Page 1

SBC8600B

Single Board Computer

Quick Start Guide

Version 1.1

23rd Jan 2014

Page 2

Copyright Statement:

SBC8600B and its related intellectual property are owned by

Shenzhen Embest Technology Co., Ltd.

Shenzhen Embest Technology has the copyright of this document and

reserves all rights. Any part of the document should not be modified,

distributed or duplicated in any approach and form without prior

written permission issued by Embest Technology Co., Ltd.

Revision History:

Version

Date

Description

1.0

21/12/2012

Original Version

1.1

23/01/2014

Localisation

Page 3

Table of Contents

1 Product Overview .............................................................. 1

2 Quick Start Guide .............................................................. 2

2.1 For Hardware Development: ............................................. 2

2.2 For Software Development: .............................................. 2

2.3 For Marketing: ................................................................ 3

2.4 For Learning: .................................................................. 3

2.5 Kit Contents .................................................................... 4

3 Establishing a Development Environment.......................... 5

3.1 Establishment of Hardware Environment ............................ 5

3.2 Establishment of Software Environment ............................. 6

3.2.1 Preparation of Windows XP System Environment ........................... 6

4 Operating System Quick Start Guide ............................... 10

4.1 Quick operation of the Linux system ................................ 10

4.1.1 Booting from a TF card ............................................................. 10

4.1.2 Boot-up From NAND Flash ........................................................ 14

4.1.3 U-boot configuration ................................................................ 16

4.2 Quick Operation of the WinCE System .............................. 17

4.2.1 Boot-up From TF Card .............................................................. 17

4.2.2 Booting-up From NAND Flash .................................................... 22

4.3 Quick Operation of the Android System ............................ 23

Appendix 1: ESD Precautions & Handling Procedures ......... 25

Appendix 2: Technical support & Warranty ........................ 26

2.1 Technical support service ................................................ 26

2.2 Maintenance service clause ............................................. 27

Page 4

2.3 Basic guidelines for protection and maintenance of LCDs .... 28

2.4 Value Added Services ..................................................... 29

Page 5

Page | 1

1 Product Overview

The primary purpose of this document is to give users an overview of the

software and hardware development environment of the SBC8600B, and to

help the user to start their development or to learn faster.

This document will cover the following points:

Where to find the useful contents for different requirements;

Packing list and DVD contents;

Default configuration of software and hardware of the Single Board

Computer;

Building a development environment for the Single Board Computer

quickly;

Booting up Linux/wince/Android operating systems quickly.

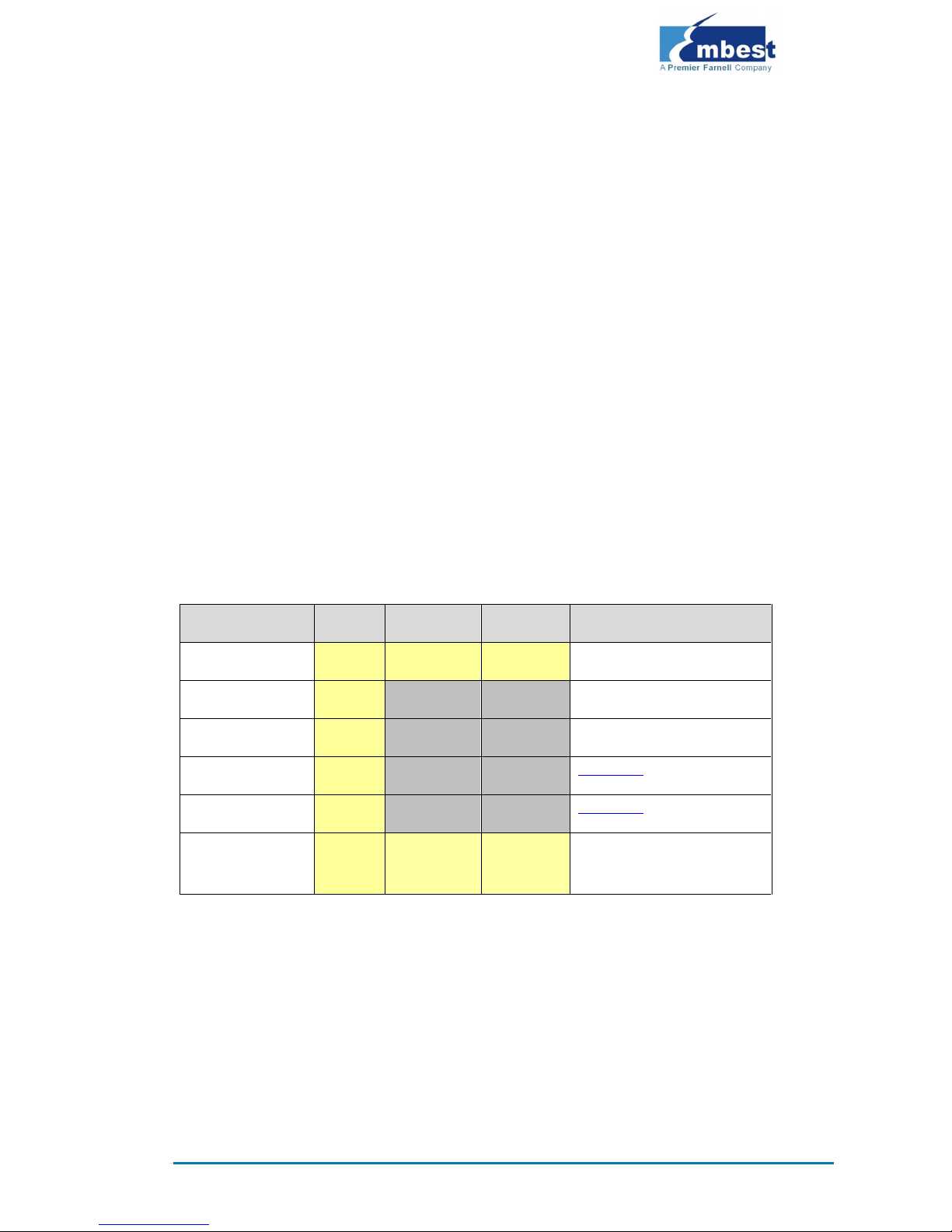

SBC8100 Plus Optional Modules List:

Names

Linux

Android

WinCE

Relevant Materials

VGA8000

YES

YES

YES

Available in DVD-ROM

WF8000-U

YES

NO

NO

Available in DVD-ROM

CAM8100-U

YES

NO

NO

Available in DVD-ROM

CDMA8000-U

YES

NO

NO

Download

WCDMA8000-U

YES

NO

NO

Download

LVDS8000

YES

YES

YES

Available in DVD-ROM and

on website

Page 6

Page | 2

2 Quick Start Guide

This section contains several tables that indicate where to find the useful

contents for different requirements, so users may get to work quickly!

2.1 For Hardware Development:

Item

Description

Location

Hardware

system

Introduces CPU, peripheral chips and hardware

interfaces

User Manual

CPU Datasheet

Shows principles and configuration of AM3359x

DVD

Schematic of

SBC8600B

Contains hardware principles of SBC8600B

DVD

Dimensions of

SBC8600B

The actual dimensions of SBC8600B used to aid in

manufacturing

User Manual

2.2 For Software Development:

Item

Description

Location

Preparations for

testing

Connecting external devices, setting up

HyperTerminal and booting up the system

Quick Start Guide

Testing

functionalities

of interfaces

Testing the interfaces on the board via an operating

system

User Manual

DEMO

demonstration

Establish a demonstration system (Android, TISDK)

User Manual

Establish

developing and

compilation

environment

Linux development and compilation environment

User Manual

Windows Embedded Compact 7 development and

compilation environment

User Manual

Recompile

system image

Recompiling Linux system image

User Manual

Recompiling Windows Embedded Compact 7 system

image

User Manual

Software

Introduction to Linux drivers and related driver

User Manual

Page 7

Page | 3

development

development processes

Introduction to Windows Embedded Compact 7

drivers and related driver development processes

User Manual

StarterWare

Describes bare-metal programming and example

execution

DVD

2.3 For Marketing:

Item

Description

Location

Hardware

system

CPU features and information about on-board

interfaces

User Manual

Software of

Linux / Windows

Embedded

Compact 7

Teaches basic Linux software components and

features, and the purpose of the compilation tool

User Manual

Teaches about the basic software components of

Windows Embedded Compact 7 and their features,

and the purpose of the compilation tool

User Manual

Dimensional

drawing of

SBC8600B

The actual dimensions of SBC8600B used to aid in

manufacturing

User Manual

DEMO

demonstration

Establish a demonstration system (Android, TISDK)

User Manual

2.4 For Learning:

It is recommended to read each part of this Manual from the beginning to

the end.

Page 8

Page | 4

2.5 Kit Contents

SBC8600B Single Board Computer(with Mini8600B)

Serial Cable (DB9-DB9)

12V, 1.25A Power Adapter

Crossover Cable

Optional 4.3” LCD display screen or 7” display screen (with touch

screen)

DVD/CD including:

o SBC8600B Quick Operation Manual

o SBC8600B User Manual

o SBC8600B Starterware User Manual

o Schematic Diagram of SBC8600B Hardware, Board Carrier

Chip Datasheet

o Development Kit of SBC8600B Software (

Linux/WinCE/Android/Starterware)

Page 9

Page | 5

3 Establishing a Development

Environment

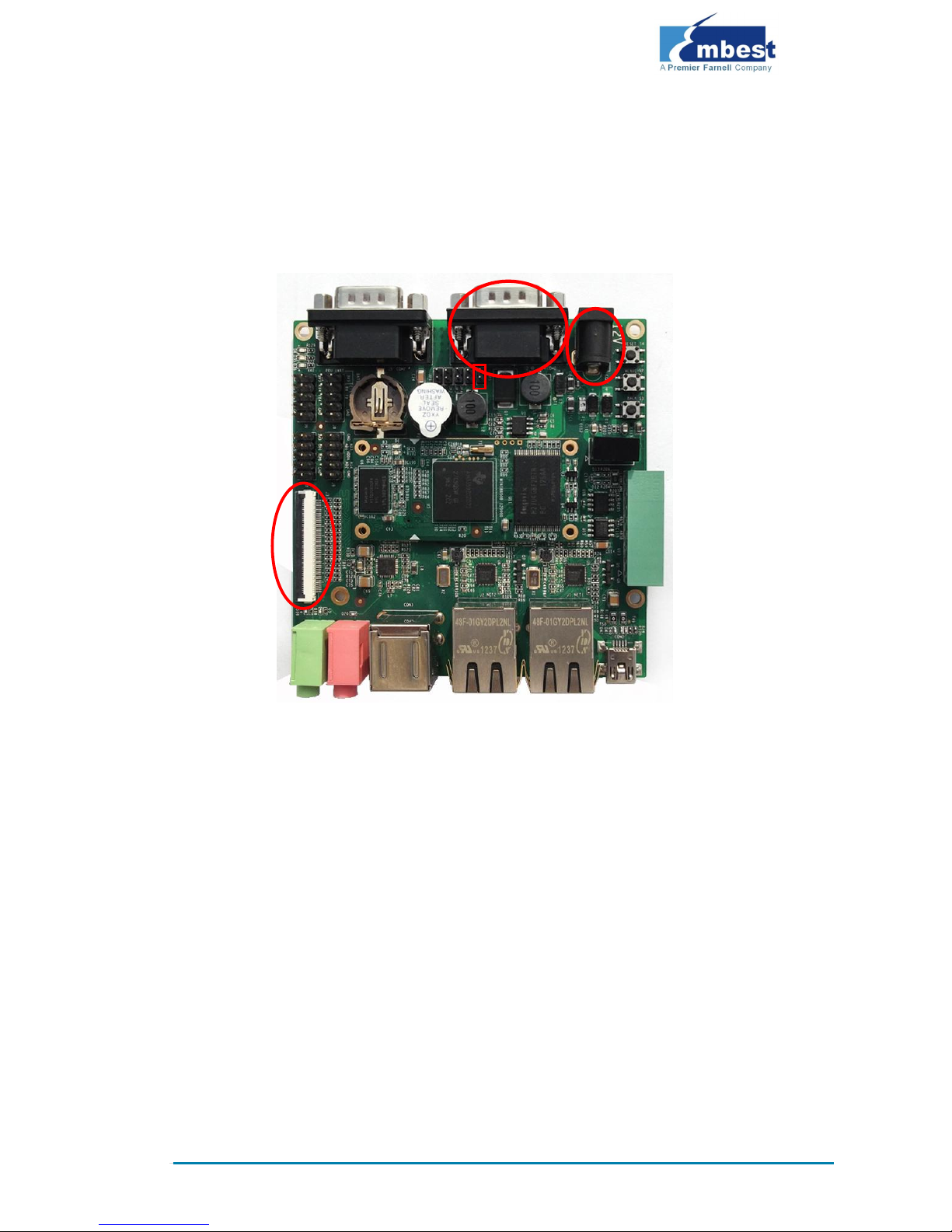

3.1 Establishment of Hardware Environment

Figure 1: SBC8600B Hardware Connections

Please establish the hardware environment according to the following steps:

1. Connect Touch-Screen LCD

2. Connect your 4.3-inch/7-inch touch-screen LCD to the LCD

interface, and keep the blue side of the FPC cable up

3. Connect Serial Ports

4. Use serial cable to connect the PC serial port to the debugger

serial port of SBC8600B.

5. If you want to boot from a TF card, you need to short the jumper

JP5

6. Connect the 12V power adapter to the evaluation board

1

2

4

JP5

Page 10

Page | 6

3.2 Establishment of Software Environment

3.2.1 Preparation of Windows XP System Environment

Before powering up SBC8600B, you need to configure HyperTerminal on the

PC, follow the process below in order to setup a Hyper Terminal connection:

1. From the desktop click:

Start

All Programs

Accessories

Communication

Hyper Terminal

As shown in the following image:

Figure 2: HyperTerminal Location on Windows XP

Page 11

Page | 7

2. Establish a new HyperTerminal connection:

Figure 3: Setting HyperTerminal Connection Name & Icon

3. Select the specific serial port from the list as per your computers

COM port configuration:

Figure 4: HyperTerminal COM Port Settings

Page 12

Page | 8

4. Set parameters for the serial port connection as follows:

Figure 5: HyperTerminal Connection Settings

5. The following image shows that we have successfully established

a Hyper Terminal connection with the PC’s serial port:

Figure 6: Successful HyperTerminal Connection

Page 13

Page | 9

Note:

If you have a 7-inch touch screen, you can change the settings in UBOOT

according to the detailed instructions contained in User Manual

Now we have successfully established both a software and a hardware

environment for the system. We can turn on the power switch to start the

development on SBC8600B.

Page 14

Page | 10

4 Operating System Quick Start

Guide

The SBC8600B supports three operating systems: Linux 3.2.0, WinCE6.0

and Android. This chapter mainly introduces how to switch between different

operating systems and how to boot up from a TF card and NAND Flash.

4.1 Quick operation of the Linux system

4.1.1 Booting from a TF card

Formatting TF Card

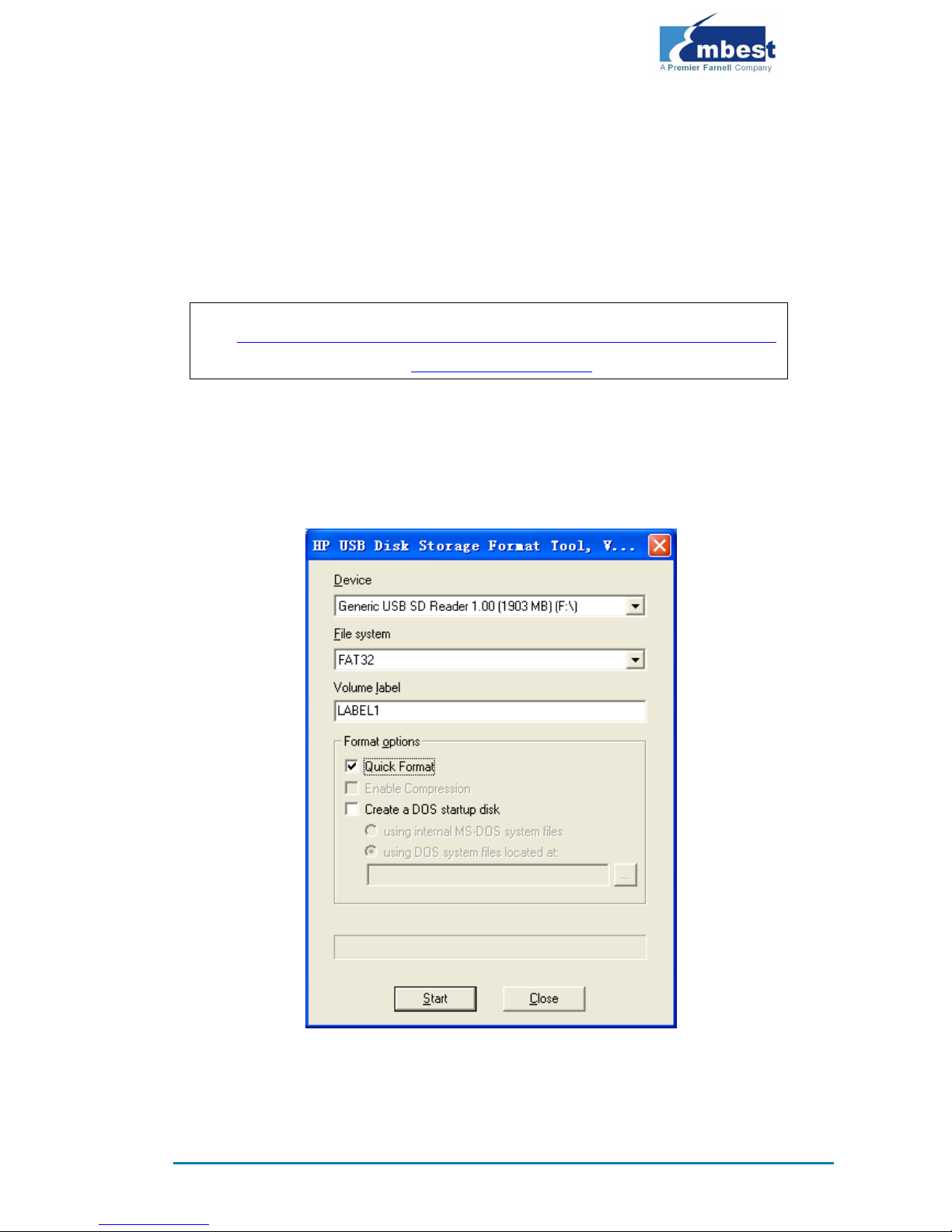

HP USB Disk Storage Format Tool 2.0.6 is recommended as the formatting

tool. Please download it from:

http://www.embest-tech.com/resource/download/HP-USB-Disk-St

orage-Format-Tool.rar

1. Insert TF card into a card reader and then insert the reader into

your PC.

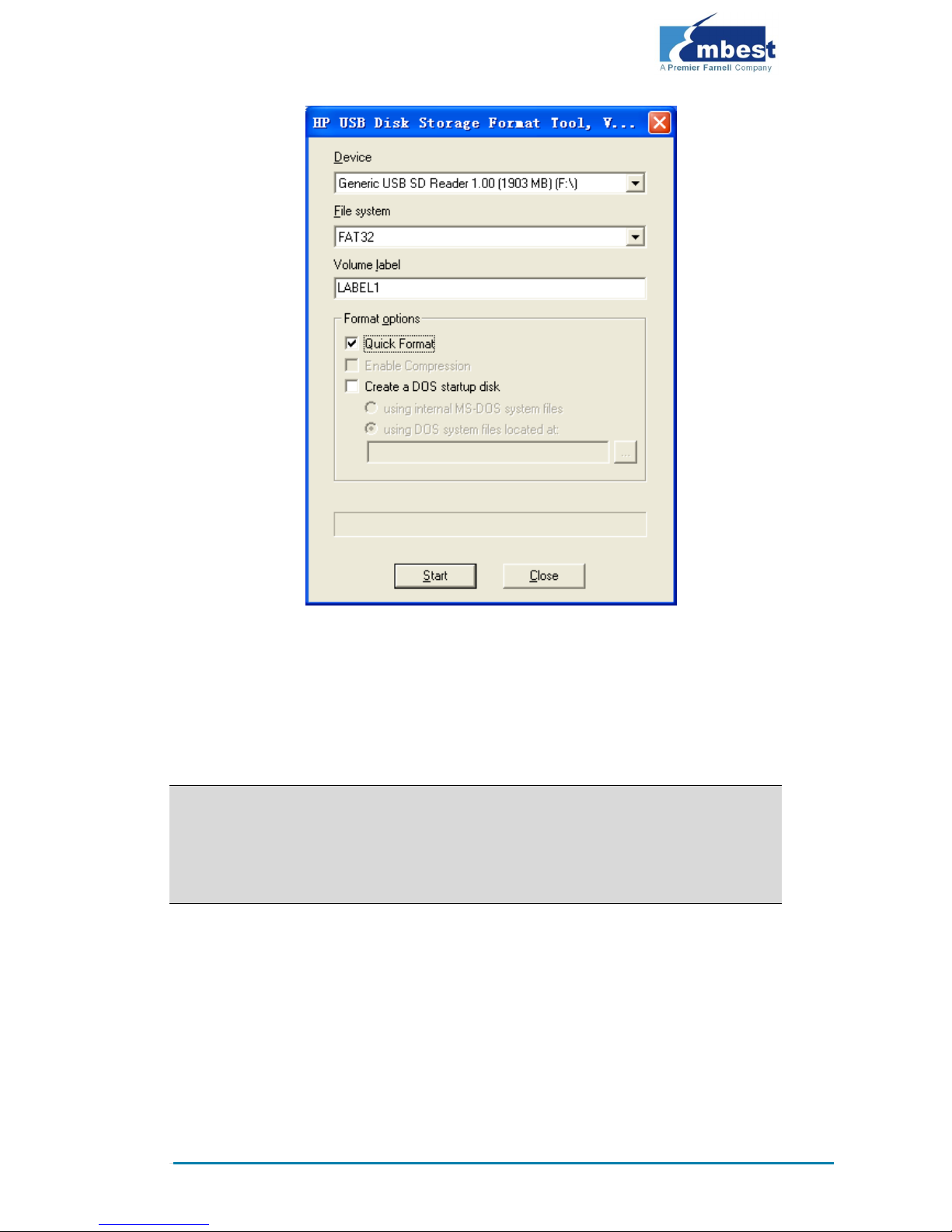

2. Open the HP USB Disk Storage Format Tool to show the following

window:

Page 15

Page | 11

3. Select “FAT32” file system

4. Click “Start”

5. When formatting is complete, click “OK”

Note:

HP USB Disk Storage Format Tool will erase the partitions of TF card.

Use other format tool may cause the failure of the TF card booting.

Image Update

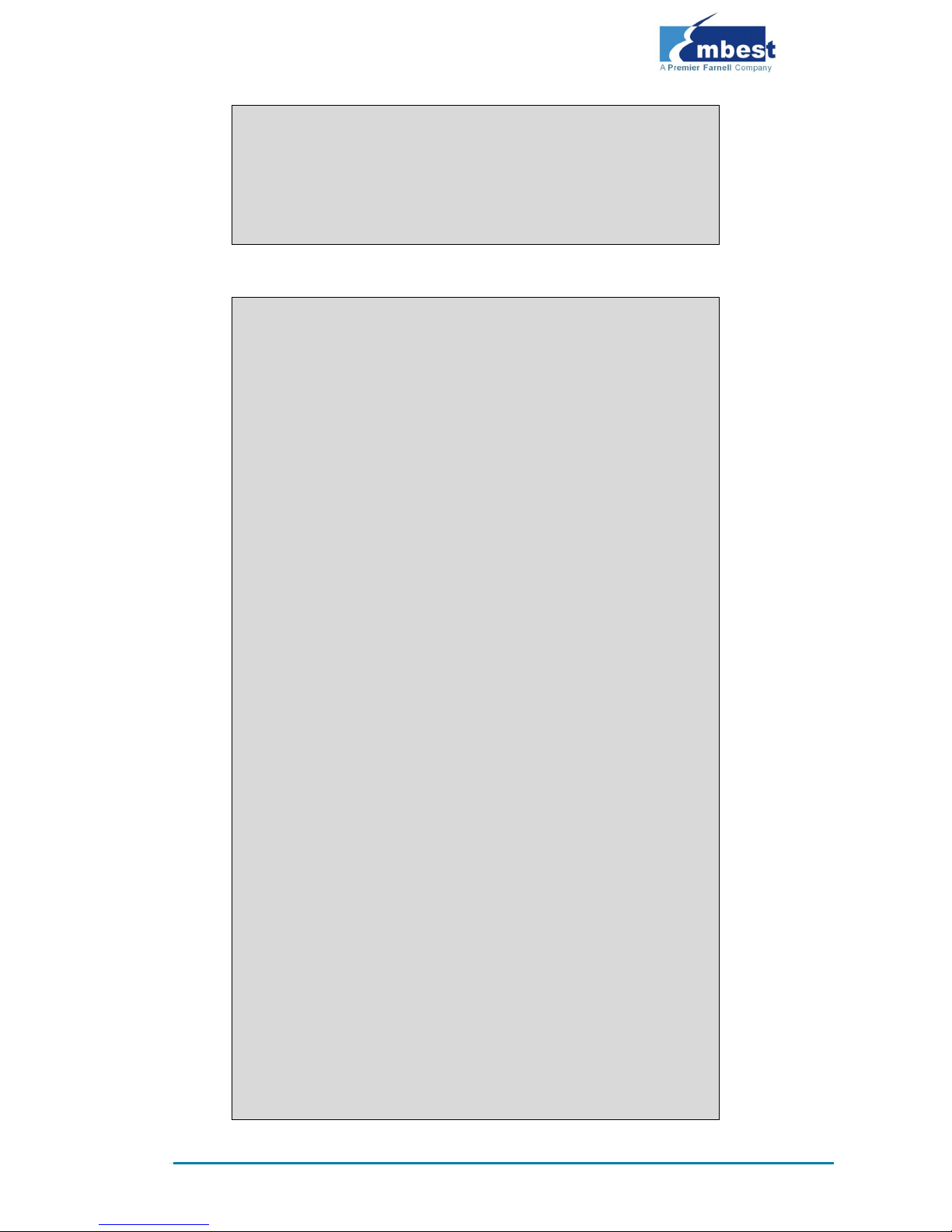

Copy all files under the directory linux\image to the TF card, insert it on the

board, and then power up the board. The information on serial interface will

be shown as below:

Page 16

Page | 12

Note:

The default display is a 4.3” LCD. If you are working with LCDs of another size,

please enter u-boot when the board is booting up to configure the display mode,

and then type boot to continue boot-up process. Please refer to the User Manual

for more details

If there is already an image in NAND Flash, you need to short the jumper JP5 on

the board so as to make it boot up from TF card. Disconnect JP5 after successful

boot-up of the system.

Booting from MMC...

OMAP SD/MMC: 0

reading u-boot.img

reading u-boot.img

U-Boot 2011.09-svn55 (Dec 04 2012 - 09:29:02)

I2C: ready

DRAM: 512 MiB

WARNING: Caches not enabled

Did not find a recognized configuration, assuming General

purpose EVM in Profile 0 with Daughter board

NAND: HW ECC Hamming Code selected

512 MiB

MMC: OMAP SD/MMC: 0

*** Warning - bad CRC, using default environment

Net: cpsw

Hit any key to stop autoboot: 0

SD/MMC found on device 0

reading uEnv.txt

** Unable to read "uEnv.txt" from mmc 0:1 **

reading uImage

3224184 bytes read

reading ramdisk.gz

12514633 bytes read

## Booting kernel from Legacy Image at 80007fc0 ...

Page 17

Page | 13

Image Name: Linux-3.2.0

Image Type: ARM Linux Kernel Image (uncompressed)

Data Size: 3224120 Bytes = 3.1 MiB

Load Address: 80008000

Entry Point: 80008000

Verifying Checksum ... OK

XIP Kernel Image ... OK

OK

Starting kernel ...

Uncompressing Linux... done, booting the kernel.

Linux version 3.2.0 (luofc@TIOP) (gcc version 4.3.3 (Sourcery

G++ Lite 2009q1-203) ) #17 Fri Dec 7 10:04:07 CST 2012

………

………

RAMDISK: gzip image found at block 0

VFS: Mounted root (ext2 filesystem) on device 1:0.

Freeing init memory: 260K

INIT: version 2.86 booting

Starting udevudevd (741): /proc/741/oom_adj is deprecated,

please use /proc/741/oom_score_adj instead.

tar: removing leading '/' from member names

Remounting root file system...

mount: mounting /dev/root on / failed: Invalid argument

mount: mounting /dev/root on / failed: Invalid argument

root: mount: mounting rootfs on / failed: No such file or

directory

Setting up IP spoofing protection: rp_filter.

Configuring network interfaces... udhcpc (v1.11.3) started

Sending discover...

udhcpc: sendto: Network is down

Sending discover...

udhcpc: sendto: Network is down

Sending discover...

udhcpc: sendto: Network is down

No lease, failing

done.

Tue Jan 27 08:47:00 UTC 2009

INIT: Entering runlevel: 5

Starting syslogd/klogd: done

.-------.

Page 18

Page | 14

| | .-.

| | |-----.-----.-----.| | .----..-----.-----.

| | | __ | ---'| '--.| .-'| | |

| | | | | |--- || --'| | | ' | | | |

'---'---'--'--'--. |-----''----''--' '-----'-'-'-'

-' |

'---'

The Angstrom Distribution SBC8600 ttyO0

Angstrom 2008.1-test-20090127 SBC8600 ttyO0

SBC8600 login: (Type ”root”)

The above information indicates a successful boot-up of Linux from the TF

card.

4.1.2 Boot-up From NAND Flash

Updating of the NAND boot-up image is accomplished by u-boot. Regardless

of whether NAND Flash contains data, u-boot can be used to update any

NAND Flash images.

Preparation

1. Format the TF card to a FAT or FAT32 file system by using the HP

USB Disk Storage Format Tool 2.0.6

2. Copy the files MLO, u-boot.img, uImage and ubi.img under

the directory linux\image from DVD-ROM into a TF card.

Update

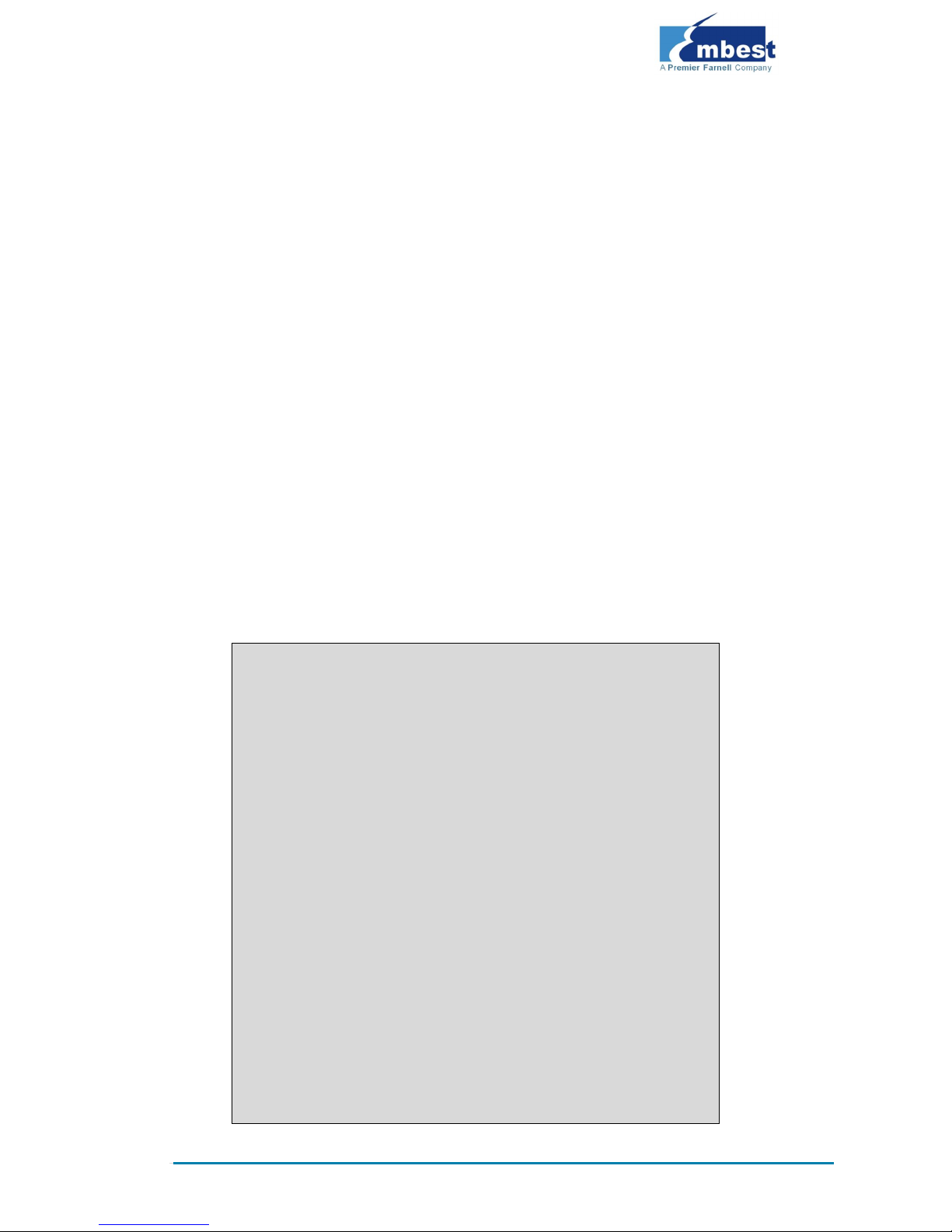

3. Insert the TF card which contains the system images into the

development board, and then connect the power supply. Press

any key on the keyboard to enter u-boot when the message "Hit

any key to stop autoboot" appears:

Page 19

Page | 15

Note:

You may short the jumper JP5 on the board to allow SBC8600B boot up from TF

card and enter u-boot to write the image in NAND Flash, and then disconnect

JP5 to allow system boot up from NAND Flash.

Alternatively, you may leave JP5 disconnected and insert the TF card on the

board to boot up from NAND Flash, and then write the image in NAND Flash

through uboot.

U-Boot SPL 2011.09-svn55 (Nov 20 2012 - 10:37:42)

Texas Instruments Revision detection unimplemented

Booting from MMC...

OMAP SD/MMC: 0

reading u-boot.img

reading u-boot.img

U-Boot SPL 2011.09-svn55 (Nov 20 2012 - 10:37:42)

I2C: ready

DRAM: 512 MiB

WARNING: Caches not enabled

Did not find a recognized configuration, assuming General

purpose EVM in Profile 0 with Daughter board

NAND: HW ECC Hamming Code selected

512 MiB

MMC: OMAP SD/MMC: 0

*** Warning - bad CRC, using default environment

Net: cpsw

Hit any key to stop autoboot: 0 (press any key to enter uboot)

4. After entering the u-boot command line, type “run updatesys” to

start the update process of the system:

SBC8600# run updatesys

NAND erase.chip: device 0 whole chip

Erasing at 0x7fe0000 -- 100% complete.

OK

reading MLO

36079 bytes read

Page 20

Page | 16

HW ECC BCH8 Selected

NAND write: device 0 offset 0x0, size 0x8cef

36079 bytes written: OK

reading u-boot.img

234896 bytes read

HW ECC BCH8 Selected

NAND write: device 0 offset 0x80000, size 0x39590

234896 bytes written: OK

reading uImage

3224184 bytes read

HW ECC BCH8 Selected

NAND write: device 0 offset 0x280000, size 0x313278

3224184 bytes written: OK

reading ubi.img

14811136 bytes read

SW ECC selected

NAND write: device 0 offset 0x780000, size 0xe20000

Skip bad block 0x00ce0000

14811136 bytes written: OK

A Flashing LED on the board indicates that the update has been finished;

please remove the TF card and reboot the board.

4.1.3 U-boot configuration

The system image is set by default for a 4.3” LCD. You can change the

settings in UBOOT by using the instructions contained within the User

Manual.

Page 21

Page | 17

4.2 Quick Operation of the WinCE System

4.2.1 Boot-up From TF Card

Formatting TF Card

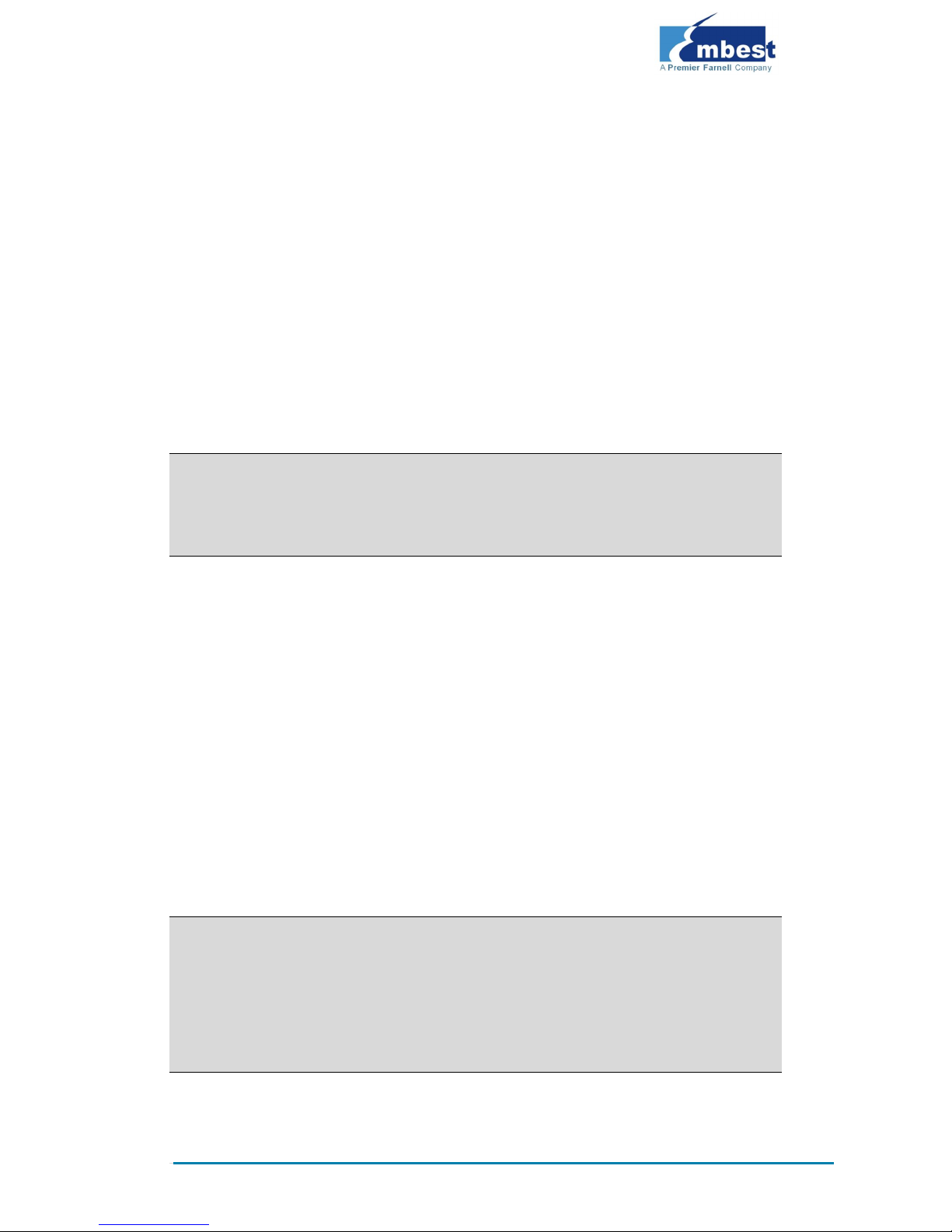

HP USB Disk Storage Format Tool 2.0.6 is recommended as the formatting

tool. Please download it from:

http://www.embest-tech.com/resource/download/HP-USB-Disk-St

orage-Format-Tool.rar

1. Insert TF card into a card reader and then insert the reader into

your PC.

2. Open the HP USB Disk Storage Format Tool to show the following

window:

3. Select “FAT32” file system

4. Click “Start”

Page 22

Page | 18

5. When formatting is complete, click “OK”

Note:

HP USB Disk Storage Format Tool will erase the partitions of TF card.

Use other format tool may cause the failure of the TF card booting.

Copy Runtime Image

Copy the MLO, EBOOTSD.nb0 and NK.bin image files to the TF card. They

are located under CD\WINCE700\image

System Boot-up

Insert a TF card, reboot the system from the TF card and press Space in a

few seconds to enter to the EBOOT menu as shown below:

6. Enter the EBOOT Menu

CCCCCCCC

Texas Instruments Windows CE SD X-Loader33X

Built Jul 27 2012 at 11:25:59

Version BSP_WINCE_ARM_A8 02.30.00.03

open ebootsd.nb0 file

Init HW: controller RST

SDCARD: requested speed 1000000, actual speed 1000000

SDCARD: requested speed 25000000, actual speed 19200000

read ebootsd.nb0 file

jumping to ebootsd image

Microsoft Windows CE Bootloader Common Library Version 1.4 Built

Jul 27 2012 11:23:05

I2C EEPROM returned wrong magic value 0xffffffff

INFO:OALLogSetZones: dpCurSettings.ulZoneMask: 0x8409

Texas Instruments Windows CE EBOOT for AM33x, Built Jul 27 2012

at 11:25:53

EBOOT Version 0.0.1, BSP BSP_WINCE_ARM_A8 02.30.00.03

AHCLKX pinmux:0

AHCLKX CTRL:0x8001

Page 23

Page | 19

pin function:0x0

pin dir:0x8000000

TI AM33X

ecc type:3

System ready!

Preparing for download...

INFO: Predownload....

Checking bootloader blocks are marked as reserved (Num = 18)

BOOT_CFG_SIGNATURE is different, read -1, expect 1111705159

WARN: Boot config wasn't found, using defaults

INFO: SW3 boot setting: 0x04

IsValidMBR: MBR sector = 0x480 (valid MBR)

OpenPartition: Partition Exists=0x1 for part 0x20.

>>> Forcing cold boot (non-persistent registry and other data

will be wiped) <<<

e0311800 56e4 -> 0 18 31 e0 e4 56

e0311800 57e4 -> 0 18 31 e0 e4 57

Hit space to enter configuration menu [56] 5...(press SPACE to

enter EBOOT menu)

7. Type [2]->[2] to set the board to boot up from the TF card

-----------------------------------------------------------

---------------------

Main Menu

-----------------------------------------------------------

---------------------

[1] Show Current Settings

[2] Select Boot Device

[3] Select KITL (Debug) Device

[4] Network Settings

[5] SDCard Settings

[6] Set Device ID

[7] Save Settings

[8] Flash Management

[9] Enable/Disable OAL Retail Messages

[a] Select Display Resolution

[b] Select OPP Mode

[0] Exit and Continue

Selection: 2

Page 24

Page | 20

-----------------------------------------------------------

---------------------

Select Boot Device

-----------------------------------------------------------

---------------------

[1] Internal EMAC

[2] NK from SDCard FILE

[3] NK from NAND

[0] Exit and Continue

Selection (actual Internal EMAC): 2

Boot device set to NK from SDCard FILE

8. Type [a] to enter “Select Display Resolution” menu and select

LCD\LVDS as the output

-----------------------------------------------------------

---------------------

Main Menu

-----------------------------------------------------------

---------------------

[1] Show Current Settings

[2] Select Boot Device

[3] Select KITL (Debug) Device

[4] Network Settings

[5] SDCard Settings

[6] Set Device ID

[7] Save Settings

[8] Flash Management

[9] Enable/Disable OAL Retail Messages

[a] Select Display Resolution

[b] Select OPP Mode

[0] Exit and Continue

Selection: a

-----------------------------------------------------------

---------------------

Select Display Resolution

-----------------------------------------------------------

---------------------

[1] LCD 480x272 60Hz //For 4.3-inch LCD

[2] DVI 640x480 60Hz(N/A)

[3] DVI 640x480 72Hz(N/A)

Page 25

Page | 21

[4] LCD 800x480 60Hz //For 7-inch LCD

[5] DVI 800x600 60Hz(N/A) //For LVDS

[6] DVI 800x600 56Hz(N/A)

[7] VGA 1024x768 60Hz //For VGA

[8] DVI 1280x720 60Hz(N/A)

[0] Exit and Continue Selection (actual LCD 480x272 60Hz): 4

9. Type [0] to continue the boot-up process

-----------------------------------------------------------

---------------------

Main Menu

-----------------------------------------------------------

---------------------

[1] Show Current Settings

[2] Select Boot Device

[3] Select KITL (Debug) Device

[4] Network Settings

[5] SDCard Settings

[6] Set Device ID

[7] Save Settings

[8] Flash Management

[9] Enable/Disable OAL Retail Messages

[a] Select Display Resolution

[b] Select OPP Mode

[0] Exit and Continue

Selection: 0

mode = 3

LcdPdd_LCD_GetMode:3

mode = 3

LcdPdd_LCD_Initialize:3

OEMPreDownload: Filename nk.bin

Init HW: controller RST

SDCARD: requested speed 1000000, actual speed 1000000

SDCARD: requested speed 25000000, actual speed 19200000

BL_IMAGE_TYPE_BIN

+OEMMultiBinNotify(0x8feb24d8 -> 1)

Download file information:

-----------------------------------------------------------

[0]: Address=0x80002000 Length=0x03c9e9bc Save=0x80002000

-----------------------------------------------------------

Download file type: 1

Page 26

Page | 22

+OEMIsFlashAddr(0x80002000) g_eboot.type 1

...........................................................

...........................................................

...........................................................

...........................................................

...........................................................

...............................................rom_offset=0

x0.

..ImageStart = 0x80002000, ImageLength = 0x3c9e9bc, LaunchAddr

= 0x8000b6a0

Completed file(s):

-----------------------------------------------------------

--------------------

+OEMIsFlashAddr(0x80002000) g_eboot.type 1

[0]: Address=0x80002000 Length=0x3c9e9bc Name="" Target=RAM

ROMHDR at Address 80002044h

Launch Windows CE image by jumping to 0x8000b6a0...

Windows CE Kernel for ARM (Thumb Enabled)

CPU CP15 Control Register = 0xc5387f

CPU CP15 Auxiliary Control Register = 0x42

I2C EEPROM returned wrong magic value 0xffffffff

+OALTimerInit(1, 24000, 200)

--- High Performance Frequecy is 24 MHz---

4.2.2 Booting-up From NAND Flash

1. Formatting TF card

Please refer to p17 for instructions

2. Copy runtime image

Copy MLO, EBOOTND.nb0, NK.bin, XLDRNAND.nb0 and

EBOOTSD.nb0 image files under CD\WINCE700\image to the TF card.

3. Update of NAND Flash image files

Insert TF card, reboot the system from TF card and press Space in a few

seconds to enter to the EBOOT menu, and then follow the steps listed below:

Type [8] to enter the Flash menu;

Page 27

Page | 23

Type [9]->[4]->[A], [9]->[3]->[B] and [9]->[2]->[C] to write

XLDR, EBOOT and NK images;

Type [0] to return to the main menu, and then type [2] and [3] to

select boot-up from NAND Flash; Type [A] to select LCD/DVI display

mode; Type [7] and [y] to save the boot-up settings;

Remove the TF card and reboot the system. The system will boot from NAND

Flash.

4.3 Quick Operation of the Android System

The SBC8600B provides an Android system demonstration, please follow the

steps listed below:

1. Copy all files under the directory \linux\demo\Android\image of

the DVD-ROM to a TF card;

2. Insert the TF card on the board and short jumper JP5, and then

power on the board. The debugging tool will show the following

information:

CCCCCCCC

U-Boot SPL 2011.09-svn55 (Dec 04 2012 - 09:36:25)

Texas Instruments Revision detection unimplemented

Booting from MMC...

OMAP SD/MMC: 0

reading u-boot.img

reading u-boot.img

U-Boot 2011.09-svn55 (Nov 22 2012 - 11:35:28)

I2C: ready

DRAM: 512 MiB

WARNING: Caches not enabled

Did not find a recognized configuration, assuming General

purpose EVM in Profile 0 with Daughter board

NAND: HW ECC Hamming Code selected

512 MiB

MMC: OMAP SD/MMC: 0

*** Warning - bad CRC, using default environment

Page 28

Page | 24

NAND erase.chip: device 0 whole chip

Skipping bad block at 0x03620000

Erasing at 0x1ffe0000 -- 100% complete.

OK

reading MLO

36079 bytes read

HW ECC BCH8 Selected

NAND write: device 0 offset 0x0, size 0x8cef

36079 bytes written: OK

reading flash-uboot.img

234620 bytes read

HW ECC BCH8 Selected

NAND write: device 0 offset 0x80000, size 0x3947c

234620 bytes written: OK

reading uImage

2719416 bytes read

HW ECC BCH8 Selected

NAND write: device 0 offset 0x280000, size 0x297eb8

2719416 bytes written: OK

reading ubi.img

72744960 bytes read

SW ECC selected

NAND write: device 0 offset 0x780000, size 0x4560000

72744960 bytes written: OK

3. When the writing process is complete, the on-board LED will be

flashing. Please remove the TF card and the jumper cap. Power

on the board again to load the Android operating system;

Note

The system is set by default for a 4.3” LCD. You can change the settings in

UBOOT according to the instructions contained in the User Manual.

Page 29

Page | 25

Appendix 1: ESD Precautions &

Handling Procedures

Please note that the board comes without any case/box and all components

are exposed. Therefore, extra attention must be paid to ESD (electrostatic

discharge) precautions. To effectively prevent electrostatic damage, please

follow the steps below:

Avoid carpets in cool, dry areas. Leave development

kits in their anti-static packaging until ready to be

installed.

Dissipate static electricity before handling any system components

(development kits) by touching a grounded metal object, such as the

system unit unpainted metal chassis.

If possible, use antistatic devices, such as wrist straps and floor mats.

Always hold an evaluation board by its edges. Avoid touching the

contacts and components on the board.

Take care when connecting or disconnecting cables. A damaged cable

can cause a short in the electrical circuit.

Prevent damage to the connectors by aligning connector pins before

you connect the cable. Misaligned connector pins can cause damage

to system components at power-on.

When disconnecting a cable, always pull on the cable connector or

strain-relief loop, not on the cable itself.

Warning:

This is a class A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate

measures.

Page 30

Page | 26

Appendix 2: Technical support &

Warranty

Embest Technology Co., Ltd. established in March of 2000, is a global

provider of embedded hardware and software. Embest aims to help

customers reduce time to market with improved quality by providing the

most effective total solutions for the embedded industry. In the rapidly

growing market of high end embedded systems, Embest provides

comprehensive services to specify, develop and produce products and help

customers to implement innovative technology and product features.

Progressing from prototyping to the final product within a short time frame

and thus shortening the time to market, and to achieve the lowest

production costs possible. Embest insists on a simple business model: to

offer customers high-performance, low-cost products with the best quality

and service.

2.1 Technical support service

Embest provides one year of free technical support for all products. The

technical support service covers:

Embest embedded platform products software/hardware materials

Assistance to customers with regards to compiling and running the

source code we offer.

Troubleshooting problems occurring on embedded

software/hardware platforms if users have followed the instructions

provided.

Judge whether a product failure exists.

The situations listed below are not covered by our free technical support

service, and Embest will handle the situation at our discretion:

Customers encounter issues related to software or hardware during

their development process

Issues occur when users compile/run the embedded OS which has

been modified by themselves.

Page 31

Page | 27

Customers encounter issues related to their own applications.

Customers experience problems caused by unauthorised alteration of

our software source code

2.2 Maintenance service clause

1. Product warranty will commence on the day of sale and last 12

months provided the product is used under normal conditions

2. The following situations are not covered by the warranty,

Embest will charge service fees as appropriate:

Customers fail to provide valid proof of purchase or the product

identification tag is damaged, unreadable, altered or inconsistent with

the product.

Products are subject to damage caused by operations inconsistent

with their specification;

Products are subject to damage in either appearance or function due

to natural disasters (flood, fire, earthquake, lightning strike or

typhoon) or natural aging of components or other force majeure;

Products are subject to damage in appearance or function due to

power failure, external forces, water, animals or foreign materials;

Products malfunction due to disassembly or alteration of components

by customers, or repair by persons or organizations unauthorized by

Embest Technology, or alteration from factory specifications, or

configured or expanded with components that are not provided or

recognized by Embest Technology;

Product failures due to the software or systems installed by

customers, inappropriate software settings or computer viruses;

Products purchased from unauthorized merchants;

Page 32

Page | 28

Embest Technology takes no responsibility for fulfilling any warranty

(verbal or written) that is not made by Embest Technology and not

included in the scope of our warranty.

3. Within the period of warranty, the cost for sending products to

Embest should be paid by the customer. The cost for returning

the product to the customer will be paid by Embest. Any returns

in either direction occurring after the warranty period has

expired should be paid for by the customer.

4. Please contact technical support with any repair requests.

Note:

Embest Technology will not take any responsibility for products returned

without the prior permission of the company.

2.3 Basic guidelines for protection and

maintenance of LCDs

1. Do not use finger nails or other hard sharp objects to touch the

surface of the LCD

2. Embest recommends purchasing specialist wipes to clean the

LCD after long time use, avoid cleaning the surface with fingers

or hands as this may leave fingerprints or smudges.

3. Do not clean the surface of the screen with unsuitable chemicals

Note:

Embest do not supply a maintenance service for LCDs. We suggest the

customer immediately checks the LCD once in receipt of the goods. In the event

that the LCD does not run or shows no display, the customer should inform

Embest within 7 business days of delivery.

Page 33

Page | 29

2.4 Value Added Services

We will provide following value added services:

Driver development based on Embest embedded platforms for

devices such as: serial ports, USB interface devices, and LCD screens.

Control system transplantation, BSP driver development, API

software development.

Other value added services including supply of power adapters and

LCD parts.

Other OEM/ODM services.

Technical training.

Please contact Embest with any technical support queries:

http://www.embest-tech.com/contact-us.html

Loading...

Loading...