Page 1

Electric Installation.

Installation and user instructions for

Eye and Media cable managed desks

BS6396: 2008 Electrical Systems in Office

Furniture & Educational Furniture

Electrical equipment and installations must be designed and

tested to ensure their safety and to comply with statutory

regulations, in particular the “Electricity at Work Regulations”.

Relevant British Standards may be used as a means of

demonstrating safety and compliance with the regulations.

In the case of electrical systems in office furniture and educational

furniture, the relevant standard for systems connected to the

mains supply by means of a 13A plug is BS 6396:2008.

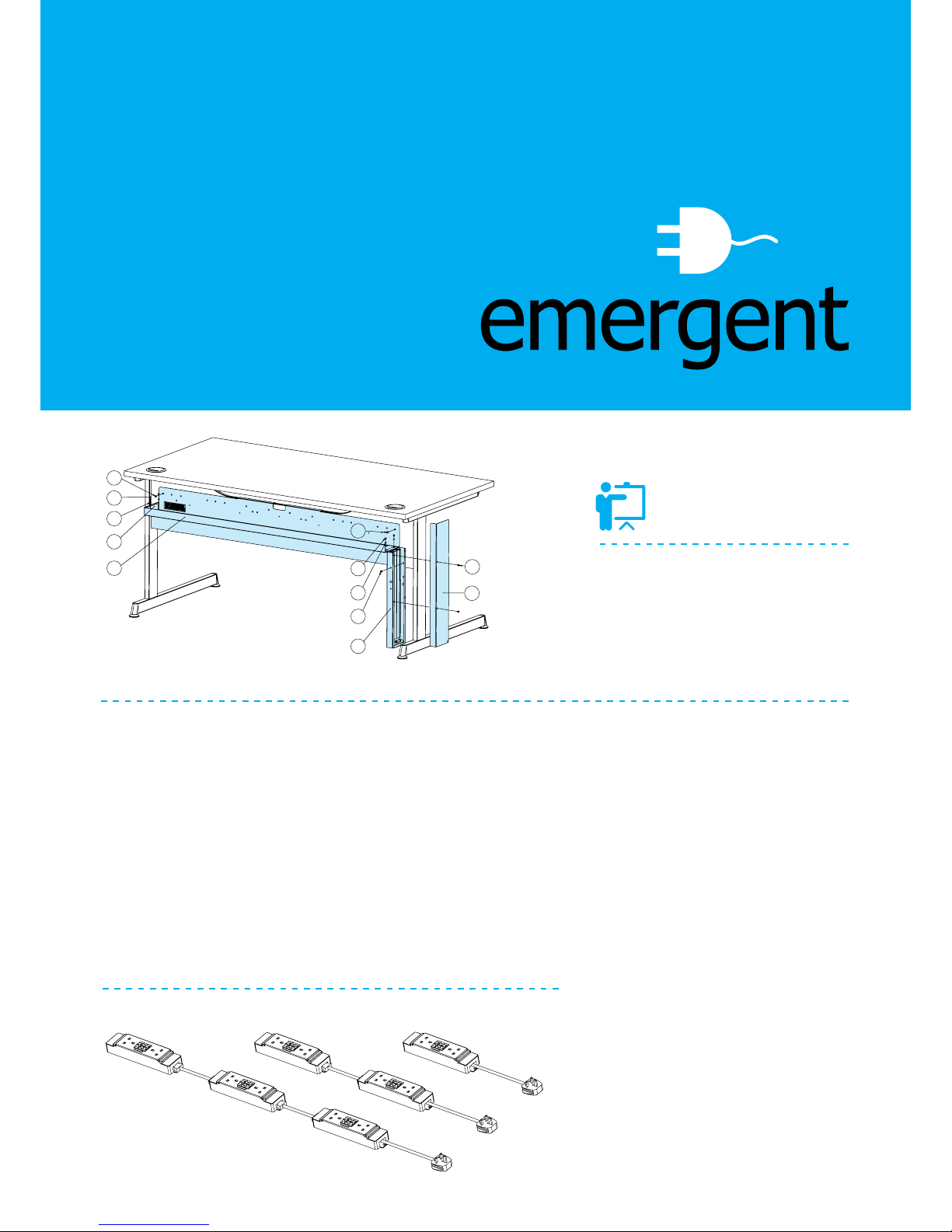

A. Media/Eye Trunking

B. No. 8 x ½” Woodscrew

C. Trunking End Cap

D. M4 Taptite Screw

E. Serrated Washer

F. Media Leg Riser

G. Leg Riser Cover

Sockets installed in office furniture are

intended to supply office equipment with

a rating not exceeding 5A with BS 6396

referring to all office furniture electrical

installations when completed must be tested.

Section 7 of BS 6396 sets out the procedures.

These tests should also be carried out on

reconfigured desks and screens as well

as new installations. Periodic inspections

and tests must be carried out to fulfil the

requirements of BS 6396 and the “Electricity

at Work Regulations” in maintaining a safe

working environment.

Sockets installed in office furniture are

intended to supply office equipment with

a rating not exceeding 5A.

The diagrams on the left indicate the

maximum number of socket outlets that may

be connected from a single power supply

cable fed from a 13 Amp BS 1363 plug and

their relevant fuse ratings.

DIAGRAM B

20mm Ceramic Fuses

DIAGRAM A

Electrical items required

B

D

E

C

A

B

D

E

B

F

D

G

6 Outlets 4 Outlets 2 Outlets

5A Fuse

5A Fuse

3.15A Fuse

3.15A Fuse

3.15A Fuse

13A Plug Fuse

Unfused

Page 2

It is important to bear in mind that there

is always some risk involved in handling

electrical equipment so all reasonable

care must be taken in following these

instructions to minimise the risk.

We recommend that a suitable qualified

electrical engineer is used to install and

test the power accessories and earthing

provision. The cable management is of

earthed construction. Maximum load 50Hz

13 amp. Maximum load per socket 5 amp.

For safety and compliance with

BS.6396:2008 the following socket

configurations and numbers must not be

exceeded. (30Ma R.C.D 13 AMP mains

plug optional) SEE DIAGRAM B.

On completion or re-configuration of

the electrical system within the furniture

the following electrical tests must be

carried out. It is recommended that these

tests are repeated at least annually for

continued safety.

Continuity & Polarity.

A test of all conductors, including the

protective earth conductor, Shall be made

to verify their continuity and correct polarity.

This test shall include the supply cord

and plug. The electrical system shall be

inspected to ensure that any fuses and any

single pole switches fitted are connected

only in the live conductor.

Insulation Resistance.

The insulation resistance of completed

electrical installations shall be tested using

a 500V D.C. test supply. The measured

resistance shall be not less than 1 M ohm.

Tests shall be made between conductors

and also to earth of the supply cable. The

duration of each test shall be not less than

5 seconds.

Note – Neon indicators shall be removed

from the circuit before carrying out this test

between conductors by switching off the

socket outlet. Where luminaries contain

sensitive electronic components, these

shall be disconnected prior to the test (see

713-04-04 of BS 7671)

Earth Continuity.

Earth connections of the installed socket

outlets and the accessible metal parts of

the earthed office furniture shall be tested

by passing a current of not less than 1.5

times the rating of the supply plug fuse

and no greater than 25 A, derived from

an a.c source with a load voltage not

exceeding 12 V. The tests shall include

the supply cord and shall be carried out

between the earth pin of the supply plug,

the earth connections of the installed

socket outlets and where applicable the

accessible metal parts of the earthed

furniture. The duration of the tests shall be

for a period 5 s and 20 s. The resistance

shall not exceed 0.1 Ohm.

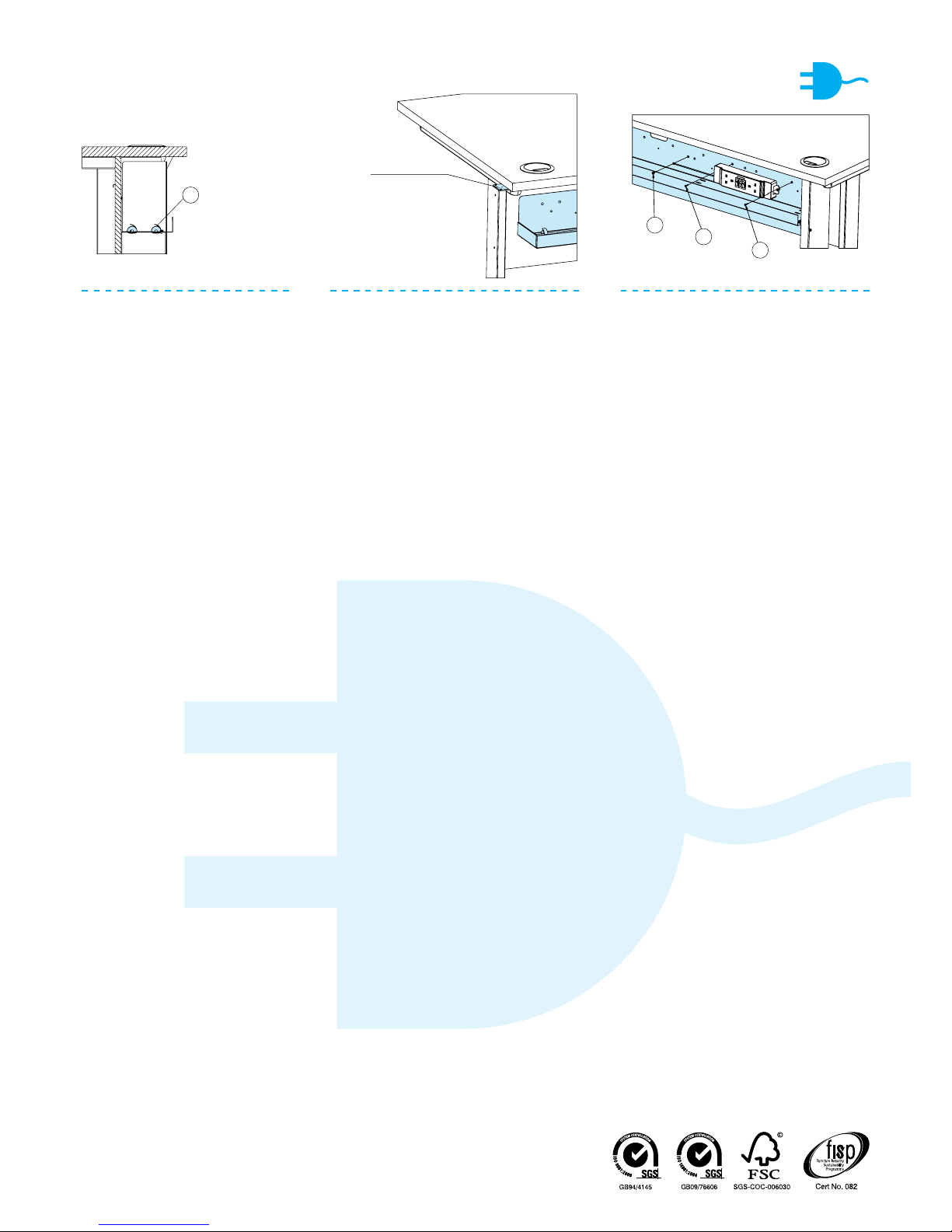

Trunking Assembly

To Desking

SEE DIAGRAM A. Hang the trunking

(A) over the modesty panel. Fasten to

the modesty panel with 2 off No. 8 x ½”

woodscrews (B). Fasten the trunking end

cap (C) to the end of the trunking with 2 off

M4 taptite screws and serrated washers (D

& E). Fasten the leg riser (F) to the trunking

with 2 off M4 taptite screws and serrated

washers (D & E). Fasten the leg riser to

the modesty panel with 1 off No. 8 x ½”

woodscrew (B). Fasten the leg riser cover

(G) to the leg riser with 2 off M4 taptite

screws (D).

Cable Routes.

Where desks are linked together the best

position for cables to enter is either at

the beginning or end of a configuration.

Cables will normally enter desks at the

bottom of the leg riser and be anchored

by the cable clamp provided. Where

cables run from the building out to the

desks, these exposed lengths [from the

plug to the cable entry point or appliance

inlet connector] should be as short as

possible and must not exceed 2 metres.

Cables should be positioned so as not

to be a hazard to people walking by. Use

cable ties (H – SEE DIAGRAM C) in the

trunking slots to segregate power and

data cables. Run power and data cables

in separate channels in the leg riser plastic

channel. Where cables run from desk to

desk, these desks must be securely linked

together using the plates provided.

(SEE DIAGRAM D).

Power Socket

Installation

SEE DIAGRAM E. First decide on the

position of the socket inside the horizontal

face of the trunking, then fasten through

the socket lugs through clearance holes in

trunking into the modesty panel with 2 off

No. 6 x ½” csk woodscrews (J ). Connect

the socket earth lead to a nearby marked

earth point with 1 off No. 8 x ½” selftapping screw (K).

DIAGRAM C

Emergent Crown Ltd, Unit 5, Browmills Industrial Estate,

Brighouse Road, Hipperholme, Halifax HX3 8EF

t.01422 349119 e.sales@emergent-crown.co.uk w.www.emergent-crown.co.uk

H. Cable Ties

K. No. 8 x ½” Self-Tapping Screw

J. No. 6 x ½” Countersunk Woodscrew

DIAGRAM D

Linking Plate

DIAGRAM E

K

J

J

H

Loading...

Loading...