-11:2009, 60079-26:2008

IEC 60079-31:2008

March 2013

2

. Therefore,

1

Flameproof:

E2

4-20 mA/HART model:

Ex d ia IIC T4 Gb/Ga

Ex ta IIIC T79 °C

Ta < +70 °C

-40 °C <

: 250 V

U

m

OUNDATION fieldbus model:

F

Ex d ia IIC T4 Gb/Ga

Ex ta IIIC T69 °C

Ta < +60 °C

-40 °C <

: 250 V

U

m

MODBUS model:

Ex d ia IIC T4 Gb/Ga

Ex ta IIIC T79 °C

Ta < +70 °C

-40 °C <

: 250 V

U

m

1) Ordering information code for Product Certifications, see the Rosemount 5300 Series Product Data Sheet

(Document No. 00813-0100-4530) or the Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530).

28

Page 29

March 2013

I21 Intrinsically safe:

4-20 mA/HART model:

Ex ia IIC T4 Ga

Ex ta IIIC T79 °C

Ta < +70 °C

-50 °C <

: 30 V, Ii: 130 mA, Pi: 1.0 W, Li: 0 μH, Ci: 7.26 nF

U

i

F

OUNDATION fieldbus model:

Ex ia IIC T4 Ga

Ex ta IIIC T69 °C

Ta < +60 °C

-50 °C <

U

: 30 V, Ii: 300 mA, Pi: 1.5 W, Li: 0 μH, Ci: 4.95 nF

i

Installation Drawing: 9240030-938

1

IB

FISCO model:

FISCO Field Device

Ex ia IIC T4 Ga

Ex ia/ib IIC T4 Ga/Gb

Ex ta IIIC T69 °C

Ta < +60 °C

-50 °C <

U

: 17.5 V, Ii: 380 mA, Pi: 5.32 W, Li: <1 μH, Ci: 4.95 nF

i

Installation Drawing: 9240030-938

Chinese certifications

Quick Installation Guide

National Supervision and Inspection Center for Explosion

Protection

Special conditions for safe use (X):

Refer to Certificates GYJ 111230X and GYJ 081131X.

1

E3

Flameproof:

HART model:

Ex d ia IIC T4 (-40 °C < T

F

OUNDATION fieldbus model:

Ex d ia IIC T4 (-40 °C < T

Approval valid for HART, F

1

Intrinsically safe:

I3

HART model:

Ex ia IIC T4 (-50 °C < T

4-20 mA/HART model: U

OUNDATION fieldbus model:

F

Ex ia IIC T4 (-50 °C < T

U

Approval valid for HART and F

1) Ordering information code for Product Certifications, see the Rosemount 5300 Series Product Data Sheet

(Document No. 00813-0100-4530) or the Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530).

and Safety of Instrumentation (NEPSI) approvals

< +70 °C) DIP A20 TA79 °C

a

< +60 °C) DIP A20 TA69 °C

a

OUNDATION fieldbus, and Modbus options.

< +70 °C) DIP A20 TA79 °C

a

= 30 V, Ii = 130 mA, Pi = 1.0 W, Ci = 7.26 nF, Li 0 μH

i

< +60 °C) DIP A20 TA69 °C

= 30 V, Ii = 300 mA, Pi = 1.5 W, Ci 4.95nF, Li 0 μH

i

a

OUNDATION fieldbus options.

29

Page 30

Quick Installation Guide

1

FOUNDATION fieldbus FISCO model:

IC

Ex ia IIC T4 (-50 °C < T

= 17.5 V, Ii = 380 mA, Pi = 5.32 W, Ci4.95 nF, Li 0.1 μH

U

i

< +60 °C) DIP A20 TA69 °C

a

N3 Type n:

HART model:

Ex nL IIC T4 (-50 °C < T

U

= 30 V, Ii = 130 mA, Pi = 1.0 W, Ci7.26 nF, Li 0 μH

i

OUNDATION fieldbus model:

F

Ex nL IIC T4 (-50 °C < T

= 30 V, Ii = 300 mA, Pi = 1.5 W, Ci4.95 nF, Li 0 μH

U

i

< +70 °C)

a

< +60 °C)

a

Japanese certifications

Technology Institution of Industrial Safety (TIIS) approval

Special conditions for safe use (X):

Refer to certificate TC20104 and TC20192.

1

E4

Flameproof:

4-20 mA/HART model:

Transmitter: Ex d [ia] IIC T4x

-20

+60 °C

~

DC 20 - 42.4 V

U

= 250 V

m

= 22.2 V

U

o

= 177.5 mA

I

o

P

= 0.985 W

o

Probe: Ex Ia IIC T4X

OUNDATION fieldbus model:

F

Transmitter: Ex d [ia] IIC T4X

-20

+60 °C

~

DC 16 - 32 V

U

= 250 V

m

= 22.2 V

U

o

= 177.5 mA

I

o

P

= 0.985 W

o

Probe: Ex ia IIC T4X

Installation Drawing: 05300-00548.

March 2013

Approval valid for HART and F

1) Ordering information code for Product Certifications, see the Rosemount 5300 Series Product Data Sheet

(Document No. 00813-0100-4530) or the Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530)

OUNDATION fieldbus options.

30

Page 31

March 2013

Quick Installation Guide

IECEx certifications

IECEx approvals

Special conditions for safe use (X)

The intrinsically safe circuits do not withstand the 500 V AC test as specified in IEC 60079-11

clause 6.4.12.

Impact and friction hazards need to be considered according to EN 60079-0 clause 8.1.2

when the transmitter and part of antennas exposed to the exterior atmosphere of the tank is

made with light metal alloys and of category EPL Ga.

The Ex ia version of model 5300 FISCO field device may be supplied by an [Ex ib] FISCO power

supply when the power supply is certified with three separate safety current limiting devices

and voltage limitation which meets the requirements for type Ex ia.

1

Flameproof:

E7

IECEx NEM 06.0001X

Ex ia/db ia IIC T4 Ga/Gb (-40 °C <

Ex ta IIIC T 79 °C

U

m = 250 V.

3

(-40 °C < Ta < +70 °C2)

Approval valid for HART, F

1

Intrinsically safe and FISCO model:

I7, IG

IECEx NEM 06.0001X

Ex ia IIC T4 (-50 °C <

Ex ia/ib IIC T4 Ga/Gb (-50 °C <

Ex ta IIIC T 79 °C

Ta < +70 °C2).

3

(-50 °C < Ta < +70 °C2).

4-20 mA/HART model: U

C

= 7.26 nF, Li = 0 H.

i

OUNDATION fieldbus model: U

F

FISCO model: U

Installation Drawing: 9240 030-938

= 17.5 Vdc, Ii = 380 mA, Pi = 5.32 W, Ci = 4.95 nF, Li < 1 μH.

i

Approval valid for HART, F

Ta < +70 °C2)

OUNDATION fieldbus, and Modbus options.

Ta < +60 °C).

= 30 Vdc, Ii = 130 mA, Pi = 1.0 W,

i

= 30 Vdc, Ii = 300 mA, Pi = 1.5 W, Ci = 4.95 nF, Li = 0 H.

i

OUNDATION fieldbus, and FISCO options.

1

Type n:

N7

Ex nAnL IIC T4 (-50 °C < T

Ex n IIC T4 (-50 °C < T

IECEx NEM 10.0005

4-20 mA/HART model: U

OUNDATION fieldbus model: U

F

Approval valid for HART and F

1) Ordering information code for Product Certifications, see the Rosemount 5300 Series Product Data Sheet

(Document No. 00813-0100-4530) or the Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530).

2) +60 °C with F

3) +69 °C with F

OUNDATION fieldbus or FISCO option.

OUNDATION fieldbus or FISCO option.

< +70 °C2)

a

< +70 °C2)

a

= 42.4 V

n

= 32 V

n

OUNDATION fieldbus options.

31

Page 32

Quick Installation Guide

Other certifications

Overfill protection

Cert. no: Z-65.16-476

U1 TÜV-tested and approved by DIBt for overfill protection according to the German WHG

regulations

Approval valid for HART and F

Suitability for intended use

Compliant with NAMUR NE 95, version 07.07.2006 “Basic Principles of Homologation”

For detailed information on product certificates, refer to the Rosemount 5300 Series

Reference Manual (Document No. 00809-0100-4530).

OUNDATION fieldbus options.

March 2013

32

Page 33

March 2013

EC Declaration of Conformity

Figure 1. EC Declaration of Conformity - page 1

Quick Installation Guide

33

Page 34

Quick Installation Guide

Figure 2. EC Declaration of Conformity - page 2

March 2013

34

Page 35

March 2013

Figure 3. EC Declaration of Conformity - page 3

Quick Installation Guide

35

Page 36

Emerson Process Management

Rosemount Measurement

8200 Market Boulevard

Chanhassen, MN 55317 USA

Tel (USA) 1 800 999 9307

Tel (International) +1 952 906 8888

Fax +1 952 906 8889

Emerson Process

Management

Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

Tel +65 6777 8211

Fax +65 6777 0947

Service Support Hotline:

+65 6770 8711

E-mail:

Enquiries@AP.EmersonProcess.com

Emerson Process

Management

Blegistrasse 23

P.O. Box 1046

CH 6341 Baar

Switzerland

Tel +41 (0) 41 768 6111

Fax +41 (0) 41 768 6300

Emerson FZE

P.O. Box 17033

Jebel Ali Free Zone

Dubai UAE

Tel +971 4 811 8100

Fax +971 4 886 5465

Emerson Process

Management Latin America

1300 Concord Terrace, Suite 400

Sunrise Florida 33323 USA

Tel +1 954 846 5030

Emerson Beijing

Instrument Co

No.6 North Street, Hepingli

Dongcheng District, Beijing

100013

China

Tel +8610 64282233

Fax +8610 642 87640

00825-0100-4530

Quick Installation Guide

00825-0100-4530, Rev EC

March 2013

© 2013 Rosemount Inc. All rights reserved. All marks property of owner.

The Emerson logo is a trade mark and service mark of Emerson Electric Co.

Rosemount and the Rosemount logotype are registered trademarks of Rosemount

Inc.

Loading...

Loading...