Emco-test DuraJet G5, DuraJet 10 G5 Instruction Manual

Hardness Tester

Introduction

DuraJet 10 G5

1-1

Instruction manual

Original instruction manual

DuraJet G5

A2015-05 EN

EMCO-TEST Prüfmaschinen GmbH

Kellau 174 A-5431 Kuchl

Tel: +43 6244 20438 – Fax: +43 6244 20438-8

office@emcotest.com – www.emcotest.com

Hardness Tester

Introduction

DuraJet 10 G5

1-2

Contents

1 Introduction 1-1

1.1 Preface 1-1

1.2 Safety notes 1-1

1.3 Manufacturer's notes 1-3

1.4 Icons and Typographic Conventions 1-5

1.5 Technical Data 1-7

2 Startup 2-1

2.1 Transporting the Machine 2-1

2.2 Scope of Supply 2-2

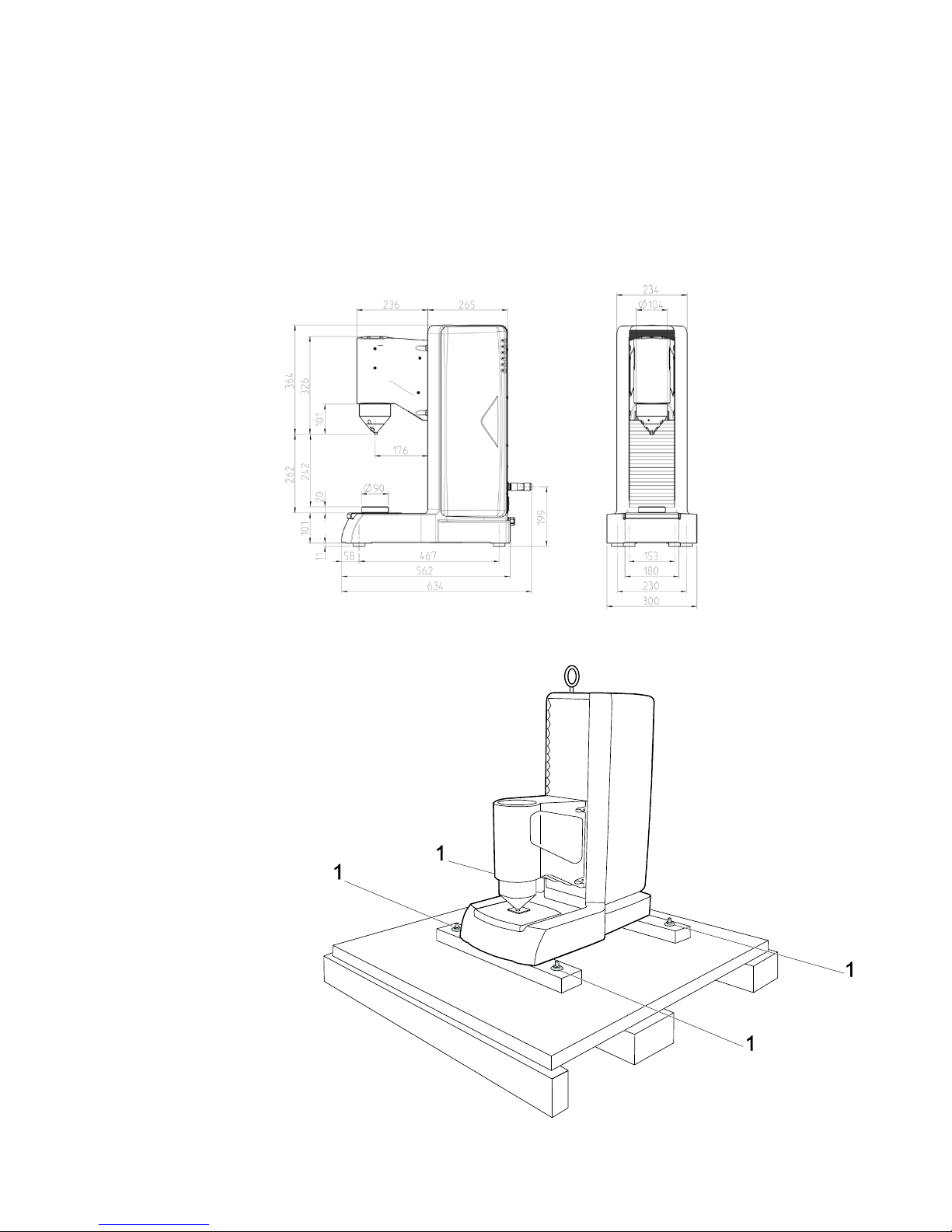

2.3 Weight and Dimensions 2-4

2.4 Installing the Machine 2-4

2.5 Initial Startup 2-9

3 Design and Functions 3-1

3.1 Design, Methods and Data Interfaces 3-1

3.2 Control Unit 3-2

4 Basic Operation 4-1

4.1 Switching the Machine On and Off 4-1

4.2 Touch Screen 4-1

4.3 Virtual Keyboard 4-1

4.4 Symbols and Buttons 4-3

4.5 Test Sequence 4-7

4.6 Testing Without the Nose Cone 4-12

5 Advanced Options 5-1

5.1 Opening the setting menu 5-1

5.2 General settings 5-2

5.3 User boxes 5-5

5.4 Export 5-6

5.5 Report 5-6

5.6 Network 5-9

5.7 Printer 5-9

5.8 Checking Load Calibration 5-9

5.9 Calibrating the Depth Gauge System 5-10

5.10 Documenting and Evaluating Results 5-11

5.10.1 Displaying, Printing and Exporting Results 5-11

5.10.2 Deleting Results 5-12

6 Cleaning and Maintenance 6-1

7 Startup and Retooling with Optional Accessories 7-1

7.1 USB 7-1

Hardness Tester

Introduction

DuraJet 10 G5

1-3

7.2 External machine control via hardware interface 7-2

7.3 Foot button 7-6

7.4 Replacing the Fuses 7-6

7.5 Replacing the Test Anvil 7-8

7.6 Test Methods and Indenters 7-11

8 Messages and Problems 8-1

Hardness Tester

Introduction

DuraJet 10 G5

1-1

1 Introduction

1.1 Preface

Our hardness testing machines represent state-of-the-art technology and comply with

current norms and standards. Both the hardware and software in our machines can be

upgraded on an ongoing basis. As a result, you can ensure that the technology in your

machine is always up-to-date.

The machines are equipped with a measuring system and electronic power control.

They are also distinguished by their ergonomic design and user-friendly software, which

complies with DIN standards.

Take your time to read this instruction manual thoroughly. You will be amazed by the

many application options available.

1.2 Safety notes

Familiarity with the applicable safety regulations is a prerequisite for safe, error-free

operation of this machine.

Refer to the instructions in this manual, and, in particular, to the safety instructions,

when operating the machine. It is also essential that you observe all rules and

regulations for accident prevention that apply in the location where the machine is

operated.

The design of this machine and its equipment is state-of-the-art and complies with

recognized safety regulations. Nevertheless, risk of injury or death to the user or third

parties may arise in certain cases, and the machine or other property may be damaged.

Icons are used to highlight these risks in the relevant chapters.

Read all operating instructions before you start the machine.

Keep the operating instructions in the vicinity of the machine. Order a new copy if you

lose it.

To avoid personal injury while moving the machine, never try to move it unassisted. The

machine's weight is approximately 110 kg.

Remove all transportation safety devices before starting the machine.

▪ Position the machine on a secure and stable working surface.

▪ Ensure that its working height is in accordance with ergonomic principles and will

not result in unnecessary physical strain.

▪ Ensure that there is sufficient space available to access the machine and that an

adequate escape route is kept clear to provide for unforeseen incidents.

▪ Ensure that the work station has adequate lighting.

▪ The hardness testing machine must be protected against shocks and vibrations that

can influence the test result.

Please bear in mind that the machine must not be used in explosive environments.

Ensure that workwear is close-fitting and cannot become entangled in the machine's

moving parts. Make sure you use your personal protective equipment.

The machine must be connected to a grounded electrical outlet (a protective conductor

contact is required).

Safety regulations

Operating instructions

Moving the machine

Transportation safety

devices

Installation

Fire and explosion

protection

Workwear and

protective equipment

Electrical power supply

Hardness Tester

Introduction

DuraJet 10 G5

1-2

Do not work with the machine for too long or when you are unable to concentrate

properly.

The machine must not come into contact with water. Protect the machine from

splashing.

Before each startup, ensure that the machine is in a flawless condition and that none of

the safety features have been removed and are all functional. Any damaged cables

must be replaced immediately by authorized personnel.

Ensure that the machine is only operated by authorized and properly trained persons.

Ensure that the machine cannot be started or operated by unauthorized persons.

Ensure that the machine is only operated by one person at all times.

Do not make any unauthorized changes to the machine's safety features. Bridging of

control features and any interference with the electrical/electronic components of the

machine are not permitted and will nullify the warranty in all cases.

In case of emergency, shut down the machine immediately with the EMERGENCY-OFF

button.

Before testing, check that the testing tools are securely clamped.

Do NOT attempt to touch the internal parts of the machine while it is operating.

Use appropriate fixings to secure any workpieces that do not stay in place without

support.

Never hold workpieces in place by hand!

Wear protective gloves when handling heavy or sharp workpieces or removing chips.

Use the main switch to turn the machine off before resetting.

Never leave the machine unsupervised while it is operating. Always switch the machine

off before leaving the work station.

Keep your work station clean and tidy. A cluttered work station increases the risk of

injury.

Use the main switch to turn the machine off. Remove the power plug to disconnect the

machine from the power supply before you carry out any maintenance or readjustments.

Any work on the machine's electrical parts unit should only be carried out by skilled

electricians or service technicians.

Comply with the stipulated inspection and maintenance intervals (see standards EN ISO

6507, EN ISO 6505, EN ISO 6508, EN ISO 4545, EN ISO 2039).

Contact your supplier in the event of collision or damage. Always specify the unit

number and software version of your machine in cases of complaint or damage or when

making inquiries or ordering replacement parts.

Work time

Protection from

splashing

Startup

Operation by

authorized personnel

Single-person machine

Unauthorized changes

EMERGENCY-OFF

Securing workpieces

Resetting the machine

Supervision

Work station

Maintenance

Claims

Hardness Tester

Introduction

DuraJet 10 G5

1-3

1.3 Manufacturer's notes

The rating plate sits at the right-hand side on the base. It shows the information that is

required to identify the machine.

1

Manufacturer information

2

Type name

3

Serial number

4

Mains voltage

5

Nominal motor voltage

6

External fuse

7

Number of the circuit diagram

8

Disposal information

9

CE sign

10

Year of manufacture

Address

EMCOTEST Prüfmaschinen GmbH

Kellau 174

5431 Kuchl

Austria

Phone

+43 6244 20438

Fax

+43 6244 20438-8

E-mail

office@emcotest.com

Internet

www.emcotest.com

The machine is intended to be used to test hardness in accordance with the following

methods:

Metals, plastic material and carbon material

▪ Rockwell EN ISO 6508, ASTM E18

▪ Plastics EN ISO 2039-1

▪ Brinell and Vickers, depth hardness only, not standardized

▪ Testing carbon material DIN 51917

Conversion standards: DIN EN 50150, EN ISO 18265, ASTM E140-05.

Testing other material is not permitted or, in exceptional cases, only after agreement

with your contact person. Never use poisonous or harmful materials. Intended use also

includes observing the specified operating and maintenance instructions.

The machine must be installed in a clean location. It is particularly important that this

location is free of metal chips, dust, smoke and other contaminants. If the ambient air at

Rating plate

Manufacturer

information

Intended use

Hardness Tester

Introduction

DuraJet 10 G5

1-4

the installation location is contaminated, the machine must be operated in a separate

closed test cell.

The machine may only be operated by persons who have been properly trained in the

operation, maintenance and repair of the machine, and are aware of the risks involved.

All accident prevention and safety instructions for operating the machine must be

observed. The manufacturer does not accept any liability in cases where the machine is

used for purposes other than those for which it is intended. In these cases, liability is

transferred to the user.

The machine is adjusted for the ambient temperature specified in the technical data.

The machine must not be used to test workpieces with low mechanical stability, which

may become distorted or may break when clamped.

Workpieces that are stable but do not have the required structural integrity may only be

clamped if they are secured using appropriate fixings.

The machine should not be used for workpieces which are toxic or harmful to health.

The CE mark and the EC conformity declaration certify that the machine and this

manual comply with the stipulations of the directives that apply to the product.

The WEEE symbol on your unit indicates that it is a WEEE-relevant machine

containing electrical/electronic components and must not be disposed of as general

waste. For more information about recycling this product, contact your relevant local

authority.

The warranty period for new machines is 24 months from the date of delivery by the

manufacturer with unlimited operating hours.

If a defect is detected, inform your sales partner or nearest service center of the

manufacturer immediately, providing a detailed description of the defect in written form,

over the phone or in person.

Defects that are properly reported and are covered by the manufacturer's warranty will

be corrected free of charge either by repair or replacement delivery. If requested,

defective parts are to be returned to the manufacturer at the customer's expense and

risk.

The manufacturer's warranty does not apply to defects that are caused by one or more

of the following:

▪ failure to fully comply with the operating instructions, safety and licensing

regulations or other instructions relating to the delivery, installation, startup or use of

the machine

▪ incorrect assembly or startup of the machine

▪ unauthorized, unapproved interference with or modifications to the machine by the

customer or a third party

▪ improper or inappropriate use of the machine for purposes other than those for

which it is intended

▪ normal wear and tear

▪ negligent or incorrect handling

▪ chemical, electrochemical or electrical exposure

▪ an insufficient or incorrect power supply

▪ force majeure

The cost of services not covered by warranty are to be borne by the customer.

Ambient temperature

Unauthorized uses of

the machine

EC conformity

Disposal

Warranty conditions for

new machines

Hardness Tester

Introduction

DuraJet 10 G5

1-5

1.4 Icons and Typographic Conventions

The following safety instructions are used in this document. The sequence starts with

the most important information, and shows the importance of the messages.

A safety instruction always begins with the hazard sign, the signal word, and a text box

that explains the hazard point and gives handling instructions.

DANGER

The safety instruction DANGER stands for an extremely dangerous situation.

Nonobservance will lead to severe and even fatal injuries (burns, for example).

Observe the danger warning, and take greatest care (using protective equipment, for

example) to face the danger. Persons must work very carefully in this area.

WARNING

The safety instruction WARNING stands for a very dangerous situation.

Nonobservance can lead to severe, irreversible and even fatal injuries, and loss of

limbs.

Observe the danger warning, and take greatest care (using protective equipment, for

example) to face the danger.

CAUTION

The safety instruction CAUTION stands for a dangerous situation. Nonobservance

can lead to injuries or material damage.

Observe the danger warning, and take greatest care (using protective equipment, for

example) to face the danger.

NOTE

The safety instruction NOTE refers to situations that can lead to material damage.

They show how damage can be avoided.

Safety instructions

Hardness Tester

Introduction

DuraJet 10 G5

1-6

The following icons and typographic conventions are used in this instruction manual:

Crushing hazard

indicates a risk of crushing, threatening life and limb of persons.

Electric current

indicates a risk of electric current, threatening life and limb of persons.

Danger

indicates a risk that threatens life and limb of persons.

Note

indicates a risk of damage to property, or the need to proceed with special care.

Information

indicates additional information and tips

Bold

indicates menu options and button labels

Italics

indicate names, software programs or figure titles

Monospace

indicates system output

"Inverted commas"

indicate chapter titles and terms of particular

importance

indicates a necessary work step

Icons

Typographic

conventions

Hardness Tester

Introduction

DuraJet 10 G5

1-7

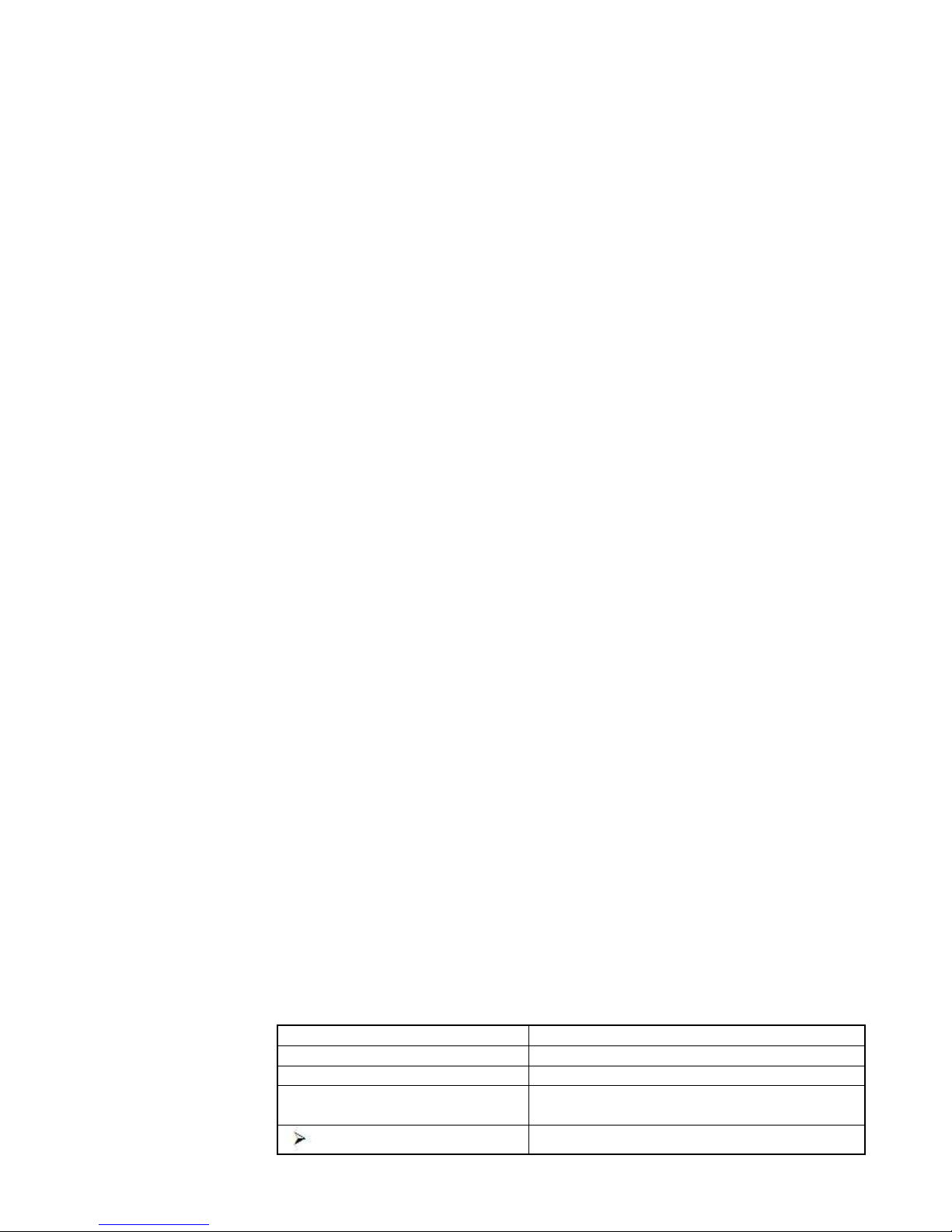

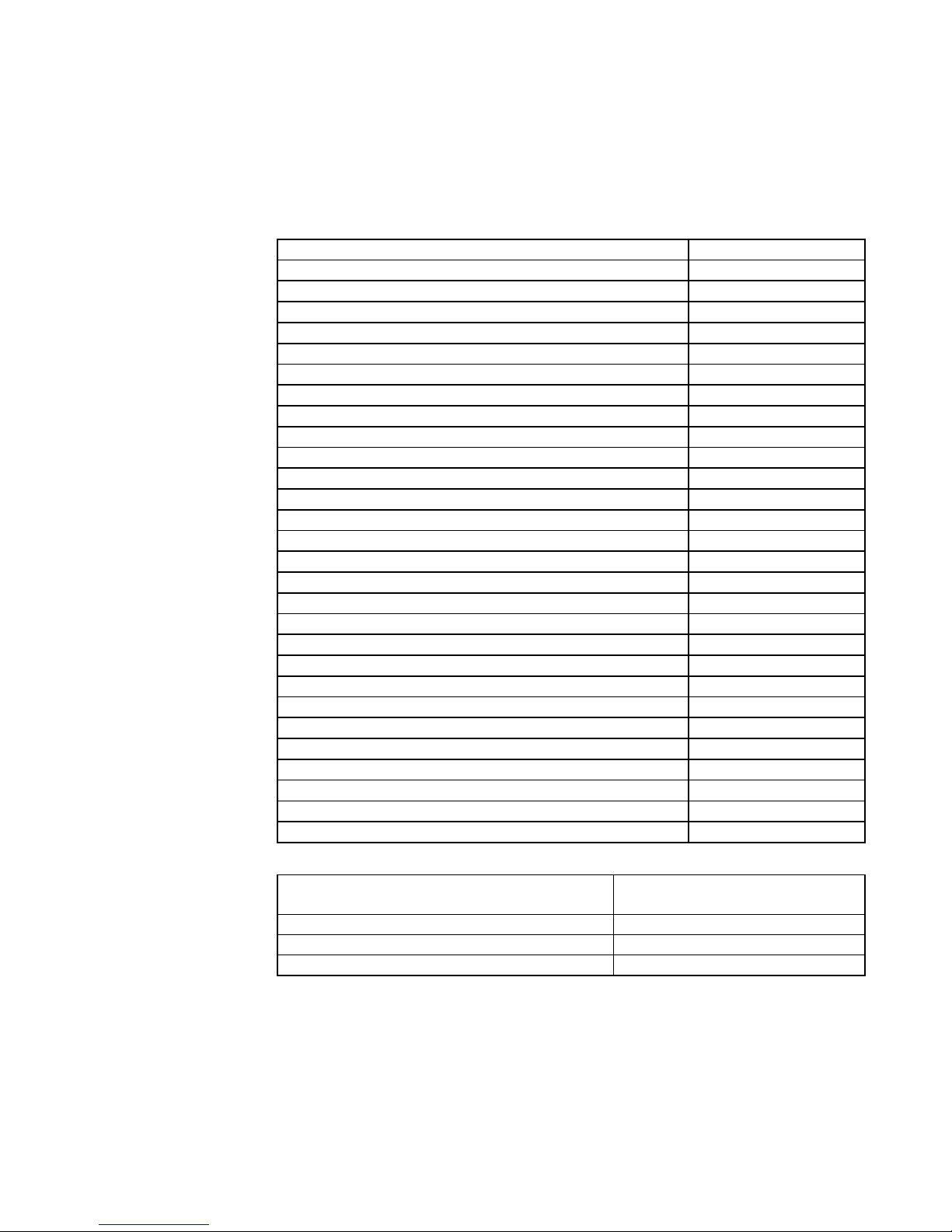

1.5 Technical Data

Test loads

[N]

9.8-2450N

[kgf]

1-250kg

Test anvil/nose cone/test unit

Test unit drive [1]

DC motor

Standard support [mm]

Diameter 25

Nose cone support [mm]

Diameter 15

Nose cone drilling [mm]

Diameter 8

Test anvil dimensions

Width x depth [mm]

180 x 185

Throat depth [mm]

175

Test height [mm]

260

Max. weight of workpiece [kg]

100

Power supply [V]

110 V / 230 V

Max. voltage fluctuations [%]

+6/-10

Frequency [Hz]

50/60

Max. power consumption [W]

max. 120 W

Main fuse rating at 230 V [A/T]

T 6.3 A

Main fuse rating at 110 V [A/T]

T 6.3 A

Touch screen [inches]

7 in.

Dimensions

Basic unit (WxHxD) [mm]

300x740x562

Footprint (WxD) [mm]

700x900

Weight of basic unit [kg]

approx. 110

Ambient conditions

Room temperature [°C]

5-40

Rel. humidity (non-condensing) [%]

up to 90

Protection category EN60529 [1]

IP20

The machine adjusts automatically to the voltage variant.

Voltage

230V~1/N/PE 50/60 Hz

110V~1/N/PE 50/60 Hz

Max. voltage fluctuations

+6%/-10%

Power consumption

120 W

Fuses

T 6.3 A

Technical data

Electrical power supply

Hardness Tester

Introduction

DuraJet 10 G5

1-8

DANGER

Electric current

Connect the machine only to a grounded electrical outlet with a protective earth

conductor contact.

Any intervention in the electrical/electronic part of the unit is prohibited.

Circuit diagram

Hardness Tester

Startup

DuraJet 10

2-1

2 Startup

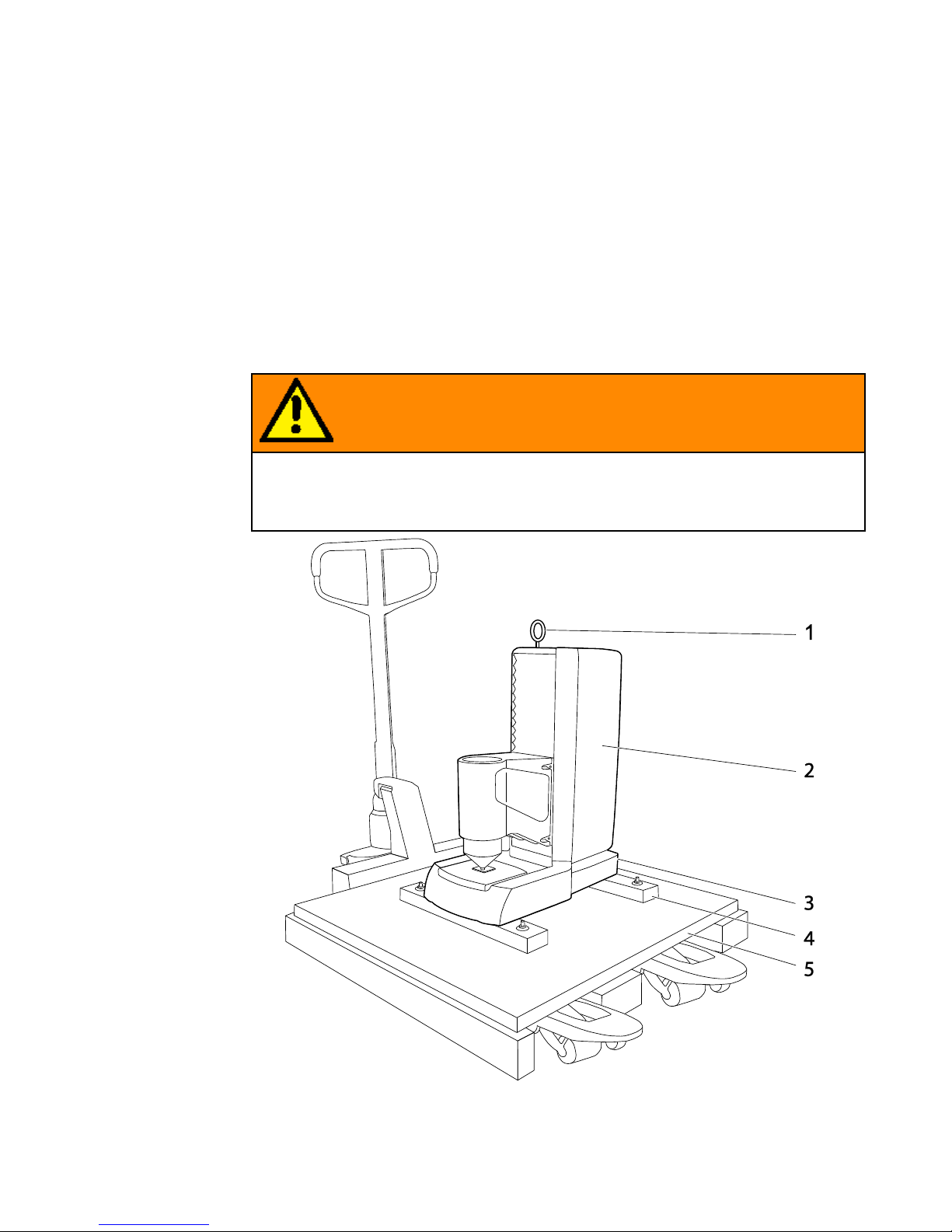

2.1 Transporting the Machine

The machine is delivered on a pallet. Its outer packaging varies depending on the

country of delivery and the delivery agreements.

Remove the packaging.

Use a lifting vehicle to move the machine on the pallet.

WARNING

Overturning parts with improper transport.

Severe injuries from overturning parts.

Secure the unit with bolts on the pallet.

Transport the unit only on the pallet and with a lifting vehicle.

Unpacking the machine

Hardness Tester

Startup

DuraJet 10

2-2

1

Ring bolt with 10 mm thread for transportation by crane

2

Hardness testing machine

3

Serial number of the unit

4

Transportation rails

5

Pallet for transporting with lifting vehicle

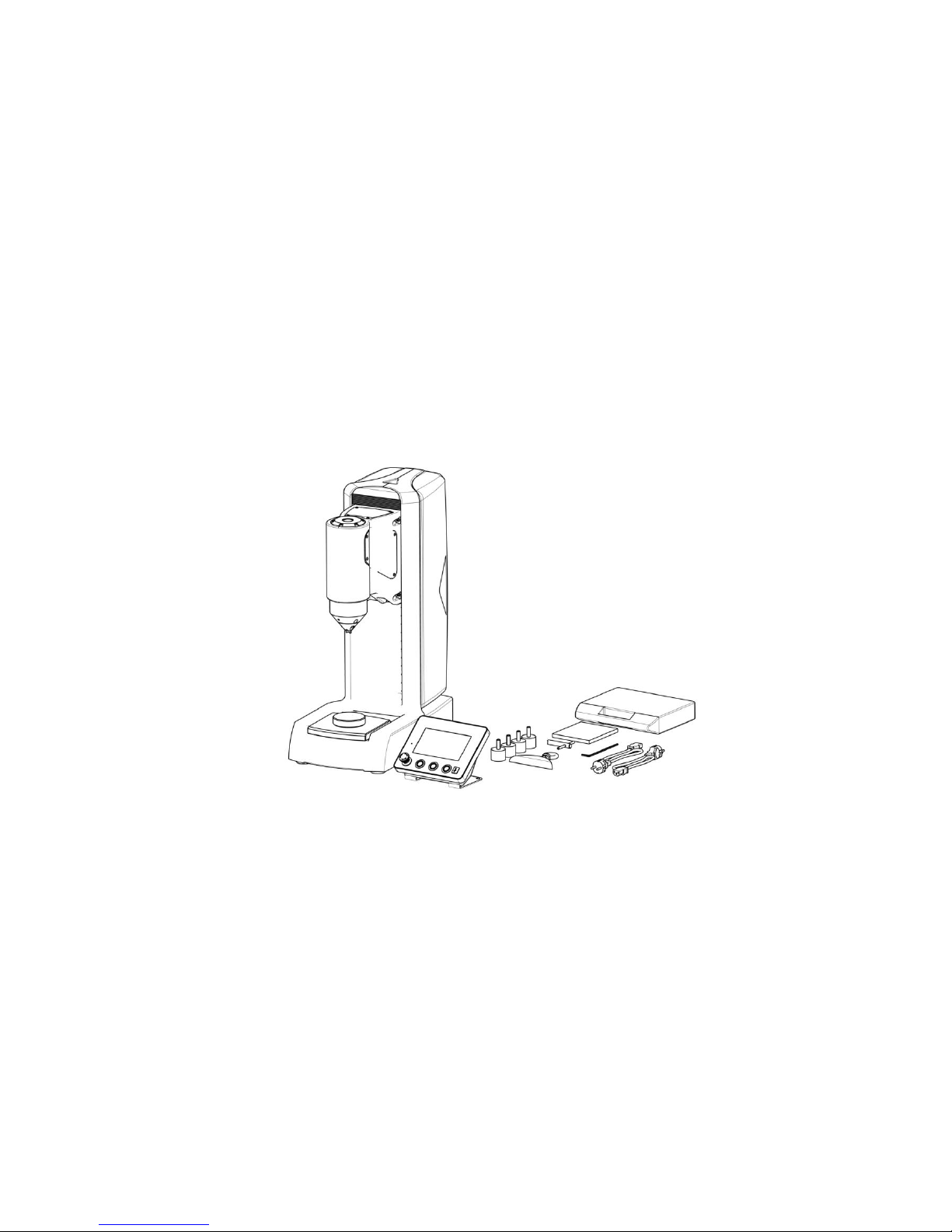

2.2 Scope of Supply

▪ Inspect the machine for any damage that may have occurred during transportation,

and check the delivery for completeness.

▪ If you detect any defects or discrepancies, contact your supplier or insurance

provider immediately.

▪ Please specify the serial number of the machine when you make a complaint. You

can find this serial number on the rating plate at the rear of the machine.

▪ Hardness tester with mounted nose cone

▪ Standard XY table DM 90mm

▪ Control part with 7-in touch screen

▪ 4x feet

▪ Cover for ring-bolt hole

▪ 2 power cables (EU/US plugs)

▪ 2 replacement fuses (slow-blow 6.3 A)

▪ 1 socket head wrench (Allen wrench)

▪ 1 socket wrench for changing the indenter

▪ CD-ROM with machine data, certificate and documentation

▪ Ring bolt

Optional accessories

▪ Indenter

▪ Nose cone

▪ Test anvils

Inspecting the delivery

Hardness Tester

Startup

DuraJet 10

2-3

If you ordered an indenter, it is included in the delivery and must be mounted.

To order additional accessories and replacement parts, contact your supplier. Only

approved products have been tested for use with this machine.

▪ Calibrated test blocks

▪ Test anvils

▪ Nose cones

▪ USB printer

▪ USB hub

▪ USB flash disk (USB stick)

Hardness Tester

Startup

DuraJet 10

2-4

2.3 Weight and Dimensions

excluding pallet and transportation rails: approx. 110 kg

including pallet and transportation rails: approx. 150 kg

2.4 Installing the Machine

Weight and dimensions

Lifting the machine off

the pallet

Hardness Tester

Startup

DuraJet 10

2-5

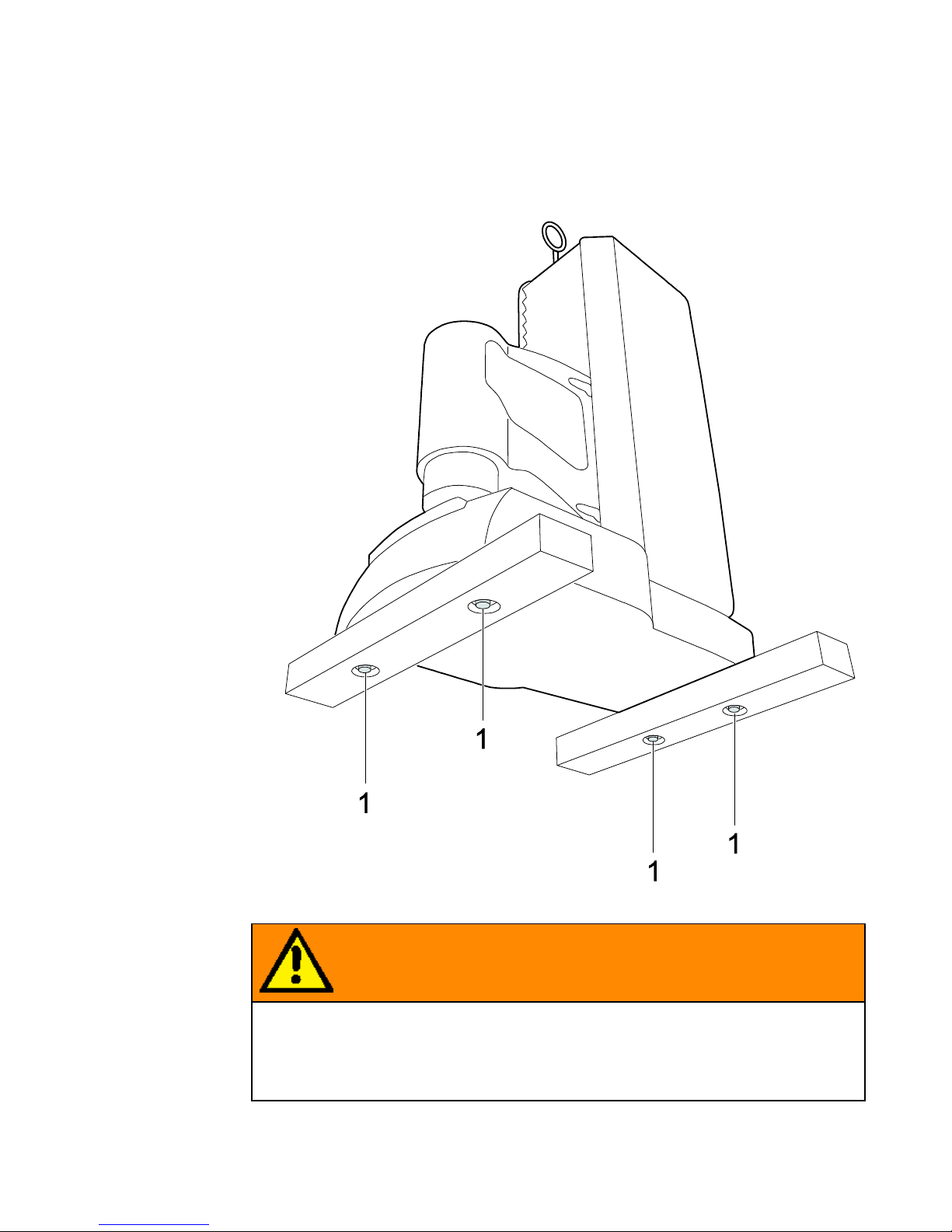

Loosen the four fastening screws (1).

Use a crane to lift the machine off the pallet by the ring screw.

Hardness Tester

Startup

DuraJet 10

2-6

Two transportation rails are screwed onto the machine in place of the feet.

Use a crane to lift the machine.

WARNING

Dropping parts.

Severe injuries of head and limbs.

When using a crane for lifting, never exceed the maximum lifting capacity of the rope or

chain.

Ensure that nobody stays under the suspended load.

Put down the unit on 2 assembly stands.

Remove the screws (1) fastening the transportation rails and remove the rails.

Removing the

transportation rails

Hardness Tester

Startup

DuraJet 10

2-7

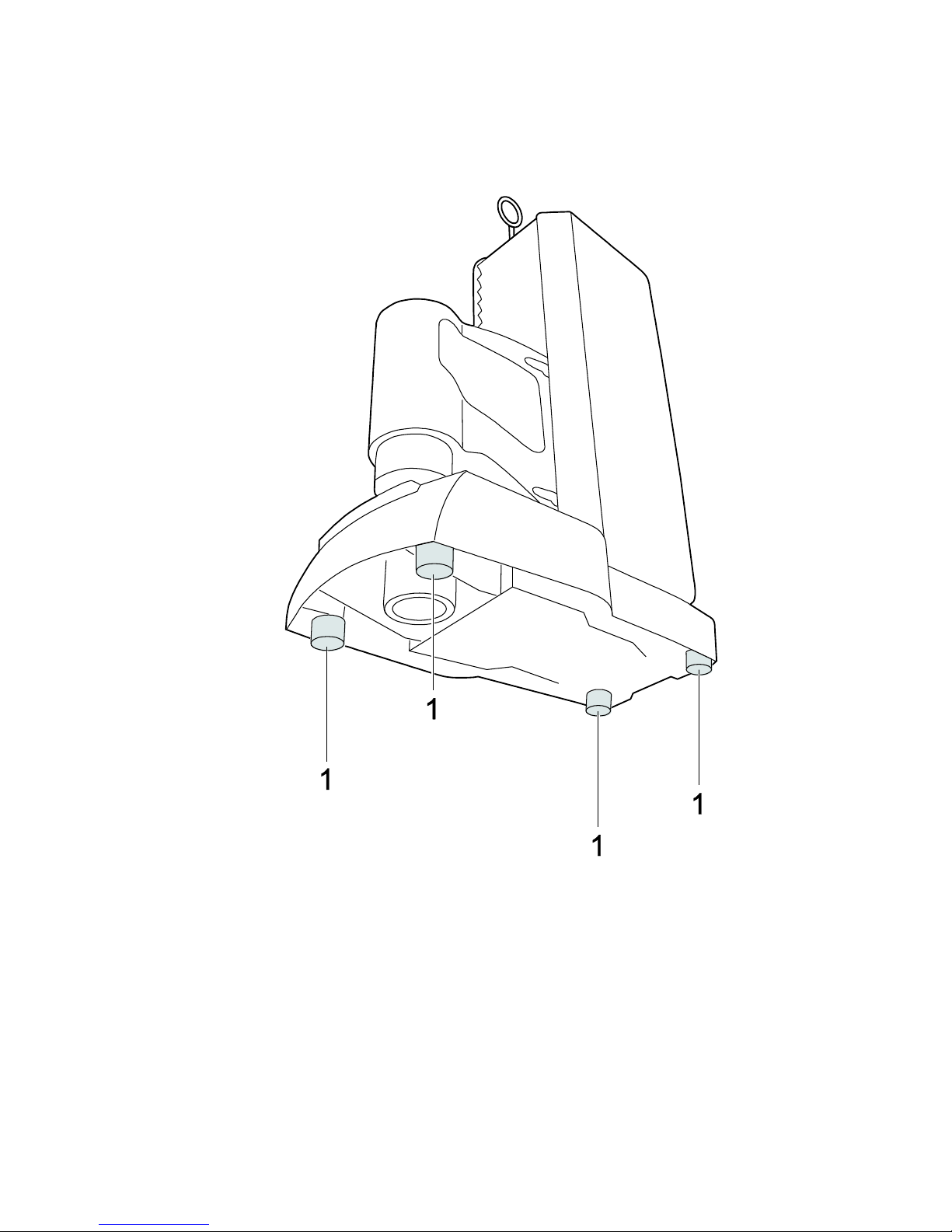

Screw the feet provided (1) to the unit while the unit is still suspended from the

crane and is supported by the assembly stands.

Otherwise, it is difficult to attach the feet because the unit weighs 110 kg and lies flat on

any surface when the feet are not attached.

The bench on which the machine is installed must meet the following requirements:

▪ The bench must be level and have a height of approx. 700 mm.

▪ It must be capable of supporting at least 220 kg.

During installation, allow sufficient space for operating the machine and for carrying out

possible maintenance work.

The machine must be professionally installed.

Attaching the feet

Installing the machine

Hardness Tester

Startup

DuraJet 10

2-8

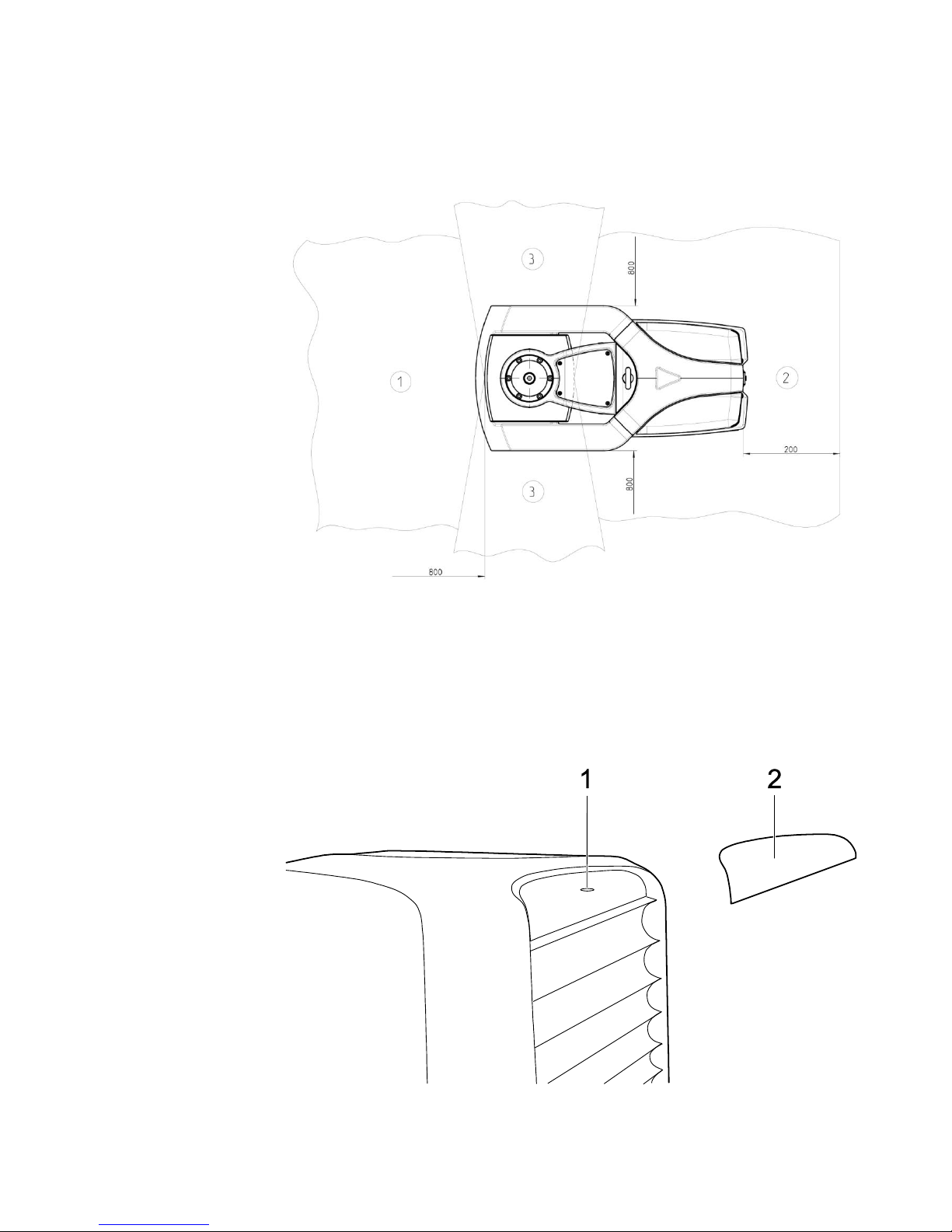

1

Space required for operation

2

Space required for maintenance

3

Space required for workpiece feed

The machine's ergonomic design is intended to optimize operation.

▪ During installation, ensure that the work station has adequate lighting.

▪ Avoid direct glare (dazzling light sources within the operator's line of vision) and

reflected glare (reflections and light reflexes) on the touch screen.

Remove the ring bolt.

Secure the cover (2) over the ring bolt (1).

The cover is supplied with a Velcro fastener.

Attaching the cover

Hardness Tester

Startup

DuraJet 10

2-9

2.5 Initial Startup

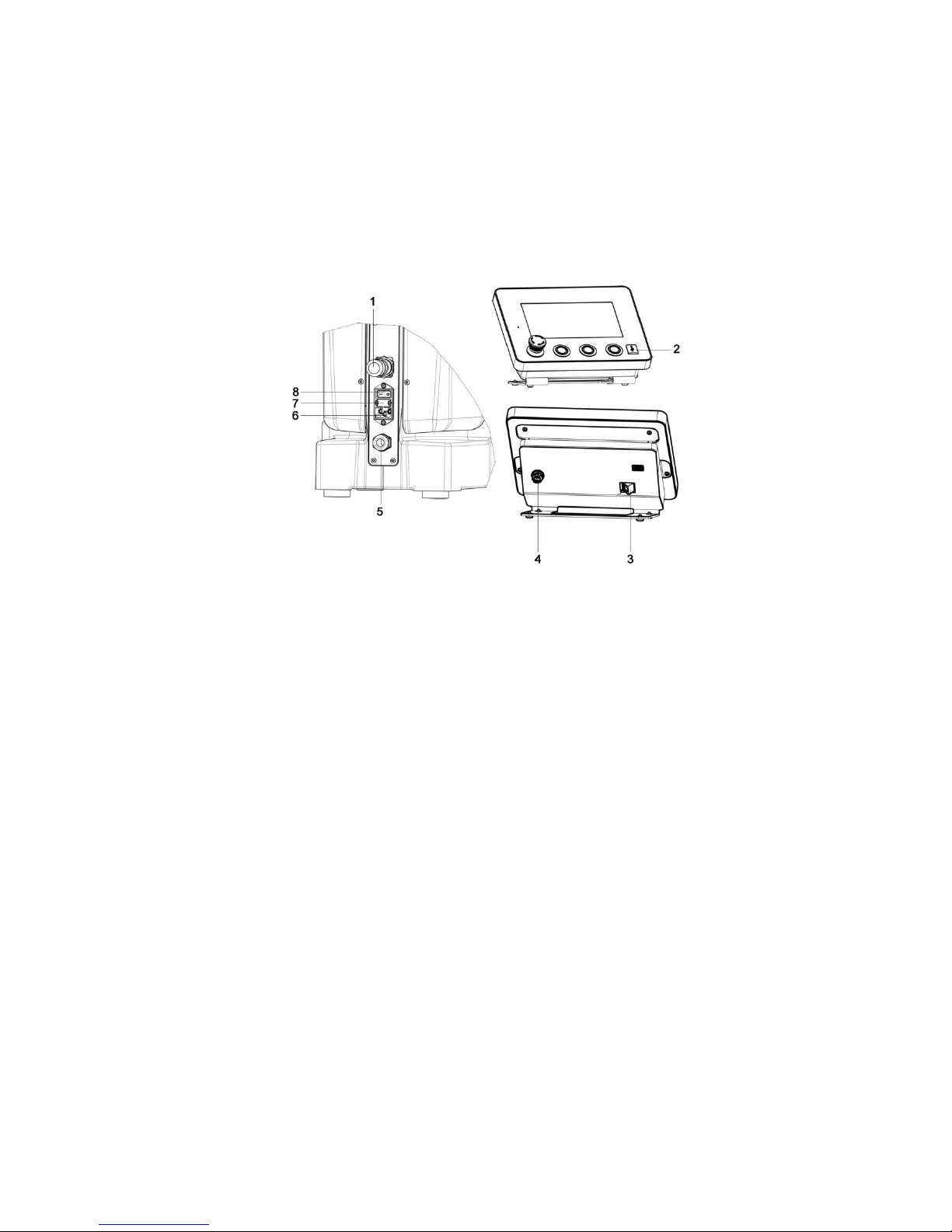

Connections on the units

1

Hardware interface (option)

2

USB connection

3

Ethernet interface

4

Control unit connection

5

Control unit connection

6

Mains connection

7

Fuses

8

Main ON/OFF switch with indicator lamp

Turn the main switch to OFF.

Plug the connector of the fixed control unit cable into the connection on the control

unit.

Ensure that the control unit cable is firmly screwed into place.

Plug the power cable into the mains connection.

Plug the opposite end of the power cable into a grounded electrical outlet with a

protective earth conductor contact.

Turn the main switch to ON.

To release the EMERGENCY OFF button on the control unit, turn it clockwise.

The software starts the initialization process.

Connecting the unit

Switching on the unit

Hardness Tester

Startup

DuraJet 10

2-10

After one to two minutes, the initial screen appears on the touch screen monitor of the

control unit, followed shortly afterwards by the main menu.

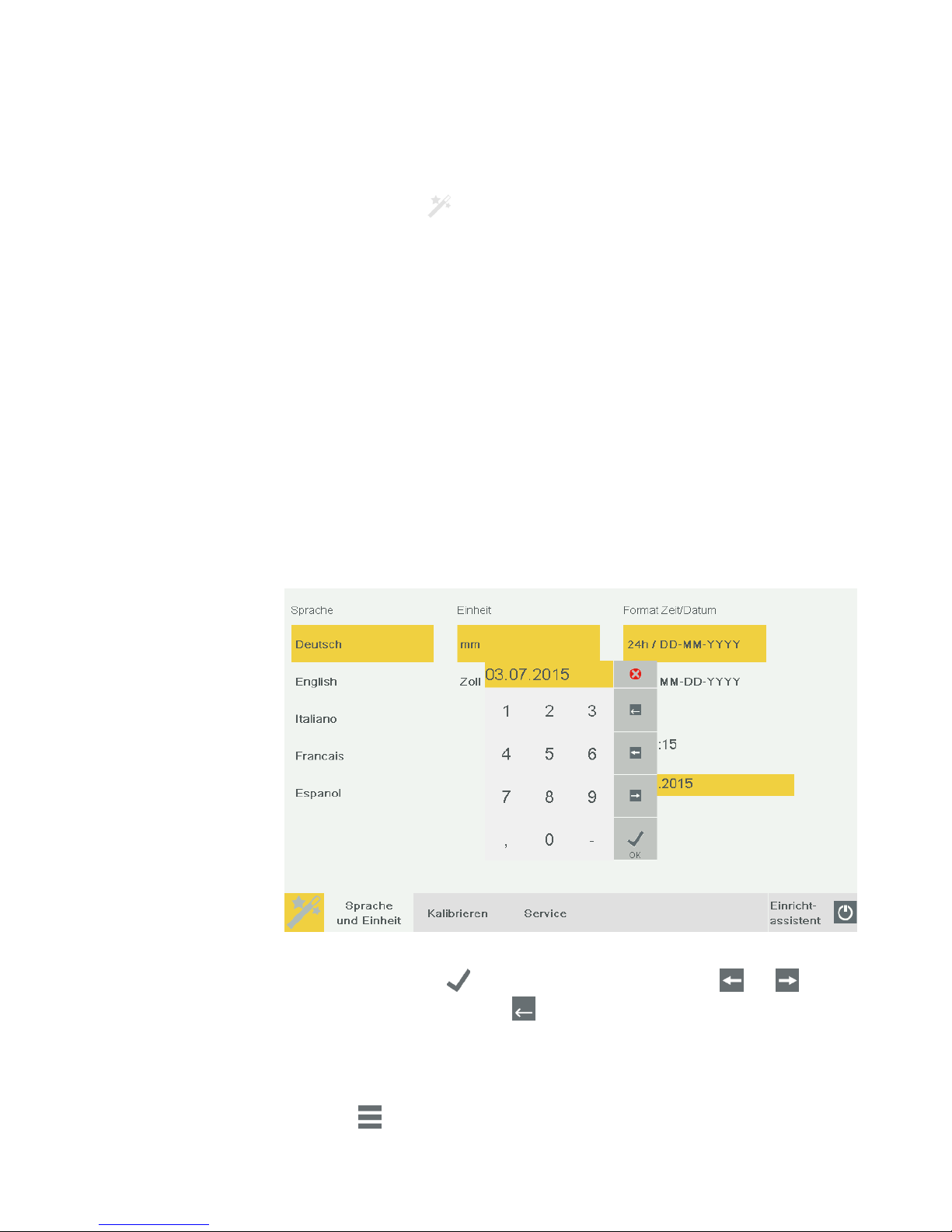

The default language of the software is English. If you want to use the software in a

language other than English, you must configure this first.

Select the button with your finger or with the touch pen.

The following screen appears on the touch screen monitor:

Select the button Settings.

Selecting language units

Hardness Tester

Startup

DuraJet 10

2-11

Select the button Open.

Select the language German.

Select the unit mm.

Language and unit have been selected.

Select data and time in the right column.

Select Time or Date.

Enter the current data and time in the numeric box. Touch the button to abort

the input. Touch the button to confirm the input. Touch the and buttons

to move the cursor. Touch the button to delete the number to the left of the

cursor.

Date and time are selected and the settings are completed.

Touch the button back to configuration.

Touch back to measuring.

Hardness Tester

Startup

DuraJet 10

2-12

The three buttons Nose Cone Up, Nose Cone Down, and Start Testing on the control

unit are only active when measuring mode is activated.

Select the Testing button with your finger or with the touch pen.

The unit is now operating in a measuring mode and you can use the Nose Cone Up,

Nose Cone Down buttons on the control unit to move the test unit up or down.

Touch the Test button

DANGER

Risk of crushing from dropping test unit.

Crushed hands, arm, or fingers.

Keep your hands away from the area around the moving test unit.

Use the Nose Cone Up button on the control unit to move the test unit upwards

until you can easily reach the nose cone.

Remove the transportation safety device (cardboard padding) from the test anvil.

If you ordered an indenter, it is included in the delivery and must be mounted.

Caution

Use the main switch to turn the tester off before mounting or dismounting the indenter.

Turn the main switch to the OFF position.

Activating the

measuring mode

Mounting the

indenter

Loading...

Loading...