Page 1

This manual contains safety information that if ignored can endanger life or result in serious injury. They are indicated by this icon.

Keep the instrument protected from sun and water.

Avoid water splashes.

OPERATING INSTRUCTIONS

FOR “WDPHCL- ECL6” INSTRUMENT

Read Carefully !

ENGLISH Version

1

R1-09-08

Page 2

“WDPHCL” instrument complies with the following European regulations:

EN60335-1 : 1995, EN55014, EN50081-1/2, EN50082-1/2, EN6055-2, EN60555,3

Based on directive CEE 73/23 c 93/68 (DBT Low voltage directive) and directive 89/336/CEE (EMC

Electromagnetic Compatibility)

GENERAL SAFETY GUIDELINES

Danger!

Caution!

In emergencies the instrument should be switched off immediately! Disconnect the power cable from

the power supply!

When installing always observe local regulations!

Manufacturer is not liable for any unauthorized use or misuse of this product that may cause injury,

damage to persons and / or materials.

Instrument must be accessible at all times for both operating and servicing. Access must not be

obstructed in any way!

Feeder should be interlocked with a no-fl ow protection device to automatically shut-off the pumps when

there is no fl ow!

Pumps and accessories must be serviced and repaired by qualifi ed and authorized personnel only!

Always discharge the liquid end before servicing the instrument!

Empty and rinse the liquid end before work on a pump which has been used with hazardous or

unknown chemicals!

Always read chemical safety datasheet!

Always wear protective clothing when handling hazardous or unknown chemicals!

Instrument must be operated / serviced by trained technicians only!

All connection operations must be performed while the instrument is not connected to main supply!

2

Page 3

1. Introduction

WDPHCL is a fully Integrated All-in-One Swimming Pool Controller. Ideal for new construction projects the WDPHCL

innovates panel mount capability into a small wall-mount package.

2 Pumps for Chlorine and pH adjustment in PVDF, small-form-factor saves space, installation time, and shipping

expense.

It includes Input for a Flow Switch. Integral pumps can handle up to 20 bar and 16 l/h (Self-Venting Liquid-end as option),

high maintenance tubing sets and roller assemblies.

Working ranges are:

pH : from 0 to 14pH

Chlorine: from 0 to 10 mg/l

All information are provided through a large LCD display. Using a revolutionary wheel control the instrument can be easily

programmed. WDPHCL is housed in a IP65 plastic box.

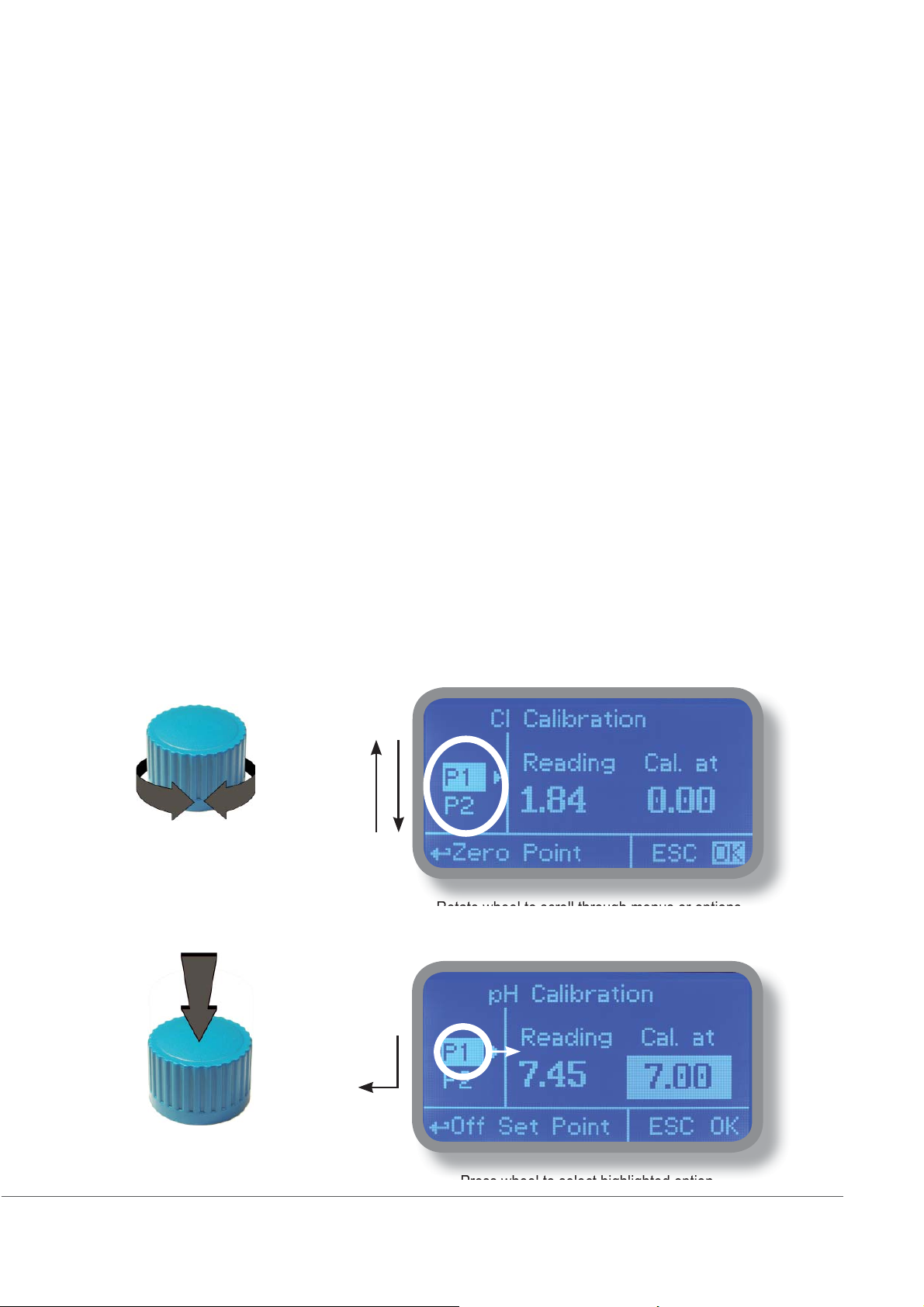

2. The wheel

Located in the upper right side of WDPHCL there is a wheel that must be used to control the instrument. Wheel can be

rotated in both directions to scroll over the menus and / or pressed to confi rm highlighted selection / value.

NOTE: Once changes are made press “OK” to save and exit from submenu. Press “ESC” to exit without saving.

SCROLL

Rotate wheel to scroll through menus or options

Press wheel to select highlighted option

SELECT

3

Page 4

3. Mainboard Connections

Unplug instrument from main power supply then perform connections to probes and / or selected outputs by following

the above picture.

(A) STAND-BY input

(B) Flow input:

LEFT PUMP HEAD (pH)

(B)

(G)

(C)

3 1

2 4

(E)

1 Blue (Ground)

2 Brown (+)

3 n/a

4 Black (Signal)

RIGHT PUMP HEAD (Cl)

(H)

(A)

(D)

(F)

(C) pH Level input (left pump head)

(D) Cl Level input (right pump head)

(E) pH EPHS probe connector

(F) Cl ECL6 probe connector

(G) Power Supply: 230VAC 50-60 Hz.

(H) Alarm contact output:

3 1

2 4

Warning: Connections must be perfomed by qualifi ed and trained personnel only.

4

1 n/a

2 Black

3 Red

4 n/a

Page 5

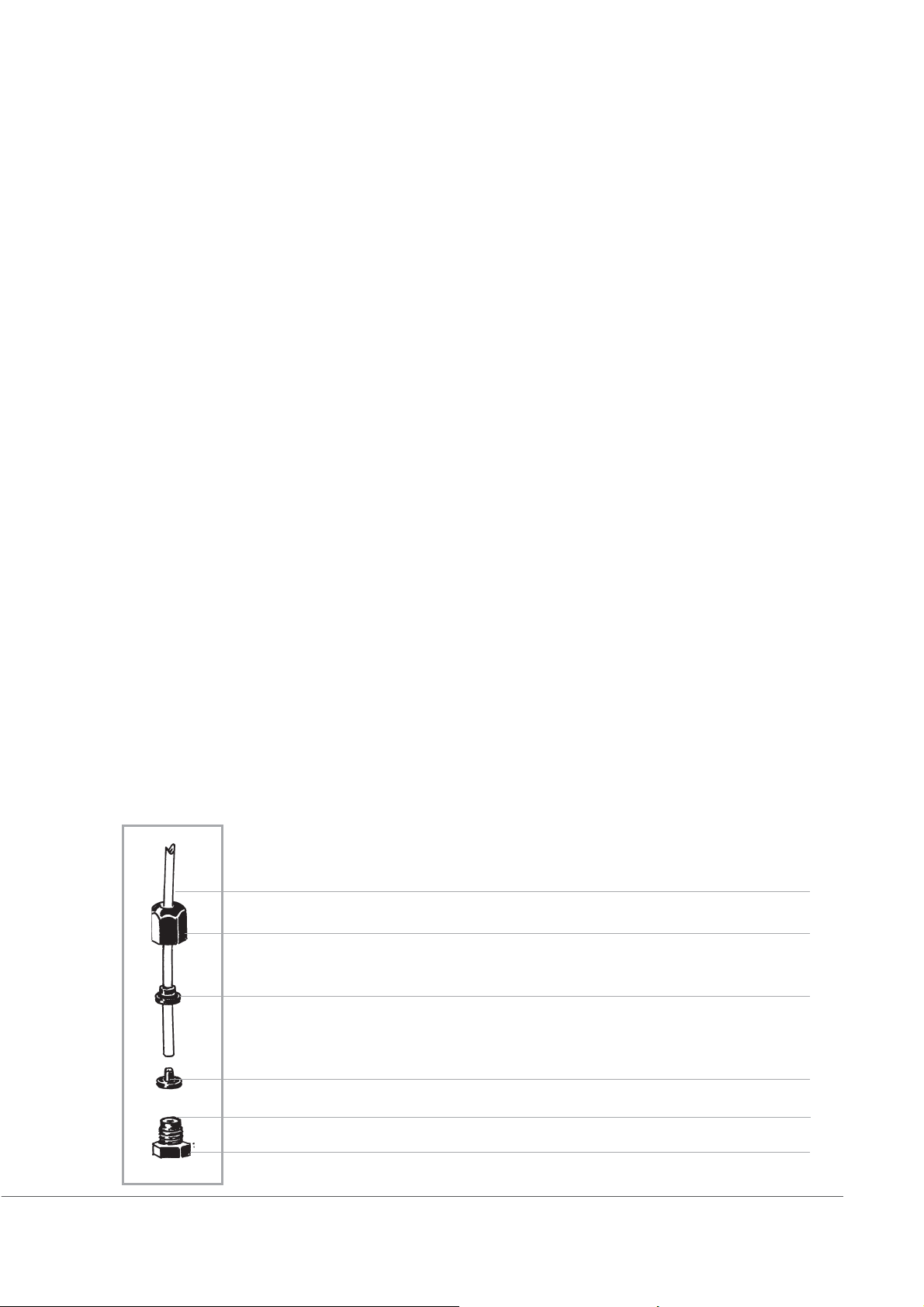

3.1 Hydraulic connections, hoses

Unplug instrument from main power supply then perform connections to probes and / or selected outputs by following the

above picture. Hydraulic connections are:

Suction Hose with level probe and foot fi lter

Delivery Hose with injection valve

Discharge Hose

Suction Hose.

Completely unscrew tightening nut from pump’s head and remove assembling

components: tightening nut, holding ring and pipe holder.

Assembly as shown. Insert hose into pipe holder until it reaches the bottom.

Lock hose on pump’s head by screwing down the tightening nut.

Use only hands to do it!

Connect other side of the hose to the foot fi lter using the same procedure.

Delivery Hose.

Completely unscrew tightening nut from pump’s head and remove assembling

components: tightening nut, holding ring and pipe holder.

Assembly as shown. Insert hose into pipe holder until it reaches the bottom.

Lock hose on pump’s head by screwing down the tightening nut.

Use only hands to do it!

Connect other side of the hose to the injection valve using the same

procedure.

Discharge hose.

Insert one side of discharge hose into pump head discharge connector.

Insert other side of discharge hose into product’s tank.

During priming procedure product exceeding will fl ow into tank.

Suction Hose

Tightening Nut

Holding Ring

Pipe Holder

O-ring

Valve

5

Page 6

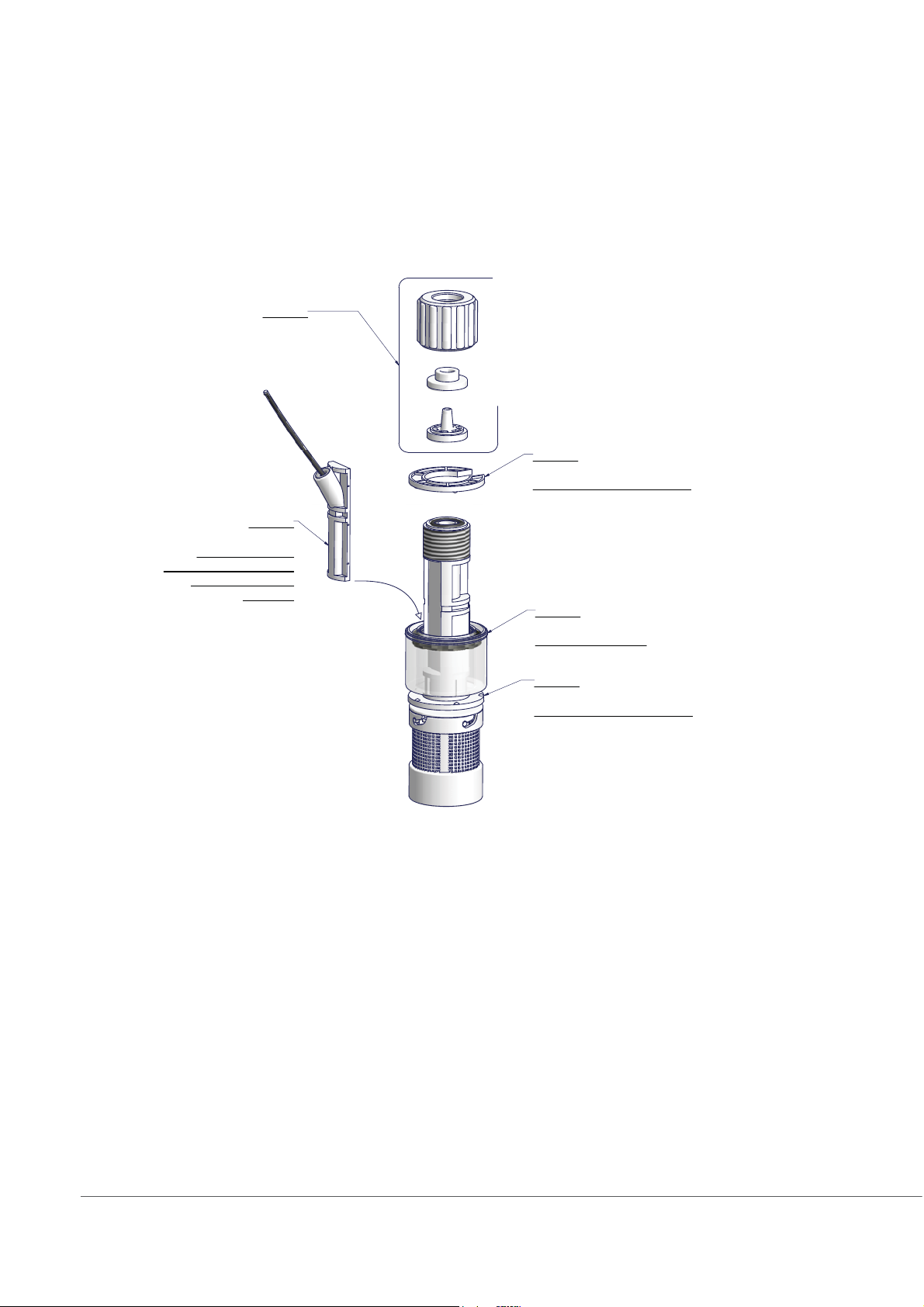

3.2 Hydraulic connections, level probes

Assembling foot fi lter with level probe.Level probe must be assembled with foot fi lter using the provided kit.

Foot valve is made to be installed into tank’s bottom without sediments priming problem.

STEP 5

STEP 4

INSERT RING AS SHOWN

STEP 3

INSERT PROBE

WITH N.O. CONTACT

UNTIL TO HEAR

A CLICK

STEP 2

INSERT FLOATER

Connect BNC from level probe into WDPHCL level inputs (“B” and “E” connectors).

Warning: If there is a mixer installed into tank, install a suction lance instead of level probe / foot fi lter.

STEP 1

INSERT RING AS SHOWN

Put level probe assembled with foot fi lter into tank’s bottom.

6

Page 7

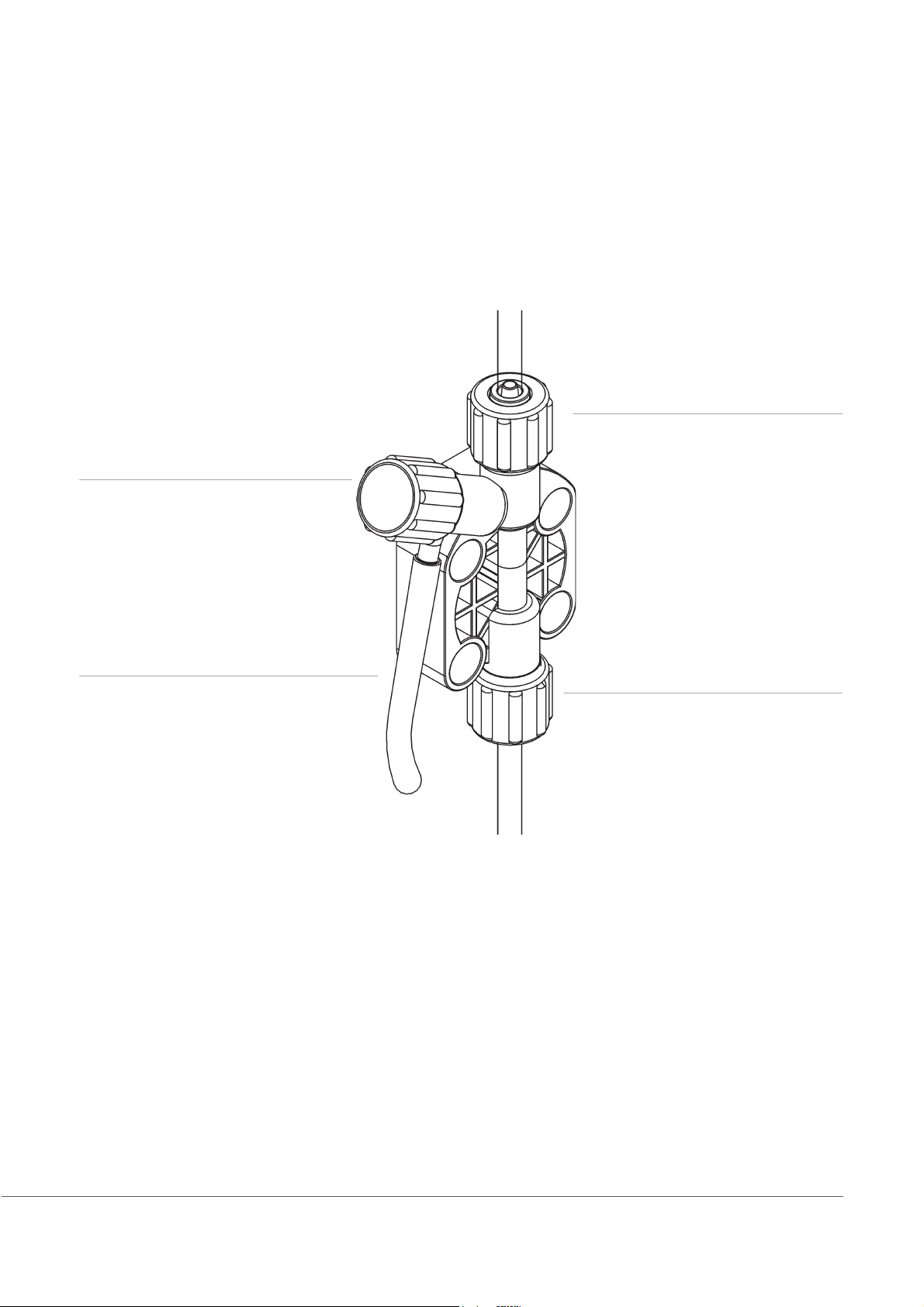

3.3 Hydraulic connections, pump heads

Injection Valve.

Injection valve must be installed on plant from water’s input.

Injection valve will open at pressure greater than 0,3bar.

Discharge Knob

To Delivery hose

Discharge hose (connector)

To Suction hose

7

Page 8

4. Main Screen

When into normal operating mode, WDPHCL shows the following main screen:

UNITS (1)

VALUES (2)

PUMPS STATUS (3)

LEFT

PUMP HEAD

STATUS

RIGHT

PUMP HEAD

STATUS

Main screen is divided int 3 zones.

(1) UNITS. “pH” is the measuring unit for pH probe.

“mg/l” is the measuring unit for Chlorine probe.

(2) VALUES These numbers are values read by the probes.

(3) PUMPS STATUS These fi elds are related to current pumps status and instrument activity.

DISPLAY EXPLANATION WHAT TO DO IF OCCURS

FEED ON Pump is dosing chemical product. No action required.

FEED OFF Pump is OFF. No action required.

LOW TANK Chemical product tank is almost empty. Check chemical tank. Restore correct level.

NO FLOW External fl ow contact stops both the pumps. Check fl ow.

OK Setpoint reached. No action required.

FEED LIMIT Time for dosing exceeded. Dosing alarm. Check pump dosing capacity.

PROBE FAIL Stuck reading values. Check probe for proper functioning.

DELAY Pump activity delayed. Countdown in progress. If not requested check PARAMETERS options.

WAIT PH pH priority dosage over Cl dosage. If not requested check PRIORITY options.

8

Page 9

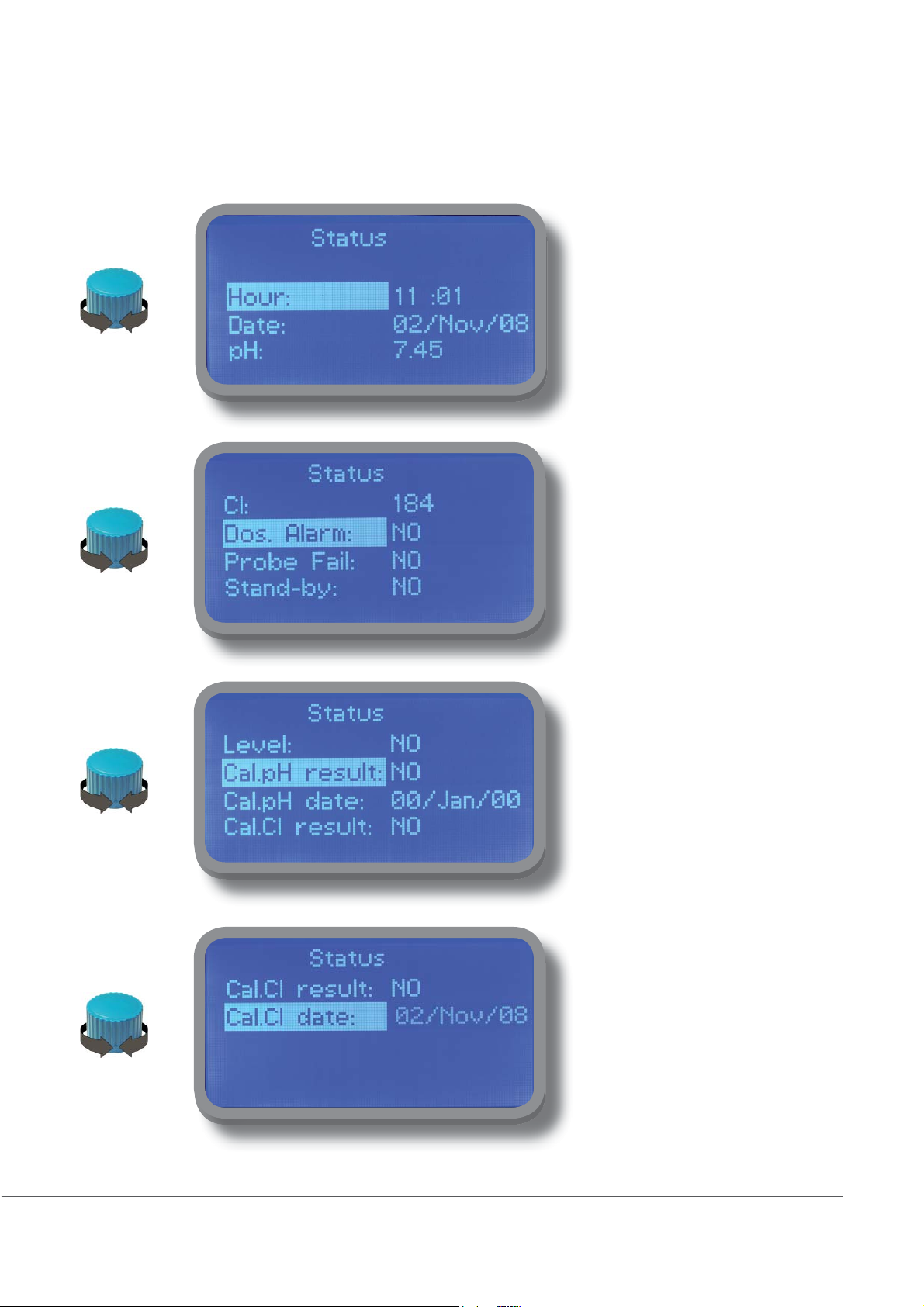

5. Quick status check

From main screen rotate the wheel to review main instrument parameters and current status conditions.

Current time

Today date

Current pH reading

Current Chlorine reading

Dosing alarm condition

Probe failure status

NO FLOW contact status

Tank Level status

Last pH calibration result

Last pH calibration date

Last Cl calibration result

Last Cl calibration date

9

Page 10

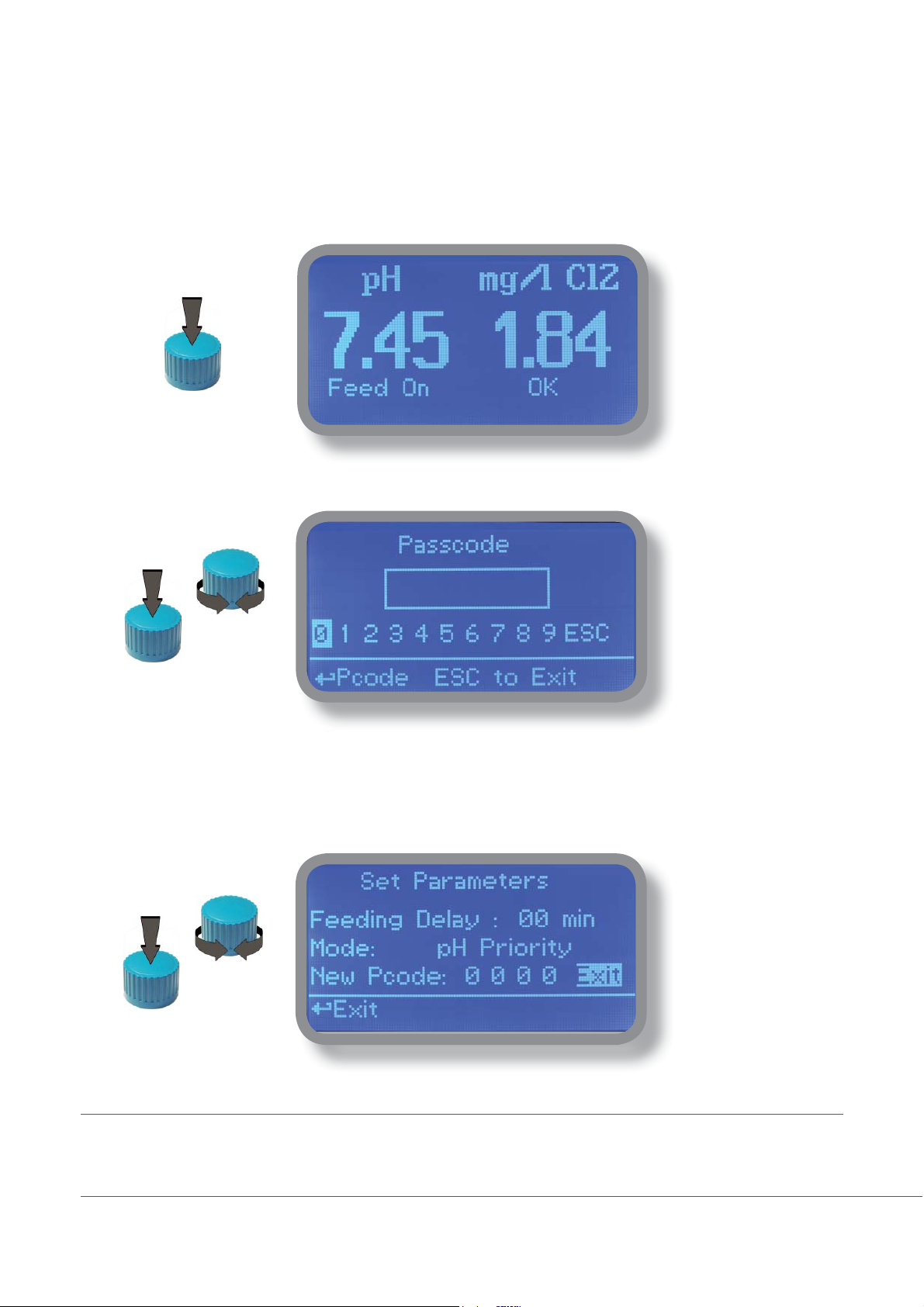

6. Password

To grant access into “Main Menu” press the wheel from main screen and enter the passcode.

If this is the fi rst time here then the passcode is 0000 (factory preset). Press wheel 5 times to enter into “Main Menu”.

Otherwise press the wheel 1 time and enter the passcode. Numbers can be selected rotating the wheel.

X5

To set a new passcode choose “PARAMETERS” from “Main Menu” , move on “New Pcode”, click on wheel and enter a

four numbers code. Click on “EXIT” and choose “YES” to save request. The new passcode is now ready.

Lost passcode ?

Please dont’ forget the passcode (if changed). In the unfortunate event, please call your local distributor for unlocking procedure. There is no way for you to

recover lost passcode.

10

Page 11

7. “Main Menu” list

To grant access into “Main Menu” enter the passcode (as described in previous chapter). Once into “Main Menu” rotate

the wheel to scroll through all the options available.

Set-Point (see page 12)

Calibration (see page 14)

Parameters (see page 20)

Pumps Activities (see page 21)

Instrument Reset (see page 22)

Max Strokes Settings (see page 22)

Dosing Alarm (see page 23)

International (see page 24)

Probe Failure (see page 25)

pH Compensation (see page 26)

Disinfectant (see page 26)

Flow (see page 27)

Service (see page 27)

Exit (to main screen)

11

Page 12

8. “Set-Point”, pH (on/off)

pH reading values can be set to operate the pH pump using 2 set-points into On/Off mode or Proportional (%).

On/Off mode set the instrument to operate using two set values that enable or disable the pH pump. To use this

mode move cursor on “Working Mode”. Press the wheel and select it.

ON/OFF mode while dosing ALKALI

Set pH value at 7.00 OFF and 6.90 ON.

Instrument will leave the pH pump active until reading value will increase up to 7.00pH.

At 7.00pH the pH pump will be disabled until reading value will decrease under 6.90pH.

Waiting Time: to let pump operate at pulses per minutes add one or more minute (1pulse every xx minutes). Otherwise (00 minutes) pump will

operate at set stroke settings (see page 22).

ON

OFF

6.90 7.00

12

Page 13

8. “Set-Point”, pH (on/off)

ON/OFF mode while dosing ACID

Set pH value at 7.00 OFF and 7.10 ON.

Instrument will leave the pH pump active until reading value will decrease up to 7.00pH

At 7.00pH the pH pump will be disabled until reading value will increase up to 7.10pH.

Waiting Time: to let pump operate at pulses per minutes add one or more minute (1pulse every xx minutes). Otherwise (00 minutes) pump will

operate at set stroke settings (see page 22).

ON

OFF

7.00 7.10

To end procedure move cursor on “OK” and press wheel to proceed to “Save” request screen. Move wheel on “YES” to

save or “NO” to discard changes.

Do you know ?

In chemistry, an alkali is a basic, ionic salt of an alkali metal or alkaline earth metal element. Alkalis are best known for

being bases (compounds with pH greater than 7) that dissolve in water. The adjective alkaline is commonly used in English

as a synonym for base, especially for soluble bases. This broad use of the term is likely to have come about because

alkalis were the fi rst bases known to obey the Arrhenius defi nition of a base and are still among the more common bases.

Since Brønsted-Lowry acid-base theory, the term alkali in chemistry is normally restricted to those salts containing alkali

and alkaline earth metal elements.

An acid (often represented by the generic formula HA [H+A−]) is traditionally considered any chemical compound that,

when dissolved in water, gives a solution with a hydrogen ion activity greater than in pure water, i.e. a pH less than 7.0.

That approximates the modern defi nition of Johannes Nicolaus Brønsted and Martin Lowry, who independently defi ned an

acid as a compound which donates a hydrogen ion (H+) to another compound (called a base). Common examples include

acetic acid (in vinegar) and sulfuric acid (used in car batteries). Acid/base systems are different from redox reactions in

that there is no change in oxidation state.

13

Page 14

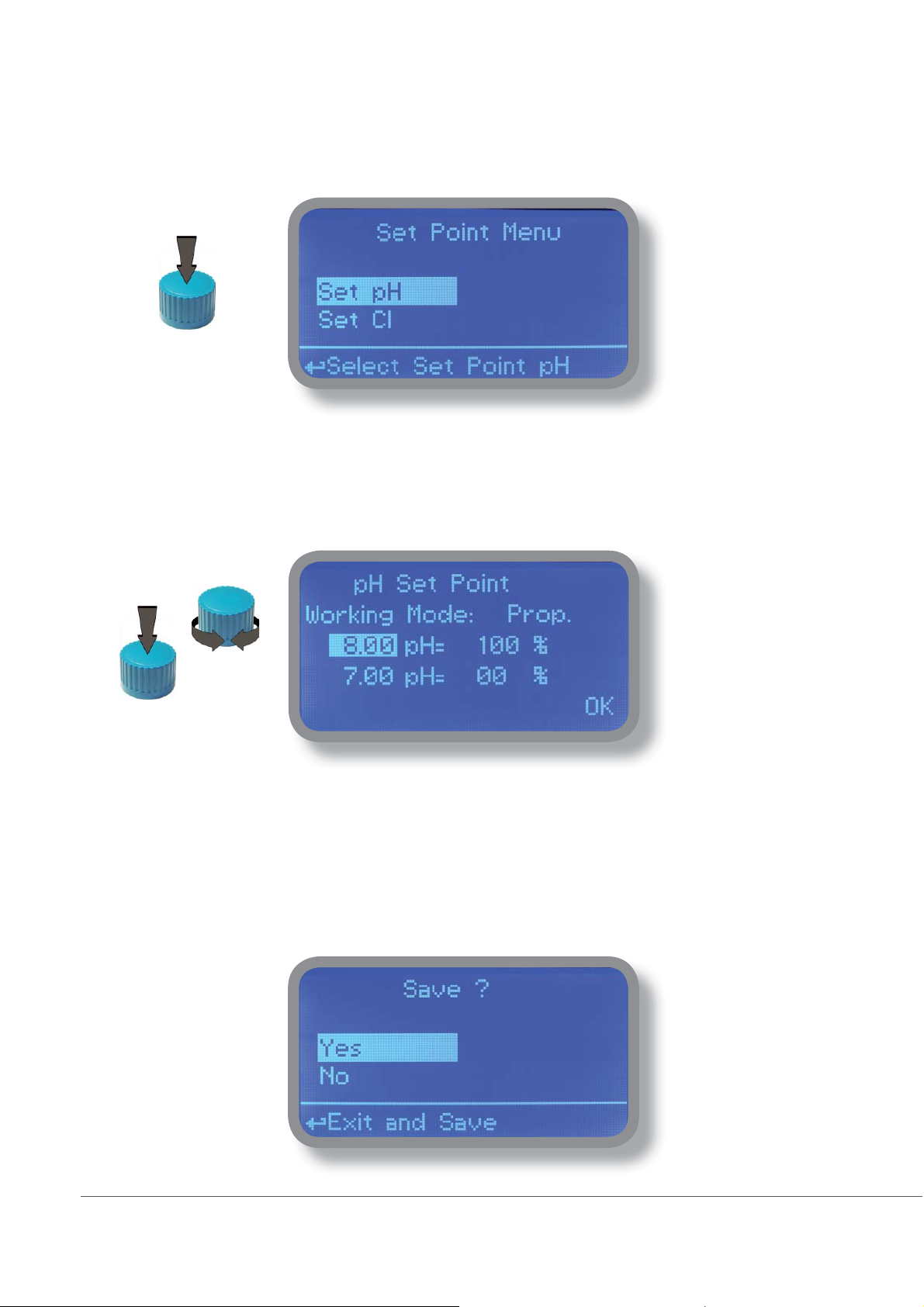

8.1 “Set-Point”, pH (proportional)

pH reading values can be set to operate the pH pump using 2 set-points into On/Off mode or Proportional (%).

Proportional mode set the instrument to operate using a calculated percentage between two set values that

enable or disable the pH pump. T o use this mode move cursor on “W orking Mode”. Press the wheel and select it.

PROPORTIONAL mode between 7pH(0%) and 8pH (100%). [Stroke setting 180]

In this mode the pH pump will be “ON” for values greater than 8pH with maximum set strokes capacity (e.g.: 180) and

it’ll be “OFF” for values lower than 7pH. For values of 7.5pH pump will be “ON” with 90 strokes capacity. The calculation

is based on 180 strokes setting (see page 22). To end procedure move cursor on “OK” and press wheel to proceed to

“Save” request screen. Move wheel on “YES” to save or “NO” to discard changes.

14

Page 15

8.2 “Set-Point”, Cl (on/off)

Cl reading values can be set to operate the Chlorine pump using 2 set-points into On/Off mode or Proportional (%).

On/Off mode set the instrument to operate using two set values that enable or disable the Chlorine pump. To

use this mode move cursor on “Working Mode”. Press the wheel and select it.

ON/OFF mode

Set Cl value at 0.80 mg/l ON and 1.00 mg/l OFF. The difference between the two Cl values is called HYSTERESIS.

Instrument will enable the Chlorine pump when reading value will decrease at 0.80mg/l

At 0.80mg/l the Chlorine pump will be enabled until reading value will increase at 1.00mg/l.

Waiting Time: to let pump operate at pulses per minutes add one or more minute (1pulse every xx minutes). Otherwise (00 minutes) pump will

operate at set stroke settings (see page 22).

ON

OFF

0.80 1.00

15

Page 16

8.3 “Set-Point”, Cl (proportional)

Cl reading values can be set to operate the pH pump using 2 set-points into On/Off mode or Proportional (%).

Proportional mode set the instrument to operate using a calculated percentage between two set values that

enable or disable the Chlorine pump. To use this mode move cursor on “Working Mode”. Press the wheel and

select it.

PROPORTIONAL mode between 1.00Cl (0%) and 0.50Cl(100%). [Stroke setting 180]

In this mode the Cl pump will be “ON” for values lower than 0.50mg/l with maximum set strokes capacity (e.g.: 180)

and it’ll be “OFF” for values greater than 1mg/l. For values of 0.75mg/l pump will be “ON” with 90 strokes capacity. The

calculation is based on 180 strokes setting (see page 22). To end procedure move cursor on “OK” and press wheel to

proceed to “Save” request screen. Move wheel on “YES” to save or “NO” to discard changes.

To end procedure move cursor on “OK” and press wheel to proceed to “Save” request screen. Move wheel on “YES” to

save or “NO” to discard changes.

16

Page 17

9. “Probe Calibration”, pH

pH calibration procedure involves two calibration points and it requires two buffer solutions. Default buffer solutions are

pH 4.00 and pH 7.00. pH reading value can be also 30°C temperature compensated from “pH compensation” menu.

From “Menu Calibration” choose “pH probe”.

In the following example instrument will calibrate pH using default buffer solutions values.

Note: this procedure assumes that instrument is correctly confi gured and a working pH probe connected.

Otherwise unattended results may occurr.

pH7

Calib 1st Point.

Once into “pH Calibration” menu move wheel on “P1” then press wheel to enter into fi rst point calibration submenu.

Prepare 7.00pH buffer solution and dip probe’s sensor on it. Wait until reading value is stable and according to buffer

solution value move wheel until it is the same on display (“Cal. at” fi eld). Default value is 7.00pH. To end procedure

move cursor on “OK” and press wheel to proceed to next step.

Note: buffer solution value may change if environment temperature it’s different than 20°C. Read solution’s

label for more information. According to this occurrence “pH Default” must be changed.

Power Supply calibration ?

To obtain the most reliable results during pulses calculation is possible to calibrate power supply read value. Press wheel on “P1” then move curso on “OK” and

confi rm power supply read value. (e.g.: 230V).

17

Page 18

9. “Probe Calibration”, pH

pH4

Calib 2nd Point.

Move wheel on “P2” then press wheel to enter into second point calibration submenu. Prepare 4.00pH buffer solution

and dip probe’s sensor on it. Wait until reading value is stable and according to buffer solution value move wheel until it

is the same on display (“Cal. at” fi eld). Default value is 4.00pH.

To end procedure move cursor on “OK” and press wheel to proceed to “Save” request screen. Move wheel on “YES” to

save or “NO” to discard changes.

Note: buffer solution value may change if environment temperature it’s different than 20°C. Read solution’s

label for more information. According to this occurrence “pH Default” must be changed.

18

Page 19

9.1 “Probe Calibration”, Cl

Cl calibration procedure involves probe’s selection, Zero (P1) and 2nd Point (P2) calibration. From “Menu Calibration”

choose “Cl probe”.

Note: This procedure assumes that instrument is correctly confi gured and a working Chlorine probe connected

and installed on system. Measurement must be performed using plant water. Otherwise unattended results

may occurr.

Calib Zero (P1).

Once into “Cl calibration” menu move on “P1” then press wheel to enter into

calibration mode. For a correct system calibration proceed as follows.

- install an “activated carbon fi lter” prior to probe’s holder.

- let system water fl ow into probe holder for about 30 minutes.

- press wheel (cursor must be on “Cal.at”). Remove fi lter.

Carbon Filter System

Calib 2nd point (P2).

Now move on “P2” then press wheel to enter into calibration mode. For a correct system calibration use a Photometer

or a DPD device to read chlorine on system. Enter value using the wheel then move cursor on “OK”. Now press the

wheel.

To end procedure move cursor on “OK” and press wheel to proceed to “Save” request

screen. Move wheel on “YES” to save or “NO” to discard changes. If an error occurred

during calibration procedure then the instrument will show an error message and will ask

to proceed to a new calibration, cancel current operation or restore default settings.

Photometer

19

Page 20

10. “Parameters”

From “Menu Calibration” choose “Parameters”. This menu allows to set a delay (max 60 minutes) before pumps begin

to feed. Furthermore use this menu to set pH pump startup priority and to change default passcode.

Feeding Delay.

Move on “Feeding Delay” then press wheel. Choose a value between 0 (disabled) and 60 minutes (maximum delay

time). This feature can be used to accord a startup delay for the pumps. Delay occurs when instrument is powered or

after a “NO FLOW” contact recovery.

Mode.

Move on “Mode” then press wheel. If both pumps need to operate, a startup priority can be set to allow the pH pump to

begin to feed prior to Cl pump. Choose “pH priority” to enable this function. Cl pump will begin to dose when pH pump

has stopped.

New Pcode.

See page 10.

To end procedure move cursor on “OK” and press wheel to proceed to “Save” request screen. Move wheel on “YES” to

save or “NO” to discard changes.

20

Page 21

11. “Pumps Activities”

From “Menu Calibration” choose “Pumps activities”. This menu allows to manually operate one or both the pumps for a

settable time.

Move on “Mode” then press wheel. Choose “Man. Pump1” for manually operate pH pumps or “Man. Pump2” for Cl

pump.

Press wheel to move cursor on “TIME” fi eld. Once here, choose a working time between 0 (disabled) or 199 minutes.

Move on “EXIT”, then press wheel.

Choose “YES” to save changes. Exit from main menu. Main display will show a countdown including the selected pump

(left for pH pump, right for Cl pump). To stop this countdown go back to “Pump activities” menu and choose “ON” as

working mode or wait until countdown ends. This function can be used for priming purposes.

21

Page 22

11. “Instrument Reset”

To restore instrument to its default values (including password) once into “Instrument Reset” menu, press wheel then

change value to “ON”, press wheel again, move on “OK” then fi nally press wheel. The instrument display will show

“CHECKSUM ERROR”. Press whell to return into “Main Menu”. Move on “EXIT”, then press wheel. The instrument is

now restored to factory default. Please repeat all calibration procedures and programming parameters.

12. “Max strokes settings”

pH and Cl pumps can be set to operate within a maximum number of strokes. Strokes are the total amount of injections

per minute made by a pump. Using wheel choose a value for one or both pumps then move on “EXIT”.

To end procedure move cursor on “OK” and press wheel to proceed to “Save” request screen. Move wheel on “YES” to

save or “NO” to discard changes.

Note: Pumps dosing capacity is based on 180 strokes per minutes

22

Page 23

13. “Dosing Alarm”

Use this menu to assign a maximum time to the pumps for reaching the setpoint. If set time ends and the pumps are

still dosing, within this menu is possible to STOP them or just to show an alarm message. Function can be disabled

selecting “OFF” instead of a number (minutes). Dosing alarm can be set for both or just one pump.

E.g. To set Cl pump to stop after time ends and setpoint isn’t still reached press wheel, choose maximum time, press

wheel move on next fi eld and choose “STOP”. Time can be set between 0 and 100 minutes. When satisfi ed with

settings move on exit and press wheel.

To end procedure move cursor on “OK” and press wheel to proceed to “Save” request screen. Move wheel on “YES” to

save or “NO” to discard changes.

23

Page 24

14. “International”

Use this menu to set international parameters as UNIT FORMAT (Europe IS or USA), Local Time and Date.

Format.

Use this option to use European or USA units format. See table for differencies.

EUROPE IS (Internationl Standard) USA

Date (DD/MMM/YY) Date (MMM/DD/YY)

Time 24h Time AM / PM

Time.

Use this option to set local time.

Date.

Use this option to set date.

Move on exit to end changes.

To end procedure move cursor on “OK” and press wheel to proceed to “Save” request screen. Move wheel on “YES” to

save or “NO” to discard changes.

24

Page 25

15. “Probe Failure”

Use this menu to assign a maximum time to connected probes to stay stuck. A stuck probe (it remains on same value

for some time) means that probably probe itself is damaged. Within this menu is possible to STOP pumps or just to

show an alarm message (probe failure) . Function can be disabled selecting “OFF” instead of a number (minutes). This

function can be set for both or just one probe.

E.g. To set Cl pump to stop after time ends and probe doesn’t change reading values press wheel, choose maximum

time, press wheel move on next fi eld and choose “STOP”. Time can be set between 0 and 100 minutes. When satisfi ed

with settings move on exit and press wheel.

To end procedure move cursor on “OK” and press wheel to proceed to “Save” request screen. Move wheel on “YES” to

save or “NO” to discard changes.

25

Page 26

16. “pH Compensation”

To enable 30°C temperature compensation for pH probe press wheel then choose “ON”. For disabling temperature

compensation choose “OFF”.

To end procedure move cursor on “OK” and press wheel to proceed to “Save” request screen. Move wheel on “YES” to

save or “NO” to discard changes.

17. “Disinfectant”

To change disinfectant product type (chlorine based or bromine based) press wheel then move wheel to change

“BROMINE” or “CHLORINE” then press wheel again. To end procedure move cursor on “OK” and press wheel to proceed

to “Save” request screen. Move wheel on “YES” to save or “NO” to discard changes. Note: this changes affect main

screen UNIT display [Br2 or Cl2].

26

Page 27

18. “Flow Contact”

Flow contact (locate connection on page 4) can be enabled to stop all dosing activities using a N.O. contact (normally

opened contact) or N.C. contact (normally closed contact). Move wheel for enabling and changing contact logic (N.O. or

N.C).

To end procedure move cursor on “OK” and press wheel to proceed to “Save” request screen. Move wheel on “YES” to

save or “NO” to discard changes.

19. “Service”

This “view only” menu shows probes reading live. Press “ESC” to exit.

27

Page 28

20. Technical information.

Power supply: 230 VAC (190÷265 VAC)

pH range: 0 ÷14 ; Cl range: 0÷10 mg/l

Pump Strokes: 0 ÷ 180

Suction Height: 1,5 metres

Environment Temperature: -10 ÷ 45°C (14 ÷ 113°F)

Chemical Temperature: 0 ÷ 50°C (32 ÷ 122°F)

Installation Class: II

Pollution Level: 2

Audible Noise (single head): 74dbA

Packaging and Transporting Temperature: -10 ÷ 50°C (14 ÷ 122°F)

Protection degree: IP 65

Product Formula Ceram. PVDF PP PVC SS 316 PMMA Hastel. PTFE FPM EPDM NBR PE

Acetic Acid, Max 75% CH3COOH 2 1 1 1 1 3 1 1 3 1 3 1

Hydrochloric Acid, Concentrate HCl 1 1 1 1 3 1 1 1 1 3 3 1

Hydrofl uoric Acid 40% H2F2 3 1 1 2 3 3 2 1 1 3 3 1

Phosphoric Acid, 50% H3PO4 1 1 1 1 2 1 1 1 1 1 3 1

Nitric Acid, 65% HNO3 1 1 2 3 2 3 1 1 1 3 3 2

Sulphuric Acid, 85% H2SO4 1 1 1 1 2 3 1 1 1 3 3 1

Sulphuric Acid, 98.5% H2SO4 1 1 3 3 3 3 1 1 1 3 3 3

Amines R-NH2 1 2 1 3 1 - 1 1 3 2 3 1

Sodium Bisulphite NaHSO3 1 1 1 1 2 1 1 1 1 1 1 1

Sodium Carbonate (Soda) Na2CO3 2 1 1 1 1 1 1 1 2 1 1 1

Ferric Chloride FeCl3 1 1 1 1 3 1 1 1 1 1 1 1

Calcium Hydroxide (Slaked Lime) Ca(OH)2 1 1 1 1 1 1 1 1 1 1 1 1

Sodium Hydroxide (Caustic Soda) NaOH 2 1 1 1 1 1 1 1 2 1 2 1

Calcium Hypochlor.(Chlor.ted Lime) Ca(OCl)2 1 1 1 1 3 1 1 1 1 1 3 1

Sodium Hypochlorite, 12.5% NaOCl + NaCl 1 1 2 1 3 1 1 1 1 1 2 2

Potassium Permanganate, 10% KMnO4 1 1 1 1 1 1 1 1 1 1 3 1

Hydrogen Peroxide, 30% (Perydrol) H2O2 1 1 1 1 1 3 1 1 1 2 3 1

Aluminium Sulphate Al2(SO4)3 1 1 1 1 1 1 1 1 1 1 1 1

Copper-II-Sulphate (Roman Vitriol) CuSO4 1 1 1 1 1 1 1 1 1 1 1 1

Resistance rating: (1: Resistant) ; (2: Fairly resistant) ; (3: Not resistant)

Polyvinyldene fl uoride (PVDF) Pump Heads, valves, fi tting, tubing

Polypropylene (PP) Pump Heads, valves, fi tting, level fl oater

PVC Pump Heads

Stainless steel (SS 316) Pump Heads, valves

Polymethyl Metacrilate (Acrylic) PMMA Pump Heads

Hastelloy C-276 Injection valve spring

Polytetrafl uoroethylene (PTFE) Diaphragm

Fluorocarbon (Viton® B) Sealings

Ethylene propylene (EPDM) Sealings

Nitrile (NBR) Sealings

Polyethylene (PE) Tubing

28

Page 29

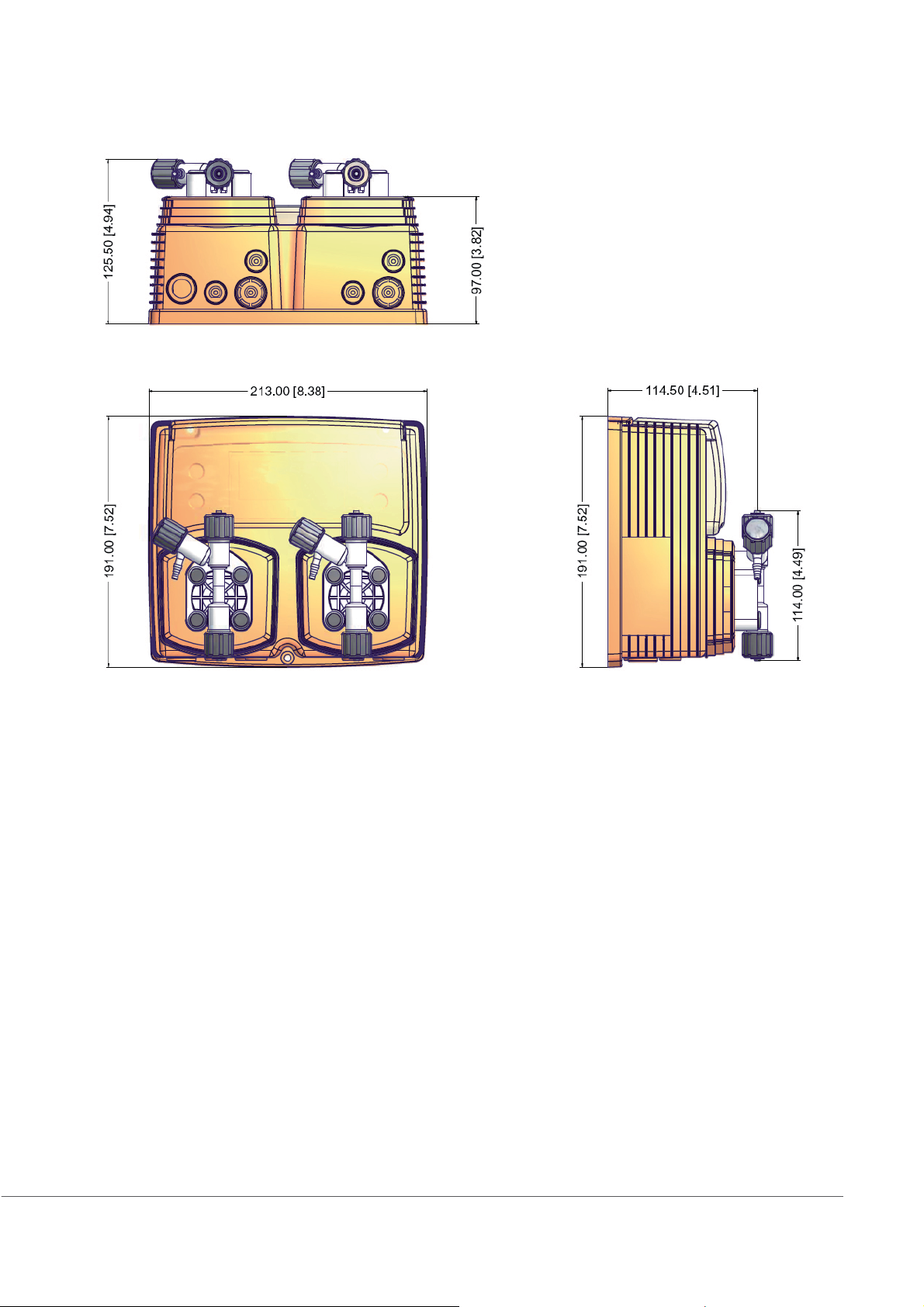

21. Dimensions.

mm [inches]

Information on this manual may contain technical inaccuracies or typographical errors.

The information contained may be changed at any time without prior notifi cation or obligation.

29

Page 30

22. Index

CE Conformity Declaration page 2

General Safety Guidelines page 2

Introduction page 3

The wheel page 3

Mainboard connections page 4

Hydraulic connections, hoses page 5

Hydraulic connections, level probes page 6

Hydraulic connections, pump heads page 7

Main screen page 8

Quick status check page 9

Password page 10

“Main menu” list page 11

“Set point” pH (ON/OFF) page 12

“Set point” pH (Proportional) page 14

“Set point”, Cl (ON/OFF) page 15

“Set point”, Cl (Proportional) page 16

“Probe Calibration”, pH page 17

“Power Supply Calibration” page 17

“Probe Calibration”, Cl page 19

“Parameters” page 20

“Pump Activities” page 21

“Instrument Reset” page 22

“Max Strokes settings” page 22

“Dosnig Alarm” page 23

“International” page 24

“Probe Failure” page 25

“pH Compensation” page 26

“Disinfectant” page 26

30

“Flow” page 27

“Service” page 27

Technical Information page 28

Dimensions page 29

Index page 30

Page 31

31

Page 32

32

When dismantling this instrument please separate material types and send them according to local recycling disposal requirements.

We appreciate your efforts in supporting your local Recycle Environmental Program.

Working together we’ll form an active union to assure the world’s invaluable resources are conserved.

Loading...

Loading...