Page 1

histnictim

book

Coordinate

Englisch

Auflage;

Milling

Order

10.

9.

92

91

and

No,

8.

7.

90

89

Maier+Co.

A-5400

Hallein/Austria

Drilling

EN 2 455

6.

5.

4.

3.

88

87

86

85

Machine

Page 2

SAFETY

1.

KNOW

Read

plication

potential

2.

GROUND

If

tool

should

If

adapter

receptacle,

a

known

3.

KEEP

and

in

4.

REMOVE

WRENCHES

Form

justing

turning

5.

KEEP

Cluttered

6.

AVOID

ENVIRONMENT

Don't

Keep

7.

KEEP

All

visitors

work

8.

MAKE

—

with

moving

9.

DON'T

It

will

for

which

YOUR

the

owner's

and

hazards

is

equipped

be

plugged

is

the

ground.

GUARDS

working

habit

of

wrenches

on

tool.

WORK

areas

DANGEROUS

use

power.tools

work

area

CHILDREN

should

area.

WORKSHOP

padlocks,

starter

FORCE

do

the

it

was

RULES

POWER

manual

limitations

peculiar

ALL

used

adapter

Never

order.

ADJUSTING

checking

are

AREA

and

well

keys.

job

better

designed.

carefully.

as

well

to

this

TOOLS

with

three-prong

into a three-hole

to

accommodate

wire

remove

IN

PLACE

to

see

removed

CLEAN

benches

in

damp

illuminated.

AWAY

be

kept a safe

master

switches,

TOOL

and

TOOL

as

tool.

must

be

third

KEYS

that

from

invite

accidents.

or

wet

distance

KID

PROOF

be

safer

FOR

Learn

its

ap

the

specific

plug,

it

receptacle.

two-prong

attached

prong.

keys

tool

locations.

or

at

AND

and

ad

before

from

by

the

rate

to

re

POWER

10.

USE

RIGHT

Don't

force

not

designed

11.

WEAR

No

loose

moving

12.

USE

Also

is

13.

SECURE

Use

tical.

hands

14.

DON'T

Keep

times.

15.

MAINTAIN

CONDITION

Keep

performance.

coting

16.

DISCONNECT

before

sories

17.

AVOID

Make

cord.

18.

USE

ACCESSORIES

Consult

accessories

parts.

SAFETY

use

dusty.

clamps

It's

to

your

tools

and

servicing

such

sure

RECOMMENDED

TOOL

tool

or

attachment

for.

PROPER

clothing

face

WORK

safer

operate

OVERREACH

proper

or

GLASSES

or

dust

or a vise

than

using

tool.

footing

TOOLS

sharp

and

Follow

changing

accessories.

TOOLS

and

OS

blades,

ACCIDENTAL

switch

the

is

owner's

may

be

hazardous.

TOOLS

to

do a job

APPAREL

jewelry

mask

to

clean

instructions

when

bits,

"OFF"

manual.

to

if

cutting

hold

work

your

and

IN

for

changing

cutters.

before

Use

get

when

hand,

balance

TOP

best

STARTING

plugging

of

it

was

caught

operation

frees

and

for

improper

in

prac

both

at

all

safest

lubri-

acces

in

WEARYOUR

FORESIGHT

THAN

NO

IS

BETTER

SIGHT

The

operation

objects

severe

shields

recommend

being

eye

before

spectacles,

Sears

retail

of

thrown

damage.

commencing

Wide

or

standard

or

catalog

any

power

into

Always

Vision

stores.

tool

the

eyes,

wear

power

Safety

safety

glasses . . . available

can

result

which

safety

glasses

tool

operation.

Mask

for

in

can

use

foreign

result

in

or

eye

We

over

at

Page 3

+

Read

later.

+

Follow

+

Check

+

Keep

+

Do

not

lathe

+

Work

+

Check

+

After

and

+

Clamp

+

To

prevent

optimum

must

Example:

all

safety

bags

the

leave

bed

only

oil

working

oil

these

all

working

be

blocked.

Important

instructions

rules

and

cartons

lathe

or

with

level

workplaces

If

longitudinal

must

clean,

cleaning

around

sharpened

regularly.

with

surfaces.

coolant,

unnecessary

results,

cross

be

slide

clamped.

- a few

for

power

for

parts.

lubricated,

rags,

moving

and

wear

tools

parts

tools.

clean

tools

of

all

feed

slide,

Tips

minutes

tools.

of

firmly.

the

movements

for

milling

pinion

now

and

adjusted

or

other

the

wet

surfaces

slides

and

may

materials

lathe.

and

other

is

than

used,

vertical

save

hours

as

instructed

on

thoroughly

to

assure

the

then

slide

feed

+

Switch

+

Never

spindle

clean

speeds

machine

only

with

when

compressed

machine

air.

is

OFF.

Page 4

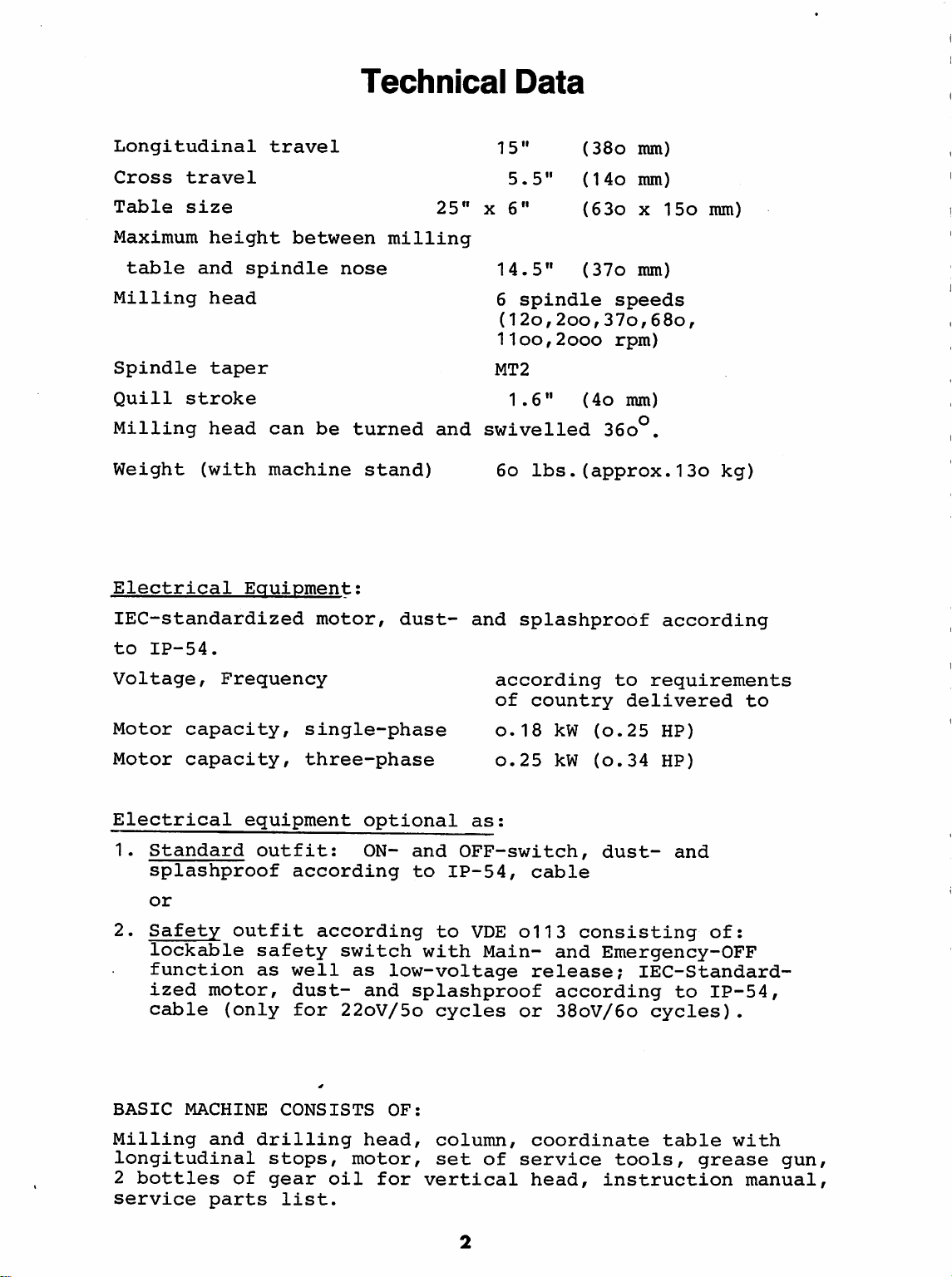

Technical

Data

Longitudinal

Cross

Table

Maximum

table

Milling

Spindle

Quill

Milling

Weight

Electrical

travel

size

height

and

head

taper

stroke

head

(with

travel

spindle

can

machine

Equipment:

lEC-standardized

between

nose

be

turned

stand)

motor,

25"

milling

and

dust-

15"

5.5"

X

6"

14.5"

6

spindle

(12o,2oo,37o,68o,

(38o

(14o

(63o

(37o

11oo,2ooo

MT2

1.6"

swivelled

6o

and

splashproof

(4o

36o°.

lbs.(approx.13o

mm)

mm)

X

15o

mm)

speeds

rpm)

mm)

according

mm)

kg)

to

IP-54.

Voltage,

Motor

Motor

capacity,

capacity,

Electrical

1.

Standard

splashproof

or

2.

Safety

lockable

function

ized

motor,

cable

BASIC

MACHINE

Frequency

single-phase

three-phase

equipment

outfit:

according

outfit

according

safety

as

well

dust-

(only

for

CONSISTS

optional

ON-

and

to

switch

as

low-voltage

and

splashproof

22oV/5o

OF:

according

of

o.18

o.25

as:

OFF-switch,

IP-54,

to

VDE

with

Main-

cycles

to

requirements

country

kW

kW

cable

delivered

(o.25

(o.34

dust-

HP)

HP)

and

oil 3 consisting

and

Emergency-OFF

release;

according

or

38oV/6o

lEC-Standard-

to

cycles).

to

of:

IP-54,

Milling

and

longitudinal

2

bottles

service

of

parts

drilling

stops,

gear

oil

list.

head,

motor,

for

column,

set

of

vertical

coordinate

service

head,

instruction

table

tools,

with

grease

manual,

gun,

Page 5

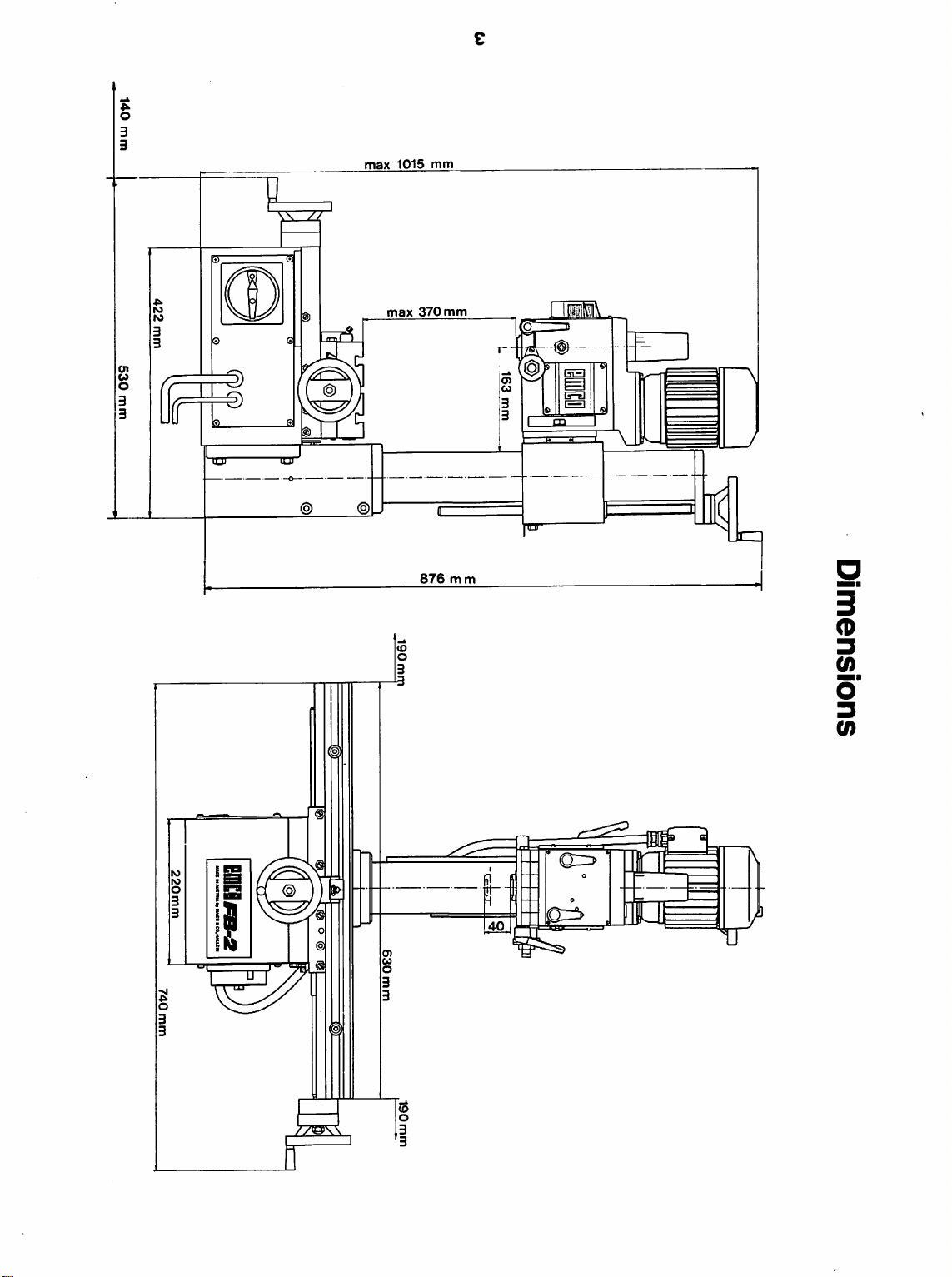

140

mm

530

mm

422

mm

0)

I

163

mm

740

mm

220

mm

Dimensions

190

mm

m

o

@

0

630

mm

190

mm

Page 6

The

machine

from

(Mlox2o)

the

.

is

delivered

underside

UNPACKING

of

the

in

crate

THE

a

MACHINE

wooden

with

crate.

4

hexagon

It

is

fixed

screws

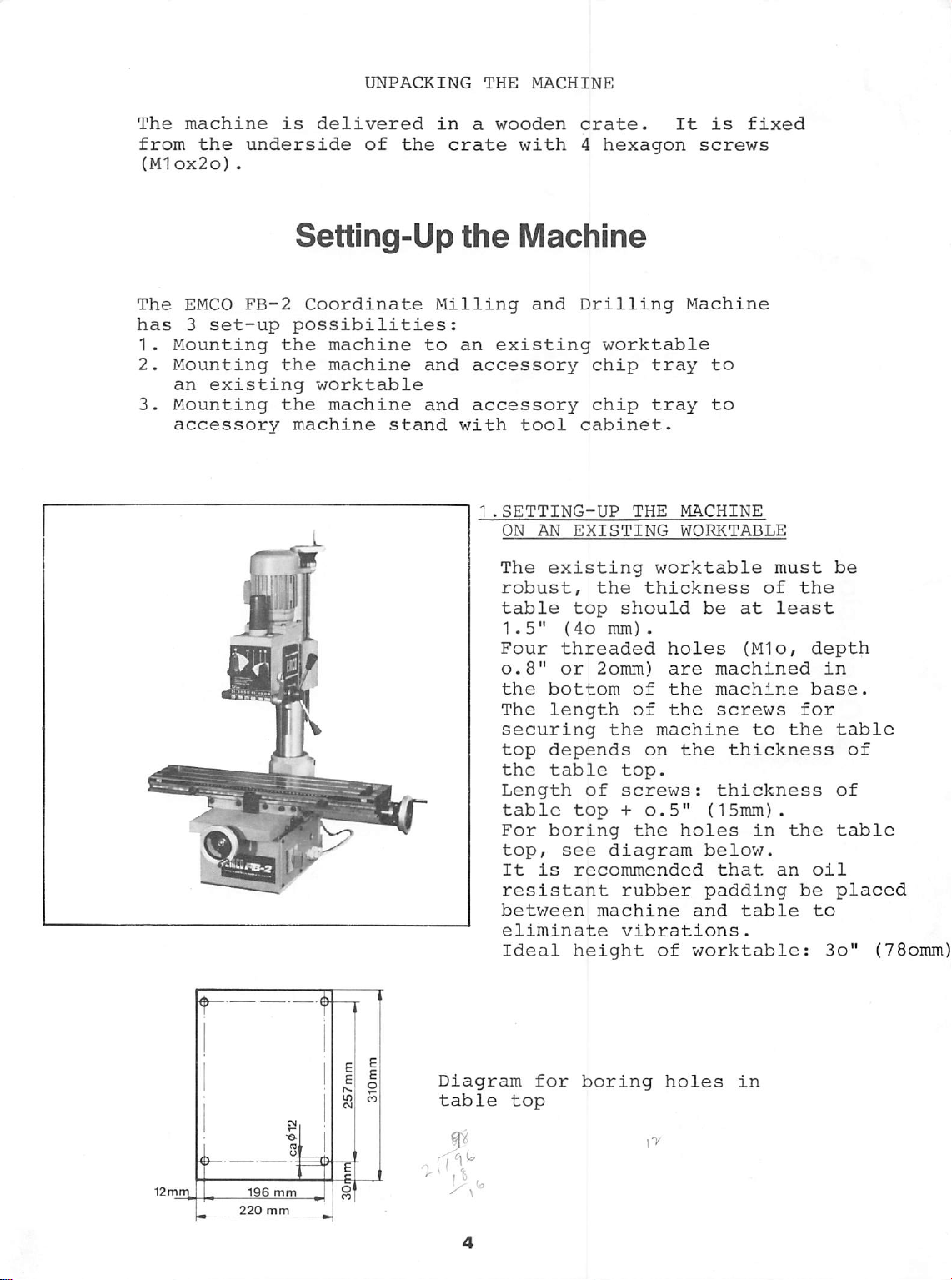

The

EMCO

has 3 set-up

1.

Mounting

2.

Mounting

an

3.

Mounting

FB-2

existing

accessory

Setting-Up

Coordinate

possibilities:

the

machine

the

machine

worktable

the

machine

machine

stand

the

Milling

to

an

and

and

with

Machine

and

existing

accessory

accessory

tool

1

.SETTING-UP

ON

AN

The

existing

robust,

table

1.5"

Four

0.8"

the

bottom

The

length

securing

top

depends

the

table

Length

table

For

boring

top,

It

is

resistant

between

eliminate

Ideal

Drilling

worktable

chip

chip

tray

tray

cabinet.

THE

EXISTING

worktable

the

thickness

top

should

(4o

mm)

.

threaded

or

2omm)

of

of

the

machine

on

top.

of

screws:

top + 0.5"

the

see

diagram

recommended

rubber

machine

vibrations.

height

of

Machine

to

to

MACHINE

WORKTABLE

be

at

holes

are

the

the

the

(Mio,

machined

machine

screws

thickness

thickness

(15mm)

holes

below.

that

padding

and

table

worktable:

of

to

in

must

the

least

depth

base.

for

the

.

the

an

oil

be

be

in

table

of

table

placed

to

3o"

of

(78omm)

196

220

Diagram

table

mm

mm

top

for

boring

holes

in

Page 7

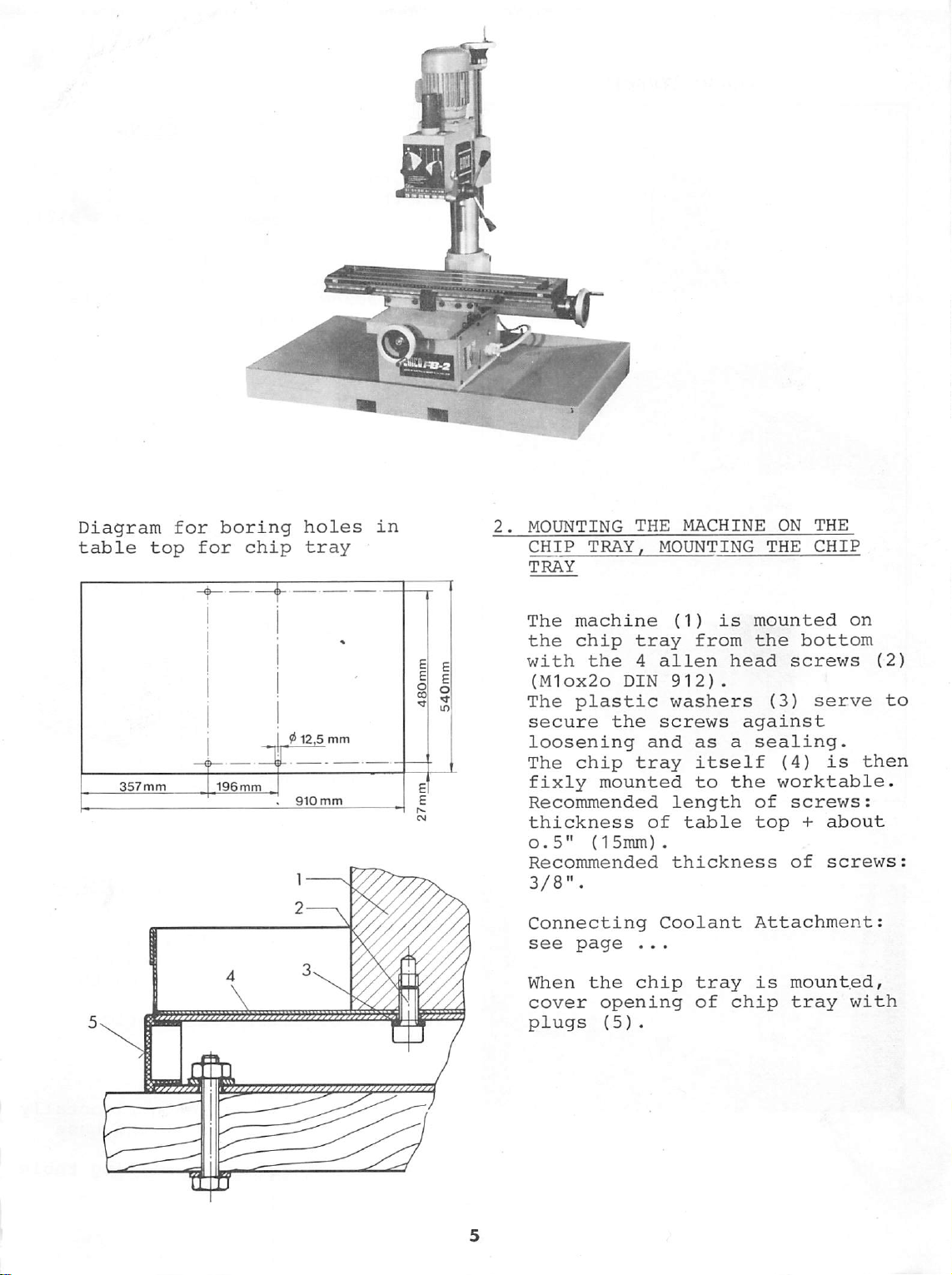

Diagram

table

357mm

for

top

boring

for

196mm

chip

holes

tray

0

12.5

910

mm

mm

in

2.

MOUNTING

CHIP

TRAY

The

the

with

(iyi1ox2o

The

secure

loosening

The

fixly

Recommended

thickness

o.5"

Recommended

3/8".

THE

TRAY,

machine

chip

the

tray

4

DIN

plastic

the

chip

tray

mounted

{15mm)

MACHINE

MOUNTING

(1)

is

from

alien

912)

.

washers

screws

and

as a sealing.

itself

to

length

of

table

.

thickness

ON

THE

mounted

the

bottom

head

screws

(3)

against

(4)

the

worktable.

of

screws:

top + about

of

THE

CHIP

on

serve

is

then

screws:

(2)

to

Connecting

see

page

When

cover

plugs

the

opening

(5)

Coolant

..

.

chip

.

tray

of

chip

Attachment:

is

mounted,

tray

with

Page 8

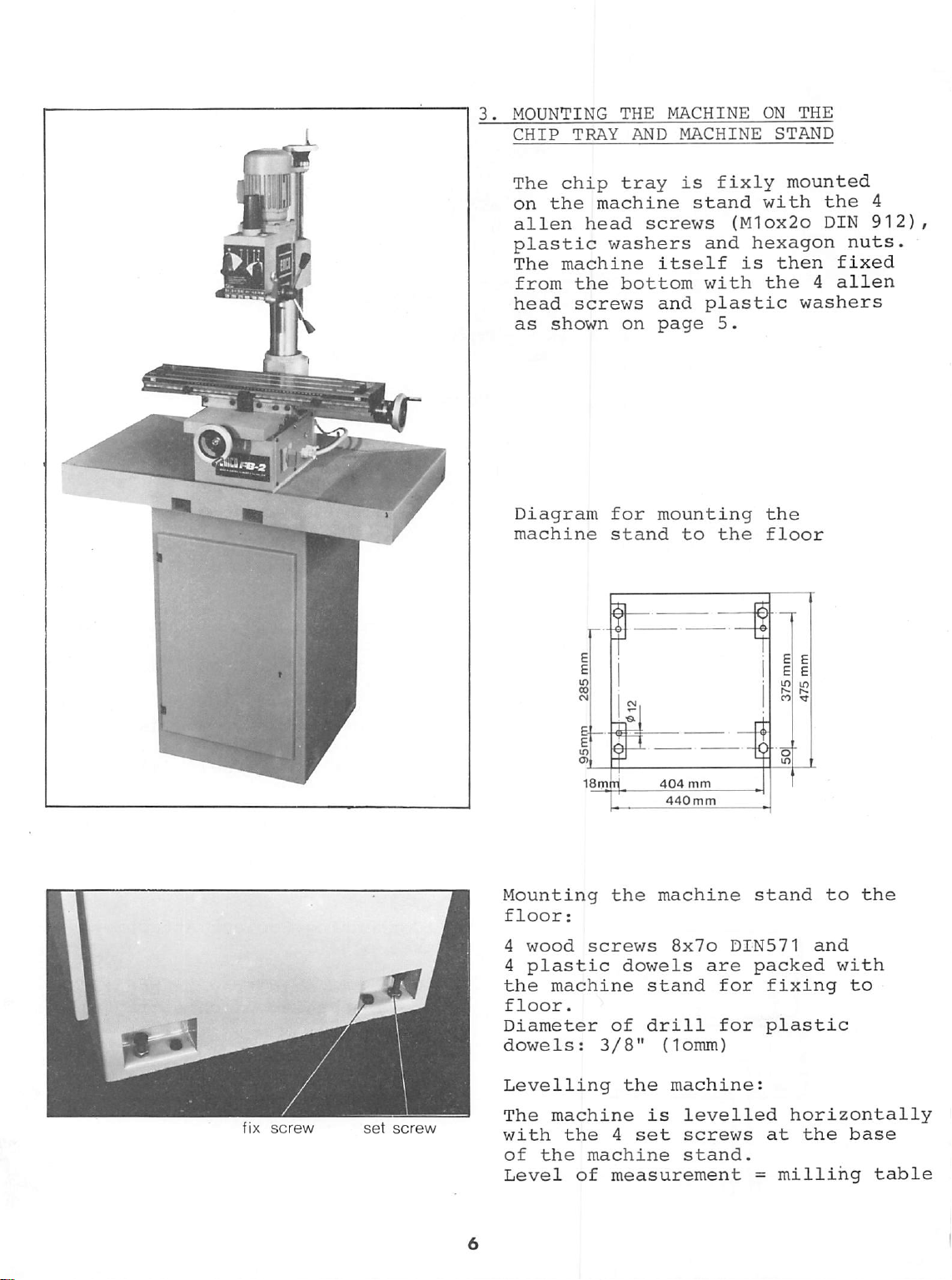

3.

MOUNTING

CHIP

The

on

alien

plastic

The

from

head

as

TRAY

chip

the

head

machine

the

screws

shown

THE

AND

tray

machine

screws

washers

itself

bottom

and

on

page

MACHINE

MACHINE

is

fixly

stand

and

with

plastic

5.

ON

STAND

mounted

with

{M1ox2o

hexagon

is

then

the

THE

the

DIN

nuts.

fixed

4

alien

washers

4

912),

Diagram

machine

Mounting

floor;

4

wood

4

plastic

the

machine

floor.

Diameter

dowels:

for

stand

the

screws

dowels

of

3/8"

mounting

to

404

mm

440mm

machine

8x7o

are

stand

drill

(lomm)

the

DXN571

for

for

the

floor

stand

packed

fixing

plastic

to

and

the

with

to

fix

screw

set

screw

Levelling

The

machine

with

of

Level

the

the

machine

of

the

machine:

is

levelled

4

set

screws

stand.

measurement

horizontally

at

the

=

milling

base

table

Page 9

- n

&

HI

mm

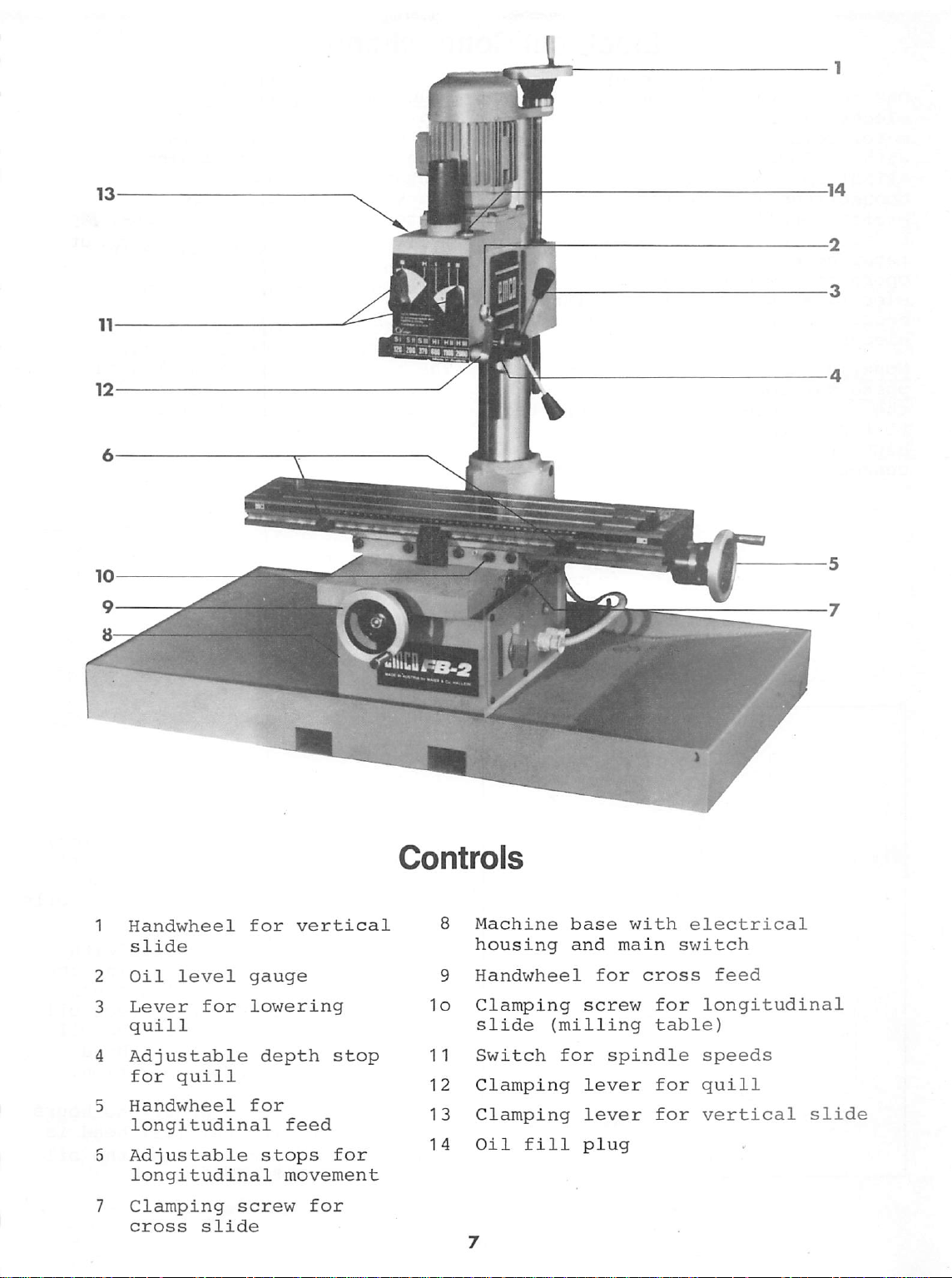

Handwheel

slide

Oil

level

Lever

quill

for

Adjustable

for

quill

Handwheel

longitudinal

Adjustable

longitudinal

Clamping

cross

screw

slide

for

vertical

gauge

lowering

depth

for

feed

stops

movement

for

stop

for

Controls

8 Machine

housing

9 Handwheel

10

Clamping

slide

11

Switch

12

Clamping

13

Clamping

14

Oil

(milling

for

fill

base

and

for

screw

spindle

lever

lever

plug

with

main

cross

for

table)

for

for

electrical

switch

feed

longitudinal

speeds

quill

vertical

slide

Page 10

Electrical

Connections

Due

to

the

various

electrical

motor

cord

receptacles,

is

with a plug.

ATTENTION:

connections

The

must

professionally.

be

connected

receptacle.

operator

electrical

occurs

electrical

Mounting

phase

the

yellow-green

to

the

blue

connected

protected

in

the

the

version;

grounding

and

brown

to

shock

equipment.

types

not

equipped

electrical

be

made

Cord

must

to a grounded

Only

then

is

from

when

motor

plug

wire

or

for

a

single-

is

contact.

wires

the

other

(MP,R)

contacts.

of

the

the

an

failure

connected

The

are

CLEANING

All

unpainted

faces

are

protective.

tective

after

machine

lightly

must

this,

surfaces

coated

THE

coated

Moxintinq

phase

The

connected

contact.

black

nected

With

it

can

runs

In

this

example,

wires)

The

shows

direction

MACHINE

machine

with

This

be

removed

all

these

must

with

the

plug

equipment:

yellow-green

to

the

The

blue,

wires

to

the

happen

in

must

arrow

the

(R,S,T)

the

other

three-phase

that

the

wrong

case,

the

blue

be

on

the

correct

of

the

sur

a

rust

rust

pro

and

unpainted

be

oil.

with

wire

three-

is

grounding

brown

are

contacts.

equipment,

the

motor

direction.

2

wires

and

(for

black

interchanged.

vertical

rotating

spindle.

and

con

head

(B

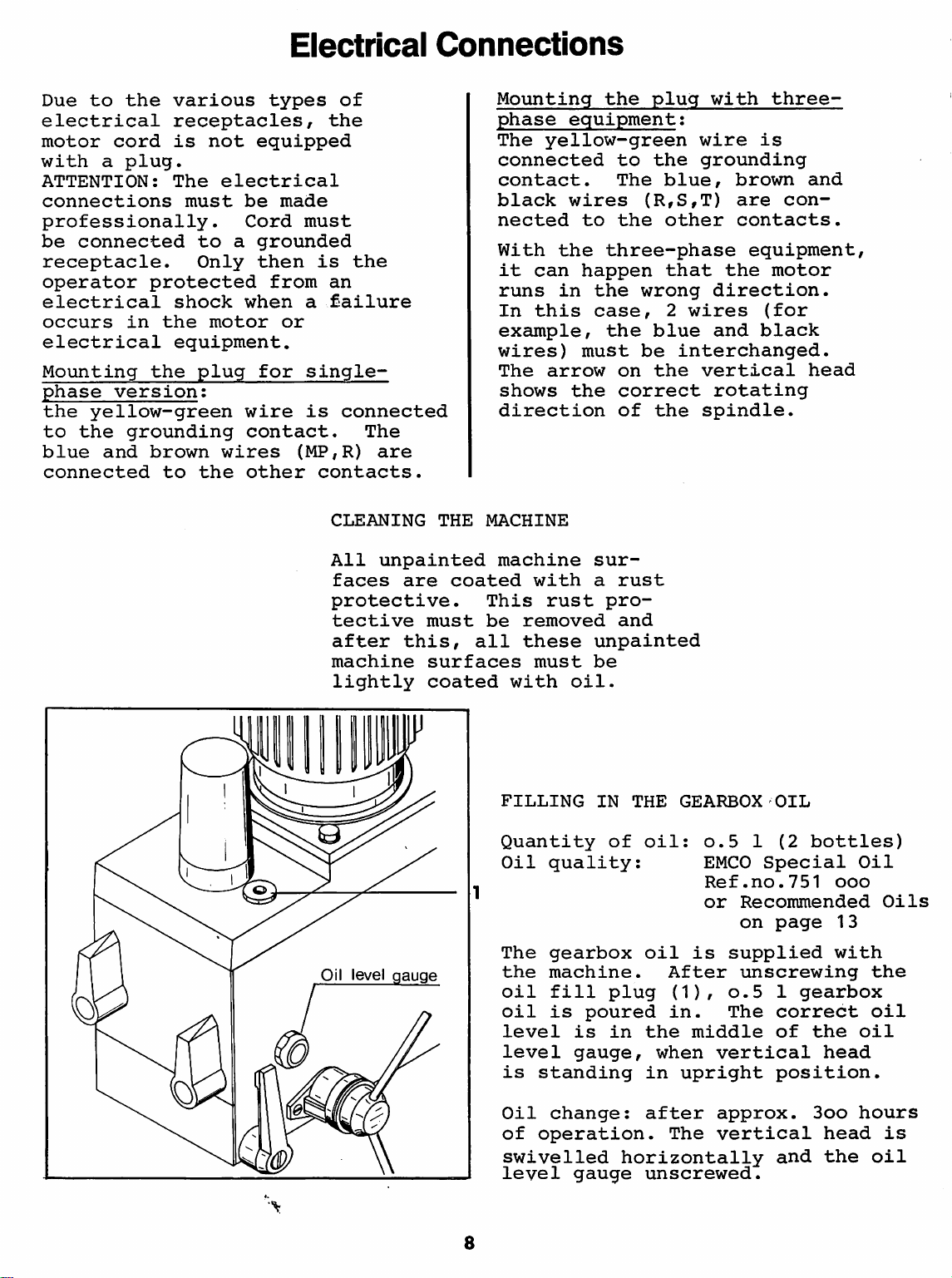

Oil

level

gauge

FILLING

Quantity

Oil

The

the

oil

oil

level

level

is

Oil

of

swivelled

level

8

IN

THE

of

quality:

gearbox

machine.

fill

is

plug

poured

is

in

gauge,

standing

change:

operation.

horizontally

gauge

GEARBOX

oil:

o.5 1 (2

EMCO

Ref.no.751

or

Recommended

on

oil

is

supplied

After

(1),

in.

the

when

in

upright

after

The

unscrewing

0.5 1 gearbox

The

middle

vertical

approx.

vertical

unscrewed.

OIL

bottles)

Special

page

correct

of

the

head

position.

Boo

head

and

the

Oil

ooo

Oils

13

with

the

oil

oil

hours

is

oil

Page 11

Operating

Tips

-

Adjustments

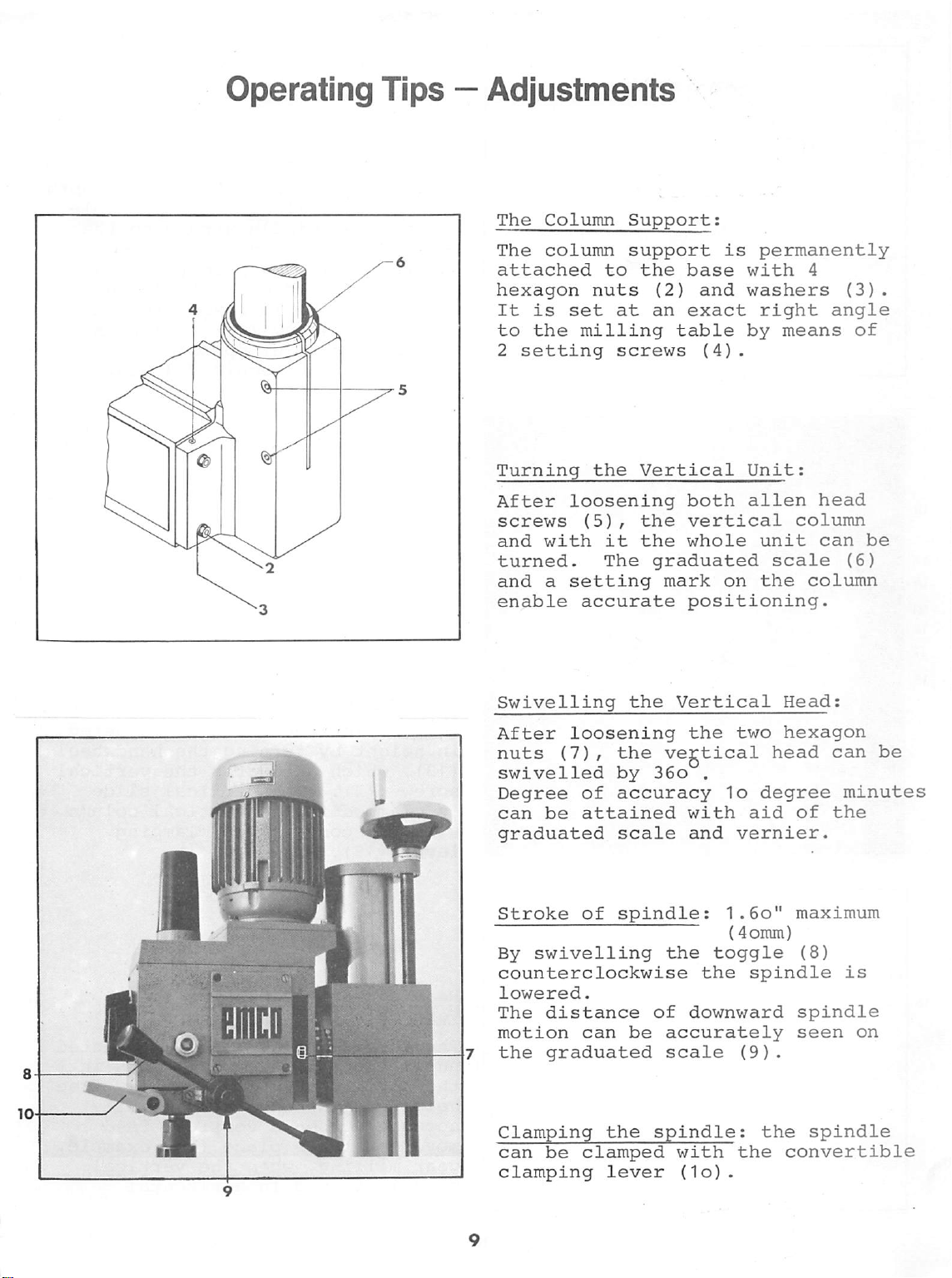

The

Column

The

column

attached

hexagon

It

is

to

the

2

setting

to

nuts

set

milling

Support;

support

the

(2)

at

an

table

screws

is

base

and

exact

(4).

permanently

with

4

washers

right

by

angle

means

(3)

of

.

Turning

After

screws

and

loosening

(5),

with

turned.

and a setting

enable

accurate

Swivelling

After

nuts

swivelled

Degree

can

loosening

(7),

of

be

attained

graduated

Stroke

By

counterclockwise

lowered.

The

motion

7 the

of

swivelling

distance

can

graduated

the

Vertical

the

it

the

The

graduated

the

the

by

accuracy

scale

spindle:

of

be

Unit:

both

vertical

whole

mark

positioning.

alien

on

Vertical

the

two

vegtical

36o

,

1o

with

and

the

downward

accurately

scale

aid

vernier.

1.6o"

{4omm)

toggle

the

spindle

(9)

head

column

unit

can

scale

the

column

Head:

hexagon

head

degree

of

maximum

(8)

spindle

seen

.

be

(6)

can

be

minutes

the

is

on

Clamping

can

be

clamping

the

clamped

lever

spindle:

with

(1o).

the

the

convertible

spindle

Page 12

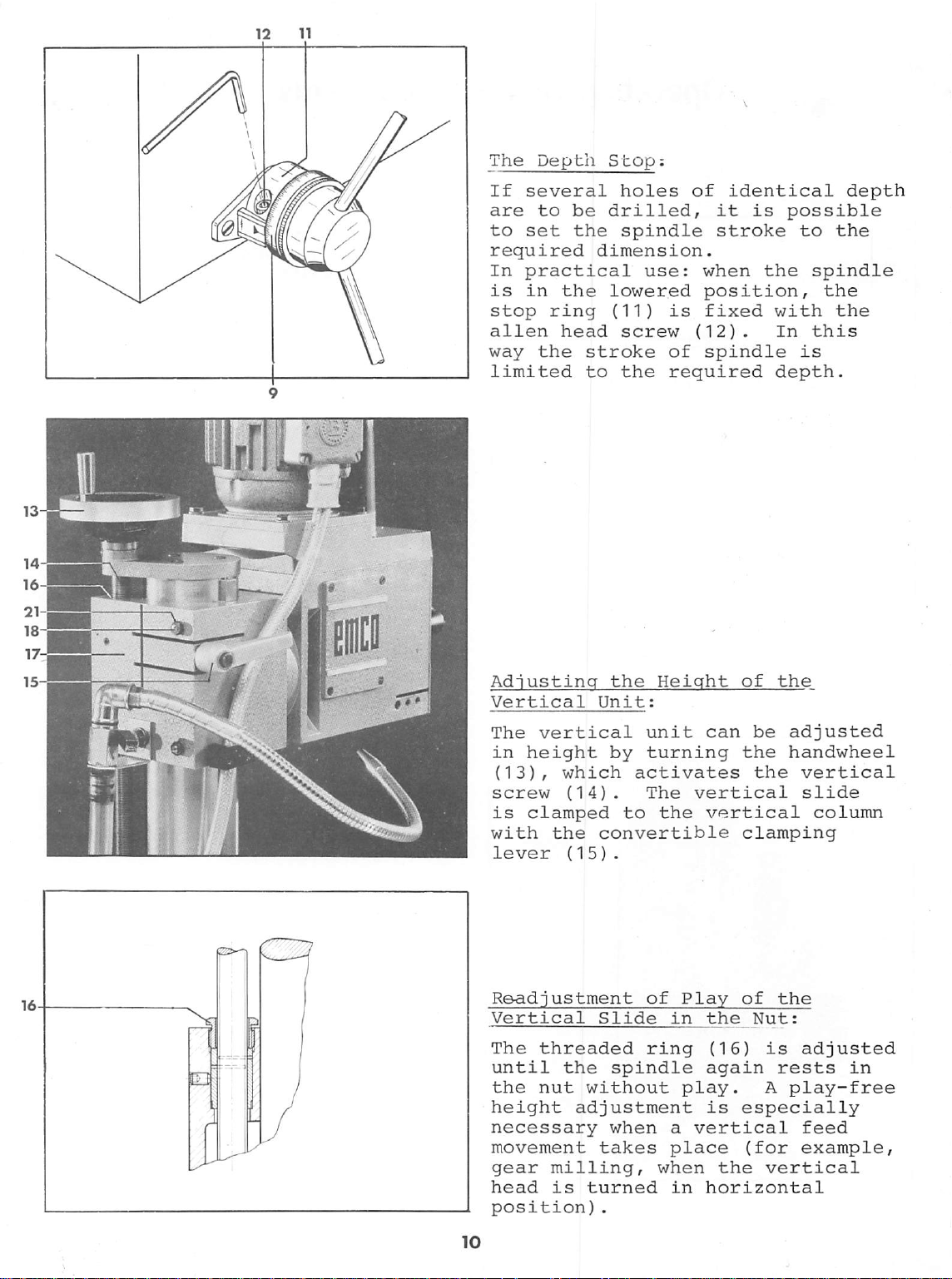

The

Depth

If

several

are

to

to

set

required

In

practical

is

in

the

stop

alien

way

ring

head

the

limited

Stop;

holes

be

drilled,

the

spindle

dimension.

lowered

(11)

screw

stroke

to

the

of

use:

is

(12)

of

required

Identical

it

is

stroke

when

the

position,

fixed

.

with

In

spindle

depth.

depth

possible

to

the

spindle

the

the

this

is

Adjusting

Vertical

The

vertical

in

height

(13)

,

which

screw

is

with

lever

Readjustment

Vertical

The

until

the

height

(14)

clamped

the

(15)

threaded

the

nut

without

adjustment

necessary

movement

gear

head

position)

milling,

is

turned

the

Height

Unit:

unit

by

turning

activates

.

The

vertical

to

the

convertible

.

of

Play

Slide

in

ring

spindle

play.

when

takes

.

a

vertical

place

when

in

of

the

can

be

the

the

vertical

clamping

of

the

the

Nut:

(16)

again

is

rests

A

is

especially

(for

the

vertical

horizontal

adjusted

handwheel

vertical

slide

column

adjusted

in

play-free

feed

example,

Page 13

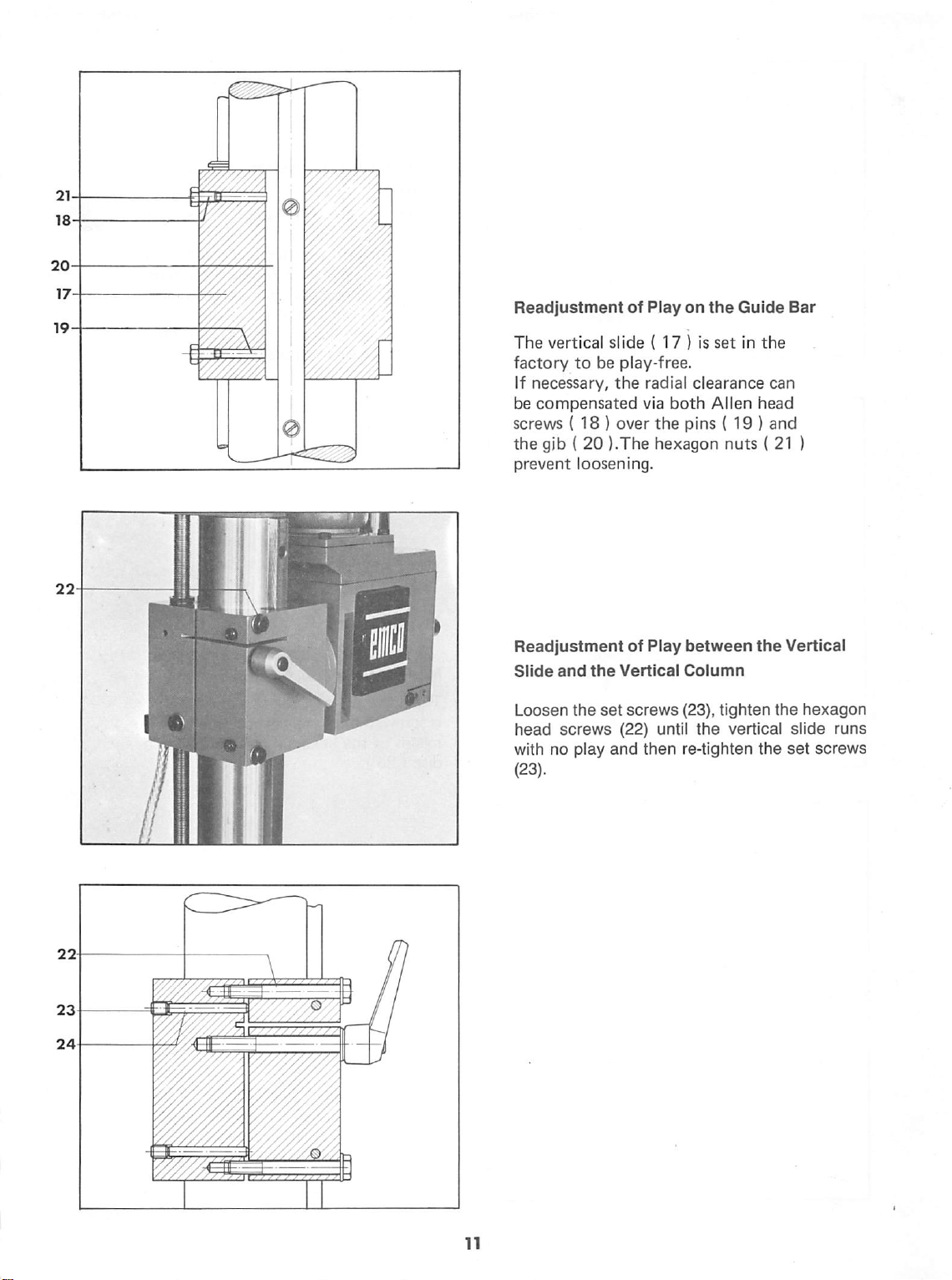

Readjustment

The

vertical

factory

If

necessary,

be

compensated

screws

the

gib ( 20

prevent

slide ( 17 ) Is

to

be

play-free.

the

(18)

over

).The

loosening.

of

Play

radial

via

both

the

hexagon

on

the

Guide

set

in

clearance

Allen

head

pins

(19)

nuts ( 21

Bar

the

can

and

)

Readjustment

Slide

and

the

Loosen

head

with

(23).

the

screws

no

play

set

(22)

and

of

Play

Vertical

screws

until

then

between

Column

(23),

the

re-tighten

the

tighten

vertical

the

Vertical

the

hexagon

slide

set

screws

runs

Page 14

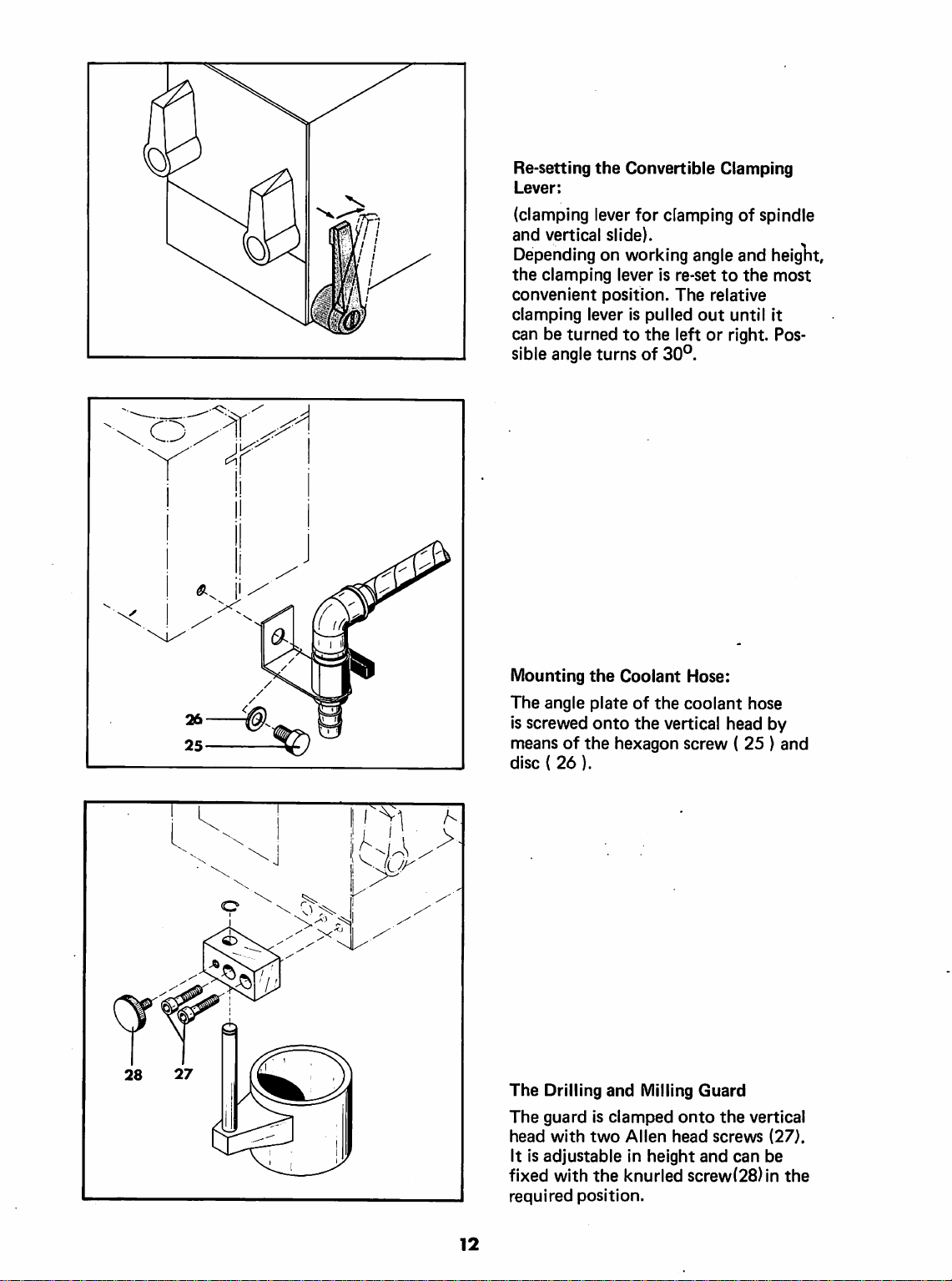

Re-setting

Lever;

(clamping

and

Depending

the

clamping

convenient

clamping

can

be

sible

the

lever

vertical

slide).

on

lever

position.

lever

turned

angle

turns

Convertible

to

for

clamping

working

is

of

angle

is

re-set

The

pulled

the

out

left

30°.

relative

or

Clamping

of

spindle

and

heiglit,

to

the

most

until

it

right.

Pos

Mounting

The

angle

is

screwed

means

disc ( 26).

The

The

head

It

fixed

required

of

the

Drilling

guard

with

is

adjustable

with

position.

the

Coolant

plate

of

onto

the

hexagon

and

is

clamped

two

Allen

in

the

knurled

Hose:

the

coolant

vertical

screw ( 25 ) and

Milling

height

Guard

onto

head

screws

and

screw(28)in

hose

head

the

vertical

can

by

(27).

be

the

12

Page 15

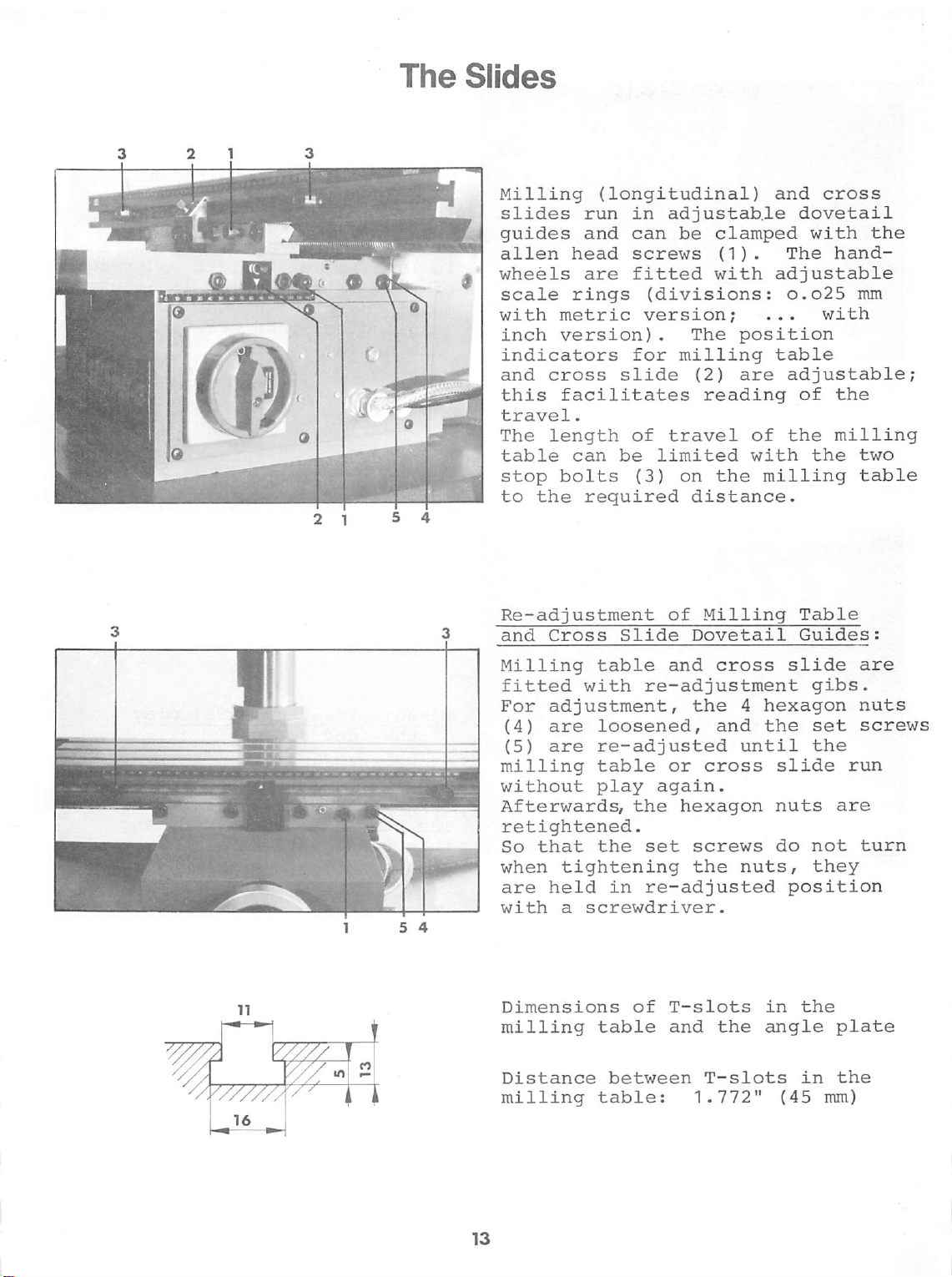

The

Slides

2 1

5

Milling

slides

guides

alien

wheels

scale

with

inch

indicators

and

this

travel.

The

table

stop

to

the

4

Re-adjustment

and

Milling

fitted

For

(4)

(5)

milling

without

Afterwards,

(longitudinal)

run

in

and

can

head

rings

metric

version)

cross

facilitates

length

can

bolts

are

screws

fitted

(divisions;

version;

.

for

slide

of

be

(3)

required

Cross

Slide

table

with

re-adjustment

adjustment,

are

loosened,

are

re-adjusted

table

play

the

adjustable

be

clamped

(1)

.

with

The

position

milling

(2)

are

reading

travel

limited

on

of

with

the

distance.

of

Milling

Dovetail

and

cross

the 4 hexagon

and

until

or

cross

again.

hexagon

and

cross

dovetail

with

The

hand-

adjustable

o.o25

.

..

with

table

adjustable;

of

the

the

milling

the

milling

Table

Guides:

slide

gibs.

the

set

the

slide

nuts

are

the

mm

two

table

are

nuts

screws

run

retightened.

So

that

when

are

with

the

tightening

held

in

a

screwdriver.

set

screws

the

nuts,

re-adjusted

do

not

they

position

turn

Dimensions

milling

Distance

milling

of

table

between

table:

T-slots

and

the

T-slots

1.772"

in

the

angle

in

(45

plate

the

mm)

Page 16

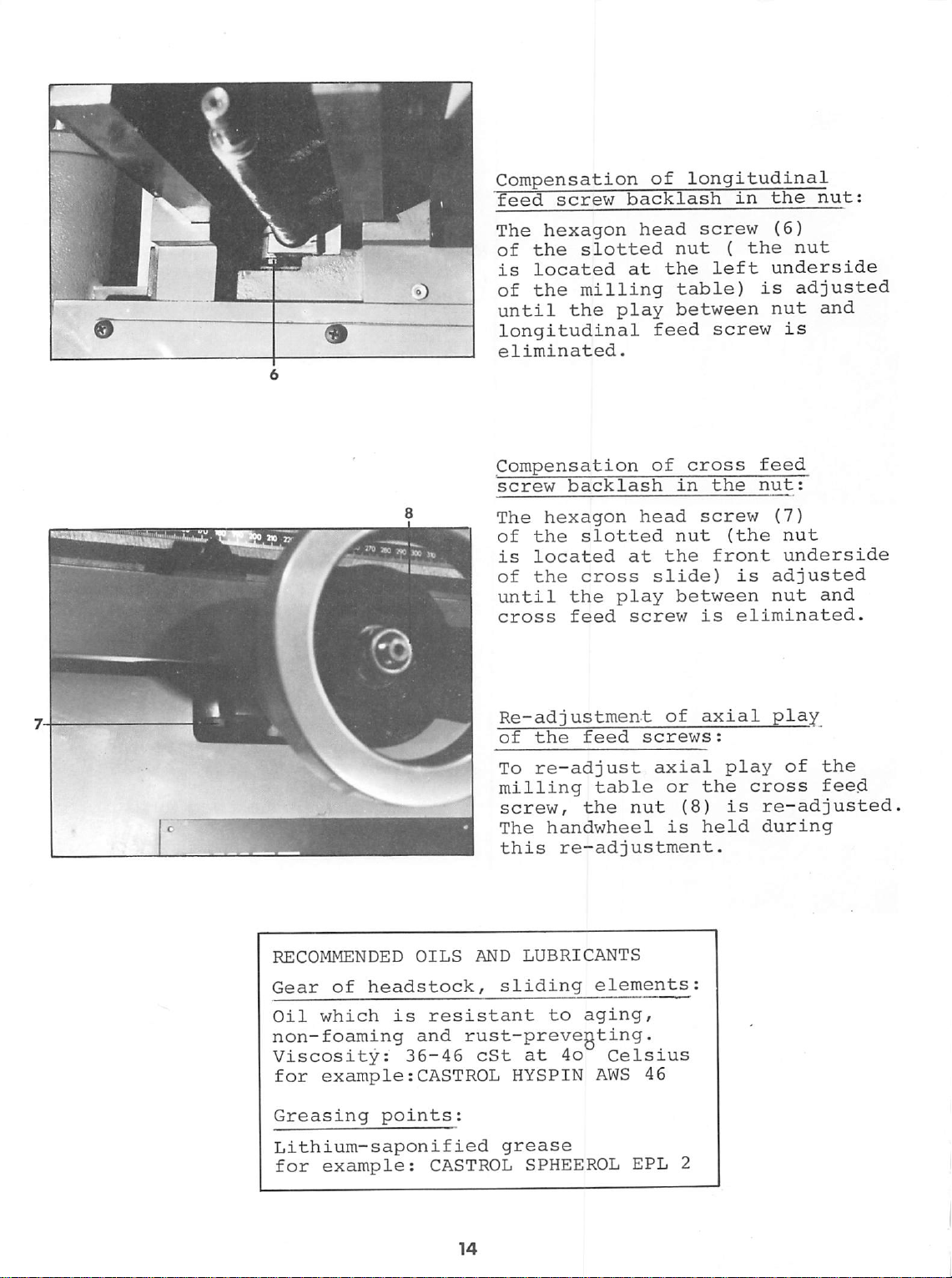

Compensation

feed

The

of

is

of

until

screw backlash

hexagon

the

slotted

located

the

milling

the

play

longitudinal

eliminated.

of

head

at

feed

longitudinal

in

screw

nut

(

the

the

left

table)

is

between

screw

the

nut:

(6)

nut

underside

adjusted

nut

and

is

Compensation

screw backlash

The

hexagon

of

the

slotted

is

located

of

the

until

cross

the

feed

at

cross

play

screw

Re-adjustment

of

the

feed

To

re-adjust

milling

screw,

The

this

table

the

nut

handwheel

re-adjustment.

of

in

head

nut

the

slide)

between

of

screws:

axial

or

(8)

is

cross

the

screw

(the

front

is

is

eliminated.

axial

play

the

is

held

feed

nut:

(7)

nut

underside

adjusted

nut

and

play

of

the

cross

feed

re-adjusted

during

RECOMMENDED

Gear

Oil

of

which

non-foaming

Viscosity:

for

example:CASTROL

Greasing

Lithium-saponified

for

example:

OILS

headstock,

is

resistant

and

36-46

points:

CASTROL

AND

LUBRICANTS

sliding

to

elements

aging,

rust-prevegting.

cSt

at

4o

Celsius

HYSPIN

grease

SPHEEROL

AWS

46

EPL

2

Page 17

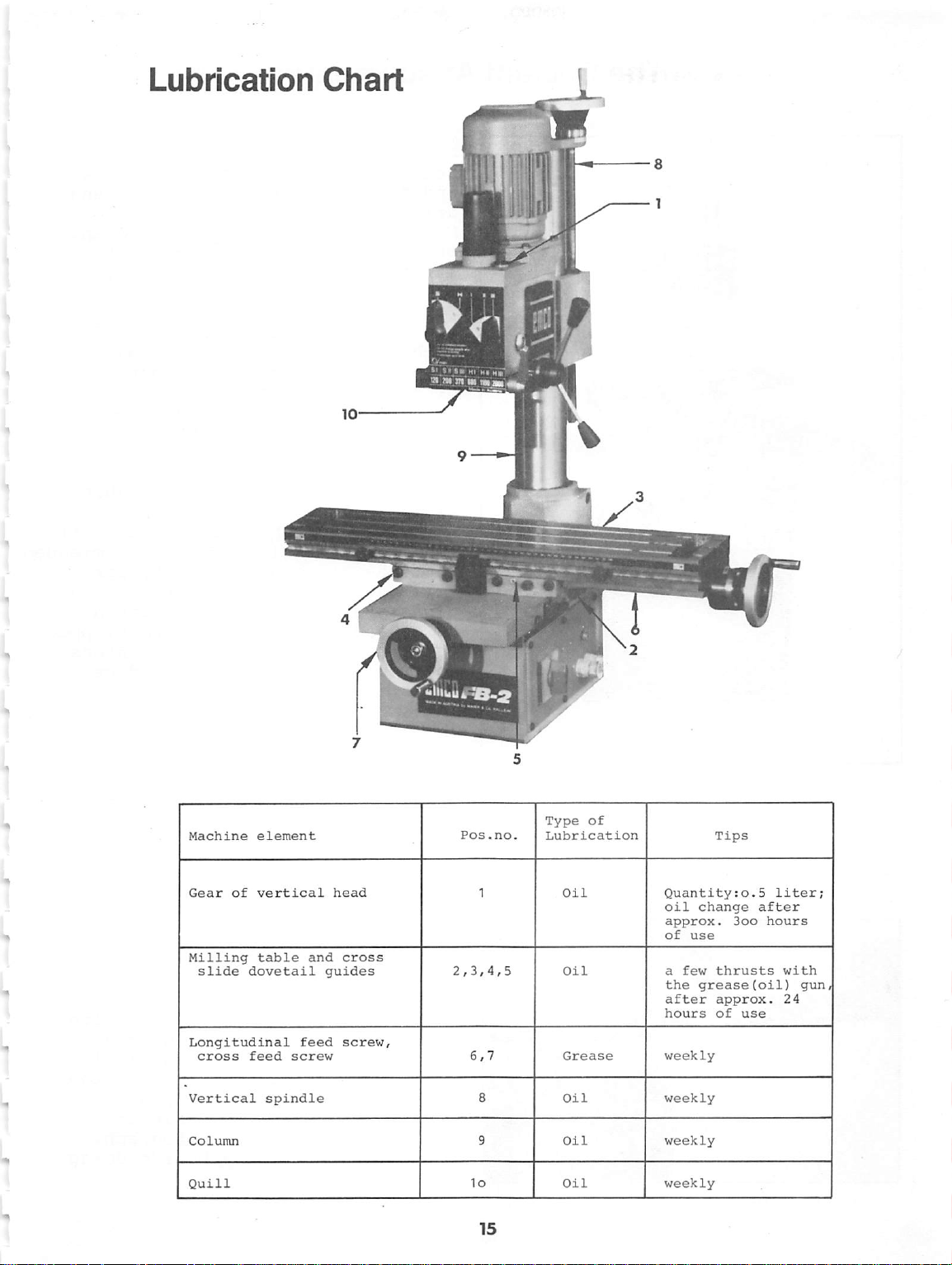

Lubrication

Chart

Machine

Gear

Milling

slide

element

of

vertical

table

dovetail

Longitudinal

cross

Vertical

Column

Quill

feed

spindle

feed

screw

and

head

cross

guides

screw

Pos.no

Type

of

Lubrication

Oil

Oil

Grease

Oil

Oil

;

1

Quantity:o.5

oil

change

approx.

of

use

a

few

the

grease(oil)

after

hours

weekly

weekly

weekly

Tips

after

3oo

thrusts

approx.

of

use

Liter;

hours

with

gun

24

Page 18

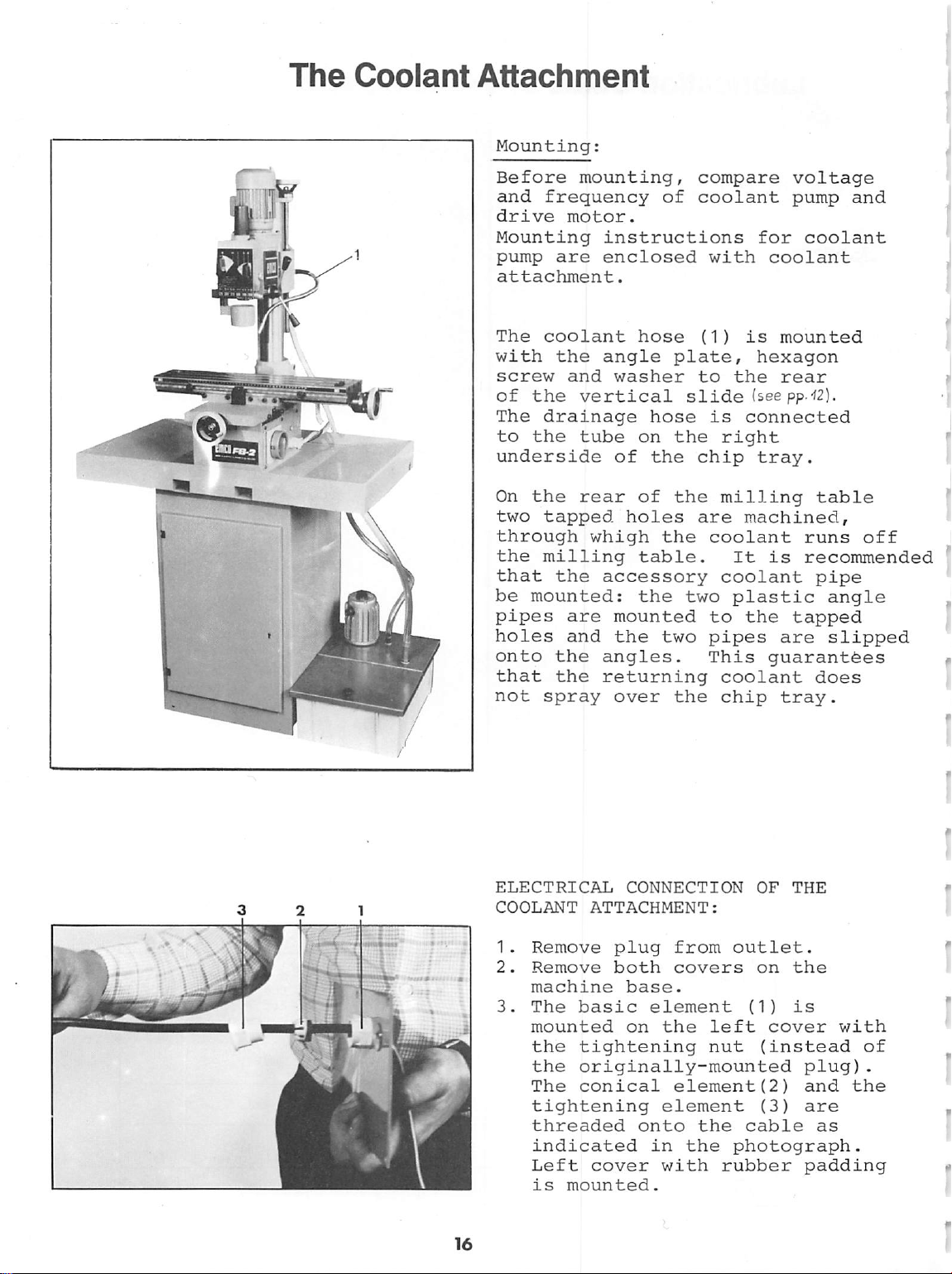

The

Coolant

Attachment

Mounting:

Before

and

drive

Mounting

pump

attachment.

The

with

screw

of

The

to

mounting,

frequency

motor.

are

coolant

the

and

the

vertical

drainage

the

tube

underside

On

the

rear

two

tapped

through

the

milling

that

be

pipes

holes

onto

that

not

the

mounted:

are

and

the

the

spray

of

instructions

enclosed

hose

angle

washer

plate,

slide

hose

on

the

of

the

of

the

holes

whigh

the

table.

accessory

the

two

mounted

the

two

angles.

returning

over

the

compare

coolant

for

with

(1)

coolant

is

hexagon

to

the

(see

is

connected

right

chip

tray.

milling

are

machined,

coolant

It

is

coolant

plastic

to

the

pipes

This

guarantees

coolant

chip

voltage

pump

mounted

rear

PP'

and

coolant

'^2).

table

runs

recommended

pipe

angle

tapped

are

slipped

does

tray.

off

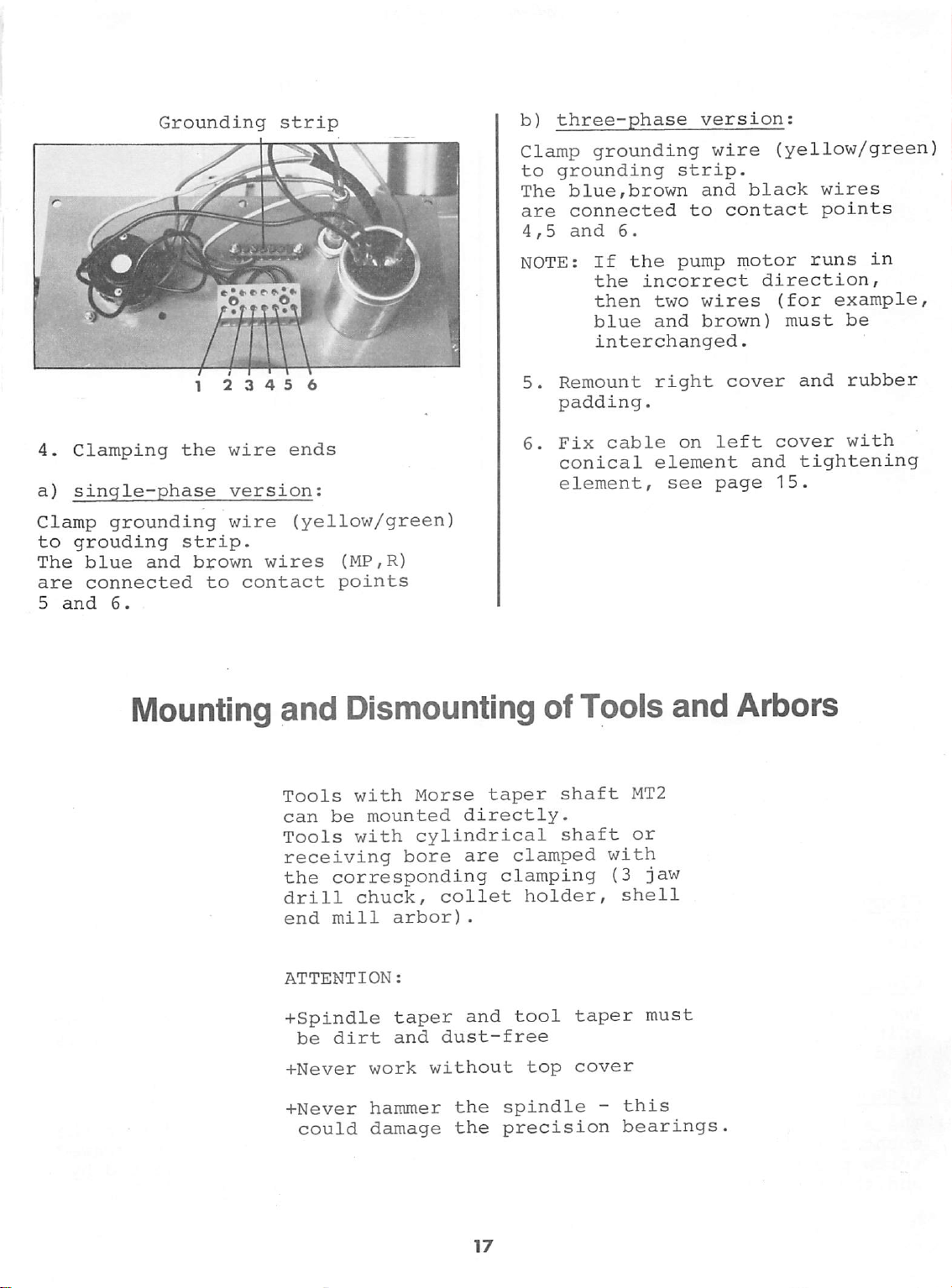

ELECTRICAL

COOLANT

1.

Remove

2.

Remove

machine

3.

The

mounted

the

the

The

tightening

threaded

indicated

Left

is

CONNECTION

ATTACHMENT:

plug

both

basic

tightening

base.

element

on

the

from

covers

left

nut

outlet.

originally-mounted

conical

cover

mounted.

element(2)

element

onto

in

the

with

the

rubber

OF

THE

on

the

(1)

is

cover

(instead

plug)

and

(3)

are

cable

as

photograph.

padding

with

of

.

the

Page 19

Grounding

strip

b)

three-phase

version;

4.

Clamping

a)

single-phase

Clamp

to

The

are

5

grounding

grouding

blue

connected

and

6.

1 2 3 4 5 6

the

strip.

and

brown

wire

version;

wire

to

contact

ends

(yellow/green)

wires

(MP,R)

points

Clamp

to

grounding

The

blue,brown

are

connected

4,5

and

NOTE:

5.

Remount

padding.

6.

Fix

conical

element,

grounding

strip.

and

to

6.

If

the

pump

the

incorrect

then

blue

interchanged.

cable

two

wires

and

brown)

right

on

element

see

wire

black

contact

motor

direction,

cover

left

and

page

(yellow/green

wires

points

runs

(for

must

and

cover

tightening

15.

in

example,

be

rubber

with

Mounting

and

Tools

can

Tools

receiving

the

drill

end

ATTENTION:

+Spindle

be

+Never

+Never

could

Dismounting

with

be

with

corresponding

chuck,

mill

dirt

Morse

mounted

cylindrical

bore

arbor)

taper

and

work

hammer

without

damage

taper

directly.

are

collet

.

and

dust-free

the

the

of

clamped

clamping

holder,

tool

top

spindle

precision

Tools

shaft

shaft

taper

cover

MT2

or

with

(3

jaw

shell

must

-

this

bearings

and

Arbors

Page 20

JZl

i

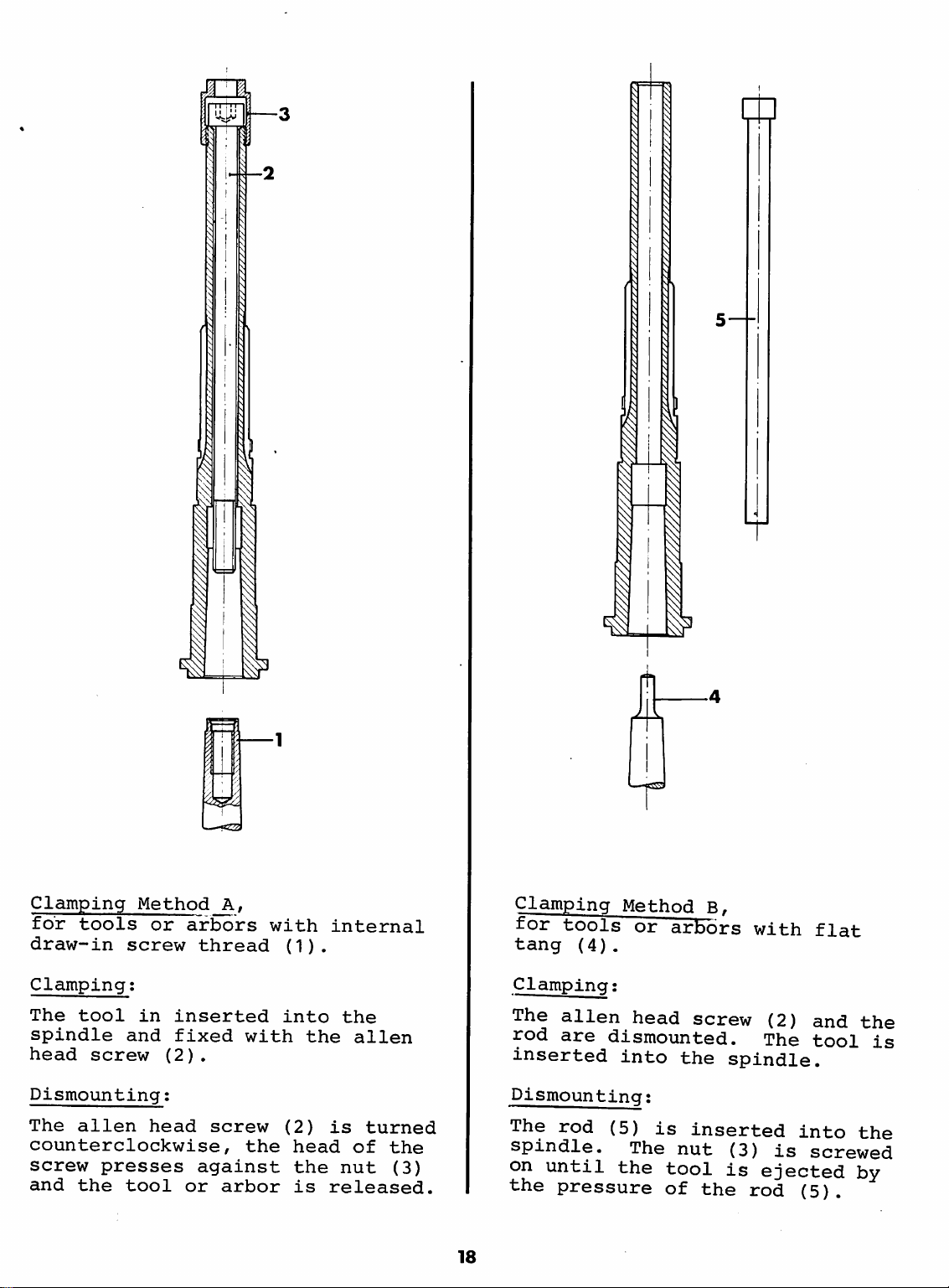

Clamping

for

tools

draw-in

Clamping;

The

tool

spindle

head

Dismounting:

The

alien

counterclockwise,

screw

and

the

Method_A,

screw

in

and

screw

presses

tool

or

arbors

inserted

fixed

(2)

.

head

against

or

thread

with

screw

the

arbor

with

(1).

into

the

(2)

head

the

is

internal

the

alien

is

turned

of

the

nut

(3)

released.

18

Clamping

for

tools

tang

Clamping:

The

alien

rod

are

inserted

Dismounting:

The

rod

Method

(4).

dismounted.

into

(5)

spindle.

on

until

the

pressure

the

or

arbors

head

is

The

nut

tool

of

B,

with

screw

(2)

The

the

spindle.

inserted

(3)

is

ejected

the

rod

into

is

screwed

(5).

flat

and

the

tool

the

by

is

Page 21

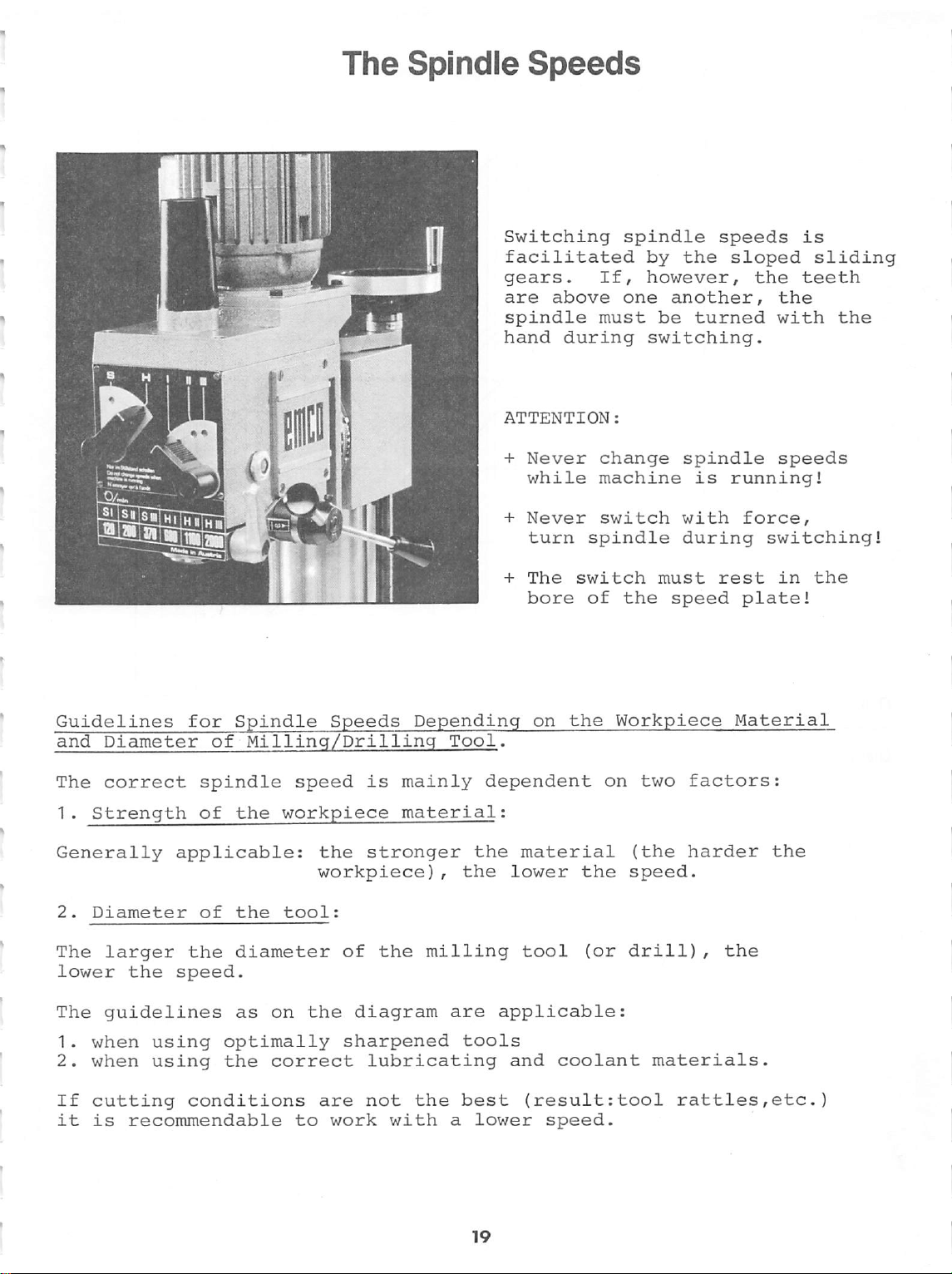

The

Spindle

Speeds

mssmr-

j

Switching

facilitated

gears.

are

spindle

hand

ATTENTION:

+

Never

while

+

Never

turn

+

The

bore

If,

above

must

during

change

machine

switch

spindle

switch

of

spindle

by

the

however,

one

another,

be

switching.

spindle

with

during

must

the

speed

speeds

sloped

turned

is

running!

force,

rest

plate!

is

sliding

the

teeth

the

with

speeds

switching!

in

the

the

Guidelines

and

Diameter

The

correct

1.

Strength

Generally

2.

Diameter

The

larger

lower

The

1.

2.

If

it

the

guidelines

when

when

cutting

is

recommendable

for

Spindle

of

spindle

of

the

applicable:

of

the

the

diameter

speed.

as

using

using

optimally sharpened

the

conditions

Speeds

Milling/Drilling

speed

is

workpiece

the

stronger

workpiece)

tool:

of

the

on

the

diagram

correct

to

lubricating

are

not

work

with a lower

Depending

Tool.

mainly

material:

the

,

the

milling

are

tools

the

best

on

the

dependent

material

lower

tool

applicable:

and

the

(or

coolant

(result:tool

speed.

Workpiece

on

two

(the

speed.

drill),

materials.

rattles,etc.)

Material

factors:

harder

the

the

Page 22

E

a

</>

•o

V

0)

Q.

to

-2400

■D

-

2C00

—445

-240

-200

Diameter

Diameter

of

tool

(mm)

of

tool

(inch)

Example;

Workpiece

Diameter

One

of

The

follows

approx.

selected

theoretical

In

this

0,1"

material:

of

case

milling

the

14oo

speed

speed.

11oo

7 8 9

0,25"

broken

rpm.

must

rpm.

10

12

Aluminum

tool:

line

always

1.6

alloy

and

III

inch

be

30

comes

under

U)

50 60

2"

to

a

60

100

3"

speed

4"

the

20

Page 23

Clamping

Devices

for

Tools

—Y

CLAMPING

AND

COLLETS

Clamping

The

collet

with

round

1.

Collet

E

25

Collets

For

clamping

the

appropriate

Clamping

engraved

E

25

collets,

The

clamping

while

2.

Collet

ESX

25

(available

The

collets

greater

When

are

drawn

annular

The

collets

No.

225

WITH

Method

holder

shanks

Holder

range: h 13.

on

see

counterforce

Holder

Collets

from

of

clamping

the

clamping

off

ring

round

are

000)

THE

A

enables

and

of

(Order

with

collets

collet

the

collet. - For

the

brochure.

nut

is

tightened

is

exerted

(Order

mid-1981)

Type

ESX

ranges

nut

the

cone

the

collet

available

or

separately.

COLLET

HOLDER

clamping

drills.

No.

721

of

Type E 25,

for

each

The

clamping

the

with a hook

with

No.

520

25

enable

(see

table).

is

unscrewed,

of

the

collet

waist.

either

as a set

of

milling

000)

shank

diameter

Order

the

key

000)

you

holder

of

tools

for

Type

you

need

diameter.

is

Nos.

of

the

spanner

wrench.

for

Type

to

bridge

the

collets

by

the

14

(Order

Nominal

2,0

2,5

3,0

4,0

5,0

6,0

7,0

8,0

9,0

10,0

11,0

12,0

13,0

14,0

diameter

in

mm

individual

Chucking

capacity

1,5-2,0

2,0-2,5

2,5-3,0

3,0-4,0

4,0-5,0

5,0-6,0

6,0-7,0

7,0-8,0

8,0-9,0

9,0-10,0

10,0-11,0

11,0-12,0

12,0-13,0

13,0-14,0

collets

in

mm

ESX-25

Chucking

capacity

'As-Vm

^35

'/64

Va-yM-ya?

"/64-3A8

'%4-'/33-'Vm

'A-"/64

8/3J-

I9/»4-5As

3V64-"/32

33/(M-3/g_35/54

'V32-"/<14

Vi6-3»/64-IV3J

31/64-Vj

33/64-IV33-35/64

in

inches

The

using

it

can

the

milling

the

Spare

Order

No.

225

020

225

025

225

030

225

040

225

050

225

060

225

070

225

080

225

090

225

100

225

110

225120

225130

225140

21

machine

the

T-slot

also

be

table.

Parts

Important

Collets

721

into

vice

is

fitted

screws.

clamped

For

On

onto

the

List.

Note:

of

Type

000.

However,

collet

holder

onto

the

Maximat

the

screw

ESX

25

collets

520

000.

the

cross

slide

Super

angled

dimensions,

can

be

of

11,

plate

and

see

used

in

Type E 25

collet

holder

do

not

fit

Page 24

CLAMPING

IN

THE

DRILL

CHUCK

Clamping

Necessary

* 3 jaw

*

Morse

Drills

(13

Method

accessories:

drill

taper

with

mm)

can

for

Drill

chuck

cylindrical

be

with

arbor

MT2

diameter

clamped

key

in

Chuck:

(1)

(2)

of

the 3 jaw

B

up

to

drill

0.52"

chuck.

HI

kuuuuwuuuiil

w

CLAMPING

Clamping

Necessary

*

shell

*

special

*

Set

spacing

spacing

spacing

spacing

Tools

(milling

cutters,

against

over

clamping

The

Method A (for

accessories:

end

key

of 4 collars

collar 4 mm

col

collar 8 mm

col

with a receiving

cutters,

circular

the

collar

the

spacing

screw

special

IN

THE

mill

arbor

(2)

lar 6 mm

lar

12

staggered

saw

of

collars

(7).

key

(2)

SHELL

shell

(1)

(3)

(4)

(5)

mm

(6)

bore

of

tooth

blades)

the

are

shell

(3,4,5,6)

is

used

for

END

end

16

mill

mm

side

milling

MILL

arbor)

diameter

clamped

end

mill

arbor

with

the

tightening.

ARBOR

2—

22

Page 25

BORING

AND

FACING

HEAD

(FLY

CUTTER)

58

mm

58 - llo

Technical

On

the

are

Toolholder

Smallest

Largest

Toolholder

Smallest

Largest

Dimensions

Scale

Working

Before

with

0

12

mm

Adjusting

—

Adjustment

done

—

mm

By

Data:

slide

two

machined.

in

left

diameter:

diameter:

in

right

diameter:

diameter:

of

turning

divisions:

tip:

machining,

the

set

screw

tips:

with

the

adjusting

backlash

of

bores

of

12

bore:

20

mm

(0.8")

58

mm

(2.3")

bore:

58

mm

(2.3")

110

mm

(4.4")

tools:

0.025

mm

clamp

(17).

of

playfree

set

the

leadscrew

the

guidance

screws

set

screw

is

mm

(0.5")

6x6

cross

dia.

mm

(V4" x V4")

slide

is

(18).

(4)

the

eliminated.

Heavy-duty

8

mm

cylindrical

Clampingrwith

Dovetail

dia. X 60°

12

mm

Clamping:with

taper

dia.

for

shaft;

attachment

milling

with

dia.

attachment

roughing

collet

cylindrical

collet

shank

end

cut,

chuck

cutter,

16

chuck

mill,

mm

shaft

All

Tools

Tools

of

HSS

Quality

Heavy-duty

15

mm

dia.,

Morse

taper

Clamping:direct

ding

Two

flute

slot

cal

shaft,

3,4,5,6

Clamping:with

attachment

taper

for

roughing

MT2;

clamping

to

drill

mm

collet

shank

end

Method

with

cylindri

dia.

chuck

mill,

cut,

accor

A

23

Page 26

Twist

drills,

1-

13

mm

1

set

consists

Clamping:

HSS,

in

steps

of

with

collet

DIN

of

25

pieces

drill

chuck

338

1/2

mm,

chuck

attachment

or

T—slot

cylindrical

T—slot

cylindrical

Clamping:

cutter,

shank,

cutter

shank,

with

12,5

mm

TO

mm

16

mm

10

mm

collet

attachment

dia. x 6

dia. x 8

chuck

mm

mm

Heavy-duty

roughing/finishing,

width

Clamping:

Circular

dia.

of

bore

16

Clamping:

20

mm,

saw

blade

mm.

shell

end

dia.

with

shell

blade,

60

mm,

with

shell

mill,

outside

of

bore

end

fine

tooth,

width

end

with

dia.

40

16

mm.

mill

0,8

mill

spiral

for

mm,

arbor

mm,

arbor

Staggered

dia.

bore

Staggered

outside

bore

of

cutter

16

16

tooth

mm

tooth

dia.

mm

Clamping:

Gear

milling

pressure,

module

module

module

bore

0,5

1

1,25

side

milling

35

mm,

width 5 mm,

side

milling

50

mm,

width 6 mm,

with

shell

end

o

cutters,

16

relieved

mm

available

pieces

or

cutter,

cutter,

mill

arbor

for

20°

in

set

of

8

individually

24

Page 27

Clamping

Devices

for

Workpieces

CLAMPING

CLAMPING

Clamping

WITH

SHOES

height:

Large-surfaced

clamped

the

Depending

workpiece,

shoes

clamp

CLAMPING

CHUCK

Necessary

to

stepped

are

the

WITH

125

the

clamping

on

the

two

necessary

workpiece

mm

dia.

accessories:

THE

STEPPED

2.36"

workpieces

cross

slide

shoes.

shape

or

more

in

securely.

THE

LATHE

{60

mm)

can

with

of

the

clamping

order

to

be

+

Lathe

+

Adaptor

The 3 bolts

lathe

threaded

mounted

with

Depending

ments,

chuck

table

NOTE:

The

with

stepped

chuck

chuck

to

the

the

is

or

lathe

one

jaws

125 ram

plate

are

with

ends.

the

hexagon

on

the

adaptor

mounted

the

angle

chuck

set

of

and

adaptor

externally-stepped

When

note

in

groove

changing

that

groove

no.2,

jaws,

jaw

no.1

no.1,

etc.

dia.

put

into

the

short

The

chuck

plate

nuts.

work

on

is

internally-

one

require

plate

the

plate.

equipped

set

jaws.

one

is

placed

jaw

no.2

the

is

with

milling

of

must

in

Page 28

CLAMPING

WITH

THE

MACHINE

VICE

Width

of

Clamping

The

machine

the

milling

using

THE

VICE

The

the

the

SWIVEL

swivel

milling

bolts,

The

base

milling

guide

pins,

T-slots

jaws:

capacityiup

vice

table

two

T-nut

BASE

base

table

washers

is

positioned

table

by

which

of

the

3.3o"

(Bo

is

clamped

or

bolts.

FOR

THE

is

mounted

with

and

hexagon

means

fit

milling

(84

to

3.15"

mm)

angle

MACHINE

4

T-nut

on

of

into

table.

mm)

to

plate

to

nuts.

the

2

the

The

machine

base

bolts

The

the

NOTE:

The

contact

machine

when

Scribing

machine

The

so

and

and

machine

centering

centering

mounting.

machine

that

parallell

slide.

zero-mark

vice

The

with

with

with

positioning

the

an

spindle

vice

fixed

hexagon

vice

surfaces

vice

vice

the

must

Zero-mark

vice

the

fix

to

the

In

this

is

made

a

scriber.

aid

of a dial

arbor

taper.

is

with

nuts.

is

ring.

ring

and

of

be

is

clamping

longitudinal

position,

on

itself

inserted

placed

the 2

centered

the

dust-free

all

base

on

on

T-nut

other

the

positioned

jaw

the

the

machine

is

done

gauge

in

the

the

with

and

is

or

Page 29

THE

ANGLE

PLATE

Clamping

Distance

Workpieces

directly

shoes

vice,

attachment

chuck.

or

lathe chuck

surface:

of

T-slots:

can

be

with

with

with

the

the

mounted

6.9"x5.5"

(175

( 9omm)

x14o

3.54"

clamped

clamping

machine

or

dividing

mm;

lathe

Page 30

The

Dividing

Attachment

TECHNICAL

Diameter

Worm

reduction

T-slots

standard

Number

plates:

Necessary

clamping

the

lathe

dividing

+

Dividing

+

Adaptor

+

Lathe

OPERATING

DATA

of

rotary

according

of

holes

accessories

the

workpieces

chuck

attachment:

attachment

plate

chuck

ELEMENTS

table:

to

in

dividing

27,33,34,36,

38,39,4o,42

on

the

125

mm

(15o

1 : 4o

factory

for

in

dia.

6"

mm)

Clamping

table

f1)

Clamping

during

itself,

before

Indexina

Duging

15

the

rotary

the

but

every

digect

to

15 , the

parameter

table.

dividing

free

dividing

graduated

must

to

The

controlling

Crank

plunger

which

wheel

indirect

be

pulled

the

left.

graduated

handle

(4)

is

of

levers

:

levers

dividing

must

machining

oin

with

dividing

notches

During

(worm

by

scale,

scale

the

with

move

engaged

the

rotary

dividing.

for

rotary

are

loosened

operation

be

clamped

handle

pin

rests

of

indirect

dividing)

means

the

indexing

out

and

(3)

divisions.

index

the

worm

with

the

table

operation.

(2):

from

into

the

or

of

the

pin

swivelled

for

wormduring

The

shears

adding

a

fraction

added.

the

serve

number

of

a

to

of

turn

facilitate

holes

is

to

when

be

Page 31

T-slots

of

the

10,5

Dividing

Attachment

:S

OF

Disengaging

The

alien

loosened.

is

turned

worm

The

hand

By

and

rotary

for

turning

clockwise,

are

engaged.

engagement

the

rotary

slightly

The

alien

again

be

operation.

DIVIDING

and

Engaging

head

counterclockwise,

wormwheel

direct

by

head

tightened

screw

When

table

the

dividing

worm

To

of

worm

table

hand.

screw

the

dividing

are

can

indexing.

and

wormwheel

facilitate

and

should

after

the

(5)

is

disengaged.

be

turned

plate

wormwheel,

be

moved

(5)

must

this

Worm:

plate

the

by

Xr

4o times,

makes

With

plates,

turns

1

revolution

help

exact

can

the

of

the

be

executed.

rotary

(36o ).

dividing

fractions

The

1st

2nd

3rd

4th

tagie"

of

Indexing

column

column

column

column:

Direct

Worm

engaged.

Possibility

dividing

indexing

possibility

(i.e.,

within

Possibility

The

freely

graduated

table.

Table:

indicates

of

divisions

36o

shows

ing

division

shogs

36o

revolutions

are

shows

holes

for

the

angle

the

crank

necessary

the

to

each

Dividing:

and

wormwheel

by

pin

maximum

36o

dividing

with

number

per

correspond

of

the

number

handle

which

number

be

added

index

plate

1:

means

(2).

from

).

2:

can

the

scale

of

of

15

of

be

aid

on

of

24

are

dis

the

gividing

to

15

divisions

done

of

the

the

rotary

29

Page 32

30

30

12°

1

9

11

12

13

14

20'

1

28

1

18

■>

(0

175°

19

12

33

1

7

2

180°

20

32

1

9

10

Q

Q}

CT

27

33

34

36

38

39

O

.(C

o

m

jiC

for

Amount

each

of

index

holes

plate

to

be

added

40

42

a

M

>

^

°

^

O)

zB

27

33

34

36

38

39

40

42

o

g

2V

CT3

for

Amount

each

of

Index

holes

plate

to

be

added

O(

o

o

Worm

n

=

No.

reduction

of

revoiutions

NDEXTABLE

z

K

=

=

No.

of

No.

the

of

of

divisions

workpiece.

revolutions

of

dividing

of

handle

head

for

1:40;

one

i.

dividing

e.

required

of

handie

for

one

for

a

revolution

complete

K

=

40.

move:

of

revolution

the

workpiece

n

=

-^

Formula

for

the

Calculation

of

the

Hole

Numbers

Required

10

11

12

25°

2

21

84

20

80

17

18

19

20

14

2

36

21

78

13

3

3

20

3 9

11

12

13

14

76

20

MC

OC

CO

MC

CM

ni

O

CM

O

O

72

5°

15

o

o

o

20

o

o

o

3

21

36°

4

70

24

9

40°

4

12 16

68

20

8

45°

5

66

20

50°

5

15

65

24

64

30

25

65°

7

6

55

24

70°

7

21

54

20

5

8

52

30

6

7

60°

55°

6

5

6

18

3

22

24

26

28

56

60

6°

18

«

30

75°

8

9

11

12

13

14

7«

21

28

50

8

24

32

4

10

48

30

35

100°

11

3

45

8°

24

32

110°

12

6

44

30

3

120°

13

9

11

12

13

14

42

40

13

24

40

9°

1

130°

14 12

39

OC

o

1

1

140°

15

15

38

1

2

150°

16

18

36

10°

1

3

4

160°

17

21

35

1

6

170°

18

24

34

1

6

22

24

26

27

25

1

27

200

8

1

38

180

2°

6

8

16°

1

21

120

3°

9

11

12

13

14

15°

1

1

1

1

13

40'

2

2

21

360

1°

3

24

270

4

18

22 24

26 28

240

6

7

18°

2

100

16

19

96

15

18

2

2

6

8

4

95

16

20

21

17

2

12

90

4°

12

16

16

88

15

2

17 18

19

20

21

15

2

18

22 24

26

28

85

16

Page 33

EXAMPLE

OPERATION;

OF

AN

INDIRECT

DIVIDING

Practical

1.

The

holes

Execution:

indexing

is

mounted.

Desired

From

be

seen

division

must

turn

the

indexing

plate

division:

the

Indexing

that

at

the

13, 3 full

be

made

of 3 additional

plus a fraction

plate

with

39

13

divisions

in

36o"

Table

desired

crank

holes

39.

it

can

turns

on

Execution

Operation:

3

full

tional

holes

that

in

One

are

the

the

dividing

completed.

of

turns

turn

made;

plunger

black

the

Dividing

plus

of

the

the

that

is

hole.

operation

frac

3

added

means

placed

is

In

Indexing

that

holes

Therefore,

fixed

4

3.

The

placed

39

drawing)

arm

the

the 4 th

at

have

so

holes.

indexing

in a hole

(marked

moved

pin

column

Table,

the

to

the

that

black

and

until

of

the

one

39

plate,

be

shears

they

plunger

the

it

plunger.

of

sees

added.

include

of

the

on

the

left

touches

the

3

are

is

shear

5.

Next

The

the

pin

operation

cribed

NOTE:

The

shears

during

otherwise

their

tation

Dividing

shears

left

arm

again;

in

may

the

dividing

they

purpose

aid.

Operation:

are

turned

touches

the

next

follows

4.

above.

not

do

as

an

the

dividing

as

des

be

moved

operation,

not

serve

orien

until

31

Page 34

Circuit

Diagram

single

^

phase

FB-2

V-®

A

m1

b1

Motor

k 1 Condenser

m1

Motor

L1

Connection

switch

k1

strip

LI

6i

02^3

O5

60

33

Page 35

Circuit

Diagram

LI

)

)

)

>—

)

>—J

three

"

►

phase

FB-

2

R

o

*1

\

<

S

o

i

o

6

T

SI

o-

J

U2>.

W2

U2

V2

§§§

U'1

V1

b1

ml

LI

A

or Y connection

Motor

Motor

Connection

switch

see

strip

Motor

V2 J W2

capacity

6

vi

W2

o o

Plate

U2

^2

o

W>1

34

Page 36

Page 37

Page 38

Page 39

Pos

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

F2A

F2A

F2A

F2A

F2A

F2B

F2A

F2A

F2B

F2A

F2B

F2A

F2B

F2A

F2A

F2A

F2A

F2A

F2A

D1A

D1B

F2A

F2A

F2A

F2A

F2A

B4A

B2A

B2A

D1Z

ZLG

ZSR

ZRG

ZFD

H4A

ZMU

ZSR

ZSR

ZSR

ZSR

ZSR

ZST

ZST

ZST

ZSR

ZSR

ZMU

ZSB

ZSR

ZFD

ZSB

Ref.

000

000 020

000

000

000

000 050

000

000

000

000 090

000

000

000

000

000

000

000

000150

000

020

020 070

000

000190

000

000

000

040

000

013

250

62

12

72

88

000

85

98

12

33

12

40

72

13

51

12

12

36

25

84

85

25

Nr.

010

030

040

050

060

070

070

090

100

100

110

120

130

140

160

070

180

200

210

220

011

080

000

060

0001

0616

3012

0337

300

1000

0003

0830

0625

1070

1030

0628

0616

0816

0816

0820

0800

0530

0510

4412

0640

DIN

M6x16DIN912-6.9

30x1,2

01N472

3x3,7

DIN

6888

M10DiN985-6

1,47x6,35

M8X30DIN912-6.9

M6x25DIN933-5.6

Ml

M10x30t)IN939-8.8

6x28DIN1472-6.8

M6X16DIN913-45H

M8x16DIN551-5.8

M8x16DIN912-6.9

M8x20DIN912-6.9

M8

B5,3

M5x10DIN84-4.8

A4x4x12DIN6885

B6,4

0x70

DIN

DIN

DIN

TYP

LL

DIN912-6.9

936-6

125

125

Benennung

Frastisch

Schlitten

Sockel

Saulantrager

Mutter

metr.

Mutter

USA

Spindeltr^er

Skalenring

Skalenring

Langsspindel

Langsspindel

Querspindel

Querspindel

Anschlag

Anschlagbolzen

Klemmschraube

Nachstelleiste

Nachstelleiste

Posltionsschild

Schild

Schild

Deckblech

Druckbolzen

Druckbolzen

Abstreifblech

Abstreiffilz

Handrad

Bogenfeder

G.

T-Nutenstein

Rillenkugellager

Zylinderschraube

Sicherungsring

Scheibenfeder

Zwischenring

Sechskantmutter

Hammerschraube

Zylinderschraube

Sechskantschraube

Zylinderschraube

Stiftschraube

PaBkerbstift

Gewindestift

Gewindestift

Zylinderschraube

Zylinderschraube

Sechskantmutter

Scheibe

Zylinderschraube

PaBfeder

Scheibe

metr.

USA

metr.

USA

metr.

USA

metr.

USA

1

2

100

Kegelgriff

Description

Milling

table

Slide

Pedestal

Column

support

Nut

metr.

Nut

USA

Screw

mount

Graduated

Graduated

Longitudinal

metr.

Longitudinal

USA

Cross

Cross

Stop

Bolt

Clamping

Gib

Gib

Setting

Scale

Scale

Cover

Adjusting

Adjusting

Wiper

Felt

Handwheel

Feed

Handle

T-nut

Ball

Allen

Circlip

Woodruff

Spacer

Hexagon

Screw

Allen

Hexagon

Allen

Stud

Grooved

Set

Set

Allen

Allen

Hexagon

Washer

Flat

Key

Washer

feed

feed

mark

mark

mark

sheet

plate

wiper

spring

bearing

head

head

head

screw

screw

head

head

head

ring

metr.

ring

USA

feed

feed

screw

screw

screw

metr.

USA

pin

1

pin

2

screw

key

nut

screw

head

screw

screw

adjusting

screw

screw

nut

screw

screw

screw

metr.

USA

pin

Designation

Table

de

fraisage

Chariot

Socle

support

Support-colonne

Ecrou

metr.

Ecrou

USA

Porte-broche

Bague

gradu^e

metr.

Bague

graduee

USA

Vis

filetle

longitudinale

Vis

filet§e

longitudinale

Vis

filetee

transversale

Vis

filet^e

transversale

Butee

Tige

de

butee

Vis

de

serr'age

Lardon

de

reglage

Lardon

de

reglage

Plaque

de

position

Echelle

metr.

Echelle

USA

Tole

de

protection

Boulon

de

pression

Boulon

de

pression

Plaquette

Racleur

Volant

Ressort

Levier

Ecrou

Roulement a bllles

Vis 6 pans

Anneau

Clavette

Douille

Ecrou 6 pans

Vis

Vis 6 pans

Vis

Vis 6 pans

Goujon

Cheville

Vis

Vis

Vis 6 pans

Vis 6 pans

Ecrou 6 pans

Rondelle

Vis

Clavette

Rondelle

de

en

feutre

arque

spherique

en

T

creux

de

retenue

d'&artement

creux

hexagonale

creux

de

posit

pointeau

pointeau

creux

creux

tete

cylindrique

racleur

metr.

USA

metr.

USA

1

2

postSrieur

post§rieur

Page 40

Pos

47

48

49

50

51

52

53

54

55

56

57

58

59

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

/7

/8

.'M

Ref.

ZKG

ZST

ZNP

ZDK

F2A

F2A

F2B

F2A

F2B

F2A

ZMU

ZSB

ZSB

ZSB

ZSB

F2H

F2A

F2A

ZPG

ZPG

ZPG

ZPG

ZDK

ZSR

ZRG

ZMU

ZKO

ZEL

ZEL

ZEL

ZEL

ZEL

F2A

ZSR

ZEL

ZSR

ZRG

ZMU

ZDK

F2A

ZEL

Nr.

00

1060

11

0632

01

2000

60

0012

000

000

000

000

000

000

341000

251050

12

1001

121002

121003

100

100

100

10

0008

10

0007

20

1100

20

1350

60

0018

83

0416

28

0040

34

0401

26

0020

26

0030

26

3222

26

1221

26

3381

100

89

0510

01

0005

83

0325

28

0030

34

0300

60

0004

100

40

0002

270

240

240

250

250

230

020

020

030

040

010

'

DIN

6,0GK3DIN5401

6h11x32

INA

M10

B10,5

10x16x0,1

10x16x0,2

10x16x0,3

MZ

MZ

PG

PG

M4x16

B4

M4

M5X10DIN7985-

A

4.0

Bk6

M3x20

83

M3

Kapsto

B13

B11

11

13,5

DIN

DIN934

Q

KrG

DIN

DIN

NIP

DIN

DIN

DIN84-4.8

127

DIN84-4.8

127

934-5

F4

DIN

A2

934-6

125

Benennung

Stahlkugal

7

Zylinderstift

Schmiernippal

VerschluBstopfen

Positionsschlld

Ska

la 1 matr.

Skala 1 USA

Skala 2 matr.

Skala 2 USA

Frontschlld

Sechskantmuttar

Schaibe

PaBscheiba

PaSschaiba

PaBschaibe

Gr.

E-Ausriistung

Description

Ball

Dowel

pin

Grease

nipple

Stopper

Setting

mark

Scale 1 metr.

Scale 1 USA

Scale 2 metr.

Scale 2 USA

Front

plate

Hexagon

Washer

Compensating

Compensating

Compensating

Electrical

nut

equipment

washer

washer

washer

Designation

Bille

acier

Tige

de

serrage

Graisseur

Boucho'n

Plaque

de

position

Echelie 1 metr.

Echelle 1 USA

Echelie 2 metr.

Echelle 2 USA

Plaque

frontale

Ecrou 6 pans

Rondelle

Rondelle

Rondelle

Rondelle

Ens.

de

compensation

de

compensation

de

compensation

equipment

electrique

compl.

Deckel

Dackel

Deckel

Kabelvarschraubung

Kabalvarschraubung

Geganmuttar

Gegan

VerschluBstopfen

Zylinderschrauba

Fedarring

Ms

Sechskantmuttar

Kondensator

Schaltar-Standard

(Wechselstrom)

Schaltar-Standard

Schalter

Schalter-VDE

Schaltar-VDE

Dichtung

Linsanschraube