Embraco North America 510 BTU User Manual

AFTERMARKET

PRODUCT LINE

EM / F / NE / NEK / NJ / NT / NTU / T

CATALOG

EMBRACO IN BRIEF

04

05

09

06

14

24

HIGH EFFICIENCY AND GREEN SOLUTIONS

PRODUCT RANGE

COMPRESSOR SELECTION

GENERAL DATA AND PERFORMANCE

EXTERNAL VIEWS AND WIRING DIAGRAMS

3

EMBRACO IN BRIEF

More than 11,500 employees

More than

Production capacity of over

More than

More than

Business conducted in more than

400 professionals in R&D

34 million compressors per year

400 million products produced to date

1,000 patents worldwide

80 countries

R&D laboratories on 4 continents

EMBRACO specializes in cooling solutions and is the world leader in the hermetic

compressor market. Our mission is to provide innovative solutions for a better quality

of life, with a strong focus on technological excellence and sustainability.

Technological leadership, operational excellence and sustainability are key pillars in EMBRACO’s

organization that set us apart from other companies in the world market. Our products are

preferred by major automakers and leading home appliance manufacturers; manufacturers of

commercial refrigeration equipment specify our products in their design.

With global operations and production capacity exceeding 34 million units per year, Embraco

offers solutions that are unique in their innovation and low energy consumption. Our factories

and offices, located in the United States, Brazil (corporate headquarters), Mexico, China, Italy

and Slovakia employ more than 11,500.

Embraco strives for energy efficiency in all of our processes and products. We build strong

relationships with the communities in which we operate. We are the absolute leader in

this regard, offering products that meet more restrictive international standards for energy

consumption than our competitors.

As a worldwide leader, EMBRACO anticipates market changes, and in doing so, is in a state

of permanent transformation. We continuously assess our processes in order to maintain

our leadership within the industry and promote growth, without forgetting the pillars of

our organization.

4

HIGH EFFICIENCY

Energy efficiency drives our product development. This means

producing compressors that consume less energy and less raw

material in manufacturing, while at the same time maintaining

Embraco brand quality. Thus, we continually invest in research

and development to create products that are increasingly more

economical, quieter and environmentally friendly.

As a result of efforts to increase energy efficiency in our products,

and to surpass our customers’ highest expectations, we have

developed Embraco Fullmotion – a compressor that varies the

cooling capacity according to the need, providing a reduction in

energy consumption by up to 40%.

We have a full product portfolio that offers compressors of the

most diverse ranges of efficiency. We are a global benchmark in

developing solutions that meet the most stringent international

standards regarding energy consumption. With a commitment to seek

continuous product and process improvement, each new generation of

Embraco compressors is more efficient than the previous one.

GREEN SOLUTIONS

Embraco has always been committed to offering solutions to the

market that go beyond the traditional. For example, we have been

at the forefront in launching products compatible with the most

environmentally advanced refrigerant gases. We were the first

organization to produce compressors that use alternative fluid

refrigerants, such as propane (R290), to replace CFCs. This natural

refrigerant has important ecological advantages, since it

does not contribute to ozone layer deterioration, nor

to the greenhouse effect. Furthermore, its noise

levels are low, while its efficiency rate gain

and cooling capacity is quite high.

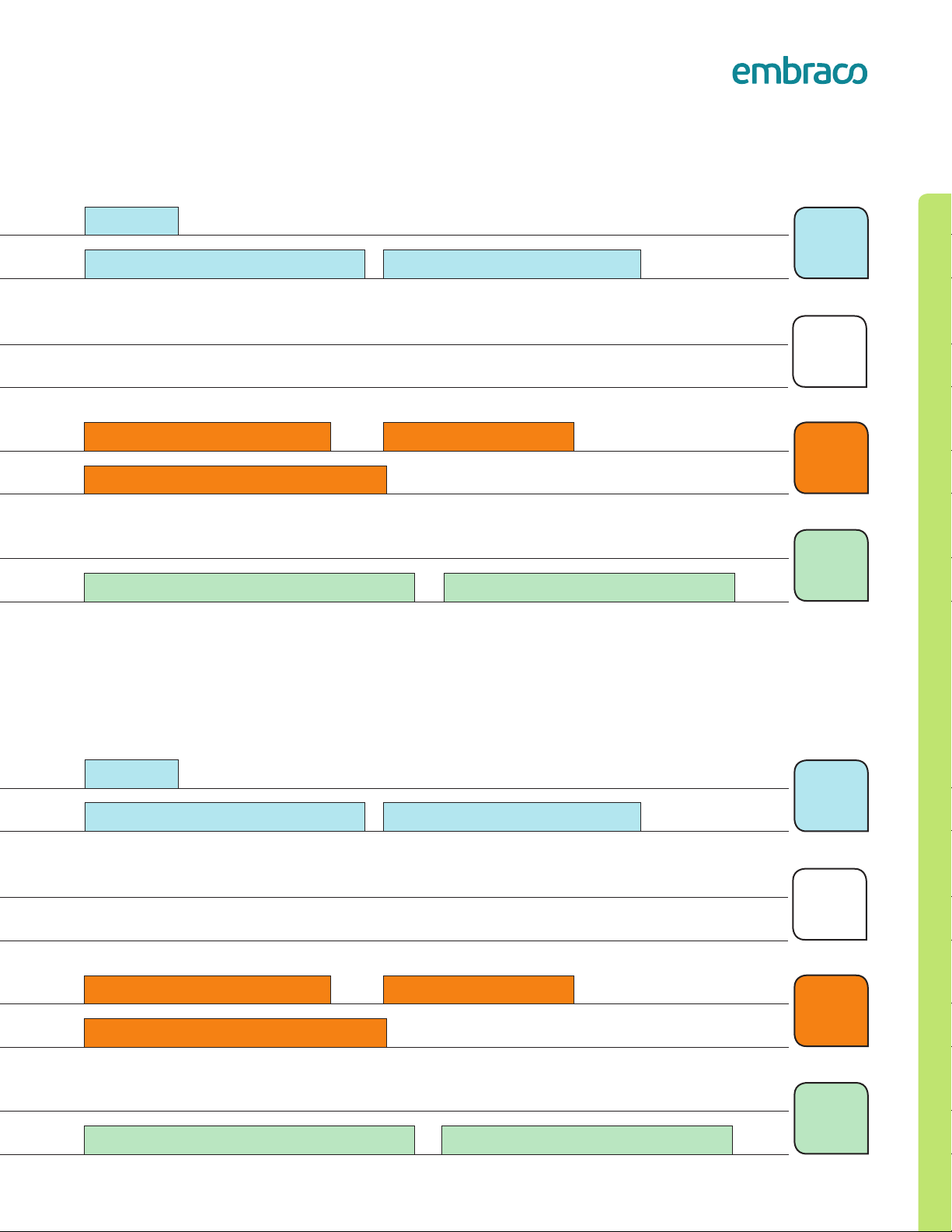

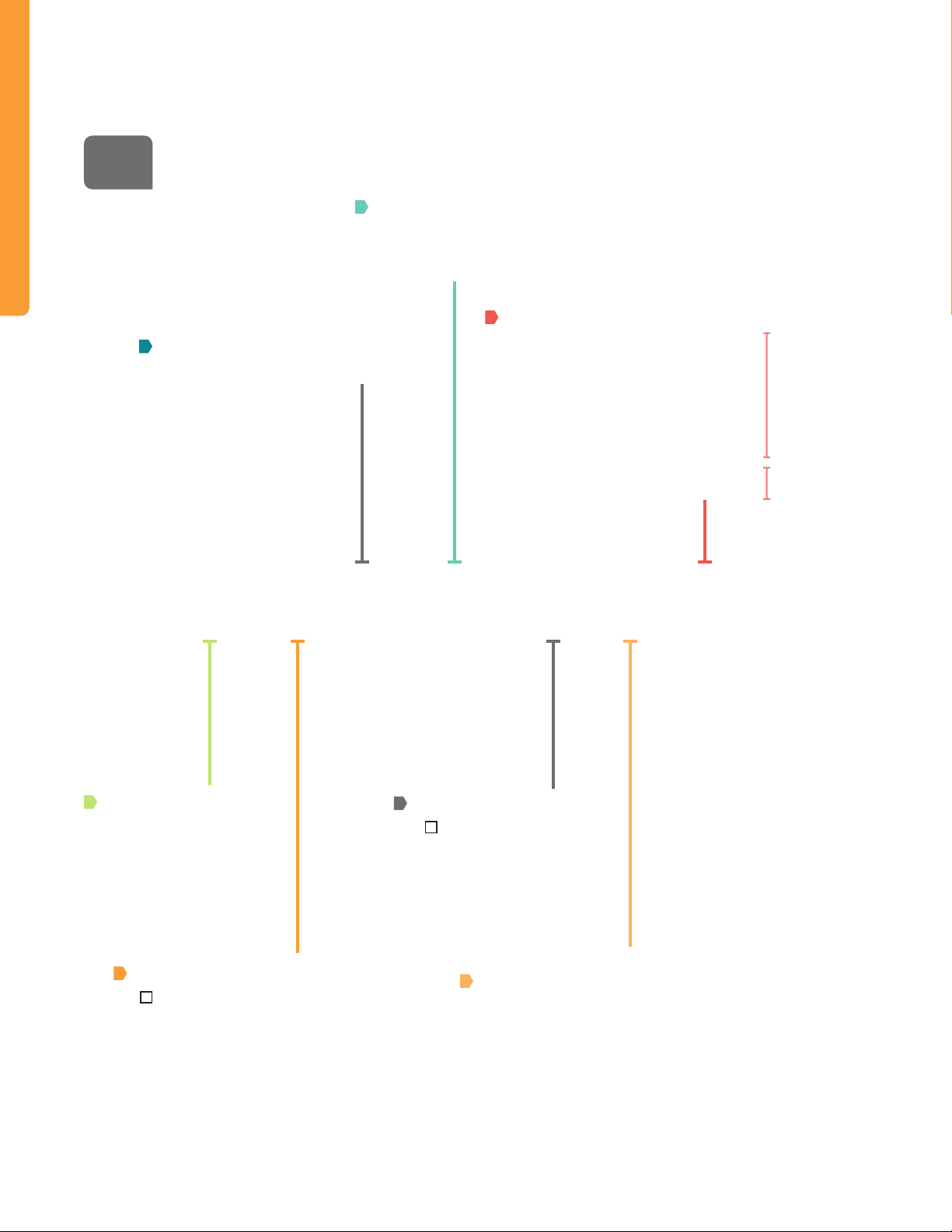

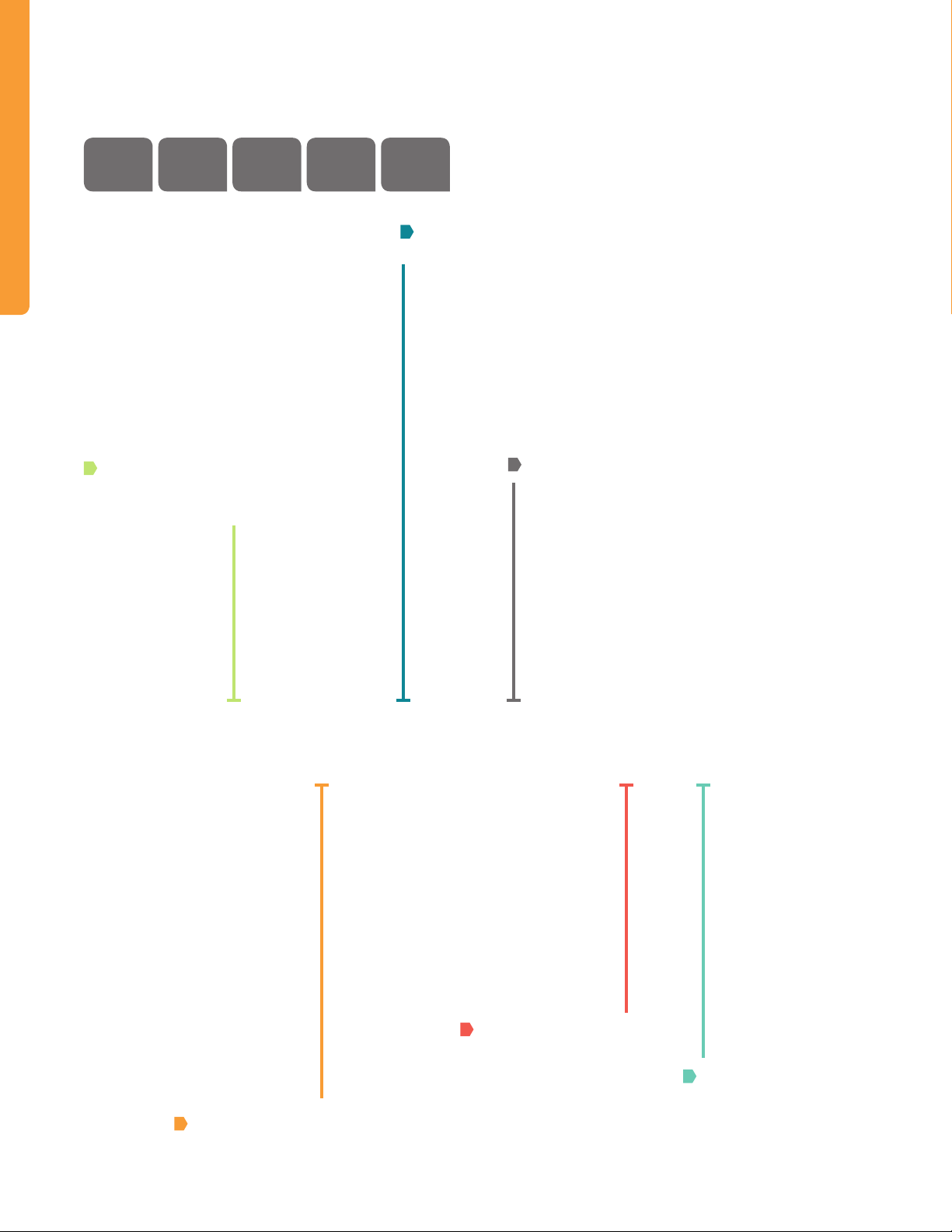

CAPACITY AND EFFICIENCY RANGE

Capacity Range BTU/H

R-134a

BLEND

R-404A

R-22

LBP

HBP

LBP

HBP

LBP

HBP

LBP

HBP

340

1480

350

EM

EM

EM

510

635 756

1775

630

2760

2791

F

F

1190

F

F

5300

1350

5000

950

1762

NE

1212

4389

4378

NEK

NEK

1706

5960

2493

NEK

NE

6855

6636

Efficiency Range BTU/Wh

R-134a

BLEND

R-404A

R-22

LBP

HBP

LBP

HBP

LBP

HBP

LBP

HBP

3.51

8.62

4.12

EM

EM

4.45 3.45

EM

4.45

9.03

3.74

7.64

5.53

F

4.33

F

F

F

4.7

9.46

8.24

3.73

6.73

NE

4.24

3.86

6.87

NEK

NEK

4.19

8.01

4.57

NEK

NE

4.72

7.61

6

1595

6401

NT

1595

NT

8414 9090

NJ

11130

LBP

R-134a

HBP

2628

7332

7452

4.25

7.54

NT

4.25

NT

NT/NTU

NT

LBP

BLEND

HBP

5710

4198

NJ

4502

LBP

R-404A

18318

HBP

LBP

R-22

T

10400

11520

NJ

19366

HBP

LBP

R-134a

8.18 7.63

NJ

8.14

HBP

4.03

6.03

NT

NT/NTU

LBP

BLEND

HBP

4.86

4.06

NJ

4.45

LBP

R-404A

9.7

HBP

LBP

R-22

T

7.73

7.92

NJ

8.216.9

HBP

7

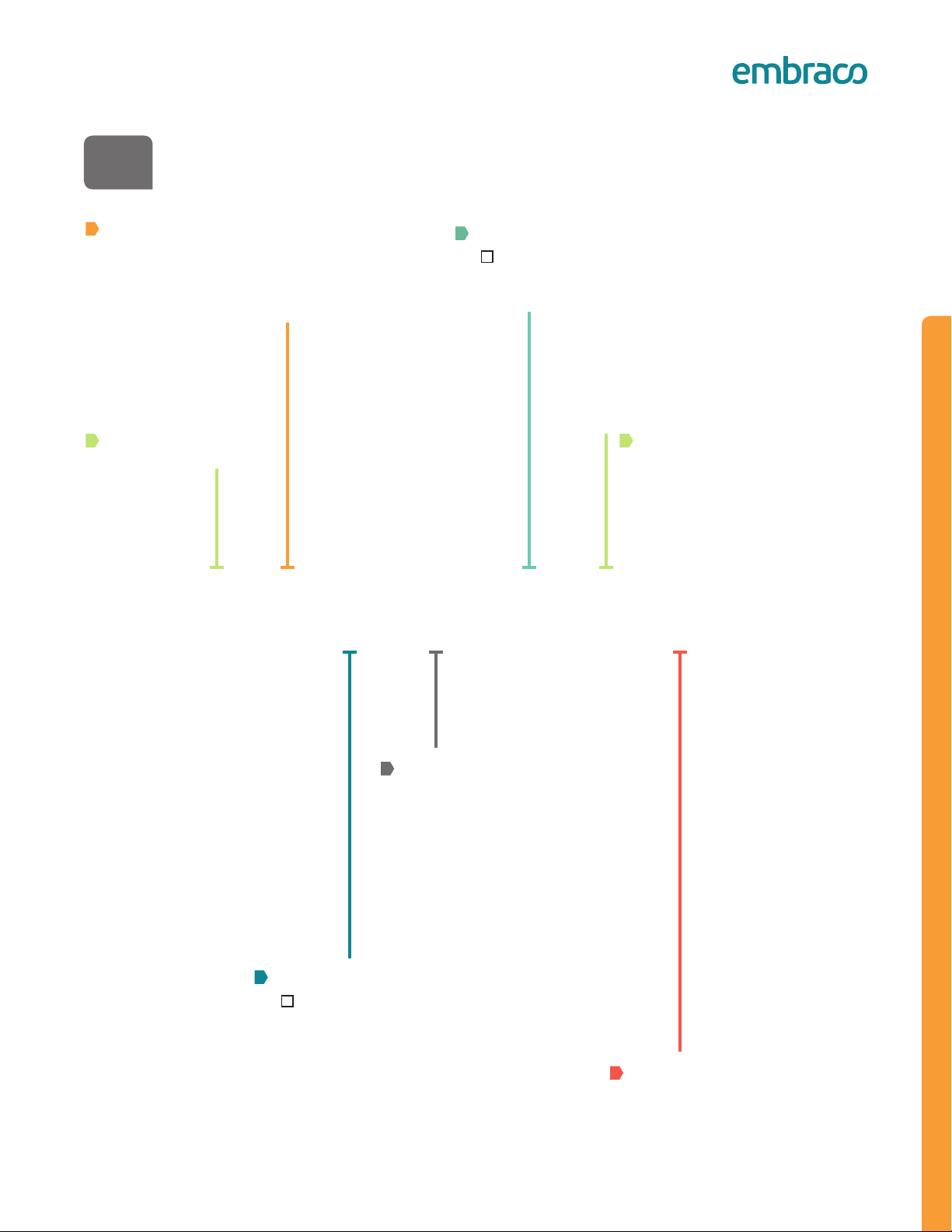

APPLICATIONS & TEST CONDITIONS

Applications

L/MBP

LBP

(Low Back Pressure)

Evaporating temperatures

between -31°F and 14°F

Applications:

refrigerators, frozen food

cabinets, frozen food

display cases, display

windows, etc.

L/M/HBP

(Low/Medium/High Back

Pressure)

Evaporating temperatures

between -31°F and 59°F

Applications:

ice makers, etc.

M/HBP

(Medium Back Pressure)

Evaporating temperatures

between 14°F and 32°F

Applications:

fresh food cabinets,

bottle coolers, ice makers,

dehumidifiers

coolers and freezers, etc.

, walk-in

(Low/Medium Back

Pressure)

Evaporating temperatures

between -31°F and 23°F

Applications:

commercial display

counters, and drinking

fountains, etc.

HBP

(High Back Pressure)

Evaporating temperatures

between 32°F and 59°F

Applications:

fresh food cabinets,

dehumidifiers, etc.

Test Conditions

LBP LBP

Evap.:

Cond.:

Liq.:

Amb.:

Suct.:

8

-10 -1045 2045 45

130 120130 120130 130

90 12090 120115 130

90 9590 9595 95

90 4090 4095 65

Rating Point (°F)

ASHRAE ARI

HBP32 MBPHBP46 HBP

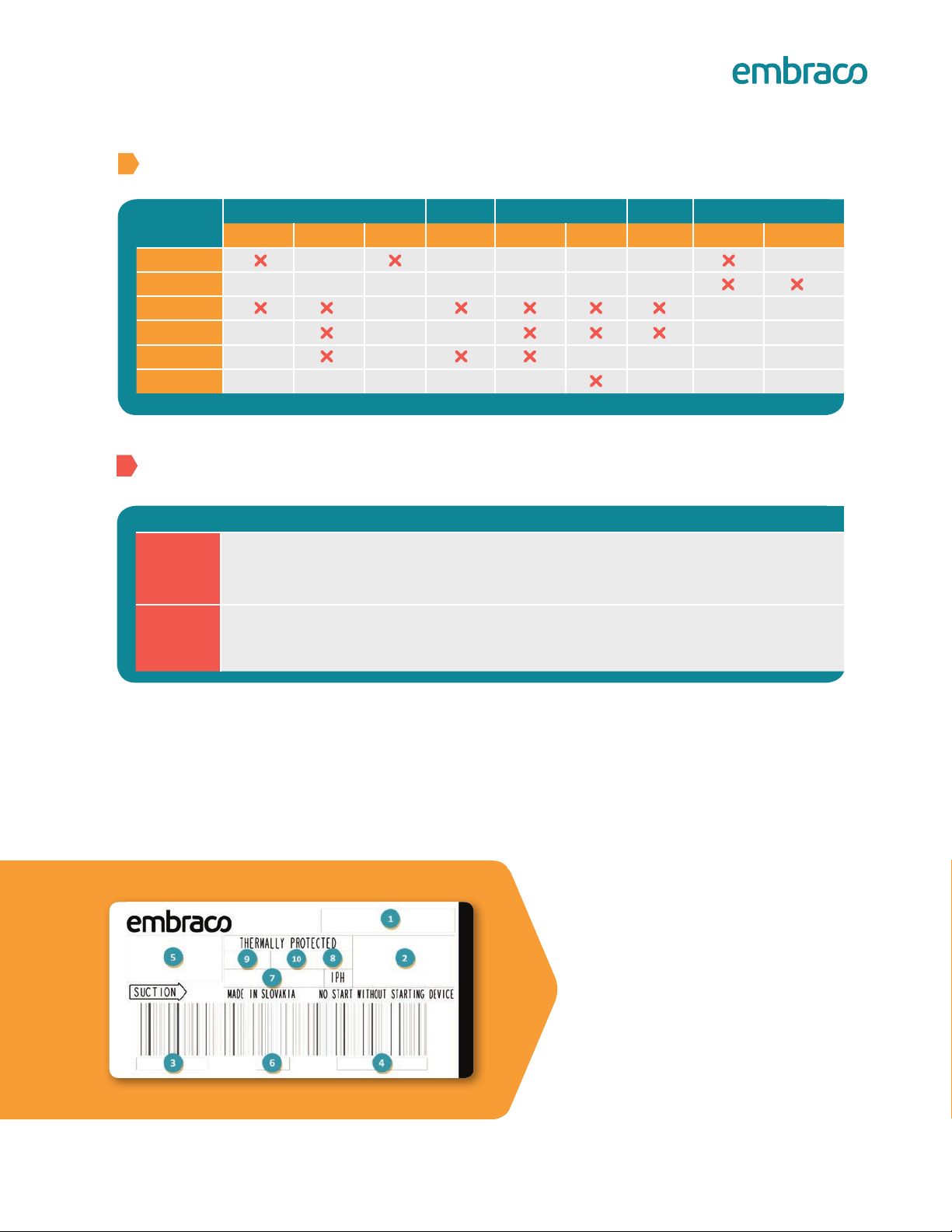

COMPRESSOR SELECTION

Families

FAMILIES

EM x

F

NE

NJ

NT

T

R-134a R-404A Blend R-404A R-134a R-22 R-22 R-134a Blend

LBP MBP HBP M/HBP L/M/HBP

Electrical Motor Starting Torque

DESCRIPTION

LST

HST

Low Starting Torque: LBP-MBP-HBP-AC applications with RSIR-RSCR-PSC electric motors.

Execution suitable for systems with a capillary tube and with balanced pressures at start up.

High Starting Torque: LBP-MBP-HBP applications with CSIR-CSR electric motors. Execution

suitable for systems with expansion valve or capillary tube, with unbalanced pressures at start up.

IDENTIFICATION LABEL

1 - Compressor model

2 - Supply voltage

3 - Bill of materials code

4 - Serial number

5 - Agency approval marks

6 - Date code or production date

7 - Oil type and quantity

8 - Refrigerant type

9 - Current consumption (Rated Load

Amperage, when applicable)

10 - Locked Rotor Amperage (when

applicable)

9

NOMENCLATURE

EM

Compressor capacity in

BTU/H – 60Hz – ASHRAE

check point divided by 10

Mechanical Kit

S - Standard mechanical kit

Electrical Equipment

P - PTC + Run Cap (optional)

R - Relay

C - PTC + Run Cap (mandatory)

S - PTC + Run Cap + Start Cap

V - PTC + Run Cap + Start Cap

(optional)

X - Relay + Start Cap (mandatory)

LST

HST

EM I S 30 H H R

Compressor Family

EM

Product Generation

- Standard Generation

I - 1 Generation

T - 2 Generation

U - 3 Generation

Y - 4ʰ Generation

Z - 5ʰ Generation

X - 6ʰ Generation

Refrigerant Code

- Blends

H - R-134a

Efficiency Level

N - Standard efficiency (LBP)

J - Intermediate efficiency (LBP)

E - Improved efficiency 1 generation (LBP)

S - Improved efficiency 2 generation (LBP)

H - Standard efficiency (L/M/HBP)

D - Standard efficiency (HBP)

B - Standard efficiency (M/HBP)

10

NOMENCLATURE

F

Electrical System

F - Relay / External Protector

Relay / External Protector

Start Cap (optional)

Compressor Family

F

F F I 12 H B X

Refrigerant Code

- Blends

H - R-134a

Application

B - L/M/HBP

Approximate compressor

displacement in cm³ for FFC:

approximate capacity in BTU/H –

60 Hz ASHRAE – Check point

divided by 10

Efficiency Level

- Standard efficiency

I - Improved efficiency

st

1

U - Improved efficiency

2

(for commercial refrigeration)

C - Improved efficiency

3

generation

nd

generation

rd

generation

Starting Characteristic

K - LST (Low Starting Torque)

X - HST (High Starting Torque)

11

NOMENCLATURE

NE NJ

Compressor Families

NE / NEK / NT / T / NJ

NEK

NT T

Application Code

1. LBP – LST

2. LBP – HST

3. M/HBP – LST

4. M/HBP – HST

5. M/HBP – LST

6. M/HBP – HST

Cooling Capacity

The first digit is the number of

zeros that must be added to

the last two digits to obtain the

cooling capacity (approx.) in

kcal/h at 50 Hz.

E.g.: 144 = 440 kcal/h at 50 Hz.

12

NE K 6 215 Z V

Refrigerant Code

Z - ZX R-134a

GK - GJ R-404A

E - F - G R-22

Efficiency Level

IPR Valve

Available for

some models

Loading...

Loading...