Page 1

Replacement Parts

List

EmberGlo Model ES5M

Designed to Operate W ithout

Distilled Water

EmberGlo

A Division of Midco International Inc.

4140 West Victoria Street

Chicago, Illinois 60646

tel 773.604.8700

fax 773.604.4070

web www.emberglo.com

EmberGlo

Quality Designed for Proven Performance

Manual Operation Steamer

with Water Pan

PRINTED IN U.S.A.

299

8472-50

Items listed are replacement parts for the current Model ES5M Tap Water Steamer and its

components.

Model ES5M first construction May, 1983.

■■

■■ Original construction featured a non-counter balanced 90° opening lid. Steamers built

after January 29, 1990 (date code 0590) feature a counter balanced adjustable 60° or

90° opening lid.

■■

■■ Original patterns for early Sand Cast Aluminum Generators replaced by Semi

Permanent Molds August 27, 1992 (date code 3592). Refer to page 3, Generators.

AVOID ERROR IN PARTS SELECTION. When ordering use complete Ember•Glo part number

and description; furnish steamer model number, date code, bill of material number, serial

number and component nameplate data where available.

Page 2

2

Page 3

3

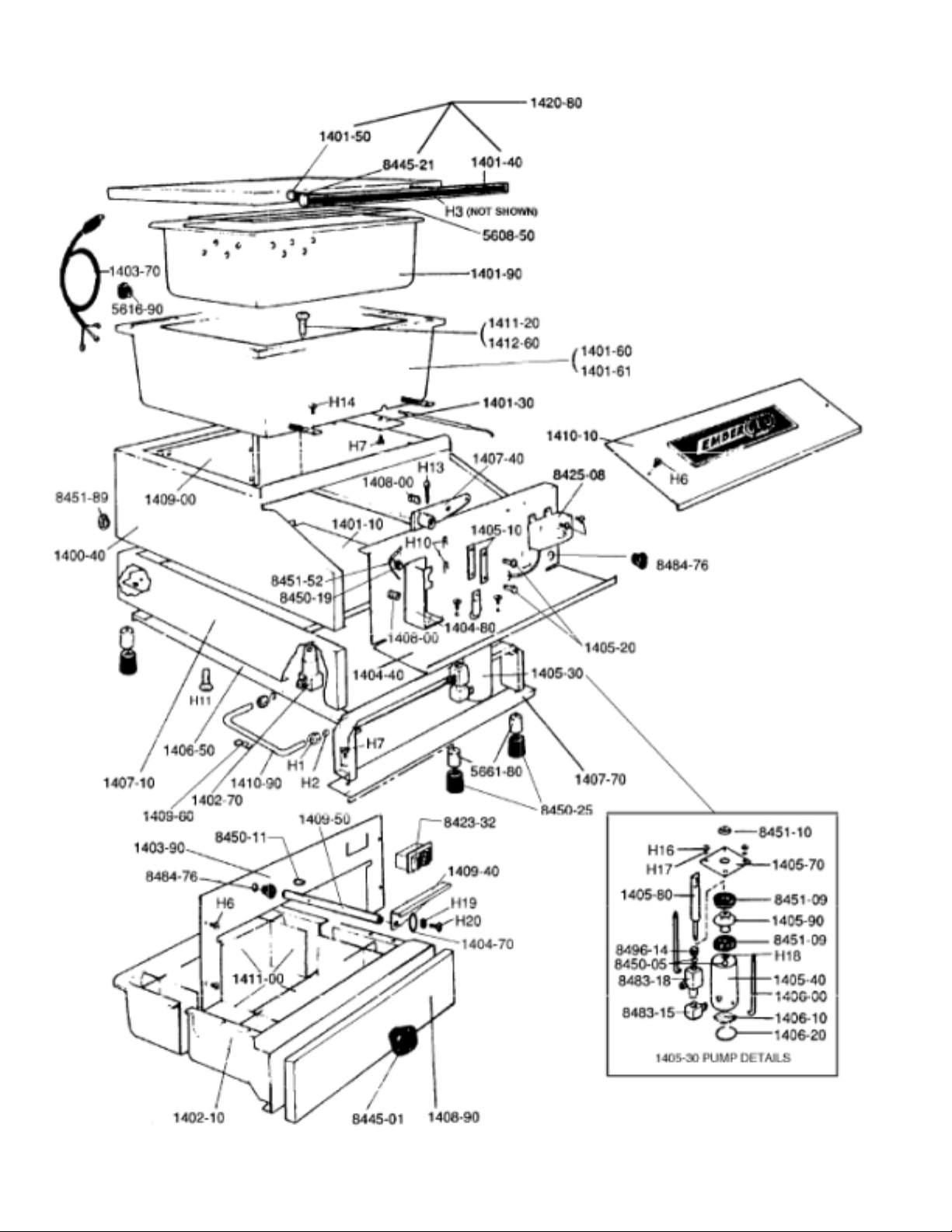

PART NUMBER DESCRIPTION

1400-20 Pump Handle Weldment

1400-40 Shell Weldment

1401-10 Rear Bottom

1401-30 Bulb Clamp

1401-60

1

Generator (120 volt)

1401-61

1

Generator (220 volt)

1401-90 Food Pan

1402-10 Water Pan Rivetment

1402-70 Water Inlet

1403-70 Power Cord (3 Prong, 120 volt)

1403-90 Switch Panel

1404-40 Front Bottom Panel

1404-70 Pump Handle Washer

1404-80 Pump Handle Support

1405-10 Pump Link (2-required)

1405-20 Pump Pin (2-required)

1405-30 Pump Assembly

1405-40 Pump Cylinder Assembly

1405-70 Pump Cylinder Mounting Plate

1405-80 Pump Piston Rod

1405-90 Pump Piston

1406-00 Pump Tie Rod (2-required)

1406-10 Pump Strainer

1406-20 Pump Retainer

1406-50 Water Pan Slide Weldment

1407-10 Water Pan Shell Weldment

1407-40 Pump Crank Assembly

1407-70 Leg Channel

1408-00 Spring Seat (2-required)

1408-90 Water Pan Front

1409-00 Stiffener

1409-60 Water Tube Clip (2 required)

1410-10 Control Box Cover and Nameplate Assembly

1410-90 Water Tube and Fittings

1411-00 Water Pan Baffle Set

1411-20 Water Nozzle with Spring

1412-60 Water Nozzle Spring only

1420-00 Hinge Spring Bar (2 required)

1420-40 Hinge Spring (2 required)

1420-80 Lid Assembly (Lid and Handle)

1421-00 Adjustable Lower Hinge

1421-50 Hinge Lid Stop Rivetment

1421-60 Adjustable Upper Hinge

1435-00 Lid Handle Replacement Kit

5608-50 Food Grid

5616-90 Strain Relief (SR-6P-4)

1. Refer to Generators below

PART NUMBER DESCRIPTION

5661-80 Aluminum Leg (4 required)

8423-14 On-Off Rocker Switch

8425-08 Thermostat

8432-08

5

/16" OD x 3/16" ID O-Ring (2 required)

8445-01 Water Pan Knob

8450-05

9

/32" Dia. Stainless Steel Ball (2 required)

8450-11 Woodruff Key

8450-19

3

/8Nyliner

8450-25 Socket Tip (4 required)

8451-09 Pump Cup (2 required)

8451-10

5

/16Nyliner

8451-52 Pump Spring

8451-89

9

/16" Dia. Plug Button

8483-15

1

/8Brass Street Ell

8483-18

1

/8Brass Adapter Tee

8484-76 Snap Bushing (B-500-375)

8496-14

1

/8" Slotted Brass Pipe Plug

The Following Are Not Shown

1410-50 Insulation Kit (Sides, Back, Front & Bottom)

1410-60 Electrical Wire Kit (less power cord)

1419-00 Adjustable Hinge Retrofit Kit and Hardware

1446-00 Thermostat Disc to Bulb Kit

PART NUMBER HARDWARE (obtain locally)

H1

1

/4Tube Compression Nut

H2

1

/4Tube Compression Sleeve

H3 10-32 x 2 Round Head Machine Screw

H4 10-32 x

3

/8Truss Head Machine Screw

H5

H6 8 x

3

/8Truss Head Type "B"

H7 10-24 x

3

/8Round Head Machine Screw

H8 6 x

1

/4Pan Head Type "AB"

H9 #10 Stainless Steel Lockwasher

H10 Hitch Pin

H11

1

/4-20 x 2 Round Head Machine Screw

H12

H13

1

/8x 1 Cotter Pin

H14 8-32 x

5

/16Pan Head Machine Screw

H15

H16 6-32 Hex Brass Nut

H17 #6 Stainless Steel Lockwasher

H18 10-32 Hex Brass Nut

GENERA TORS

Original patterns for Sand Cast Aluminum generators replaced by Semi Permanent Molds August 27, 1992 (Date Code 3592).

Generators from Semi Permanent Molds feature vertical ribs on each wall of Generator cavity. These ribs inhibit the food pan

from nesting against any wall. When replacing an early (without ribs) Generator, the two bolt holes in the REAR BOTTOM panel

must be filed to accommodate the new Generator. The distance between centers on the two 1/4-20 mounting bosses has been

reduced

1

/4inch (was 121/2" now 121/4"). If this is not acceptable, order 1401-10 REAR BOTTOM panel when ordering a

replacement Generator.

Note: Replacing the REAR BOTTOM panel is labor intensive. We recommend filing the existing REAR BOTTOM panel.

Page 4

ADJUSTABLE HINGE FOR 2-POSITION LID OPENING

(60° OR 90° OPEN)

First construction January 29, 1990 (date code 0590). Steamers built before this date featured a 90° opening lid. Replacement

parts for the early construction are no longer available. When replacing any parts on the early design or if converting to 2position lid opening, order Part Number 1419-00 ADJUSTABLE HINGE RETROFIT KIT.

TO REMOVE LID OR CHANGE OPENING

Remove lid stop rivetment by sliding it up and away from steamer. Raise lid as far back as it will go, remove springs. Remove lid.

Inverting lid stop rivetment changes lid opening from 60° to 90° or from 90° to 60°.

TO RESET LID

Remove lid stop rivetment and springs. Loosen four 10-32 x 3/8Phillips truss head screws in lower hinge. Place a coin under lid

and on top of generator rim at both rear corners. Hold lid down along front edge. Tighten screws. Reinstall springs and lid stop

rivetment.

4

Loading...

Loading...