Page 1

EMC Enterprise Storage

EMC Fibre Channel

Disk-Array Processor Enclosure (DPE)

Rackmount FC4500

HARDWARE REFERENCE

P/N 014002901-04

EMC Corporation 171 South Street, Hopkinton, MA 01748-9103

Corporate Headquarters: (508) 435-1000, (800) 424-EMC2 Fax: (508) 435-5374 Service: (800) SVC-4EMC

Page 2

Copyright © EMC Corporation 2000, 2001. All rights reserved.

Printed February 2001

No part of this publication may be reproduced or distributed in any form or by any means, or stored in a

database or retrieval system, without the prior written consent of EMC Corporation.

The information contained in this document is subject to change without notice. EMC Corporation assumes

no responsibility for any errors that may appear.

All computer software programs, including but not limited to microcode, described in this document are

furnished under a license, and may be used or copied only in accordance with the terms of such license.

EMC either owns or has the right to license the computer software programs described in this document.

EMC Corporation retains all rights, title and interest in the computer software programs.

EMC Corporation makes no warranties, expressed or implied, by operation of law or otherwise, relating to

this document, the products or the computer software programs described herein. EMC CORPORATION

DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTIBILITY AND FITNESS FOR A PARTICULAR

PURPOSE. In no event shall EMC Corporation be liable for (a) incidental, indirect, special, or consequential

damages or (b) any damages whatsoever resulting from the loss of use, data or profits, arising out of this

document, even if advised of the possibility of such damages.

Trademark Information

EMC2, EMC, MOSAIC:2000, Symmetrix, CLARiiON, and Navisphere are registered trademarks and EMC Enterprise Storage, The Enterprise Storage

Company, The EMC Effect, Connectrix, EDM, SDMS, SRDF, Timefinder, PowerPath, InfoMover, FarPoint, EMC Enterprise Storage Network, EMC

Enterprise Storage Specialist, EMC Storage Logic, Universal Data Tone, E-Infostructure, Celerra , and Access Logix are trademarks of EMC Corporation.

All other trademarks used herein are the property of their respective owners.

ii

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 3

Regulatory Notices

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Testing was done with shielded cables. Therefore, in order to comply with the FCC regulations, you must use

shielded cables with your installation. Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

This Class A digital apparatus complies with Canadian ICES-003

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada

Manufacturer’s Declaration of Conformity - CE mark

This equipment has been tested and found to comply with the requirements of European Community Council

Directives 89/336/EEC, 73/23/EEC, and 98/68/EEC relating to electromagnetic compatibility and product safety

respectively.

This product complies with EN55022, CISPR22 and AS/NZS 3548 Class A.

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

iii

Page 4

iv

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 5

Contents

Preface..............................................................................................................................xi

Chapter 1 About the Rackmount Disk-Array Processor Enclosure

Introduction.......................................................................................1-2

DPE Components..............................................................................1-4

Enclosure.....................................................................................1-4

Midplane.....................................................................................1-8

Storage Processors (SPs) ...........................................................1-9

Link Control Cards (LCCs)............................................................1-11

Disk Modules ...........................................................................1-12

Disk Drives ...............................................................................1-12

Drive Carrier ............................................................................1-13

Power Supplies ........................................................................1-13

Standby Power Supply (SPS).................................................1-14

Drive Fan Pack .........................................................................1-14

SP Fan Pack...............................................................................1-15

Redundancy in Configurations.....................................................1-17

What Next? ......................................................................................1-18

Chapter 2 Installing a Rackmount DPE

Requirements.....................................................................................2-1

Site Requirements......................................................................2-1

Cabling Requirements...............................................................2-2

Addressing Requirements........................................................2-2

Installing a DPE in a Cabinet ..........................................................2-3

Installing DPEs on the Mounting Rails in the Cabinet ........2-4

DPE Powerup and Initialization...................................................2-16

DPE Powerdown.............................................................................2-16

Binding Disk Modules into Groups .............................................2-18

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

v

Page 6

Contents

Chapter 3 Servicing and Upgrading a DPE

Monitoring DPE Status....................................................................3-1

Handling CRUs.................................................................................3-4

Power Issues and CRUs............................................................3-4

Avoiding Electrostatic Discharge (ESD) Damage ........................3-6

Precautions When Removing, Installing, or Storing CRUs........3-7

Precautions When Handling Optical Cables ................................3-8

Replacing or Adding a Disk Module.............................................3-9

Replacing the SP Fan Pack ............................................................3-14

Replacing an Optical GBIC............................................................3-17

Installing an Optical GBIC Connector..................................3-19

Removing an SP or an SP Filler Module .....................................3-21

Installing or Replacing an SP Memory Module.........................3-24

Installing an SP or SP Filler Module ............................................3-26

Installing an SP or SP Filler Module.....................................3-27

Replacing or Adding an LCC Module.........................................3-30

Removing an LCC ...................................................................3-30

Installing an LCC.....................................................................3-32

Replacing the Drive Fan Pack.......................................................3-34

Removing the Drive Fan Pack...............................................3-35

Installing the Drive Fan Pack.................................................3-35

Replacing or Adding a Power-Supply Module..........................3-36

Removing a Power-Supply Filler Module ...........................3-37

Installing a Power-Supply Module.......................................3-41

Appendix A Technical Specifications and Operating Limits

Technical Specifications .................................................................A-1

AC Power Requirements.........................................................A-1

Size and Weight ........................................................................A-2

Drive Type .................................................................................A-3

SP Optical Cabling....................................................................A-3

LCC Copper Cabling................................................................A-3

Standards Certification and Compliance..............................A-3

Operating Limits .............................................................................A-5

Shipping and Storage Requirements ...........................................A-6

Glossary .........................................................................................................................g-1

Index.................................................................................................................................i-1

vi

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 7

Figures

1-1 DAE ................................................................................................................ 1-2

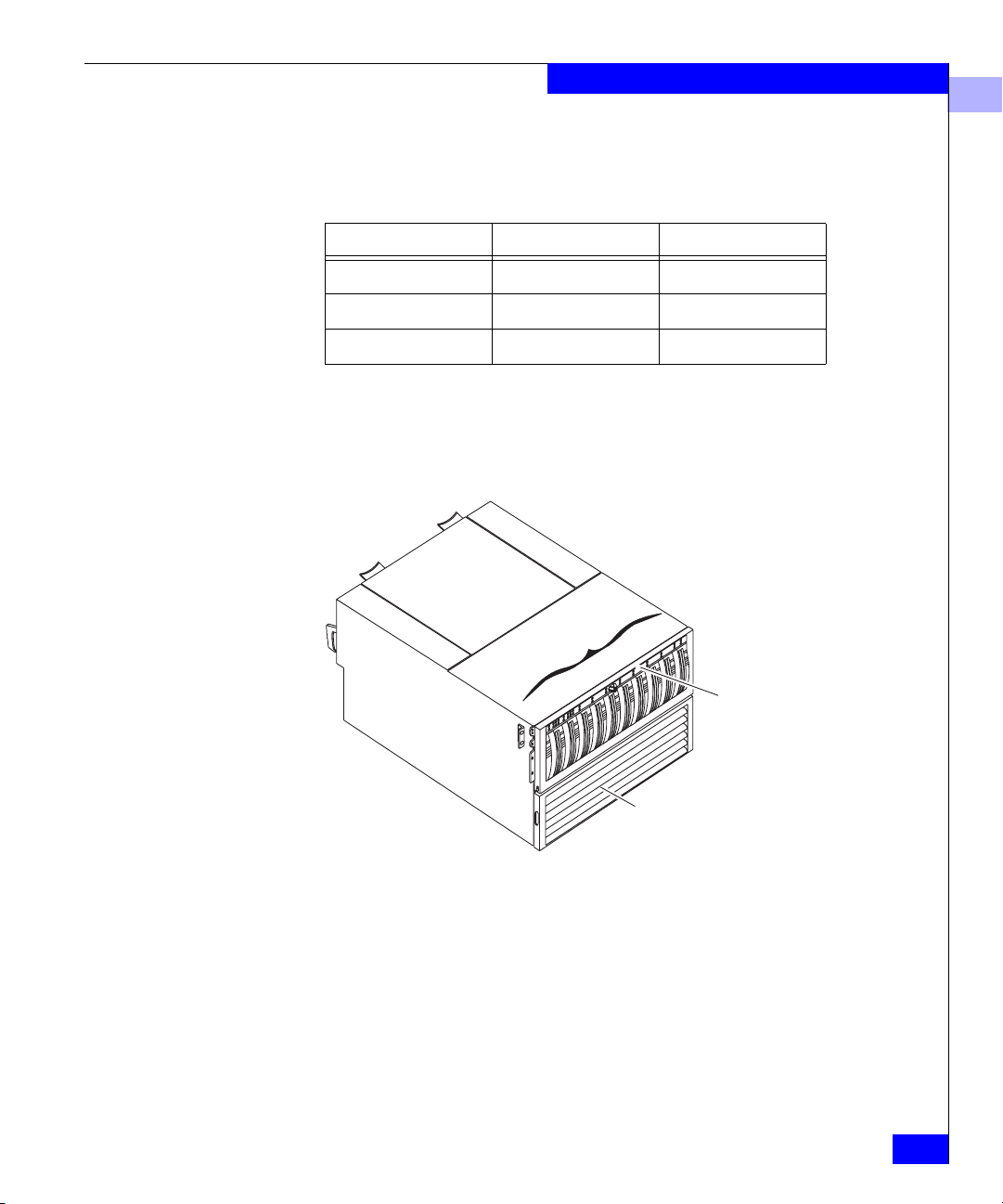

1-2 DPE Front View ............................................................................................ 1-5

1-3 DPE Front View with SP Fan Cover and Door Removed ...................... 1-6

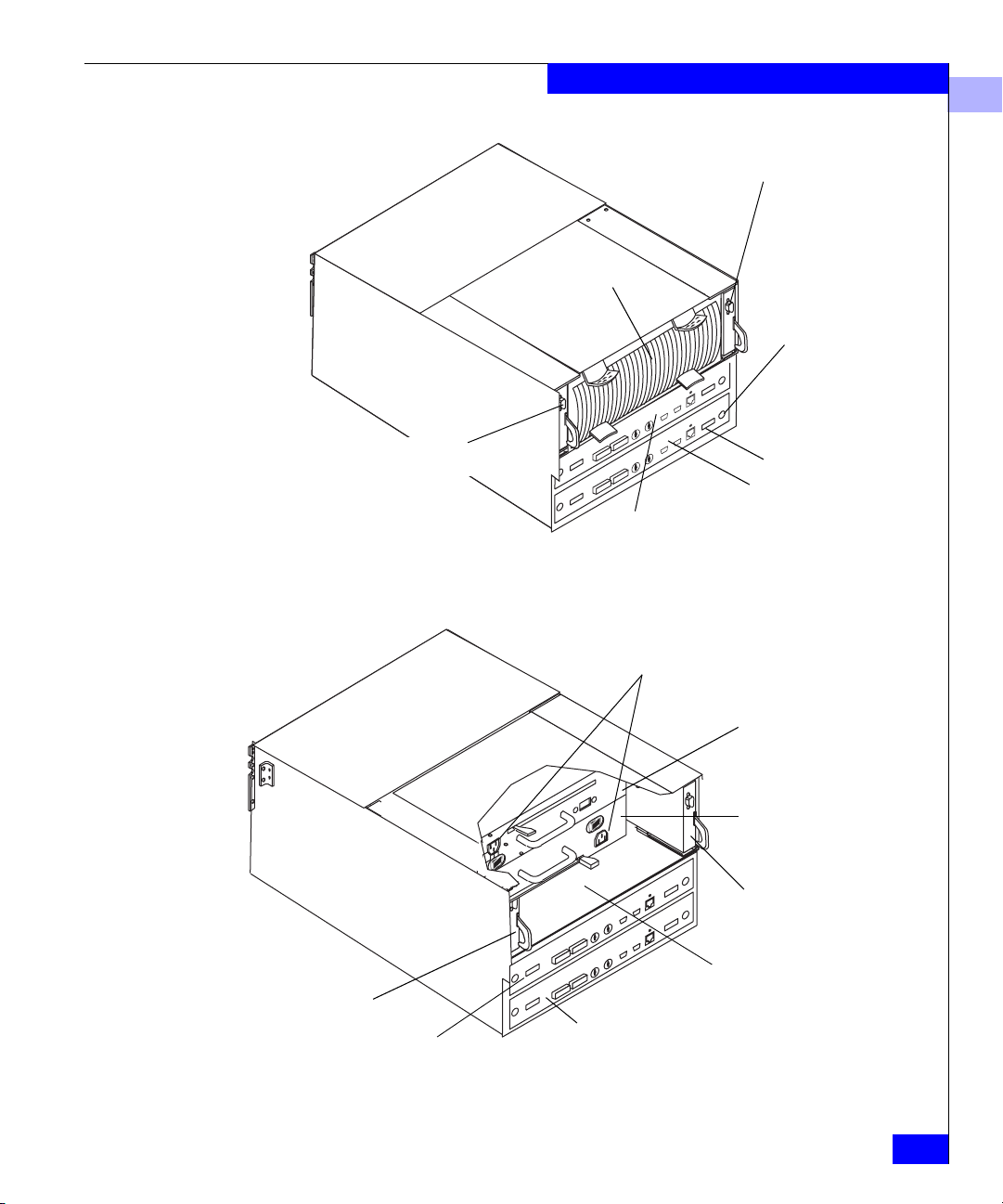

1-4 DPE Back View ............................................................................................. 1-7

1-5 DPE Back View with Drive Fan Pack Removed ...................................... 1-7

1-6 Front Door ..................................................................................................... 1-9

1-7 SP Back Panel .............................................................................................. 1-10

1-8 LCC ............................................................................................................... 1-11

1-9 Disk Module ................................................................................................ 1-12

1-10 Power Supply .............................................................................................. 1-13

1-11 SPS ................................................................................................................ 1-14

1-12 Drive Fan Pack ............................................................................................ 1-15

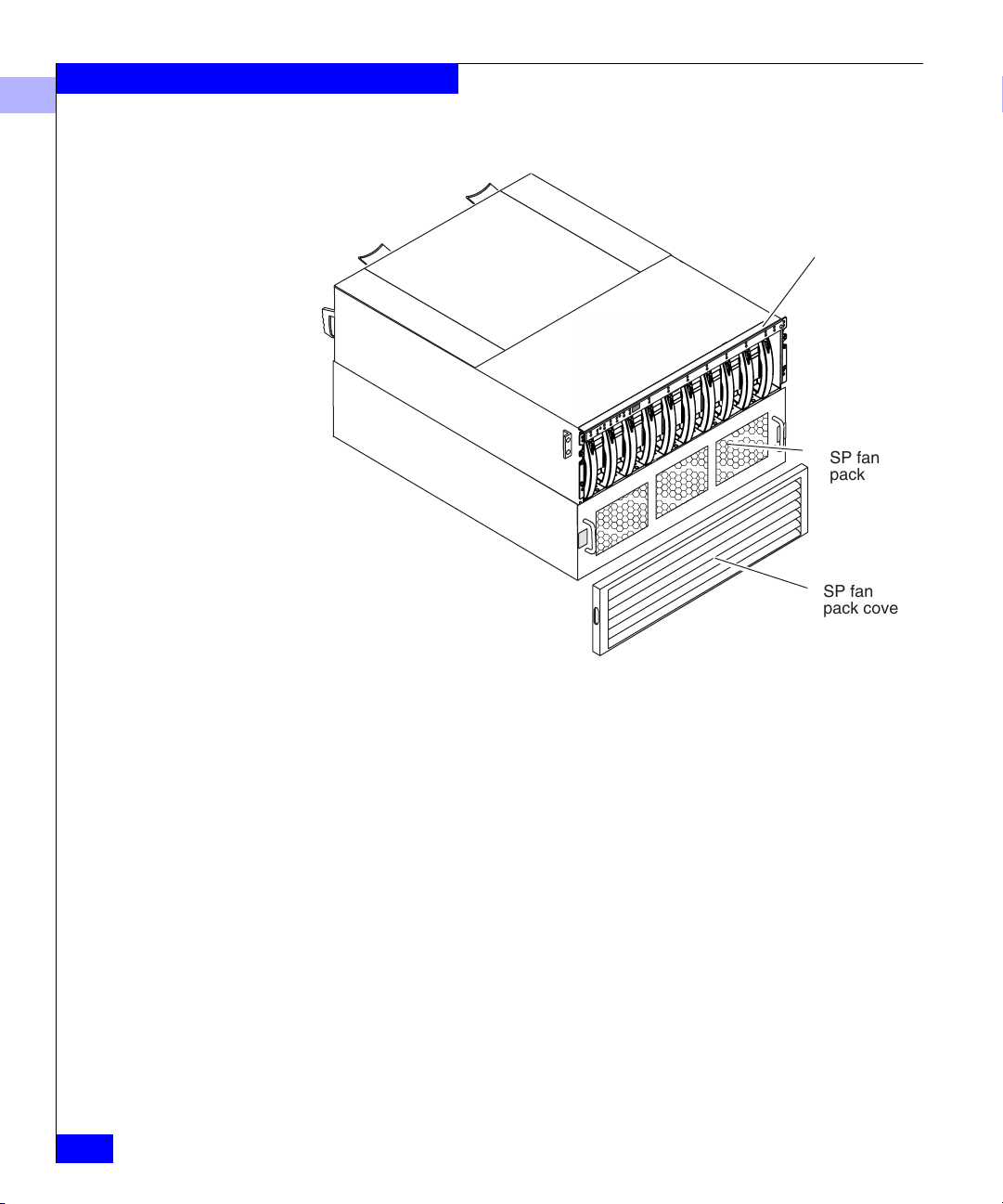

1-13 SP Fan Pack ................................................................................................. 1-16

2-1 Opening the Front Door .............................................................................. 2-5

2-2 Securing the DPE to the Cabinet Front Channel ...................................... 2-6

2-3 Securing the DPE to the Cabinet Back Channel ....................................... 2-7

2-4 Closing and Locking the Front Door ......................................................... 2-8

2-5 SP Fibre Channel Arbitrated Loop Address ID Switches

(Back of SP)................................................................................................... 2-10

2-6 Removing the Drive Fan Pack .................................................................. 2-11

2-7 Plugging the AC Line Cord into the Power Supply and Turning on the

Power Switch ............................................................................................... 2-12

2-8 Installing the Drive Fan Module .............................................................. 2-13

2-9 Attaching Optical Cables to a DPE .......................................................... 2-14

2-10 Cabling a DPE to a DAE ............................................................................ 2-15

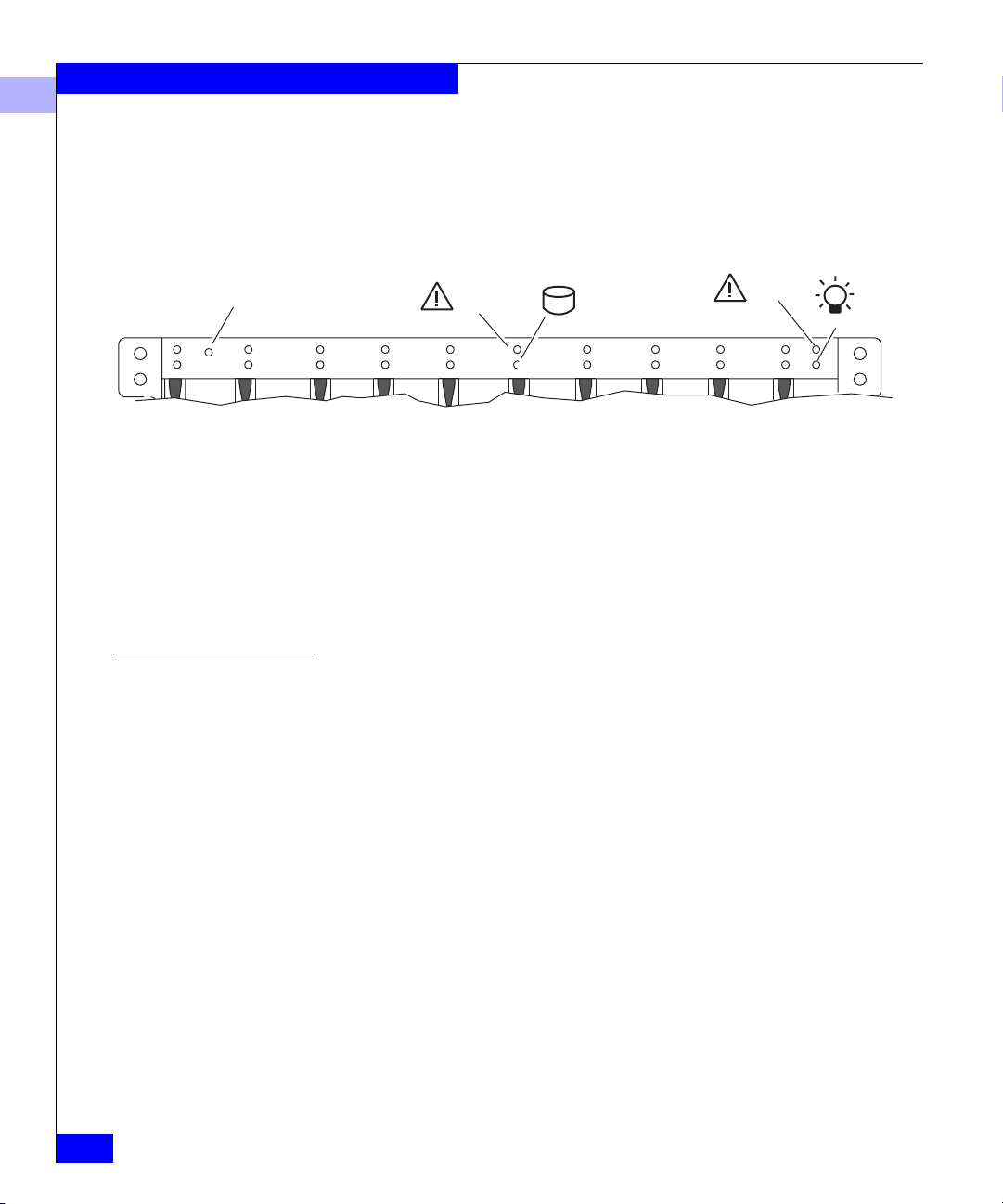

3-1 Status Lights Visible from the Front of the DPE ...................................... 3-2

3-2 Unlocking and Opening the Front Door ................................................. 3-10

3-3 Removing a Disk Filler Module ............................................................... 3-11

3-4 Removing a Disk Module .......................................................................... 3-11

3-5 Installing a Disk Module ........................................................................... 3-12

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

vii

Page 8

Figures

3-6 Closing and Locking the Front Door ........................................................ 3-13

3-7 Removing the SP Fan Pack Cover ............................................................ 3-14

3-8 Removing the SP Fan Pack ........................................................................ 3-15

3-9 Installing the Replacement SP Fan Pack .................................................. 3-16

3-10 Installing the SP Fan Pack Cover .............................................................. 3-17

3-11 Removing an Optical Cable from an SP .................................................. 3-18

3-12 Removing an Optical GBIC Connector from an SP ............................... 3-19

3-13 Installing an Optical GBIC Connector on an SP ..................................... 3-20

3-14 Installing an Optical Cable on an SP ........................................................ 3-21

3-15 Removing an SP or Filler Module ............................................................. 3-23

3-16 Removing the Memory Module from the SP .......................................... 3-25

3-17 Installing the Memory Module on the SP ................................................ 3-26

3-18 Setting the SP Address ID .......................................................................... 3-28

3-19 Installing an SP or SP Filler Module ......................................................... 3-29

3-20 Removing an LCC Filler Module .............................................................. 3-31

3-21 Removing a Copper Cable from an LCC ................................................. 3-31

3-22 Installing an LCC Module .......................................................................... 3-33

3-23 Reconnecting a Copper Cable to an Expansion LCC ............................. 3-34

3-24 Removing the Drive Fan Pack ................................................................... 3-35

3-25 Installing the Drive Fan Pack .................................................................... 3-36

3-26 Removing the Bottom Filler Module ........................................................ 3-37

3-27 Removing the Top Filler Module .............................................................. 3-38

3-28 Turning off a Supply’s Power and Unplugging the AC Line Cord ..... 3-39

3-29 Removing the Top Power-Supply Module ............................................. 3-40

3-30 Removing the Bottom Power-Supply Module ....................................... 3-41

3-31 Installing the Bottom Power Supply ........................................................ 3-42

3-32 Installing the Top Power Supply .............................................................. 3-43

3-33 Plugging in the AC Line Cord and Turning on Power ......................... 3-44

viii

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 9

Tables

3-1 Status Lights Color Codes, Front of DPE .................................................. 3-2

3-2 Status Lights Color Codes, Back of DPE .................................................. 3-3

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

ix

Page 10

Tab les

x

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 11

How This Manual Is

Organized

Preface

This manual describes how to install the EMC Fibre Channel

Disk-Array Processor Enclosure (DPE) Rackmount Model FC4500,

and how to replace and add customer-replaceable units (CRUs).

If you will install and service the rackmount DPE, you should read

this manual. After reading it, you will be able to install a rackmount

DPE, replace any CRUs that may fail, and upgrade a rackmount DPE

by adding disk modules and redundant CRUs.

Chapter 1 Introduces the rackmount DPE’s components.

Chapter 2 Explains requirements and describes how to

install the rackmount DPE and cable it to the

server and to rackmount Disk Array Enclosures

(DAEs).

Chapter 3 Describes how to replace CRUs such as disk

modules.

Appendix A Lists the rackmount DPE’s technical

specifications.

Glossary Defines terms used in the Fibre Channel

environment.

Related

Documentation

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Other EMC publications include:

• EMC Fibre Channel Disk-Array Enclosure (DAE) Rackmount Hardware

Reference (P/N 014002591).

• DC Standby Power Supply (SPS) Hardware Reference

(P/N 014002887).

xi

Page 12

Preface

Conventions Used in

This Manual

!

EMC uses the following conventions for notes, cautions, warnings,

and danger notices.

A note presents information that is important, but not hazard-related.

CAUTION

A caution contains information essential to avoid damage to the

system or equipment. The caution may apply to hardware or

software.

WARNING

A warning contains information essential to avoid a hazard that can

cause severe personal injury, death, or substantial property damage

if you ignore the warning.

DANGER

A danger notice contains information essential to avoid a hazard

that will cause severe personal injury, death, or substantial property

damage if you ignore the warning.

EMC uses the following type style conventions in this guide:

Boldface Specific filenames or complete paths. Window

names and menu items in text. Emphasis in

cautions and warnings.

Italic Introduces new terms or unique word usage in

text. Command line arguments when used in text.

Fixed space

Examples of specific command entries that you

would type, displayed text, or program listings.

For example:

xii

QUERY [CUU=cuu|VOLSER=volser]

Fixed italic Arguments used in examples of command line

syntax.

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 13

1

About the Rackmount

Disk-Array Processor

Enclosure

Topics in this chapter include:

• Introduction ........................................................................................1-2

• DPE Components...............................................................................1-4

• Link Control Cards (LCCs).............................................................1-11

• Redundancy in Configurations......................................................1-17

About the Rackmount Disk-Array Processor Enclosure

1-1

Page 14

About the Rackmount Disk-Array Processor Enclosure

1

Introduction

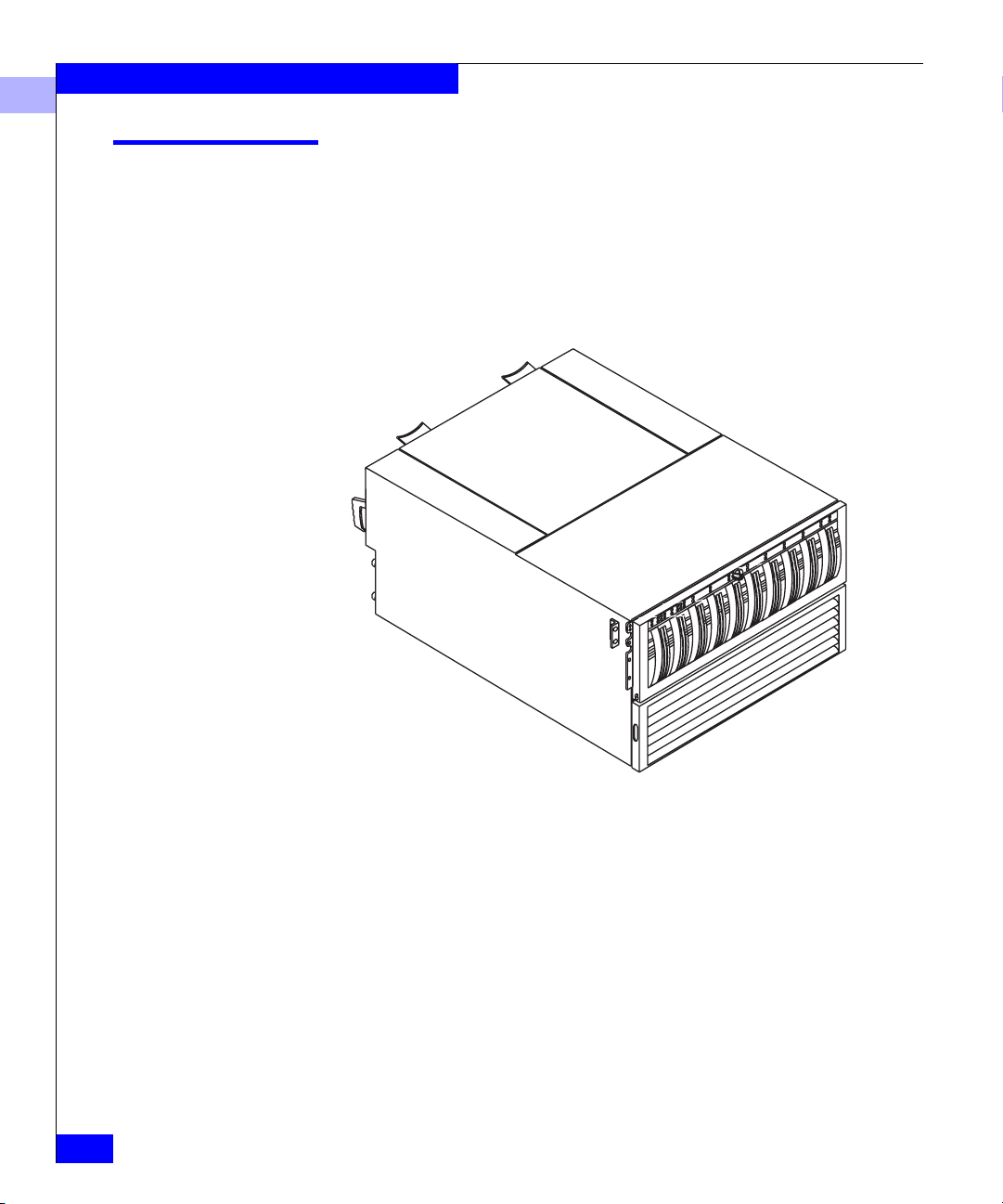

The DPE is a highly available, high-performance, high-capacity,

disk-array storage system that uses a Fibre Channel Arbitrated Loop

(FC-AL) as its interconnect interface. Its modular, scalable design

provides additional disk storage as your needs increase.

1-2

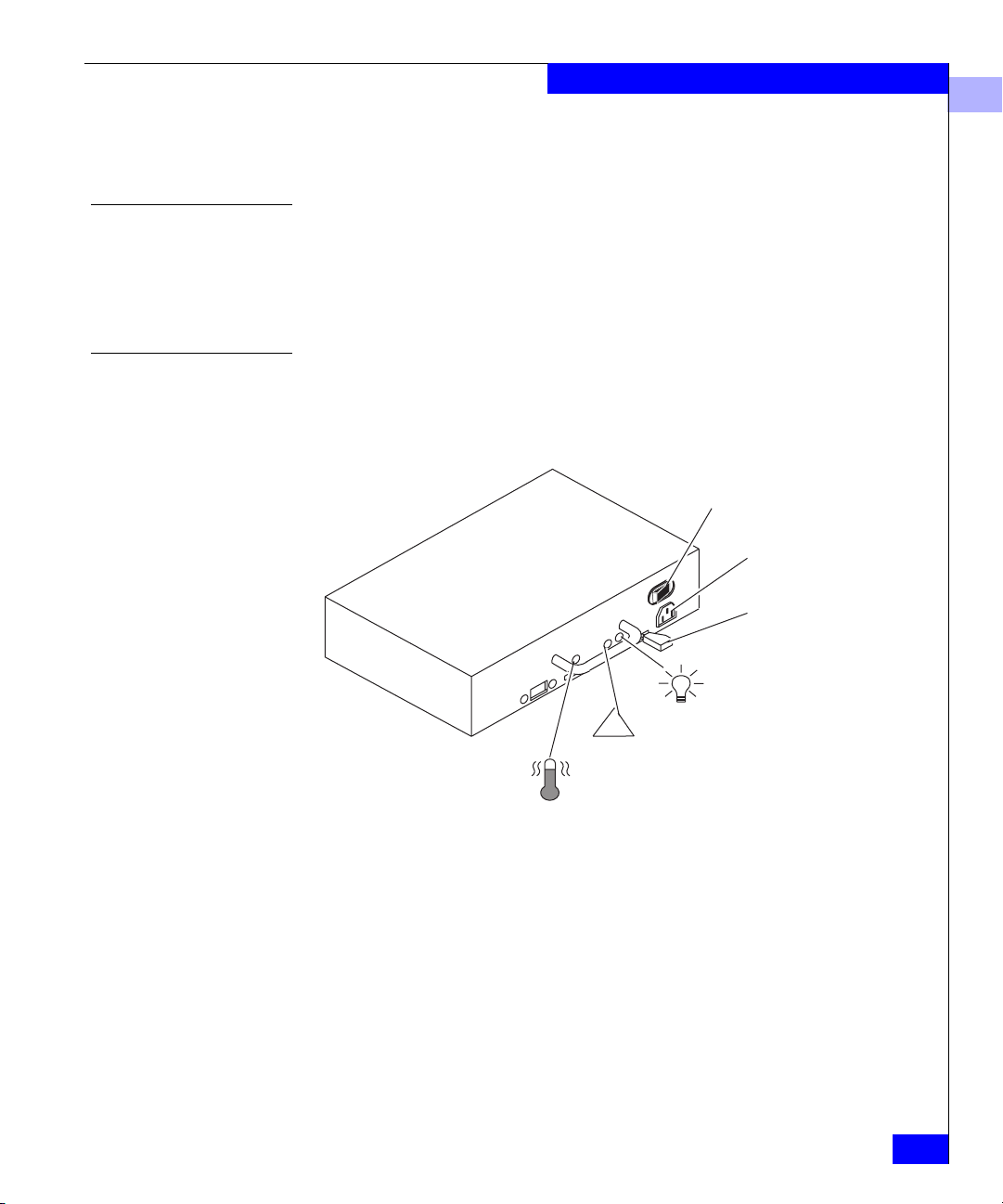

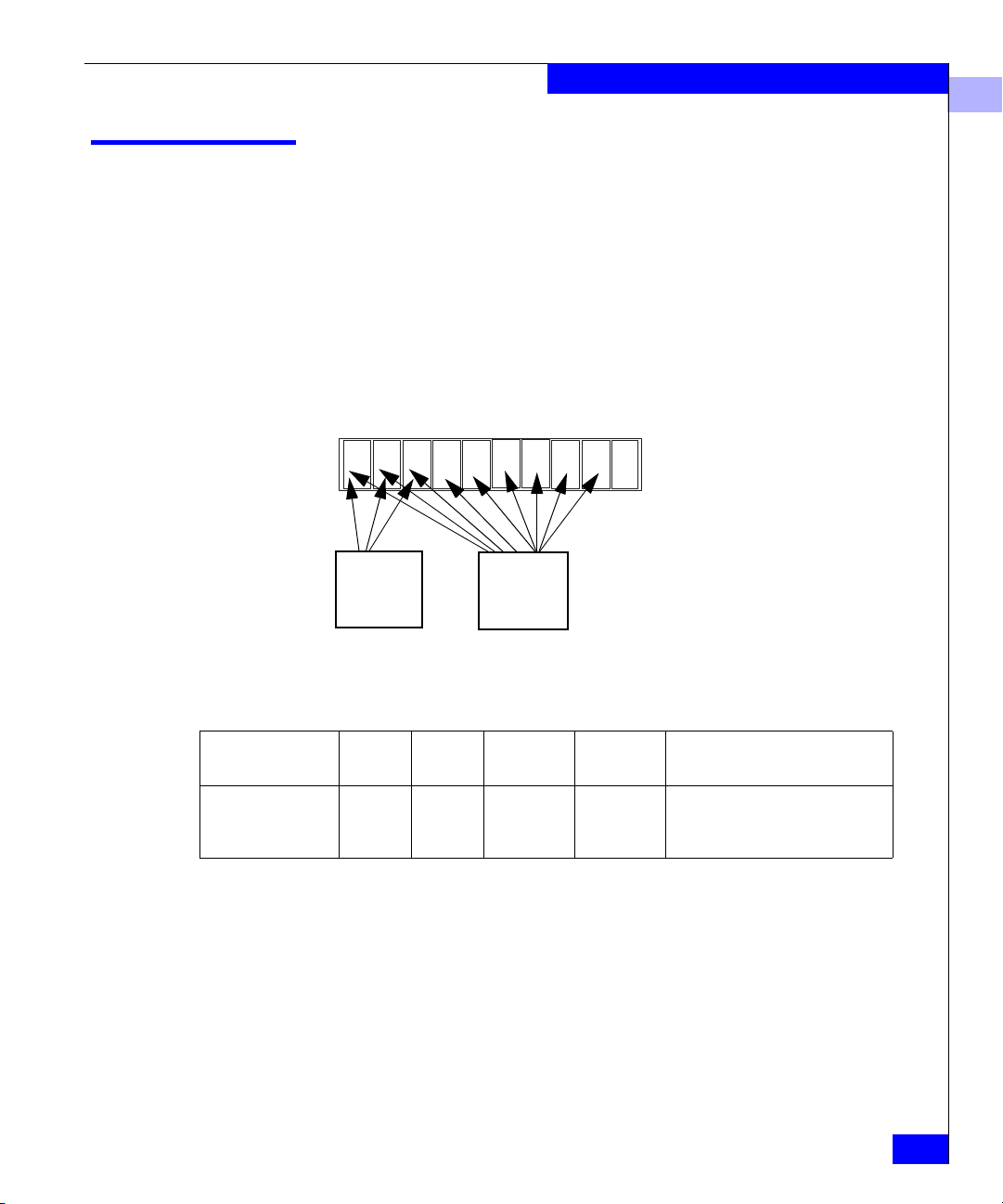

Figure 1-1 DAE

Using its interface, with simple FC-AL serial cabling, the FC4500

DPE can support up to 11 DAEs A DAE is a basic enclosure without a

storage processor (SP). The FC4500 and 11 DAEs support up to 120

disk modules in a single disk-array file storage system.

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 15

About the Rackmount Disk-Array Processor Enclosure

You can place the DAEs in the same cabinet as the DPE, or in one or

more separate cabinets. The DPE connects to the external Fibre

Channel environment using GBIC connectors on the storage

processor. High-availability features are standard.

The EMC Access Logix™ option provides Storage Group

functionality for the FC4500 DPE.

1

Introduction

1-3

Page 16

About the Rackmount Disk-Array Processor Enclosure

1

DPE Components

The DPE components include:

• A sheet-metal enclosure with a midplane, front door, and SP fan

pack cover

• One or two SPs

• One or two link control cards (LCCs)

• Up to ten disk modules

• One or two power supplies

• One drive fan pack

• One SP fan pack

Any unoccupied slot (SP, LCC, disk module, or power supply) has a

filler module to maintain air flow and compliance with

electromagnetic interference (EMI) standards.

The SPs, LCCs, disk modules, power supplies, fan packs, and filler

modules are customer-replaceable units (CRUs), which you can add

or replace without tools while the DPE is powered up.

1-4

The high-availability features for a DPE include:

• Second SP and LCC

• Second power supply

• Standby power supply (SPS) (See “Related Documentation” on

page xi.)

A second SP (with required second LCC) provides continued access

to the DPE and any connected DAEs if the first SP or LCC fails. The

second SP can improve performance and connects easily to a second

server.

The disk drives are FC-AL compliant and support dual-port FC-AL

interconnects through the two LCCs and their cabling.

Enclosure

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

The enclosure is a sheet-metal housing with a front panel, a

midplane, front door, and slots for the SPs, LCCs, disk modules,

power supplies, and fan packs.

The following figures show the DPE components. Details on each

component follow the figures. If the enclosure provides slots for two

Page 17

About the Rackmount Disk-Array Processor Enclosure

identical components, the component in slot A is called

component-name A. If there is a second component, it is in slot B and is

called component-nameB, as follows.

Component Name in Slot A Name in Slot B

SP SP A SP B

LCC LCC A LCC B

Power supply PS A PS B

If you have one power supply, it can be in either slot A or slot B. If

you have one SP and one LCC, they can be in either slot A or B, but

not mixed.

s

e

l

u

d

o

m

k

s

i

D

1

0

5

4

3

2

9

8

7

6

Front

door

1

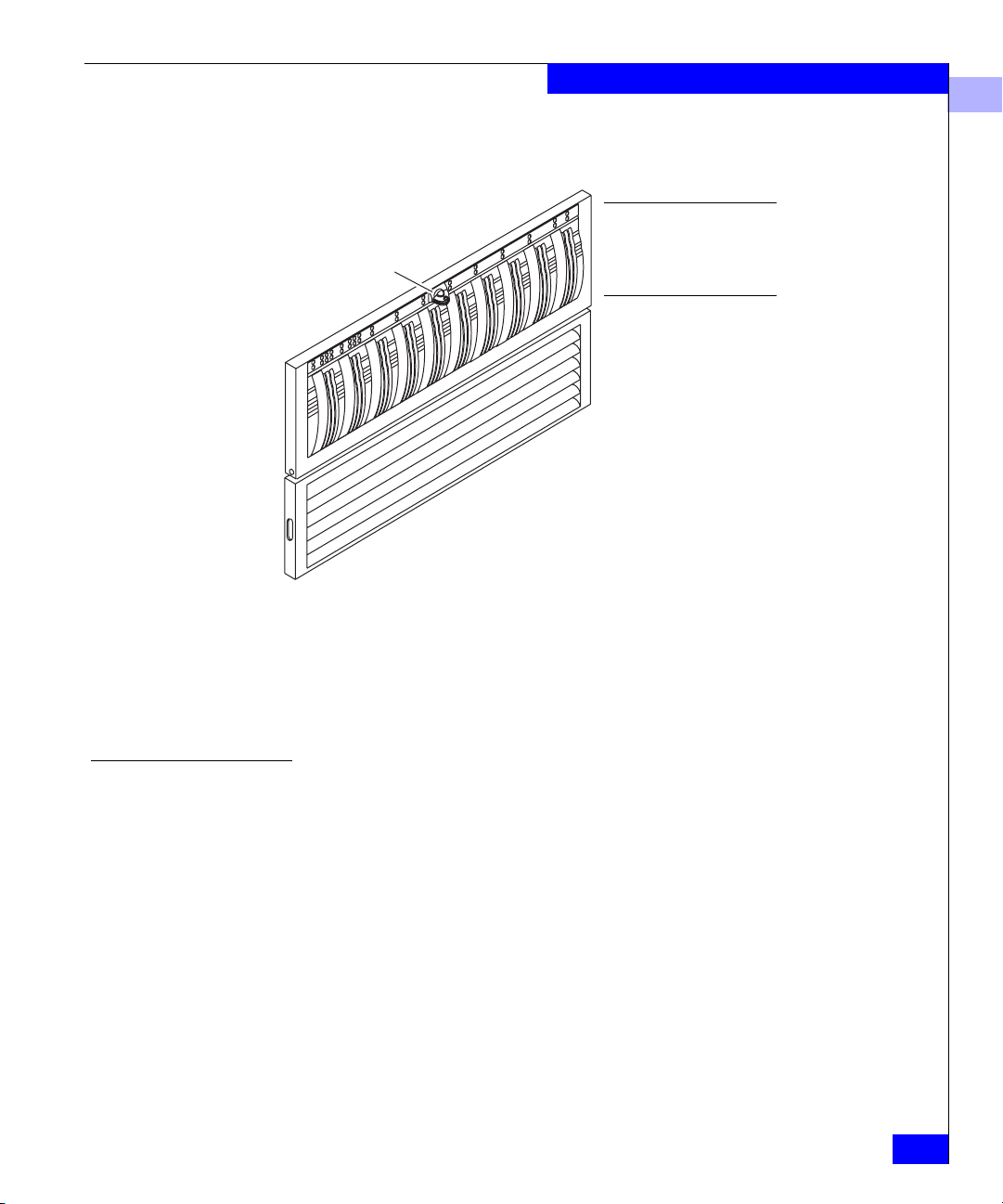

Figure 1-2 DPE Front View

SP fan pack cover

DPE Components

1-5

Page 18

About the Rackmount Disk-Array Processor Enclosure

1

Front panel with door

removed for clarity

SP fan

pack

SP fan

pack cover

1-6

Figure 1-3 DPE Front View with SP Fan Cover and Door Removed

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 19

About the Rackmount Disk-Array Processor Enclosure

Drive fan pack

1

LCC A with expansion

connector (marked EXP)

SP retaining screw

(2 per SP)

LCC B with expansion

connector (marked EXP)

Figure 1-4 DPE Back View

LCC B

SP B

SP ejector (2 per SP)

SP A

SP B

ac line cord

connectors

Power supply

PS A

Power supply

PS B

LCC A

Location of DPE EMI

rating label - Class A

SP A

Figure 1-5 DPE Back View with Drive Fan Pack Removed

DPE Components

1-7

Page 20

About the Rackmount Disk-Array Processor Enclosure

1

SP A works with LCC A to run SP A’s disk modules; SP B works with

LCC B to run SP B’s disk modules.

Front Panel

Enclosure address light

(0 for a DPE)

Midplane

Disk module status lights

(two per module)

Check

1023 4 5 6 7 8 9

Active

Check

The front panel contains the enclosure address (EA) light, two status

lights for each disk module slot, and two DPE status lights. All lights

are visible with the front door closed.

The enclosure address light displays the enclosure address setting for

the DPE, which is always 0. This address cannot be changed.

The DPE status lights are described in the “Monitoring DPE status”

section in Chapter 3.

The midplane distributes power and signals to all the enclosure

components. All CRUs except the fan packs plug directly into

midplane connectors.

DPE status lights

Power

1-8

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 21

Locking latch

with key

About the Rackmount Disk-Array Processor Enclosure

1

The front door must be closed for the

DPE to be EMI compliant. Opening

the door to access the disk modules is

a service procedure.

Figure 1-6 Front Door

Storage Processors (SPs)

The front door has a locking latch and an EMI shield. The latch is a

push button with a removable locking key that you can use in any

DPE or DAE. When the door is open, you can remove or install disk

modules.

The SP is the DPE’s intelligent component. It defines the DPE and

differentiates the DPE from a DAE. An SP is a printed-circuit board

with dual in-line memory modules (DIMMs), a bezel with status

lights, and securing latches. The following figure locates the SP ports,

the status lights, the location of the DIMMs, and the FC-AL ID rotary

switches.

DPE Components

1-9

Page 22

About the Rackmount Disk-Array Processor Enclosure

1

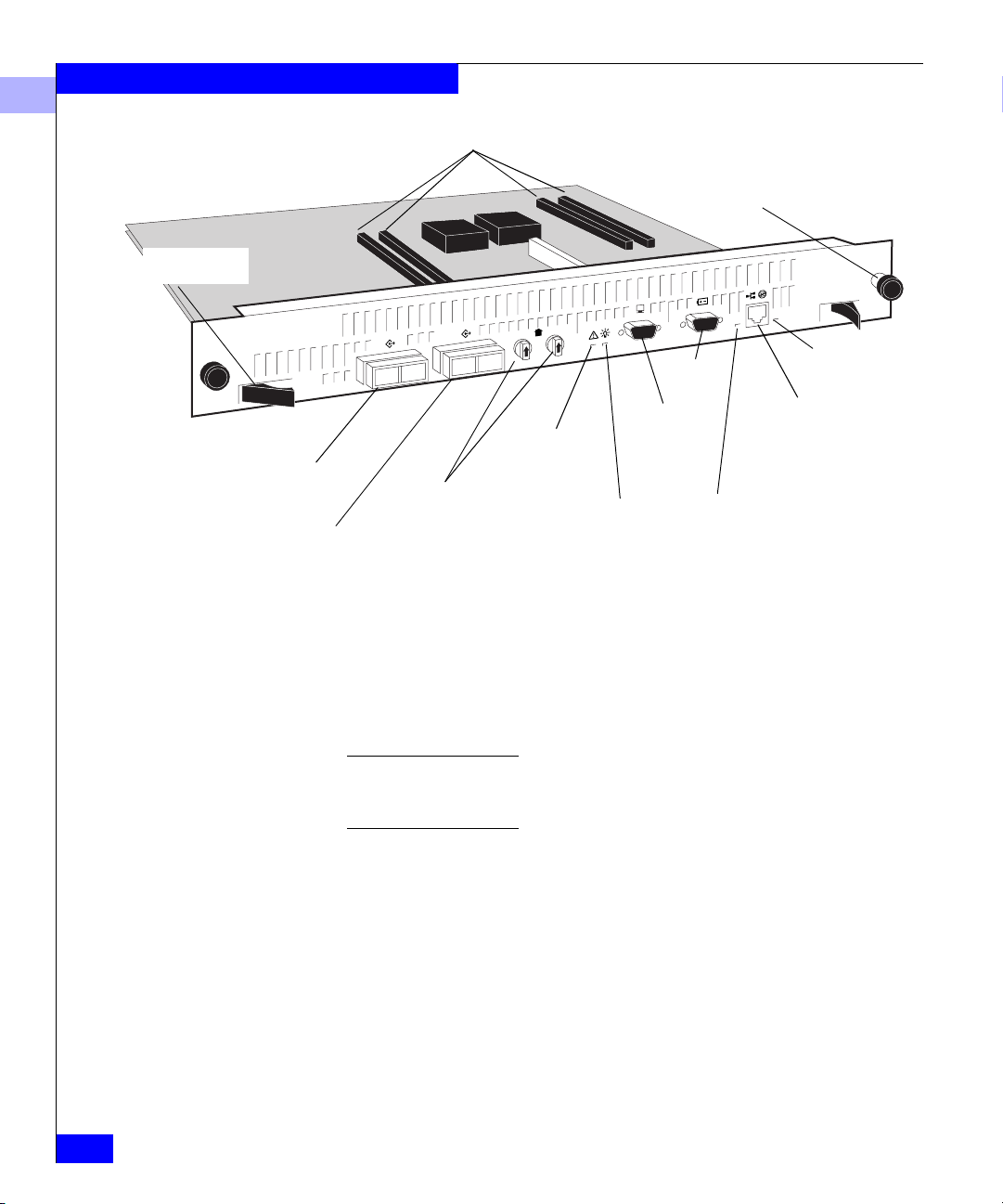

Connectors for DIMMS

Captive retaining

screw (2 per SP)

Release lever

(2 per SP)

Port A (with optical GBIC)

Port B (with optical GBIC)

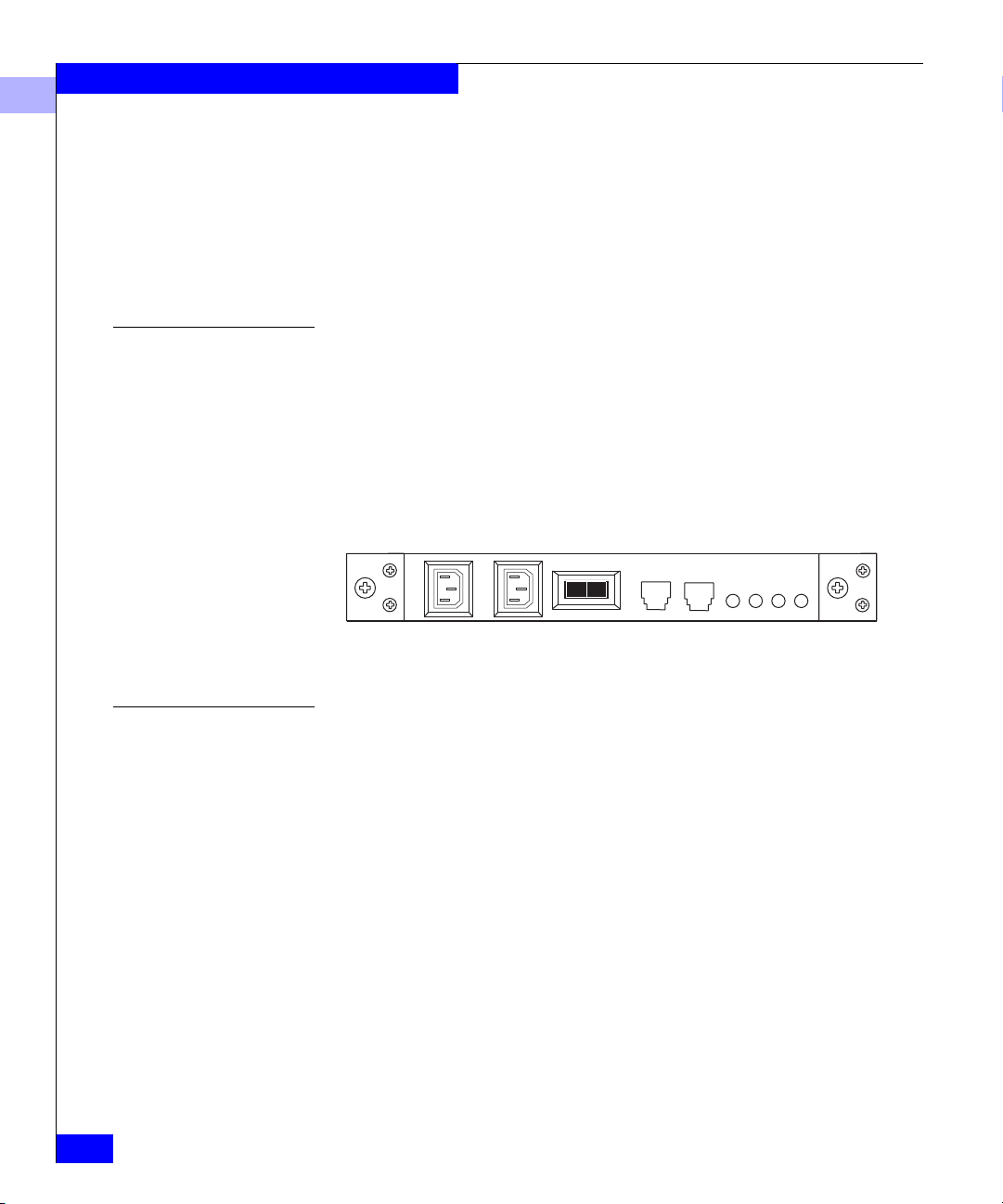

Figure 1-7 SP Back Panel

Speed light

Network/RJ45

connection

reserved for

future use

Check Light

(amber)

FC-AL ID switches

(required only for Fibre

Channel Arbitrated

Loop environment)

Console

Active light

(green)

SPS

Link/activity light

As shown in the figure, the SP has 4 connectors for DIMMs that

comprise both read and write caches. These DIMMs come in 128-,

256-, or 512-Mbyte capacity. Memory allocation is handled by

Navisphere

® Manager or another Navisphere array management

utility.

When the DPE is configured to operate in a fabric environment, only one of

the SP ports (A or B) can be used to connect to the external Fibre Channel

environment.

The SP has two Fibre Channel ports (A and B) referred to as the SP

front end, for connecting to the external Fibre Channel environment.

It also has two rotary switches for setting the FC-AL address ID when

operating in a Fibre Channel Arbitrated Loop environment.

1-10

The SP connects to disk modules and to its corresponding LCC via an

internal FC-AL. SP A connects to LCC A, and SP B to LCC B. The

SP-LCC interface is called the SP back end.

The SP also has an Console connector (with a terminal icon), a

connector for communication with the standby power supply,

marked SPS, and a LAN connection. Each SP has four status lights

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 23

visible from the back of the DPE. For a definition of these light colors,

see the “Monitoring DPE Status” section in Chapter 3.

If a DPE has one SP, you can install a second one while the DPE is

running.When both SPs are installed, you can replace either SP while

the DPE is running. You should never attempt to replace any of the

SP’s components, except the memory modules and GBICs.

Link Control Cards (LCCs)

A link control card (LCC) is a CRU in an enclosure that connects Fibre

Channel signalling to the disk modules. The LCC provides:

• Fibre channel connectivity between the SP, disks, and other

enclosures

• Bypass capability for faulted or missing units

• Monitor and control of the enclosure elements

About the Rackmount Disk-Array Processor Enclosure

1

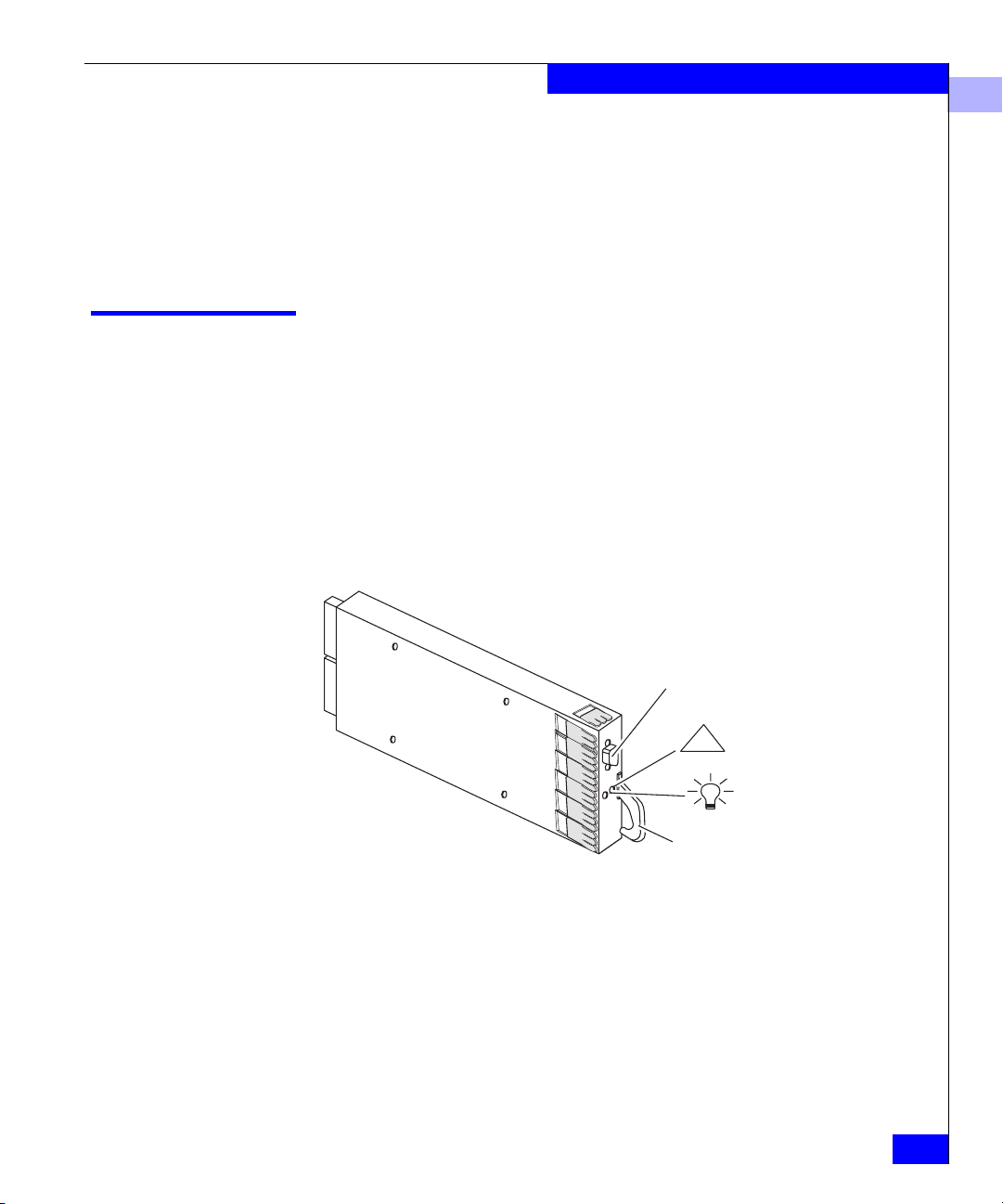

Figure 1-8 LCC

Each LCC independently monitors the environmental status of the

entire DPE, using a microcomputer-controlled CRU monitor. The

CRU monitor communicates status to the SP server using special

protocols. These protocols let the SP poll DPE status and send

commands that control the port LCC bypass circuits and the

disk-module check lights.

EXP

Latch

Link Control Cards (LCCs)

Expansion FC-AL

cable connector

Check light

!

(amber)

Active light

(green)

1-11

Page 24

About the Rackmount Disk-Array Processor Enclosure

1

Each LCC has two status lights visible from the back of the DPE. For

definitions of these light colors, see the “Monitoring DPE Status”

section in Chapter 3.

A latch on the LCC locks it into place to ensure proper connection to

the midplane. You can add or replace an LCC while the DPE is

powered up.

Disk Modules

Disk Drives

Each disk module (see figure below) consists of a Fibre Channel disk

drive in a carrier assembly. You can add or remove a disk module

while the DPE is powered up.

Disk drive

Figure 1-9 Disk Module

The disk drives are 3.5-inch FC-AL drives that conform to the

following standards:

Carrier

Shock mount (4)

Latch

Handle

ESD clip (2)

1-12

• SFF-8067

• Fibre Channel Arbitrated Loop (FC-AL)

• FC-AL Private Loop Direct Attach (PLDA) profile

The disk module slots in the enclosure accommodate drives with

heights of either 2.54 cm (1.0 inch) or 4.06 cm (1.6 inches). You can

combine drives of either height, and from different manufacturers,

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 25

About the Rackmount Disk-Array Processor Enclosure

within the same DPE, subject to the restrictions imposed by the Core

Software running in the DPE’s SPs.

1

Drive Carrier

Power Supplies

The disk-drive carrier is a plastic assembly that slides into the

enclosure slot guides and midplane connectors. It has a handle with a

latch and electrostatic discharge (ESD) clips, which connect to the

drive’s head-disk assembly. The latch holds the disk module in place

to ensure proper connection with the midplane.

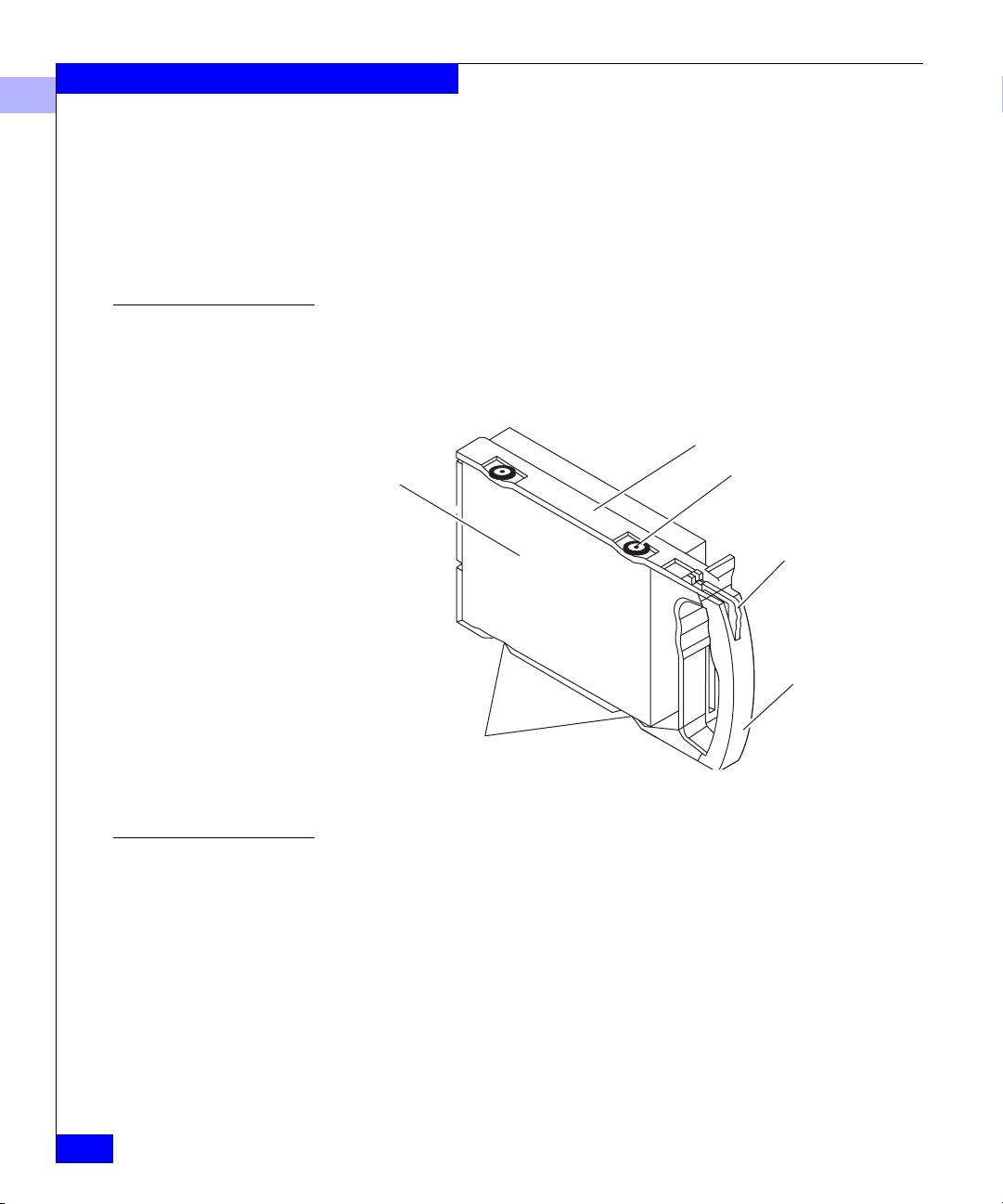

The power supplies (see figure below) are located behind the drive

fan pack. With two power supplies, the top supply is installed

inverted with respect to the bottom supply.

On/Off switch and

circuit breaker

Ac line cord

connector

Latch

Active light

(green)

Check light

!

(amber)

Figure 1-10 Power Supply

Each power supply is an auto-ranging, power-factor-corrected,

multi-output, off-line converter with its own line cord and on/off

switch. Each supply supports a fully configured DPE and shares load

currents with the other supply, if it is present. The drive and LCC

voltage lines have individual soft-start switches that protect the disk

drives and LCCs if you install them while the DPE is powered up. A

CRU with power-related faults will not adversely affect the operation

of any other CRU.

Cooling Check

light (amber)

Link Control Cards (LCCs)

1-13

Page 26

About the Rackmount Disk-Array Processor Enclosure

1

Each power supply has status lights. These status lights are partially

visible through the drive fan pack, and fully visible with the drive fan

pack removed. The status lights are described in the “Monitoring

DPE Status” section of Chapter 3.

A latch on the power supply locks it into place to ensure proper

connection to the midplane. You can add or remove one power

supply in a highly available DPE while the DPE is powered up.

Standby Power Supply (SPS)

Figure 1-11 SPS

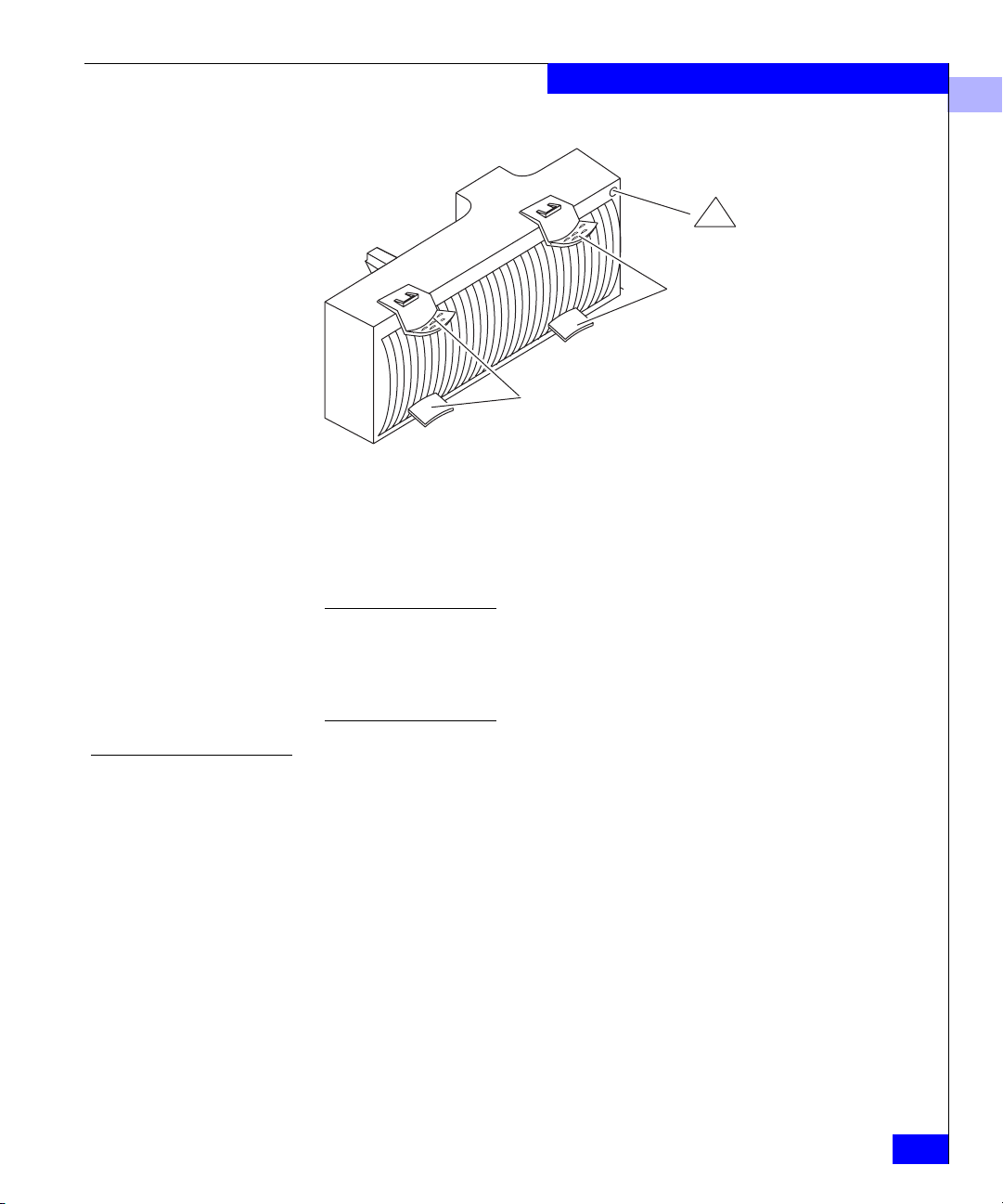

Drive Fan Pack

Disk configurations that use write caching, such as RAID 5, require a

standby power supply (SPS) to prevent data loss during a power

failure. Data is maintained after a power loss.

One or two SPS units fit beneath the DPE and maintain power until

write cache data can be safely stored to the disk. Installing an SPS and

cabling it to the DPE are explained in the manual DC Standby Power

Supply (SPS) Installation (014002887).

The drive fan pack (see Figure 1-11) cools the disk modules, power

supplies, and LCCs in the DPE. A separate pack, described next, cools

the SPs. The drive fan pack contains three fans that draw ambient

room air through the front door, across the drive modules, and

through the midplane and power supplies. The drive fan pack

connects directly to both power supplies, and either supply can

power it. The fans operate at a lower voltage and speed during

normal operation to minimize acoustic noise. If a fan fails, the voltage

and speed of the remaining fans increase to compensate, resulting in

higher acoustic noise.

1-14

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 27

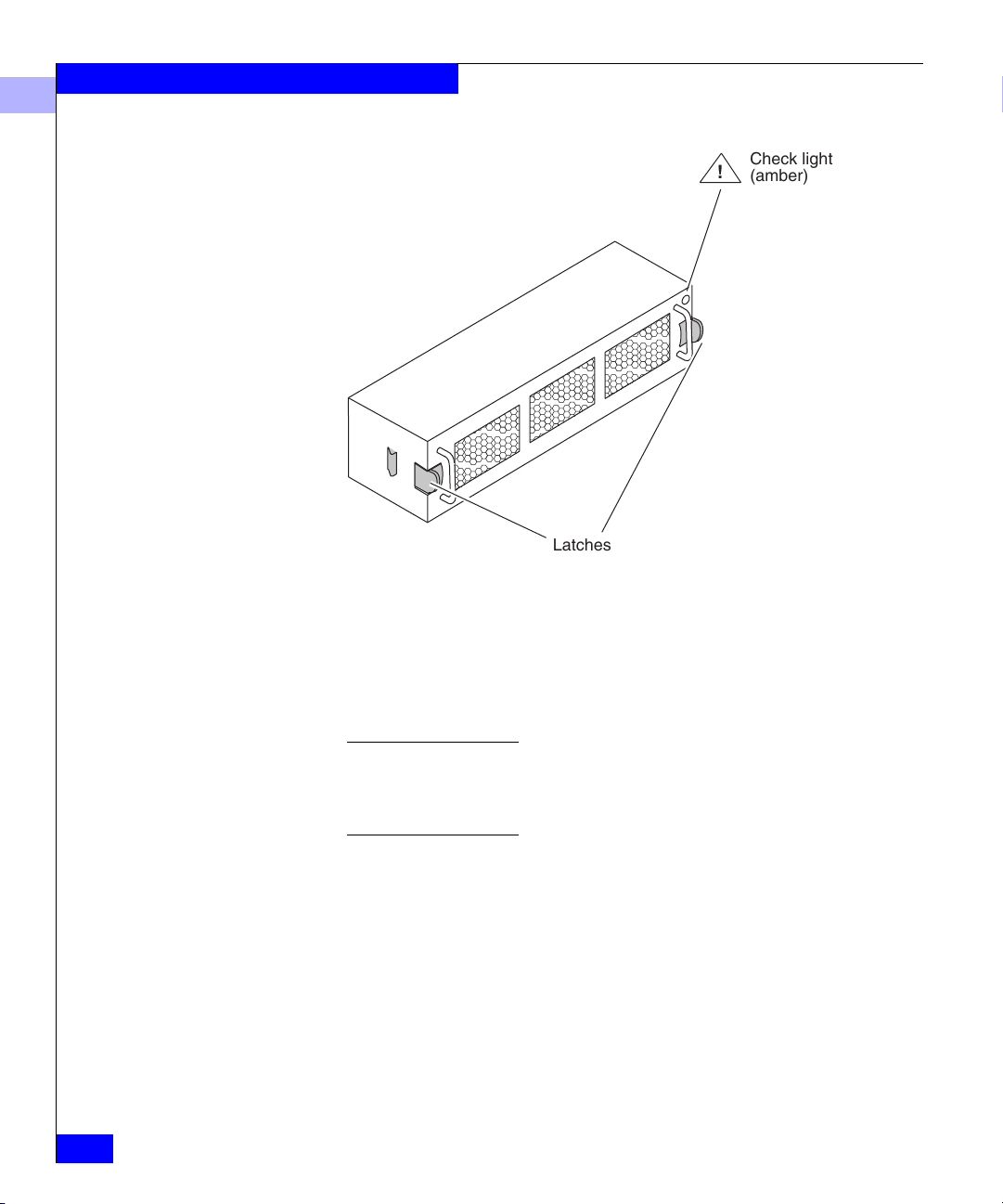

Figure 1-12 Drive Fan Pack

The drive fan pack has one status light. The status light is described

in the “Monitoring DPE Status” section of Chapter 3.

Latches on the drive fan pack hold the pack in place.

About the Rackmount Disk-Array Processor Enclosure

Check light

!

(amber)

Latches

Latches

1

SP Fan Pack

You can remove the drive fan pack while the DPE is powered up. While the

pack is removed, the cooling check light on each power supply flashes. If the

pack is removed for more than approximately two minutes, the disk modules

and SPs power down. The disk modules and SPs power up when you

reinstall the drive fan pack.

The SP fan pack (see Figure 1-12) cools the SPs. It contains three fans

that draw ambient room air through the SP fan pack cover, through

the midplane, and across the SPs. The SP fan pack connects to the

DPE midplane via an internal cable, and either supply can power it.

The fans operate at a lower voltage and speed during normal

operation to minimize acoustic noise. If a fan fails, the voltage and

speed of the remaining fans increase to compensate, resulting in

higher acoustic noise.

Link Control Cards (LCCs)

1-15

Page 28

About the Rackmount Disk-Array Processor Enclosure

1

Check light

!

(amber)

Latches

Figure 1-13 SP Fan Pack

1-16

Latches on the SP fan pack hold the pack in place.

The SP fan pack has one status light visible when the SP fan pack

cover is removed. The status light is described in the “Monitoring

DPE Status” section of Chapter 3.

You can remove the SP fan pack while the DPE is powered up. If the pack is

removed for more than approximately two minutes, the SPs and disk

modules power down. The SPs and disk modules power up when you

reinstall the SP fan pack.

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 29

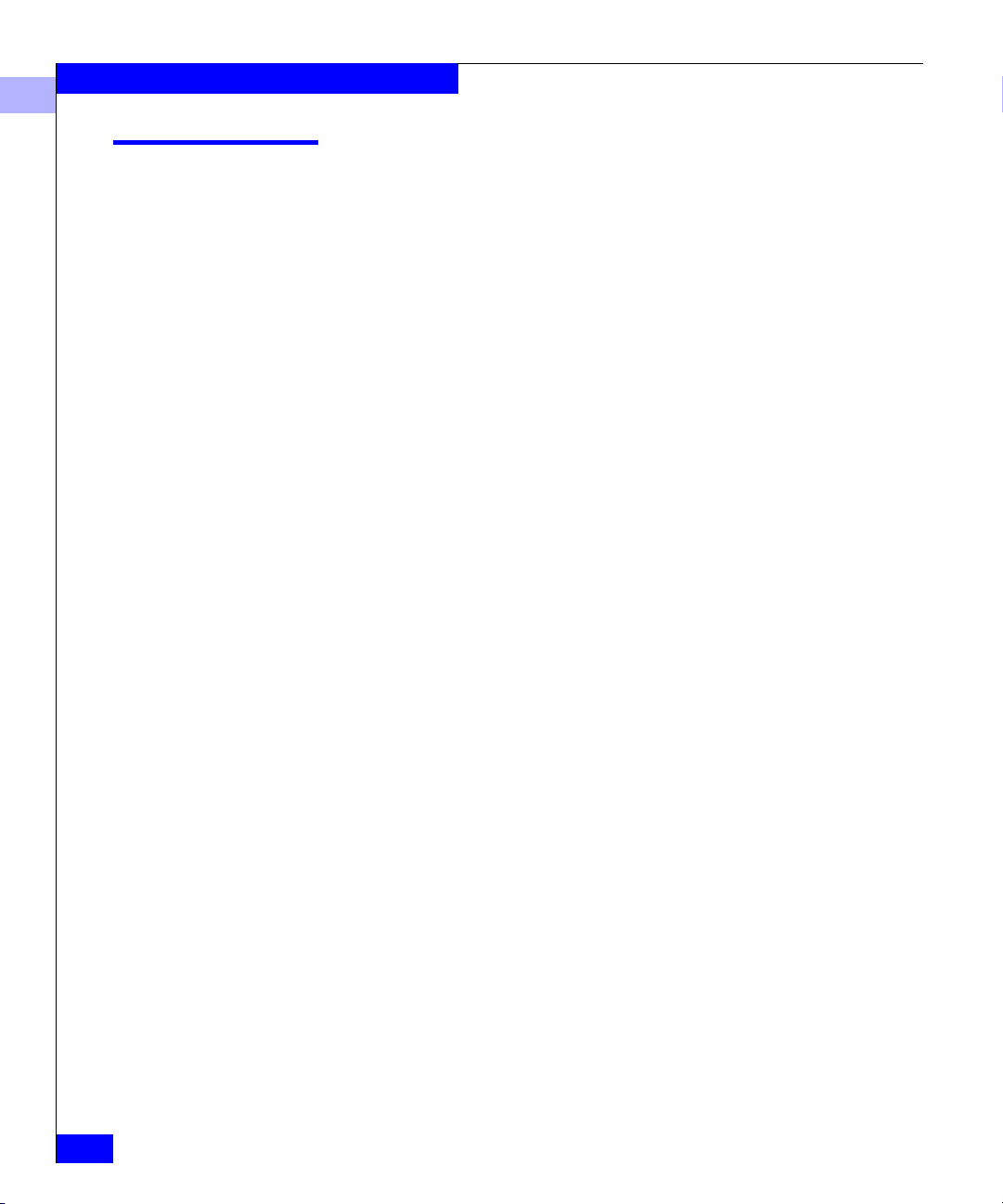

Redundancy in Configurations

Mirrored storage-system write caching requires:

• Two SPs with equal memory of at least 128 Mbytes

• Two power supplies

• Two LCCs in the DPE and each DAE

• Disks in slots 0:0 through 0:8

• SPS (standby power supply) with a fully charged battery

DPE Rackmount

0123456789

About the Rackmount Disk-Array Processor Enclosure

1

Database

drives for

LIC

(0 thru 2)

The following table describes the DPE’s high-availability

configurations.

Configuration SPs LCCs

Maximum - HA 2

2

2

2

These configurations provide more redundancy, and therefore a

higher degree of system availability. The drive fan packs and SP fan

pack provide redundant cooling for all the configurations listed

above.

Vault

drives for

caching

(0 thru 8)

Power

supplies

2

2

Disk

modules SPSs

3 or more

9 or more

0 (no write caching)

2 (high-availability write caching)

Redundancy in Configurations

1-17

Page 30

About the Rackmount Disk-Array Processor Enclosure

1

What Next?

Continue to the next chapter, which explains how to install a DPE.

1-18

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 31

2

Installing a Rackmount

DPE

This chapter describes the DPE installation requirements and

procedures. Topics in this chapter include:

• Requirements......................................................................................2-1

• Installing a DPE in a Cabinet............................................................2-3

• DPE Powerup and Initialization....................................................2-16

• DPE Powerdown..............................................................................2-16

• Binding Disk Modules into Groups ..............................................2-18

Requirements

Site Requirements

Power To deter mine a DPE’s power requirements, use the power rating on

This section explains site, cabling, and addressing requirements.

For proper DPE operation, the installation site must conform to

certain environmental specifications. These are detailed below and in

Appendix A.

the enclosure label. This rating is the maximum power required for a

fully loaded enclosure. The input current, power (VA), and

dissipation for the DPE are based on the maximum capability of the

power supplies and cooling system to provide internally regulated

power. Typical values will be less, depending on the number and

manufacturer of disk drives. These values represent either the values

for the power cord of a DPE with a single power supply, or the total

values shared by the line cords of two power supplies in the same

DPE, with the division between the power cords and supplies at the

current sharing ratio. If one of the two power supplies fails, the

Installing a Rackmount DPE

2-1

Page 32

Installing a Rackmount DPE

2

remaining supply and cord support the full load. You must use a

rackmount cabinet with ac power distribution, and have main branch

ac distribution that can handle these values for the number of DPEs

and DAEs that you will interconnect.

Cooling The ambient temperature specification is measured at the front door

inlet. The site must have air conditioning of the correct size and

placement to maintain the specified ambient temperature range. The

air conditioning must be able to handle the BTU requirements of the

DPEs and any connected DAEs.

Cabling Requirements

Use optical cables for connections to the external Fibre Channel

environment. Use a copper cable only (not an optical cable) to

connect a DPE to a DAE. The optical cables connect to the optical

GBIC on the SP.

DPE and DAE interconnections should maintain LCC consistency.

That is, one FC loop should connect the DPE’s SP A (which connects

internally to LCC A) and each DAE’s LCC A. The other FC loop

should connect the DPE’s SP B (which connects internally to LCC B)

and each DAE’s LCC B.

Do not leave an unused (that is, dangling) cable connected to any

Fibre Channel port because it may cause excess noise on the Fibre

Channel.

Addressing Requirements

The addressing requirements vary depending on the environment,

fibre port (fabric), or the fibre loop (FC-AL).

Fabric Environments In a fabric environment, the DPE is addressed using the Source_ID

(SID) and the Enclosure Address (EA).

Source_ID

The Source_ID (SID) is a value that a switch in the external Fibre

Channel environment automatically assigns.

Enclosure Address (EA)

Each DPE and DAE on a back-end loop needs a unique enclosure

address (EA) that identifies the enclosure and determines disk

module addresses. The DPE has a fixed EA of 0 that you cannot

change. If you cable any DAEs to the DPE, you might want to set the

nearest DAE’s EA to 1, the next to 2, and so on. The enclosure address

is displayed in lights visible behind the front door.

2-2

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 33

Installing a Rackmount DPE

Loop Environments In an FC-AL environment, the DPE is addressed using the FC-AL

address ID and the enclosure address (EA).

Fibre Channel Arbitrated Loop Address ID (FC-AL Address ID)

Each node (such as an SP) on the Fibre Channel front-end loop must

have a unique Fibre Channel arbitrated loop address ID (FC-AL

address ID). The FC-AL protocol translates the FC-AL address ID into

an 8-bit arbitrated loop physical address (ALPA). You set the SP

FC-AL address ID using switches, as explained later in this chapter.

Enclosure Address (EA)

Each DPE and DAE on a back-end loop needs a unique enclosure

address (EA) that identifies the enclosure and determines disk

module addresses. The DPE has a fixed EA of 0 that you cannot

change. If you cable any DAEs to the DPE, you might want to set the

nearest DAE’s EA to 1, the next to 2, and so on. The enclosure address

is displayed in lights visible behind the front door.

Installing a DPE in a Cabinet

The cabinet in which you will install the DPE(s) must have a full

earth ground to provide reliable grounding. Also, the cabinet should

have its own switchable power distribution. If any DPE you will

install has two power supplies, we suggest that you use a cabinet that

has dual power distribution units, one on each side.

2

WARNING

The rackmount DPE is heavy and should be installed into a rack by

two people. To avoid personal injury and/or damage to the

equipment, do not attempt to lift and install the DPE into a rack

without help from another person.

WARNING

WARNUNG: Das Rackmount-DPE ist schwer und sollte nur von

zwei Personen in einem Gehäuse installiert werden. Zur Vermeidung

von körperlichen Verletzungen und/oder der Beschädigung des

Gerätes, bitte die DPE nicht ohne die Hilfe einer zweiten Person

anheben und einbauen.

We recommend that you use cabinet anti-tip devices, especially if you

are installing or removing a DPE in the upper half of the cabinet

when the lower half is empty.

Installing a DPE in a Cabinet

2-3

Page 34

Installing a Rackmount DPE

2

You install each DPE on two L-shaped mounting rails connected to

the cabinet’s vertical channels.

• Installing the cabinet itself is explained in another manual. For

some standard cabinets, the information is in a cabinet

installation manual shipped with the cabinet.

• Installing the mounting rails in the cabinet is explained in a rails

installation manual shipped with the rails.

Installing DPEs on the Mounting Rails in the Cabinet

1. In the cabinet, set the main circuit breaker switches to the off

position.

2. Attach the clip of the ESD wristband (strap) to bare metal on the

cabinet, and put the wristband around your wrist with the metal

button against your skin.

3. With help, lift the DPE and, from the front of the cabinet, slide the

DPE onto the lowest rails.

2-4

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 35

4. Open the DPE front door as shown below.

Installing a Rackmount DPE

2

Latch

Key

To unlock, turn

180o clockwise.

A.

If the door is locked:

Insert the key in the door’s latch.

Turn the key 180o clockwise.

Remove the key from the latch, if desired. (If you do not

remove the key, it may fall to the floor after you open the door.)

Latch

B.

Depress the door latch.

C.

Lower the door until it is

perpendicular to the

front of the enclosure.

Figure 2-1 Opening the Front Door

CAUTION: Do not force the door open.

If the door snaps off its hinges,

reinstall it by positioning it at a 45

o

angle to the enclosure, and snapping it

into the hinge openings.

Installing a DPE in a Cabinet

2-5

Page 36

Installing a Rackmount DPE

2

5. Secure the DPE to the vertical channels of the cabinet as shown

next.

Fasten the front of the enclosure to

the front channels in the cabinet

using two screws (one per side).

NOTE: Only one hole in the enclosure bracket aligns

with a hole on the channel. The hole you use depends

on where the rails are mounted in the cabinet.

Figure 2-2 Securing the DPE to the Cabinet Front Channel

2-6

6. Secure the rear mounts of the DPE to the back channels of the

cabinet, as shown in Figure 2-3.

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 37

Installing a Rackmount DPE

Fasten the bracket at the back

of each rail to the bottom left

and right of the DPE using two

screws (one per side).

2

Figure 2-3 Securing the DPE to the Cabinet Back Channel

7. Close the DPE front door, as shown in Figure 2-4.

The door must be closed for EMI compliance. Open the door only to

service the DPE.

Installing a DPE in a Cabinet

2-7

Page 38

Installing a Rackmount DPE

_

2

A. Raise the door until

it latches into place.

B. If desired, lock the door as follows:

Insert the key in the door’s latch.

Turn the key 180o counterclockwise.

Remove the key, if desired.

Latch

Figure 2-4 Closing and Locking the Front Door

Latch

Key

To lock, turn 180o

counterclockwise.

2-8

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 39

Installing a Rackmount DPE

8. Perform this step only if you are installing the DPE into an FC-AL

environment. Otherwise, continue to the next step.

To communicate in an FC-AL environment, each SP requires a

unique FC-AL address ID (the front-end address). The FC-AL

protocol translates the address ID into an 8-bit arbitrated loop

physical address (ALPA). Valid Fibre Channel address IDs range

from 0 through 125 (decimal) (0 through 7D hexidecimal).

Each SP’s Fibre Channel address ID must be unique on the Fibre Channel

loop.

At the back of the DPE, for each SP use the SP FC-AL ID switches

(see Figure 2-5) to set the address ID.

2

Installing a DPE in a Cabinet

2-9

Page 40

Installing a Rackmount DPE

2

0

1

2

3

4

5

6

7

8

FC-AL address ID

(decimal) Left switch setting Right switch setting

000

101

0

1

F

E

D

C

B

A

2

3

4

5

6

7

9

8

2-10

.

.

.

.

.

.

15 0 F

16 1 0

.

.

.

.

.

.

31 1 F

32 2 0

.

.

.

.

.

.

125 7 D

Figure 2-5 SP Fibre Channel Arbitrated Loop Address ID Switches (Back of SP)

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

.

.

.

.

.

.

.

.

.

Page 41

9. For access to the ac power inlets, you must remove the drive fan

pack. Remove the drive fan pack as shown below.

Figure 2-6 Removing the Drive Fan Pack

Installing a Rackmount DPE

A.

Grasp the latches on the drive fan pack.

B.

Squeeze the latches together and

pull the pack from the enclosure.

2

10. From the back of the cabinet, plug the ac line cord into each

power supply and turn on the supply’s power, as shown in Figure

2-7.

Installing a DPE in a Cabinet

2-11

Page 42

Installing a Rackmount DPE

2

ac inlet

Bottom power supply Top power supply

ac power cord

ac inlet

(right-angle plug)

Power switch and

circuit breaker

Figure 2-7 Plugging the AC Line Cord into the Power Supply and Turning on the

Power Switch

ac power cord

(right-angle plug

Channel

Channel

Power switch and

circuit breaker

2-12

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 43

Installing a Rackmount DPE

11. Reinstall the drive fan pack on the back of the DPE.

You can install the drive fan pack in either horizontal position.

However, for a consistent image with DAEs, we recommend you

install it with the check light in the upper right corner, as shown

below.

Check light

A. Grasp the latches on the drive fan

module.

B. Squeeze the latches together and

gently push the module into the

enclosure until it clicks into place.

2

Figure 2-8 Installing the Drive Fan Module

12. Attach the Fibre Channel cable from SP A and/or B Port to the

external environment) as shown next.

When working with optical cables, observe the following precautions:

• Keep the covers on all optical cables and optical GBICs until

you are ready to insert the cables. The covers protect the cables

and connectors, and prevent foreign particles, such as dust,

from entering and affecting the connection.

• Do not leave an unused (that is, dangling) cable, connected to

an SP port because it may cause excess noise on the loop.

Installing a DPE in a Cabinet

2-13

Page 44

Installing a Rackmount DPE

2

• Avoid tight bends. If you need to make a 90º bend, do it over 6

to 12 inches.

• Do not use optical cables to support weight. That includes

long cable runs without support.

• Do not pull long runs of cable. It is best to lay the cable in

place or pull only a few feet at a time.

• Run the cables so that they are not stepped on or rolled over

by anything.

A. Remove the protective covers

from each optical GBIC

connector and each fibre

optic cable.

B. Plug the fibre optic cable into

Port A and/or Port B on the

SP.

Cover

2-14

Optical GBIC

connector

B

A

Figure 2-9 Attaching Optical Cables to a DPE

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Cover

Fibre optic cable

Page 45

Installing a Rackmount DPE

13. To expand this DPE, cable its LCC EXP connector to the next

corresponding DAE’s PRI (primary) connector, as shown below.

IMPORTANT: Do not connect a cable between

an LCC in slot A and an LCC in slot B.

2

Primary

connector

Copper cable

Expansion

connector

Figure 2-10 Cabling a DPE to a DAE

14. If the DPE has another SP, LCC, and DAE, connect the DPE’s

other LCC and the DAE’s other LCC as above.

15. To connect additional DAEs, attach a copper cable between the

DAE’s LCC EXP connector and the next DAE’s PRI (primary)

connector (detailed in the DAE Installation Manual). If this DAE

and the next DAE have a second LCC, repeat this step for the

second LCC.

16. Make sure all the slots in the DPE and in each DAE contain either

CRUs or filler modules. At least two disk modules are required in

the DPE. We recommend inserting them in slots 0 and 1.

A. Plug one end of a copper cable

into the expansion (EXP)

connector on an LCC in the DPE.

B. Tighten the two thumb screws

on the cable’s connector.

C. Plug the other end of the copper

cable into the primary (PRI)

connector on the matching LCC

in the DAE.

D. Tighten the two screws on the

cable’s connector.

17. In the cabinet, set the main circuit breaker switches to the on

position.

The DPE and any DAEs in the cabinet will power up.

Installing a DPE in a Cabinet

2-15

Page 46

Installing a Rackmount DPE

2

DPE Powerup and Initialization

The only power switches on a DPE are those on the power supply,

which are normally covered by the drive fan pack. As a result, a DPE

is always active.

When ac power is initially applied to a DPE, the disk drives power up

and spin up in a specified sequence. The maximum delay is 48

seconds for the last drive to start spinning in a DPE, and 84 seconds

for the last drive to start spinning in a DAE. The same delays occur

when you insert a drive while a DPE is powered up.

DPE Powerdown

If DPE (with an SPS option) is powered down abnormally (e.g., a

brown out or ac failure), data is saved to the storage-system vault

disks, and not lost. However, when the DPE is powered back up

again, it may take longer to come online.

2-16

Turning Off the Power 1. Stop all I/O activity to the DPE.

Stopping the I/O allows the SP to destage cache data, and may take some

time. The length of time will be based on criteria such as the amount of cache,

the amount of data in the cache, the type of data in the cache, and the target

location on the disks.

2. If the server connected to the DPE is running the UNIX®

operating system, unmount the file systems.

3. Shut off power to the ac distribution strips that supply the DPE.

The power in the distribution strips may be controlled by a circuit

breaker located inside the cabinet (if the cabinet has such

breakers) or externally to the cabinet.

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 47

Installing a Rackmount DPE

Power switches

ac distribution strips

SP B

SP A

SPS power switches

4. If the DPE has SPS protection, use the power switch on each SPS

to turn off power.

2

When you turn off power to a storage system with an SPS, the On

Battery light may come on for a maximum of 90 seconds during

which time the DPE will continue to run. This is a normal

condition. Wait for the light to go off and the fans to stop before

proceeding with further service to the storage system.

Never remove the fan pack and then shut off the power supply to shut

down an DPE. Doing that effectively cuts out the SPS and write cache

data cannot be saved to the vault drives, which results in a cache dirty

condition (data loss). When that happens, LUNs become inaccessible and

the unsolicited event log displays a message similar to:

“Enclosure 0 Disk 5 0x90a (Can’t Assign - Cache Dirty)

0 0xafb40 0x14362c.” Navisphere Manager or Supervisor will show

that the inaccessible LUNs are unowned. Contact your service provider if

this situation occurs. The LUNs may need to be unbound and rebound.

Powering On Reverse the steps in the previous section to power up the DPE.

DPE Powerdown

2-17

Page 48

Installing a Rackmount DPE

2

Binding Disk Modules into Groups

After cabling a DPE and any DAEs, you can bind disk modules into

groups and set up storage-system caching. To bind disk modules and

set up caching, you will use a utility described in the server setup or

installation manual.

2-18

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 49

3

Servicing and

Upgrading a DPE

This chapter describes how to monitor DPE status, handle CRUs, and

replace or add a CRU. Topics in this chapter include:

• Monitoring DPE Status .....................................................................3-1

• Handling CRUs ..................................................................................3-4

• Power Issues and CRUs ....................................................................3-4

• Avoiding Electrostatic Discharge (ESD) Damage..........................3-6

• Precautions When Removing, Installing, or Storing CRUs .........3-7

• Precautions When Handling Optical Cables .................................3-8

• Replacing or Adding a Disk Module ..............................................3-9

• Replacing the SP Fan Pack..............................................................3-14

• Replacing an Optical GBIC.............................................................3-17

• Removing an SP or an SP Filler Module.......................................3-21

• Installing or Replacing an SP Memory Module ..........................3-24

• Installing an SP or SP Filler Module..............................................3-26

• Replacing or Adding an LCC Module..........................................3-30

• Replacing the Drive Fan Pack ........................................................3-34

• Replacing or Adding a Power-Supply Module...........................3-36

Monitoring DPE Status

Status lights on the DPE and its CRUs indicate error conditions.

These lights are visible outside the DPE. Some lights are visible from

the front, and the others from the back. The following figure and table

describes the status lights.

Servicing and Upgrading a DPE

3-1

Page 50

Servicing and Upgrading a DPE

3

The Check status light for the SP fan pack is not visible with the fan pack

cover in place. If the DPE system Check light is on with no other Check light

on, remove the fan pack cover, as shown on page 3-14, to examine the SP fan

pack Check status light.

Enclosure address light

(0 for a DPE)

1023 4 5 6 7 8 9

Figure 3-1 Status Lights Visible from the Front of the DPE

Table 3-1 Status Lights Color Codes, Front of DPE

Disk module status lights

(two per module)

Check

Active

DPE status lights

Check

Light Quantity Color Meaning

Enclosure Address 1 Green On to indicate enclosure address zero.

DPE Check 1 Amber On when any fault condition exists; if the fault is not

obvious from another fault light on the front, look at

the back of the DPE.

SP Fan Pack Check 1 Amber On when the SP fan pack is faulty (not visible with

fan pack cover on; to remove cover, see page 3-14).

Power

3-2

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 51

Table 3-1 Status Lights Color Codes, Front of DPE (continued)

Light Quantity Color Meaning

Servicing and Upgrading a DPE

3

Disk Active 1 per disk module

slot

Green Off when the module slot is empty or contains a filler

module.

Flashing (mostly off) when the drive is powered up

but not spinning; this is a normal part of the spin-up

sequence, occurring during the spin-up delay of a

slot.

Flashing (at a constant rate) when the disk drive is

spinning up or spinning down normally.

On when the drive is spinning but not handling any

I/O activity (the ready state).

Flashing (mostly on) when the disk drive is spinning

and handling I/O activity.

Disk Check 1 per disk module

slot

Amber On when the disk module is faulty or as an

indication to remove the disk module.

DPE Active 1 Green On when the DPE is powered up.

DPE Check 1 Amber On when any fault condition exists; if the fault is not

obvious from another fault light on the front, look at

the back of the DPE.

SP Fan Pack Check 1 Amber On when the SP fan pack is faulty (not visible with

fan pack cover on; to remove cover, see page 3-14).

Table 3-2 Status Lights Color Codes, Back of DPE

Light Quantity Color Meaning

SP Active 1 per SP Green On when the SP is operating normally

or flashing when firmware is being loaded.

SP Check 1 per SP Amber On when an SP fault condition exists.

LAN Link/Activity 1 per SP Green On when there is a valid Ethernet connection; blinks

during Ethernet activity.

LAN Speed 1 per SP Amber On when the Ethernet connection is a 100Base-TX

connection.

LCC Active 1 per LCC Green On when the LCC is powered up.

LCC Check 1 per LCC Amber On when either the LCC or a FC-AL connection is

faulty.

Power Supply Active 1 per supply Green On when the power supply is operating.

Monitoring DPE Status

3-3

Page 52

Servicing and Upgrading a DPE

3

Table 3-2 Status Lights Color Codes, Back of DPE (continued)

Light Quantity Color Meaning

Power Supply Check 1 per supply Amber On when the power supply is faulty or is not

Cooling Check 1 per supply Amber Flashing when multiple fans in the drive fan pack

Drive Fan Pack Check 1 on fan pack Yellow On when a fan in the drive fan pack is faulty.

Handling CRUs

receiving ac line voltage.

are faulty or the drive fan pack is removed.

The DPE powers down the SPs and disk drives

when the fault persists for more than about two

minutes.

• If the DPE Check light is on, you should look at the other Check

lights to determine which CRU(s) are faulty. If the Check light for

a CRU remains on, replace the CRU as soon as possible.

• If a CRU fails in a DPE that is highly available, the DPE’s high

availability and write cache functionality (if any) will be

compromised until you replace the faulty CRU.

This section describes the precautions that you must take, and the

general procedures you must follow when removing, installing, and

storing CRUs.

Power Issues and CRUs

3-4

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

The DPE is designed to be powered up at all times and hot repairable.

Its front door should be closed and each of its compartments should

contain a CRU or filler panel to ensure EMI compliance and proper

air flow over the CRUs.

While the DPE is powered up, you can service or replace any CRU,

although removing an active LCC or SP will affect operating system

access to the LUNs it controls. Do not remove a faulty CRU until you

have a replacement available.

You can remove the drive fan pack or SP fan pack while the DPE is powered

up. If the pack is removed for more than two minutes, the SPs and disk

modules power down. The SPs and disk modules power up when you

reinstall the drive or SP fan pack.

Page 53

Servicing and Upgrading a DPE

Since you can replace or add any CRU without sliding the DPE out of

the cabinet, you do not have to use cabinet anti-tip devices when you

upgrade or service a DPE.

If you need to power down a DPE, either:

• Shut down the main ac lines to the DPE, or

• Remove the drive fan pack (described on page 3-35) and set the

power switch on each power supply to the off (O) position.

3

Handling CRUs

3-5

Page 54

Servicing and Upgrading a DPE

3

Avoiding Electrostatic Discharge (ESD) Damage

When you replace or install CRUs, you can inadvertently damage the

sensitive electronic circuits in the equipment by simply touching

them. Electrostatic charge that has accumulated on your body

discharges through the circuits. If the air in the work area is very dry,

running a humidifier in the work area will help decrease the risk of

ESD damage. You must follow the procedures below to prevent

damage to the equipment.

Read and understand the following instructions.

• Provide enough room to work on the equipment. Clear the work

site of any unnecessary materials or materials that naturally build

up electrostatic charge, such as foam packaging, foam cups,

cellophane wrappers, and similar items.

• Do not remove replacement or upgrade CRUs from their

antistatic packaging until you are ready to install them.

• Gather together the ESD kit and all other materials you will need

before you service a DPE. Once servicing begins, you should

avoid moving away from the work site; otherwise, you may build

up an electrostatic charge.

3-6

• Use the ESD kit when handling any CRU. If an emergency arises

and the ESD kit is not available, follow the procedures in the

“Emergency Procedures (Without an ESD Kit)” section.

• An ESD wristband (part no. 129002319) is supplied with your

DPE. To use it, attach the clip of the ESD wristband (strap) to any

bare (unpainted) metal on the DPE enclosure; then put the

wristband around your wrist with the metal button against your

skin.

Emergency

Procedures (Without

an ESD Kit)

In an emergency when an ESD kit is not available, use the following

procedures to reduce the possibility of an electrostatic discharge by

ensuring that your body and the subassembly are at the same

electrostatic potential.

These procedures are not a substitute for the use of an ESD kit. Follow them

only in the event of an emergency.

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 55

Servicing and Upgrading a DPE

• Before touching any CRU, touch a bare (unpainted) metal surface

of the enclosure.

• Before removing any CRU from its antistatic bag, place one hand

firmly on a bare metal surface of the enclosure, and at the same

time, pick up the CRU while it is still sealed in the antistatic bag.

Once you have done this, do not move around the room or contact

other furnishings, personnel, or surfaces until you have installed

the CRU.

• When you remove a CRU from the antistatic bag, avoid touching

any electronic components and circuits on it.

• If you must move around the room or touch other surfaces before

installing a CRU, first place the CRU back in the antistatic bag.

When you are ready again to install the CRU, repeat these

procedures.

Precautions When Removing, Installing, or Storing CRUs

Use the precautions listed below when you remove, handle, or store

CRUs.

3

• Do not remove a faulty CRU until you have a replacement

available.

• Handle a CRU only when using an ESD wristband as follows:

attach the clip of the ESD wristband to the ESD bracket or bare

metal on the DPE enclosure, and put the wristband around your

wrist with the metal button against your skin.

• Handle CRUs gently. A sudden jar, drop, or vibration can

permanently damage a CRU.

• Never use excessive force to remove or install a CRU.

• Store a CRU in the antistatic bag and specially designed shipping

container in which you received it. Use that container if you need

to return the CRU for repair.

• Maintain the location where you store CRUs within the limits

specified in Appendix A.

Precautions When Removing, Installing, or Storing CRUs

3-7

Page 56

Servicing and Upgrading a DPE

3

Precautions When Handling Optical Cables

When working with optical cables, observe the following

precautions:

• Keep the covers on all optical cables and optical GBICs until you

are ready to insert the cables. The covers protect the cables and

connectors, and prevent foreign particles, such as dust, from

entering and affecting the connection.

• Avoid tight bends. If you need to make a 90º bend, do it over 6 to

12 inches

• Do not use optical cables to support weight. That includes long

cable runs without support.

• Do not pull long runs of cable. It is best to lay the cable in place or

pull only a few feet at a time.

• Run the cables so that they are not stepped on or rolled over by

anything.

3-8

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 57

Replacing or Adding a Disk Module

Servicing and Upgrading a DPE

3

!

CAUTION

When replacing or adding a disk module, observe the following:

• Remove or install disk modules only while the storage system

is powered up.

• Do not move a disk module that is part of an existing LUN to

another slot in the storage system. If you do, you risk

destroying the storage system beyond recovery, or data loss at

the very least. Each disk module has LUN-identifying

information assigned to it when it is bound. Moving it to

another slot can make the information stored on the disk

module from the original LUN inaccessible. If you must move a

disk module to another slot, unbind the LUN first; unbinding

destroys all data on the LUN.

• A disk module must be inserted all the way or removed

entirely. Do not leave a disk module partially removed except

for periods when you are allowing it to spin down. A disk

module being inserted or removed may be damaged by a

partially removed adjacent module.

• Handle a disk module gently and use an ESD wristband. Do

not remove a faulty disk module until you have a replacement

module (with the same part number) or a filler module

available. The part number (PN005xxxxxx) appears on the top or

bottom of the module. A replacement disk module should have

the same format (52- byte-per-sector format is required for

arrays) and the same capacity (size and speed) as the disk it is

replacing. An add-on can be any capacity but must be the

520-byte-per-sector format. LUNs should be created using disk

modules of equal size and speed.

• When removing or installing multiple disk modules, wait for

the activity lights on all other disk modules to resume a steady

flicker before removing or installing the next disk module. The

activity lights show that the Core Software has rediscovered the

FC loop.

If you want to use a previously used disk module as a spare, contact your

service provider for assistance.

Replacing or Adding a Disk Module

3-9

Page 58

Servicing and Upgrading a DPE

3

You must open the DPE’s front door to access the disk modules. The

door must be closed for EMI compliance when the DPE is powered

up. Open it only to replace or add a disk module.

Removing a Disk or

Disk Filler Module

Latch

Key

To unlock, turn

180o clockwise.

1. Unlock and open the front door as shown below.

A.

If the door is locked:

Insert the key in the door’s latch.

Turn the key 180o clockwise.

Remove the key from the latch, if desired. (If you do not

remove the key, it may fall to the floor after you open the door.)

Latch

B.

Depress the door latch.

C.

Lower the door until it is

perpendicular to the

front of the enclosure.

3-10

CAUTION: Do not force the door open.

If the door snaps off its hinges,

reinstall it by positioning it at a 45

angle to the enclosure, and snapping it

into the hinge openings.

Figure 3-2 Unlocking and Opening the Front Door

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

o

Page 59

2. Locate the slot where you want to install the new or replacement

disk module.

3. Remove the disk or disk filler module from the slot as shown

below.

Figure 3-3 Removing a Disk Filler Module

Servicing and Upgrading a DPE

3

Latch

A. Grasp the filler module

handle so your thumb is on

the latch.

B. Push the latch, and pull

the module from its slot.

Figure 3-4 Removing a Disk Module

After removing a disk module, wait for the activity lights on the other

disk modules to resume a steady flicker before removing another disk

module. The activity lights show that the Core Software has rediscovered

the FC loop.

Latch

A.

Check the light.

B.

Grasp the disk module’s handle

so your thumb is on the latch.

C.

If the active light is on steadily, push

the latch, and slowly pull the module

about 3 cm (1 in) from its slot. Wait 30

seconds for the disk to stop spinning.

Then remove the module.

If the active light is off or mostly off,

you do not need to wait for the disk to

stop spinning. Push the latch, and

slowly pull the module from its slot.

Replacing or Adding a Disk Module

3-11

Page 60

Servicing and Upgrading a DPE

3

Continue to the next section to install the new or replacement

disk module.

Installing a Disk

Module

Figure 3-5 Installing a Disk Module

1. Gently insert the module as follows:

Latch

A. Grasp the disk module’s handle.

B. Align the module with the

guides in the slot.

C. Gently push the module into the

slot until the latch engages.

The disk module Active light flashes to reflect the spin-up

sequence (see page 3-2).

After inserting a disk module, wait for the activity lights on the other

drives to resume a steady flicker before inserting another module. The

activity lights show that the Core Software has rediscovered the FC loop.

3-12

2. Remove and store the ESD wristband.

The door must be closed for EMI compliance when the DPE is powered

up. Open it only to replace or add a disk module.

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 61

3. Close and lock the front door as shown below.

A. Raise the door until

Servicing and Upgrading a DPE

3

it latches into place.

B. If desired, lock the door as follows:

Insert the key in the door’s latch.

Turn the key 180o counterclockwise.

Remove the key, if desired.

Latch

Latch

Key

To lock, turn key 180o

counterclockwise.

Figure 3-6 Closing and Locking the Front Door

Replacing or Adding a Disk Module

3-13

Page 62

Servicing and Upgrading a DPE

3

Replacing the SP Fan Pack

!

Removing the SP Fan

Pack

CAUTION

Handle a fan pack gently and use an ESD wristband. Do not

remove a faulty fan pack until you have a replacement available.

You can remove the fan pack while the DPE is powered up. If the

pack is removed for more than about two minutes, the SPs and disk

modules power down. The SPs and disk modules power up when

you reinstall the SP fan pack.

1. At the front of the DPE, grasp the SP fan pack cover at its sides

and pull it from its ballstud mounts as shown below.

3-14

Ballstud

Figure 3-7 Removing the SP Fan Pack Cover

2. Remove the fan pack as shown next.

EMC Fibre Channel Disk-Array Processor Enclosure (DPE) Hardware Reference

Page 63

A.

Slide the latches on the fan pack

inward as shown, and hold them in.

Servicing and Upgrading a DPE

B.