Page 1

Page 2

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 2 of 36

Table of Contents

1. Preface .............................................................................................3

2. Characteristics ................................................................................4

2.1. Functional Description.............................................................4

2.2. Safety Considerations & Quality..............................................6

2.3. Connections.............................................................................8

3. Properties of the DPSI TWIN Mini................................................ 11

3.1. Data Logger...........................................................................12

3.2. Functional Principal of the Switching..................................... 13

4. Packing Contents..........................................................................16

5. Mounting Details ...........................................................................16

5.1. Mounting of the DPSI TWIN Mini...........................................16

5.2. Connecting the Receiver ....................................................... 17

5.3. Arranging the Antennas.........................................................18

5.4. Current Supply and Servo Connections ................................ 19

5.5. Failsafe Channel....................................................................25

6. Beginning of Operation ................................................................ 25

7. Error Indications ...........................................................................26

8. Programming.................................................................................27

8.1. Firmware-Update...................................................................29

9. Application Examples...................................................................30

10. Safety Instructions...................................................................... 32

11. Technical Data of the DPSI TWIN Mini ...................................... 33

12. Warranty.......................................................................................34

Page 3

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 3 of 36

1. Preface

With the DPSI TWIN MINI you purchased a high grade, modern and

secure product for your valuable radio controlled model. We apprec iate

your trust and assure you that you made the right choice!

Long lasting experience for years in development and manufacturing of

electronically systems as well as the knowledge of the world’s best

model airplane pilots has influenced the development of the DPSI

TWIN MINI systems. All products are manufactured at EMCOTEC

GmbH in Germany on our own pr oduction line. Extensive optically and

electronically end tests for every system, which leaves our house,

assure that you, our customer, acquire an absolute reliable product

which considerably increases the reliability of your valuable RC-Model.

Of course, the DPSI TWIN MINI not only has been tested extensively

in the laboratory, but also went through intensive flight-testing. Like

done in the automobile industry an FMEA (failure mode and effect

analysis) reduces the possibility of damage and malfunction on

operating errors to a minimum.

Hint:

We kindly ask you to read these instructions carefully and to observe the

installation hints. Thus, errors can be avoided in advance.

We are all ears for your wishes and questions. Challenge us!

Bobingen, September 2007

The Staff of EMCOTEC GmbH

Page 4

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 4 of 36

2. Characteristics

2.1. Functional Description

The DPSI TWIN Mini provides a kind of ”Receiver diversity“. Two

receivers can be connected. The receiver with undisturbed radio

reception provides for the servos signals. If this receiver fails, the

signals for the servos are provided from the other undisturbed receiver

by automatic switch over. Therefore, the model remains fully

controllable if a receiver fails. In summary, 16 channels are switched

completely. The DPSI TWIN Mini can be operated stand-alone or in

conjunction with the battery-switches from then EMCOTEC’s DPSI

product range.

Several applications are possible with the DPSI TWIN Mini:

1. Failsafe-Function “A“:

(Two identical receivers using same frequency)

If one receiver fails, all (!) servos are switched to the second receiver.

The pilot can continue his flight without disturbances or adverse

effects. The receivers should feature a failsafe function (e.g. PCM).

Even by using two PPM (or IPD) receivers without failsafe capability,

switching of the servo signal can occur caused by a disturbed (or

missing) servo signal.

2. Failsafe- Function “B“:

(Two receivers using different frequencies, e.g. using the EMCOTEC HF TWIN)

If one receiver fails OR channel double-allocation occurs, all servos are

switched to the second (backup) receiver.

3. Pilot-Backup:

(Two receivers and two transmitters using different frequencies)

If the receiver OR the transmitter of the pilot fails, all servos are

switched to the second (backup) pilot. He can then land the model

safely.

Page 5

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 5 of 36

4. Teacher-Student-Function:

(Two receivers and two transmitters using different frequencies)

The teacher switches between his and the students radio back and

forth by using a switching channel of his transmitter. The student can

now take over all functions of the model with his transmitter (passing

single

functions to the student are not possible). The teacher can gain

full control with one single switching event in critical situations.

Herewith, each model-pilot can fly his friend’s model (which has

installed the DPSI TWIN MINI) with his own radio using his own stick

assignment. He just must program the model parameters into his radio.

5. Autopilot for Drones (UAV´s):

(Regular remote radio control and an autopilot)

The pilot switches between the receiver and the autopilot by using a

switching channel on his radio. The drones therefore can takeoff and

land under control of a regular remote control and be switched to the

autopilot on demand to fly its corresponding program.

Additional Functions:

Additionally, the DPSI TWIN Mini works as data logger, i.e. all

operation relevant data of the last flight are stored in non volatile

memory. The data can be read by a PC afterwards. The cause of an

eventual crash (failsafe signals, number and duration of receiver

disturbances) can be evaluated from the stored information.

Two built in bicolor LED’s indicate optically the operational state of the

DPSI TWIN Mini. In order to receive additional information about the

status of the entire system, the optional DPSI ICE (Information Ce nter),

an external LED or the DPSI LCD can be connected to the DPSI TWIN

Mini.

Page 6

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 6 of 36

2.2. Safety Considerations & Quality

Exclusively highly modern electronically parts are used in the DPSI

TWIN Mini. Electronics are built in as safe as possible in all areas of

the product. All vendor parts such as PCB’s, cables, connectors, etc.

are provided by German companies. The elaborated manufacturing of

the housing provides for best EMC safety, which is especially important

for drones usage. The 4-multilayer PCB allows for highest packing

density and therefore for smallest dimensions and low weight.

Maximum safety is also guaranteed by elaborated software quality

assurance. Individual measuring systems were developed for

qualification, which were used for signal conditioning and analysis.

Thinking about quality continues all the way through manufacturing.

Each step in production is monitored and each system is tested for all

its functions before leaving the house.

Quality over Quantity!

Hint:

The following parameters are factory programmed:

Operating Mode: Failsafe

Fail-Position = 1200µs (ca. –75% of Servo Channel)

Pass-Position = 1800µs (ca. +75% of Servo Channel)

If other parameters are desired, programming is in order (see programming

instructions). The default values best correspond to the +100% and -100%

settings of the failsafe channel of the receiver. Reprogramming of these values is

therefore not mandatory.

Page 7

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 7 of 36

Page 8

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 8 of 36

2.3. Connections

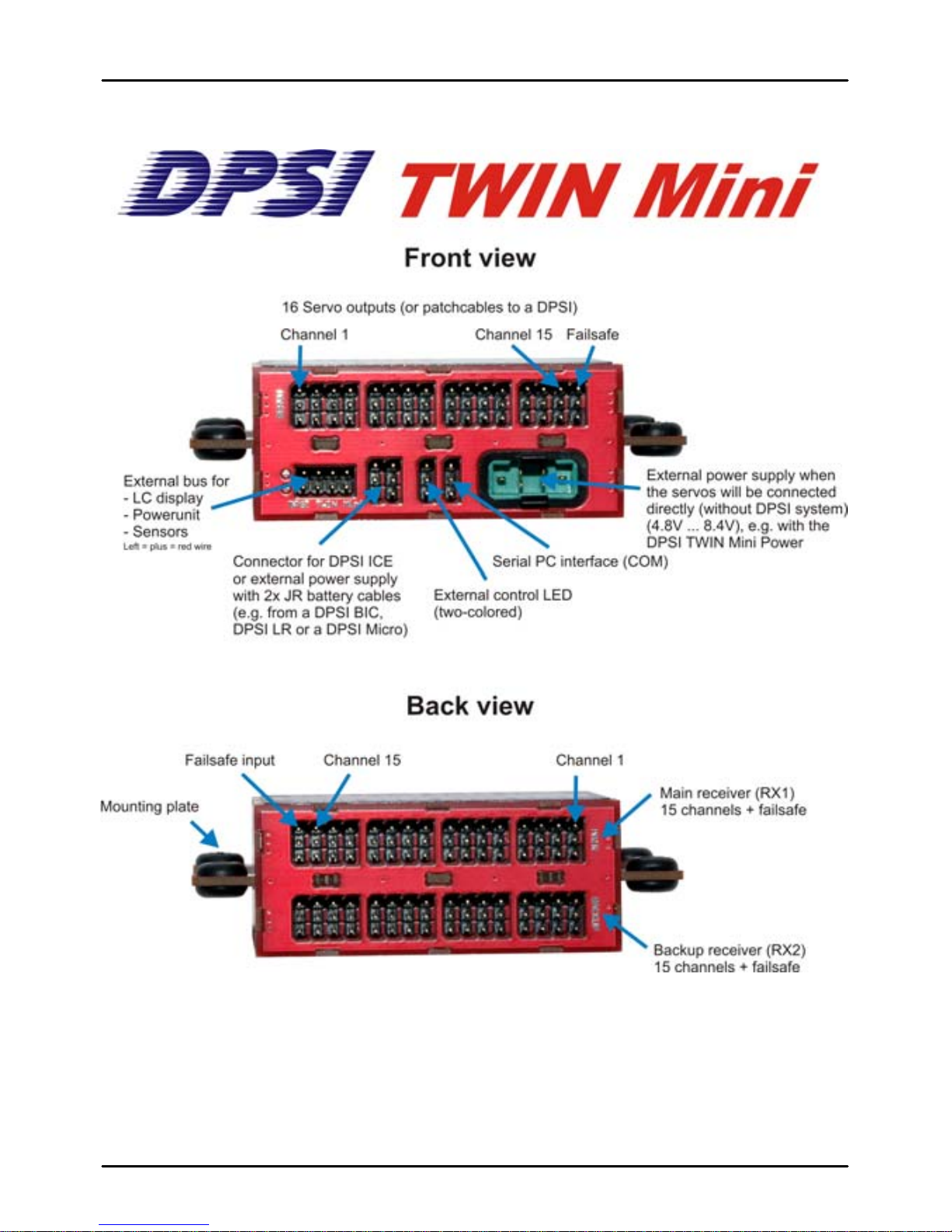

Rear View:

You find pin-connectors at the rear for both receivers (or r eceiver and

autopilot). There are 16 connectors each for the “main”-receiver as well

as 16 connectors for the “backup”-receiver or autopilot respectively.

The connectors are JR/UNI compatible.

The 16

th

connector functions as the failsafe-input at the same time

(“FS1” or “FS2”). The failsafe signals of the connected receivers are

evaluated by the DPSI TWIN Mini internall y for switch-over. As long as

the signals value is larger than 75% (percentage of the corresponding

servo channels) the receiver is considered error free. As soon as the

signal drops down to less than 75%, the DPSI TWIN Mini recognizes

an error condition (failsafe) and switches all 16 servo signals to the

error free receiver.

Page 9

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 9 of 36

If the failsafe pulses are totally missing or are out of specification, this

is recognized as an error condition too. The 75% values are factory set

and can be reprogrammed at any time.

The receivers are connected to the DPSI TWIN Mini using the

accompanying patch cables.

Hint:

Both connected receivers are supplied by the DPSI TWIN MINI via the patch

cables. The battery connectors of the receivers ALWAYS remain unused!

Front View:

You find the pin connectors of the outputs in the upper row

(connections to servo current distribution or to the servos directly).

Page 10

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 10 of 36

When using a DPSI RV system the patch cables are here connected to

the DPSI. Servos can be directly connected if an optional current

supply is available.

You find in the lower row (from left to right):

AUX1 and AUX2:

here, optional products from the EMCOTEC product

range can be connected (LC display, bridging PCB for th e DPSI power

part, external sensors for RPM, temperature, height, velocity, etc.).

B1 and B2:

connection for the optional DPSI ICE. Furthermore, an

external power supply can be connected, if the DPSI TWIN Mini is to

be used stand-alone (without current distribution), i.e. the servos are

directly connected. For instance, a DPSI BIC, a DPSI LR or a DPSI

Micro can be used as power supply.

EXT:

connection for an optional external bicolor LED, which can be

mounted in the fuselage’s sidewall, providing information about the

current status of the DPSI TWIN Mini (see error indications).

COM:

connection for the RS232 interface cable to a PC (COM

interface) or using an optional USB convert on an USB port of the PC.

Using the PC software, the parameters of the DPSI TWIN Mini can be

programmed and the data logger can be read. Furthermore, new

firmware can be downloaded.

Opt. Bat:

here, an external power supply can be connected if the DPSI

TWIN MINI is being used in the stand-alone version and if the servos

are directly connected. If many servos are to be used, this connection

is to be preferred over the B1 B2 connections. 15A continues current is

possible. The external power supply can be an optional DPSI power

part (contacting a bridging PCB) or a current source ranging from 4.8

volts up to 8.4 volts. Servos and receivers are supplied with this

voltage. Voltages of 5.2 volts up to 6.0 volts are reasonable.

Page 11

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 11 of 36

Hint:

If an external voltage is supplied to “B1” / “B2” or “opt. Bat”, the DPSI TWIN MINI

must not be connected to a servo current distribution!

3. Properties of the DPSI TWIN Mini

Failsafe operation with automatic switching between two receivers

with up to 16 channels each

Teacher student operation with manual switching between two

receivers using a switching channel on radio

“Pilot-Backup" using two separate frequencies possible (2

transmitters, 2 receivers)

Receiver/autopilot switching for drones

All control functions fully available after switching from one receiver

to the other

Failsafe positions freely programmable

Integrated PC interface for reading and programming of the data

and for software updates of the firmware

Data logger, i.e. important parameter of the last 22 (!) flights are

stored and can be read later by a PC

2 x 16 receiver channels

Integrated bicolor LED’s indicate status of the system

Two failsafe channels for evaluation of receiver function

Cable free system, i.e. all connections are pluggable and therefore

replaceable

Special grounding concept for flawless operation and highest safety

Future-proof concept achieved through extendibility (DPSI ICE,

DPSI LCD, DPSI Power, external sensors etc.)

Each system 100% tested prior to delivery

Page 12

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 12 of 36

3.1. Data Logger

The integrated data logger (“black box”) stores all relevant operati onal

data of 22 turn-on cycles (flights). Each time, the DPSI TWIN Mini is

turned on, a counter is incremented and the data logger advances one

entry. All data of the last 22 flights remain stored and a possible crash

can be analyzed even after some time (or after several turning on

cycles). Usually, one tests the radio right after a crash. This means, the

set is turned on and off several times, before the data is read off o f the

data logger at home using the PC.

Due to a turn-on counter, the number of cycles is known (since

purchase of the DPSI TWIN Mini). This provides for the real number of

flights of a model.

Page 13

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 13 of 36

The following data is stored by the data logger:

System-Information:

- Operating Mode (Failsafe or Teaching)

Receiver-Status:

- Number of errors for each receiver (pulse gap greater than

40ms => total malfunction of the receiver)

- Number of errors for each receiver (failsafe, pulse gap

smaller than 10ms, pulse width < 0.8ms, pulse width > 2.2ms

(failsafe only for PCM))

- Time in seconds, where both receivers were in an error condition

simultaneously

The data can provide for exposure of an eventual crash. It is recorded,

if both receivers are failing SIMULTANEOUSLY for e.g. 5 seconds.

This probably causes a model to crash.

3.2. Functional Principal of the Switching

Because two separate receivers are used with the DPSI TWIN Mini, it

must be able to recognize the necessity to switch from the first receiver

(“main”) to the second receiver (“backup”).

This happens based on any receiver output. This output is named

“failsafe output” in this document. For most PCM receivers (Graupner

JR PCM/SPCM as well as Futaba PCM1024), channels 1 through 8

are failsafe capable. Usually, channel 8 is used. Sets from Multiplex do

not use PCM, but rather call it the IPD function. Here too, each IPD

capable channel can be used for failsafe. But even non PCM/IPD

systems can be used with the DPSI TWIN Mini because a total

qualification of the signals takes place and not just only the evaluation

of the failsafe threshold alone.

Page 14

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 14 of 36

The failsafe outputs of both receivers connected to the DPSI TWIN

Mini are constantly monitored for thei r signal quality. If an e rror occ urs,

this error is qualified after a certain time. A single “one off” does not

lead to switching from one receiver to the other.

For better appreciation, it is helpful to understand how the signals are

provided by the receivers. Most of the remote controls on the market

as of today provide the servos a pulse length coded signal. All approx.

20ms (this is 50 times a second), the receiver sends a pulse to the

servo. Depending on the desired position of the servo, the pulse length

varies between 0.9ms and 2.1ms. In the center position, the pulse

length is 1.5ms, for end positions 0.9ms or 2.1ms respectively. The

DPSI TWIN Mini receives these pulses via the failsafe channels and

evaluates them. The following events are recognized as errors:

Error qualification in DPSI TWIN Mini qualification time

Pulse width is smaller than 0.8ms (100ms)

Pulse width is greater than 2.2ms (100ms)

Pulse gap is smaller than 10ms (100ms)

Pulse gap is greater than 40ms (400ms)

Pulse exceeded failsafe threshold (100ms)

In brackets: error qualification time, i.e. time, after which switching

takes places.

This shows, that also non-PCM-systems can be used, because not

only a certain programmed position (failsafe position) causes a switch

between the two receivers, but also an erroneous signal. If e.g. a

receiver totally fails, it doesn’t provide a signal on its outputs anymore.

The pulse gaps would be greater than 40ms. This is recognized and

switched to the other receiver after a qualification time of 400ms (if t his

one works error free).

Page 15

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 15 of 36

If the receiver provides for totally wrong signals (e.g. pulse length

greater than 2.2ms), this is also recognized and causes a switch over.

Switching only occurs, if the second (backup) receiver works error free.

If an error exists in the second receiver as well, no switching occurs.

Hint:

Due to a special algorism, it is impossible that switching occurs rapidly inbetween short intervals (which could lead to signal corruption). Each active

receiver remains active for a minimum period of time before switching can occur

(hysteresis).

Hint:

If switching occurred to the second receiver, this receiver remains active, even if

the first one should become error free.

Hint:

Due to the design of the hardware it is assured, that the servos are NEVER

supplied by both or none receiver. Only ONE receiver is connected to the servos

at any point of time.

Hint:

In order to test switching of the receivers the corresponding failsafe connector

can be pulled out from the DPSI.

If uncertain about the failsafe programming of the transmitter, you can connect a

servo in parallel to the failsafe signal. Now you can monitor the correct

adjustments immediately.

Page 16

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 16 of 36

4. Packing Contents

Content of delivery of the DPSI TWIN Mini

DPSI TWIN Mini base device

20 pieces receiver connection cables (17cm long)

(patch cables with servo connectors on both sides)

=> additional cables available in e-shop

Operating instructions (instructions in English language as

PDF for download from RC-Electronic Homepage)

EMCOTEC adhesive label

5. Mounting Details

5.1. Mounting of the DPSI TWIN Mini

Mounting on 4 silicon hoses has proofed to be the best technical

method. Mount the total packet onto 4 stilts in a shock absorbing

manner.

Mounting using 4pcs. M4 screws with pieces of fuel hoses:

Page 17

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 17 of 36

In general, always watch for vibration free mounting. Vibration damping

is especially important for the receivers, because they are much more

sensitive to mechanically vibrations than the DPSI TWIN Mini.

Holes spacing for mounting:

5.2. Connecting the Receiver

Although the DPSI TWIN Mini provides especially for connecting two

receivers, operation with one receiver (main) is possible. In this case,

the channel connections of the backup receiver will remain unused.

The DPSI TWIN Mini indicates an error for receiver two (backup

receiver) and will show this failure with the build-in LED in this case.

The actual purpose of the device is to connect two receivers. Because

the DPSI TWIN Mini can handle 16 channels, receivers with up to 16

channels can be connected. The failsafe channel is also “fed through”

and therefore is also available for additional functions.

Page 18

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 18 of 36

Of course, not all inputs of the DPSI TWIN Mini must be used. If only 5

channels are needed, 5 patch cables suffice for connecting the DPSI

TWIN Mini to the corresponding receiver (plus failsafe channel).

Hint:

When connecting a second (backup) receiver, all servo outputs must be identical

to the first (main) receiver. This means, no servo outputs must be swapped.

BOTH failsafe inputs of the DPSI TWIN Mini must always be connected, because

error recognition of the corresponding receiver takes place here.

Hint:

If the DPSI TWIN Mini is used in conjunction with an autopilot, the autopilot is

connected instead of the backup receiver. Servo connections must be identical to

the main receiver’s assignment.

5.3. Arranging the Antennas

When defining the positions of the antennas, make sure not to mount

the antennas in parallel. Best is a rod aerial for the mail receiver. Guide

the antenna first in parallel to the fuselage from the receiver, than in

90° to the rod aerial. Don’t change the total length of the antenna. If the

rod aerial is 20 cm / 8”, shorten the receiver’s antenna wire by 20 cm /

8”.

The antenna of the second receiver can either be wired to the elevator,

wired inside the wing (not recommendable due to the plug-in-tube) or

also ending in a rod aerial (eventually down wards). The distance

between the antennas should be as large as possible.

Page 19

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 19 of 36

5.4. Current Supply and Servo Connections

There are several ways to provide power to the equipment. This

depends on connecting the servos directly to the DPSI TWIN Mini or if

the DPSI TWIN Mini is to be used in conjunction with a current

distribution unit (e.g. a DPSI RV).

The most reasonable solution is to use a current distributor (e.g. DPSI

RV Mini 5 or Mini 6, DPSI RV, DPSI 2001 RV or other vendor’s

products).

Page 20

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 20 of 36

DPSI TWIN Mini in connection with DPSI RV Mini 5:

In this example, the DPSI RV Mini is used as a current distributor. The

DPSI TWIN Mini serves just as receiver switch and is supplied with

voltage by the DPSI RV Mini 5 via the patch cables. Both receivers are

supplied from the DPSI TWIN Mini via their patch cables.

Page 21

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 21 of 36

DPSI TWIN Mini in connection with DPSI 2001 RV:

Here too, the DPSI TWIN Mini serves as pure receiver switch and is

fully supplied by the DPSI 2001 RV’s patch cables. The DPSI 2001 RV

distributes 10 receiver-outputs to 26 servos. The SPCM receivers in

this example have 10 channels.

Channels 1 through 7 are connected to the corresponding channels of

the DPSI TWIN Mini. Channels 8 (failsafe capable!) of the receivers

are plugged into the failsafe inputs of the DPSI TWIN Mini. Connect

the failsafe output of the DPSI TWIN Mini to channel 8 of the DPSI

2001. It is (partially) available as servo output, too.

Channels 9 and 10 are therefore connected to inputs 9 and 10 of the

DPSI 2001 RV respectively.

Page 22

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 22 of 36

DPSI TWIN Mini in connection with DPSI RV:

The DPSI RV serves also as current source for the DPSI TWIN Mini

and both receivers. Because the DPSI RV provides 12 inputs,

receivers with 12 channels can be utilized (e.g. Futaba G3).

Page 23

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 23 of 36

DPSI TWIN Mini in connection with DPSI RV Mini 6 and additional ser v os:

If, in the case of using a DPSI RV Mini 5 (or Mini 6) in combination with

a DPSI TWIN Mini, 8 (or 7) servo connections of t he DPSI RV Mini ar e

not sufficient, additional servos can be connected directly to the DPSI

TWIN Mini.

In this example, all 10 receiver channels are used. 6 channels lead to

the DPSI RV Mini 6, which controls 7 servos (the most loaded servos,

like elevator, aileron, rudder, etc.). Additional 3 servos (e.g. throttle,

choke and landing gear) are directly connected to the DPSI TWIN

Mini. Now, 9 channels are fully usable, the 10

th

channel serves as

failsafe connection.

Page 24

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 24 of 36

DPSI TWIN Mini with direct connection of servos and external power supply:

In this example, the DPSI TWIN Mini is used in the stand-alone

version, i.e. without current distribution. The supply is realized via the

optional battery connector (MPX connection cable). Current source can

be e.g. a DPSI LR, DPSI BIC or a DPSI Micro. A direct connection of a

5-cell NiMH battery is possible (or any other current source with 4.8

volts up to 8.4 volts).

Page 25

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 25 of 36

5.5. Failsafe Channel

The failsafe channel (channel “FS1” or “FS2” of the DPSI TWIN Mini)

is also switched when changing to the error free receiver. Therefore, it

can also be used partially as remotely controlled channel.

If settings in the DPSI TWIN Mini are not reprogrammed, a receiver

will be recognized as error free, if the failsafe signal is greater than

1.8ms (+75% servo movement). The receiver is considered erroneous,

if the failsafe signal is lower than 1.2ms (-75% servo movement). The

range in-between is considered as “grey area”.

A receiver switch over therefore only occurs, if the failsafe signal is less

than 1.2ms (-75% servo movement). The failsafe position on the

transmitter therefore must be smaller than -75% (e.g. -80% or -100%).

The range between -75% and +75% is freely usable, because no

switching occurs here. If the failsafe channel is used, the servo must

only be operated in range from -75% up to +150%. It must be made

sure, that the servo path is not mechanically limited when reaching the

failsafe threshold.

6. Beginning of Operation

After turning on, the DPSI TWIN Mini passes the following phases (5

seconds duration):

Advancing the data logger entry and incrementing the turn-on counter

Polling the COM interface whether a PC communication is desired

(diagnosis mode or firmware update)

After a successful self-test, the DPSI TWIN Mini changes into normal

mode after 5 seconds. The built-in LED’s indicate the current status,

i.e. the “Main”-LED turns to green (see error indications). From now on,

the COM interface is inactive.

Page 26

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 26 of 36

7. Error Indications

There are two indicator LED’s built into the DPSI TWIN Mini (“Main”receiver and “Backup”-receiver). They are bicolor LED’s, which can

shine green as well as red (or mixed as kind of yellow).

In case of errors, the error indication is repeated approximately every

12 seconds. The integrated LED’s indicate the current status of the

DPSI TWIN Mini as follows:

System State LED “Main“ LED “Backup“

Main-receiver active green --Backup- receiver active --- green

Error in Main- receiver

(e.g. failsafe)

red LED blinks:

1x = 1 error

2x = 2 errors

9x = 9 errors

constantly =

more than 9

errors

Example: 5x

blinking means

“5 receiver

errors occurred“

green

Error in Backup- receiver

(e.g. failsafe)

green red LED blinks:

1x = 1 error

2x = 2 errors

9x = 9 errors

constantly =

more than 9

errors

PC communication red red

firmware update Quick alternating blinking red/green

Always, the receiver whose green LED is lit, is “active”, i.e. the

receiver’s servo signals are wired to the servo connectors (as well as

the failsafe channel!).

Page 27

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 27 of 36

Hint:

The error indication of the ”Main”-receiver only occurs in “failsafe”-mode. In

“teaching”-mode (teacher/student operation) switching between receivers is

desired, therefore no error is indicated from the „Main“-receiver. The “Backup”(or student-receiver) can indicate errors if the failsafe signal indicates

corresponding values.

In order to indicate errors, optional external indicators are available:

the “DPSI ICE” (Information CEnter of DPSI TWIN), the “DPSI LCD” (3line LC-Display with 3 buttons for changing display) as well as a bicolor

LED, which can be mounted at the fuselages sidewall. Displaying

capabilities of “DPSI ICE” and “DPSI LCD” are available from the

corresponding operating instructions.

Error indications of the optional external LED:

State of LED State of System

green System is turned on (Power-On)

red 1x blinking The Main-receiver was or is erroneous

red 2x blinking The Backup-receiver was or is erroneous

red 15x blinking

(fast blinks)

Supply voltage of the DPSI TWIN Mini is less than

4.8V. This is a critical range!

All of these errors are indicated until the power is turned off. Error

output is repeated every 12 seconds. In case of multiple errors, these

are output sequentially.

8. Programming

In order to adapt the DPSI TWIN Mini to desired requirements, all

relevant parameters can be programmed. The programming is non

volatile, i.e. programmed values remain in memory even after turning

the device off until eventual reprogramming occurs. Programming is

accomplished using an external PC via the COM interface of the DPSI

TWIN Mini.

Page 28

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 28 of 36

Programming using the PC:

You need the TWIN_MINI_ADMIN.EXE software. This program runs

under the Windows operating system and can be downloaded from

www.rc-electronic.com

or from http://shop.rc-electronic.com with no

charge. The program is self explanatory and has h elp-texts in Germ an,

English and French.

Hint:

The connection cable for the serial interface of the PC is not included in the

delivery and must therefore be ordered separately.

When delivered, the DPSI TWIN Mini is programmed in Failsafe-Mode.

A correct receiver is recognized, if the failsafe-pulse is ≥ 1.8ms (greater

than approx. +75% servo path), where as an erroneous receiver is

recognized if the failsafe-signal is ≤1.2 ms (less than approx. -75%

servo path).

Operating mode and pass/fail values can be changed using the PC

software.

The following explanations apply:

In failsafe mode, a signal reaching the failsafe value causes a switch to

the other receiver. Because this switch happens undesired (caused by

a disturbance of the receiver) an error is indicated (by LED).

In teaching mode, the switching is desired (if the “teacher” s witches to

or from the “student”). This switch is not indicated by an error.

For this reason, the DPSI TWIN Mini must be told, which operating

mode it is in.

Page 29

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 29 of 36

Hint:

In order to allow for correct switching in failsafe operation, the corresponding

channel (failsafe) in the transmitter (e.g. from Graupner JR) or at the receiver

(e.g. from Multiplex) must be programmed to failsafe of course (not in hold

mode)! Please see the operating instructions of your remote control.

Hint:

For programming of the pass/fail settings (or teacher/student settings), a switch

should be installed in the transmitter for this task in advance.

If channel 8 is to be used as the failsafe channel, a switch (preferably a switch,

which can not accidentally be toggled) in the transmitter must be programmed

such, that a servo at receiver output 8 has a position greater +75% in the “pass”

or “teacher” switch position and a position of less than -75% in switch position

“fail” or “student”. You can verify that easily in the transmitter’s menu “servo

position”.

When programming the values for the DPSI TWIN Mini using the PC software,

just bring the transmitters switch to the pass position. Then confirm the value.

Now bring the switch into the other (fail) position programming the fail value.

8.1. Firmware-Update

The built-in micro controller allows for loading new software versions

into the DPSI TWIN Mini (“Firmware-Update“). Here, a program named

TWIN_MINI_FLASH.EXE is to be used (available on the homepage for

download as well). Select the COM port first after starting the program.

In order to establish a connection to the DPSI TWIN Mini, the connect

symbol must be clicked within 5 seconds. Afterwards, the DPSI TWIN

Mini locks out PC communication.

Page 30

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 30 of 36

After a successful connection, the button “Get Hex File” appears. After

clicking, the Windows Explorer opens. Here, select the previously (from

the homepage) loaded firmware file with the “.hex” extension. If this file

is loaded, the “flash” button can be clicked.

Now, flashing starts (first deletion, then programming, then

verification). This event lasts about 3 minutes. Under no circumstances

remove power from the DPSI TWIN Mini during this time!

Hint:

The supply voltage must not be removed from the DPSI TWIN Mini during

flashing (firmware update) in any circumstances! This leads to data loss, which

can not be rolled back. If this happens, the device must be sent in to EMCOTEC.

9. Application Examples

Teacher/Student operation or Autopilot operation

Task:

The DPSI TWIN Mini is to be used as a teacher/student system. Here,

2 transmitters and 2 receivers equipped with different channels are

utilized. When using a drone control, only one transmitter and one

receiver as well as the autopilot system are used.

Procedure:

Define a free output on the teachers transmitter (e.g. servo output or

actuator 9) for switching from the teacher’s transmitter to the student’s

transmitter. Assign a free mixer to actuator 9. Both switching positions

of the switch are programmed in the transmitter according to the values

for the teacher (e.g. +100%) or student (e.g. -100%). Both positions

are to be verified by using the servo position display of the transmitter.

Page 31

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 31 of 36

Hint:

In teacher/student mode (or pilot backup) the receivers must have the

corresponding crystal which fits the transmitter’s channel. The student’s

transmitter (backup transmitter) must be programmed with the same model

parameters as the teacher’s transmitter, i.e. all servo-, mixer- and trim- settings.

Please verify all functions on ground IN ADVANCE!

Failsafe-System with Graupner MC24 (receiver PCM)

Task:

A MC24 transmitter with two SMC20 receivers with the same channel

is to be used.

Procedure:

Define a free output for failsafe switching on the transmitter (e.g. servo

output or actuator 8). Assign a switch to actuator 8 using a free mixer.

Both switching positions of the switch are programmed for pass (e.g.

+100%) and fail (e.g. -100%) corresponding to their values

respectively. Verify both positions using the servo position display of

the transmitter. Change channel 8 in the transmitter using menu

“failsafe settings” from “Halt” to “Pos”. Toggle the switch to the failsafe

position and store the value using “STO”.

You find additional instructions about failsafe programming in the

operating manuals of the corresponding manufacturers.

Hint:

For most radios, only channels 1 through 8 are capable of indicating failsafe in

PCM mode. This means, one of these channels is to be selected for switching

failsafe.

Hint:

In order to test the failsafe settings, it is reasonable to connect an additional

servo to the failsafe output of the receiver (“Main“ and/or “Backup“), e.g. using a

V-cable. According to the servo position, you can immediately see, based on the

position of the servo, whether the receiver outputs the correct failsafe signal in

case of a failsafe (turn off transmitter or dual channel assignment).

Page 32

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 32 of 36

Hint:

The easiest way to test switching between the receivers is to pull off the failsafe

patch cable from the failsafe pin connector of the DPSI TWIN Mini.

10. Safety Instructions

In general, all connecting lines should be run so that they do not

come into contact with moving or hot parts of the model (such as

servos, gears or mufflers).

The DPSI TWIN MINI must be protected from humidity and

moisture.

The DPSI TWIN MINI must be located at a sufficient distance

from neighboring surfaces to enable good heat dissipation of the

cooling element in case of using the optional power supply unit.

Improper handling of the DPSI TWIN MINI can result in serious

damage/injury to property or persons!

Carry out a general inspection of all connections in your model

before each use! All plugs must be correctly polarized and have

clean contacts (i.e. fit tightly). Loose cables present a potential

hazard!

Under no circumstances may power sources that do not meet the

specified voltages be used.

The current-conducting contacts of the connector plugs may not

be short-circuited. If you fail to observe this warning, the shortcircuited cables may overheat and even melt.

The DPSI TWIN MINI may not be taken apart or technically

altered under any circumstances.

Never use the DPSI TWIN MINI for purposes other than for RC

model making as a hobby. Above all, their use in passengercarrying equipment is strictly prohibited.

Operate the DPSI TWIN MINI only with the remote control

components provided for model making.

Page 33

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 33 of 36

Always ensure that you have fully charged batteries when

operating your model. Empty batteries inevitably lead to failure of

the RC components, which cause the model to crash.

Do not expose the DPSI TWIN MINI to any extremely hot or

extremely cold temperatures, moisture or humidity. This would

lead to danger of malfunction, damage or decreased efficiency.

11. Technical Data of the DPSI TWIN Mini

Supply Voltage 4.8V … 8.4V

Nominal Input Voltage 5.2V ... 7.4V

Quiescent Current (when “On”) ca. 15 mA total (without external wiring)

Max. continuous current using

“opt. Bat.“

25A

Max. continuous current using

“B1“ and “B2“

8A

Number of Receivers 2 receiver with 16 channels each incl. failsafe-channel

Servo Pulse Width

(nominal values)

0.8ms …. 2.2ms

Servo Pulse Width (error

recognition)

< 0.8 ms or > 2.2ms or

pulse spacing < 10ms or distance > 40ms

Number of Servos 16 servo outputs

Interface (Data) RS232 compatible (optional USB adapter available)

CE-Test according to 2004/108/EC

Environmental Conditions -10°C / 14°F... +50°C / 122°F (operating)

Permissible Temperature Range -25°C / 77°F.... +85°C / 185°F (storage)

Filtering (EMI) for 16 servo outputs

Dimensions incl. Flanges 88mm x 60mm x 28mm (L x W x H)

3.46” x 2.36” x 1.10” (L x W x H)

Screw Size for Mounting 4 x 4.2mm / 0.16” for M4 screws

Hole Spacing for Mounting 77.6mm / 3.06” x 48.2mm / 1.9”

Weight 82 grams / 0.18 lb

Warranty 24 month

Technical modifications and errors excepted!

Page 34

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 34 of 36

12. Warranty

EMCOTEC GmbH shall issue a 24 month warranty on the DPSI TWIN

MINI. The guarantee period shall begin with delivery of the equipment

by the retailer and shall be not extended by any guarantee repair or

guarantee replacement.

During the period of guarantee, the warranty shall cover the repair or

replacement of any proven manufacturing or material defects at no

charge. There shall be no specific entitlement to repair work. In case of

a guarantee claim, the manufacturer shall reserve the right to

exchange the equipment for a product of equal value if repair of the

item is not feasible for economic reasons. There shall be no

assumption of liability for consequential damages that are brought

about by a proven defect during operation of the DPSI TWIN MINI.

There shall be no extended claims for damages.

All transportation, packaging and travel expenses shall be borne

by the purchaser.

No liability shall be assumed for any damages during transport.

If repair is needed, the equipment must be sent to the appropriate

service center of the respective country or directly to EMCOTEC

GmbH.

The guarantee shall only be valid when the following conditions

are met:

The guarantee document (original invoice) must include the

delivery date, the company stamp, the serial number and

signature of the retailer.

No intervention in the equipment may have been undertaken.

It must have been operated in accordance with our operating

instructions.

Only the power sources and other accessory devices and

components that were recommended by us may have been used.

Page 35

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 35 of 36

The guarantee document, the original invoice and other pertinen t

information regarding the malfunction (a short description of the

defect) must be included with the transmittal.

The equipment must still be the property of the initial purchaser.

If equipment is sent in that later proves to be functional following

an initial inspection, we shall impose a flat processing fee of € 15.

In all other respects, the general business terms a nd conditions of

EMCOTEC embedded controller technologies GmbH shall apply

for any items not listed.

(P) Version 1.0 from September, 26 2007 Robert Hussmann

Page 36

DPSI TWIN Mini Operating Instruc tions Version 1.0

Page 36 of 36

Legal information:

Trademarks:

The following names are registered trademarks:

- EMCOTEC

- DPSI

- DPSI RV

Other product names mentioned in this manual may also be trademarks or registered

trademarks of their respective owners.

Copyright info rmation:

This manual is copyrighted by EMCOTEC GmbH. All rights reserved. This document may not

be copied either entirely or in part, nor may it be transferred to any type of medium or

translated into any other language without the express written approval of EMCOTEC GmbH.

Manual Note:

EMCOTEC GmbH reserves the right make changes to this manual and to equipment

described herein without notice. Considerable effort has been made to ensure that this manual

is free of errors and omissions. We shall n ot assume responsib ility or liability f or any errors th at

may be contained in this manual nor for any incidental, concrete or consequential damage that

may arise from the provision of this manual, or the use of this manual in operating the

equipment, or in connection with the performance of the equipment when so operated.

Loading...

Loading...