Emcotec DPSI RV Mini 5, DPSI RV Mini 6, DPSI RV Mini 5 Magic, DPSI RV Mini 6 Magic Operating Instructions Manual

Page 1

Bedienungsanleitung

Page 2

DPSI RV Mini Family Operating Instructions Version 1.0

Contents

1. Preface .............................................................................................4

2. History..............................................................................................5

3. DPSI RV Mini at a glance................................................................ 6

4. Overall layout ................................................................................ 11

5. Characteristics ..............................................................................12

5.1. Dual Current Supply .............................................................. 13

5.2. Electronically Switches..........................................................13

5.3. Detached Voltage Regulators................................................14

5.4. Servo Current Distribution ..................................................... 15

5.5. APP (Advanced Push Pull Servo Pulse Amplification).......... 15

5.6. HFIB (High Frequency Interference Blocking)....................... 16

5.7. Built-in V-Cable......................................................................16

5.8. Servo-Matching ("Magic" option only).................................... 16

6. Error Detection and Indication..................................................... 17

6.1. IVM (Intelligent Voltage Monitoring)....................................... 17

7. Safety Features of DPSI RV Systems..........................................18

8. Contents of Delivery .....................................................................20

9. Mounting Hints and Programming .............................................. 21

9.1. Mounting the DPSI RV Mini................................................... 21

9.2. Hole-Spacing for Mounting....................................................22

9.3. Mounting the Receiver...........................................................22

9.4. Connecting the Switch Actuator............................................. 23

9.5. Connecting the Receiver ....................................................... 27

9.6. Selecting Batteries.................................................................28

9.7. Soldering Battery Sockets ..................................................... 31

9.8. Charging the Batteries........................................................... 32

9.9. Setting the Voltages............................................................... 33

9.10. Programming the Batteries.................................................. 35

9.11. Connecting Servos .............................................................. 38

Page 2 of 54

Page 3

DPSI RV Mini Family Operating Instructions Version 1.0

10. Servo-Matching ...........................................................................39

10.1. Programming .......................................................................40

10.2. Changing Servo Direction....................................................41

10.3. Setting Servo Center ........................................................... 41

10.4. Setting End-Limits................................................................ 42

10.5. Deletion of all Programming ................................................ 43

10.6 Supplemental Hints for MAGIC-Version ...............................43

10.7. Changing the Model............................................................. 44

10.8. Sequence of Programming.................................................. 44

10.9. Limitation of Range Settings................................................44

10.10. Technical Data of Servo-Matching..................................... 45

11. Connecting Optional Products .................................................. 46

12. Operating .....................................................................................46

13. Error Indication ........................................................................... 47

14. Safety Directions.........................................................................50

15. Technical Data of DPSI RV Mini-Systems................................. 52

16. Warranty....................................................................................... 53

Page 3 of 54

Page 4

DPSI RV Mini Family Operating Instructions Version 1.0

1. Preface

With a DPSI RV Mini dual current supply from EMCOTEC you

purchased a high grade, modern and secure product for your remotely

controlled model. We appreciate your trust and assure you that you

made the right choice!

Long lasting experience for years in development and manufacturing of

electronically systems as well as the knowledge of the world’s best

model airplane pilots has influenced the development. All products are

developed by experienced engineers and manufactured at EMCOTEC

GmbH in Germany on our own production line. Extensive optically and

electronically end tests for every system, which leaves our house,

assure that you, our customer acquire an absolute reliable product,

which considerably increases the reliability of your valuable RC-Model.

Of course, the products not only have been tested extensively in the

laboratory, but also went through intensive flight-testing. Extensive

series of tests with especially in house developed data loggers have

been accomplished to measure the real current consumption in model

airplanes. Like done in the automobile industry FMEA (Failure Mode

and Effect Analysis) reduces the possibility of damage and malfunction

on operating errors to a minimum.

Hint:

We kindly ask you to read these operating instructions carefully and to

observe the installation hints. Thus, errors can be avoided in advance.

We are all ears for your wishes and questions. Challenge us!

Bobingen, October 2008

The Staff of EMCOTEC GmbH

Page 4 of 54

Page 5

DPSI RV Mini Family Operating Instructions Version 1.0

2. History

For all times, EMCOTEC was and is the leader in "safe current

supplies" around RC-Models. Novelties and developments were

initiated by EMCOTEC:

• First dual current supply with servo current distribution and

electronically switches (DPSI 2001)

• First and only "genuine" fail-proof switch actuator for current supplies;

no mechanical influences or microcontroller errors can lead to

malfunctions (DPSI pin switch actuator)

• First LiPo capable dual current supply with regulated output voltage

(DPSI RV Mini, DPSI RV)

• First provider of LiPo-Batteries for supplying receivers (LongGo und

LongGo „S“)

• First and only provider who's products output error information

acoustically (e.g. low voltage)

• First dual current supply with integrated receiver-switches worldwide

(DPSI TWIN)

• First remote control system which transmits in two different

frequencies (HF TWIN)

• First LiPo capable dual current supply with LC-Display for indicating

all relevant data (DPSI BIC)

• First electronically fuse with current monitor which shuts off defective

servos causing an overload (DPSI OCP)

• First electronically switches which are actuated contact free using a

magnet instead of any mechanically switching elements (e.g. push

buttons or switches)

• Smallest and most light weight LiPo capable dual current supply of its

class (DPSI Micro – DPSI RV)

• First receiver switch with 16 channels (DPSI TWIN Mini)

• First dual current supply with integrated receiver switch, 16 channels

and LC-Display (DPSI TWIN Maxi)

• First dual current supply with separate supply voltage for receiver,

servos and pulse amplifiers and integrated servo-matching (DPSI RV

Mini 5/6 Magic)

Innovation and Quality – Made in Germany by EMCOTEC!

Page 5 of 54

Page 6

DPSI RV Mini Family Operating Instructions Version 1.0

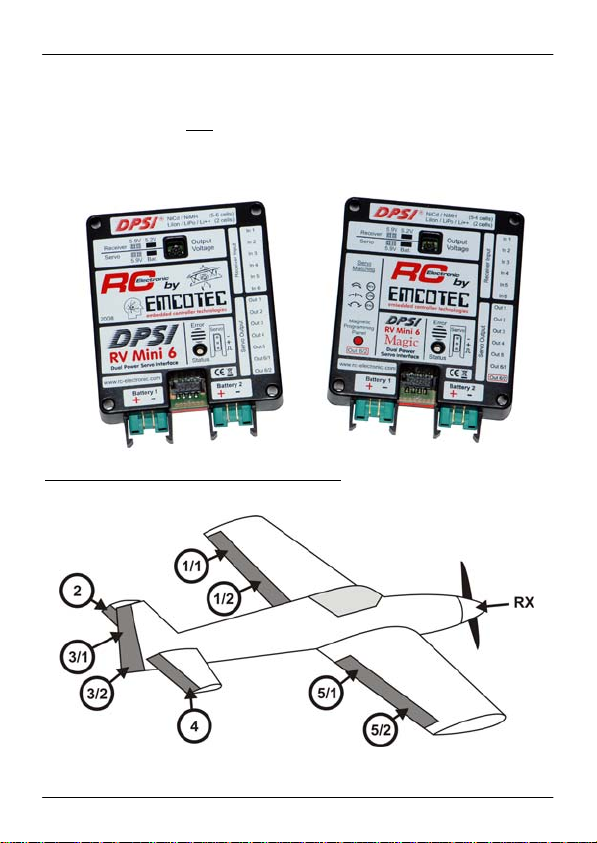

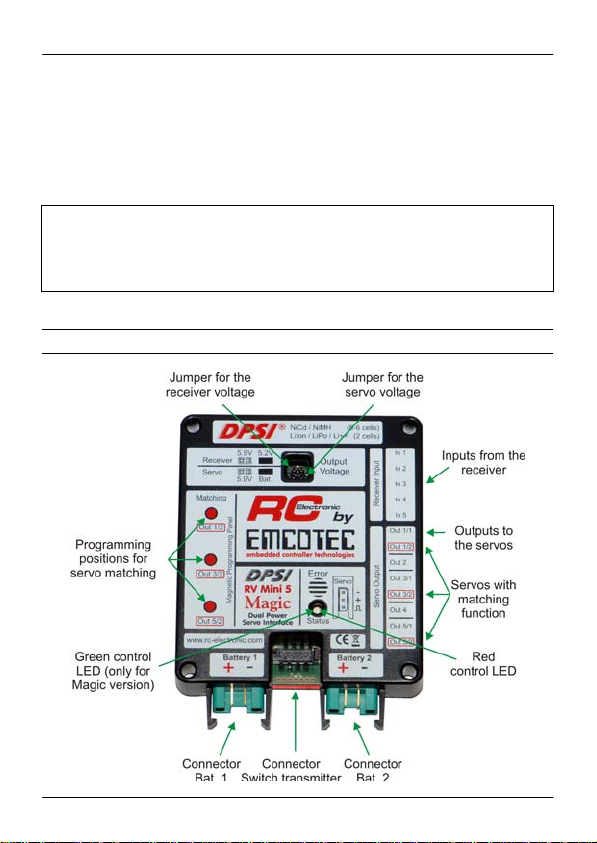

3. DPSI RV Mini at a glance

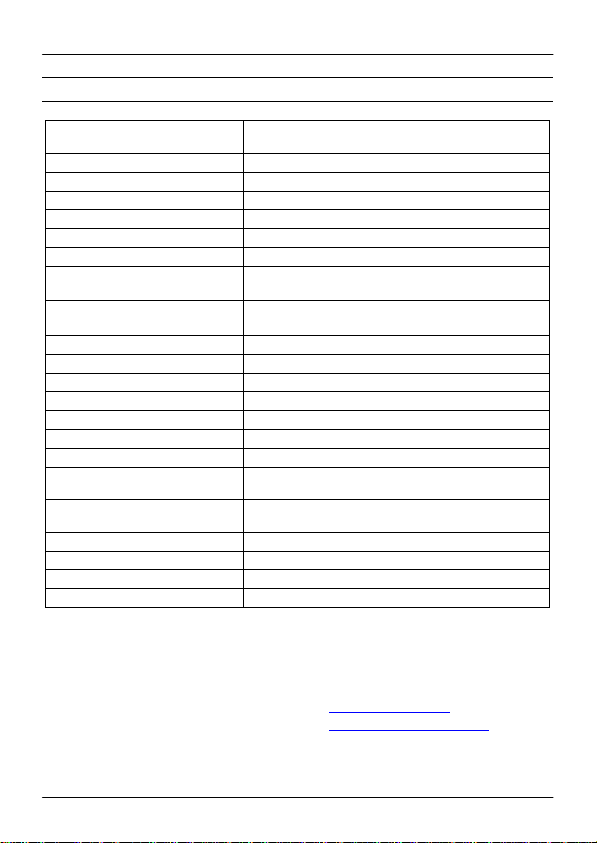

The DPSI RV Mini – family consists of four different dual current

supply systems with servo current distribution for models of medium

size which fit all applications:

DPSI Version Receiver-

DPSI RV Mini 5 5 8 3 built in V-cable

DPSI RV Mini 6 6 7 1 built in V-cable

DPSI RV Mini 5

Magic

DPSI RV Mini 6

Magic

channels

5 8 3 built in V-cable with

6 7 1 built in V-cable with

Servo-

connections

Specifics

servo-matching

servo-matching

The DPSI RV Mini 5 corresponds to pilots of the 2m to 2.7m air

acrobatic class who need up to 10 servos and where up to 2 servos

actuate one rudder. Therefore, only heavy loaded rudders are supplied

by the DPSI (aileron, elevator and yaw rudder). Servos for additional

functions (e.g. engine, retractable landing gear, etc.) are connected

directly to the receiver.

Page 6 of 54

Page 7

DPSI RV Mini Family Operating Instructions Version 1.0

The DPSI RV Mini 6 is mainly used by jet- and glider-pilots (as well as

engine driven planes and helicopters) were more channels are

necessary but only one

powerful servo actuates one rudder. Here too,

additional (less powered) servos can be directly supplied by the

receiver.

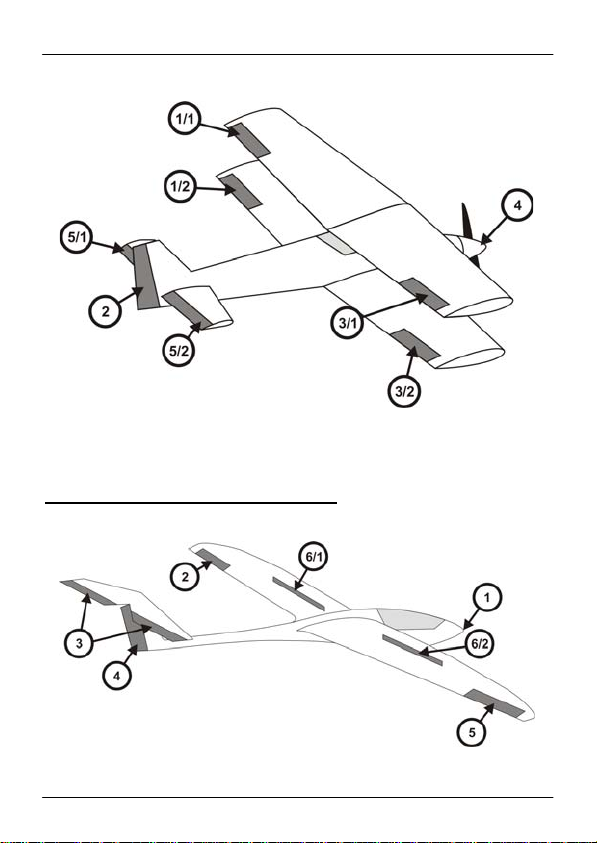

Examples for the DPSI RV Mini 5 (Magic)

An acrobatic airplane with 2 servos per aileron and 2 servos for the yaw rudder. The throttle

servo is directly connected to the receiver.

Page 7 of 54

Page 8

DPSI RV Mini Family Operating Instructions Version 1.0

A biplane with 4 aileron servos, split elevator- and one yaw-rudder servo. The throttle servo

may be directly connected to the receiver as an option.

Examples for the DPS RV Mini 6 (Magic)

A glider with spoilers and tow release.

Page 8 of 54

Page 9

DPSI RV Mini Family Operating Instructions Version 1.0

A glider with flaps and spoilers. The yaw rudder (and if so one tow release) are directly

connected to the receiver.

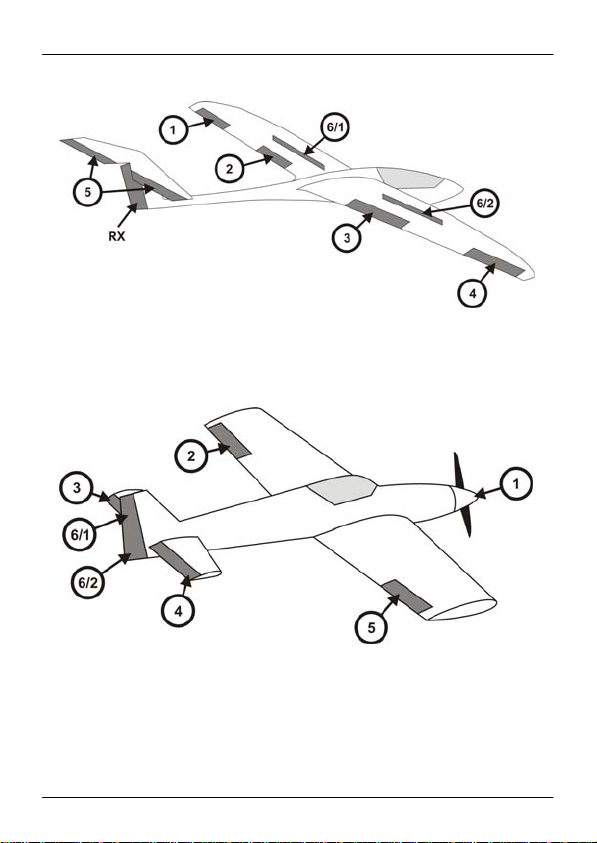

An acrobatic airplane with one servo per rudder, the yaw rudder is actuated by 2 servos.

Page 9 of 54

Page 10

DPSI RV Mini Family Operating Instructions Version 1.0

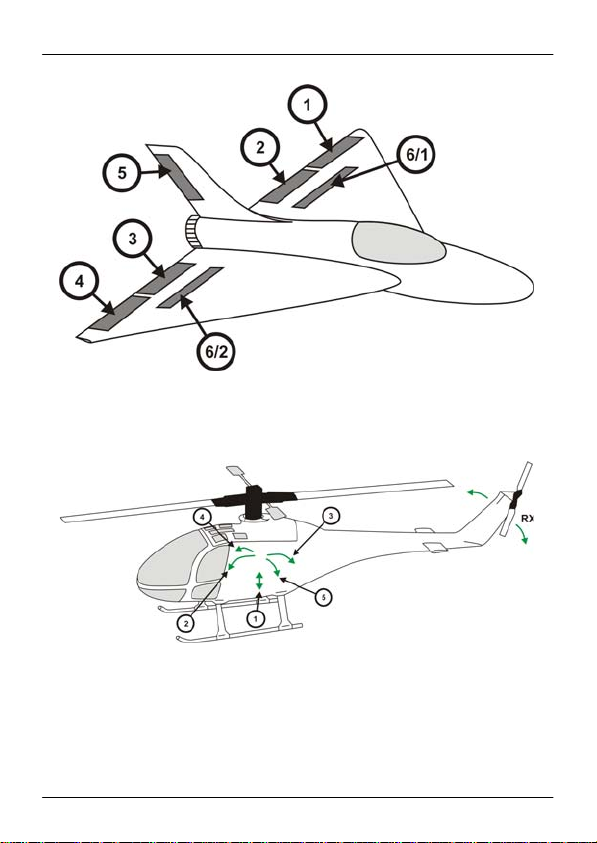

A jet with flaps and spoilers. The turbine-ECU is directly connected to the receiver,

as well as landing gear doors or other electronically systems.

A helicopter with 4-point-control of swash plate (2 roll- und 2 pitch-servos). 1 = throttle. The

gyro (tail rotor) is supplied directly by the receiver (5.2V) or via channel 6/1 of the DPSI (5.9V).

Page 10 of 54

Page 11

DPSI RV Mini Family Operating Instructions Version 1.0

In these examples, the outputs of the DPSI RV Mini are assigned to

the corresponding rudders. Outputs at the DPSI are labeled "Out 1/1",

"Out2", and so on.

Additional servos and auxiliaries can be directly connected to the

receiver.

Hint:

Assignment of the receiver channels to the DPSI is totally arbitrary and therefore

not stringent. Mapping according to the manufacturer (e.g. channel 1 = throttle,

etc.) is not necessary. Receiver channel 3 can be connected to DPSI input 1 just

as well. Any combination is allowed and possible.

4. Overall layout

Page 11 of 54

Page 12

DPSI RV Mini Family Operating Instructions Version 1.0

5. Characteristics

With the DPSI RV Mini - systems a new dimension is reached as far

as safety and comfort about current supplies for RC receiver

equipment is concerned:

Dual current supply (battery switch)

Separate electronically high power switches for both batteries

Up to 50A peak current load

Switching without microcontroller and therefore failsafe (CSHC=

Controller-less Self Holding Circuitry)

Possibility to connect an external LED voltage indicators onto switch

actuator

Due to voltage regulators usage of all battery types available

Selectable output voltage for receiver

Selectable output voltage for servos

Usage of 7.4V servos unlimited

Compliant to all RC receiver-equipment's manufacturers

specifications

Continuously constant servo power due to constant voltage supply

Servo current distribution for heavy loaded servos in system

Optimal recognition and conditioning of servo signals from 2.7V

receivers

Short-circuit proof servo pulse amplifier in current-saving APP-

Technology (Advanced Push Pull) for each individual servo

HFIB (High Frequency Interference Blocking) suppression of induced

HF interference caused by long servo cables (for each individual

servo)

Built-In "V-cable“ for conne cting two servos per channel

Servo-matching for built-in "V-cable“ (in Magic versions)

Failsafe function of programmable servos (in Magic versio ns)

Optically and acoustically warnings on malfunctions, e.g. battery low

voltage or total battery loss

IVM (Intelligent Voltage Monitoring) – intelligent voltage monitoring

with acoustically and optically state indication for six different battery

types (programmable)

Protection of receiver against the so-called "Dynamo Effect“

(feedback of servo counter electromotive force)

Cable free system, i.e. all lines are pluggable and therefore

replaceable at any time

Special grounding concept for flawless operation and highest safety

Page 12 of 54

Page 13

DPSI RV Mini Family Operating Instructions Version 1.0

High grade plastic housing with integrated latches for battery

connectors

Large area heat sink for heat dissipation

Each system 100% tested and provided with individual serial number

Delivery inclusive all accessories

Developed and manufactured by market leader (Made in Germany)

5.1. Dual Current Supply

First of all the DPSI RV Mini is a dual current supply with regulated

output voltage which allows for usage of all commercially available

batteries as a receiver power supply (NiCd, NiMH, LiIon, LiPo, LiFePo,

etc.).

It's a dual current supply because two batteries can be connected to

the system. If one battery fails, secure operation is guaranteed by the

second battery. Normally, both batteries are discharged equally at the

same time. Additionally, current drawn from each battery is cut in half

due to the two batteries connected in "parallel" which allows for

batteries with lower current load capabilities.

5.2. Electronically Switches

The batteries are switched using fail-proof electronically switches. The

external switch actuator only generates the On/Off signal. Power is

switched by highly loadable semiconductors. Thanks to the

electronically switches there is no power loss, contacting problems or

transition resistance. All DPSI RV Mini systems are built with separate

electronically switches, i.e. all electronics are dual. The switches are

fail-proof and are controlled by a self holding circuitry (not by means of

a microcontroller!).

An operating DPSI RV Mini stays turned on even if the On/Off switch

actuator is removed or broken or should the microcontroller

malfunction.

Page 13 of 54

Page 14

DPSI RV Mini Family Operating Instructions Version 1.0

5.3. Detached Voltage Regulators

Until now, the receiver set was supplied directly by the connected

battery (or corresponding battery switch). The output voltage of

batteries depends heavily on the actual discharging state. Because 5cell NiCd or NiMH batteries are utilized more often for optimal servo

power, a fully charged battery reaches voltages up to 7.5V after turning

the charger off. Although this peak voltage usually drops quickly it can

shorten the life cycle of servos in adverse cases because servos

usually are approved only for 6V by the manufacturer. Due to

increased usage of light weight Lithium Polymer batteries voltage

regulation is mandatory because these batteries carry a nominal

voltage of 7.4V.

The electronics in the DPSI RV Mini make sure that the voltage is

reduced to a permissible value, independent of the higher input voltage

of the battery. Jumper (small pluggable bridges) allow for selection of

the desired output voltage. This way, the power requirements can be

adapted to the pilot needs and technical data of the servos.

As a specialty, two separate voltage regulators are built into the DPSI

RV Mini each having its own selectable output voltage. Servos directly

connected to the DPSI are supplied by their own voltage regulator. Its

output voltage is either 5.9V or battery voltage. This means: the servos

are supplied either with a regulated 5.9V (regular permissible voltage)

or directly with the (unregulated) battery voltage. Later is about 7.4V for

2-cell LiPo batteries. Some servos can be supplied with this higher

voltage already.

A receiver connected to the DPSI RV Mini is supplied by its own

voltage regulator. This is very advantageous and gains safety

significantly.

The output voltage of the receiver can be set between 5.2V and 5.9V.

Besides direct connections of high power servos the concept of the

DPSI RV Mini allows for connection of additional low power servos to

the receiver (e.g. a throttle servo), where 5.2V normally suffice.

Page 14 of 54

Page 15

DPSI RV Mini Family Operating Instructions Version 1.0

Even fast tail rotor servos or gyro systems which only "allow for" small

voltages can be supplied by the receiver with 5.2V. Additionally, the

receiver supply is protected against voltage peaks. This means: all

disturbing pulses induced into the supply voltage are limited to safe

values.

5.4. Servo Current Distribution

Furthermore, a DPSI RV Mini provides current distribution for high

power servos, in order not to connect these to the sensitive receiver.

All servos directly connected to the DPSI RV Mini are supplied with full

power and each individual servo gets its maximum possible current.

This can be recognized by a significantly better servo actuating force.

5.5. APP (Advanced Push Pull Servo Pulse Amplification)

In order to provide each servo optimally conditioned control signals

from the receiver, these signals are electronically amplified. This is

especially important if receivers operate on low voltage (e.g. 2.7V);

their pulse amplitude is too low for some servos.

Each individual servo output of the DPSI RV Mini has its own pulse

amplifier and specific HF suppression. The amplifiers recognize even

very weak servo signals from the receiver and elevate the level up to

an exactly defined value. They are short-circuiting proof and are

supplied with their own voltage regulator for safety reasons (i.e. not

with the regular servo voltage). Therefore, the signals always carry a

defined and constant level over the total operating range.

An additional advantage is the current-saving APP-Technology. The

amplifiers consist of special output stages which actively control the

low- as well as the high-phase of the servo signal. In connection with

highly effective filters which practically eliminate induced disturbances

caused by long servo cables completely, best pulse quality and highest

possible safety is guarantied.

Page 15 of 54

Page 16

DPSI RV Mini Family Operating Instructions Version 1.0

5.6. HFIB (High Frequency Interference Blocking)

In order to even increase safety, a highly effective filter is looped in into

each servo's signal path. Disturbances, "caught" by long servo cables

are almost completely eliminated directly at the servo connector and

therefore do not reach the receiver. Ferrite cores, as often utilized, can

be omitted, which saves weight and cost. The filters in the DPSI RV

Mini are tremendously more effective than cheap ferrite cores; their

effectiveness is controversial anyway.

5.7. Built-in V-Cable

Depending on the system (Mini 5 or Mini 6) V-cables are built in to the

DPSI. This means, two servos can be connected to one receiver

output. This is especially handy, if two servos actuate one rudder (e.g.

the aileron of a larger acrobatic plane). The DPSI RV Mini 5 has three,

the Mini 6 one built-in V-cable (e.g. for the yaw

rudder and nose gear).

5.8. Servo-Matching ("Magic" option only)

DPSI RV Mini with "MAGIC" option allow for setting the servos which

are connected to V-cables arbitrarily, i.e. direction, center- and endlimit positions.

This means: one receiver channel serves actually two servos; their

direction, center position and end positions can be aligned. A split

elevator rudder can be controlled by one servo on each side with one

single receiver channel. Therefore one receiver channel and one mixer

in the transmitter get freed up.

The same holds true for controlling the yaw

rudder with coupled nose

gear. Here too, "matching" helps to adapt both servos and saves one

channel.

There is no external programming device (e.g. a PC) necessary for

programming or adapting the servos. A delivered magnet initiates

programming.

Page 16 of 54

Page 17

DPSI RV Mini Family Operating Instructions Version 1.0

Each matching system has its own microcontroller (there are three in

the DPSI RV Mini 5 Magic, one in the DPSI RV Mini 6 Magic).

Resolution (precision) is more than 3000 steps and the delay of the

servo signals is only 1500 micro-seconds!

6. Error Detection and Indication

6.1. IVM (Intelligent Voltage Monitoring)

An internal microcontroller monitors all voltages using an intelligent

algorithm and indicates different errors (overload, low voltage, voltage

errors, battery malfunctions) acoustically by means of a built-in piezobuzzer. Furthermore, errors are visualized by blink codes by a LED in

the switch actuator.

Additionally, the DPSI RV Mini allows for connection of external LED-

Displays (battery monitors) directly at the switch actuator.

In order for the DPSI RV Mini to detect low voltages correctly the

battery type must be programmed once. Simple programming allows

for selection of 6 different battery types.

Page 17 of 54

Page 18

DPSI RV Mini Family Operating Instructions Version 1.0

Hint:

At delivery, low voltage recognition of the DPSI RV Mini systems is programmed

for 2-cell LiPo batteries. If other battery types are to be used, the corresponding

battery type must be programmed in first place (see chapter 9.10.)!

Output voltages for receiver and servos are both set to 5.9 volts at delivery.

7. Safety Features of DPSI RV Systems

Because of the results of FMEA and an elaborate design DPSI RV

Mini is especially safe:

Short-circuits at contacts of the male multi point connector where the

switch actuators cable is connected to, do not damage the DPSI RV

Mini. Therefore even not a defective (squeezed) switch actuator cable.

Shorts on servo pulse lines, no matter whether to ground or positive,

do not any damage, too. All other servos of that channel, where there

is a short-circuit pending, remain fully functional. Even reverse polarity

of a servo does not harm to the DPSI RV Mini.

Mistakenly shorted servo cables usually burn up or melt without

damaging the DPSI RV Mini. The heat sink naturally gets very hot at

events like this!

Both batteries are totally decoupled and also the electronically

switches (inclusive peripheral electronics) are doubled. There are no

dual diodes (two diodes in one housing) built in. Therefore, no

malfunctioning part can cause total fail of the system. This circuitry has

been proven outstandingly several thousand times.

A DPSI RV Mini must not be disconnected from its batteries during

long breaks (e.g. in winter time) because the self discharge of the

batteries is much higher than the quiescent current consumption which

practically is not measurable.

Page 18 of 54

Page 19

DPSI RV Mini Family Operating Instructions Version 1.0

In order to allow for optical power-on control, an ultra bright LED has

been built into the switch actuator of the DPSI RV Mini. It signals

power-on and low voltage or other errors of the battery / batteries by

blinking even over large distances.

All commercially available remote control systems (JR, Futaba,

Multiplex, Spektrum) with all available modulations (PCM, SPCM,

PCM1024, PPM, IPD), 2.4GHz as well, were tested in connection with

DPSI RV Mini systems. Therefore all systems can be utilized with no

problems.

Receivers which are supplied with 2.7 volts internally (e.g. Futaba

6014), can be used without hesitation, because the servo pulses in the

DPSI RV Mini are already recognized at 1.6 volts reliably. Servo

amplifiers in the DPSI RV Mini are supplied by their own voltage which

is totally independent from the regular servo and receiver voltage.

Therefore, voltage peaks and voltage drops do not have any influence

to the pulse quality. Due to its sophisticated safety features in

connection with elaborate testing, operating errors and outside

influences usually do not lead to damage of the DPSI RV Mini.

Page 19 of 54

Page 20

DPSI RV Mini Family Operating Instructions Version 1.0

8. Contents of Delivery

Delivery of DPSI RV Mini 5 (6):

"DPSI RV Mini 5 (6)“ Base Device

On/Off switch actuator with pin and mounting material

5 (6) pieces receiver connection cables (with servo

connectors on both ends => patch cable)

2 pieces MPX high-current sockets for the batteries

4 pieces of shrink tubing for MPX high-current sockets

2 pieces of voltage selection jumpers

Operating instructions, EMCOTEC 3D sticker

Delivery of DPSI RV Mini 5 (6) Magic:

"DPSI RV Mini 5 (6) Magic" Base Device

On/Off switch actuator with pin and mounting material

5 (6) pieces receiver connection cables (with servo

connectors on both ends => patch cable)

Switching-magnet for programming of the matching-functions

2 pieces MPX high-current sockets for the batteries

4 pieces of shrink hoses for MPX high-current sockets

2 pieces of voltage selection jumpers

Operating instructions, EMCOTEC 3D sticker

Each individual DPSI RV Mini system carries its own serial number

and is tested several times prior to delivery!

Page 20 of 54

Page 21

DPSI RV Mini Family Operating Instructions Version 1.0

9. Mounting Hints and Programming

9.1. Mounting the DPSI RV Mini

The DPSI RV Mini is simply mounted onto 4 pieces of silicon hoses

(gasoline hose). Just mount the package vibration damped onto 4

"stilts", as shown in the picture.

In general, always observe vibration free mounting including good air

circulation. Vibration damping is especially important for the receiver

because it is much more sensitive to mechanical stress than the DPSI

RV Mini.

Page 21 of 54

Page 22

DPSI RV Mini Family Operating Instructions Version 1.0

9.2. Hole-Spacing for Mounting

9.3. Mounting the Receiver

The receiver can be directly glued onto the DPSI RV Mini by means of

dual sided adhesive foam rubber (approx. 5-10 mm thick). The

programming marks must remain free for Magic versions.

Separate mounting of the receiver is also possible and even

recommended for 2.4GHz receivers. At high current loads and under

combat conditions, the upper surface of the DPSI RV Mini should

remain uncovered in order to allow for unrestricted heat dissipation.

Hint:

The lower side of the DPSI RV Mini where the heat sink resides, must not be

covered or pasted up with something at all and should have at least a distance of

30mm to the next area (fuselage's bottom or similar)! Good air ventilation

(eventually with air hoods or guided cooling air) is especially reasonable when

operating many servos.

Page 22 of 54

Page 23

DPSI RV Mini Family Operating Instructions Version 1.0

9.4. Connecting the Switch Actuator

Mechanical switches risk malfunctions. There are vibrations at a

fuselage's side wall especially with large models. In order to avoid any

mechanically influence in DPSI RV systems electronically switches

with self-holding circuitry are utilized.

The electronically switches are only controlled by a pulse from the

external switch actuator. The receiving set therefore is turned on or off

by means of a pin or magnet (Magic version). The corresponding

switch actuator just delivers the on/off signal.

Dimensions of the switch transmitters:

Rear side of the switch transmitter with connected battery controllers (optionally)

Page 23 of 54

Page 24

DPSI RV Mini Family Operating Instructions Version 1.0

Pin-Switch-Actuator in DPSI RV Mini:

The pin, put into the "ON" socket (red) turns the DPSI RV Mini on.

Putting it into the "OFF" (black) socket turns the DPSI RV Mini off.

Even if the pin gets lost a powered system remains on.

A DPSI RV Mini only can be turned off if the pin is put into the OFF

socket (in other words swapped from red to black)!

DPSI RV pin-switch-actuator:

Of course, two pins must not be put into each of the sockets at the

same time although this does not damage the DPSI RV Mini. In this

case, the set would be turned off and the batteries would be

discharged slowly with approx. 12mA. In the powered state the pin

should always remain in the ON socket!

Hint:

Should the pin get lost, a 2mm wire or 2mm screw suffices by putting it into the

corresponding socket.

Page 24 of 54

Page 25

DPSI RV Mini Family Operating Instructions Version 1.0

The On/Off switch can be arbitrarily positioned (e.g. at the fuselage's

side wall). Put the connection cable with its plug into the multi point

connector of the DPSI RV Mini until it locks (see picture). If eventually

a swap or disconnect is in order, carefully remove by moving upwards

out of the multi point connector (grapple the cable directly at the plug).

Correctly mounted switch actuator at DPSI RV:

Switch Actuator in Magic versions:

Magic versions of the DPSI RV Mini (with servo-matching) are not

delivered with the pin switch actuator but rather with a magnetically

switch actuator. Because a magnet is necessary for programming the

servo-matching functions it can be used as switching element for the

switch actuator as well.

The magnet is positioned close to the on-position of the switch actuator

(green marking on housing) for about 1 second.

For turning off, hold the magnet close to the opposite marking of the

switch actuator for about 2 seconds.

Hinweis:

For regular DPSI RV Mini versions, a magnetically switch actuator is available as

optional accessory.

Page 25 of 54

Page 26

DPSI RV Mini Family Operating Instructions Version 1.0

DPSI RV magnetically switch-actuator:

The central ultra bright LED in the switch actuator housing is lit when

the DPSI RV Mini is powered. In case of errors (e.g. low voltage) or

during programming, the LED indicates the states by different blink

codes.

Two commercially available battery controllers with JR-Uni connectors

can be connected directly at the rear of the switch actuator. The prints

"B1" and "B2" indicate battery 1 and battery 2 respectively. Herewith,

additional voltage monitoring is possible. When using such voltage

controllers, observe required cell numbers and/or correct battery type.

A turned off DPSI RV Mini system also turns off eventually connected

battery controllers, too.

Page 26 of 54

Page 27

DPSI RV Mini Family Operating Instructions Version 1.0

9.5. Connecting the Receiver

Connect the receiver to the DPSI RV Mini using the delivered patch

cables (see print on housing). When connecting the receiver not all

inputs of the DPSI RV Mini must be used. Just connect as many

cables as needed. Each of the cables provides the receiver with

voltage.

Hint:

All receiver connection cables supply the receiver with regulated output voltage!

Therefore it is not relevant which cable (channel) is connected.

Hint:

At all DPSI RV Mini systems the negative wire (brown) points to top i.e. towards

the print. The pulse wire (orange) points towards the heat sink.

Hint:

If the equipment does not work please make sure that all cables are correctly

connected and that the modulation mode of the transmitter corresponds to that of

the receiver (e.g. PPM, PCM, SPCM, IPD and so on).

Hint:

Assignment of the receiver channels on the DPSI housing's print is only a

suggestion! Assignment is arbitrary in any case. This means: receiver channel 1

must not necessarily be connected to channel 1 of the DPSI. It is only important

that servo outputs correspond to the receiver inputs of the DPSI (e.g. receiver

input 2 to servo output 2). Therefore, receiver channel 1 can be connected to

DPSI input 2. In this case servos at output 2 are controlled by receiver channel 1.

Hint:

Under no circumstances connect a patch-cable between receiver and a servo

output of the DPSI RV Mini. Both, the DPSI RV Mini or the receiver could

become damaged!

Page 27 of 54

Page 28

DPSI RV Mini Family Operating Instructions Version 1.0

9.6. Selecting Batteries

All commercially available batteries are selectable (NiCd and NiMH) as

well as Lithium-Ion (LiIon), Lithium-Polymer (LiPo) or LiFePo (A123).

Independent of the selected output voltage these batteries are usable

with no restrictions.

Page 28 of 54

Page 29

DPSI RV Mini Family Operating Instructions Version 1.0

6-cell NiCd batteries are also connectable. This only makes sense if

the output voltage for the servos is set to "Bat." and servos with a

corresponding higher supply voltage are connected (e.g. 7.4V servos).

Usually 5-cell NiCd/NiMH or 2-cell LiPo batteries are used.

Battery capacities

In general observe current load and capacities of the utilized batteries.

Battery packs of 2 times 450mAh are far too small for a model carrying

10 servos. There should be at least two "2000th" which can be

discharged with 5C (peak current). (C is nominal capacity in Ah => a

battery with 2Ah can be loaded with 5 * 2A = 10A at 5C). Especially

when using digital servos higher current consumption must be

observed.

Our elaborated measurements with a 3m model using 15 digital servos

resulted in a current consumption of about 0.6 – 0.8Ah at 10 minutes

flight time. Dimension your batteries very carefully! If in doubt, ask your

model manufacturer.

Furthermore, make sure, that the connection cables of the battery are

thick enough when selecting the batteries. If a battery with 0.25 mm

2

cable area is being used, the advantage of using the DPSI is lost

because of losses in such thin cables. Therefore, battery wires for

large models should have an area of 1.0 – 1.5mm

2

.

Solder the battery connection cables to the delivered Multiplex high

current connectors to make them compatible to the DPSI RV Mini (if

no readily conditioned batteries are utilized). Shrink tubes for isolating

the solder connections are delivered as well.

If the batteries must be placed far away from the DPSI RV Mini due to

COG (Center of Gravity) purposes (long connection cables) it is

desirable to twist the wires. We recommend using our EMCOTEC

Lithium Polymer batteries. These are delivered completely wired and

can be connected to the DPSI RV Mini right away. An additional

charging connector at the battery allows for charging without removing

the battery from the DPSI. Charging devices for all battery types are

available from EMCOTEC, too.

Page 29 of 54

Page 30

DPSI RV Mini Family Operating Instructions Version 1.0

Selecting the output voltage

Meanwhile almost all servos are suitable for a 5.9V supply voltage.

Therefore, the default setting for servos directly connected to the DPSI

RV Mini is 5.9V. If 7.4V servos are to be used, the output voltage can

be set to battery level ("Bat.") by jumper. In case LiPo batteries are

used servos are supplied with 7.4V.

Some servos are restricted to 4.8V according to manufacturer's

specifications (e.g. fast tail rotor servos for helicopters). Connect these

servos directly to the receiver. Its supply voltage then is set to 5.2V by

jumper at the DPSI RV Mini. 5.2V correspond to the voltage of 4-cell

NiCd batteries which are the reference for 4.8V servos.

As of today, all commercially available receivers can be operated with

5.9V with no limitation. Therefore, the receiver voltage at the DPSI RV

Mini is set to 5.9V by default.

Hint:

The higher the difference between input and output voltage, the higher is the

power dissipation which must be converted to heat. If using many servos it is

advisable to select a higher output voltage at the DPSI RV Mini.

Hint:

Using a 4-cell battery pack (NiCd/NiMH) on a DPSI RV Mini is not permissible!

Page 30 of 54

Page 31

DPSI RV Mini Family Operating Instructions Version 1.0

9.7. Soldering Battery Sockets

Delivered Multiplex high current sockets are marked + and – on their

soldering side. Observing this marking is mandatory! Dismantle the

cable about 5mm, and then tin it. Before soldering, push the delivered

shrink hose over the corresponding cable. Solder the cable to all 3 pins

on one side of the socket; it must contact all 3 pins from the inside (see

picture). If the cables are thin, bend the pins of the socket a little to

their common center. Use plenty of tin to assure good contact to all 3

pins. Shrink the hose using a heat gun.

Soldering Multiplex connectors:

Hint:

DPSI RV Mini systems are not inverse polarity protected by design! Please

observe correct connection of the batteries, i.e. connect red wire to positive and

black wire to negative. Better control once too many than too little!

Page 31 of 54

Page 32

DPSI RV Mini Family Operating Instructions Version 1.0

9.8. Charging the Batteries

All DPSI RV Mini systems switch battery-positive, i.e. both batteries

are interconnected with their negative pole (ground) if connected to a

DPSI. Simultaneously charging therefore is not always possible

because most chargers with more than one charging output measure

the current in their negative line while interconnecting the positive lines.

Separate charging of the batteries is possible at an y time when

connected to a DPSI RV Mini!

If one wishes to charge the batteries while connected to a DPSI RV

Mini a second cable must be soldered to the battery which serves as a

charging cable. This cable then is in parallel to the connection cable of

the DPSI RV Mini.

Simultaneous charging of both connected batteries while connected to

a DPSI RV Mini is only possible with Lithium Polymer batteries. LiPo

batteries may be charged in parallel because the DPSI discharges

these batteries absolutely identically and therefore having identically

discharge states. This means: both batteries are interconnected in

parallel for charging by means of a V-cable (positive to positive,

negative to negative). This makes it a "2S2P“-battery. Cell number

(voltage) stays the same, charging current may be doubled.

Corresponding charging cables are available from EMCOTEC.

If in doubt it is reasonable and safer to disconnect the batteries from

the DPSI RV Mini for charging. Just tilt the plug a little (to the side) and

pull it from its DPSI RV Mini latches with slight zigzag moves.

Hint:

It is possible to charge the battery when still connected to the DPSI RV Mini (e.g.

via an additional soldered charging cable). Only charge one battery at a time

(exception: LiPo batteries). Please observe correct polarity!

Page 32 of 54

Page 33

DPSI RV Mini Family Operating Instructions Version 1.0

Removing the battery plugs from the DPSI RV Mini:

9.9. Setting the Voltages

The output voltage of the DPSI RV Mini can be set in 2 steps for the

receiver as well as the servos. This is done using delivered jumpers

which are plugged to the multi-pin connectors of the DPSI RV Mini

depending on the desired output voltage. Best use a tweezers or small

pliers.

Setting the voltage of the receiver and the servos to 5.9 Volt:

Page 33 of 54

Page 34

DPSI RV Mini Family Operating Instructions Version 1.0

Selecting full battery voltage for the servos (receiver stays at 5.9V):

The positions of the jumpers on their multi-pin connectors and their

corresponding output voltage are printed onto the housing of the DPSI

RV Mini. Because a DPSI RV Mini should be mounted vibration-less

the jumpers can not fall out.

Page 34 of 54

Page 35

DPSI RV Mini Family Operating Instructions Version 1.0

9.10. Programming the Batteries

Because DPSI RV Mini systems monitor the battery voltage

intelligently, they need to know the utilized battery type (e.g. 5-cell or 6cell batteries or LiPo batteries). Therefore the battery type must be

programmed once – the programmed state is memorized in the

microcontroller of the DPSI RV Mini until programmed again.

Programming starts when only one

battery (no matter which type and

at which connector) is connected to the DPSI RV Mini and when the

system is turned on.

After power on, the internal buzzer (signaling device) of the DPSI RV

Mini turns on for 3 seconds and pauses for another 3 seconds. This

indicates operating mode "programming".

Now one beep follows which indicates "battery type no. 1". If the

missing battery is now connected to the DPSI RV Mini within 3

seconds, "battery type no. 1" is selected and programmed.

If the missing battery is not connected within 3 seconds, two beeps

follow for indicating "battery type no. 2". Again, the user has 3 seconds

to connect the missing battery if he/she wishes to select (program) this

battery type.

This principal is repeated until the buzzer beeps seven times

(deactivate all tests). If no battery is connected within 3 seconds there

is no programming at all and the system changes to normal operation.

Page 35 of 54

Page 36

DPSI RV Mini Family Operating Instructions Version 1.0

Battery types are defined as follows:

Type no. Buzzer Code Battery Type / Programming

1 1x beep 5 cells NiCd / NiMH

2 2x beeps 6 cells NiCd / NiMH

3 3x beeps 2 cells Lithium-Ion

4 4x beeps 2 cells Lithium-Polymer

5 5x beeps 2 cells LiFePo (e.g. A123)

6 6x beeps 7 cells NiCd / NiMH (res.)

7 7x beeps All tests deactivated

By default "battery type 4" (LiPo battery) is programmed at delivery.

Selection "7 beeps" (all tests deactivated) causes the DPSI RV Mini

not to conduct any voltage tests. No empty batteries or other errors are

indicated anymore.

Hint:

Always use two identical batteries (i.e. same battery type: NiCd, NiMH or LiPo

and same number of cells). Battery capacity may be different - although it makes

no sense.

Hint:

The battery type is output after powering the DPSI RV Mini on by means of

buzzer codes. Multiple beeps after turning the system on therefore do not

indicate an error!

Page 36 of 54

Page 37

DPSI RV Mini Family Operating Instructions Version 1.0

Programming the battery type at a glance:

Page 37 of 54

Page 38

DPSI RV Mini Family Operating Instructions Version 1.0

9.11. Connecting Servos

The DPSI RV Mini 5 (Magic) distributes 5 receiver channels to 8

servos in total (with 3 "built-in“ V-cables).

The DPSI RV Mini 6 (Magic) distributes 6 receiver channels to 7

servos in total (with 1 "built-in“ V-cable).

In the example at page 28, 8 servos are connected to the DPSI RV

Mini 5 in total, the throttle servo however directly at the receiver. For all

servos connected to the DPSI RV Mini the pulse wire points

downwards (as pretended by chamfered noses in housing). We do not

recommend connecting more than 10 servos in a receiver system

powered with a DPSI RV Mini in total because current limits can be

reached or thermal load could get too high.

Observe sufficient cooling when using digital servos, in any case.

Hint:

Dependent on number and force of servos total current consumption varies in the

system. The higher the total current consumption, the higher is the energy which

is converted to heat. The heat sink of the DPSI RV Mini can get very hot. This is

not an error, but rather represents normal function. Therefore, observe for

sufficient cooling (distance to neighboring walls like fuselage's side walls or

similar – eventually arrange for cooling air supply). On request, an additional heat

sink can be mounted.

Hint:

Printed assignment connections on top of the DPSI RV systems are only a

suggestion! Receiver channels may be connected to any DPSI inputs. Receiver

channel "1" might be connected to DPSI input "3". Servo outputs "3" of the DPSI

are then controlled by receiver channel "1". Assignment therefore is arbitrary!

Page 38 of 54

Page 39

DPSI RV Mini Family Operating Instructions Version 1.0

10. Servo-Matching

This is especially helpful if e.g. two servos actuate one rudder and

synchronized movement is not possible by mechanically adjustments

(e.g. two servos for one aileron). Often it suffices to change one

servo's direction. This is also simply possible with the MAGIC version.

Failsafe-Function:

Additionally a failsafe function has been integrated. An erroneous or

missing receiver signal stops both servos (master and slave) at their

current position (hold) until a valid receiver signal is recognized again.

This state is indicated by a flashing green LED on the upper side of the

housing ("status") which stays active until power is turned off. After the

flight the flashing LED indicates a failsafe situation.

High Precision:

Due to the intelligent software design and a highly accurate crystal

oscillator resolution is more than 3000 steps. Therefore, the system is

suitable even for modern remote controls with high servo positioning

accuracy (number of steps).

There are built-in V-cables in a DPSI RV

Mini allowing two servos to connect to one

receiver channel (Mini 5 has three Vcables; Mini 6 has one V-cable). As a

specialty, MAGIC versions allow to

program the direction, center- and end

positions for one of both servos ("slave"

servo). This servo therefore can be

"matched" to the main servo (MSTR).

Page 39 of 54

Page 40

DPSI RV Mini Family Operating Instructions Version 1.0

10.1. Programming

No external operating unit is necessary for programming the slaveservos such as a PC or a programming box. Only the delivered magnet

serves to activate the corresponding programming function. Everything

else is done with the transmitter (the remote control system).

During programming settings of the original servo (master) do not

change! Programming always refers to the slave servo. The slave

servo connects to the red encircled output. This is the servo at output

"Out 6/2" for the DPSI RV Mini 6 Magic; for the DPSI RV Mini 5

Magic these are outputs "Out 1/2“, "Out 3/2“ and "Out 5/2“.

Hint:

Setting and programming of the slave servo is only possible within the first 10

seconds after powering the DPSI on. Afterwards programming is inhibited for

safety reasons!

Hint:

Prior to EACH programming the corresponding transmitter stick (or switch

actuator) must be positioned in the center!

Hint:

If both servos, MSTR and SLAVE share one rudder at least one link must be

released in order to avoid mechanically blocking of the servos.

Hint:

Whenever the servo center is changed, end-limits should be reprogrammed as

well!

Hint:

Implemented basic settings correspond to servo values of Graupner/JR sets.

Center position is 1.50ms; end-positions are set to 100% each. Of course, all

remote control sets can be utilized.

Page 40 of 54

Page 41

DPSI RV Mini Family Operating Instructions Version 1.0

Hint:

Whenever programming is activated the green LED blinks for controlling

purposes in the DPSI RV Mini Magic at a rate of 0.5Hz (1s on, 1s off). A fast

blinking of this green LED indicates a failure (=> missing receiver signal).

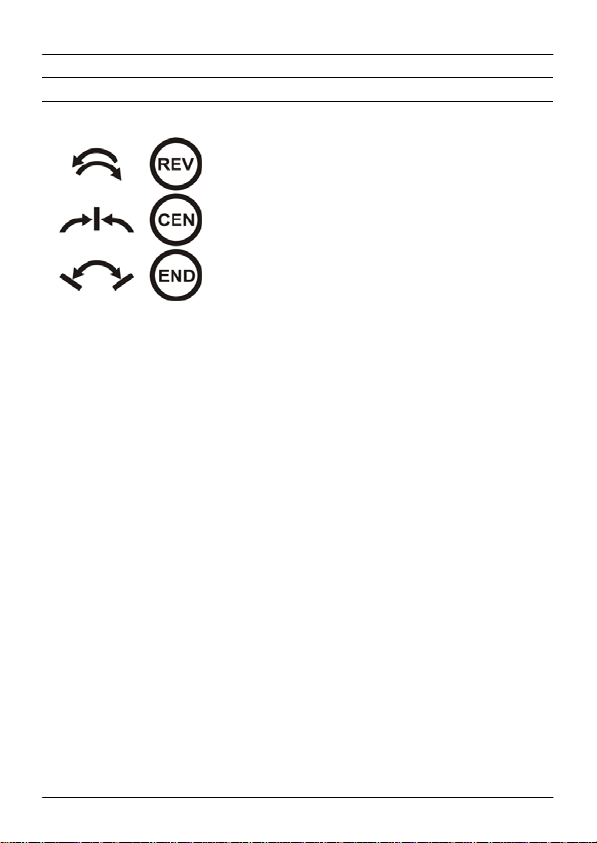

10.2. Changing Servo Direction

programming panel" field) within the first 10 seconds after power on.

Distance of the magnet may be up to 8mm. It is easiest to set the

magnet onto the housings upper surface.

2.5 seconds after placing the magnet the slave servo makes a short

move back and forth (approx. 10% deflection). If the magnet is then

removed within 5 seconds, the direction of the servo changes and is

permanently stored.

current position (on the red dot). The transmitter's stick or switch

actuator must not be moved anymore, i.e. it must remain on its center

position. After another 5 seconds the servo turns again. Now

programming of the servo's center position is activated.

The master servo now remains in its current center position and does

not move even if the transmitter's stick is moved. Each move of the

stick out of its center position increases or decreases the servo

position (servo center) of the slave servo for one step.

If the direction of a servo is to be changed, all

other settings remain! For changing the direction

of the servo, the magnet is to be put close to the

corresponding position (red dot in the "magnetic

10.3. Setting Servo Center

Programming also starts by positioning the

magnet close to the red dot. The servo turns

shortly (just as when changing direction). Do

not remove the magnet now but keep it on the

Page 41 of 54

Page 42

DPSI RV Mini Family Operating Instructions Version 1.0

Holding the stick in its end position the steps increase or decrease

automatically after 2.5 seconds. This serves for quicker settings.

Hint:

Due to the high resolution it is possible that the change in servo positions is only

visible after several single steps.

As soon as the slave servo reaches its final center position remove the

magnet from the red dot. Programming of servo center is finished.

Hint:

If the servo center position is newly programmed, the end-positions should be reprogrammed as well in order to gain linear curves.

10.4. Setting End-Limits

Programming of end limits starts identically to

programming servo center. Here, the stick (or

switch actuator) is put into its maximum end

position within 5 seconds after the servo

makes its short move. After these 5 seconds the servo moves again

and both servos remain in their maximum-position. The stick is now

moved to its center position – servo positions do not change!

Here too, deflection of the slave servo is accomplished by moving the

stick out of its center position in order to increase or decrease the

steps.

Page 42 of 54

Page 43

DPSI RV Mini Family Operating Instructions Version 1.0

If the desired end position is reached, remove the magnet.

Hint:

Whenever changes of servo deflections are programmed, all values should be

reprogrammed, i.e. center position and end-positions! Sequence of programming

(center, end-positions) is actually unimportant.

Caution:

Programmable values for end positions of the servos can be higher than the

mechanically resolution of the servo. The servo therefore could be damaged or

function incorrectly if the full range is being used. Therefore approach limits

carefully. An additionally connected servo tester (e.g. EMCOTEC Mini Servo

Tester – part number A71050) which indicates the corresponding servo position

digitally can be helpful if in doubt.

10.5. Deletion of all Programming

Total reset of all programmed settings is also

possible. Just position the magnet close to the

red dot after powering the DPSI RV Mini on

and keep it there for about 30 seconds. After

2.5 and additional 5 seconds, the servo makes its short move (just like

when programming center / end values). The stick must not be moved

at all during this time and the magnet must remain at its position close

to the red dot. After 30 seconds have elapsed all settings are deleted.

Hint:

Whenever programming is activated the green LED on the DPSIs top side blinks

for controlling purposes in the DPSI RV Mini Magic at a rate of 0.5Hz (1s on, 1s

off).

10.6 Supplemental Hints for MAGIC-Version

These additional hints are valuable for the ambitious user who likes to

know more about the functions of servo-matching by explaining its

behavior under certain circumstances.

Page 43 of 54

Page 44

DPSI RV Mini Family Operating Instructions Version 1.0

10.7. Changing the Model

If an already programmed DPSI RV Mini is to be used in another

application (e.g. changing the model) all settings should be generally

deleted (see "Deleting of all Programming"). This holds true if even a

servo with different direction is built in.

10.8. Sequence of Programming

When programming the slave servo, set direction first (if necessary).

Then center position and end-positions follow, while the sequence is

not important.

Hint:

Whenever a change of e.g. then servo center position is reprogrammed, endpositions should be reprogrammed as well!

10.9. Limitation of Range Settings

The DPSI RV Mini only allows for certain values during programming

of the slave servo. Because the slave servo is to be adapted to the

master servo both servos should have a similar basic setting e.g. a

similar center position.

If the servo center of the master servo already exceeds 100% of the

servo deflection it does not make much sense to offset the slave servo

even further. Therefore only a setting of a servo center for a maximum

of +/-100% is possible.

Setting of the slave servo is generally accomplished by a so called 3point curve (i.e. center position, maximum value left / upper, maximum

value right / lower).

"Distance" of maximum value to the center position is 20% minimum

otherwise the value is not programmable.

Page 44 of 54

Page 45

DPSI RV Mini Family Operating Instructions Version 1.0

A range check takes place at every programming attempt. It is

therefore not possible to position the servo center position outside of

the maximum value. This inhibits malfunctions (e.g. V-curve of servos).

10.10. Technical Data of Servo-Matching

Servo Signal Level Input:

Low-Level 0V ... 0.8V

High-Level 2.0V ... 8.4V

Servo Signal Level Output approx. 5.0V

Permissible Center Position +/-100% (1.10ms .... 1.90ms)

Permissible End-Limits* +/-200% (0.70ms .... 2.30ms)

Permissible Signal Period min. 6.9ms, max. 34.868ms

Resolution (steps) 3200

Page 45 of 54

Page 46

DPSI RV Mini Family Operating Instructions Version 1.0

* Caution:

Programmable values for end positions of the servos can be higher than the

mechanically resolution of the servo. The servo therefore could be damaged or

function incorrectly (e.g. wheel spinning) if the full range is being used. Therefore

approach limits carefully.

11. Connecting Optional Products

Operating the DPSI RV Mini with Gyros

It is possible without any difficulty to operate the DPSI RV Mini in

connection with a gyro. The gyro and its connected servos can be

supplied by the receiver without problems.

Varios, Smoke-Pumps, Retractable Gears and other Consumers

All other types of consumers can be connected to the DPSI RV Mini

just like a normal servo. Using a DPSI RV Mini also allows for

connecting additional auxiliary functions directly at the receiver if the

available slots (channels) of the DPSI RV Mini are not sufficient. Just

observe maximum current (see also technical data).

Ignitions

Even if it appears appealing to supply the ignition system for gasoline

engines by a DPSI we strongly recommend not doing so! Ignitions

induce considerable disturbances which influence the range of the

remote control if integrated into the receiving set. Always supply the

ignition system with a separate battery!

12. Operating

After powering the DPSI RV Mini on, the red ultra bright LED in the

switch actuator and the LED in the DPSI RV Mini illuminate. This

signals operation. Immediately after power on, the signaling device

(buzzer) indicates the programmed battery type (once, twice, three-,

four-, five-, six- or seven times). Afterwards, the algorithm for error

recognition starts.

Page 46 of 54

Page 47

DPSI RV Mini Family Operating Instructions Version 1.0

In case one battery is not connected, the DPSI RV Mini starts in

programming mode. This programming mode automatically ends after

approx. 30 seconds. Within these 30 seconds, the second battery must

not be connected if reprogramming is not desired.

Hint:

If the buzzer beeps 3 seconds after turning the DPSI RV Mini on, only one

battery is connected and the DPSI starts in programming mode. If no

reprogramming is desired, either turn the DPSI RV Mini off or wait approx. 30

seconds before connecting the second battery.

Hint:

If the DPSI RV Mini indicates errors for low voltage after a short period of time

although the batteries are fully charged, probably the wrong battery type is

programmed.

It is also possible, that a battery with a too high internal resistance is used which

breaks down when loaded (e.g. NiMH batteries in AA size). Only utilize batteries

for high current load!

13. Error Indication

There is a microcontroller integrated into the DPSI RV Mini which

constantly monitors all voltages and the function of the voltage

regulator. An intelligent algorithm makes sure that low voltage of a

connected battery not only is detected during shortly dropping voltages

(e.g. in case all servos move at once). The algorism is especially

designed for operating RC-models (this is cyclic load of the batteries)

i.e. not constant load of the batteries. Now, reliable recognition of low

voltages is possible.

Despite this, don't trust blindly low voltage recognition. A good and

responsible model pilot knows how long he/she can fly with fully

charged batteries and recharges them in time (not just when low

voltage is indicated).

Different error types are indicated by the internal piezo-buzzer and the

red LED in the switch actuator.

Page 47 of 54

Page 48

DPSI RV Mini Family Operating Instructions Version 1.0

1. Overload (short circuit):

Error signal: constant beep

⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯

If current consumption of the DPSI RV Mini gets too high a constant

beep is output. In this case, an external short-circuit is detected which

can lead to total damage of the DPSI RV Mini (depending on the

duration of the short). Immediately turn the system off or disconnect

the batteries. This error type has highest priority. If the short (during

operation) gets away, the buzzer stops beeping after a "dequalification" time of approx. 4 seconds.

2. Battery empty: ⎯⎯⎯ ⎯⎯⎯ ⎯⎯⎯ ⎯⎯⎯

Error signal: endless 0.5 seconds beeps / 0.5 seconds

pause

If the voltage at the receiver (not at batteries!) drops below 4.5V, error

type 2 is output. The batteries (no matter which type) are totally

discharged and safe operation not possible any more. This error is

extremely critical because the whole RC-system can drop out of

operation at any time (due to low voltage).

Error type 2 has second highest priority and is active until the DPSI RV

Mini is turned off. If using LiPo-cells, a state is reached where the

batteries are irrevocable destroyed if not turned off immediately and

the batteries being recharged.

3. Voltage Regulator defective:

Error signal: endless 0.5 seconds beep / 0.1

⎯⎯⎯⎯ ⎯ ⎯⎯⎯⎯ ⎯

seconds pause, 0.1 seconds beep

This error signal is output if the voltage regulator for supplying the

receiver malfunctions. Send in the DPSI for repair in this case. Error

type 3 has third highest priority and stays active until turning the DPSI

RV Mini off.

Page 48 of 54

Page 49

DPSI RV Mini Family Operating Instructions Version 1.0

4. Battery Malfunction:

Error signal: endless 0.1 seconds beeps / 0.1 seconds

⎯ ⎯ ⎯ ⎯ ⎯ ⎯ ⎯ ⎯ ⎯

pause

If a battery fails of a DPSI RV Mini (e.g. broken cable, loose contact or

battery defective) a fast buzzer signal is output (5Hz). This error type

has forth highest priority. If the disconnection stops during operation,

the error stays active (until power off)!

5. Low Voltage battery 1:

Error signal: 3 times 0.1 seconds beeps with 0.1

⎯ ⎯ ⎯ ⎯⎯⎯⎯⎯⎯⎯⎯

seconds pause each, then 1 second beep

If the voltage of battery 1 drops a certain level this buzzer code is

output. Usually capacity suffices for one more flight before recharge is

in order. It is better to recharge right away if this error code is indicated.

A correctly programmed battery type of course is prerequisite

(NiCd/NiMH, LiIon, LiPo or LiFePo with corresponding cell number).

This error code repeats every 7 seconds. If this error is qualified the

first time, it stays active until the DPSI RV Mini is turned off.

6. Low Voltage battery 2:

Error signal: 3 times 0.1 seconds beeps with 0.1

⎯ ⎯ ⎯ ⎯⎯⎯⎯⎯ ⎯⎯⎯⎯⎯

seconds pause each, then 2 times 0.65 seconds

beeps with 0.1 seconds pause

If the voltage of battery 2 drops a certain level this buzzer code is

output. Usually capacity suffices for one more flight before recharge is

in order. It is better to recharge right away if this error code is indicated.

A correctly programmed battery type of course is prerequisite

(NiCd/NiMH, LiIon, LiPo or LiFePo with corresponding cell number).

This error code repeats every 7 seconds. If this error is qualified the

first time, it stays active until the DPSI RV Mini is turned off.

If battery 1 as well as battery 2 indicates low voltage, both error codes

are output alternatively. Low voltage errors 5 and 6 have lower priority

(importance) than errors 1-4. In case of an error of type 1.-4., output of

low voltage errors is interrupted.

Page 49 of 54

Page 50

DPSI RV Mini Family Operating Instructions Version 1.0

Hint:

Limits for recognizing low voltage are especially set up for operating RC models.

When utilizing the DPSI RV Mini for other purposes erroneous information could

eventually be output. If this is the case the error indication (if disturbing) can be

completely inhibited (see also "Programming the Battery Type“).

Hint:

Low voltage recognition is only pointing to batteries getting weak and do not

absolve the user from his/her care of only to fly with fully charged batteries! Due

to different characteristics of batteries from different manufacturers low voltage

recognition does not feature 100% safety.

14. Safety Directions

In general, all connecting lines should be run so that they do not

come into contact with moving or hot parts of the model (such as

servos, gears or mufflers).

The DPSI RV Mini must be protected from humidity and moisture.

The DPSI RV Mini must be located at a sufficient distance from

neighboring surfaces to enable good heat dissipation of the

cooling element.

Improper handling of the DPSI RV Mini can result in serious

damage/injury to property or persons!

Carry out a general inspection of all connections in your model

before each use! All plugs must be correctly polarized and have

clean contacts (i.e. fit tightly). Loose cables present a potential

hazard!

Under no circumstances may power sources that do not meet the

specified voltages be used.

The current-conducting contacts of the connector plugs may not

be short-circuited. If you fail to observe this warning, the shortcircuited cables may overheat and even melt.

The DPSI RV Mini may not be taken apart or technically altered

under any circumstances.

Page 50 of 54

Page 51

DPSI RV Mini Family Operating Instructions Version 1.0

Never use the DPSI RV Mini for purposes other than for RC

model making as a hobby. Above all, their use in passengercarrying equipment is strictly prohibited.

Operate the DPSI RV Mini only with the remote control

components provided for model making.

Always ensure that you have fully charged batteries when

operating your model. Empty batteries inevitably lead to failure of

the RC components, which cause the model to crash.

Do not expose the DPSI RV Mini to any extremely hot or

extremely cold temperatures, moisture or humidity. This would

lead to danger of malfunction, damage or decreased efficiency.

Only use EMCOTEC approved accessories in connection with the

DPSI RV Mini (e.g. switch actuator, external voltage monitors,

etc.)

We recommend the usage of EMCOTEC Lithium-Polymer batteries for

the DPSI RV Mini systems. There are several capacities available as

well as chargers, balancers and other accessories.

Page 51 of 54

Page 52

DPSI RV Mini Family Operating Instructions Version 1.0

15. Technical Data of DPSI RV Mini-Systems

Current sources 5, 6, (7)-cell NiCd / NiMH Cells, 2-cell Lithium-Ion

Operating voltage range 5.0V .... 13V

Nominal input voltage 6.0V .... 8.4V

Output voltage receiver 5.2V or 5.9V settable by jumper

Output voltage servos 5.9V or full battery voltage settable by jumper

Quiescent current (turned off) approx. 1µA per battery

Quiescent current (turned on) approx. 55mA totally (MAGIC versions approx. 70mA)

Max. continuous current @ 5.9V

(15 minutes with LiPo batteries)

Max. peak current @ 5.9V

(10 seconds with LiPo batteries)

Drop-out losses @ 4A 0.4V

Maximum power dissipation 8W

Number of servos Up to 10 servos in the complete system

CE approvals according to 2004/108/EC

Environmental conditions -10°C .... +50°C

Permissible temperature range -25°C .... +85°C

LCL filtering (EMI) For each individual servo output

Interference Suppression at

35MHz

Dimensions incl. latches for

battery connections

Screw diameter for mounting 4 x 4.2mm

Hole spacing for mounting 78.7mm x 67.7mm

Weight approx. 105 grams

Warranty 24 month

batteries, Lithium-Polymer batteries, LiFePo batteries

5 Ampère

50 Ampère

-20dB @ 35MHz, -34dB @ 100MHz

77mm x 99mm x 15.8mm

Technical modifications and errors excepted!

(C) EMCOTEC embedded controller technologies GmbH

(P) July 2008 Version 1.0 from 01.October 2008

Robert Hussmann www.emcotec.de

www.rc-electronic.com

Page 52 of 54

Page 53

DPSI RV Mini Family Operating Instructions Version 1.0

16. Warranty

EMCOTEC GmbH shall issue a 24-month warranty on the DPSI RV Mini. The

guarantee period shall begin with delivery of the equipment by the retailer and

shall be not extended by any guarantee repair or guarantee replacement.

During the period of guarantee, the warranty shall cover the repair or

replacement of any proven manufacturing or material defects at no charge. There

shall be no specific entitlement to repair work. In case of a guarantee claim, the

manufacturer shall reserve the right to exchange the equipment for a product of

equal value if repair of the item is not feasible for economic reasons. There shall

be no assumption of liability for consequential damages that are brought about by

a proven defect during operation of the DPSI RV Mini. There shall be no

extended claims for damages.

All transportation, packaging and travel expenses shall be borne by the

purchaser.

No liability shall be assumed for any damages during transport.

If repair is needed, the equipment must be sent to the appropriate service

center of the respective country or directly to EMCOTEC GmbH.

The guarantee shall only be valid when the following conditions are met:

The guarantee document (original invoice) must include the delivery date,

the company stamp, the serial number and signature of the retailer.

No intervention in the equipment may have been undertaken.

It must have been operated in accordance with our operating instructions.

Only the power sources and other accessory devices and components that

were recommended by us may have been used.

The guarantee document, the original invoice and other pertinent

information regarding the malfunction (a short description of the defect)

must be included with the transmittal.

The equipment must still be the property of the initial purchaser.

If equipment is sent in that later proves to be functional following an initial

inspection, we shall impose a flat processing fee of € 15.

In all other respects, the general business terms and conditions of

EMCOTEC embedded controller technologies GmbH shall apply for any

items not listed.

Page 53 of 54

Page 54

DPSI RV Mini Family Operating Instructions Version 1.0

Legal information:

Trademarks:

The following names are registered trademarks:

- EMCOTEC

- DPSI - Dual Power Servo Interface

- DPSI RV

Other product names mentioned in this manual may also be trademarks or registered

trademarks of their respective owners.

Copyright information:

This manual is copyrighted by EMCOTEC GmbH. All rights reserved. This document may not

be copied either entirely or in part, nor may it be transferred to any type of medium or

translated into any other language without the express written approval of EMCOTEC GmbH.

Manual Note:

EMCOTEC GmbH reserves the right make changes to this manual and to equipment

described herein without notice. Considerable effort has been made to ensure that this manual

is free of errors and omissions. We shall not assume responsibility or liability for any errors th at

may be contained in this manual nor for any incidental, concrete or consequential damage that

may arise from the provision of this manual, or the use of this manual in operating the

equipment, or in connection with the performance of the equipment when so operated.

Page 54 of 54

Loading...

Loading...