Page 1

EMC®VNX™Procedure Generator

T o p i c

S e l e c t i o n s

Generated:

2013/7/24 11:21:15

SolVe Generator Updated:

Replacing the Data Mover Enclosure (DME)

VNX5300 Procedures

VNX5300 Activity Type: Hardware Replacements

VNX5300 File/Unified HW Replacements: Data Mover Enclosure (DME)

五月 30, 2013

IMPORTANT: To be sure you have the latest SolVe generator application and content, always choose Yes

when asked if you want to update the application or repository.

REPORT PROBLEMS

If you find any errors in this procedure or have comments regarding this application, send email to

SolVeFeedback@emc.com

Copyright©2010 –2013 EMC Corporation. All rights reserved.

Publication Date: July, 2013

EMC believes the information in this publication is accurate as of its publication date. The information is subject to

change without notice.

THE INFORMATION IN THIS PUBLICATION IS PROVIDED “AS IS.” EMC CORPORATION MAKES NO

REPRESENTATIONS OR WARRANTIES OF ANY KIND WITH RESPECT TO THE INFORMATION IN THIS

PUBLICATION, AND SPECIFICALLY DISCLAIMS IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

Use, copying, and distribution of any EMC software described in this publication requires an applicable software

license.

For the most up-to-date regulatory document for your product line, go to the Technical Documentation and Advisories

section on EMC Powerlink.

For the most up-to-date listing of EMC trademarks, see the list of EMC Corporation Trademarks on EMC.com.

All other trademarks used herein are the property of their respective owners.

EMC CONFIDENTIAL version: 4.5

1 of 51

Page 2

EMC®VNX™Procedure Generator

Contents

Handling Field Replaceable Units (FRUs).........................................................................4

FRUs and Power Issues..........................................................................................................................4

Avoiding Electrostatic Discharge (ESD) damage......................................................................................4

Emergency procedures (without an ESD kit).......................................................................................5

Removing, installing, or storing FRUs .................................................................................................5

Replacing a Blade Enclosure (DME)................................................................................. 6

Task Summary ........................................................................................................................................6

Task 1: Diagnose and identify Faulted FRU.......................................................................................6

Receive an email notification.......................................................................................................7

Log in to EMC Unisphere ............................................................................................................7

Check the Fault LED...................................................................................................................7

Check the Blade enclosure fault LEDs.........................................................................................8

Task 2: Disabling ConnectHome and Email Notifications...................................................................9

Task 3: Saving Resume PROM Configuration Information.................................................................9

Task 4: Halting the Secondary Control Station.................................................................................11

Task 5: Prepare for Replacement....................................................................................................12

Single-Blade system.........................................................................................................................13

Multi-Blade system ...........................................................................................................................13

Task 6: Remove Faulted DME.........................................................................................................16

Task 7: Install the Replacement DME..............................................................................................18

Transfer Components to the Replacement DME........................................................................19

Removing a Power/Cooling module...........................................................................................19

Remove the CPU Filler Assembly..............................................................................................20

Removing a CPU module..........................................................................................................21

Installing a CPU module............................................................................................................21

Reinstall the CPU Filler Assembly .............................................................................................22

Installing a Power/Cooling Module.............................................................................................22

Transfer Management Modules and I/O Modules..............................................................................23

Removing a Management Module.............................................................................................23

Installing a Management module...............................................................................................24

Removing an I/O module...........................................................................................................24

Installing an I/O module.............................................................................................................25

Transfer the Serial Number Tag ................................................................................................26

EMC CONFIDENTIAL version: 4.5

2 of 51

Page 3

EMC®VNX™Procedure Generator

Reconnect Blade Enclosure Cables ..........................................................................................27

Task 8: Configure the replacement BE Resume PROM...................................................................27

Set up the Work Environment on the Blade...............................................................................27

Configure the BE Resume PROM.....................................................................................................28

Task 9: Collect System Information .................................................................................................31

Set up the Work Environment on the Control Station.................................................................31

Collect System Information and Save SP Logs..........................................................................32

Task 10:Configure the HBA/Initiator Records....................................................................................35

Set Up the Replacement BE......................................................................................................35

Remove the old initiator records................................................................................................36

Collect the New WWNs.............................................................................................................37

Zone the FC switch(s)...............................................................................................................39

Recreate the initiator records ....................................................................................................39

Verify the New Connections ......................................................................................................42

Configure the Blades.................................................................................................................43

Task 11:Test the Functionality of the System....................................................................................44

Task 12:Installing the Blade Enclosure Front Bezel ..........................................................................46

Task 13:Check System Status..........................................................................................................47

Task 14:FRU failures .......................................................................................................................48

Task 15:Enabling ConnectHome and Email Notifications..................................................................48

Finish ....................................................................................................................................................49

Parts Return..............................................................................................................................51

EMC CONFIDENTIAL version: 4.5

3 of 51

Page 4

EMC®VNX™Procedure Generator

Handling Field Replaceable Units (FRUs)

This section describes precautions you must take and generalprocedures you must follow when removing,

installing, or storing field-replaceable units (FRUs). The procedures in this section apply to FRU handling

during hardware upgrades as well as during general replacement.

FRUs and Power Issues

FRUs are designed to be powered up at alltimes. This means you can replace FRUs and accomplish most

hardware upgrades while the cabinet is powered up. To maintain proper airflow for cooling and to ensure

EMI compliance, make sure all front bezels, filler panels, and filler modules are reinstalled after the FRU

replacement or hardware upgrade is completed. Do not remove a faulty FRU from the system until you have

a replacement available.

CAUTION: When you want to power down a storage processor enclosure (SPE), turn off the power

switch on the enclosure’s standby power supply (SPS). Never turn off the SPE’s power supply

switches. Turning off the SPE power supply switches instead of the SPS power switch shuts down

the storage processors before they have enough time to save the write-cache data to the vault

drives. This causes data loss.

If write-cache data is not saved, the storage processor log displays an error message similar to the

following:

Enclosure 0 Disk 5 0x90a (Can’t Assign - Cache Dirty) 0 0xafb40 0x14362c.

If you see this error message, contact Customer Service immediately.

Avoiding Electrostatic Discharge (ESD) damage

When replacing or installing FRUs, you can inadvertently damage the sensitive electronic circuits in the

equipment by simply touching them. Electrostatic charge that has accumulated on your body discharges

through the circuits. If the air in the work area is very dry, running a humidifier in the work area helps

decrease the risk of ESD damage. You must use the following procedures to prevent damage to the

equipment, so read the following instructions carefully.

Provide enough room to work on the equipment. Clear the work site of any unnecessary materials or

materials that naturally build up electrostatic charge, such as foam packaging, foam cups, cellophane

wrappers, and similar items.

Do not remove replacement or upgrade FRUs from their antistatic packaging until you are ready to

install them.

Gather the ESD kit and all other materials you will need before you service a component. Once

servicing begins, you should avoid moving away from the work site; otherwise, you may build up an

electrostatic charge.

Use the ESD kit when handling any FRU.

If an emergency arises and the ESD kit is not available, follow theprocedures in the section

procedures (without an ESD kit)

.

Emergency

Use the ESD wristband that is supplied with your system.

EMC CONFIDENTIAL version: 4.5

4 of 51

Page 5

EMC®VNX™Procedure Generator

To use it, attach the clip of the ESD wristband (strap) to any bare (unpainted) metal on the cabinet

enclosure; then secure the wristband around your wrist with the metal button against your skin.

Emergency procedures (without an ESD kit)

In an emergency, when an ESD kit is not available, use the following procedures to reduce the possibility of

an electrostatic discharge by ensuring that your body and the subassembly are at the same electrostatic

potential.

IMPORTANT: These procedures are not a substitute for the use of an ESD kit. You should follow them

only in the event of an emergency.

Before touching any FRU, touch a bare (unpainted) metal surface of the enclosure.

Before removing any FRU from its antistatic bag, place one hand firmly on a bare metal surface of the

enclosure, and at the same time, pick up the FRU while it is still sealed in the antistatic bag. Once you

have done this, do not move around the room or contact other furnishings, personnel, or surfaces until

you have installed the FRU.

When you remove a FRU from the antistatic bag, avoid touching any electronic components and

circuits on it.

If you must move around the room or touch other surfaces before installing a FRU, first place the FRU

back in the antistatic bag. When you are ready again to install the FRU, repeat these procedures.

Removing, installing, or storing FRUs

Use the following precautions when you remove, handle, or store FRUs:

Do not remove a FRU from the cabinet until you have the replacement available.

Handle a FRU only when wearing a properly attached ESD wristband:

Attach the clip of the ESD wristband to the ESD bracket or to a bare metal portion of the FRU’s

enclosure.

Secure the wristband around your wrist with the metal button against your skin.

Handle a FRU gently. A sudden jar, drop, or vibration can permanently damage some FRUs.

The weight of some FRUs is not evenly distributed. To prevent personal injury or equipment damage

when removing, installing, or handling theses FRUs, use both hands and provide extra support at the

heavy end of the FRU.

Never use excessive force to remove or install a FRU.

Store a FRU in the antistatic bag and the specially designedshipping container in which you received it.

Use this special shipping container when you need to return the FRU.

If you need to store a FRU for a short time, make sure the temperature of the location where you store

FRU is within the limits specified by the FRU’s Technical Specifications.

Disk modules are sensitive to the extreme temperatures sometimes encountered during shipping. We

recommend that you leave a new disk modules in its shipping container and allow it to acclimate to the

installation site’s ambient temperature for at least four hours before operating the new module in the

system.

When removing a disk module, pull the module part way out of the slot, then wait 30 seconds for the

drive to spin down before removing it.

EMC CONFIDENTIAL version: 4.5

5 of 51

Page 6

EMC®VNX™Procedure Generator

When installing multiple disks in a powered-up system, wait at least 6 seconds before sliding the

second and each subsequent disk into the system.

Place a disk module on a soft, antistatic surface, such as an industry-standard antistatic foam pad or

the container used to ship the module. Never place a disk module directly on a hard surface.

WARNING: The weight of some FRU assemblies is not evenly distributed. To prevent personal

injury or equipment damage when handling FRU assemblies, make sure you provide extra support

at the heavy end of a FRU assembly.

Replacing a Blade Enclosure (DME)

This procedure explains how to replace a Blade enclosure (aka, Data Mover, DME). The tasks apply to

DMEs in VNX5300 through 7500 models with VNX for File systems.

CAUTION: Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry.

Always follow ESD prevention procedures when removing and replacing Customer-Replaceable

Units (CRUs) and Field-Replaceable Units (FRUs).

Task Summary

This procedure assumes that you are reinstalling (transferring) the power/cooling modules, management

modules, Blades, and I/O modules from the faulted Blade enclosure to the replacement Blade enclosure.

So that you can understand what is involved, the table of Contents lists the high-level tasks required for this

procedure. Take a moment to become familiar with these tasks. If you have any questions, contact

Customer Support before you begin the procedure.

CAUTION: This procedure takes approximately three hours to complete. During this time, the NAS

service is stopped and service is disrupted. Any process initiated by the Control Station (CS) or

any commands run from the

time.

Note: This procedure shows command output collected from a two X-Blade (Blade) system, unless

otherwise specified. Be aware that the actual command output will differ depending on the number of

Blades in the system. Additionally, output values displayed in the document are for the specific system used

to create this procedure.

WARNING: The weight of some FRU assemblies is not evenly distributed. To prevent personal

injury or equipment damage when handling an assembly, make sure you provide extra support at

the heavy end of the assembly.

Task 1: Diagnose and identify Faulted FRU

/nas directory is inhibited. You cannot manage the system during this

There are multiple ways to diagnose and identify a faulted FRU component. Follow the instructions below to

diagnose a problem with an FRU:

EMC CONFIDENTIAL version: 4.5

6 of 51

Page 7

EMC®VNX™Procedure Generator

Receive an email notification

If the system detects a problem with an internal component, the system may send an email notification

outlining the problem detected and recommending steps to correct the problem. If you receive an email

notification, follow the recommended steps described in the email.

Log in to EMC Unisphere

You can log in to Unisphere to diagnose a problem with a hardware component. Do the following:

1. [ ] Open Unisphere in an Internet browser using the following URL:

https://<control_station>

where <control_station> is the hostname or IP address of the primary Control Station (CS).

a. At the login prompt, log in as

b. Set the scope to

After logging in, the Unisphere

component status and the alerts for managed systems on the

new alert in the

Note: Alerts will not automatically clear. Delete old alerts by right-clicking on the alert and selecting

Delete.

2. [ ] Use the drop-down list at the top left of the Dashboard to select the system that contains faulted

hardware.

3. [ ] Select

components.

4. [ ] Check the system inventory for faulted hardware components.

5. [ ] Record the full component name for any faulted hardware found on the

The component name contains important information about hardware location.

For example, a Blade enclosure is listed in Unisphere as

number.

System > Hardware > Hardware for File to view information about the hardware

Global.

Alerts quadrant and select Details to view the associated error message.

sysadmin. The default password is sysadmin.

Dashboard page appears. Unisphere displays the system’s hardware

Dashboard. You can right-click on any

Hardware for File page.

DME 0, where 0 is the Blade enclosure (DME)

Check the Fault LED

To check the fault LEDs found on the front of the system, you must remove the front bezel to expose them

and then check for faulted components.

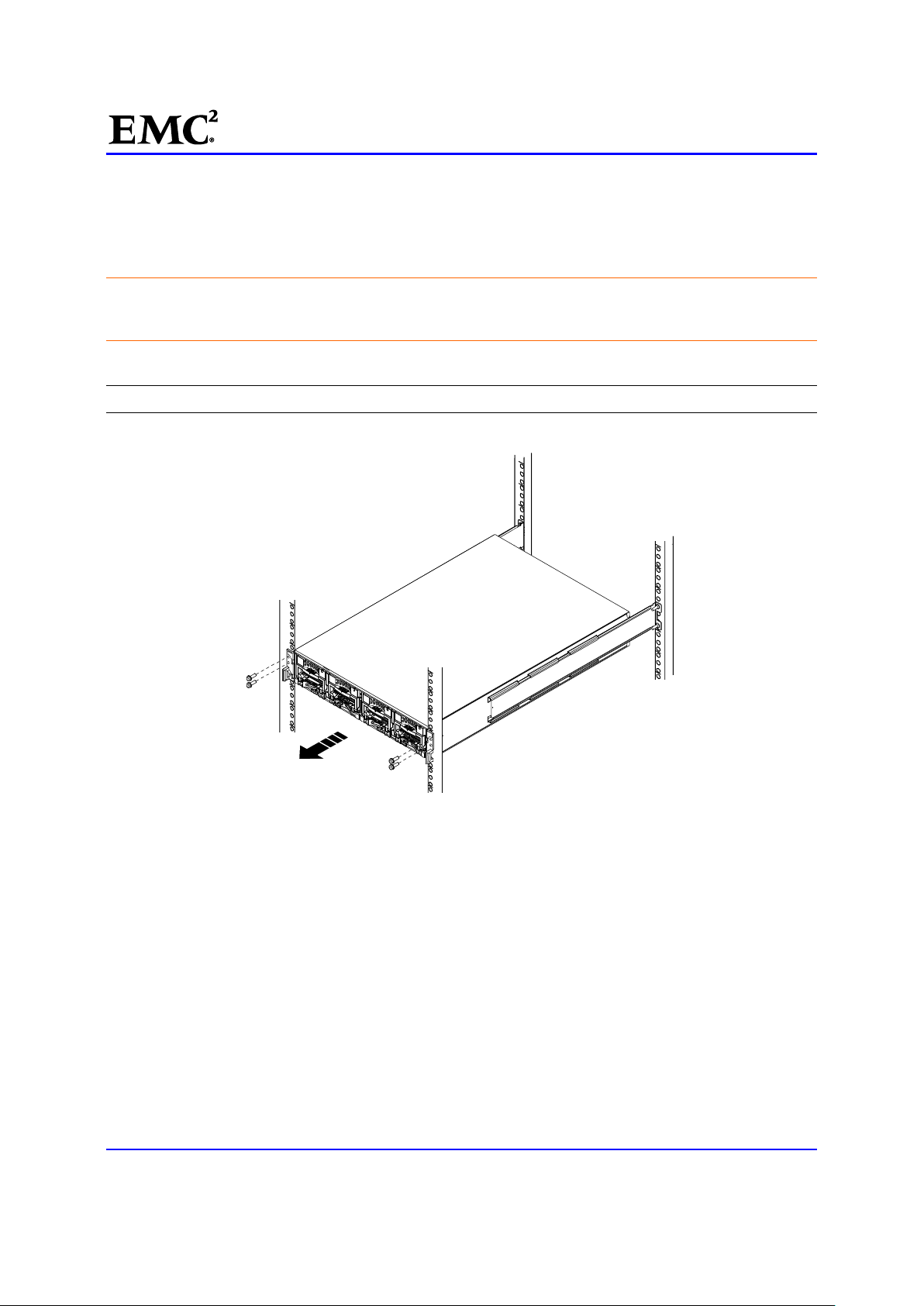

6. [ ] Turn the key at the front of the bezel enclosure counterclockwise.

7. [ ] Press the latches on the front of the bezel, and pulling the bezel toward you (Figure 1).

EMC CONFIDENTIAL version: 4.5

7 of 51

Page 8

EMC®VNX™Procedure Generator

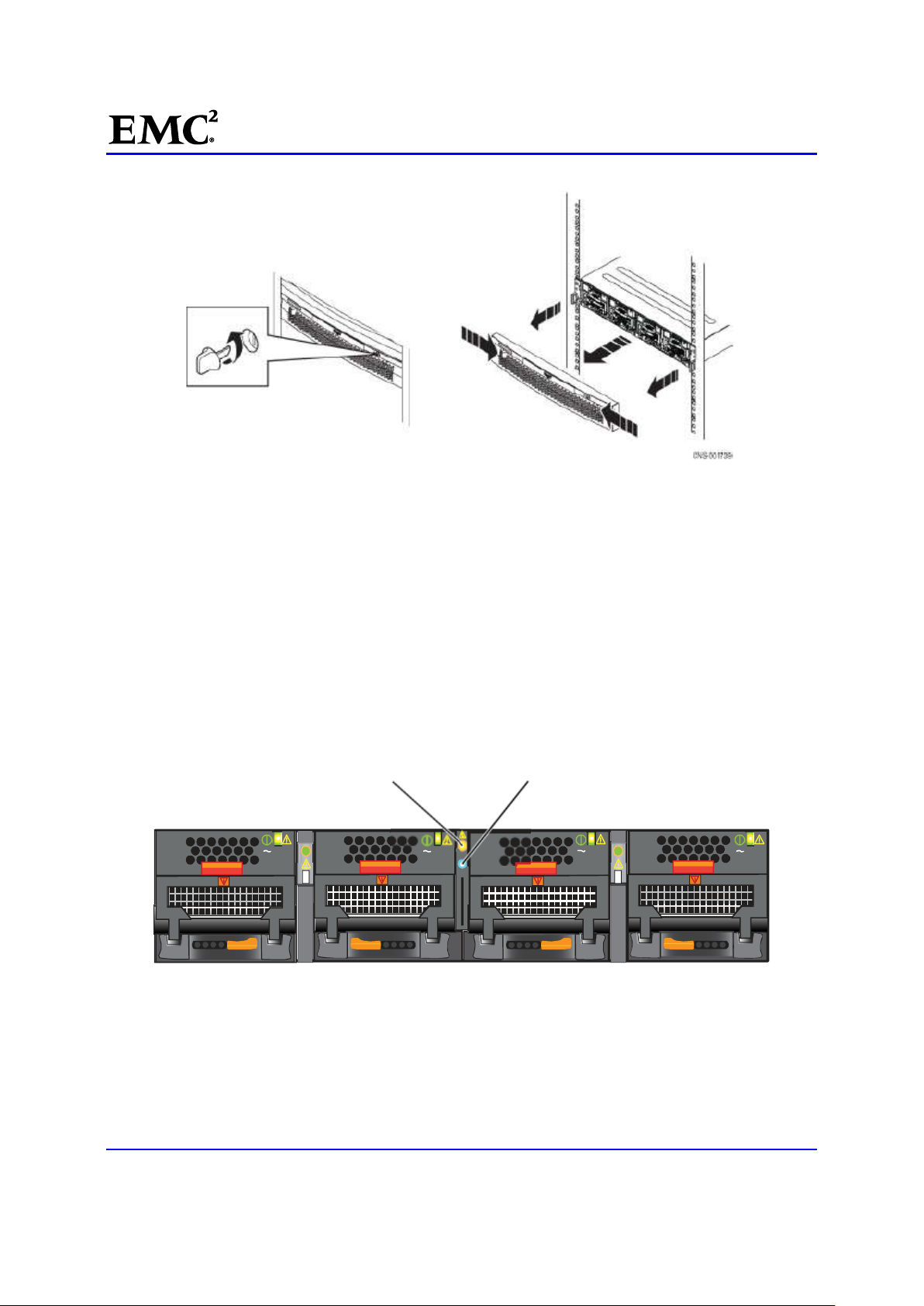

Blade enclosure

Blade enclosure

CNS-001667

Figure 1 Unlocking and removing the Blade enclosure (front bezel)

Check the Blade enclosure fault LEDs

If you are near the front of the system, you can easily check the Blade enclosure fault LED.

8. [ ] Locate the Blade enclosure.

For a multi-Blade enclosure system, if you recorded the information listed in Unisphere during the

previous task, find the faulted Blade enclosure using the management module seven-segment LED on

the rear of each Blade enclosure and the recorded fault information.

9. [ ] Check the Blade enclosure fault LED. Figure 2 shows the LEDs visible for the Blade enclosure

from the front of the Blade enclosure.

fault LED

AC AC AC AC

Figure 2 Blade enclosure fault LED (frontview)

power LED

10. [ ] If a Blade enclosure LED or Unisphere show a faulted Blade enclosure, continue with this

replacement procedure.

11. [ ] If each Blade enclosure LED or Unisphere does not show a faulted Blade enclosure, it does not

need to be replaced.

EMC CONFIDENTIAL version: 4.5

8 of 51

Page 9

EMC®VNX™Procedure Generator

Recheck the Unisphere to see if another component has faulted. If the Unisphere shows another

component has faulted, it might need to be replaced instead of a Blade enclosure.

Task 2: Disabling ConnectHome and Email Notifications

For VNX OE for File 7.0 or later, use a HyperTerminal or PuTTY session to disable ConnectHome:

12. [ ] From the root directory, disable ConnectHome:

/nas/sbin/nas_connecthome -service stop

13. [ ] Disable the email notification service:

/nas/bin/nas_emailuser -modify -enabled no

14. [ ] Verify that the email notification service has stopped (is not enabled):

/nas/bin/nas_emailuser –info

15. [ ] ConnectHome and email notifications are now disabled on your VNX OEFile system. Skip over the

next Block task to begin the service activity.

Task 3: Saving Resume PROM Configuration Information

Save the Resume PROM configuration information for the faulted Blade enclosure (BE). You use this

information later to reconfigure the replacement enclosure.

1. [ ] Open the

in

/nas/log directory.

where

<Blade_enclosure_number> is the ID (0, 1, 2, or 3) of the faulted BE.

enclosure_resume.enclosure_<Blade_enclosure_number>.xml file located

Table 1 lists the BEs associated with each enclosure.

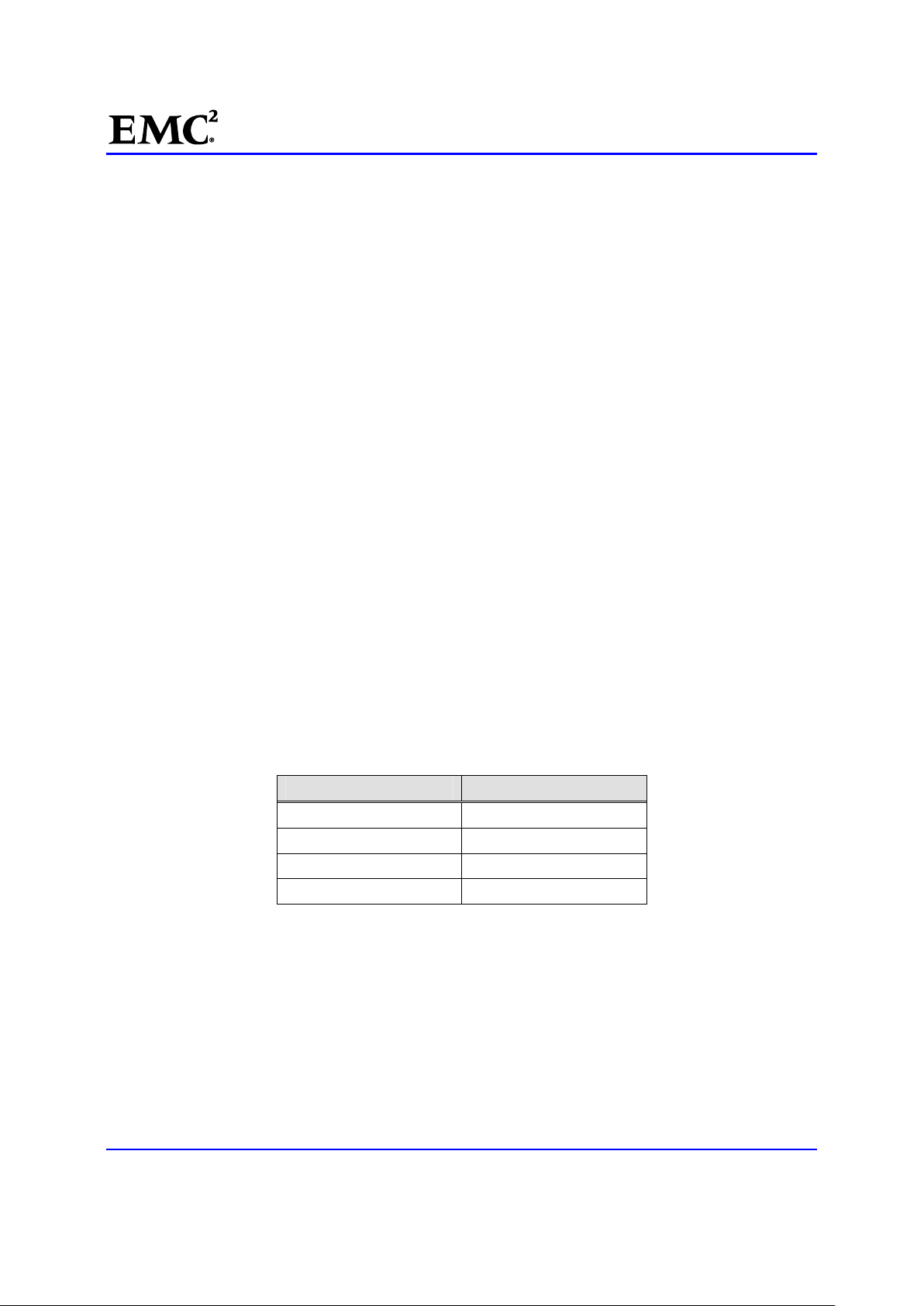

Table 1 Blade Enclosure ID and Blade mapping

Blade Enclosure ID Blades

0 2 and 3

1 4 and 5

2 6 and 7

3 8 and 9

2. [ ] Within this file, find and record, in Table 2, thevalues for the Resume PROM information contained

in the

RESUME_INFORMATION_MIDPLANE section.

Example XML file:

EMC_BARE_ASSEMBLY_PART_NUMBER="100-562-440 "

EMC_BARE_ASSEMBLY_REVISION="A03"

EMC_BARE_ASSEMBLY_SERIAL_NUMBER="FCNTR082900499 "

EMC_PART_NUMBER=" "

EMC_ARTWORK_REVISION=" "

EMC_ASSEMBLY_REVISION=" "

EMC_SERIAL_NUMBER=" "

EMC_PRODUCT_PART_NUMBER="900-567-002 "

EMC CONFIDENTIAL version: 4.5

9 of 51

Page 10

EMC®VNX™Procedure Generator

EMC_PRODUCT_SERIAL_NUMBER="FCNCH095103338 "

VENDOR_NAME="Blank "

LOCATION_OF_MANUFACTURE="Blank "

YEAR_OF_MANUFACTURE=" "

MONTH_OF_MANUFACTURE=" "

DAY_OF_MONTH_OF_MANUFACTURE=" "

ASSEMBLY_NAME=" "

/>

Table 2 Resume PROM information

RESUME_INFORMATION_MIDPLANE

field name

EMC_PART_NUMBER EMC SYSTEM HARDWARE TLA PN

EMC_ASSEMBLY_REVISION EMC SYSTEM HARDWARE TLA Rev

EMC_SERIAL_NUMBER EMC SYSTEM HARDWARE TLA SN

EMC_PRODUCT_PART_NUMBER PRODUCT PN

EMC_PRODUCT_SERIAL_NUMBER PRODUCT SN

ASSEMBLY_NAME ASSEMBLY_NAME

Note 1: All of this information except the ASSEMBLY_NAME should also be on the serial number tag located on the rear of the BE

enclosure.

Note 2: The field names listed in Corresponding Resume PROM Field correspond to the value prompts found in Configure the

BE Resume PROM.

Value Corresponding Resume PROM Field

Note: The CE should contact support and get the Resume PROM configuration data from CSI if not

available locally.

3. [ ] The Resume PROM values for the faulted BE have been collected.

EMC CONFIDENTIAL version: 4.5

10 of 51

Page 11

EMC®VNX™Procedure Generator

Task 4: Halting the Secondary Control Station

If your system is a dual Control Station system, the secondary CS (CS 1) must be stopped before NAS

services on the primary CS are stopped; otherwise, the secondary CS will takeover. If your system does not

have dual Control Stations (CS 0 and CS 1), skip this section.

Note: If the secondary CS is currently acting as the primary CS, you may need to failback and then

continue to power down the secondary CS.

This task halts the secondary control station:

1. [ ] At the rear of the cabinet, connect the null modem cable from a serial port on your management

console to the secondary Control Station, CS 1.

2. [ ] Open the HyperTerminal or PuTTY session using the following settings:

Bits per second: 19200

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

Emulation: Auto Detect

Telnet terminal ID: ANSI

Bits per second:

_

Data bits: _8 _

Parity: _None _

Stop bits: _1 _

Flow control: _None _

Emulation: _Auto Detect _

Telnet terminal ID: _ANSI _

EMC CONFIDENTIAL version: 4.5

11 of 51

Page 12

EMC®VNX™Procedure Generator

Control Station (front)

Powerb

utton

3. [ ] Login in to CS 1 as

nasadmin.

4. [ ] Change to the root user by entering the following command:

$ su root

5. [ ] Halt the secondary CS by entering the following command:

# /sbin/halt

Note: This may take a few minutes to complete. Ensure it is finished before you continue.

6. [ ] Press and hold the power button to power down CS 1. The Control Station power button is shown

in Figure 3. Remove the bezel to access this button.

CNS-000876

Figure 3 Control station power button

7. [ ] Wait 30 seconds for the internal disk drive to stop spinning and safely park its heads before

continuing.

8. [ ] Disconnect the CS 1 power cable from the power distribution panel (PDP).

9. [ ] Close the HyperTerminal or PuTTY session with CS 1.

10. [ ] Reconnect your management console to the serial port on CS 0 and reopen the HyperTerminal or

PuTTY session on CS 0 using the settings found in Step 2.

11. [ ] The secondary CS is halted and powered off.

Task 5: Prepare for Replacement

To prepare a faulted BE for removal from the system, its internal components must be halted and removed.

This section provides steps for preparing the system for the replacement of a BE.

Note: This document uses the term Blade to refer to a component that is defined as a logical construct of a

CPU module with its associated I/O modules.

Follow the procedure that best matches the system’s Blade configuration to prepare the system for the BE

replacement:

Multi-Blade system

Single-Blade system

Multi-Blade system

EMC CONFIDENTIAL version: 4.5

12 of 51

Page 13

EMC®VNX™Procedure Generator

Single-Blade system

For a single-Blade system, prepare the Blade for removal by doing the following:

1. [ ] Unmount the file systems and prepare the Blade to be halted by typing:

# /nas/bin/server_cpu server_2 -q now

2. [ ] Stop the NAS service on the primary CS by entering:

CAUTION: Stopping the NAS service disrupts service on the system. Any process initiated

by the Control Station or any commands run from the /nas directory are inhibited. Do not to

attempt to run this command while working in the

# /sbin/service nas stop

This command takes up to five minutes to complete. If this command fails, reboot the CS and try

again.

3. [ ] Halt the Blade by typing:

CAUTION: When you shut down the Blade, you will lose access to the public networks and file

systems. Verify that the customer is prepared for this action.

# /nasmcd/sbin/t2reset pwroff -s 2

/nas directory.

4. [ ] Wait three minutes for the previous command to complete and then verify that the Blade has

powered off:

Note: The getreason command can be augmented to provide continuous monitoring of the system

reason codes by adding the watch command. Use Ctrl/C to stop end the monitoring. For example # watch

/nasmcd/sbin/getreason

Example Output:

# /nasmcd/sbin/getreason

6 - slot_0 primary control station

- slot_2 powered off

5. [ ] Remove the enclosure from the NAS database:

# /nasmcd/sbin/setup_enclosure -removeEnclosure 0

6. [ ] The BE is removed from the NAS database and the NAS service is stopped.

Disconnect the faulted Blade enclosure's two power cables from the rack.

Multi-Blade system

For a multi-Blade system, prepare the Blade enclosure for removal by doing the following:

1. [ ] Determine the failover status of the Blades by entering:

# /nas/bin/nas_server -info –all

Sample Output:

id = 1

name = server_2.faulted.server_3

acl = 0

type = standby

EMC CONFIDENTIAL version: 4.5

13 of 51

Page 14

EMC®VNX™Procedure Generator

slot = 2

member_of =

standbyfor= server_2

status :

defined = out_of_service

actual = online, ready

id = 2

name = server_2

acl = 0

type = nas

slot = 3

member_of =

standby = server_2.faulted.server_3, policy=manual

status :

defined = enabled

actual = online, ready

Refer to Table 3 for command reference information.

Table 3 nas_server output definitions

Value Definition

id ID of the Blade.

name Name given to the Blade.

acl Access control level value assigned to the Blade or VDM.

type Type assigned to the Blade. (nas=primary; standby=standby)

slot Physical slot in the system where the Blade resides.

member_of Group to which the Blade is a member.

standby If the Blade has a local standby associated with it.

standbyfor If the Blade has a local standby, lists associated primary.

status Whether the Blade is enabled or disabled, and whether it is active.

2. [ ] Go to Step 4 if the system is configured with only one Blade enclosure, otherwise continue.

3. [ ] For a multi-Blade enclosure system, prepare each Blade in the faulted BE for removal. Repeat this

step for each Blade in the faulted enclosure before continuing to the next step.

a. If the Blade is a primary Blade and has no standby Blade configured, no action is required.

b. If the Blade is a primary Blade that has a standby Blade configured in another BE, failover to that

standby Blade:

# /nas/bin/server_standby <server_name> -activate mover

Where <server_name> is the name of the server. Use the nas_server –list command to get

the server name.

c. If the Blade is configured as a standby Blade and is currently standing in for an available primary Blade

contained in another BE, enter the following command:

# /nas/bin/server_standby <server_name> -restore mover

where <server_name> is the name of the server. Use the nas_server –list command to get

the server name.

Example:

EMC CONFIDENTIAL version: 4.5

14 of 51

Page 15

EMC®VNX™Procedure Generator

In a four Blade system with BE 1 faulted, Blade 2 has failed over to Blade 4, its standby. The

command to restore Blade 2 as the primary Blade is:

# /nas/bin/server_standby server_2 -restore mover

d. If the Blade is configured as a standby Blade and is not currently standing in for a primary Blade

contained in another BE, remove the Blade as a standby. Enter the following command:

Note: A Blade can be configured as a standby for multiple primary Blades. Repeat this step for each

primary Blade for which the Blade is a standby. Afterwards, go to step 4.

# /nas/bin/server_standby <server_name> -delete mover

where <server_name> is the name of the primary Blade. Use the nas_server -list command to get

the Blade name.

4. [ ] Stop the NAS service by entering:

CAUTION: Stopping the NAS service disrupts service on the system. Any process initiated by

the Control Station or any commands run from the /nas directory is inhibited. Do not to

attempt to run this command while working in the

# /sbin/service nas stop

This command will take up to five minutes to complete. Make sure it is finished before you continue. If

this command fails, reboot the CS and try again.

/nas directory.

5. [ ] Power off each Blade in the faulted BE:

CAUTION: When you shut down a Blade in a single BE system, you will lose access to the

public networks and file systems. Verify that the customer is prepared for this action.

# /nasmcd/sbin/t2reset pwroff -s <slot_number>

Where <slot_number> is the slot ID number of the Blade inside the BE.

6. [ ] Wait three minutes for the previous commands to complete and then verify that the Blades have

powered off:

Note: The getreason command can be augmented to provide continuous monitoring of the system

reason codes by adding the watch command. Use Ctrl/C to stop the monitoring. For example, watch

/nasmcd/sbin/getreason

Example:

6 - slot_0 primary control station

- slot_2 powered off

- slot_3 powered off

.

7. [ ] Remove the enclosure from the NAS database:

# /nasmcd/sbin/setup_enclosure -removeEnclosure <Blade_enclosure_number>

where <Blade_enclosure_number> is the BE number (shown on the LED display on the

management modules) of the faulted BE.

8. [ ] The BE is removed from the NAS database and the NAS service is stopped. Disconnect the faulted

Blade enclosure's two power cables from the rack.

EMC CONFIDENTIAL version: 4.5

15 of 51

Page 16

EMC®VNX™Procedure Generator

CL4138a

Task 6: Remove Faulted DME

You should remove the faulted chassis with all its components installed. After you install the replacement

chassis in the cabinet, you must transfer the components from the faulted chassis to the replacement

chassis. This process helps to ensure the correct placement of the components.

CAUTION: The enclosure is heavy and should be installed into a rack by two people (or a

data-center lift tool). To avoid personal injury and/or damage to the equipment, do not attempt to lift

and install the enclosure without a mechanical lift or help from another person.

1. [ ] Remove four M5 12.7 mm screws (two per side) to release the chassis from the cabinet (Figure 4).

Note: The screws also secure the latch brackets mounted on the front of the chassis.

Figure 4 Removing Securing Screws

2. [ ] From the front of the cabinet and, with help from another person, lift the chassis and slide it out of

the cabinet (Figure 5).

3. [ ] Place the enclosure on a work surface.

EMC CONFIDENTIAL version: 4.5

16 of 51

Page 17

EMC®VNX™Procedure Generator

CL4137a

Figure 5 Removing Chassis from Cabinet

4. [ ] Place the enclosure on a work surface.

EMC CONFIDENTIAL version: 4.5

17 of 51

Page 18

EMC®VNX™Procedure Generator

CL4137b

Task 7: Install the Replacement DME

This task installs the DME chassis in the cabinet:

1. [ ] From the front of the cabinet, lift the chassis and slide it onto the rails (Figure 6).

When the chassis slides to the back of the cabinet, the two notches in the rear of the chassis insert into

the rear tabs on each rail. The tabs secure and support the rear of the chassis.

If the chassis does not slide all the way into the cabinet, you may need to loosen the screws that hold

the rear of the rails in place, then adjust the rails to allow the tabs to fit into the notches.

Figure 6 Sliding the DME into the Cabinet

EMC CONFIDENTIAL version: 4.5

18 of 51

Page 19

EMC®VNX™Procedure Generator

CL4138b

2. [ ] Secure the front of the chassis to the vertical channels of the cabinet using four M5 12.7 mm

screws (two per side) (Figure 7).

Figure 7 Securing the DME to the Cabinet

Transfer Components to the Replacement DME

You must transfer the power/cooling modules, CPU modules, management modules, and I/O modules from

the faulted chassis to the corresponding locations in the replacement chassis. Use the procedures in the

sections that follow to transfer these components.

You must transfer the power/cooling modules and the CPU modules from the faulted chassis to the same

locations in the replacement chassis one component at a time. Transfer components from the A side first

(from the rear of the system, this is the right side), then transfer components from the B side (from the rear

of the system, this is the left side).

For each Blade, starting with the components on the A side (from the front of the system, this is the left side),

complete the following steps, as described in the sections that follow, to transfer the power/cooling modules

and the CPU modules:

Removing a Power/Cooling module

3. [ ] Locate and press the orange tab on the power/cooling module (Figure 8)

EMC CONFIDENTIAL version: 4.5

19 of 51

Page 20

EMC®VNX™Procedure Generator

You hear an audible click when the tab is pressed and the latch is released.

4. [ ] Lower the latch to release the power/cooling module from the CPU module.

Note: The orange tabs on the power/cooling module are labeled with a 1.

5. [ ] Pull the power/cooling module out of the chassis (Figure 8) and place it on an antistatic surface.

CL3972

Figure 8 Removing a Power/Cooling module

Remove the CPU Filler Assembly

If present, remove the CPU filler assembly. Otherwise, skip to the next task. To remove the CPU filler

assembly:

6. [ ] Locate and press the orange latches away from each other to fully release the CPU filler assembly

(Figure 9).

ACAC

AC

Figure 9 CPU Filler assembly Location (front)

7. [ ] Using these latches, remove the CPU filler assembly.

8. [ ] Place the CPU filler assembly on a static-free work bench, mat, or static-free bags for protection.

AC

EMC CONFIDENTIAL version: 4.5

20 of 51

Page 21

EMC®VNX™Procedure Generator

9. [ ] Install the CPU modules from the Blade in the replacement chassis in the corresponding locations

from which they were removed.

10. [ ] Install power/cooling modules into the replacement chassis in the corresponding locations from

which they were removed.

Removing a CPU module

Both power supply cooling modules must be removed before the CPU module can be removed from the

chassis.

11. [ ] Press the orange tabs (labeled with a 2) toward each other to unlock the latches (Figure 10).

12. [ ] Push the latches away from each other to fully release the CPU module (Figure 10).

13. [ ] Pull the CPU module from the chassis (Figure 10).

Figure 10 Removing a CPU module

Installing a CPU module

14. [ ] Align the CPU module with the chassis and slide it into position (Figure 11).

15. [ ] Push the latches toward each other to fully seat and lock the CPU module in place (Figure 11)

EMC CONFIDENTIAL version: 4.5

21 of 51

Page 22

Figure 11 Installing a CPU modu.le

Reinstall the CPU Filler Assembly

If present, reinstall the CPU filler assembly:

EMC®VNX™Procedure Generator

16. [ ] Slide it into the BE, ensuring it is fully seated.

17. [ ] Push the latches toward each other to fully seat and lock the CPU filler assembly into place.

Installing a Power/Cooling Module

18. [ ] Align the power/cooling module with the chassis.( Figure 12)

19. [ ] Push the power/cooling module into the chassis.

The power/cooling module is fully seated when the yellow line with caution symbols is no longer visible.

( Figure 12)

20. [ ] Raise the latch to secure it in place. ( Figure 12)

You will hear an audible

click when the latch is in place.

EMC CONFIDENTIAL version: 4.5

22 of 51

Page 23

EMC®VNX™Procedure Generator

Figure 12 Installing a Power/Cooling module

21. [ ] Reconnect the power cord to the power/cooling module.

Transfer Management Modules and I/O Modules

You must transfer the management modules and I/O modules from the faulted chassis to the same

locations in the replacement chassis.

For each Blade, starting with the components on the A side (from the rear of the system, this is the right

side), complete the following steps, as described in the sections that follow, to transfer the management

modules and I/O modules:

Removing a Management Module

To remove a management module from a Blade enclosure in the system:

CAUTION: Observe ESD procedures; handle the Blade components with care. You can remove a

management module while the system is powered up.

22. [ ] Use masking tape or similar material to label each cable to correctly reconnect them later.

23. [ ] Disconnect the Ethernet cables from the module.

Carefully press the connector latches to release them before you remove the cables.

CAUTION: Do not bend, pull, or stress other cables. Dress and secure the cables to one side so

that you can remove a management module without damaging the cables.

24. [ ] On the management module, pull the trigger mechanism on the module handle to release it from

the Blade enclosure Figure 13.

EMC CONFIDENTIAL version: 4.5

23 of 51

Page 24

EMC®VNX™Procedure Generator

CNS-001759

CNS-001759

Figure 13 Removing Blade Management module

25. [ ] Using the handle, gently pull the module from the Blade enclosure.

Installing a Management module

26. [ ] Carefully align the module with the guide on the sides of the Blade enclosure (Figure 14).

Figure 14 Install Blade Management Module

27. [ ] Slide the module into the Blade enclosure.

28. [ ] Push and release the small button on the handle to test its seating.

If the button remains in the module is fully seated.

If the button springs back, gently push the module further into the chassis, the push the button again. If

the button still does not rest flush with its handle, remove the module and repeat the installation

process.

29. [ ] Follow the labeling to reconnect and dress the previously removed cables.

Removing an I/O module

Any faulted I/O module would display an amber LED on its handle.

30. [ ] Remove the cables connected to the I/O module. If the cables are not already labeled, label them

clearly for reinstallation later.

31. [ ] Pull the trigger mechanism on the I/O module handle to release it.

32. [ ] Gently pull the module from the chassis (Figure 15).

EMC CONFIDENTIAL version: 4.5

24 of 51

Page 25

EMC®VNX™Procedure Generator

Figure 15 Removing an I/O Module

Installing an I/O module

You must install a replacement I/O module in the same slot from which you removed the faulted I/O module

and a new I/O module in the same slot from which you removed the I/O filler module.

33. [ ] Align the module with the empty slot (Figure 16).

Install the replacement I/O module in the same slot from which the faulted I/O module was removed.

34. [ ] When the I/O module appears seated, push and release the small button on the handle

(Figure 16).

If the button remains in, the module is fully seated .

If the button springs back, gently push the module further into the chassis, then push it again.

If the button still does not rest flush with its handle, remove the module and repeat steps 1 and 2.

EMC CONFIDENTIAL version: 4.5

25 of 51

Page 26

EMC®VNX™Procedure Generator

Figure 16 Installing an I/O module

35. [ ] If the I/O module you installed is a replacement for a faulted I/O module, attach the cables to the

replacement I/O module in the exact same locations that they were attached in the faulted I/O module.

Transfer the Serial Number Tag

36. [ ] Remove the serial number tag from the faulted chassis.

37. [ ] Attach the serial number tag to the replacement chassis (Figure 17).

EMC CONFIDENTIAL version: 4.5

26 of 51

Page 27

EMC®VNX™Procedure Generator

Figure 17 Serial Number Tag location

Reconnect Blade Enclosure Cables

CAUTION: Do not bend, pull, or stress any other cabinet cables. Dress and secure the cables

without damaging the cables.

38. [ ] Reconnect the Blade enclosure communication cables and all remaining of the cables to the rear

of the Blade enclosure by following the cable labels.

Note: Do not reconnect the Blade enclosure power cables at this time.

Task 8: Configure the replacement BE Resume PROM

This task sets up the work environment and configures the replacement BE Resume PROM:

Set up the Work Environment on the Blade

To set up the work environment on a Blade:

1. [ ] Connect the null modem cable from the COM 1 port of your service laptop to the RS-232 serial

port on the rear of the A-side management module (Figure 18).

EMC CONFIDENTIAL version: 4.5

27 of 51

Page 28

EMC®VNX™Procedure Generator

CNS-001679MOD

Port 2

Port 0

Management

module B

Figure 18 Management Module Serial Connection

Management

module A

2. [ ] Open the HyperTerminal or PuTTY session using the following settings:

Port 1

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

Emulation: Auto Detect

Telnet terminal ID: ANSI

CAUTION: Do not bend, pull, or stress any other cabinet cables. Dress and secure the cables

without damaging the cables.

3. [ ] Reconnect the BE AC power cords, carefully pressing the connector latches to restrain these

cables after you connect them.

Configure the BE Resume PROM

To configure the Resume PROM of the replacement BE you use the values you collected in Table 2.

4. [ ] When the Extended POST starts, you will see AabcBabCa... appear on the screen. Press the

Ctrl/C key to cancel POST and the following error appears:

EMC CONFIDENTIAL version: 4.5

28 of 51

Page 29

EMC®VNX™Procedure Generator

...Storage System Failure - Contact your Service Representative...

5. [ ] Enter the password SHIP_it and press Enter. The Diagnostic Menu appears.

6. [ ] Select the

Resume PROM Sub-Menu, and press Enter. The Resume PROM Sub-Menu

appears.

7. [ ] Select

8. [ ] Select

9. [ ] Press

Enter EMC TLA Part Number (16 characters)[100-562-956]:

Enter EMC TLA Artwork Revision (3 characters)[]:

Enter EMC TLA Assembly Revision (3 characters)[A01]:

Enter EMC TLA Serial Number (16 characters)[FCNDN082300025]:

Set Resume, and press Enter. A list of the devices in the enclosure appears.

XP Chassis, and press Enter.

Enter for each of the following prompts to accept the default values:

Note: The prompts will include examples of what should be populated in the system, shown in brackets [].

10. [ ] The system prompts with:

Enter EMC System Hardware TLA PN (16 characters)[100-520-839]:

11. [ ] Enter the EMC Part Number field from Table 2 of the Resume PROM information you gathered in

the Saving Resume PROM configuration information procedure, then press

Enter.

12. [ ] The system prompts with:

Enter EMC System Hardware TLA SN (16 characters)[FNM00084100038]:

13. [ ] Enter the EMC_SERIAL_NUMBER from Table 2 of the Resume PROM information you gathered

in the Saving Resume PROM configuration information procedure, then press

Enter.

14. [ ] The system prompts with:

Enter EMC System Hardware TLA Rev (3 characters)[A01]:

Enter Support Contact Info (128 characters)[]:

15. [ ] Enter the EMC_ASSEMBLY_REVISION from Table 2 of the Resume PROM information you

gathered in the Saving Resume PROM configuration information procedure, then press

16. [ ] Enter the value for the Support Contact Info, and then press

Enter.

Enter.

17. [ ] The system prompts with:

Enter EMC PN (16 characters)[900-525-002]:

18. [ ] Enter the PRODUCT PN (16 characters) = EMC_PRODUCT_PART_NUMBER from Table 2 of the

Resume PROM information you gathered in the Saving Resume PROM configuration information

procedure, then press

Enter.

19. [ ] The system prompts with:

Enter Product SN (16 characters)[FNM00000000000]:

20. [ ] Enter the PRODUCT SN (16 characters) = EMC_PRODUCT_SERIAL_NUMBER from Table 2 of

the Resume PROM information you gathered in the Saving Resume PROM configuration information

procedure, then press

21. [ ] Press

Enter to accept the default values until the system prompts with: Enter Assembly Name

Enter.

(32 characters)[GALILEO A DUAL DATAMOVER -INT]:

EMC CONFIDENTIAL version: 4.5

29 of 51

Page 30

EMC®VNX™Procedure Generator

22. [ ] Enter the value from the

you gathered in the Saving Resume PROM configuration information procedure, then press

ASSEMBLY_NAME field from Table 2 of the Resume PROM information

Enter.

23. [ ] The system prompts:

Enter Number of Programmables (0-84) [0]:

Enter World Wide Name (WWN) Seed (0x200000-0x7FEFFFFF) [0x3B200E19]:

Vendor ID: 0x7

Model ID: 0x0C

Seed: 0x00E19

Enter PCBA Part Number (16 characters)[005348742]:

Enter PCBA Assembly Revision (3 characters)[A10]:

Enter PCBA Serial Number (16 characters)[FCNBD082021620]:

Enter Channel Technology/Speed (0x00-0xFFFF) [0x00]:

Note: In the above example, the information enclosed in brackets shows you an example of what should be

populated.

24. [ ] Continue pressing Enter to accept the default values until the system prompts: System Types:

0 - Agnostic

1 - Clariion

2 - Celerra

3 - Clariion AUX

4 - Symmetrix

5 - Centera

6 - E3 Diag Mode

Enter System Type (0-6) [2]:

25. [ ] Select Celerra and press Enter. The system prompts:

26. [ ] Enter the

Enclosure ID and press Enter. Table 4 lists the Enclosure ID and the Blades associated

with each enclosure.

Enter Enclosure ID (0-255) [0]:

Enter Rack ID (0-255) [0]:

Enter Slot ID (0-255) [0]:

Family ID:

0x0000 - No Family

0x0005 - I/O Module

0x0007 - WildcatS

0x0008 - Midplane

0x000B - Power Supply

Enter Family ID (0x00-0xFFFF) [0x08]:

FRU ID:

0x0000 - None

0x0001 - Fogbow

Enter FRU ID (0x00-0xFFFF) [0x01]:

Enter EMC Sub-Assembly Part Number (16 characters)[ ]:

Enter EMC Sub-Assembly Artwork Revision (3 characters)[ ]:

Enter EMC Sub-Assembly Assembly Revision (3 characters)[ ]:

Enter EMC Sub-Assembly Serial Number (16 characters)[ ]:

----------------------------------Resume PROM Unique Information Area

----------------------------------Enter NAS Enclosure ID (0x00-0xFFFFFFFF) [0x01]: 0

EMC CONFIDENTIAL version: 4.5

30 of 51

Page 31

EMC®VNX™Procedure Generator

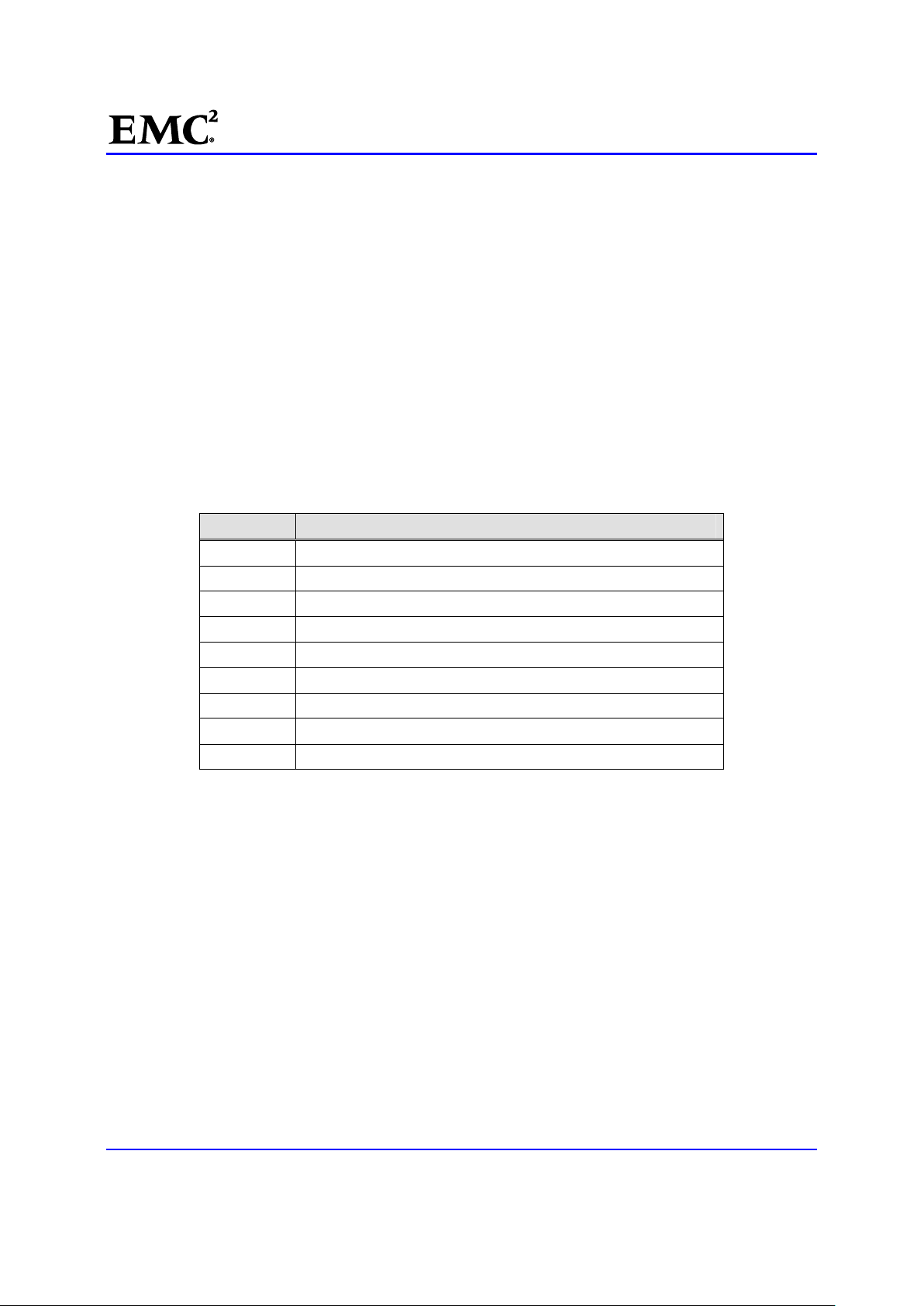

Table 4 Blade Enclosure ID and Blade mapping

Enclosure ID Blade within the enclosure

0 2 and 3

1 4 and 5

2 6 and 7

3 8 and 9

27. [ ] When the system prompts for the NAS Enclosure ID, enter the number of the replacement BE.

Table 4 lists the NAS Enclosure ID and the Blades associated with each enclosure.

28. [ ] Continue pressing

Continue (y or n) [yes]?

Enter to accept the default values until the system prompts:

29. [ ] Enter y and press Enter.

30. [ ] Press

0 and press Enter to return to the Diagnostic Menu, select Reset Controller, and press

Enter.

31. [ ] Close your HyperTerminal or PuTTY session on the Blade and disconnect the service laptop from

the Blade management module.

Task 9: Collect System Information

In this task you set up the work environment on the primary Control Station and save a record of the current

Blade port to Storage Processor (SP) port connections. It is important that these records are saved in case

they need to be reapplied.

In this task you will set up the work environment on the Control Station and collect system information and

save SP logs

Set up the Work Environment on the Control Station

1. [ ] Connect the null modem cable from the COM 1 port of your service laptop to the serial port on the

rear of Control Station CS 0 (Figure 19).

Serial port

CNS-000918

Figure 19 Control station (rear view)

2. [ ] Open the HyperTerminal session using the following settings:

Bits per second: 19200

Data bits: 8

EMC CONFIDENTIAL version: 4.5

31 of 51

Page 32

Parity: None

Stop bits: 1

Flow control: None

Emulation: Auto Detect

Telnet terminal ID: ANSI

EMC®VNX™Procedure Generator

3. [ ] Log in to Control Station CS 0 as

nasadmin. Change to the root user by entering the following

command:

$ su root

The default password for root is nasadmin.

4. [ ] After 5 minutes, check for

enclosure, all

a. Check if

# ps axwf|grep nas_mcd

nas_mcd services must be stopped.

nas_mcd services is running:

nas_mcd services running on the CS. To continue adding the new

Sample output with a nas_mcd service running:

3554 ? Sl 0:02 /nasmcd/nas_mcd -h /nasmcd /nas/sys/nas_mcd.cfg

6513 ttyS1 S+ 0:00 \_ grep nas_mcd

Sample output with no nas_mcd services running:

14085 ttyS1 S+ 0:00 \_ grep nas_mcd

b. If no nas_mcd services are running, skip to Collect System Information and Save SP Logs.

c. If any

nas_mcd services are running, type:

# killall nas_mcd

d. If the killall command was used, recheck that all nas_mcd services are stopped:

# ps axwf|grep nas_mcd

Collect System Information and Save SP Logs

Collect the current connections from the BE to SP and complete Table 5 by recording necessary system

information.

Table 5 Current system values

hostname

Host IP address

SP A IP address

Storage Group Name

5. [ ] Collect the hostname of the system by typing the following command. Record the hostname in

Table 5.

# hostname

Sample output:

EMC CONFIDENTIAL version: 4.5

32 of 51

Page 33

EMC®VNX™Procedure Generator

Celerra_naut3

6. [ ] Use the hostname parameter to collect host IP address. Record the Host IP address in Table 5.

# cat /etc/hosts | grep "<hostname>"

Example Output:

# cat /etc/hosts | grep "Celerra_naut3"

10.6.4.125 Celerra_naut3.rtp.lab.emc.com Celerra_naut3

7. [ ] Collect the IP address assigned to SP A, shown in bold in the following example output. Record

SP A’s IP address in Table 5.

# cat /etc/hosts | grep "SP"

Example output:

10.6.4.126 A_FCNTR074200022 Celerra_naut3.rtp.lab.emc.com # CLARiiON SP

10.6.4.127 B_FCNTR074200022 Celerra_naut3.rtp.lab.emc.com # CLARiiON SP

8. [ ] Collect the SP logs.

a. Collect the port list for SPs. Save this output in the event of a rollback.

# /nasmcd/sbin/navicli -h <SPA_IP_Address> port –list

Example Output:

# /nasmcd/sbin/navicli -h 128.221.252.200 port -list

Information about each HBA:

HBA UID: 50:06:01:60:BC:E0:08:9F:50:06:01:60:3C:E0:08:9F

Server Name: Celerra_naut3

Server IP Address: 10.6.4.125

HBA Model Description:

HBA Vendor Description:

HBA Device Driver Name:

Information about each port of this HBA:

SP Name: SP A

SP Port ID: 0

HBA Devicename:

Trusted: NO

Logged In: NO

Defined: YES

Initiator Type: 3

StorageGroup Name: Celerra_naut3

...

...

Information about each SPPORT:

SP Name: SP A

SP Port ID: 0

SP UID: 50:06:01:60:BE:A0:01:A8:50:06:01:60:3E:A0:01:A8

Link Status: Up

Port Status: Online

Switch Present: NO

.....

....

EMC CONFIDENTIAL version: 4.5

33 of 51

Page 34

EMC®VNX™Procedure Generator

b. Display the information about each user-defined storage group in the system. Save this output in the

event of rollback. Record the Storage Group Name in Table 5. Output of this command contains the

HBA UID which will be used to remove initiator records, later in the procedure.

IMPORTANT: The information in this output will be used to remove the current initiator records, or in

the event of a roll-back scenario, to recreate the current configuration.

Use the command below that best represents the system type:

If you are replacing a Blade enclosure in a VNX VG2 or VNX VG8 gateway, use the following command

to complete this task:

# /nasmcd/sbin/navicli -h <SPA_IP_Address> storagegroup -list –host

IMPORTANT: Fabric connected gateway systems may attach to a storage array with multiple hosts

connected. This command will display all storage groups implemented on the storage array. Ensure

that you record only the storage group associated with the correct host name and only for the

connections stemming from the faulted Blade enclosure.

Example:

# /nasmcd/sbin/navicli -h 10.6.4.126 storagegroup -list –host

Storage Group Name: Celerra_naut3

Storage Group UID: 3E:86:BB:3D:70:64:DF:11:9C:6F:00:60:16:36:9C:7D

HBA/SP Pairs:

HBA UID SP Name SPPort

------- ------- ----- 50:06:01:60:BC:E0:08:9F:50:06:01:61:3C:E0:08:9F SP B 0 Host name:

Celerra_naut3

50:06:01:60:BC:E0:08:9F:50:06:01:69:3C:E0:08:9F SP B 1 Host name:

Celerra_naut3

50:06:01:60:BC:E0:08:9F:50:06:01:60:3C:E0:08:9F SP A 0 Host name:

Celerra_naut3

50:06:01:60:BC:E0:08:9F:50:06:01:68:3C:E0:08:9F SP A 1 Host name:

Celerra_naut3

HLU/ALU Pairs:

HLU Number ALU Number

---------- --------- 0 0

1 1

2 2

3 3

4 4

5 5

16 16

17 17

Shareable: YES

Note: Fabric connected gateway systems will have eight paths per enclosure.

If you are replacing a Blade enclosure on any other VNX Unified or File system, use the following

command to complete this step:

EMC CONFIDENTIAL version: 4.5

34 of 51

Page 35

EMC®VNX™Procedure Generator

# /nasmcd/sbin/navicli -h <SPA_IP_Address> storagegroup -list -gname "~filestorage"

Example:

# /nasmcd/sbin/navicli -h 10.6.4.126 storagegroup –list –gname "~filestorage"

Storage Group Name: ~filestorage

Storage Group UID: 3E:86:BB:3D:70:64:DF:11:9C:6F:00:60:16:36:9C:7D

HBA/SP Pairs:

HBA UID SP Name SPPort

------- ------- ----- 50:06:01:60:BC:E0:08:9F:50:06:01:61:3C:E0:08:9F SP B 0

50:06:01:60:BC:E0:08:9F:50:06:01:69:3C:E0:08:9F SP B 1

50:06:01:60:BC:E0:08:9F:50:06:01:60:3C:E0:08:9F SP A 0

50:06:01:60:BC:E0:08:9F:50:06:01:68:3C:E0:08:9F SP A 1

HLU/ALU Pairs:

HLU Number ALU Number

---------- --------- 0 0

1 1

2 2

3 3

4 4

5 5

16 16

17 17

Shareable: YES

Task 10: Configure the HBA/Initiator Records

The replacement BE contains a new midplane that is assigned different identifiers than were assigned to

the midplane in the faulted BE.

To configure the HBA/Initiator records maintaining the connections running from the replacement BE to the

storage array or switch:

Set up the replacement BE

Remove the old initiator records

Collect the new WWNs

Recreate the initiator records

Verify the new connections

Configure the Blades

Test the functionality of the system

Set Up the Replacement BE

1. [ ] Add the replacement BE to the database, and set up the enclosure ID on the backplane by issuing:

# /nasmcd/sbin/setup_enclosure -addEnclosure <Blade_enclosure_ID>

Note: If the setup_enclosure -addEnclosure command fails, use the setup_enclosure

-checkCable and setup_enclosure -checkSystem commands to identify the reason for the failure.

EMC CONFIDENTIAL version: 4.5

35 of 51

Page 36

EMC®VNX™Procedure Generator

2. [ ] Check the system status to ensure its health:

# /nasmcd/sbin/setup_enclosure –checkSystem

3. [ ] Check that the system shows the proper number of Blades by typing:

# /nasmcd/sbin/getreason –e

Sample output:

6 - slot_0 control station ready

0 - slot_2 reset(Post Code = 0x61 ; Mid Code = 0x80 ; Blade Code = 0x3e

0 - slot_3 reset(Post Code = 0x61 ; Mid Code = 0x80 ; Blade Code = 0x39

Remove the old initiator records

To remove the previous set of initiator records:

4. [ ] Remove the initiator records for the Blades contained in the replaced BE. Use the information

collected in Collect system information and save SP logs to determine the necessary initiator records to

remove.

CAUTION: Entering the wrong HBA UID will cause the removal of valid initiator records. Ensure

that the HBA UID entered matches the record you wish to remove, which were found in Collect

system information and save SP logs.

# /nasmcd/sbin/navicli -h <SPA_IP_Address> port -removeHBA -o -hbauid

<Blade_port_HBA_UID>

IMPORTANT: The command requires the HBA UID to be input with the necessary colons, as shown in

the example below.

Example:

# /nasmcd/sbin/navicli -h 10.6.4.126 port -removeHBA -o -hbauid

50:06:01:60:BC:E0:08:9F:50:06:01:61:3C:E0:08:9F

HBA: 50:06:01:60:BC:E0:08:9F:50:06:01:61:3C:E0:08:9F(y/n)?

y

Warning: This is an active HBA. Do you still want to remove it (y/n)?

y

5. [ ] Repeat the previous step for each Blade port initiator record to be removed for the BE being

replaced.

6. [ ] After removing the necessary initiator records, display the storage group list for the existing

configuration to verify that all necessary records have been successfully removed. Compare this output

to the output collected in Collect system information and save SP logs to verify that the necessary

initiator records have been removed.

Note: If the system is configured with more than two Blades, initiator records for the Blades in non-faulted

Blade enclosure(s) should still appear.

Use the command below that best represents the system type:

If you are replacing a Blade enclosure in a VG2 or VG8 gateway, use the following command to

complete this step:

# /nasmcd/sbin/navicli -h <SPA_IP_Address> storagegroup –list –host

Example Output:

EMC CONFIDENTIAL version: 4.5

36 of 51

Page 37

EMC®VNX™Procedure Generator

# /nasmcd/sbin/navicli -h 10.6.4.126 storagegroup –list –host

Storage Group Name: Celerra_naut3

Storage Group UID: 3E:86:BB:3D:70:64:DF:11:9C:6F:00:60:16:36:9C:7D

HLU/ALU Pairs:

HLU Number ALU Number

---------- ---------5 35

4 34

1 31

2 32

0 30

3 33

Shareable: YES

If you are replacing a Blade enclosure on any other VNX Unified or File system, use the following

command to complete this step:

# /nasmcd/sbin/navicli -h <SPA_IP_Address> storagegroup -list -gname "~filestorage"

Example:

# /nasmcd/sbin/navicli -h 10.6.4.126 storagegroup –list –gname "~filestorage"

Sample Output:

Storage Group Name: ~filestorage

Storage Group UID: 3E:86:BB:3D:70:64:DF:11:9C:6F:00:60:16:36:9C:7D

HLU/ALU Pairs:

HLU Number ALU Number

---------- ---------5 35

4 34

1 31

2 32

0 30

3 33

Shareable: YES

Collect the New WWNs

To collect the WWNs assigned to the replacement enclosure:

7. [ ] Start the PXE Services by typing:

# /nasmcd/sbin/t2pxe -s -R 8

8. [ ] PXE Boot the Blades in the replacement BE:

Note: If this command fails to PXE boot the Blade, repeat until the PXE boot completes.

# /nasmcd/sbin/t2tty -p <slot_number>

where <

9. [ ] Stop the PXE Services:

# /nasmcd/sbin/t2pxe –e

10. [ ] Check the fault LED on the front of the BE Figure 20. If the LED is amber, there is still a faulted

component in the BE or the BE is still faulted.

EMC CONFIDENTIAL version: 4.5

slot_number> is the slot number of the Blade(s) in the replacement BE.

37 of 51

Page 38

EMC®VNX™Procedure Generator

CPU p

ower LED

Power supply/cooling

(fan) LED

AC AC AC AC

Figure 20 BE, power/cooling module, and CPU module fault LEDs (bezel removed)

Blade enclosure

fault LED

Blade enclosure

power LED

CPU fault LED

CPU unsafe to

remove LED

CNS-001668

11. [ ] Query the system to display the new WWNs assigned to each Blade in the enclosure by typing the

following command.

IMPORTANT: Ensure that you capture the output returned for the following commands. The new

initiator records cannot be created without this information.

# /nasmcd/sbin/t2tty -c <slot_number> "fcp topology”

Example Output for BE 0:

# /nasmcd/sbin/t2tty -c 2 "fcp topology"Output:

FCP HBA 0: FC-AL ALPA 000001 Node 50060160c4602075 Port 5006016044602075

FCP HBA 1: FC-AL ALPA 000001 Node 50060160c4602075 Port 5006016144602075#

/nasmcd/sbin/t2tty -c 3 "fcp topology"Output:

FCP HBA 0: FC-AL ALPA 000001 Node 50060160c4602075 Port 5006016044602075

FCP HBA 1: FC-AL ALPA 000001 Node 50060160c4602075 Port 5006016144602075

12. [ ] Construct the new Blade port WWNs (HBA UIDs) and record these values in Table 6.

Construct each WWN by grouping the unformatted Node and Port values of each Blade port into a

single string delimited with colons between every two digits.

For example, using the values shown for Blade 2 in the output shown in the previous step, the WWNs

for Blade 2 are:

Blade 2 - port 0: 50:06:01:60:c4:60:20:75:50:06:01:60:44:60:20:75

Blade 2 - port 1: 50:06:01:60:c4:60:20:75:50:06:01:61:44:60:20:75

EMC CONFIDENTIAL version: 4.5

38 of 51

Page 39

EMC®VNX™Procedure Generator

Table 6 Construct the new Blade port WWNs

Blade number Blade port Blade port WWN (HBA UID) SP and port SP ports marked with an * only

apply to a fabric-connected gateway. Do not

use for a direct-connected gateway.

Blade ____

(even-numbered

Blade)

Blade ___

(odd-numbered

Blade)

1

SP ports marked with an * only apply to fabric-connected gateway. Do not sue for a direct-connected

0 (HBA 0) SP A - port ___

SP B* - port ___

1 (HBA 1) SP A* - port ___

SP B - port ___

0 (HBA 0) SP A - port ___

SP B* - port ___

1 (HBA 1) SP A* - port ___

SP B - port ___

gateway.

Zone the FC switch(s)

For fabric-connected gateway platforms, configure the switch zoning at this time. Otherwise, skip to

Recreate the initiator records.

If the Blade enclosure contains Blades with fibre channel optical ports connected to a Fibre Channel (FC)

switch, the FC switch will need to be rezoned with the new WWNs of these FC optical ports. Follow the

instructions in the "Zoning FC Switches and Manually Configuring System LUNs" appendix in the

(R)

EMC

www.Powerlink.EMC.com.

VNX

(TM)

VG2/VG8 Gateway Configuration Phase 1 and 2 Setup Guide (P/N 300-012-157) found on

Recreate the initiator records

To recreate the initiator records:

13. [ ] Display the Blade port to SP port FCP records for each Blade in the replacement BE. Record the

SP port value in Table 6.

# /nasmcd/sbin/t2tty -c <slot_number> "fcp show" | egrep "HBA 0 HBA 1"

where <slot_number> is the slot number of each Blade in the replacement BE.

Two examples are presented below. Example 1 shows the commands and output for Blade enclosure 0

in a Unified, File, or direct-connect gateway. Whereas, Example 2 is a model for a gateway in a

fabric-connect configuration. Follow the example that reflects the system’s configuration.

Example 1:

Example 1 shows the commands and output for Blade enclosure 0 in a Unified, File, or direct-connect

gateway. With:

Blade 2 - port 0 (HBA 0) connected to SP A - port 0

Blade 2 - port 1 (HBA 1) connected to SP B - port 1

Blade 3 - port 0 (HBA 0) connected to SP A - port 0

EMC CONFIDENTIAL version: 4.5

39 of 51

Page 40

EMC®VNX™Procedure Generator

Blade 3 - port 1 (HBA 1) connected to SP B - port 1

# /nasmcd/sbin/t2tty -c 2 "fcp show" | egrep "HBA 0|HBA 1"FCP ONLINE HBA 0: ALPA 000001

WWN: 5006016044602075 QE8 4G

FCP scsi-0: HBA 0: ALPA 0000ef SP-a00: 50060160BCE02EA7 Class 3

FCP ONLINE HBA 1: ALPA 000001 WWN: 5006016144602075 QE8 4G

FCP scsi-16: HBA 1: ALPA 0000ef SP-b00: 50060160BCE02EA7 Class 3

# /nasmcd/sbin/t2tty -c 3 "fcp show" | egrep "HBA 0|HBA 1"FCP ONLINE HBA 0: ALPA 000001

WWN: 5006016844602075 QE8 4G

FCP scsi-0: HBA 0: ALPA 0000ef SP-a01: 50060160BCE02EA7 Class 3

FCP ONLINE HBA 1: ALPA 000001 WWN: 5006016944602075 QE8 4G

FCP scsi-16: HBA 1: ALPA 0000ef SP-b01: 50060160BCE02EA7 Class 32:

Example 2 shows the commands and output for Blade enclosure 0 in a gateway in a fabric-connect

configuration. With:

Blade 2 - port 0 (HBA 0) connected to SP A - port 0 and SP B - port 0

Blade 2 - port 1 (HBA 1) connected to SP A - port 1 and SP B - port 1

Blade 3 - port 0 (HBA 0) connected to SP A - port 0 and SP B - port 0

Blade 3 - port 1 (HBA 1) connected to SP A - port 1 and SP B - port 1

# /nasmcd/sbin/t2tty -c 2 "fcp show" | egrep "HBA 0|HBA 1"FCP ONLINE HBA 0: S_ID 014500

WWN: 5006016044602075 QE8 8G

FCP scsi-0: HBA 0: D_ID 043f00 SP-a00: 50060160BCE02EA7 Class 3

FCP scsi-16: HBA 0: D_ID 043b00 SP-b00: 50060160BCE02EA7 Class 3

FCP ONLINE HBA 1: S_ID 014700 WWN: 5006016144600544 QE8 8G

FCP scsi-32: HBA 1: D_ID 043900 SP-b01: 50060160BCE02EA7 Class 3

FCP scsi-48: HBA 1: D_ID 043d00 SP-a01: 50060160BCE02EA7 Class 3

# /nasmcd/sbin/t2tty -c 3 "fcp show" | egrep "HBA 0|HBA 1"FCP ONLINE HBA 0: S_ID 014300

WWN: 5006016844600544 QE8 8G

FCP scsi-0: HBA 0: D_ID 043f00 SP-a00: 50060160BCE02EA7 Class 3

FCP scsi-16: HBA 0: D_ID 043b00 SP-b00: 50060160BCE02EA7 Class 3

FCP ONLINE HBA 1: S_ID 014100 WWN: 5006016944600544 QE8 8G

FCP scsi-32: HBA 1: D_ID 043900 SP-b01: 50060160BCE02EA7 Class 3

FCP scsi-48: HBA 1: D_ID 043d00 SP-a01: 50060160BCE02EA7 Class 3

14. [ ] Enter the following command to assign a storage group to a specific HBA by creating an initiator

record. You must create an initiator record for each connection (physical or logical) from the Blade ports

(0 and 1) to the SP ports.

CAUTION: Before issuing the command, verify that the values used to create the new initiator

record contain the correct information for each connection. Incorrect information can cause a

misconfiguration of the initiator record.

Use the command below that best represents the system type:

Use the following command for a VNX VG2 or VNX VG8 gateway:

# /nasmcd/sbin/navicli -h <SPA_IP_Address> storagegroup -setpath -o –gname

<StorageGroup_Name> -hbauid <Blade_Port_HBA_UID> -sp <SP_Letter> -spport

<SP_Port_Number> -ip <Host_IP_Address> -host <Hostname>

Use the following command for all other VNX Unified or File systems:

EMC CONFIDENTIAL version: 4.5

40 of 51

Page 41

EMC®VNX™Procedure Generator

# /nasmcd/sbin/navicli -h <SPA_IP_Address> storagegroup -setpath -o -gname

~filestorage-hbauid <

-type 32 -ip <

Host_IP_Address> -host <Hostname> :

Blade_Port_HBA_UID> -sp <SP_Letter> -spport <SP_Port_Number>

Where:

<SPA_IP_Address> is the SP A IP address in Table 5.

<StorageGroup_Name> is the Storage Group Name in Table 5

<Blade_Port_HBA_UID> is the Blade port WWN in Table 6

<SP_Letter> is the letter of the SP to which the Blade port it is to be connected. Refer to Table 6

<SP_Port_Number> is the SP port number to which the Blade port it is to be connected. Refer to

Table 6

<Host_IP_Address> is the system Host IP address in Table 5.

<Hostname> is the hostname in Table 5.

Example for a non-gateway VNX platform:

# /nasmcd/sbin/navicli -h 10.6.4.126 storagegroup -setpath -o –gname ~filestorage -hbauid

50:06:01:60:c4:60:20:75:50:06:01:60:44:60:20:75 -sp a -spport 0 -type 32 –ip 128.221.252.2 -host

Celerra_naut3

Warning: Changing configuration options may cause the array to stop functioning correctly.

Failover-related Initiator settings for a single host MUST BE CONSISTENTfor all paths from the host

to the storage system. Please verify after reconnect.

Do you wish to continue (y/n)?

y

15. [ ] Repeat Step 2 for each necessary initiator record. When all initiator records have been created go

to Step 4.

Note: For a fabric-connected gateway, Step2 must be issued a total of eight times, since each Blade port is

fabric connected to a the same port on each storage processor.

16. [ ] Confirm the new initiator records are correct by comparing the new initiator records with the original

initiator records.

17. [ ] Use the command below that best represents the system type:

For a VG2 or VG8 gateway, use the information collected in Collect system information and save SP

logs for the original configuration.

# /nasmcd/sbin/navicli -h <SPA_IP_Address> storagegroup -list - hosts

Sample output:

Storage Group Name: Celerra_naut3

Storage Group UID: 3E:86:BB:3D:70:64:DF:11:9C:6F:00:60:16:36:9C:7D

HBA/SP Pairs:

HBA UID SP Name SPPort

------- ------- ----- 50:06:01:60:C4:60:20:75:50:06:01:68:44:60:20:75 SP B 0 Host name:

Celerra_naut3

50:06:01:60:C4:60:20:75:50:06:01:69:44:60:20:75 SP B 1 Host name:

Celerra_naut3

50:06:01:60:C4:60:20:75:50:06:01:60:44:60:20:75 SP A 0 Host name:

Celerra_naut3

EMC CONFIDENTIAL version: 4.5

41 of 51

Page 42

EMC®VNX™Procedure Generator

50:06:01:60:C4:60:20:75:50:06:01:61:44:60:20:75 SP A 1 Host name:

Celerra_naut3

HLU/ALU Pairs:

HLU Number ALU Number

---------- --------- 0 0

1 1

2 2

3 3

4 4

5 5

16 16

17 17

Shareable: YES

18. [ ] For any other VNX Unified or File systems, use the information collected in Collect system

information and save SP logs for the original configuration.

# /nasmcd/sbin/navicli -h <SPA_IP_Address> storagegroup -list -gname "~filestorage"

Sample output:

Storage Group Name: ~filestorage

Storage Group UID: 3E:86:BB:3D:70:64:DF:11:9C:6F:00:60:16:36:9C:7D

HBA/SP Pairs:

HBA UID SP Name SPPort

------- ------- ----- 50:06:01:60:C4:60:20:75:50:06:01:68:44:60:20:75 SP B 0

50:06:01:60:C4:60:20:75:50:06:01:69:44:60:20:75 SP B 1

50:06:01:60:C4:60:20:75:50:06:01:60:44:60:20:75 SP A 0

50:06:01:60:C4:60:20:75:50:06:01:61:44:60:20:75 SP A 1

HLU/ALU Pairs:

HLU Number ALU Number

---------- --------- 0 0

1 1

2 2

3 3

4 4

5 5

16 16

17 17

Shareable: YES

Verify the New Connections

To verify the new initiators created valid connections:

19. [ ] Start PXE Services by typing:

# /nasmcd/sbin/t2pxe -s -R 8

20. [ ] PXE Boot the Blades contained in the BE:

Note: If this command fails to PXE boot the Blade, repeat until the PXE boot completes.

# /nasmcd/sbin/t2tty -p <slot_number>

EMC CONFIDENTIAL version: 4.5

42 of 51

Page 43

EMC®VNX™Procedure Generator

<slot_number> is the slot number of the Blade(s) in the replacement BE.

where

21. [ ] Check that the Blades have successfully PXE booted. The Blades should appear with reason code

4.

# /nasmcd/sbin/getreasonoutput:

6 - slot_0 control station ready

4 - slot_2 configured

4 - slot_3 configured

22. [ ] Verify that each PXE Booted Blade shows No root file system in the output of the following

command:

# /nasmcd/sbin/t2tty -C <slot_number> "ls"

where <slot_number> is the slot number of each PXE Booted Blade.

23. [ ] Verify that each PXE Booted Blade shows the output the following command: