Page 1

Chlorine Dioxide Generator

LOTUS MINI

Operation Manual

Read this manual completely before you start LOTUS.

Do not trash this manual and store it nearby the generator for later use.

This manual contains important information about the installation and operation safety.

Take care about the following instructions to avoid personal injuries and material damages!

The operator is responsible in case of damages caused by installation and operation failures!

English

R5-02-16

DOWNLOAD ERMES COMMUNICATION SOFTWARE

www.ermes-server.com

Page 2

2

NORME CE

EC RULES(STANDARD EC)

NORMAS DE LA CE

Direttiva Bassa Tensione

Low Voltage Directive

Directiva de baja tensión

Direttiva EMC Compatibilità Elettromagnetica

EMC electromagnetic compatibility directive

EMC directiva de compatibilidad electromagnética

2014/35/UE

2014/30/UE

⎬

⎬

Danger!

GENERAL SAFETY GUIDELINES

In emergencies the instrument should be switched off immediately! Disconnect the power cable

from the power supply!

When installing always observe local regulations!

Manufacturer is not liable for any unauthorized use or misuse of this product that may cause injury,

damage to persons and / or materials.

Caution!

Instrument must be accessible at all times for both operating and servicing. Access must not be

obstructed in any way!

Feeder should be interlocked with a no-flow protection device to automatically shut-off the pumps

when there is no flow!

Pumps and accessories must be serviced and repaired by qualified and authorized personnel only!

Always discharge the liquid end before servicing the instrument!

Empty and rinse the liquid end before work on a pump which has been used with hazardous or

unknown chemicals!

Always read chemical safety datasheet!

Always wear protective clothing when handling hazardous or unknown chemicals!

Instrument must be operated / serviced by trained technicians only!

All connection operations must be performed while the instrument is not connected to main

supply!

Page 3

3

Directory

1.

General Safety Guidelines

4

1.1

Symbols

4

1.2

Safety instructions

4

1.3

CE-Conformity

5

2.

General Description

6

3.

Construction

7

3.1

Construction overview

7

3.2

Description and details

7

4.

„LOTUS“ - Controller

8

4.1

Start display

8

4.2

Main display

8

4.3

Control element „Click-Wheel“

8

4.4

Status displays

9

4.5

Logbook

10

4.6

Help

10

5.

Adjustment of production capacity

11

5.1

Proportional mode

12

5.2

Constant mode

13

5.3

Analog mode

13

5.4

Batch mode

14

6.

Replacement of chemical cans and pump priming

15

7.

LOTUS Terminal board

16

8.

Technical Data

17 9.18

Failure Messages

Communication

21

NOTE:

WHEN CHANGING WORKING MODE, SETPOINT PARAMETERS SHOULD BE ENTERED

AGAIN.

Page 4

4

1. General Safety Guidelines

1.1 General remarks

This manual includes basic directions for the assembling, operation and maintenance. Therefore it is obligatory

for the assembly technician as well as for the operator to study the complete manual before starting with the

installation and start-up. This manual must be present at the generator at any time.

It is also obligatory for the operator to consider the general directions in chapter “Safety instructions” as well as

the specific safety instructions included in the other chapters of this manual.

Notice:

• For some of the following described functions additional accessories (not included in the delivery

scope of LOTUS) may be required.

• Depending to the software release of the LOTUS-controller some of the described features may

not be available. Or some functions are available, but not described in this manual. Please contact

your dealer in case of the requirement for more information.

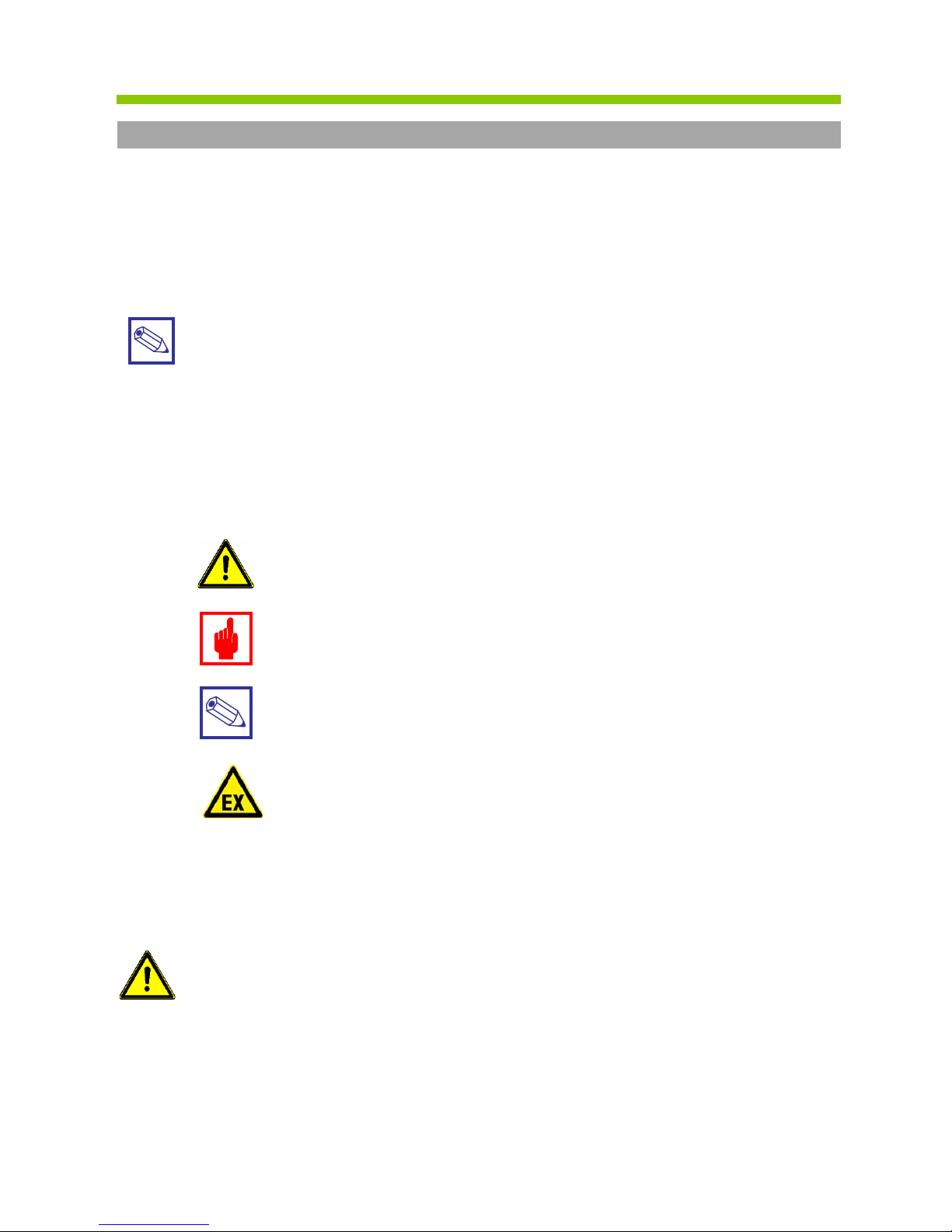

1.2 Symbols

In accordance to the guideline DIN 4844-W9 about the characterization of special risks all safety instructions in

this manual are labeled with the following symbols:

Warning:

This symbol is waring about risks.

Disregarding may cause heavy personal injuries and material damages.

Caution!

This symbol is warning about troubles caused by incorrect operation.

Notice or advice:

This symbol shows important additional information.

1.3 Safety instructions

The appropriate use of the LOTUS generator is described in this manual.

Warning:

• The un-appropriate use affects the safety function of this generator and other connected devices

and is therefore strictly forbidden.

• Assembling and maintenance has to be done by authorized technicians only.

• Maintenance repairs have to be executed only by the manufacturer or authorized technicians. Inter-

ventions or changes at the device in opposite to the regular maintenance in accordance to this

manual are incorrect and make the all warranty claims nugatory.

• The operator is liable for the observance of the local safety instructions.

• For the operation and service the device must be accessible at all times.

• Before starting service at the dosing pumps make the pump-heads pressure-less.

Warning: risk of explosion

Page 5

• Drain and flush the pump-heads with clean water before starting the service.

• Take attention to the chemical safety data sheets!

• Wear protection clothes for the handling with unknown and hazardous chemicals.

HCl 9% NaClO2 7,5%

PEF1/E

Probe

holder

ECL1

Chlorine probe

MF

Multivalve

Pulse sender water meter

WARNING: INSTALL NFIL/60 BEFORE WATER INPUT TO AVOID OCCLUSIONS

Page 6

6

Directions for the operator

(Specific information for applicable regulations in Germany):

• Accident prevention regulation (UVV) „Chlorination of water“, GUV V-D5 E.

• „Dosing plants for chlorine dioxide“, DVGW guideline W 624 (latest version respectively).

• „Chlorine dioxide in water treatment“, DVGW worksheet W 224 (latest version respectively).

• Guidelines for the protection of groundwater against polution.

(§ 19 Federal Water Act – WHG dated 23.9.1986).

• Ordinance of hazardous substances (GefStoffV) – especially § 17 (obligatory protection)

and § 20 (operation instruction).

1.4 CE - Conformity

The LOTUS gener

ator is corresponding to the following EU-standards:

The following standards are considered:

• Machinery directive 89/392/EWG IIA inclusive all actual changes within the year of

Manufacturing 91/368/EWG – Mod. 1

, and 93/44/EWG – Mod. 2.

• Guideline 2004/108 EG about the electromagnetic tolerance of electric equipment.

• Low-voltage directive 2006/95/EG.

• EC – Pressure Equipment Directive (97/23/EG)

The following harmonized safety guidelines are considered:

• UNI EN 292/1 – Safety of machines

• UNI EN 292/2 – Safety of machines; technical principles.

• CEI EN 60204-1-98 – General requirements for electric equipment in machines.

Notice:

A declaration of conformity can be ordered from the manufacturer.

Page 7

7

2. General Description

The chlorine dioxide generator is used for the production of liquid chlorine dioxide. This disinfection agent kills

all bacteria, germs, viruses and fungi within shortest time – and it works with very low concentration.

The generator is working with the hydrochloric acid – chlorite process and uses diluted chemicals like hydrochloric acid (HCl 9%) and sodium chlorite (NaClO

2

7.5%) in accordance to the following chemical equation:

Hydrochloric acid + Sodium Chlorite = Chlorine dioxide + Sodium chloride + Water

4 HCl + 5 NaClO

2

= 4 ClO2 + 5 NaCl + 2 H2O

In the process each chemical is pumped with a specific proportion into a chamber vessel [ 5 ] by two dosing

pumps [ 2 and 4 ]. Each stroke from each pump is triggered by the LOTUS-controller [ 1 ] and countercontrolled by a “SEFL” [ 6 ].

Inside the chamber vessel the chemicals are reacting to chlorine dioxide with a concentration of 2% (= 20 g/l).

In the next step a specific proportion of water is pumped into the chamber by a third dosing pump [ 3 ] to dilute

the chlorine dioxide down to a concentration of approx. 2 g/l.

The finished chlorine dioxide leaves the chamber vessel through a back pressure valve [ 7 ] on the top of the

chamber.

The advantages are:

• The chlorine dioxide can be pumped direct into pressurized systems with the pressure of the pumps and

likewise into pressure-less storing tanks, to distribute the disinfection to different points of use.

• The System can work in proportional mode with contact water meter, current signal or chlorine dioxide

measurement.

2

3

4

1

5

6

7

Page 8

8

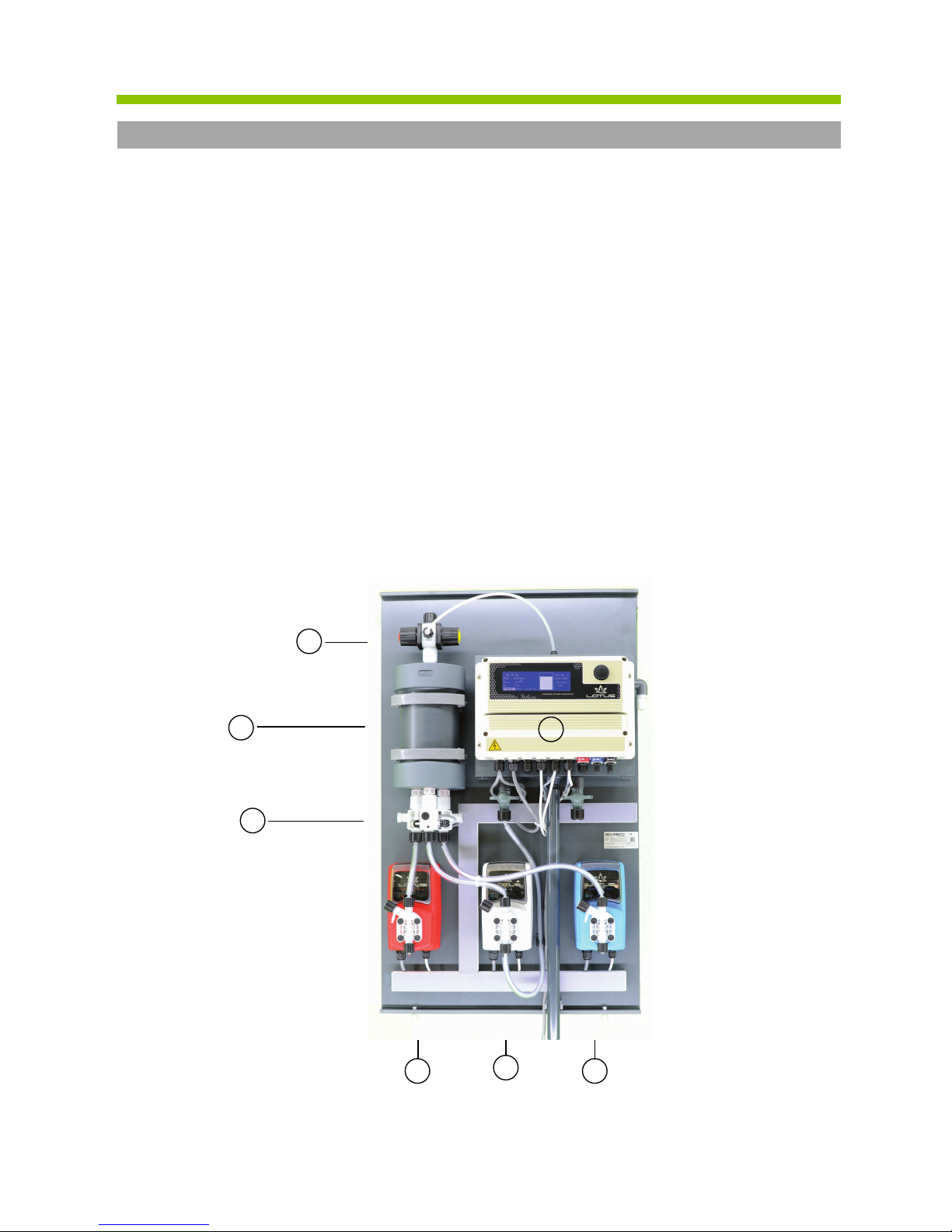

3. Construction

3.1 Construction overview

3.2 Description and details

1 LOTUS-controller 10 Drain nozzle ½“

2 Dosing pump for hydrochloric acid (HCl 9%) 11 Level switch „Dilution water tank empty“

3 Dosing pump for dilution water 12 Can with hydrochloric acid 9 % (ca. 95 g/l)

4 Dosing pump for sodium chlorite (NaClO

2 7,5%) 13 Suction lance with level-switch „Hydrochloric acid“

5 Chamber 14 Can with sodium chlorite 7,5 % (ca. 80 g/l)

6 Dosing control “SEFL” 15 Suction lance with level-switch „Sodium chlorite“

each for hydrochloric acid, sodium chlorite

and dilution water

7 PVDF check-valve with hose-connection 4x6 mm

8 Storage tank for dilution water

(located behind the dosing pumps)

9 Floating valve

A Hose-connection 4x6 mm for dilution water

B Hose-connection 4x6 mm for chlorine dioxide (for PVDF hose)

C Dilution water storage tank overflow

4

HCl 9%

NaClO2 7,5%

8

10

9

11

C

12

13

14

15

A

A

3

2

5

7

B

6

8

4

Page 9

9

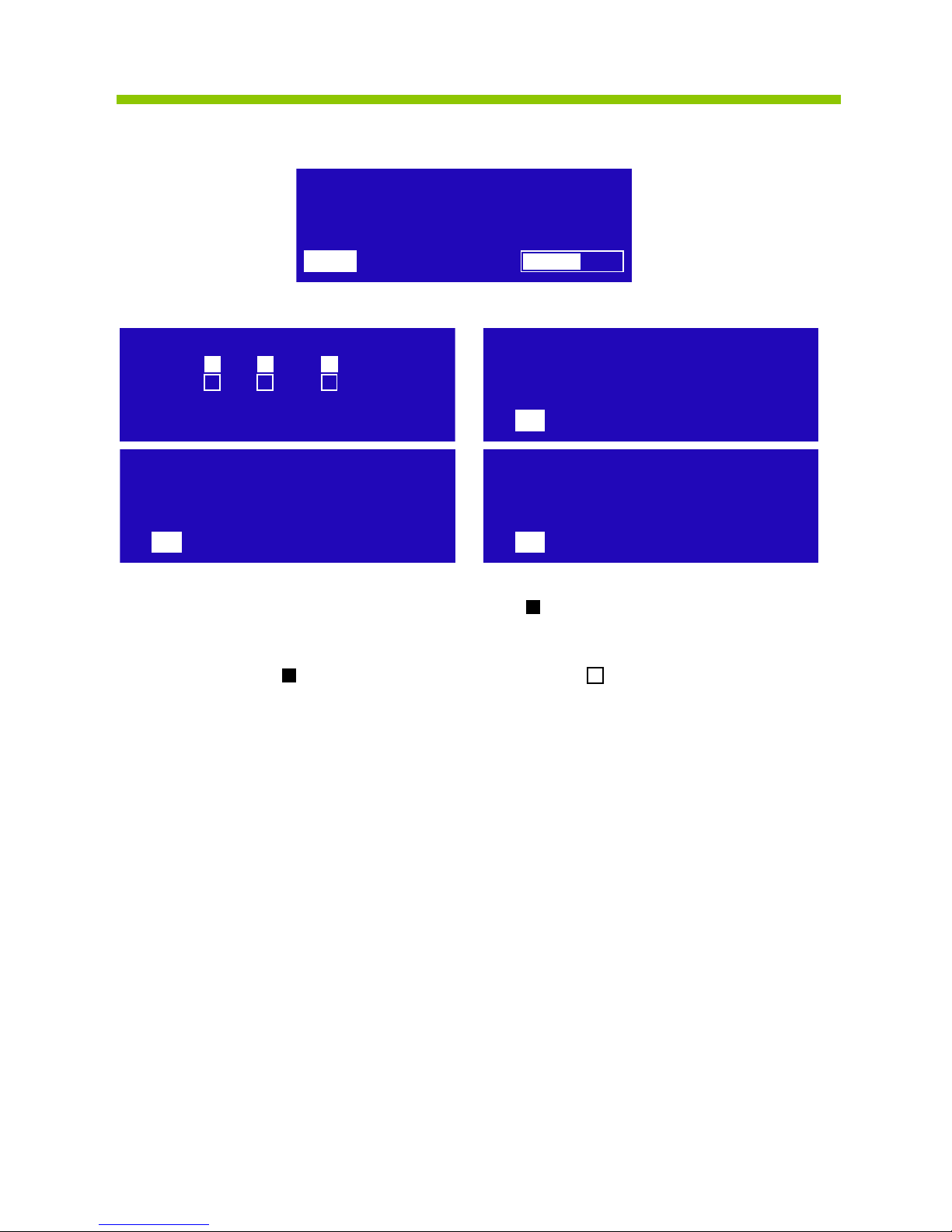

4. „LOTUS“ Controller

4.1 Start display

When the power supply is switched on the start display appears and shows the actual software release for

some seconds.

After approx. 3 seconds the program goes onto the main display.

4.2 Main display

The mai

n display is separated into 5 lines::

1: Date and time

2: Measuring value for temperature (in case this option is implemented)

3: Type of plant

4: Information line for operation, status or failure messages (blinking)

5: “Click-Wheel” operation and duty line.

A constant running bar shows that LOTUS is active.

4.3 Control element „Click-Wheel“

On the right side of the display a turning- and push-button is located. It is called „Click-Wheel“.

You can turn the click-wheel into both directions to scroll through the menus or select a function. The selected

function is shown in an inverse color.

The actual position is shown .

Push the click-wheel for selection.

Inverse

LOTUS

Rel: x.x.x

1

2

3 4 5

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Stand-by

Status Menu Logbook Help

Status

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Stand-by

Status Menu Logbook Help

Status

Turn for scroll

Push for selection

Page 10

10

4.4 Status Displays

Push th

e click-wheel on “Status” to open 4 different operation displays:

Check: The signal lights are showing the function of the dosing controls.

At stagnant production the signal light shows .

During production the signal lights from the dosing controls “Check” are blinking inverse

corresponding to the signals from the „Pump“.

That means: in the moment when a pump is doing a stroke

(light = ), the light of the dosing control has to show .

Pump: See also „Check“.

Mode: Shows the activated operation mode.

Production: Shows the actual chlorine dioxide production capacity.

Water Meter: Shows the actual flow capacity of the contact water meter.

Next Service: Shows the remaining time until the next service is required.

Operating hours: Shows the operating hours counter.

In the operation displays you have different options:

ON/OFF Start/Stop LOTUS

STAND-BY Switches LOTUS into the “Stand-by” mode,

independent to the function of the “Stand-by” – Input

PRIMING Opens the display for dosing pumps priming resp. for manual mode

ESC Go back to the main display

< or > Scroll in the operation displays

Status LOTUS

Production [g/h] : 4.25 Mode:

Water Meter [m³/h]: 42.5 Proportional

< ESC >

On

Totalizer

Acid [ltr.] : 9123.5 Mode:

Chlorite [ltr.]: 9124.9 Proportional

Water Meter [m³]: 99999.9

< ESC

On

Status LOTUS

Next Service in [h]: 4375 Mode:

Operating hours [h]: 9999999 Proportional

< ESC >

On

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Stand-by

Status Menu Logbook Help

Status

Status LOTUS

Check : Mode:

Pump : Proportional

Acid Water Chlorite

ON Stand-by Priming ESC >

Page 11

11

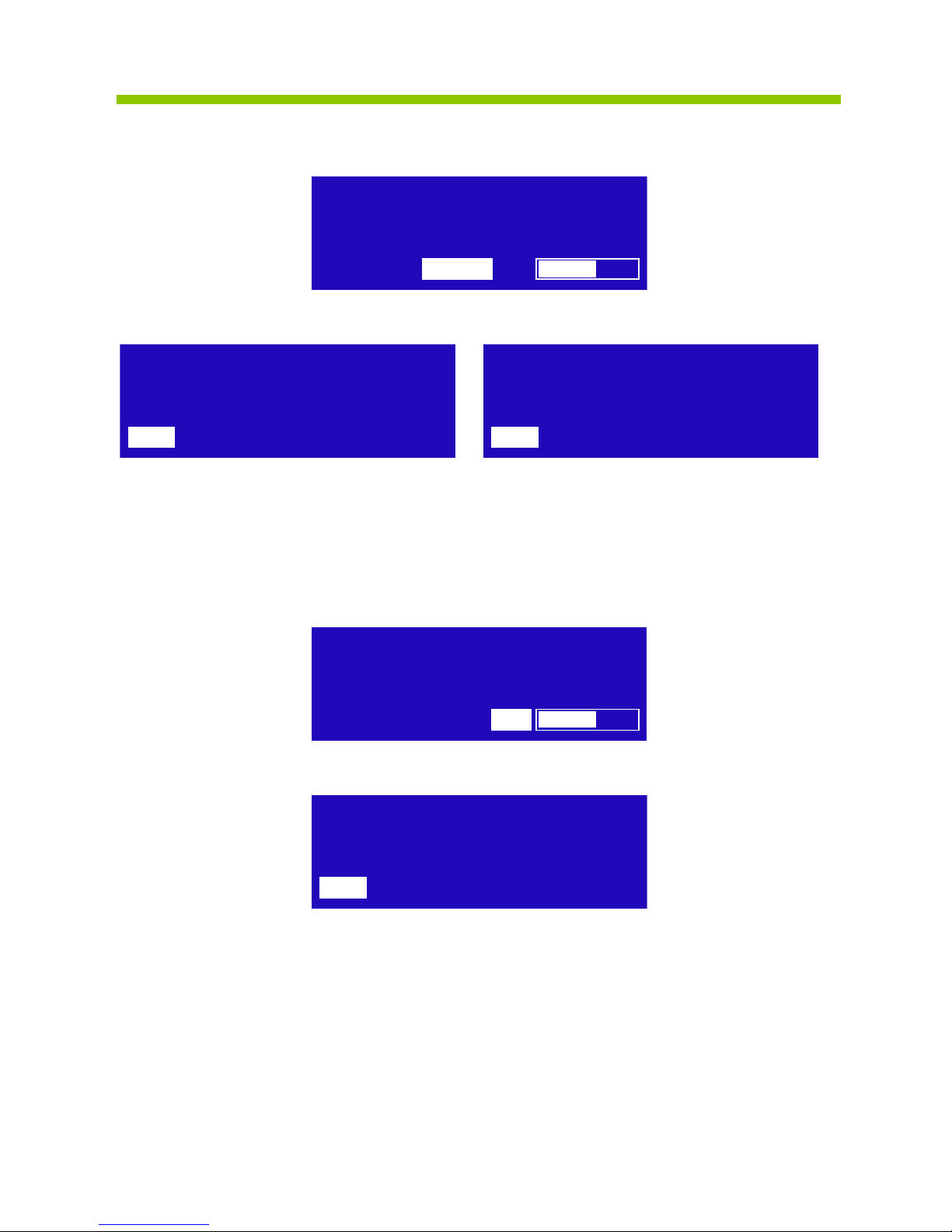

4.5 Logbook

Turn th

e click-wheel onto the field “Logbook” and push it to open the sub-menu.

The LOTUS-controller has an internal logbook-memory. Two different types of data are stored together with a

time-stamp: Operation data in periodic intervals and failure messages as soon as they appear.

Turn the click-wheel to scroll forward and backwards through the logbook.

Push the click-wheel on “ESC” for return to the main display.

4.6 Help

Turn the c

lick-wheel onto the field “Help” and push it to open the “Help” display.

The “Help” display shows the contact data of your dealer.

Push the click-wheel on “ESC” for the return to the main display.

Logbook

˄

07-12-10 23:59:59 Mode: Proportional

Acid:109.0 l Chlorite: 109.7 l Water: 298.6 m³

˅

ESC

Logbook

˄

07-12-10 12:35:55 Failure level acid

07-12-10 13:10:20 Restart

˅

ESC

LOTUS

LIQUID Water Treatment

Phone: 01234-567890

ESC

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Stand-by

Status Menu Logbook Help

Logbook

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Stand-by

Status Menu Logbook Help

Help

Page 12

12

5. Adjustment of production capacity

Depending

to the operation mode the production capacity of LOTUS can be changed.

Push the click-wheel “Menu” to open the display for the adjustment of the production capacity.

The access is protected by an operator passcode:

Select a four-digit number-code. As soon as the fourth correct digit is selected the next display opens automatically.

Notice:

The factory default for the operator passcode is “0 0 0 0”.

In case you like to change your passcode please ask your dealer and his technician will do the

implementation for you.

Depending to the selected operation mode, different displays are available:

Passcode

0 1 2 3 4 5 6 7 8 9 ESC

Enter Passcode

* * * *

0

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Stand-by

Status Menu Logbook Help

Menu

Page 13

13

5.1 Proportional mode

In the proportional mode LOTUS produces an adjustable capacity of chlorine dioxide proportional to a water

flow recorded by a water meter.

Prod. Capacity: Here you can adjust the requested chlorine dioxide concentration.

Warning:

• The controller takes the inserted value in “Prod. Capacity” for the calculation of the required stroke

frequency of the dosing pumps for the production of chlorine dioxide proportional to the flow.

This

means that it is a theoretically value and not the real concentration in the water!

• The operator is responsible by its own for the proper adjustment of this control-value!

• The operator has to countercheck the chlorine dioxide concentration in the connected water system

with a suitable photometer to verify the real concentration and to readjust the “Prod. Capacity” until

the required concentration is stable achieved.

General Notices:

Theoretically it is possible to adjust the production capacity up to 9.99 mg/l.

But for very low water flows, resp. water consumption it can be dangerous to do this and

should be absolutely avoided!

In case the water flow exceeds the maximum production capacity a proportional production is not

longer possible. In the following table you can find the maximum water flow corresponding to the

maximum production capacity:

LOTUS

8

20

Production capacity

[mg/l]

Water flow

[m³/h]

0,10

80

200

0,20

40

100

0,30

26.6

66.6

0,40

20

50

0,50

16

40

0,60

13.3

33.3

0,70

11.4

28.5

0,80

10

25

0,90

8.8

22.2

1,00

8

20

The ove

rriding of the maximum possible production capacity caused by the water flow is shown on the display

with a special blinking message “Overflow”:

As soon as the water flow drops down under the maximum acceptable value, the message disappears.

Proportional Mode

Prod. Capacity: 0.15 mg/l Mode:

Proportional

ESC

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Overflow

Status Menu Logbook Help

Page 14

14

5.2 Constant mode

In this mode LOTUS is producing chlorine dioxide with a constant and adjustable capacity as long as input

“Stand-by” is not activated. Two different capacities can be adjusted depending to the digital inputs “Batch tank

empty” [terminal 34 and 35] and “Stand-by” [terminal 44 and 45].

Capacity 1: Here you can adjust the production capacity for the digital input “Batch tank empty”.

Capacity 2: Here you can adjust the production capacity for the digital input “Stand-by”.

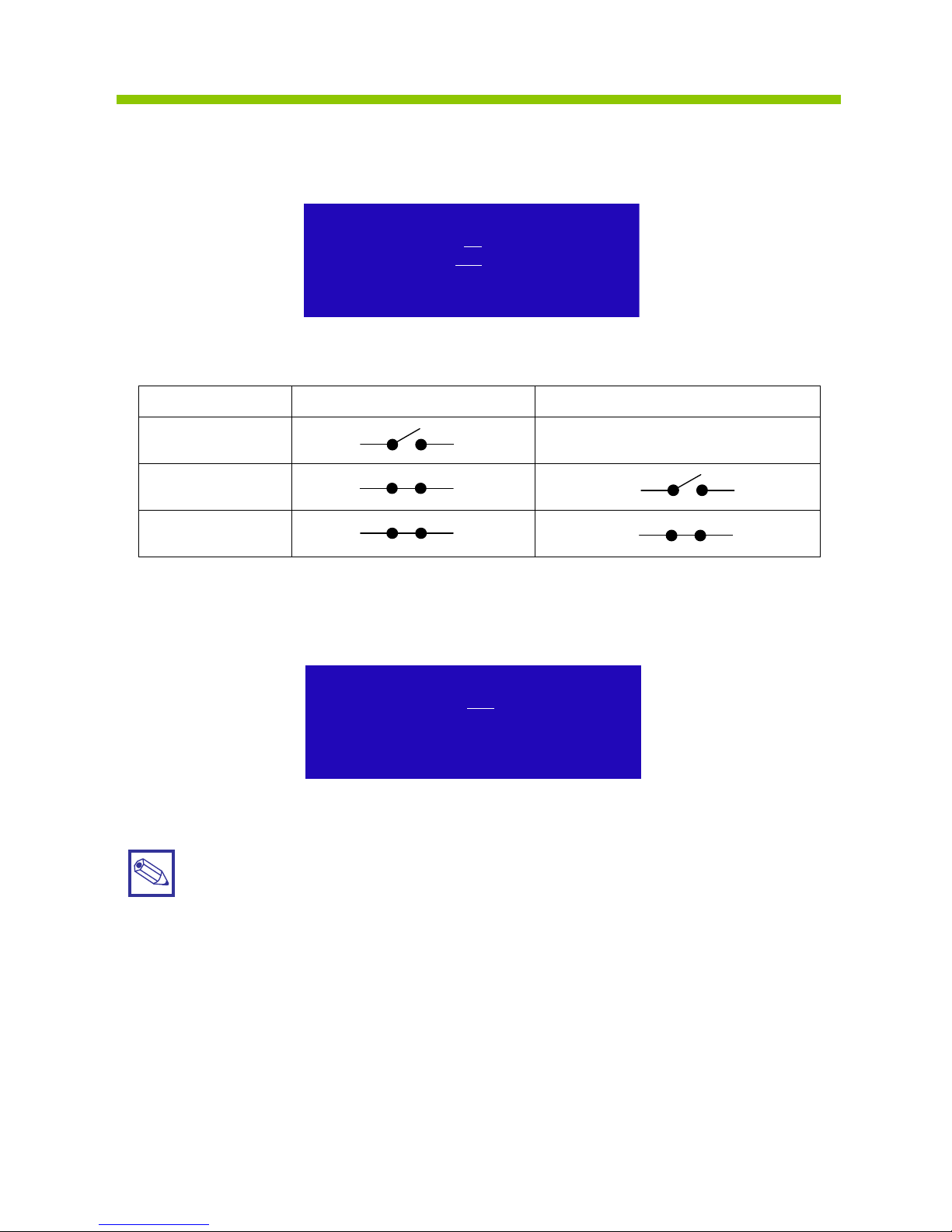

Situation

STAND-BY (44, 45)

BATCH TANK EMPTY (34, 35)

LOTUS “STAND-BY”

Capacity 1

Capacity 2

5.3 Analog mode

In this mode the chlorine dioxide production capacity is controlled by an external analog signal (0/4 – 20 mA).

Capacity at 20 mA: Here you adjust the maximum production capacity for a 20 mA input signal.

Notice:

Independent to the selected operation mode LOTUS stops as soon as the digital input “Standby” appears!

Constant Mode

Capacity 1: 50 %

Capacity 2: 100 %

ESC

Analog Mode

Capacity at 20 mA: 100 %

ESC

Page 15

15

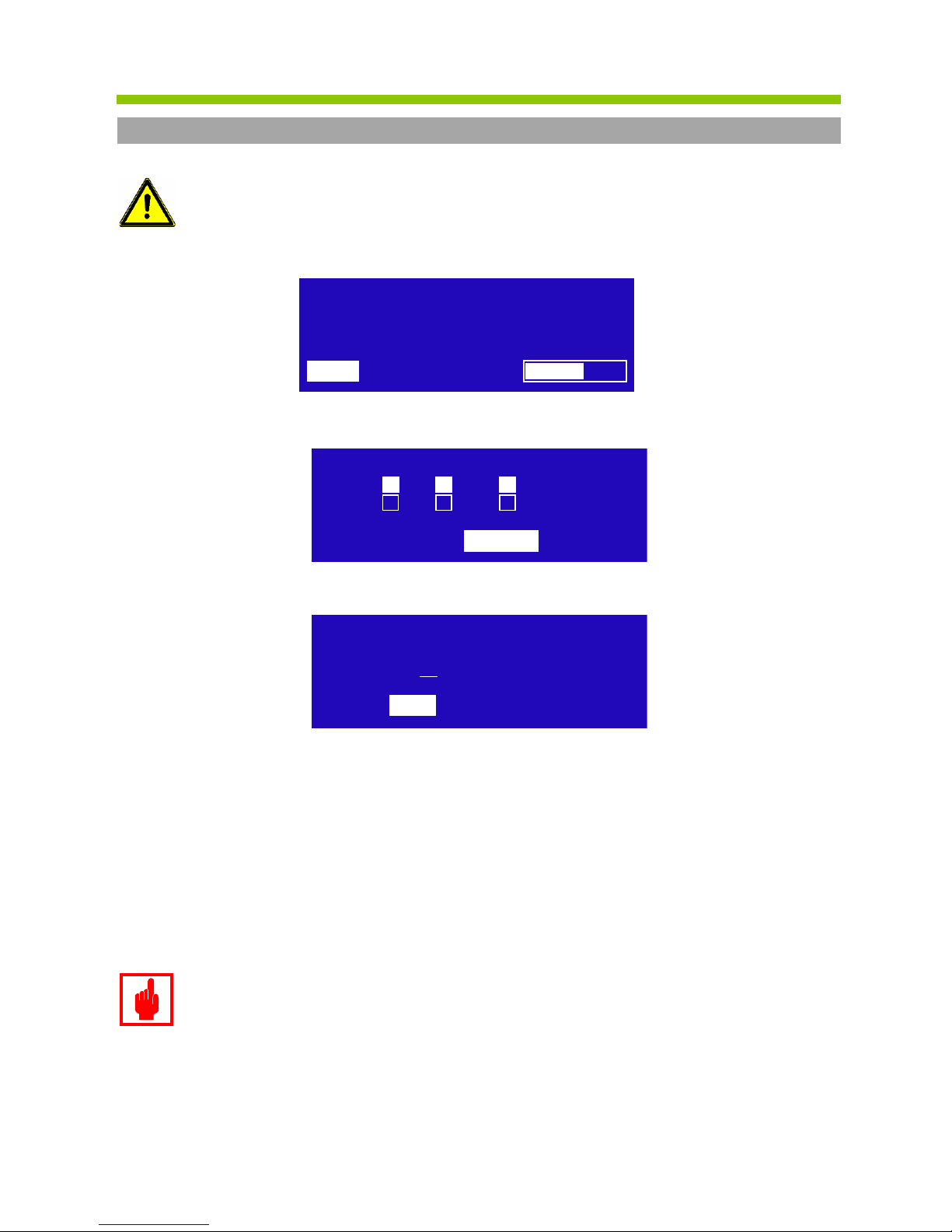

5.4 Batch mode

In this mode LOTUS fills up a level-controlled batch tank with chlorine dioxide in an adjustable concentration.

The two digital inputs “Batch tank empty” [terminal 34 and 35] and “Stand-by” [terminal 44 and 45] are used for

the level-control.

Because LOTUS runs always wit 100% production capacity as soon as it starts, no extra display for the capacity adjustment is available.

Situation

Step

Terminal

34, 35

Level tank

empty

Terminal

44, 45

Level

tank full

Tank empty

1

Level is rising

2

Tank full

3

Level falls down

4

Tank empty

1

Step 1: St

ep 2:

Step 3: Step 4:

In case one of the level-switch failed or the cable is damaged a failure message appears:

Failure Level-switch:

Status

Level Tank full : Mode:

Level Tank empty : Batch

Filling Batch Tank

< ESC >

Status

Level Tank full : Mode:

Level Tank empty : Batch

Start Filling Batch Tank

< ESC >

Status

Level Tank full : Mode:

Level Tank empty : Batch

Batch Tank full

< ESC >

Status

Level Tank full : Mode:

Level Tank empty : Batch

Draining Batch Tank

< ESC >

Status

Level Tank full : Mode:

Level Tank empty : Batch

Failure Level-Switch

< ESC >

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Failure Level-Switch

Status Menu Logbook Help

Status

Page 16

16

6. Replacement of chemical cans and pump priming

Warning:

Wear protective clothes for the handling with hazardous chemicals!

• Replace the chemical can.

• Use the click-wheel, go to „Status“ and then to „Priming“. Push the click-wheel and open the sub-display for

the manual mode.

• Insert a time of approx. 1 or 2 minutes in field „Input“ and start the count-down with “Start”. All three pumps

start running with max. pulse frequency.

• Open the priming valves at the dosing pump you want to prime.

The pumps keep on running until the count-down stops

or the process is interrupted with the “Stop” button.

• Shut the priming valves as soon as the chemicals flow out of the pump-head without gas-bubbles through

the priming hose back into the cans.

• Let the pumps keep on running for some more seconds to be sure that rely all gas-bubbles leaved the suc-

tion hose and the pump-head in direction to the chamber.

• Push the click-wheel on “ESC” and leave the priming mode.

• At least check the signal-lights “Check” and “Pump” in the “Status” display for correct working when LOTUS

is running. In case the lights are not corresponding LOTUS will stop after a while and you have to repeat the

priming procedure.

Caution!

Do not run the plant in priming mode for a longer period without visual control because of

the risk for overriding the maximum operation pressure!

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Status Menu Logbook Help

Status

Status LOTUS

Check : Mode:

Pump : Proportional

Acid Water Chlorite

ON Stand-by Priming ESC >

Priming

LOTUS

Count-down: 00 minutes Mode:

Input: 05 minutes Manual

Start Stop ESC

Start

Page 17

17

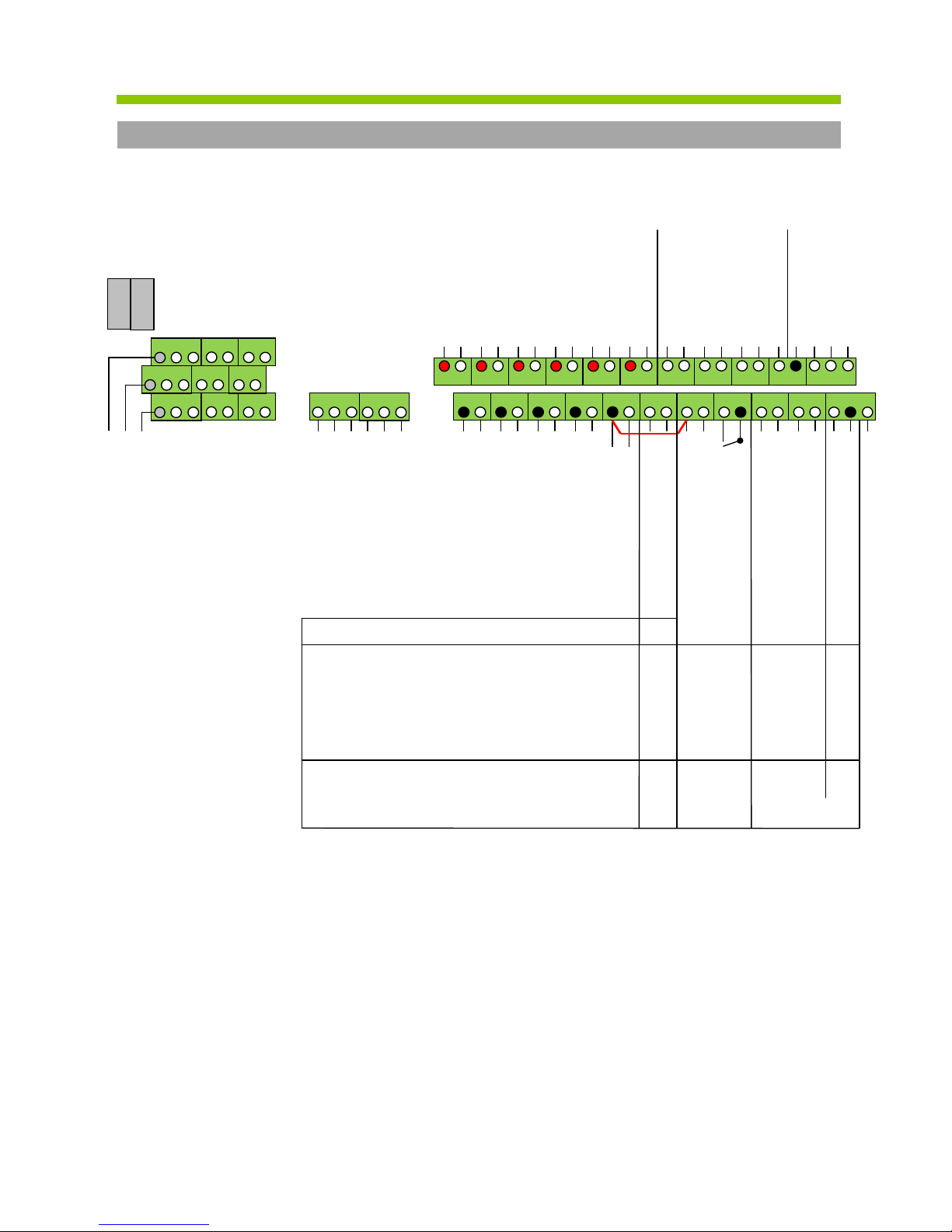

7. LOTUS Terminal board

* Input for Contact Water Meter:

- Reed-/Magnetic Contact (max. 3 pulse per second) - Optic Coupler

- Hall-Sensor (up to 1200 pulse per second)

COURRENT OUTPUT VERSION (mA):

Output 0-20 or 4-20 based on gr/h production)<<<<<<

13 (-) ; 15 (+)

SEFL „Acid“

SEFL „Chlorite“

SEFL „Water“

Level „Acid“

Level „Chlorite“

10 11 12

07 08 09

N N

N N N

N N

PE

PE

PE

05 06

L 01 02

03 04

1-E-N Bypass-Pump „Water“

2-E-N

3-E-N

4-E-N

5-E-N Alarm Output

5-E-N

Power Supply

90 – 265 VAC

Relay Outputs

current-free

Relay Outputs

NC C NO

NC C NO

+12 VDC

Signal

GND

Green

Brown

White

Yellow

Optic coupled Outputs mA Outputs RS485

for pump type …-IS (Option)

F2

F1

44 45 46

42 43

40 41

36 37

30 31

– +

28 29

– +

26 27

– +

24 25

– +

32 33

– +

15 16

A2 A3

19 20

A6

17 18

A4 A5

21 22 23

+ –

13 14

– A1

11 12

07 08

– +

09 10

– +

05 06

– +

03 04

– +

01 02

– +

34 35

+ – +

System in „Operation“ (N.C.)

or „Stand-by“ (N.O.)

Alarm Output

38 39

*Contact Water Meter

Temperature Probe

„ETEPT“

„STAND-BY“

Batch-Tank „Empty“

Batch-Tank „Full“

Capacity 2

Capacity 1

Proportional – Mode

Batch – Mode

Constant – Mode

Slot 3

Page 18

LOTUS Terminal board

SEPR module for proximity

switch

Slot 1

Contact (Black)

n/a

+12VDC (Brown)

GND (Blue)

MDSEPR

01 02 03 04

To set the proximity switch enter into configuration menu and select

Probe Flow Alarm

Flow contact can be enabled to stop a dosing procedure using a N.O.

contact mode (normally open) or N.C. contact mode (normally clo-

sed) when status on blocks changes. Rotate wheel to choose

between: “DISABLE”, “REVERSE” (N.O. contact) or “DIRECT”

(N.C. contact). Furthermore “Flow contact” can starts after a speci-

fied time when contact status changes. To set it move wheel on

“Time:00 min”, click it and rotate to choose time (from 0 to 99 minutes). Confirm selection by clicking wheel

.

This function is available only with Cl module installed.

MDMA module

0/20 mA water meter

input Slot 4

+

-

MDMA

01 02

Slot 3

Page 19

18

8. Technical Data

LOTUS MINI 8 LOTUS MINI 20

ClO2 production capacity

g/h

8

20

Maximum operation pressure

bar

10

10

Chemical consumption at max. production

l/h

each 0.2

each 0.5

Concentration of ClO2 stock solution

g/l

approx. 2 - 20

Power supply

90 – 265 V, 50/60 Hz

Energy consumption

w/h

50

Protection class

IP 65

Dimension:

Width

mm

450

Height

mm

1080

Depth

mm

360

Transportation weight

kg

approx. 30

Page 20

19

9. Failure messages

In case of a malfunction a message appears on the display and LOTUS stops.

Remove the malfunction and restart LOTUS.

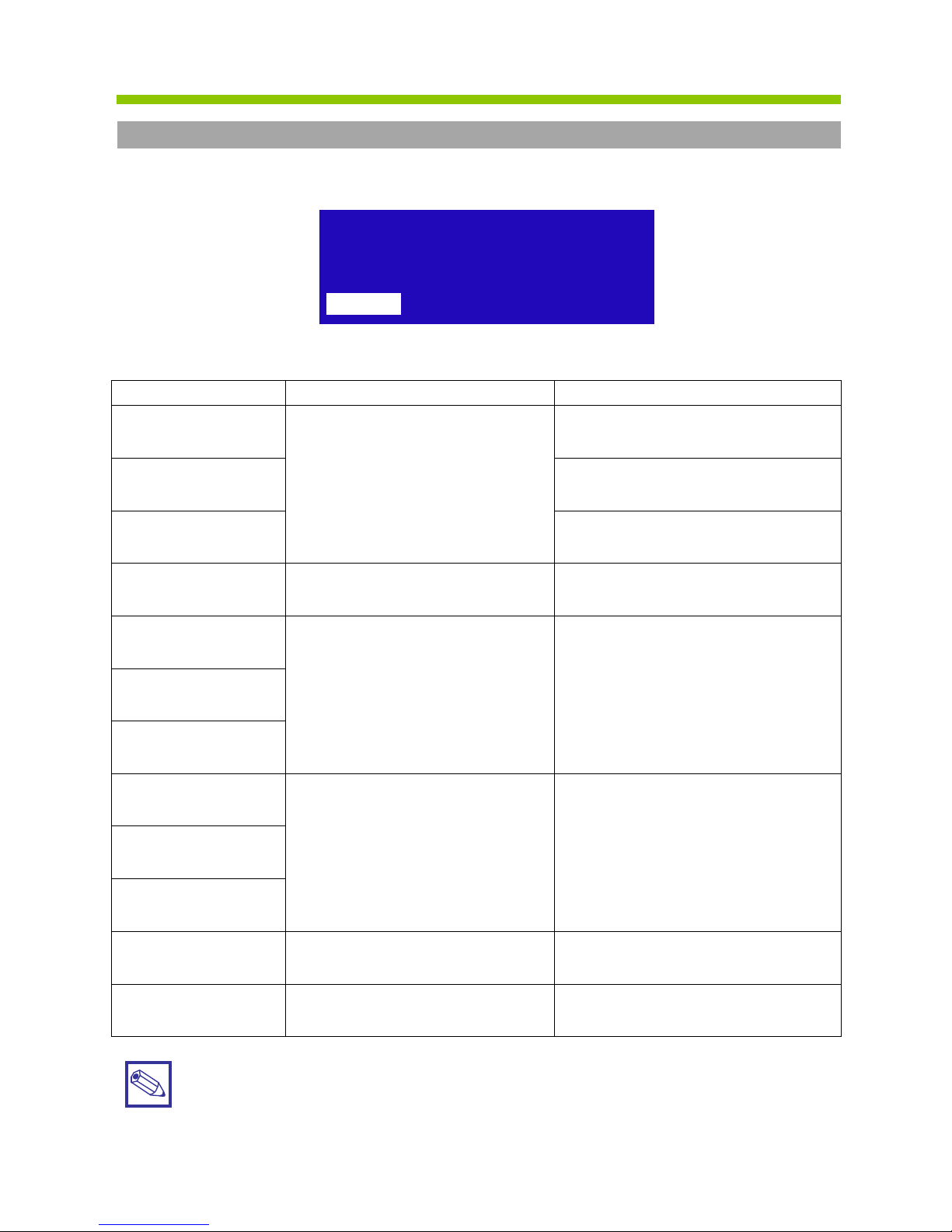

Message

Problem

Solution

Level Acid

One of the chemical cans or the dilution water storage tank is empty.

Change the chemical can and prime the

pump.

Level Water

Check the supply line for the dilution

water storage tank. Prime the pump.

Level Chlorite

Change the chemical can and prime the

pump.

Contact Batch Tank

Empty Level

The cable of the level-switch is

disconnected or has a damage

Check the proper function of the levelswitch. Call the service in case the levelswitch is damaged.

Flow control Acid

A dosing control is recognizing lack of

or no dosing.

Prime the corresponding pump.

Readjust the flow-sensitivity at the dosing

control.

Call the service in case priming is not

successful.

Flow control Water

Flow control Chlorite

Contact SEFL Acid

A cable of the dosing control is

damaged or disconnected.

Call the service.

Contact SEFL Water

Contact SEFL Chlorite

Analog Input

The analog input signal

is lower 3.5 mA.

Check the signal supply device.

Check the signal cable for damages.

Call the service.

Service required

Call an authorized service technician for

periodic maintenance.

Notice:

The two alarm output relays (terminal 5-E-N) and (terminal 10 (NC) – 11 (C) – 12 (NO)) are

switching on in case of a malfunction. The relays are falling off as soon as the removal of the malfunction is confirmed with the “Restart” button.

Failure:

07-12-10 14:35:42

Level Acid

Restart

Page 21

COMMUNICATION

Page 22

COMMUNICATION MENU (TCP/IP - GPRS with MODEM OR ETHERNET MODULE

This instrument can be controlled and programed remotely using the system called ERMES and a standard web browser

(i.e.: Google Chrome or Safari). In order to use this service an internet connection is required (lan or wan) and user must

configure the instrument to obtain a valid IP address (through a valid DHCP service or manually). If this instrument is

installed within an office network please contact your system-administrator to obtain required parameters and eventually

unlock TCP/IP port 2020.

Things to do before setup.

1. Ensure that on instrument MAC ADDRESS (see SERVICE menu) the TCP/IP port 2020 is

unlocked. Check it with your system-administrator.

2. Connect to your ERMES account or create a new one at: www.ermes-server.com

3. Within ERMES account add the new instrument using the 6 digits code located into SERVICE

menu. (choose LAN DEVICE or MODEM code based on connection type choosen prior to buy the

instrument)

Parameters to be configu ed in the communication menu (TCP/IP)

In order to communicate via LAN cable to ERMES server the following parameters must be set:

If configuration requires the presence of a ROUTER with automatic IP address assignment

from TCP/IP menu select IP MODE and set it to DYNAMIC.

If local LAN needs to provide static IP address then from TCP/IP menu select STATIC IP MODE

and enter the following parameters:

IP address: enter the unit unique available IP address using syntax xxx.xxx.xxx.xxx

SUBNET (netmask): range of belonging to the host within a subnet IP. For example: 255.255.255.0

GATEWAY: The IP address of the device that routes packets. For example: 192.168.1.1

DNS: IP address of the device that resolves the names of network nodes.

It is usually the same as the GATEWAY. It can bel also a public DNS address (e.g.: 8.8.8.8)

Parameters to be configu ed in the communication menu (GPRS)

In order to communicate via GPRS modem to ERMES server insert SIM into modem’s slot the slot.

A data plan subscription is suggestes to reduce SIM costs. From GPRS menu set the following parameters:

Ermes SERVER: select YES to activate the traffic data with Ermes server or select NO

to use the GPRS modem only for SMA and/or EMAIL alerts messages.

APN: ask SIM mobile company what is the name of the access point designated

APN Username & Password: ask SIM mobile company both these parameters

PIN: Enter the assigned 4 digits code to automatically unlock the SIM

Network

administrstor

required

Basic Network

skills required

Page 23

COMMUNICATION (MESSAGES Setup - RS485)

This instrument can send emails and / or sms when a system failure or warning happens. If instrument is configured to

operate through the LAN only email messages can be send. Otherwise if instruments has a mobile modem both SMS and

emails messages can be send.

MESSAGES Setup

Within this menu is possible to setup up to three SMS (SMS1, SMS2, SMS3) recipients and two email (email 1, email 2)

addresses. Editing MSG ALARM and MSG WARNING ALARM is possible to setup which type of error must be notified

(see below table).

MSG warning MSG alarm

MAXIMUM TIME REACHED PROBE FLOW ALARM

HCl LEVEL CHLORINE DIOXIDE IN STORAGE NO LONGER USABLE

NaClO2 LEVEL SYSTEM NOT READY

ST.Tank Full

SYSTEM NOT READY

RS485 Setup

This instrument can be connected in a network of instruments via RS485 (max 32) to take advantage of a single modem

or LAN connection for remote programming (through ERMES server) or local (ask your provider).

Make the cable connections as described in RS485 terminal blocks and then in the RS485 menu, set the RS485

unique

ID NAME for each instrument.

CHECK if entered in ID NAME has been properly accepted by clicking on ID CHECK, if an error message is reported by

the instrument modify it.

Page 24

33

COMMUNICATION (LOG MENU & LOGBOOK MENU)

This function, when enabled, allows to record and send to ERMES server all instrument activities (date, time, temperature,

levels, alarms, totalizers, outputs status) for a set period (EVERY) and starting from a certain time (TIME) .

Note: SET TIME AND DATE PRIOR TO ENABLE THE LOG. If not fed after 30 days the instrument will lose current date

and time.

TIME: log starting time (format 23h 59min)

EVERY: frequency of recording (format 23h 59min)

E.g.: To set the instrument to begin logging events starting from 16:00 every hour set TOME to 16h: 00 and EVERY of 1h: 00m

Note: To view on instrument’s display the archived logs select LOGBOOK

Page 25

ERMES

The web-based application ERMES allows plants remote control: with it is possibile to read, analize and modify

instruments parameters from PCs, smartphones or tablets.

PLUS

• It reduces plant intervention and inspections.

• It reports on the current status of the network’s devices and connections (probes, outputs, alarms, setpoints)

• It instantly gives notification of alarms by sms or email

• It generates an up to date report of all plant instruments

• It can display the instruments activity log as line graphs and charts and it can download it to your pc in excel or

pdf format

HOW TO USE WEB ERMES

Enter the website www.ermes-server.com and, after registration, set plants.

EMEC instruments with ETHERNET or GSM/GPRS Configuration will be immediatly connected and available for remote

control. Furthermore, with ERMES you can receive alarm messages via email, with different report option on instrument

status. If instrument has been bought with the GSM/GPRS option it’s possible to receive SMS reports on any mobile

phone.

Read “COMMUNICATION” chapters to better understand how to configu e the instrument.

Page 26

Troubleshooting

Problem Possible solution

What to do before to install the SIM into instru-

ment’s modem

Check best signal coverage for operator choice.

Modem is compatible with the following GSM frequencies: 900

-1800 -1900 MHz (three-band). Not compatible with 3G only

operators.

SIM type is:

Mini-SIM (classica SIM card in uso nei telefoni)

Lenght 25 (mm) - Width 15 (mm) - thickness 0,76 (mm)

Subscribe to a data plan for monthly traffic activity of about 500MB

Make sure PIN REQUEST is OFF. If not insert SIM into a standard

mobile phone and disable it.

Several instruments are connected in RS485 mode

but the software displays only one

Make sure the termination jumper on the first and last instrument

of the chain are closed

The GPRS modem does not connect to the network

Verify the correct insertion of the SIM

Verify APN parameters and enter them

manually if necessary

Make sure the SIM has a data plan active for internet access

Make sure the provider supports international roaming DATA if the

connection is abroad

The instrument is unable to obtain a valid IP ad-

dress from the LAN or the software does not

connect to it

Make sure the pre-existing network allows auto-assignment of the

IP address (automatic DHCP); if it does not, contact the network

administrator to obtain the data to enter manually

Make sure the network cable is connected to the instrument. Make

sure it is a good quality cable and not the “cross” type.

CAT 5, 6 and 7 cable types are compatibles

ERMES does not find the instruments via internet

that are correctly connected to a LAN

Make sure the internet connection is active

Make sure there are no port-blocking third part programs and/or

firewalls active that prevent data traffic through the TCP 2020 port

FIRST TIME CONNECTION TO ERMES

ERMES is asking for CODE and SERIAL NUMBER

during first time access, where are they ?

CODE and SERIAL NUMBER are located on instrument’s main label

ADDING AN INSTRUMENT TO ERMES

Where is the CODE NUMBER required to add an

instrument to the account?

For instrument with LAN access: see SERVICE menu within

instrument’s software

For instrument with GPRS access: enter SIM phone number

Page 27

MODBUS

Modbus is a serial communications protocol originally published by Modicon (now Schneider Electric) in 1979 for

use with its programmable logic controllers (PLCs). Simple and robust, it has since become a de facto standard

communication protocol, and it is now a commonly available means of connecting industrial electronic devices.

From main menu select COMMUNICATION then MODBUS to access the options. Set the communication speed

according to the PLC system available. Set the ID assigning an UNIQUE address to avoid conflict .

1 2 3

1: GND

2: A-RS485 (+)

3: B-RS485 (-)

To access the module MODBUS open the

instrument only after power is switched off!

Never make connections with the instrument

powered!

WARNING

Page 28

ADDENDUM DIOXIDE PROBE SAFETY SYSTEM

Dioxide Probe

Use this function to setup sensor that detects dioxide into air. This option is useful during a plant’s dioxide

leakage to prevent dangerous high dioxide concentration. To set this valure refer to the sensor sensitiveness

as printed on head’s label (see below picture). Do not edit this function if not otherwise specified or

if unsure of value to enter.

Other options are:

MAIN MENU: HIDE to not show a warning message. Use exclusively if no sensor is connected.

MAIN MENU: SHOW to enable warning message and related alarm on main screen. Enabled by default.

Attention: this procedure assumes that the instrument is congured properly and connected to a

working sensor, otherwise the results may not be reliable.

Dioxide into air alarm

Use this menu to set a maximum dioxide into air concentration value into environment. Don’t change this value

if unsure of value to enter. Do not edit this function if not otherwise specified.

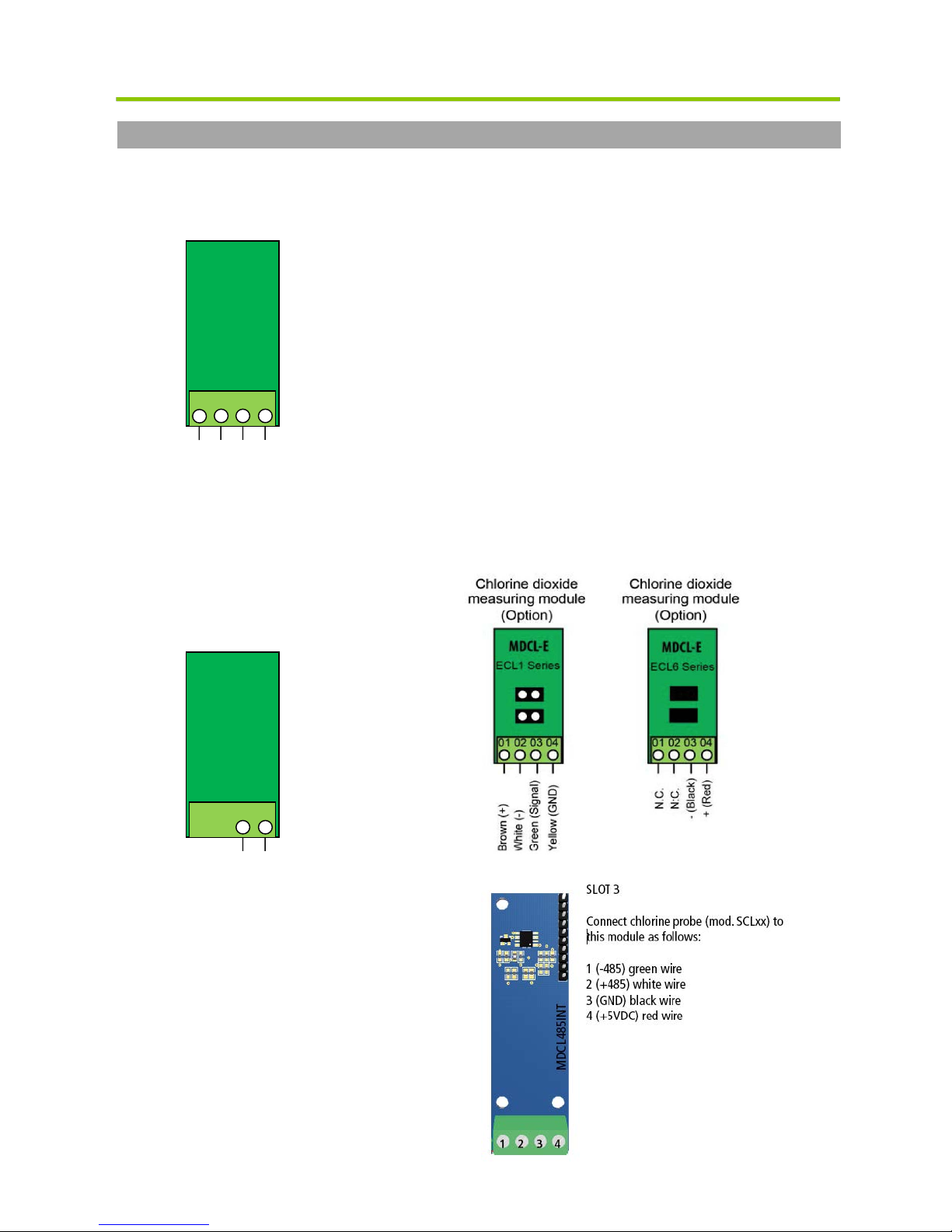

Dioxide into air main sensor head

Connection:

Block 1 : (+12VDC) Brown

Block 2 : (-12VDC) White

Block 3 : (V-out) Green

Block 4 : (GND) Yellow

DIOXIDE SENSOR MODULE

1 2 3 4

Page 29

20

Appendix A: Test Certificate

Order No.:

LOTUS type:

Serial No.:

Software release:

Chamber:

Test pressure:

Test temperatur

Test period:

bar

° C

hours

Dosing pumps:

Acid

Water

Chlorite

Type:

Calibration value:

ml

ml

ml

Calibration pressure:

bar

Number of strokes:

System settings:

Dos-Check:

Pass-Code 2:

Default:

Pass-Code 1:

Default:

Language

Deutsch / English

Water meter:

Pulse/Liter Liter/Pulse

Max. value:

m³/h at 20 mA

Date

Signature

Page 30

Page 31

Page 32

R3-10-14

21

Page 33

R3-10-14

1

Chlorine Dioxide

Generator LOTUS MINI

Installation and Operation Manual

Read this manual completely before you start with the installation and start-up.

Do not trash this manual and store it nearby the generator for later use.

This manual contains important information about the installation and operation safety.

Take care about the following instructions to avoid personal injuries and material damages!

The operator is responsible in case of damages caused by installation and operation failures!

English

Page 34

R3-10-14

2

Page 35

3

Directory

1.

General Safety Guidelines

4

1.1

Symbols

4

1.2

Safety instructions

4

1.3

CE-Conformity

5

2.

General Description

6

3.

Construction

7

3.1

Construction overview

7

3.2

Description and details

7

4.

Installation

8

4.1

General requirements for the installation location

8

4.2

Requirements to the water

9

4.3

Assembly

9

4.4

Hydraulic installation

10

4.4.1

Installation to a pressure system

10

4.4.2

Installation to a batch tank

13

4.5

Electric Installation

15

4.5.1

Power supply

15

4.5.2

Types of Control

15

5.

First Startup

16

5.1

Preparations

16

5.2

Hydraulic start-up

16

6.

„LOTUS“ - Controller

17

6.1

Start display

17

6.2

Main display

17

6.3

Control element „Click-Wheel“

18

6.4

Status displays

19

6.5

Logbook

20

6.6

Help

20

7.

Main Menu

21

7.1

Pumps – Calibration of the dosing pumps

22

7.2

Probes – Calibration of the chlorine dioxide probe and temperature sensor

22

7.3

Contact water meter

23

7.4

Analog outputs

24

7.5

Operation mode

25

7.5.1

Proportional mode

26

7.5.2

Constant mode

27

7.5.3

Analog mode

27

7.5.4

Batch mode

28

7.5.5

Proportional & Measuring mode

29

7.6

System settings

30

9.

LOTUS Terminal board

31

10.

Technical Data

32

11

Failure Messages

33

Appendix A: Test Certificate

Page 36

4

1. General Safety Guidelines

1.1 General remarks

This manual includes basic directions for the assembling, operation and maintenance. Therefore it is obligatory

for the assembly technician as well as for the operator to study the complete manual before starting with the

installation and start-up. This manual must be present at the generator at any time.

It is also obligatory for the operator to consider the general directions in chapter “Safety instructions” as well as

the specific safety instructions included in the other chapters of this manual.

Notice:

• For some of the following described functions additional accessories (not included in the delivery

scope of LOTUS) may be required.

• Depending to the software release of the LOTUS-controller some of the described features may

not be available. Or some functions are available, but not described in this manual. Please contact

your dealer in case of the requirement for more information.

1.2 Symbols

In accordance to the guideline DIN 4844-W9 about the characterization of special risks all safety instructions in

this manual are labeled with the following symbols:

Warning:

This symbol is waring about risks.

Disregarding may cause heavy personal injuries and material damages.

Caution!

This symbol is warning about troubles caused by incorrect operation.

Notice or advice:

This symbol shows important additional information.

1.3 Safety instructions

The appropriate use of the LOTUS generator is described in this manual.

Warning:

• The un-appropriate use affects the safety function of this generator and other connected devices

and is therefore strictly forbidden.

• Assembling and maintenance has to be done by authorized technicians only.

• Maintenance repairs have to be executed only by the manufacturer or authorized technicians. Inter-

ventions or changes at the device in opposite to the regular maintenance in accordance to this

manual are incorrect and make the all warranty claims nugatory.

• The operator is liable for the observance of the local safety instructions.

• For the operation and service the device must be accessible at all times.

Warning: risk of explosion

Page 37

5

• Before starting service at the dosing pumps make the pump-heads pressure-less.

• Drain and flush the pump-heads with clean water before starting the service.

• Take attention to the chemical safety data sheets!

• Wear protection clothes for the handling with unknown and hazardous chemicals.

Page 38

6

Directions for the operator

(Specific information for applicable regulations in Germany):

• Accident prevention regulation (UVV) „Chlorination of water“, GUV V-D5 E.

• „Dosing plants for chlorine dioxide“, DVGW guideline W 624 (latest version respectively).

• „Chlorine dioxide in water treatment“, DVGW worksheet W 224 (latest version respectively).

• Guidelines for the protection of groundwater against polution.

(§ 19 Federal Water Act – WHG dated 23.9.1986).

• Ordinance of hazardous substances (GefStoffV) – especially § 17 (obligatory protection)

and § 20 (operation instruction).

1.4 CE - Conformity

The LOTU

S generator is corresponding to the following EU-standards:

The following standards are considered:

• Machinery directive 89/392/EWG IIA inclusive all actual changes within the year of

Manufacturing 91/368/E

WG – Mod. 1, and 93/44/EWG – Mod. 2.

• Guideline 2004/108 EG about the electromagnetic tolerance of electric equipment.

• Low-voltage directive 2006/95/EG.

• EC – Pressure Equipment Directive (97/23/EG)

The following harmonized safety guidelines are considered:

• UNI EN 292/1 – Safety of machines

• UNI EN 292/2 – Safety of machines; technical principles.

• CEI EN 60204-1-98 – General requirements for electric equipment in machines.

Notice:

A declaration of conformity can be ordered from the manufacturer.

Page 39

7

2. General Description

The chlorine dioxide generator is used for the production of liquid chlorine dioxide. This disinfection agent kills

all bacteria, germs, viruses and fungi within shortest time – and it works with very low concentration.

The generator is working with the hydrochloric acid – chlorite process and uses diluted chemicals like hydrochloric acid (HCl 9%) and sodium chlorite (NaClO

2

7.5%) in accordance to the following chemical equation:

Hydrochloric acid + Sodium Chlorite = Chlorine dioxide + Sodium chloride + Water

4 HCl + 5 NaClO

2

= 4 ClO2 + 5 NaCl + 2 H2O

In the process each chemical is pumped with a specific proportion into a reactor vessel [ 5 ] by two dosing

pumps [ 2 and 4 ]. Each stroke from each pump is triggered by the LOTUS-controller [ 1 ] and countercontrolled by a “SEFL” [ 6 ].

Inside the reactor vessel the chemicals are reacting to chlorine dioxide with a concentration of 2% (= 20 g/l).

In the next step a specific proportion of water is pumped into the reactor by a third dosing pump [ 3 ] to dilute

the chlorine dioxide down to a concentration of approx. 2 g/l.

The finished chlorine dioxide leaves the reactor vessel through a back pressure valve [ 7 ] on the top of the reactor.

The advantages are:

• The chlorine dioxide can be pumped direct into pressurized systems with the pressure of the pumps and

likewise into pressure-less storing tanks, to distribute the disinfection to different points of use.

• The System can work in proportional mode with contact water meter, current signal or chlorine dioxide

measurement.

1 2 3

4 5 6

7

Page 40

8

3. Construction

3.1 Construction overview

3.2 Description and details

1 LOTUS-controller 10 Drain nozzle ½“

2 Dosing pump for hydrochloric acid (HCl 9%) 11 Level switch „Dilution water tank empty“

3 Dosing pump for dilution water 12 Can with hydrochloric acid 9 % (ca. 95 g/l)

4 Dosing pump for sodium chlorite (NaClO

2 7,5%) 13 Suction lance with level-switch „Hydrochloric acid“

5 Reactor 14 Can with sodium chlorite 7,5 % (ca. 80 g/l)

6 Dosing control “SEFL” 15 Suction lance with level-switch „Sodium chlorite“

each for hydrochloric acid, sodium chlorite

and dilution water

7 PVDF check-valve with hose-connection 4x6 mm

8 Storage tank for dilution water

(located behind the dosing pumps)

9 Floating valve

A Hose-connection 4x6 mm for dilution water

B Hose-connection 4x6 mm for chlorine dioxide (for PVDF hose)

C Dilution water storage tank overflow

1

2

3

4 5 6

7

HCl 9%

NaClO2 7,5%

8

10 9 11

C

12

13

14

15 B A

A

Page 41

9

4. Installation

Warning:

• For the operation of the LOTUS generator the absolute observance of the national and local

regulations is required.

The operator is liable for the observance of the local safety instructions.

• The generator must be installed and started up in accordance to the regulations in this manual.

• The usage of installation parts not approved by the manufacturer or supplier is prohibited.

• The operation of the generator is allowed only with suitable safety-valves approved by the

manufacturer. The contempt of this regulation results the ultimate loss of any warranty claims!

• Before starting works at the plant decompress all parts of the system.

• The plant never has to work against closed valves because of the risk of bursting hoses or

pipes.

• Disconnect the power supply before opening the controller housing.

• Take care of all national regulations during installation!

4.1 General requirements to the installation location

Notice

• The plant must not be placed outdoors.

• The plant must be protected against unauthorized access.

• The installation location must be protected against sunlight and frost and well ventilated.

• For temperatures less than 10° C suitable tempering systems are required.

• It must be possible to carry the chemical cans to the plant without any restrictions.

• An escape route is stringent required!

• The plant must be mounted onto a vertical solid wall without tensions.

• The plant must be mounted in a way that no vibrations can be produced.

• Take care of free entrance from all sides for the operation and maintenance!

• A tap-valve and a lockable floor gully should be present for the risk-free removal of spilled

chemicals.

• A fuse-protected power-supply (230 V CE-connector, 16 A) is required.

Page 42

10

4.2 Requirements for the water

Warning:

Serious malfunctions at the plant or corrosion damages in the pipe-work of the treated water should be possible in case the following requirements to the water the chlorine dioxide

is produced for as well as for the dilution water are not fulfilled:

Dilution water:

Temperature: 10 – 30° C

Pressure: 0.3 - 1 bar

Quality: Free of iron, manganese and particles, non-corrosive.

Treated water:

Temperature: > 5°C

Pressure: 6 bar max.

The following directions are based on a concentration for chlorine dioxide of 0.4 mg/l to prevent

pipe-corrosion:

• The pH-level should be always higher than pH 6.5.

It should be controlled during operation.

• In case the carbonate hardness is lower 1.1° dH (German hardness) or the alkalinity is lower

0.4 mMol/l the dosing of suitable chemicals for the increase of the pH-level is required.

• In case the carbonate hardness is lower 19° dH (German hardness) the installation place of the

injection valve for the chlorine dioxide (already made of PVDF) should be made of corrosion

resistance materials (like PVC).

4.3 Assembly

• The plant must be mounted onto a vertical solid wall without tensions.

• The plant must be mounted in a way that no vibrations can be produced.

• The location should be nearby the chlorine dioxide injection point.

• Take care of free entrance from all sides for the operation and maintenance!

• The plant-bottom should be minimum 1 m over the floor-level.

• The level of the complete filled chemical cans must always be under the level of the dosing pumps.

• The maximum suction-height for the dosing pumps should be not more than 2 meters.

• Fix the plant with the two mounting-holes [ P ] on the backside to the wall.

Open the front door to reach the mounting-holes.

Notice

For a safety fastening hanger bolts M8 x 60 mm are suggested.

P

Page 43

11

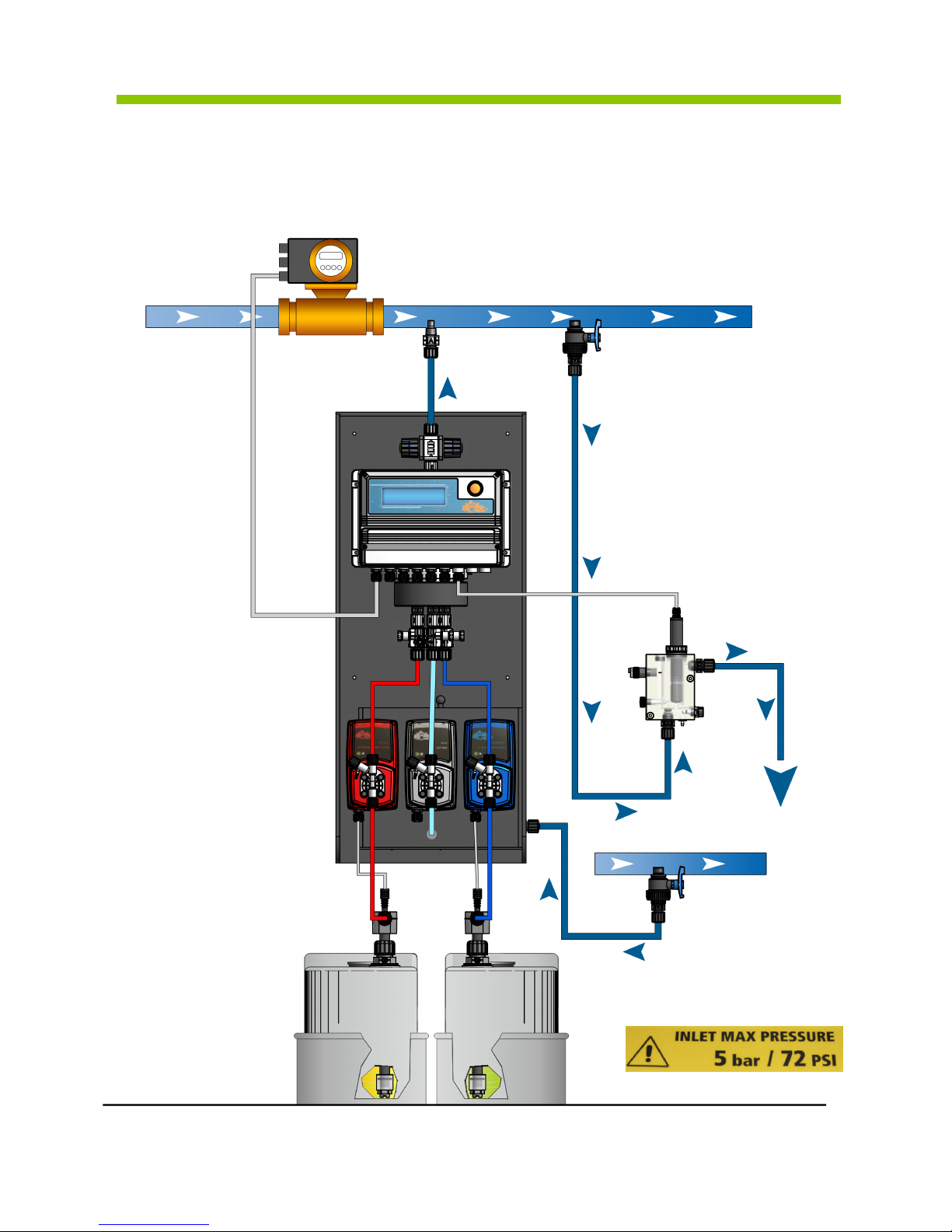

4.4 Hydraulic Installation

4.4.1 Installation to a pressure system

Systems with more than 0.5 bar operation pressure like drinking water treatment for hospitals, municipal buildings, retirement homes as well as cooling water treatment etc.

A Connection for dilution water (PE-hose 4x6 mm)

B Chlorine dioxide injection point (PVDF-hose 4x6 mm)

C Overflow dilution water storage tank

(20 mm PVC adhesive sleeve)

20 Valve

21 Protection filter

22 System separator

23 Contact water meter (like type CTFI)

or magnetic flow meter with current output

24 DMU Injection and intermixture device

(made of PVC suggested)

25 Valve

26 Protection filter (like NFIL/60)

27 LASP suction-lance for hydrochloric acid

28 LASP suction-lance for sodium chlorite

HCl 9%

NaClO2 7,5%

27

28

20

21

22

23

24

25

26

FQI

C B A

Page 44

12

General information:

Warning:

In accordance to DIN 1988 a system separator is required in the main building feed line.

Notice:

• Take equal pipe dimensions and connections for the contact water meter and the intermixture

device to ensure optimal hydraulic conditions.

• Take absolute care for the maximum permitted operation pressure (see label on the LOTUS)!

Contact water meter [ 23 ]

Warning:

Between the contact water meter and the point of injection no possibility for tapping water

is allowed. Otherwise it can happen that the chlorine dioxide concentration can rise undue.

The LOTUS – controller is able to work with the following signals:

• Contact water meter with Reed-contact (like type CTFI)

• Contact water meter with open collector

• Water meter with analog output 4…20 mA

The water meter has to be placed after the system separator [ 22 ] and before the point of injection [ 24 ]. He

must gather the complete amount of water which has to be injected with chlorine dioxide.

Use the following formula for the calculation of the optimal contact water meter to achieve a continuous dosing

of chlorine dioxide without producing „clouds“:

Pulse spacing ≤ [ Pulse/Liter ] ≤

F = Factor based on the nominal size of the contact water meter:

DN 15 = 2

DN 20 = 2

DN 25 = 4

DN 32 = 7

DN 40 = 15

DN 50 = 20

Example 1:

In a well water supply with a nominal size of DN 20 a chlorine dioxide concentration of 0.1 mg/l is required:

Pulse spacing = = 5 Selection: Contact water meter type CTFI 20 – ¾“ with 4 pulse/liter

Example 2:

In a well water supply with a nominal size of DN 50 a chlorine dioxide concentration of 0.1 mg/l is required:

Pulse spacing = = 0.5 Selection: Contact water meter type CTFI 50 – 2“ with 1 pulse/ 2 liter

Notice:

Find more information in chapter “7.5.1 Proportional Mode”.

1

F x [ mg/l ]

1

2 x 0.1 mg/l

1

20 x 0.1 mg/l

1

F x ClO

2

– desired concentration

Page 45

13

Injection and intermixture device [ 24 ]

Caution!

Don´t install the injection valve direct into a metal tube. The chlorine dioxide will destroy the tube

by corrosion in a short time. Select one of the following devices for the installation into metal pipeworks:

• Injection and intermixture device type „DMU“ [ 24 ]

• Injection lance made of PVDF like type „LINI-K“ (Option) as

Take care that the dosing hose [ B ] is protected against direct sunshine. The sun radiation degrades the chlorine dioxide back into its basic chemicals. Use a suitable protection hose (Option).

Multifunction valve

Warning:

• Don´t remove the multifunction valve!

• The counter-pressure in the dosing line must be minimum 1 bar at any time!

• With the yellow knob you can adjust the counter-pressure

between 1 – 5 bar depending to the actual installation situation.

• The overpressure and priming hose is laid to the dilution water

storage tank. In case of an overpressure the chlorine dioxide

flows into the tank and will be diluted. From there it overflows into the drain.

Dilution water connection [ A ]

Inside LOTUS is a storage tank [ 8 ] for the dilution water. The automatic refill is controlled by a float valve [ 9 ].

The float valve has to be connected to the water line with a 4x6 mm PE-hose (2 m included in the delivery

scope).

Notice:

• In case the pressure in the water line is more than 5 bar a pressure regulator valve in the re-

filling line is required. The adjusting range should be 0.3 – 4 bar.

• For a proper function of the pressure regulator valve and the float valve inside the tank a pro-

tection filter like a ”NFIL/60“ is recommended.

Overflow connection [ C ] for the dilution water storage tank

The dilution water storage tank [ 8 ] has a overflow connection with a 20 mm PVC adhesive connection.

The overflow should be connected to a floor drain.

Overpressure and priming hose

Multifunction valve type „MFKT“

Page 46

14

4.4.2 Installation to a batch tank

A Connect

ion for dilution water (PE-hose 4x6 mm)

B Connection for chlorine dioxide outlet (PVDF-hose 4x6 mm)

C Overflow of dilution water storage tank (PVC 20 mm adhesive muffle) to drain

20 Shut-off valve

21 Protection filter (like NFIL/60)

22 LASP suction-lance for hydrochloric acid

23 LASP suction-lance for sodium chlorite

24 Power supply controlled by a level-control in the batch tank [ 27 ] for „overflow emergency“

25 Batch tank

26 Active carbon filter for tank venting

27 Level-switch „Batch tank overflow“

28 Level-switch „Batch-Tank empty/start refill“

29 Level-switch „Batch-Tank full/stop refill“

30 Multifunction valve “MFKTS”

HCl 9%

NaClO2 7,5%

22

23

26

25

20

21

C

B

A

27

28

29

24

Page 47

15

Caution!

Take care that the “MFKTS” – multifunction valve on the top of the reactor (inside LOTUS)

is adjusted with a counter-pressure of minimum 1 bar!

Dilution water connection [ A ]

Inside LOTUS is a storage tank [ 8 ] for the dilution water. The automatic refill is controlled by a float valve [ 9 ].

The float valve has to be connected to the water line with a 4x6 mm PE-hose (2 m included in the delivery

scope).

Notice:

• In case the pressure in the water line is more than 5 bar a pressure regulator valve in the re-

filling line is required. The adjusting range should be 0.3 – 4 bar.

• For a proper function of the pressure regulator valve and the float valve inside the tank a pro-

tection filter like a ”NFIL/60“ is recommended.

Overflow connection [ C ] for the dilution water storage tank

The dilution water storage tank [ 8 ] has a overflow connection with a 20 mm PVC adhesive connection.

The overflow should be connected to a floor drain.

Page 48

16

4.5 Electrical Installation

Caution!

• Installation only made from an authorized expert!

• In Germany: Take the instructions of VDE 0165 into consideration.

In foreign countries: Consider the current national regulations!

• Risk of electric shock!

• Take care that the power supply meets the power requirements of LOTUS (see plant-label).

• Disconnect power supply before opening the controller housing!

4.5.1 Power supply

LOTUS has a standard cable with CE-connector. For the power supply a fail-saved humid room damp proved

electric socket is required.

Notice:

• The electric socket has to be placed nearby LOTUS for easy disconnection in case of emer-

gency stop or maintenance.

• The electric socket must be placed free for easy access from all sides.

• An overload protection for the power supply is stringent required!

4.5.2 Types of Control

Three different types of control are selectable:

• Proportional to the flow, controlled by a pulse frequency input:

- e.g. by a contact water meter with Reed-contact (type „CTFI“),

- a contact water meter with open collector or Hall-sensor,

- or a magnetic flow meter (IDM).

• Analog with a current signal (4 … 20 mA),

- from a magnetic flow meter (IDM),

- or a external chlorine dioxide measuring system (in Germany prohibited)

• Level-controlled filling of a batch tank

Depending to the required control the LOTUS-controller has to be configured and an option has to be ordered.

Contact your dealer for more information.

Page 49

17

5. Startup

5.1 Preparations

• Open the valve [ 25 ] for the dilution water storage tank. The tank starts filling until the float valve [ 9 ] shuts

the line.

• Put the suction lances for hydrochloric acid (HCl 9%) and sodium chlorite (NaClO2 7.5%) into the cans.

Warning:

Wear protective clothes for the handling with hazardous chemicals!

5.2 Hydraulic startup

• Plug the power supply into the socket.

The LOTUS-controller starts with the start-display and shifts to the main-display after some seconds.

• Use the click-wheel, go to „Status“ and then to „Priming“. Push the click-wheel and open the sub-display for

the manual mode.

• Insert a time in field „Input“ and start the count-down with “Start”. All three pumps start running with max.

pulse frequency.

• Open the priming valves at the dosing pumps. The pumps keep on running until the count-down stops or

the process is interrupted with the “Stop” button.

• Shut the priming valves as soon as the chemicals flow out without gas-bubbles back into the cans.

• Let the pumps keep on running to fill-up the reactor with chemicals and dilution water until the count-down

stops.

• Push the click-wheel on “ESC” and leave the manual mode.

When the pumps are still running because the count-down is still activated you can verify with the blinking

signals “Check” for the dosing control and “Pumps” for the dosing pumps if the pumps and suction- and delivery-hoses are proper vented.

In case it is not, go back again into the “Priming” display and repeat the process.

• After successful priming start the configuration of LOTUS for the adaption to the local requirements.

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Status Menu Logbook Help

Status

Status LOTUS

Check : Mode:

Pump : Proportional

Acid Water Chlorite

ON Stand-by Priming ESC >

Priming

LOTUS

Count-down: 00 minutes Mode:

Input: 05 minutes Manual

Start Stop ESC

Start

Status LOTUS

Check : Mode:

Pump : Proportional

Acid Water Chlorite

ON Stand-by Priming ESC >

Page 50

18

6. „LOTUS“ Controller

6.1 Start display

When the power supply is switched on the start display appears and shows the actual software release for

some seconds.

After approx. 3 seconds the program goes onto the main display.

6.2 Main display

The mai

n display is separated into 5 lines::

1: Date and time

2: Measuring value for temperature (in case this option is implemented)

3: Type of plant

4: Information line for operation, status or failure messages (blinking)

5: “Click-Wheel” operation and duty line.

A constant running bar shows that the LOTUS is active.

LOTUS

Rel: x.x.x

1 2 3 4 5

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Stand-by

Status Menu Logbook Help

Status

Page 51

19

6.3 Control element „Click-Wheel“

On the right side of the display a turning- and push-button is located. It is called „Click-Wheel“.

You can turn the click-wheel into both directions to scroll through the menus or select a function. The selected

function is shown in an inverse color.

The actual position is shown .

Push the click-wheel for selection.

When you leave a sub-menu wi

th or you will be asked if you want to save the inputs or changes:

• Select „Yes“ to accept the inputs and changes.

• Select „No“ in case the previous settings should be preserved.

In case you leave a sub-menu with and without any changes the previous settings are preserved.

Inverse

OK

Ex

ESC

Save?

Yes

No

Save and exit

Yes

Main Menu

Proportional

Probes

Water meter

Pumps calibration

Pumps

Turn for scroll

Push for selection

Page 52

20

6.4 Status Displays

Push th

e click-wheel on “Status” to open 4 different operation displays:

Check: The signal lights are showing the function of the dosing controls.

At stagnant production the signal light shows .

During production the signal lights from the dosing controls “Check” are blinking inverse

corresponding to the signals from the „Pump“.

That means: in the moment when a pump is doing a stroke

(light = ), the light of the dosing control has to show .

Pump: See also „Check“.

Mode: Shows the activated operation mode.

Production: Shows the actual chlorine dioxide production capacity.

Water Meter: Shows the actual flow capacity of the contact water meter.

Next Service: Shows the remaining time until the next service is required.

Operating hours: Shows the operating hours counter.

In the operation displays you have different options:

ON/OFF Start/Stop LOTUS

STAND-BY Switches LOTUS into the “Stand-by” mode,

independent to the function of the “Stand-by” – Input

PRIMING Opens the display for dosing pumps priming resp. for manual mode

ESC Go back to the main display

< or > Scroll in the operation displays

Status LOTUS

Production [g/h] : 4.25 Mode:

Water Meter [m³/h]: 42.5 Proportional

< ESC >

On

Totalizer

Acid [ltr.] : 9123.5 Mode:

Chlorite [ltr.]: 9124.9 Proportional

Water Meter [m³]: 99999.9

< ESC

On

Status LOTUS

Next Service in [h]: 4375 Mode:

Operating hours [h]: 9999999 Proportional

< ESC >

On

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Stand-by

Status Menu Logbook Help

Status

Status LOTUS

Check : Mode:

Pump : Proportional

Acid Water Chlorite

ON Stand-by Priming ESC >

Page 53

21

6.5 Logbook

Turn th

e click-wheel onto the field “Logbook” and push it to open the sub-menu.

The LOTUS-controller has an internal logbook-memory. Two different types of data are stored together with a

time-stamp: Operation data in periodic intervals and failure messages as soon as they appear.

Turn the click-wheel to scroll forward and backwards through the logbook.

Push the click-wheel on “ESC” for return to the main display.

6.6 Help

Turn th

e click-wheel onto the field “Help” and push it to open the “Help” display.

The “Help” display shows the contact data of your dealer.

Push the click-wheel on “ESC” for the return to the main display.

Logbook

˄

07-12-10 23:59:59 Mode: Proportional

Acid:109.0 l Chlorite: 109.7 l Water: 298.6 m³

˅

ESC

Logbook

˄

07-12-10 12:35:55 Failure level acid

07-12-10 13:10:20 Restart

˅

ESC

LOTUS

LIQUID Water Treatment

Phone: 01234-567890

ESC

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Stand-by

Status Menu Logbook Help

Logbook

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Stand-by

Status Menu Logbook Help

Help

Page 54

22

7. Main Menu

Push the cl

ick-wheel to open the main menu.

The access to the main menu is protected by a passcode:

Select a four-digit number-code. As soon as the fourth correct digit is selected the main menu opens automatically.

Caution!

• Access to the main menu for authorized service technicians only!

• The passcode is stored in appendix A: “Test Certificate”

or you find it in chapter „7.7 System Settings“ (factory defaults).

Sub-menues:

Calibration of the dosing pumps

Calibration of the chlorine dioxide and temperature probe

Configuration of the input for a water meter

Configuration of the analog outputs

Selection of operation mode

System settings

Back to main display

Main menu

Proportional

Exit

Exit

Main Menu

Proportional

Operation Mode

System Settings

Analog Outputs configuration

Analog Outputs

Main Menu

Proportional

Probes

Water Meter

Pumps calibration

Pumps

Passcode

0 1 2 3 4 5 6 7 8 9 ESC

Enter Passcode

* * * *

0

02-12-10 EMEC 09:10:55

LOTUS 25.9° C

Chlorine Dioxide Generator

Stand-by

Status Menu Logbook Help

Menu

Page 55

23

7.1 Pumps – Calibration of dosing pumps

For an accurate production of chlorine dioxide a proper calibration of the dosing pumps is essential. The exact

calibration ensures the maximum yield of the chemicals and the minimization of the chemical consumption. For

this a periodic maintenance with a pumps calibration is required.

A calibration has to be executed:

• At the first startup or restart after a shut-down period.

• At every periodic maintenance.

Calibration:

1. Attach the calibration cylinder sidewise to the LOTUS housing.

2. Disconnect the suction hose from one pump and connect the PVC-hose

from the calibration cylinder to the pump.

3. Fill the calibration cylinder with water.

4. Go into the “Priming” mode and vent the suction hose of the calibration cylinder.

5. Refill the calibration cylinder until the “0” ml tag.

5. Enter the Main menu and open the sub-menu “Pumps”.

5. Push the click-wheel on “Start”.

All three dosing pumps are executing 100 strokes (see the count-down in field “Strokes”). An additional display opens when they finished.

6. Read the “ml”-level from the calibration cylinder and insert the value into the input-field depending to the

corresponding pump.

7. Leave the display with “Exit” and save the changes with „Save“. Repeat the procedure with the two other

pumps as shown above.

Main Menu

Proportional

Probes

Water Meter

Pumps calibration

Pumps

Pump Calibration

Check : Strokes:

Pump : 100/100

Acid Water Chlorite

ESC >

Start

Pump Calibration

Acid [ml]: 36

Water [ml]: 64

Chlorite [ml]: 36

Exit

36

Page 56

24

7.3 Contact water meter

For the proportional production of the chlorine dioxide the connection of a contact water meter is required.

The LOTUS-controller can work with the following types of water meters:

• Contact water meter with Reed-contact (like type CTFI)

• Contact water meter with open collector

• Water meter with analog output 4…20 mA (like a magnetic flow meter)

In the sub-menu „Water Meter“ LOTUS can be optimal adapted to the connected water meter.

Enter the main menu and open the sub-menu “Water Meter”.

Dimension: Select the dimension you want to insert in field “Value”. Chose between pulse per liter „Imp./Ltr.“,

or liter per pulse „Ltr./Imp.“.

Value: Insert the pulse spacing (see also chapter 4.4.1).

Max. Value: This input is only for water meters with analog output (0/4…20 mA). You have to insert the max-

imum flow of the water meter in m³/h corresponding to 20 mA.

Resolution: Here you have to select the type of analog output of the water meter. You can chose „0/20 mA“

or „4/20 mA“.

Notice:

This function is activated only in case the option “Analog” was ordered.

Timeout: The “Timeout” function acts as an optimizer for the proportional mode in case a contact water

meter is connected to LOTUS and

a) The flow is fluctuating very strong in short periods

b) The pulse spacing of the water meter is extreme inconvenient.

The range is between 0 – 20 seconds. “0” deactivates the function.

What is the principle?

As soon as the first pulse from the water meter is noticed, Lotus starts the production with 100%

capacity (= maximum stroke frequency). Parallel the controller is counting the time until the next

pulse appears. With this information LOTUS can calculate the flow and the required production

capacity to readjust the stroke frequency for the pumps.

In case the water meter produces more pulses than LOTUS is able to produce chlorine dioxide

proportional to the flow (failure message “OVERFLOW”), the controller buffers the pulses and

execute them later. But only for the timeout span to avoid overdosing in case the water flow

stops immediately during the timeout.

Water Meter

Dimension: Imp/Ltr

Value: 0004.0

Max. Value: 05000.0

Resolution: 4/20 mA ESC

Imp./Ltr.

Water Meter

Timeout:

ESC

05

Main Menu

Pumps

Probes

Water Meter

Water meter configuration

Water Meter

Page 57

7.5 Analog outputs

Optional there are 2 analog outputs available for the chlorine dioxide and the temperature measuring values.

In case LOTUS is equipped with the option you can select the output resolution in this sub-menu.

Enter the main menu and open the sub-menu “Analog Outputs”.

Capacity: Here you have to select the analog output value based on production gr/h.

Choose between 0/20 or 4/20 mA.

Main menu

Water Meter

Analog-Ausgänge

Operation Mode

Analog output configuration

Analog Outputs

Analog Outputs

Capacity: 4/20 mA

0/4 mA: 0 [g/h]

20 mA: 8 [g/h]

Reading: 4/20 mA

0/4 mA: 0 [mg/l]

20 mA: 8 [mg/l]

Reading: Here you have to select the analog output value based on ClO2 probe reading.

Choose between 0/20 or 4/20 mA.

CURRENT OUTPUT VERSION (mA) main board blocks:

Capacity: 13 (-) ; 15 (+)

Reading: 13(-) ; 16(+)

Page 58

26

7.5 Operation mode

LOTUS can work in different operation modes.

Enter the main menu and open the sub-menu “Operation Mode”.

Proportional: In this mode LOTUS produces an adjustable capacity of chlorine dioxide proportional to a

water flow recorded by a water meter.

Constant: In this mode LOTUS is producing chlorine dioxide with a constant and adjustable capacity

as long as input “Stand-by” is not activated.

Batch: In this mode LOTUS fills up a level-controlled batch tank with chlorine dioxide in an adjust-

able concentration.

Analog: In this mode the chlorine dioxide production capacity is controlled by an external analog

signal (0/4 – 20 mA).

Notice:

The “Analog” mode is available only in case the option is ordered.

Prop. & Reading: In this mode LOTUS produces an adjustable capacity of chlorine dioxide proportional to a

water flow recorded by a water meter. In addition a internal chlorine dioxide measurement

controls the concentration and downsizes the production capacity in case of an set-point

overriding.

Notice:

The “Prop. & Reading” mode is available only in case the option is ordered.

Main Menu

Water Meter

Analog Outputs

Betriebsmodus

Select operation mode

Operation Mode

Operation Mode

Proportional !

Constant

Batch

Analog

Proportional

Operation Mode

Prop. & Reading

Exit

Operation Mode (options)

Production: within this menu user can choose dioxide production gr/h (grams per hour)

based on maximum controller capacity

Proportional Cl: dosing activity based on ClO2 setpoint

Page 59