Page 1

iistnictioH

book

Service

BIDCD

compacts

parts

Englisch

Auflage:

Order

10.

92

Maier+Co.

A-5400

9.

91

No.

8.

7.

6.

90

89

88

Hallein/Austria

EN 2 490

5.

4.

3.

87

86

85

2.

84

Page 2

SAFETY

When

In

private

Wear

eye

Have

hair

Do

not

Only

service

Do

not

PRECAUTIONS

using

in

workshop:

workplace:

protection.

covered

grip

moving

the

remove

Safety

and

do

machine

machine

the

drive

WHEN

Observe

plugs

not

have

parts.

when

it

cover,

and

TURNING

accident

(prevention

loose

is

isolated

when

prevention

against

floppy

from

working

instructions.

starting

sleeves.

electrical

make

sure

up

by

supply.

it

is

always

children

etc.

closed.

When

working

covered

Always

given

Do

Never

Always

Do

Do

by a stationary

use a wire

on

not

fit

measure

remove

not

leave

not

use

WVS

or

your

with

bars,

hook

sheet

remove

the

work

the

chuck

the

machine

hand

tubes

guard.

or

similar

No.

36

"Guard

turning

when

key

when

to

slow

etc.

which

implement

against

tools

when

it

is

rotating.

(even

it

is

switched

down

extend

the

when

the

the

workpiece

beyond

for

removal

injury

from

spindle

machine

on.

or

the

of

swarf.

turnings

is

rotating.

is

switched

chuck.

tailstock,

and

the

Never

use

borings.")

off),

protruding,

bare

rotating

hands

.(Information

part

must

be

is

Page 3

INDEX

Standard

Technical

Setting

General

Lathe

Equipment

Data

up

and

preparing

Description

bed

Headstock

Slides

Carriage

Tailstock

Leadscrew

Drive

Controls

Working

Setting

Manual

Longitudinal

Taper

Taper

Turning

Screw

Example

Thread

Choosing

Slipping

apron

and

electrical

with

the

the

turning

turning

turning

turning

turning

using

by

between

Cutting

of

mounting

cutting

tables

the

correct

clutch

setting

centres

for operation

equipment

COMPACT

tool

with

tailstock

the

speed

8

auto-feed

set-over

the-top

gear

slide

wheels

3

4

4

5

5

0

5

7

7

7

3

g

g

g

10

1q

10

11

11

12

I3

I3

Lathe

Accessories

Universal

4-Ja'w

Drill

Morse

Live

Fixed

Travel

Setting

Box

Four-way

Chip

Change

Cabinet

Toolpost

Bearing

Adjustment

Adjustment

Adjustment

Adjustment

Adjustment

Adjustment

Replacinglthe

Re-positioning

Lubrication

Wiring

Spare

lathe

chuck

independent

chuck

taper

arbor

centre

centre

ling

steady

the

steady

with

turning

tool

guard

tools

post

gears

stand

grinder

and

Slide

of

main

of

cross

of

feed

of

feed

of

half-nut

of

leadscrew

shear

the

Plan

diagram

parts

list

chuck

Adjustments

spindle

and

screw

screw

pin

Vee-belt

bearings

top

slides

end

float

backlash

guide

backlash

in

leadscrew

in

nuts

18^

14

14

14

14

14

I5

I5

I5

15

15

15

15

17

19

20

20

20

20

21

21

21

22

23

24

Page 4

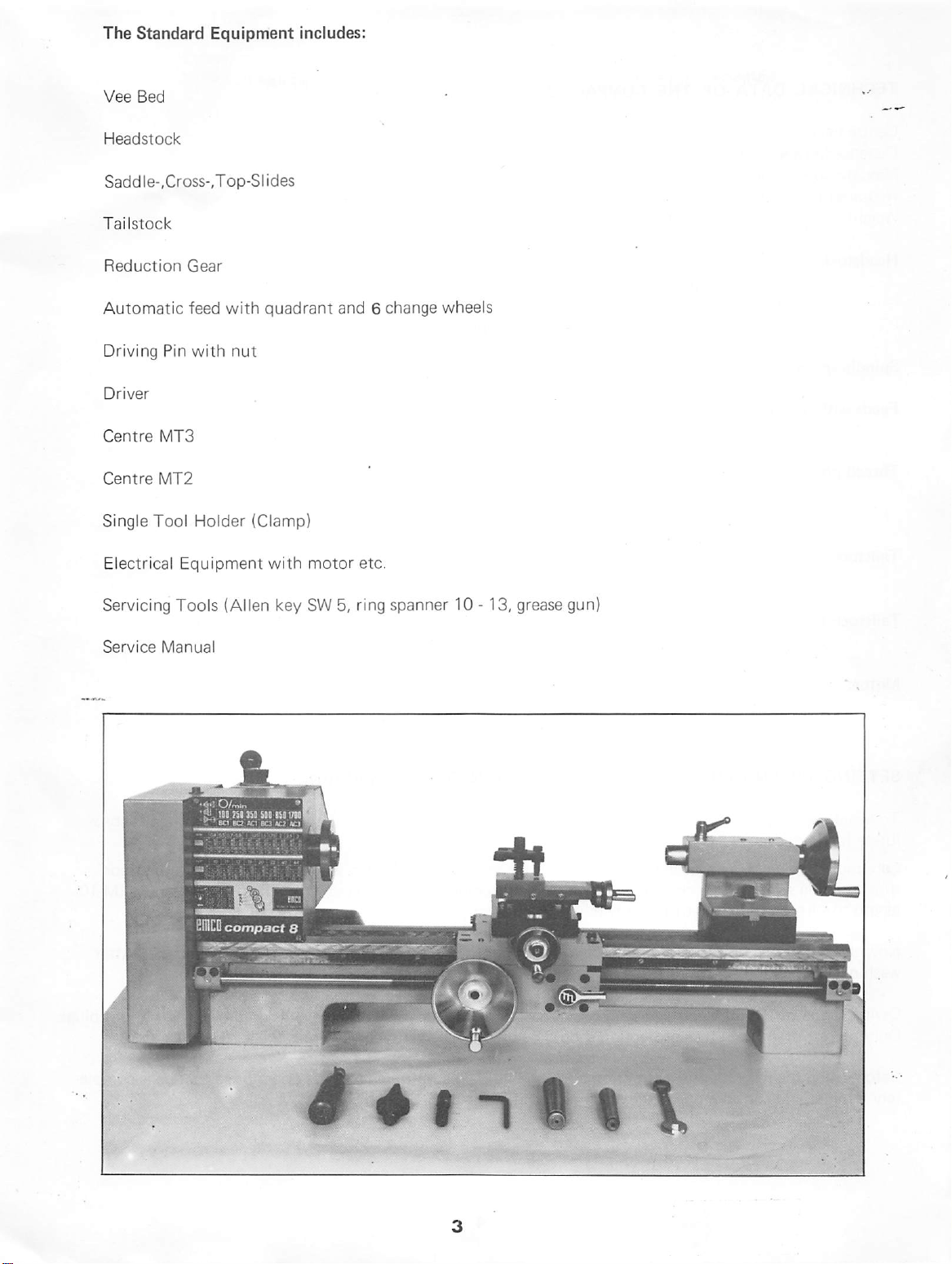

The

Standard

Vee

Bed

Headstock

Saddle-.Cross-,Top-Slides

Tai

lstock

Equipment

includes:

Reduction

Automatic

Driving

Driver

Centre

Centre

Single

Electrical

Servicing

Service

Gear

feed

Pin

with

MT3

MT2

Tool

Holder

Equipment

Tools

Manual

with

quadrant

nut

(Clamp)

with

(Allen

key

and 6 change

motor

SW

5,

ring

etc.

wheels

spanner

10-13,

grease

gun)

O

Page 5

TECHNICAL

DATA

OF

THE

COMPACTS

Centre

Distance

Max.

Required

height

between

jdia.

over

floor

Weight

Headstock:

spindle'nose

morse

hol

spindle

Spindle

Feeds

Thread

speeds:

with

leadscrew:

pitches:

Tailstock:

Tailstock

travel:

centres

slide

space

DIN

55021

taper

No.

3

low

spindle

(inside

bearings: 2 adjustable

100,

250,

350,

500,

105

mm

450

mm

118

mm

940 x 500

58

kg

dia.)

20

mm

mm

precision

850,

1700

revs/min.

0,09

mm/rev.

0,18

mm/rev.

metric

inch

module

spindle

spindle

morse

forward

backward 8 mm

0,4 - 3mm

10-44

thread/inch

0,2 - 0,7

diameter

travel

taper

12

mm

taper

roller

26mm

40mm

MT2

bearings

Motor:

SETTING

To

avoid

twisting

lutely

flat

and

Care

must

thus

avoiding

length

Now

washing,

Owing

Only

Before

tely

to

suit

the

protecting

clean

to

the

plugs

using

familiar

UP

AND

level.

also

be

swing

the

with

variety

with

built-in

the

machine

and

confident

PREPARING

of

the

bed,

taken

that

the

and

working

thickness

oil

dry,

of

of

film

(for

soft

cloth.

electric

fuse

protection

the

with

care

should

stand

single

speed

phase

1375

capacity

FOR

OPERATION

be

on

which

inaccuracies.

table)

firmly

storage

Finally

plugs,

onto

and

oil

EMCO

should

instruction

the

book

machine

a.

c.

rpm

0,5

PS

OF

taken

that

the

the

machine

The

machine

the

stand.

transport)

the

machines

be

should

and

should

slide

ways

are

used.

The

be

its

controls.

read

THE

MACHINE

location

should

with

supplied

to

is

mounted

be

be

removed

acid-free

with

which

is

fixed

bare

green/yellow

throughly

by

the

machine

securely

is

bolted

fastened

with 2 hex-headed

by

washing

with

paraffin.

oil.

ends

on

the

cables,without

wire

is

the

earth

connection!

its

operator

so

that

to

the

screws

he

is

is

abso

floor,

(M

10,

After

plugs.

comple

Page 6

GENERAL

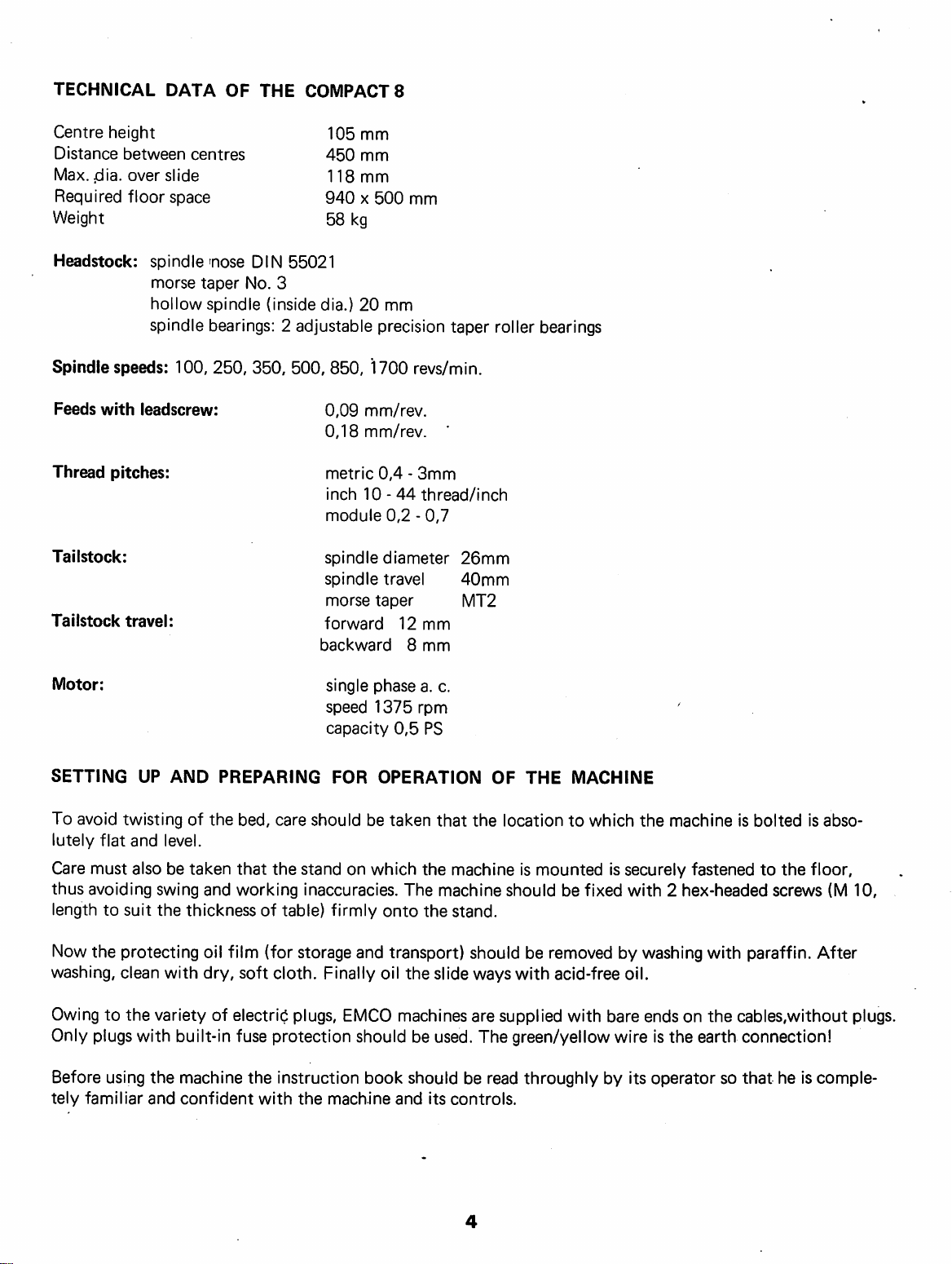

Lathe

Bed

The

lathe

bining

low

The

rate

age

drive

quick

the

high

vibration

two

guide

and

motor

traverse

front.

DESCRIPTION

bed

is

made

of

high-grade

Cheeks

precision-ground

for

tai

lstock

is

with

and

rigid

the

carriage

travel

mounted

rack

and

strong

qual

ities

Vee

and

on

individual

to

the

the

leadscrew

cast

iron.

cross

ribs,

a bed

is

produced.

slideways

the

rear

give

tai

lstock.The

Vees.The

of

the

bed.

are

mounted

By

an

main

The

com

with

accu

carri

on

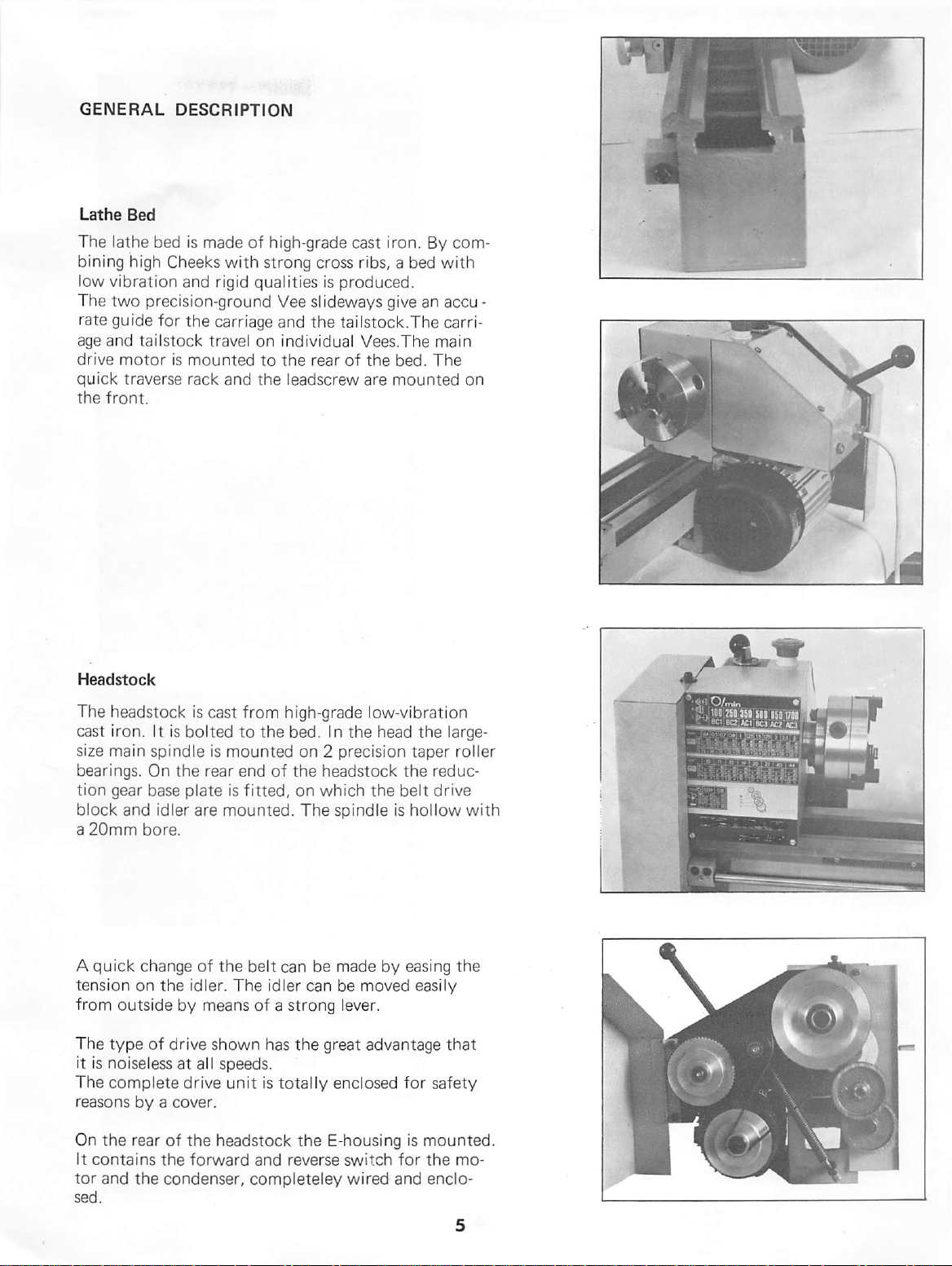

Headstock

The

headstock

cast

iron.

It

size

main

spindle

bearings.

tion

block

a

20mm

A

quick

tension

from

The

It

is

The

reasons

On

It

contains

tor

sed.

On

gear

base

and

bore.

change

on

outside

type

of

noiseless

complete

by a cover.

the

rear

and

the

is

cast

from

is

bolted

the

plate

idler

the

idler.

by

drive

at

drive

of

the

the

forward

to

is

mounted

rear

end

is

fitted,

are

mounted.

of

the

The

means

shown

all

speeds.

unit

headstock

condenser,

high-grade

the

bed.

In

the

on 2 precision

of

the

headstock

on

which

The

spindle

belt

can

be

made

idler

can

be

of a strong

has

is

total

and

reverse

completeley

lever.

the

great

ly

enclosed

the

E-housing

switch

wired

low-vibration

head

the

large-

taper

roller

the

reduc

the

belt

drive

is

hol

low

with

by

easing

moved

advantage

for

for

and

the

easily

that

safety

is

mounted.

the

mo

enclo

Page 7

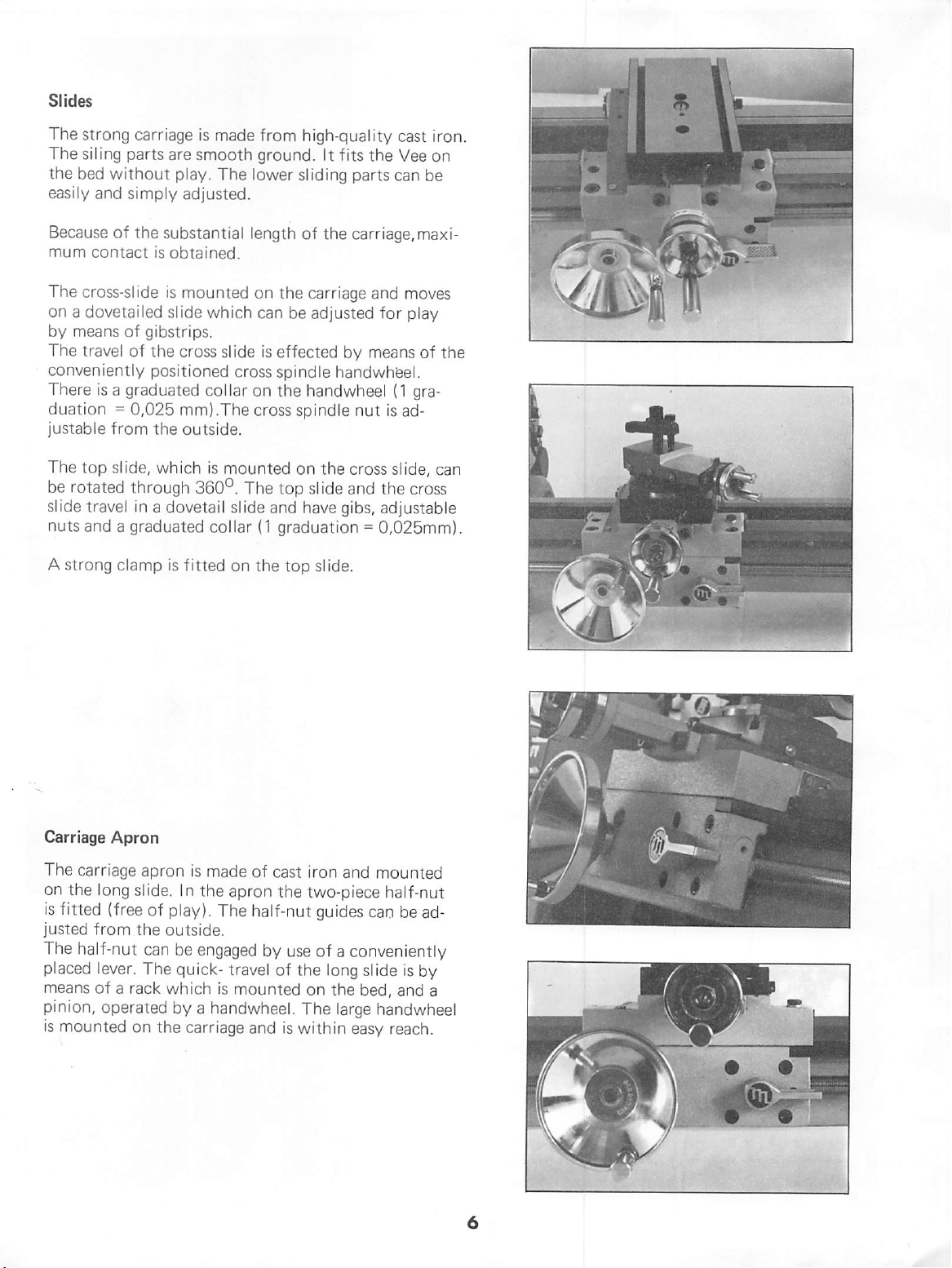

Slides

The

strong

The

siling

the

bed

easily

and

carriage

parts

are

without

play.

simply

is

made

from

smooth

adjusted.

The

ground.

lower

high-quality

It

fits

sliding

cast

the

Vee

parts

can

iron.

on

be

Because

mum

The

on a dovetailed

by

The

conveniently

There

duation = 0,025

justable

The

be

slide

nuts

A

strong

of

the

substantial

contact

cross-slide

is

obtained.

is

mounted

slide

means

of

travel

of

gibstrips.

the

cross

positioned

is a graduated

mm).The

from

the

outside.

top

slide,

which

rotated

through

travel

in a dovetail slide

and a graduated

clamp

is

fitted

length

on

which

slide

cross

col

lar

on

cross spindle

is

mounted

360°.

The

collar

on

the

of

the

carriage,maxi

the

carriage

can

be

adjusted

is

effected

spindle

the

handwheel

on

top slide

and

have

(1

graduation = 0,025mm).

top

slide.

and

for

by

means

handwheel.

(1

nut

is

the

cross

slide,

and

the

gibs,

adjustable

moves

play

gra

ad

cross

of

can

the

M-

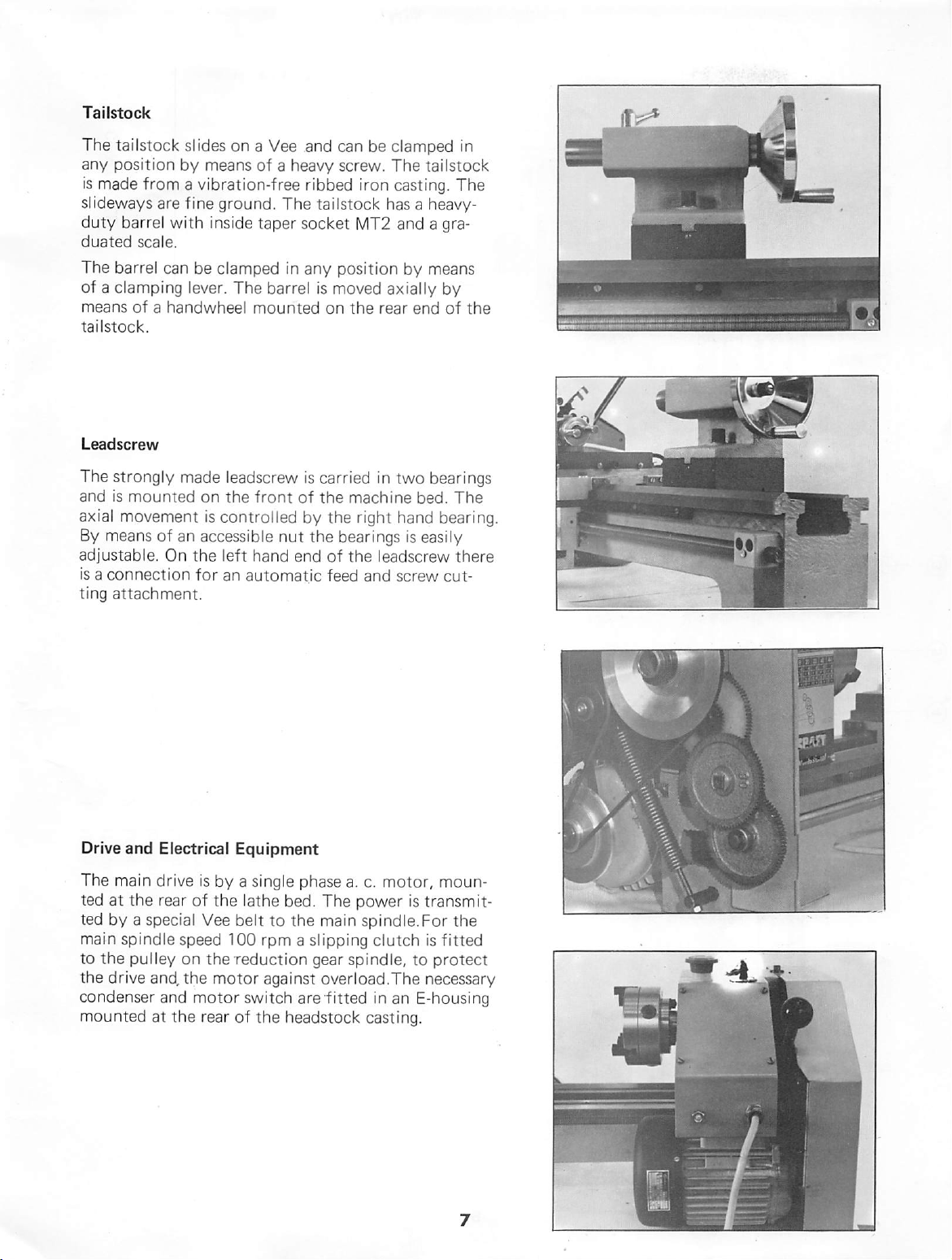

Carriage

The

on

is

fitted

justed

The

placed

means

pinion,

is

mounted

Apron

carriage

the

long

(free

from

half-nut

lever.

of a rack

operated

apron

slide,

the

The

In

of

play).

outside.

can

be

quick-

which

is

made

the

apron

The

engaged

travel

is

mounted

by a handwheel.

on

the

carriage

of

cast

iron

the

two-piece

half-nut

by

guides

use

of a conveniently

of

the

long

on

the

The

and

is

within

and

mounted

half-nut

can

slide

bed,

large

handwheel

easy

reach.

be

ad

is

by

and

a

Page 8

Tailstock

The

tailstock

any

position

is

made

slideways

duty

barrel

duated

The

scale.

barrel

of a clamping

means

tailstock,

Leadscrew

The

and

axial

By

adjustable.

is a connection

ting

of a handwheel

strongly

is

mounted

movement

means

attachment.

slides

by

from a vibration-free

are

fine

with

can

be

lever.

made

of

an

On

the

for

on a Vee

means

ground.

inside

clamped

The

mounted

leadscrew

on

the

front

is

control

accessible

left

hand

an

automatic

and

of a heavy

The

taper

socket

in

any

barrel

is

of

led

by

nut

end

can

be

screw.

ribbed

iron

tailstock

MT2

position

is

moved

on

the

rear

carried

the

the

the

of

feed

in

machine

right

bearings

the

leadscrew

and

clamped

The

casting.

tai

lstock

in

The

has a heavy-

and a gra

by

means

axial

ly

by

end

of

the

two

bearings

bed.

The

hand

bearing.

is

easily

there

screw

cut

Drive

and

Electrical

The

main

drive

ted

at

the

rear

ted

by a special

main

spindle

to

the

pul

ley

the

drive

and,

condenser

mounted

and

at

the

Equipment

is

by a single

of

the

Vee

belt

speed

on

the

the

100

reduction

motor

motor

rear

of

phase

a.

lathe

bed.

The

to

the

main

rpm a slipping

gear

spindle,

against

switch

the

overload.The

are

fitted

headstock

c.

motor,

power

spindle.For

clutch

moun

is

transmit

the

is

fitted

to

protect

necessary

in

an

E-housing

casting.

Page 9

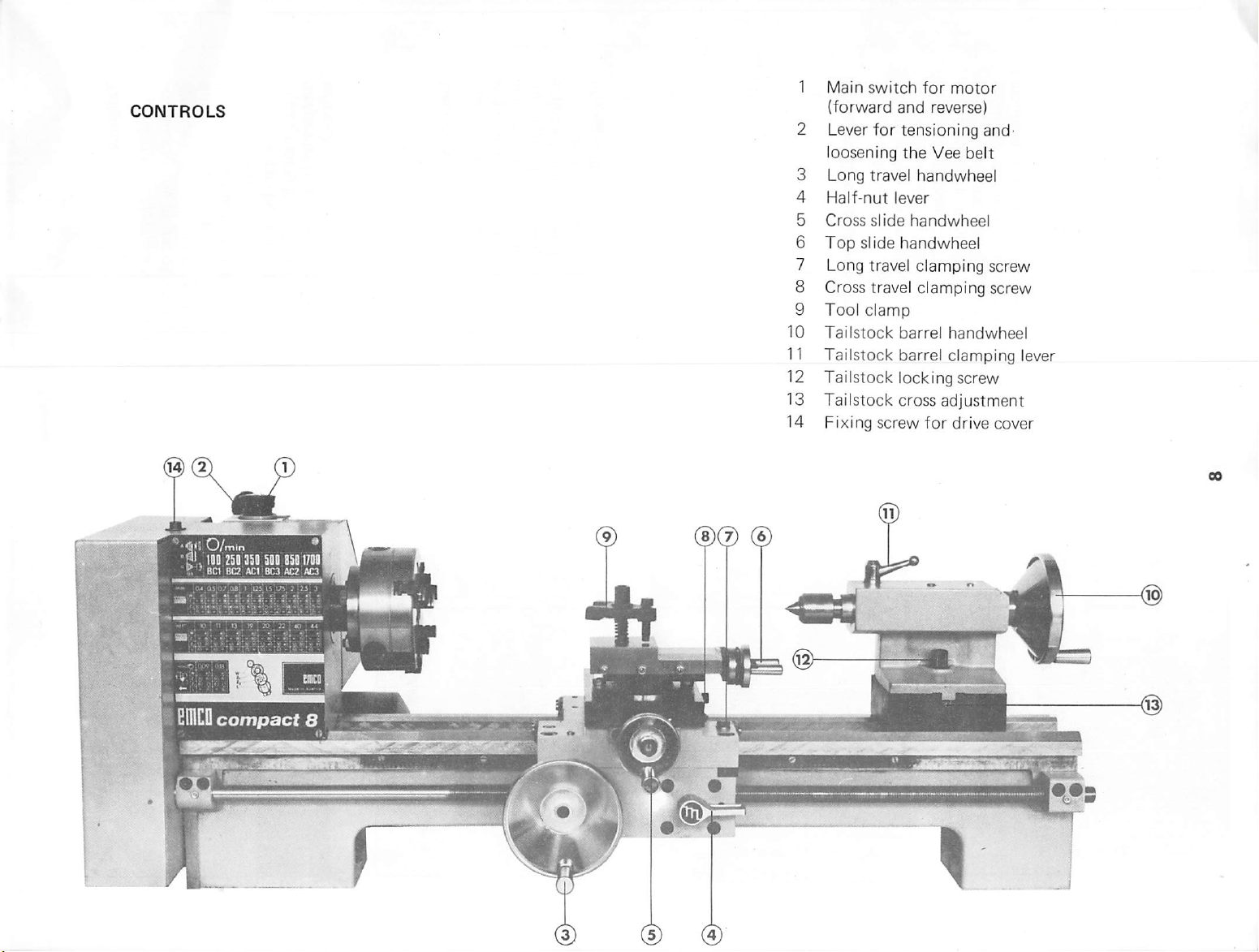

CONTROLS

1

Main

{forward

2

Lever

loosening

3

Long

4

Half-nut

5

Cross

6

Top

7

Long

8

Cross

9

Tool

10

Tai

11

Tai

12

Tailstock

13

Tai

14

Fixing

switch

and

for

tensioning

the

travel

lever

slide

slide

handwheel

travel

travel

clamp

lstock

lstock

barrel

barrel

locking

lstock

cross

screw

for

motor

reverse)

Vee

belt

handwheel

handwheel

clamping

clamping

handwheel

clamping

screw

adjustment

for

drive

and'

screw

screw

lever

cover

a'iO/min

! 100

250

350

500

V

BC1

BQ

ciUCu

compact

ACl

05017081

BC3

ACZ

*

ACS'

CBICDK

B

T-

•

-tv

•li

•:

Page 10

WORKING

WITH

THE

COIVIPACT

8

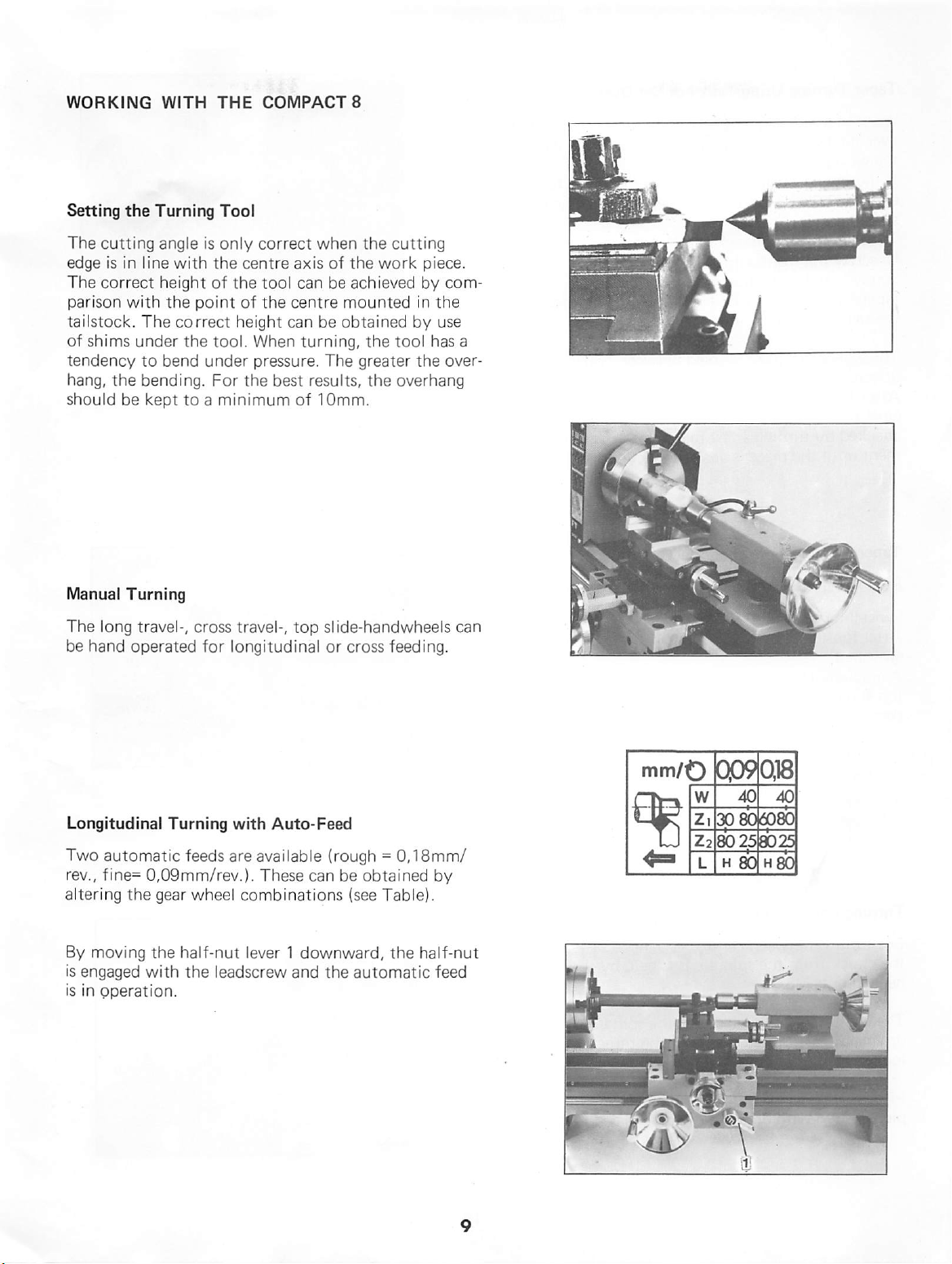

Setting

The

edge

The

parison

tai

of

tendency

hang,

should

Manual

The

be

the

cutting

is

in

line

correct

with

lstock.

shims

hand

The

under

to

the

bending.

be

Turning

long

travel-,

operated

Turning

angle

is

with

height

the

point

correct

the

bend

kept

to a minimum

cross

for

Tool

only

correct

the

centre

of

the

tool

of

the

centre

height

tool.

under

For

travel-,

longitudinal

can

When

pressure.

the

best

top slide-handwheels

when

the

axis

of

the

can

be

achieved

mounted

be

obtained

turning,

The

greater

results,

of

10mm.

or

cross

cutting

work

the

tool

the

overhang

feeding.

piece.

by

com

in

the

by

use

has

the

over

a

can

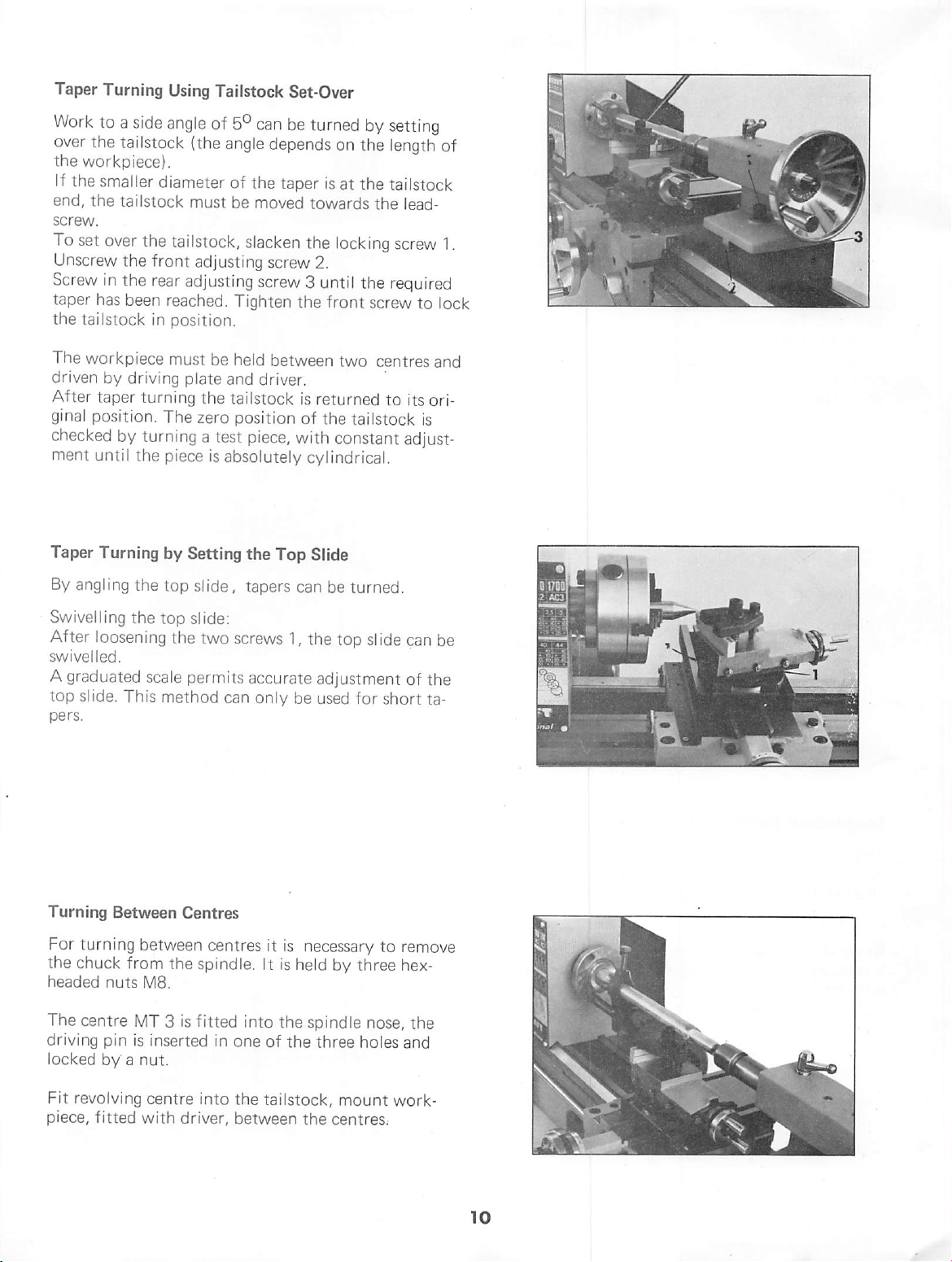

Longitudinal

Two

automatic

rev.,

fine=

altering

By

moving

is

engaged

is

in

operation.

Turning

0,09mm/rev.).

the

gear

the

half-nut

with

with

feeds

are

wheel

the

leadscrew

Auto-Feed

avai

lable

(rough = 0,18mm/

These

can

be

obtained

combinations

lever 1 downward,

and

(see

the

automatic

Table).

the

half-nut

by

feed

mm/O

-|W

0090,18

Iw"

40 40

zi

opaotfo

Z2

80

25

L H 80

80

H

Page 11

Taper

over

the

end,

screw.

To

Screw

taper

the

The

driven

After

ginal

checked

ment

Taper

Turning

Work

to a side

the

tailstock

workpiece}.

If

the

smaller

the

tailstock

set

over

Unscrew

the

In

the

has

been

tai

lstock

workpiece

by

taper

position.

by

until

Turning

driving

the

Using

Tailstock

angle

of

5°

can

(the

angle

diameter

the

tailstock,

front

rear

reached.

in

position.

must

turning

The

turning a test

piece

by

of

the

must

be

moved

slacken

adjusting

adjusting

plate

the

zero

screw 3 until

Tighten

be

held

and

driver.

tai

lstock

position

piece,

is

absolutely

Setting

the

Set-Over

be

turned

depends

taper

screw

between

Top

on

Is

at

towards

the

locking

2.

the

front

two

is

returned

of

the

with

constant

cylindrical.

Slide

by

setting

the

length

the

tai

the

screw

the

required

screw

centres

to

tai

lstock

of

lstock

lead-

1.

to

lock

and

its

ori

is

adjust

By

angling

Swivel

swivel

top slide.

Turning

For

the

headed

The

driving

locked

ling

After

loosening

led.

A

graduated

This

pers.

Between

turning

chuck

from

nuts

centre

pin

by a nut.

the

top

slide,

the

top

slide:

the

scale

permits

method

Centres

between

the

M8.

MT 3 is

is

inserted

tapers

two

screws

accurate

can

only

centres

spindle.

fitted

in

It

into

one

it

of

can

be

turned.

1,

the

top

adjustment

be

used

is

necessary

is

held

by

the

spindle

the

three

slide

can

of

for

short

to

remove

three

hex-

nose,

holes

and

be

the

ta

the

Fit

revolving

piece,

fitted

centre

with

driver,

into

the

between

tai

lstock,

the

mount

centres;

work-

Page 12

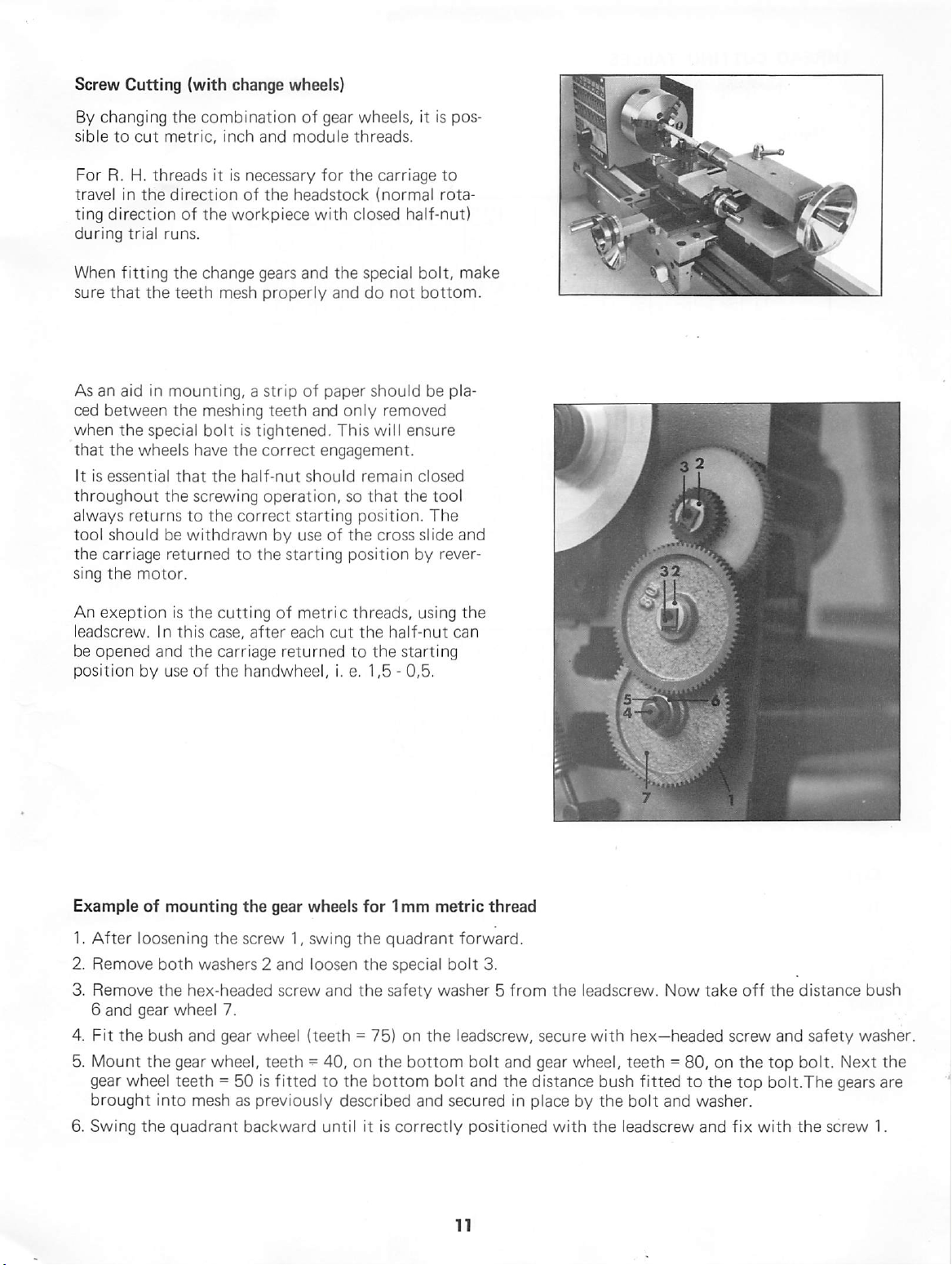

Screw

sible

For

travel

ting

during

When

sure

As

ced

when

that

It

throughout

always

tool

the

sing

Cutting

By

changing

to

cut

R.

H.

in

direction

trial

fitting

that

an

aid

between

the

the

is

essential

returns

should

carriage

the

metric,

threads

the

runs.

the

in

special

wheels

the

be

motor.

(with

change

the

combination

inch

it

is

direction

of

the

workpiece

the

change

teeth

mesh

mounting, a strip

the

meshing

bolt

is

have

the

that

the

screwing

to

the

correct

withdrawn

returned

to

wheels)

of

and

module

necessary

of

the

headstock

gears

and

properly

teeth

tightened.

correct

half-nut

operation,

starting

by

use

the

starting

gear

wheels,

threads.

for

the

carriage

(normal

with

closed

the

special

and

do

of

paper

should

and

only

This

will ensure

engagement.

should

remain

so

that

position.

of

the

cross

position

it

is

half-nut)

bolt,

not

bottom.

be

removed

closed

the

tool

The

slide

by

rever

pos

to

rota

make

pla

and

An

exeption

leadscrew.

be

opened

position

Example

1.

After

2.

Remove

3.

Remove

6

and

4.

Fit

5.

Mount

gear

brought

6.

Swing

In

and

by

of

loosening

the

gear

the

bush

the

wheel

into

the

is

the

cutting

this

case,

the

carriage

use

of

the

mounting

the

both

washers 2 and

hex-headed

wheel

7.

and

gear

gear

wheel,

teeth = 50

mesh

quadrant

of

metric

after

each

returned

handwheel,

the

gear

wheels

screw

1,

swing

loosen

screw

wheel

(teeth = 75)

teeth - 40,

is

fitted

as

previously

backward

threads,

cut

the

half-nut

to

the

i.

e.

1,5 - 0,5,

for

1mm

the

quadrant

the

special

and

the

safety

on

the

to

the

bottom

described

until

it

is

correctly

using

the

can

starting

metric

forward.

bolt

washer 5 from

on

the

leadscrew,

bottom

bolt

and

secured

thread

3.

the

secure

bolt

and

gear

and

the

distance

in

place

positioned

with

:^ii

leadscrew.

with

hex—headed

wheel,

by

teeth = 80,

bush

fitted

the

bolt

the

leadscrew

Now

to

and

take

off

screw

on

the

the

top

washer.

and

fix

with

the

distance

and

safety

top

bolt.

Next

bolt.The

the

gears

screw

bush

washer.

the

are

1.

Page 13

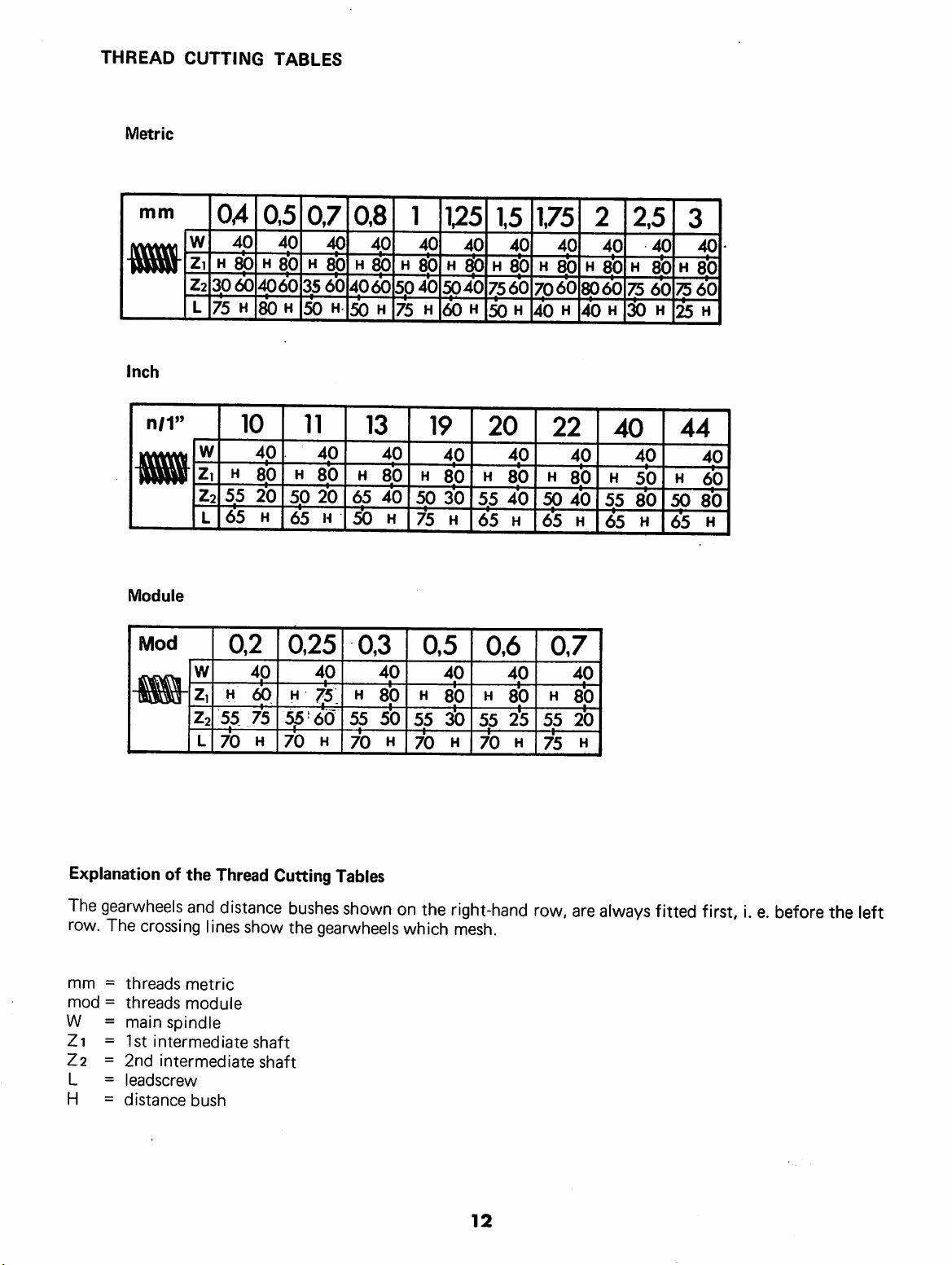

THREAD

Metric

CUTTING

TABLES

mm

m

Inch

n/1"

Mil

Module

Mod

laSSjiLr

OA

w

40

ZiH 80

Z2

3060

L

75

w

Zi

H 80

55

Z2

L

65

0,2

w

H 60

Z,

55

Z2

L

70

H

10

4p

0,5

H

4060

80

40

20

H

75

H

07

40

80

35

H

50

11

H

50

65

0,25

H

55'60

70

0,8

40

40

H

80

H

80

60

4060

H

50

13

40

80

H

20

65

H

50

0,3

40 40

75

H

55

H

70

5p40

H

75

40

80

40

H

80

50

H

1

H

40

8b

H

19

50

75

z

Z

0,5

55

70

175

40

H fib

5040

60

40

.o.

,o

30

OC

00

H

40

:ib

H

H

50

20

H

55

65

0,6

H

55

70

15

40

H

8b

7560

40

80

40

40

80

2*5

H

H

H

1,75

40

H

80

7060

40

H

22

40

H

80

50

40

65

0,7

H

55

75

8060

40

H

40

80

20

H

H

2

40

80

H

H

55

65

40

2,5

H

75

30

40

50

80

H

40

8*0

60

H

3

H

75

25

44

H 60

50

65

40

80

60

H

40

80

H

Explanation

The

gearwheels

row.

The

mm = threads

mod = threads

W =

Zi

=

7.2 = 2nd

L =

H =

of

the

and

crossing lines

metric

module

main

spindle

1st

intermediate

intermediate

leadscrew

distance

Thread

distance

show

shaft

shaft

bush

Cutting

Tables

bushes

the

shown

gearwheels

on

the

which

right-hand

row,

are

mesh.

12

always

fitted

first,

i.

e.

before

the

left

Page 14

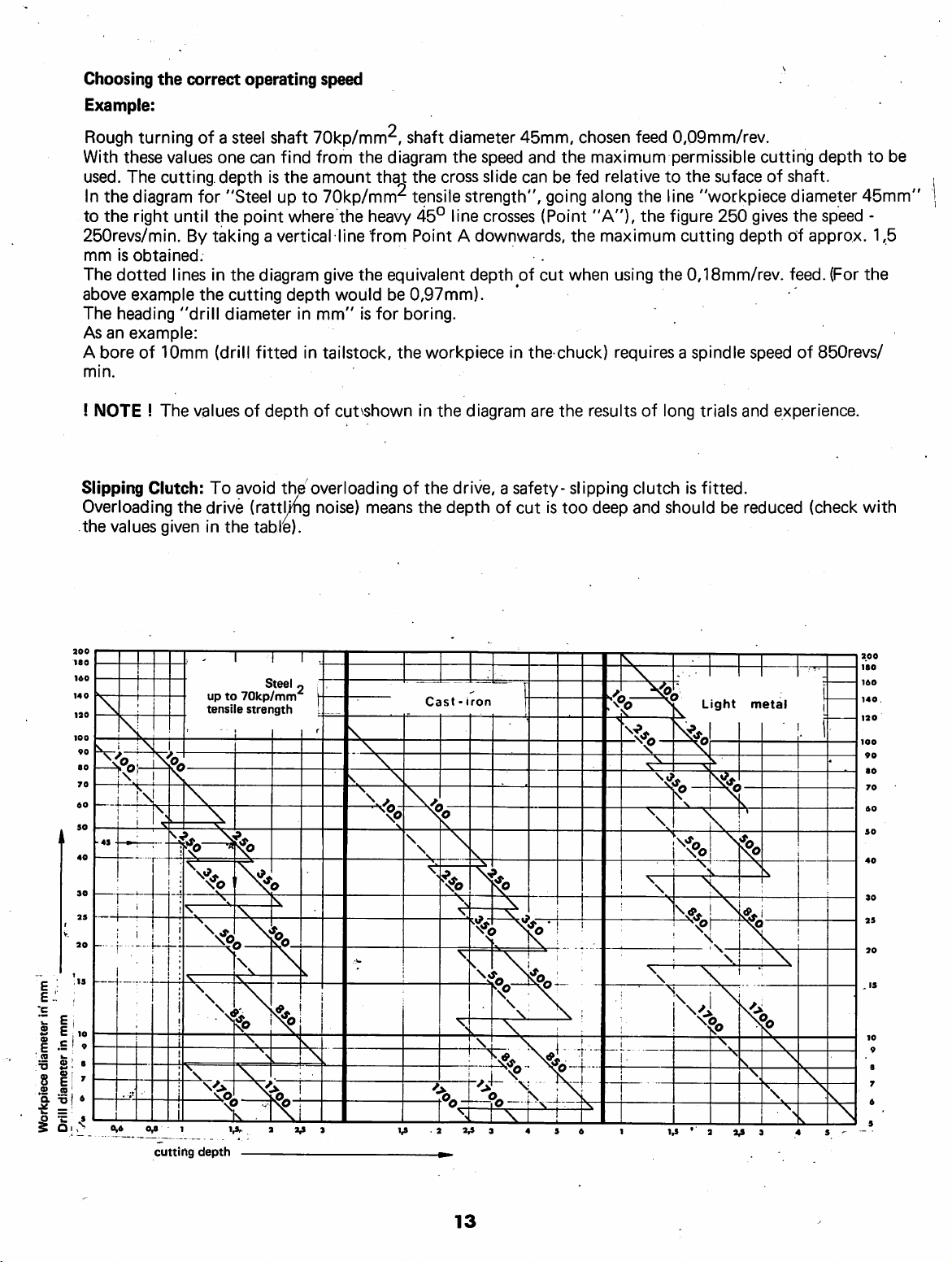

Choosing

Example:

the

correct

operating

speed

Rough

With

used.

In

to

250revs/min.

mm

The

above

The

As

A

min.

!

Slipping

Overloading

the

turning

these

values

The

cutting.depth

the

diagram

the

right

until

is

obtained.

dotted

lines

example

heading

an

example:

bore

NOTE I The

"drill

of

10mm

Clutch:

the

values

given

of a steel

one

for

the

By

taking a vertical

in

the

(drill

values

To

drive

in

shaft

can

find

is

the

"Steel

cutting

diameter

point

the

diagram

fitted

of

depth

avoid

up

to

where

depth

in

in

the

(ratth^g

the

table).

70kp/mm^,

from

the

amount

70kp/mm^

the

line

give

the

would

mm"

tailstock,

of

cut^shown

overloading

noise)

shaft

diagram

that

the

tensile

heavy

45°

from

Point A downwards,

equivalent

be

0,97mm).

is

for

boring.

the

workpiece

in

of

the

means

the

diameter

the

cross

strength",

line

the

diagram

drive, a safety-

depth

45mm,

speed

and

slide

can

crosses

depth

of

in

the

are

of

cut

going

(Point

cut

is

chosen

the

maximum

be

fed

relative

along

"A"),

the

maximum

when

using

chuck)

the

too

requires a spindle

results

slipping

deep

feed

0,09mm/rev.

permissible

to

the

suface

the

line

"workpiece

the

figure

250

cutting

the

0,18mm/rev.

of

long

trials

clutch

and

is

fitted.

should

be

cutting

of

depth

shaft.

diameter

gives

the

speed

depth

of

approx.

feed.

(For

speed

of

850revs/

and

experience.

reduced

(check

to

be

45mm"

-

1,5

the

with

0,6

0,6

cutting

I

up

to

tensile

1,6,. a V

depth

70kp/mm

strength

Cast - iron

3

1,6

.2

3,6

3

Light

1,6 ' 3

3,6

metal

3

4

6

13

Page 15

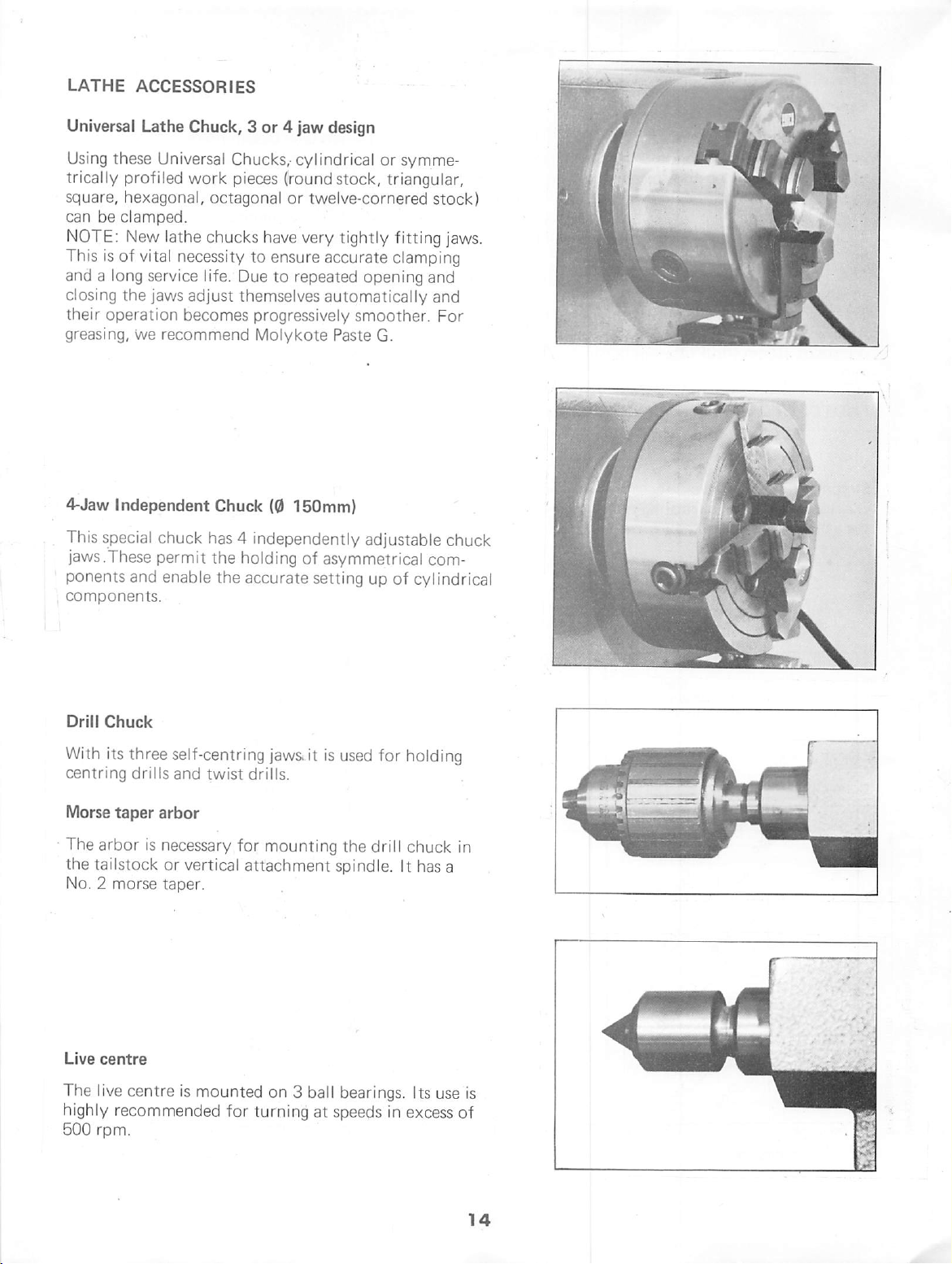

LATHE

ACCESSORIES

Universal

Using

trical

square,

can

NOTE:

This

and a long

closing

their

greasing,

4-Jaw

This

jaws.'These

ponents

components.

Lathe

Chuck, 3 or 4 jaw

these

Universal

ly

profiled

hexagonal,

be

clamped.

New

is

of

vital

work

lathe

necessity

service

the

jaws

adjust

operation

Independent

special

becomes

we

recommend

chuck

permit

and

enable

design

Chucks,'

pieces

octagonal

chucks

life.

Due

themselves

Chuck

has 4 independently

the

holding

the

accurate

cylindrical

(round

have

to

ensure

to

progressively

Molykote

(0

stock,

or

twelve-cornered

very

tightly

accurate

repeated

150mm)

opening

automatically

smoother.

Paste

G.

adjustable

of

asymmetrical

setting

up

or

symme

triangular,

stock)

fitting

jaws.

clamping

and

and

For

chuck

com

of

cylindrical

Drill

Chuck

With

its

three

centring

Morse

The

the

No. 2 morse

Live

The

highly

500

drills

taper

arbor

is

tai

lstock

centre

live

centre

recommended

rpm.

self-centring

and

twist

arbor

necessary

or

vertical

taper.

is

mounted

jaws

drills.

for

mounting

attachment

on 3 ball bearings.

for

turning

it

is

used

the

spindle.

at

speeds

for

holding

drill

chuck

It

has

Its

in

excess

in

a

use

is

of

Page 16

Fixed

steady

The

fixed

steady

shafts

on

the

the

tailstock

tool

or

the

moved

which

running

on

position

require

with

from

functions

of

the

bedway

by

continuous

the

workpiece

serves

free

tailstock

cannot

drilling

the

the

means

be

tool,

machine.

as

end

machine.

and

secured

of a locking

lubrication

to

predominantly

end.

For

many

used

as

it

obstructs

and

therefore

It

is

then

the

support

The

prevent

ensuring a chatter-free

fixed

steady

from

below

plate.

The sliding

at

the

contact

their

premature

as a support

operations

the

must

be

fixed

is

mounted

in

the

for

turning

re

steady

desired

fingers

points

wear.

Travelling

The

thus

centre

the

height

quired,

tool.

tions

ging"

ning

The

xed

be

adequately

Setting

1.

Slacken

2.

Unscrew

ding

steady

travelling

follows

part

of

as

the

The

travel

on

long,

of

the

tool.

sliding

fingers

steady,

the

steady

the

fingers 2 by

ficiently

with

its

fingers

fixed

steady

3.

By

turning

sliding

must

tight.

sl

4.

Whemafter

wear,

fingers

be

Tighten

iding

the

applied

points

steady

the

of

the

the

place

slender

is

movement

travelling

tool,

of

ling

steady

workpiece

are

free

of

play,

lubricated

three

laterally

the

knurled

hand.

wide

until the

around

in

its

position.

the

knurled

can

be

free

the

hexagonal

with

machine

prolonged

tips

of

the

mounted

only

the

third

workpieces.

under

set

similarly

but

during

screws 3 and

Open

fixed

the

screws

set

of

play

operating

fingers

on

of

the

turning

steady

two sliding

is

is

taken

used

for

the

pressure

is

It

to

not

binding.

the

located

the

sliding

steady

workpiece.

into

to

the

workpiece.

but

must

nuts.

oil.

time

can

be

the

saddle

always

fingers

by

turning

prevents

those

and

tool.

level

are

the

opera

"sprin

of

the

of

the

They

operation.

hexagonal

advance

can

position,

Lubricate

remilled

fingers

be

Secure

They

not

be

the

jaws

the sli

moved

or

As

the

with

re

turning

tur

fi

should

nuts

1,

suf

the

the

too

the

show

filed.

Page 17

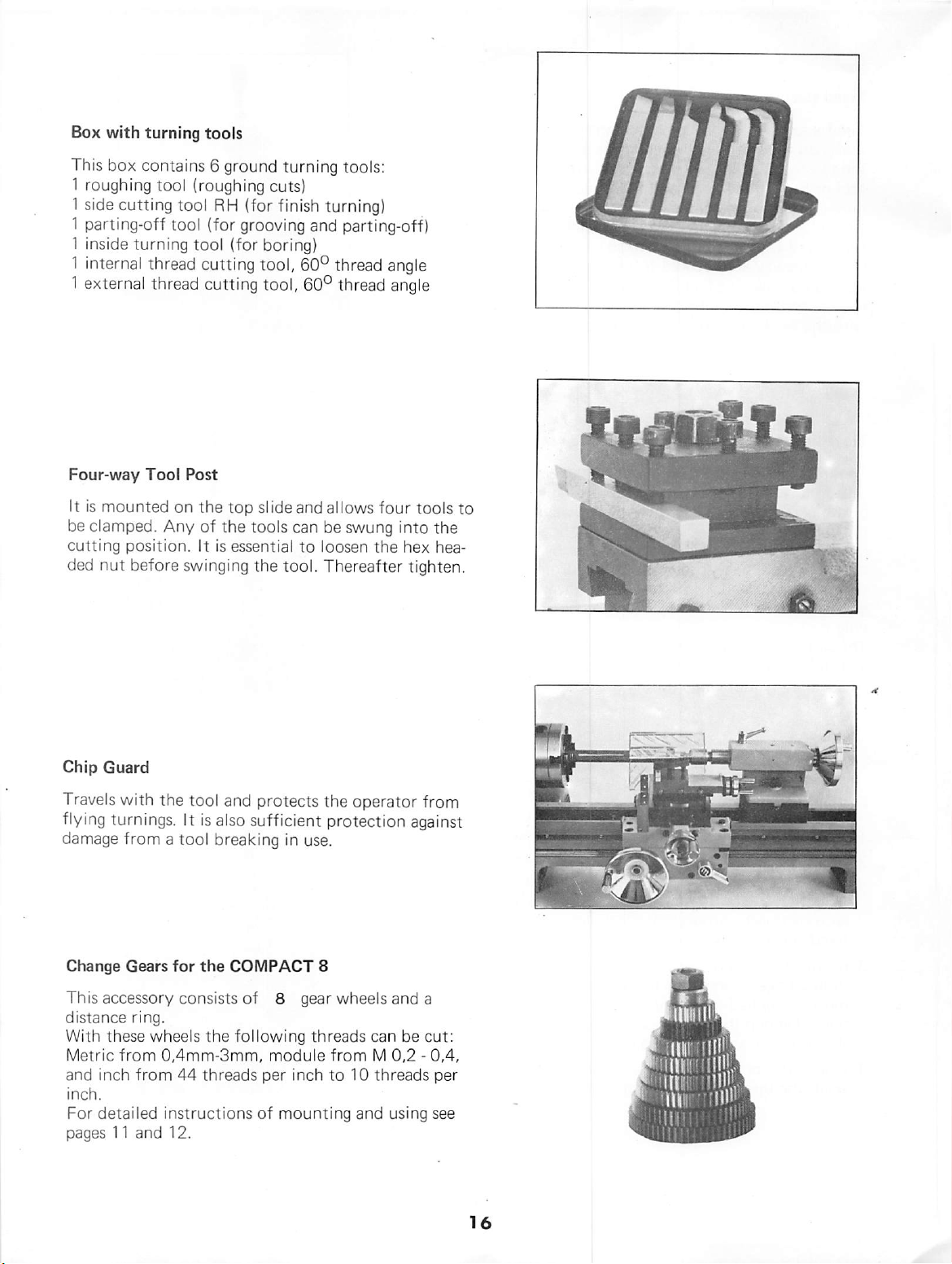

Box

with

turning

This

box

contains 6 ground

1

roughing

1

side

1

parting-off

1 inside

1 internal

1

external

tool

cutting

tool

tool

turning

thread

thread

tools

turning

(roughing

RH

(for

tool

cutting

cutting

cuts)

(for

finish

grooving

(for

boring)

tool,

tool,

tools;

turning)

and

parting-off)

60°

thread

60°

thread

angle

angle

Four-way

It

is

mounted

be

clamped.

cutting

ded

Chip

Travels

flying

damage

position.

nut

before

Guard

with

turnings.

from a tool

Tool

Post

on

Any

swinging

the

tool

It

the

top

slide

of

the

tools

It

is

essential

the

and

protects

is

also

sufficient

breaking

and allows

can

be

swung

to

loosen

tool.

Thereafter

the

operator

protection

in

use.

four

into

the

hex

tighten.

against

tools

to

the

hea

from

Change

This

distance

With

Metric

and

inch.

For

pages

Gears

for

the

accessory

these

from

inch

detailed instructions

11

consists

ring.

wheels

0,4mm-3mm,

from

44

and

12.

the

threads

COMPACT

of 8 gear

following

module

per

inch

of

mounting

8

wheels

threads

from M 0,2 - 0,4,

to

can

10

threads

and

and

be

using

a

cut:

per

see

Page 18

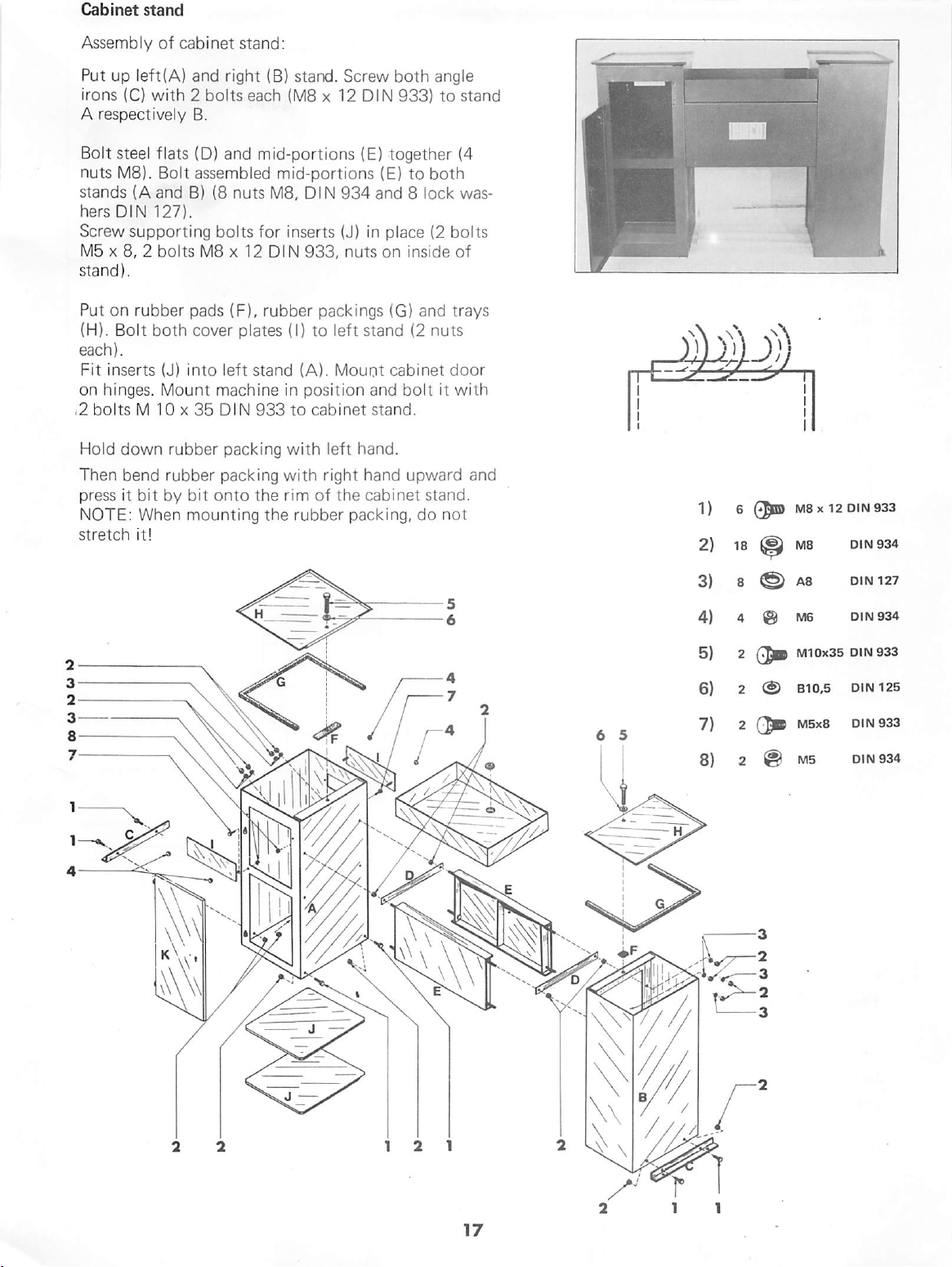

Cabinet

stand

Assembly

Put

irons

A

respectively

Bolt

nuts

stands

hers

Screw

M5 X 8, 2 bolts

stand).

Put

on

(H).

each).

Fit

inserts

on

hinges.

.2

bolts M 10 X 35

Hold

Then

press

NOTE:

stretch

of

cabinet

up

left(A)

(C)

with 2 bolts

steel

flats

M8).

Bolt

(A

and

DIN

127).

supporting

rubber

Bolt

both

(J)

Mount

down

rubber

bend

rubber

it

bit

by

When

it!

stand:

and

right

(B)

each

B.

(D)

and

mid-portions

assembled

B)

(8

nuts

bolts

for

M8 x 12

pads

(F),

rubber

cover

plates

into

left

stand

machine

Dl N 933

packing

packing

bit

onto

the

mounting

the

stand.

(MS x 12

Screw

DIN

(E)

mid-portions

M8,

DIN

inserts

DIN

933,

(E)

934

and 8 lock

(J)

in

nuts

packings

(I)

to

left

stand

(A).

Mount

in

position

to

cabinet

with

with

rim

of

rubber

left

hand.

right

hand

the

cabinet

packing,

and

stand.

both

angle

933)

to

stand

together

place

on

(G)

cabinet

bolt

(4

to

both

(2

bolts

inside

of

and

trays

(2

nuts

door

it

with

upward

stand.

do

not

was

and

)MjD

1) 6 0pn

2)

18 ^ M8

M8x12

0iN933

DIN

934

i

i

I

3) 8 ®

4)

4

@

5)

2

6)

2

7) 2 O

8) 2 @

A8

M6

M10x35

B10.5

M5x8

MB

DIN

127

DIN

934

DIN

933

DIN

125

DIN

933

DIN

934

Page 19

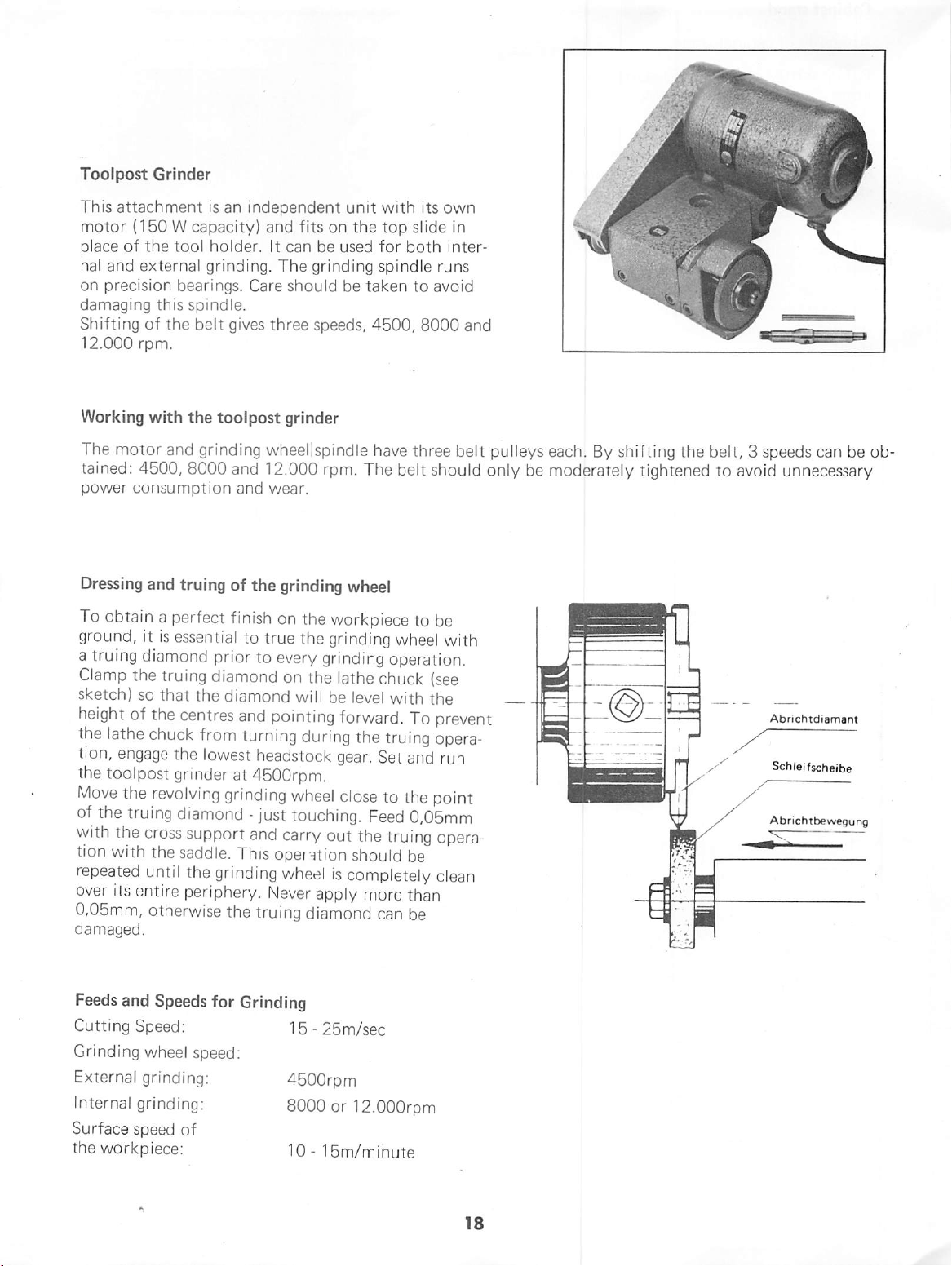

Toolpost

This

motor

place

nal

on

precision

damaging

Shifting

12.000

Grinder

attachment

{150 W capacity)

of

the

and

external

this

of

rpm.

is

an

tool

holder.

grinding.

bearings.

spindle.

the

belt

gives

independent

and

fits

It

can

The

Care

should

three

unit

on

be

used

grinding

be

speeds,

with

the

top

for

spindle

taken

4500,

its

own

slide

both

inter

runs

to

avoid

8000

in

and

Working

The

tained:

power

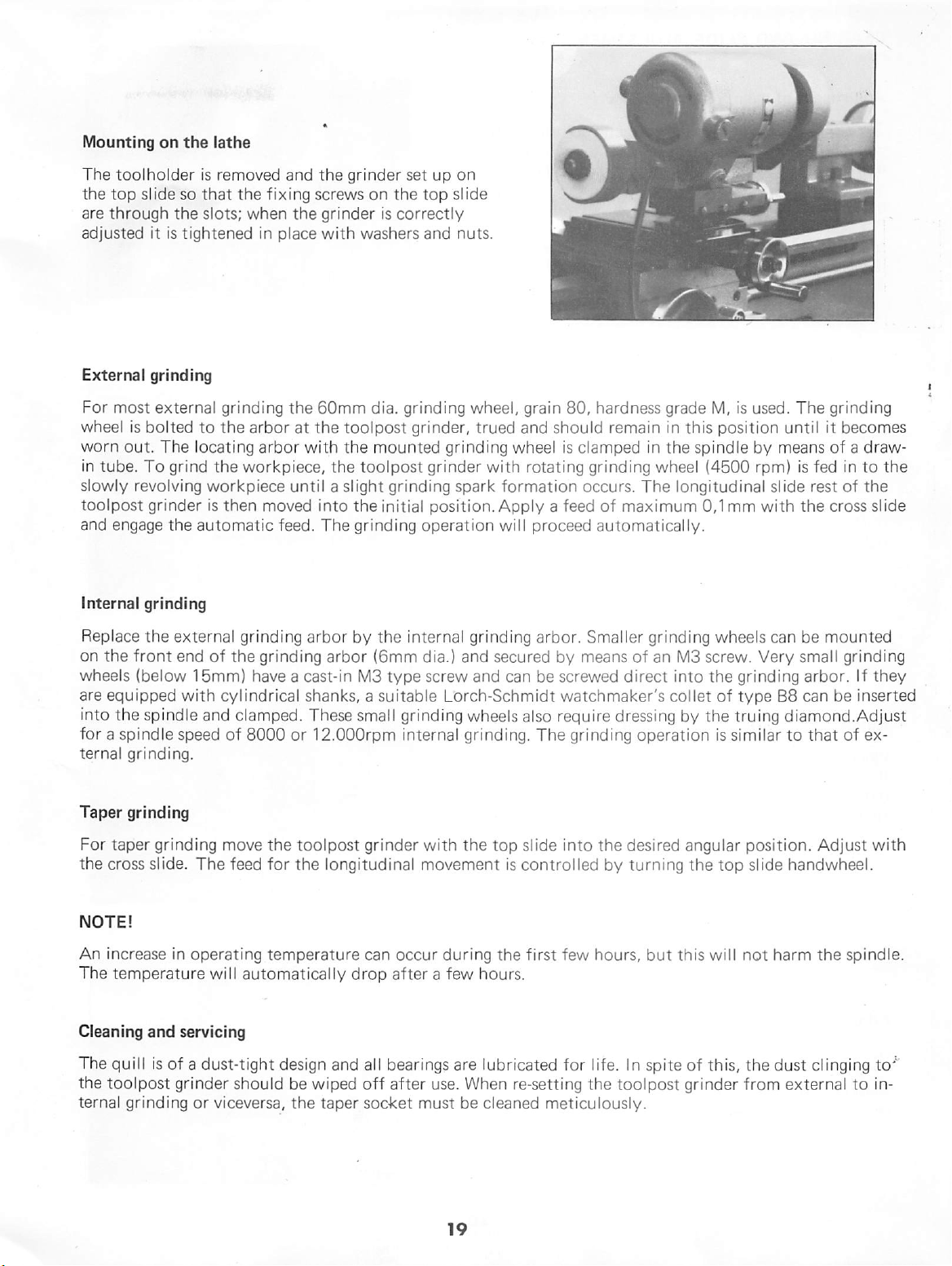

Dressing

To

ground,

a

truing

Clamp

sketch)

height

the

tion,

the

Move

of

the

with

tion

repeated

over

0,05mm,

damaged.

with

the

motor

and

4500,

8000

consumption

and

truing

obtain a perfect

it

is

essential

diamond

the

truing

so

that

of

the

centres

lathe

chuck

engage

toolpost

the

the

with

its

the

grinder

revolving

truing

diamond - just

cross

support

the

saddle.

until

the

entire

periphery.

otherwise

toolpost

grinding

and

and

of

the

wheel

12.000

wear.

finish

to

true

prior

to

diamond

the

diamond

and

pointing

from

turning

lowest

headstock

at

4500rpm.

grinding

and

This

grinding

Never

the

truing

grinder

.spindle

rpm.

grinding

on

the

the

every

grinding

on

the

will be

have

The

wheel

workpiece

grinding

lathe

level

forward.

during

the

gear.

wheel

close

touching.

carry

operation

wheel

apply

diamond

Feed

out

the

should

is

completely

more

three

belt

belt

should

to

be

wheel

with

operation.

chuck

(see

with

the

To

prevent

truing

Set

to

opera

and

run

the

point

0,05mm

truing

opera

be

clean

than

can

be

pulleys

only

each.

be

moderately

By

shifting

tightened

the

belt, 3 speeds

to

avoid

/"

can

be

unnecessary

Abrichtdismant

Schletfscheibe

Abrichtbewegung

ob

Feeds

and

Cutting

Grinding

External

Internal

Surface

the

Speed:

wheel

grinding:

grinding:

speed

workpiece:

Speeds

for

speed:

of

Grinding

15 - 25m/sec

4500rpm

8000

10 - 15m/minute

or

12.000rpm

Page 20

Mounting

The

toolholder

the

top

slide

are

through

adjusted

it

on

the

iathe

is

removed

so

that

the

slots;

is

tightened

the

when

in

and

the

fixing

screws

the

grinder

place

with

grinder

set

on

the

is

correctly

washers

up

on

top slide

and

nuts.

External

For

wheel

worn

in

tube.

slowly

toolpost

and

Internal

Replace

on

wheels

are

into

for a spindle

ternal

Taper

For

the

grinding

most

external

is

bolted

out.

The

To

grind

revolving

grinder

engage

the

grinding

the

the

front

(below

equipped

the

spindle

grinding.

grinding

taper

grinding

cross

slide.

external

end

15mm)

with

speed

grinding

to

the

arbor

locating

arbor

the

workpiece,

workpiece

is

then

moved

automatic

feed.

grinding

of

the

grinding

have a cast-in

cylindrical

and

clamped.

of

8000

move

the

The

feed

for

the

60mm

at

the

with

until a slight

into

The

arbor

shanks, a suitable

These

or

12.000rpm

toolpost

the

dia.

grinding

toolpost

the

the

toolpost

grinder,

mounted

grinding

the

initial

grinding

by

the

internal

arbor

(6mm

M3

type

small grinding

internal

grinder

longitudinal

wheel,

grinding

grinder

spark

position.

grain

trued

and

wheel

with

rotating

formation

Apply a feed

operation wil l

grinding

dia.)

and

secured

screw

and

can

Lorch-Schmidt

wheels

also

grinding.

with

the

top

slide

movement

is

control

80,

hardness

should

remain

is

clamped

grinding

occurs.

of

proceed

arbor.

be

The

automatically.

Smal

by

means

screwed

watchmaker's

require

dressing

grinding

into

the

led

by

grade

in

this

in

the

spindle

wheel

(4500

The

longitudinal

maximum

ler

grinding

of

direct

an

col

0,1

M3

screw.

into

let

by

the

operation

desired

turning

angular

the

M,

is

used.

position

by

rpm)

slide

mm

with

wheels

the

of

can

Very

grinding

type

truing

is

simi

lar

position.

top

slide

The

grinding

until

it

becomes

means

B8

of a draw-

is

fed

in

rest

of

the

cross

be

mounted

small

grinding

arbor.

can

be

to

the

the

slide

If

they

inserted

diamond.Adjust

to

that

of

ex

Adjust

with

handwheel.

NOTE!

An

increase

The

temperature

Cleaning

The

the

ternal

and

quill is

toolpost

grinding

in

operating

will

servicing

of a dust-tight

grinder

or

viceversa,

temperature

automatical

design

should

be

the

ly

drop

and all

wiped

off

taper

socket

can

occur

after a few

bearings

after

must

during

are

use.

When

be

the

first

few

hours.

lubricated

for

re-setting

cleaned

meticulously.

hours,

life.

In

the

toolpost

but

this

spite

of

grinder

will

not

this,

the

from

harm

the

spindle.

dust clinging

external

to

to'^

in

Page 21

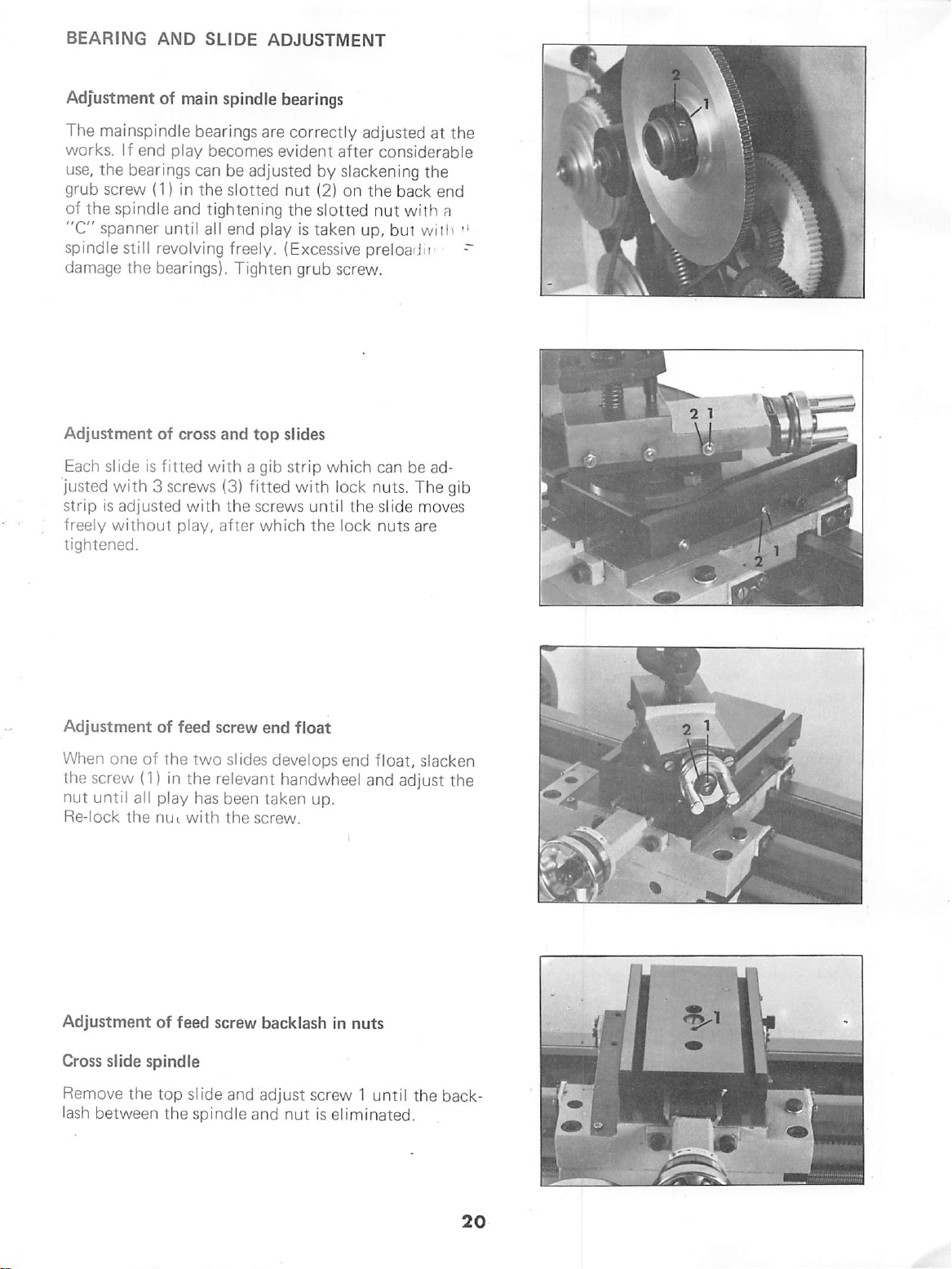

BEARING

AND

SLIDE

ADJUSTMENT

Adjustment

The

mainspindle

works.

use,

the

grub

screw

of

the

"C"

spanner

spindle

damage

Adjustment

Each

slide

justed

strip

is

freely

tightened.

of

If

end

play

bearings

(1)

spindle

until all end

still revolving

the

bearings).

of

is

fitted

with 3 screws

adjusted

without

main

spindle

bearings

becomes

can

be

in

the

slotted

and

tightening

freely.

Tighten

cross

and

with a gib

(3)

with

the

play,

after

bearings

are

correctly

evident

adjusted

play

top

fitted

screws

which

by

nut

(2)

the

slotted

is

taken

(Excessive

grub

slides

strip

which

with

until

the

adjusted

after

considerable

slackening

on

the

nut

up,

at

the

back

with

but with

preloadn'

screw.

can

be

ad

lock

nuts.

The

the

slide

moves

lock

nuts

are

the

end

a

"

~

gib

Adjustment

When

one

of

the

screw

(1)

nut

until all play

Re-lock

Adjustment

Cross

Remove

lash

the

slide

spindle

the

between

of

feed

the

in

nui

of

feed

top

the

the

with

screw

two

slides

relevant

has

been

the

screw

slide

and

spindle

and

end

float

develops

handwheel

taken

up.

screw.

backlash

adjust

screw 1 until

nut

is eliminated.

end

in

nuts

float,

slacken

and

adjust

the

the

back

Page 22

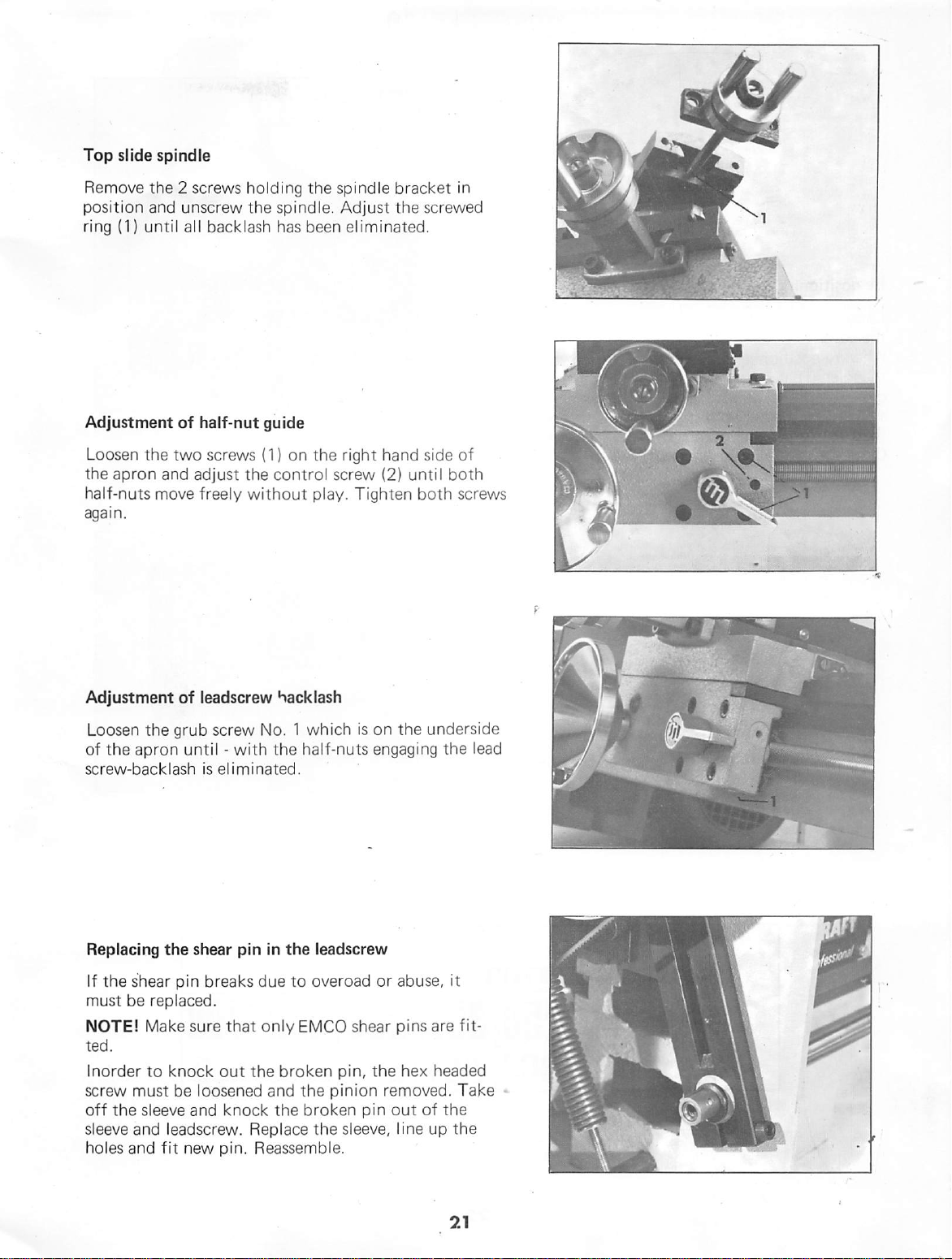

Top

slide

spindle

4/

Remove

position

ring

Adjustment

Loosen

the

half-nuts

again.

the 2 screws

and

(1)

until

the

two

apron

and

move

unscrew

all

backlash

of

half-nut

screws

adjust

freely

holding

the

spindle.

has

guide

(1)

on

the

control

without

the

spindle

Adjust

been

eliminated.

the

right

screw

play.

Tighten

bracket

the

screwed

hand

side

(2)

until both

both

in

of

screws

Adjustment

Loosen

of

the

screw-backlash

Replacing

If

the

must

be

NOTE!

ted.

Inorder

screw

off

the

sleeve

holes

and

of

the

grub

apron

shear

must

and

until -

the

pin

replaced.

Make

sure

to

knock

be

sleeve

leadscrew.

fit

new

shear

and

leadscrew

screw

is

eliminated.

breaks

that

out

loosened

knock

pin.

hacklash

No. 1 which

with

the

pin

in

due

only

the

and

the

Replace

Reassemble.

half-nuts

the

leadscrew

to

overoad

EMCO

broken

pin,

the

pinion

broken

the

sleeve, line

is

on

the

engaging

or

abuse,

shear

pins

the

hex

removed.

pin

out

underside

the

lead

it

are

fit

headed

Take

of

the

up

the

Page 23

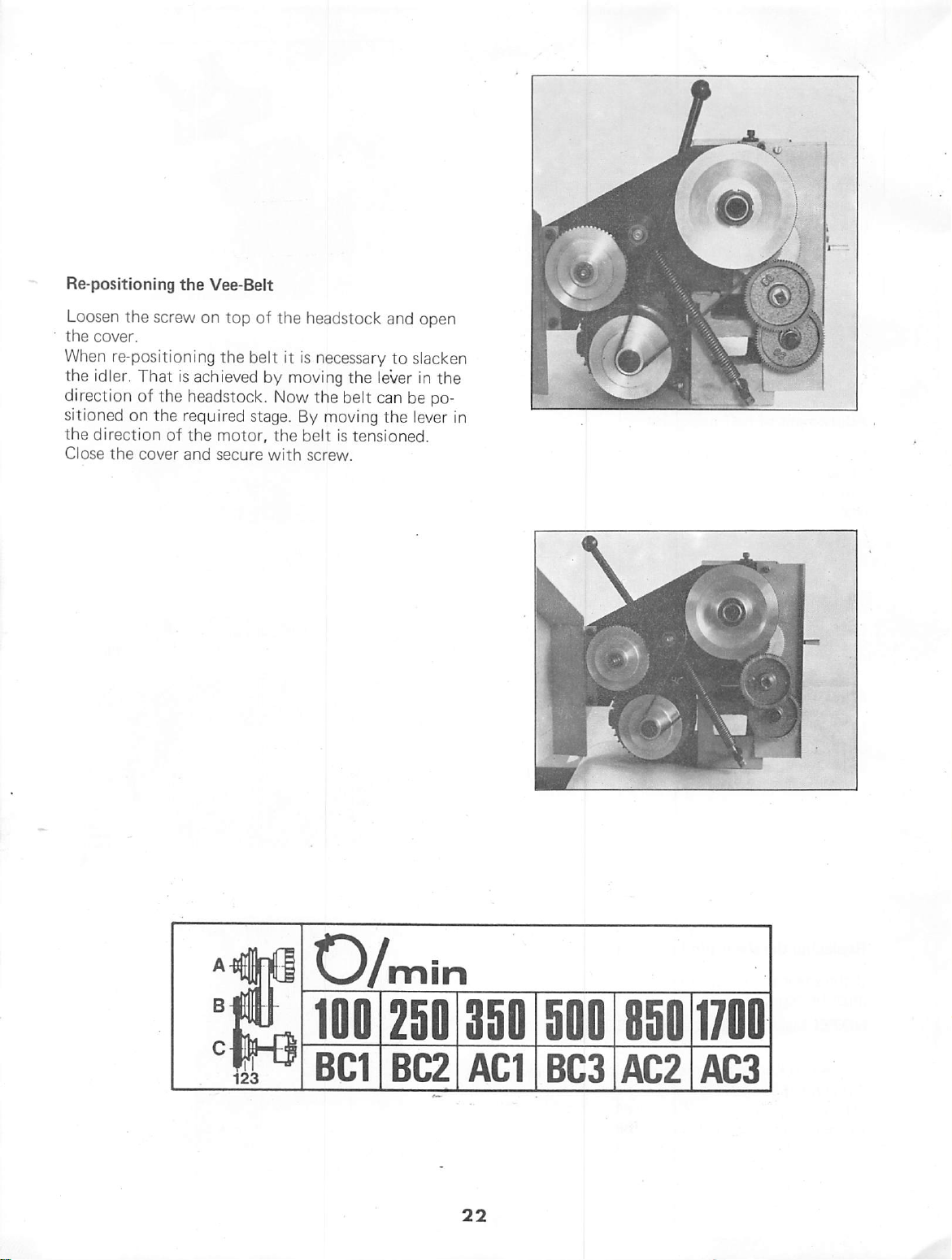

Re-positioning

the

Vee-Belt

Loosen

the

When

the

direction

sitioned

the

Close

the

screw

cover.

re-positioning

idler.

That

of

the

on

the

direction

the

cover

on

top

the

belt

is

achieved

headstock.

required

of

the

and

stage.

motor,

secure

of

by

Now

the

with

the

headstock

it

is

necessary

moving

By

the

moving

belt

is

screw.

the

belt

tensioned.

and

open

to

slacken

lever

in

can

be

the

lever

the

po

in

^3/min

100

BC1

250

BC2

AC1

BC3

AC2

AC3

Page 24

Page 25

Wiring

Diagram

"EMCO

COMPACTS"

"M

r'

O

3

J

R

O

Mp

SI

1

6

10

^612

11

J

k1

b1

k1

ml

m

1

Motor

switch

Condenser

Motor

o'

O

black

w

blue

grey

u

C>

(>—

brown

..

J

Motor

forward

hi

—

switch

diagram

123

—

—

4

X X

—

9

10

X

11

12

X

—

—

7

5

8

6

—

—

0

—

reverse

—

X

—

—

—

—

—

—

X

—

X

X

24

Page 26

Mounting

of

Vertical

Milling

and

Drilling

Unit

COMPACT

Technical

8

Data

Motor;

lEC-standard

and

splashproof

Input

Output

For

on

Spindle

5o

6o

Spindle

power

power

voltage

motor.

speeds;

cycles:

cycles:

nose

single-phase

according

(PI)

2oo

W,

(P2)

loo

W,

and

frequency - see

38o/7oo/16oo

45o/8oo/19oo

(main

spindle)

motor,

to

IP

44

S3-6o % ID

S3-6o % ID

label

rpm.

rpm.

:

dust

O

CN

82(3.22"

according

M14 X 1

Weight:

For

dimensions

Electrical

The

vertical

may

only

grounding

tical

of

the

Mounting

Due

to

different

not

delivered

Mounting

professionally!

Clamp

to

the

Clamp

and

N.

to

thread.

6,5

kg

Connection

be

plugged

contacts

must

be

machine)»

the

the

different

countries,

of

plugs

tdie

grounding

grounding

the

other

factory

(14

pounds)

-

refer

milling

(a

available

plug;

with

must

contact

two

standard,

to

sketch

and

drilling

into

outleds

grounding

for

requirements

the

machines

plugs

everywhere.

be

carried

wire

(yellow-green)

(symbol@

wires

to

with

unit

with

recep-

connection

in

are

out

contact

).

R

25

Page 27

Accident

Prevention:

Milling

-

Drilling

+ Always

prevention

Additional

+ Clamping

When

drilling

piece

order

being

of

Clamping

ing

chuck,

+

Work

sharpened

+ Clpse

■ machine.

+ Remove

ly

is

+ Loose

must

to

loosened

the

table

only

belt

with

not

clothing

pecially

can

easily

grooves

follow

on

tips;

the

be

the

page

workpiece

or

clamped

prevent

by

tool.

tools:

with

clamping

4-jaw

independent

with

perfectly

tools!

cover

milling

brush

switched

and

and

and

dangerousi

get

caught

of

the

millers

rules

1!

milling,

the

workpiece

the

machine

before

drilling

only

on.

hairs

Hair

in

for

accident

the

work-

securely,

cutting

vice,

force

mill

shoes,

chuck

ground

switching

chips

when

machine

can

be

or

clothing

the

spiral

and

drills.

in

from

3-jaw

...

and

on

on

es

+ Never

+ Never

ning.

+ The

clamped

circular

in

the

Note:

To

enable

milling

drawings.

however.

wear

clean

milling

so,

saw

uppermost

better

guard

The

rings

machine

guard:

that

blade)

is

guard

when

working!

while

the

the

is

position.

illustration,

not

must

ring

tool

covered

shown

be

it

must

(miller,

in

mounted,

is

some

run

be

when

the

Note;

The

vertical

is

also

used

Therefore

tions

are

of

valid

milling

on

the

you

will

the

Compact 8 if

for

both

Compact

find

machines.

26

and

drilling

same

unit

5.

illustra

informations

Page 28

TO

255(10")

Mounting

of

Vertical

Milling

o

and

1.

If

tdie

please

rough

Drilling

there

rear

prepare

holes).

are

side

Upit

no

threaded

of

the

threaded

holes

machine

holes

at

bed,

(tho

in

cd'

='

70

90

ir

■o

2.76"

3.54"

10

.39".

Pre-drilling

4

mm

dia.

Pre-drilling

6,5

mm

dia.

Note:

If

the

bores

taps

ded

the

Get 2 cap

are

holes,

illustration.

lo-24x6/8")

not

make

screws

to

and 4 hexagonal

(pos.3)

and

drilling

to

mount

threaded

threaded

are

not

available

inch

(Allen

mount

bolts

the

unit.

hole

M5:

hole

M8:

machined

to

make

bores

as

screws,

the

adaptor

5/16"-18x1

vertical

and

the

shown

pos.l)

plate

3/4"

milling

metric

threa

in

27

Page 29

2.

Screw

gonal

tighten

3.

Adjusting

tion

(pos.2)

rectangular

4.

Mount

using

and

to

be

on

support

screws

the 4 threaded

base

too

the

such

bracket

M5x20

firmly.

support

that

to

cross

the 4 hexagonal

washers.

The

rectangular

plate

(pos.1);

plate:

bolts

support

slide.

of

vertical

screws

vertical

to

the

with 2 hexa

do

not

posi

M8xl6

plate

is

unit

M8x40(Pos3^

column

cross

slide.

has

700

210

r—

4.1.

4.2.

Rectangular

nally

the

ded

to

cross

support

bolts

Rectangular

ly

to

cross

bracket

of

adjustment

slide:

plate

(pos.2).

adjustment

slide:

vertical

adjusting

using

clamp

unit

longitudi

the 4 threa

transversal-

base

at

90°

angle.

28

Page 30

Operating

Elements

Height

Loosen

clamping

unit

height.

adjustment

the

head

into

The

cross

5o

mm

(1.96") . By

cal

unit

match

cross

the

slide

Swivelling

socket

the

in

the

quill

and

turning

head

and

bring

required

slide

throat

different

working

travel.

holder

the

vertical

screw

position

clamping

the

vertical

is

angles,

on

the

and

limited

the

requirements

unit

verti

you

to

to

can

the

Moving

Insert

ling

A

to

Clamping

The

The

The

rate

drilling

Mounting

1.

the

toggle

the

built-in

the

original

quill

Always

never

Vertical

vertical

depth

Loosen

toggle

onto

toggle.

quill

into

toggle,

spring

screw

for

is

fixed

clamp

force

Fine

fine

adjustment

operations.

set

screw

(2)

and

the

pinion

the

bore.

the

quill

returns

position.

the

quill

with

quill

the

toggle.

the

(3)

the

when

Feed

feed

serves

for

milling

(1), pull

mount

worm

(4), re-tighten

By

swivel

is

lowered.

quill

socket

milling,

in

head

Attachment

for

accu

and

out

wheel

(3)

Loosen

the

The

positioning.

socket

quill

graduated

Through

movements,

>;•:

any

required

head

holder

scale

these

the

screw

to

the

enables

turning

quill

angle.

(1)

and

required

accurate

and

swivelling

can

be

set

swivel

angle.

at

2.

3.

.unit

Insert

Place

into

the

socket

worm

wheel

pinion

centering

into

the

bore

head

is

engaged with

the

bolt

and

screw,

quill

(5)

clamp

so

of

that

holder.

the

with

the

feed

the

worm.

Page 31

If

the

sion,

If

loosen

Worm

The

worm

the

quill

the

fine

socket

and

pinion

(6)

feed

worm

can

is

turned

moves

is

head

wheel

be

o,l

not

screw

are

moved

by

one

mm.

required,

and

not

engaged

with

divi

swivel

the

Adjusting

Open

cover

(2)

and

The

belt

onto

the

Tighten

the

(1),

swivel

is

loosened

required

belt

and

again.

Note;

Never

work

with

Spindle

loosen

motor

fix

belt

socket

toward

and

pulley

socket

cover

Speed

head

the

front.

can

be

shifted

combination.

head

screw

opened

1

screw

Spindle

The

spindle

drilling

the

tool

of

workpiece

The

values

for

sharpened

Diameter

miller

drill

to

5-10

10-15

15-20

20-40

or

(mm)

5

Speed

speed

depends

{miller,

material.

shown

tools.

of

SPINDLE

Steel

1600

during

on

drill)

below

700

700

380

380

the

SPEED

Chart

milling

diameter

and

are

valid

Cast

1600

700

380

380

380

the

Iron

and

of

type

only

Aluminium/

Brass

1600

1600

700

700

380

Page 32

Clamping

Devices

for

Drills

(Summary)

and

Millers

3-jaw

drill

Spiral

Centering

Countersunk

drill

chuck

drill

Collet

(not

the

with

the

Millers

and

attachment

same

as

lathe)

fly

cutter

Millers

Arbor

with

I

I

16

mm

bore

31

Page 33

Tighten

Note:

from

the

tion,

clamping

if

you

top,

however,

look

the

looks

nut

(3)

at

the

tightening

counterclock

clockwis

clamping

dire

Clamping

It

is

mounted

Collet

The

onto

Clamping

25:

Attachment

collet

the

1,5 - 14

Millers

with

highest

this

reason,

necessary.

by

means

ded.

Mounting

-

Insert

that

the

tioned

-

Mount

capacity

holder

spindle

capacity

must

be

round-run

the

Clamping

of

the

The

ESX-25

the

groove

in

the

nut

with

1-8

directly

is

nose.

using

mm

clamped

collet

is

pins

collet

of

ring

collet

mm

(o.o4"-o.3")

onto

mounted

the

securely

accuracy.

attachment

accomplished

which

collets:

in

the

the

(2)

are

collet

of

on

the

directly

collets

and

For

inclu

nut

(2)

is

the

nut.

the

holder.

spindle

ESX

is

so

posi

Dismounting

Open

nut.

The

collet

the

ring

of

Nominol

dio.

The

clamping

the

collet.

Do

not

clamp

catalog)

the

collets:

is

automatically

the

nut.

Individual

in

mm

Chucking

copocily

capacities

other

collets

in

ESX-25

mm

Shaft

dio-

Vf,

'V6<-'/33-IV64

^/33-'Vg.-Vl6

2

Vs.- I V33

?V6.-3/9-"/sr~

'V3:-"/6.

3V6.-V3

33/a.-l'/33-3V6<

are

diameters!

ejected

in

Inches

engraved

(See

by

on

also

The

It

serves

circular

and

millers with

bore

of

milling

saw

16

for

mm

arbor

mounting

blades

a

(o.63")

.

Page 34

Clamping

Devices

for

Workpieces

1.

Machine

Width

Opening:

It

shers

is

of

mounted

and

vice:

jaws:

60

5o ram

mm

(2.36")

with

hexagon

(2.36")

the

nuts

T-nut

to

the

bolts,

cross

wa

slide

3.Clamping

ing

chuck

Mount

-

Mount

smaller

xagonal

chuck

support

with

to

T-nut

nuts

or

to

the

self-center

independent

the

support

plate

bolts,

the

with

washers

cross

plate

the

slide.

two

and

chuck

he

2.

Stepped

Clamping

Workpieces

cross

must

height

slide.

be

used

clamping

up

to

2o

are

clamped

At

least 2 clamping

for safe

clamping.

shoes;

mm

(.8")

directly

to

shoes

the

Page 35

Drilling

in

Generai

Clamping

Drills

or

in

the

Clamping

The

workpiece

or

on

the

the

appropriate

Spindle

The

spindle

on

the

ler

and

Drill

Drill

feed;

feed

the

drill

are

clcimped

collet

the

workpiece

dividing

speed:

speed

diameter

the

material

is

in

chuck.

is

fixed

attachment,

clamping

of

of

the

achieved

the

on

the

drill,

of

the

via

drill

the

top

device.

drill

resp.

workpiece.

the

chuck

slide

using

depends

mil

quill.

The

smaller

it

is

that

it

feed

must

be

feeling

Coordinate

With

longitudinal

wheels,

dinates

(very

aid

of

drilling

can

drilling

Please_note:

The

scale

to

the

during

cross

2,5

mm

tion.

ly

1,25

on

diameter

turning.

slide

after

The

slide,

mm.

the

drill,

will

carried

carefully)

the

scale

and

cross

in

be

carried

the

cross

of

The

handwheel

one

complete

however,

the

break.

out

.

rings

slide

accurate

out.

slide

the

workpiece

scale

indicates

Working

easier

Drill

with

on

the

hand-

coor

refers

on

the

revolu

moves

on

Tips - Driiiing

Place a wooden

der

the

workpiece

ing

table,

not

damaged

Use

the

vertical

rate

depth

When