Page 1

Installation, Service Instructions & Parts

C

O

M

P

A

N

Y

R

E

G

I

S

T

E

R

E

D

Electric Char Broiler

E2436

36″ Wide Electric Char Broilers

Model Voltage Model Number

MADE in the USA

E2436 208 V Single Phase 5700301

E2436 208 V Three Phase 5700303

E2436 240 V Single Phase 5700300

E2436 240 V Three Phase 5700304

Warranty

See the back of this manual for the warranty.

This warranty does not apply to damages resulting from

accident, misuse, abuse or alteration. No equipment may be

returned without written authorization from EmberGlo (or Midco

International Inc.) . Returned goods must be shipped prepaid

to the factory. Warranty card must be fi lled in and returned to

EmberGlo (or Midco) to validate warranty.

E2436 440 V Three Phase 5700305

E2436 480 V Three Phase 5700306

Model Voltage Model Number

E2436F 208 V Single Phase 5700501

E2436F 208 V Three Phase 5700503

E2436F 240 V Single Phase 5700500

E2436F 240 V Three Phase 5700504

E2436F 440 V Three Phase 5700505

E2436F 480 V Three Phase 5700506

CAUTION: This manual contains suffi cient information

for installation of the EmberGlo Broiler in normal locations.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause property

In the United States, installation must conform with local codes.

damage, injury or death. Read the installation, operating

and maintenance instructions thoroughly before installing

CODE COMPLIANCE IS THE SOLE RESPONSIBILITY OF

or servicing this equipment.

THE INSTALLER.

Do not store or use gasoline or other fl ammable liquids

CAUTION: Cooking equipment should be used in an

and vapors in the vicinity of this or any other appliance.

environment protected by an automatic fi re suppression system.

Consult the National Fire Protection Association NFPA Code 96

PURCHASER: Retain these instructions for future use.

or the latest edition of Standards for Installation of Equipment for

Removal of Smoke and Grease-Laden Vapors From Commercial

Cooking Equipment.

INSTALLER: Inform and demonstrate to the user the correct

operation and maintenance of the equipment. Inform the user

of the hazards of storing fl ammable liquids and vapors in the

CAUTION: To avoid grease fi lter fi re hazard,

vicinity of this equipment and remove such hazards.

commercial kitchen exhaust hoods should be positioned at

a minimum of 3½ feet above the broiler cooking surface, as

specifi ed by Commercial Grease Removal, Building Offi cials

& Code Administrators International Inc. and the National

Mechanical Code, 1990 Seventh Edition (or latest edition), Article

5, Section M504.0, Table M504.3.2.

WARNING: Additions, changes, conversions and

service must be performed by an authorized EmberGlo

representative or service agency. Use only EmberGlo specifi ed

and approved parts.

USER: Retain this manual for future reference. If other than

routine service or maintenance as described in this manual

and associated literature is required, contact a qualifi ed service

agency. DO NOT ATTEMPT REPAIRS. An inadvertent service

error could result in a dangerous condition.

AVOID ERROR IN PARTS SELECTION. When ordering

use complete EMBERGLO Part Number and Description.

Furnish Model Number, Bill of Material Number and Serial

Number (if available) from the specifi cation plate found on

the product.

IMPORTANT: Availability of parts as well as specifi cations

are subject to change without notice. Please consult factory

for item availability.

SAFETY INFORMATION TERMS: The following terms are used to identify hazards, safety precaution of

special notations and have standard meanings throughout this manual. They are printed in all capital letters

using a bold type face as shown below, and preceded by the exclamation mark symbol. When you see the

safety alert symbol and one of the safety information terms as shown below, be aware of the hazard potential.

EmberGlo

A Div of Midco® International Inc.

4140 West Victoria Street

Chicago, Illinois 60646

toll free 866.705.0514

tel 773.604.8700

fax 773.604.4070

web www.emberglo.com

e-mail sales@emberglo.com

DANGER: Identifi es the most serious hazards which will result in severe personal injury or

death.

WARNING: Signifi es a hazard that could result in personal injury or death.

CAUTION: Identifi es unsafe practices which would result in minor personal injury or product and

property damage.

As an ISO 9001:2008 certifi ed company, we proudly design, manufacture and assemble our products in Chicago, Illinois, USA.

Quality Designed for Proven Performance

Counter Top Models

Floor Models

FOR YOUR SAFETY

318

8471 65

Printed in USA

Page 2

E2436 - Installation and Maintenance

Installation

Preventative

Maintenance

Wiring: All units are shipped wired for single phase current.

Ventilation: Do not install broiler closer than 5″ to the back or 8″ on the side walls. LEGS SHIPPED

WITH THE UNIT MUST BE INSTALLED WITH LEG CHANNELS. Minimum leg height, with no

blockage around the bottom of the broiler, must be maintained for proper ventilation.

FAILURE TO INSTALL OR REMOVAL OF THE LEGS IS A VIOLATION OF THE APPROVAL

SEALS AND VOIDS THE MANUFACTURER’S WARRANTY.

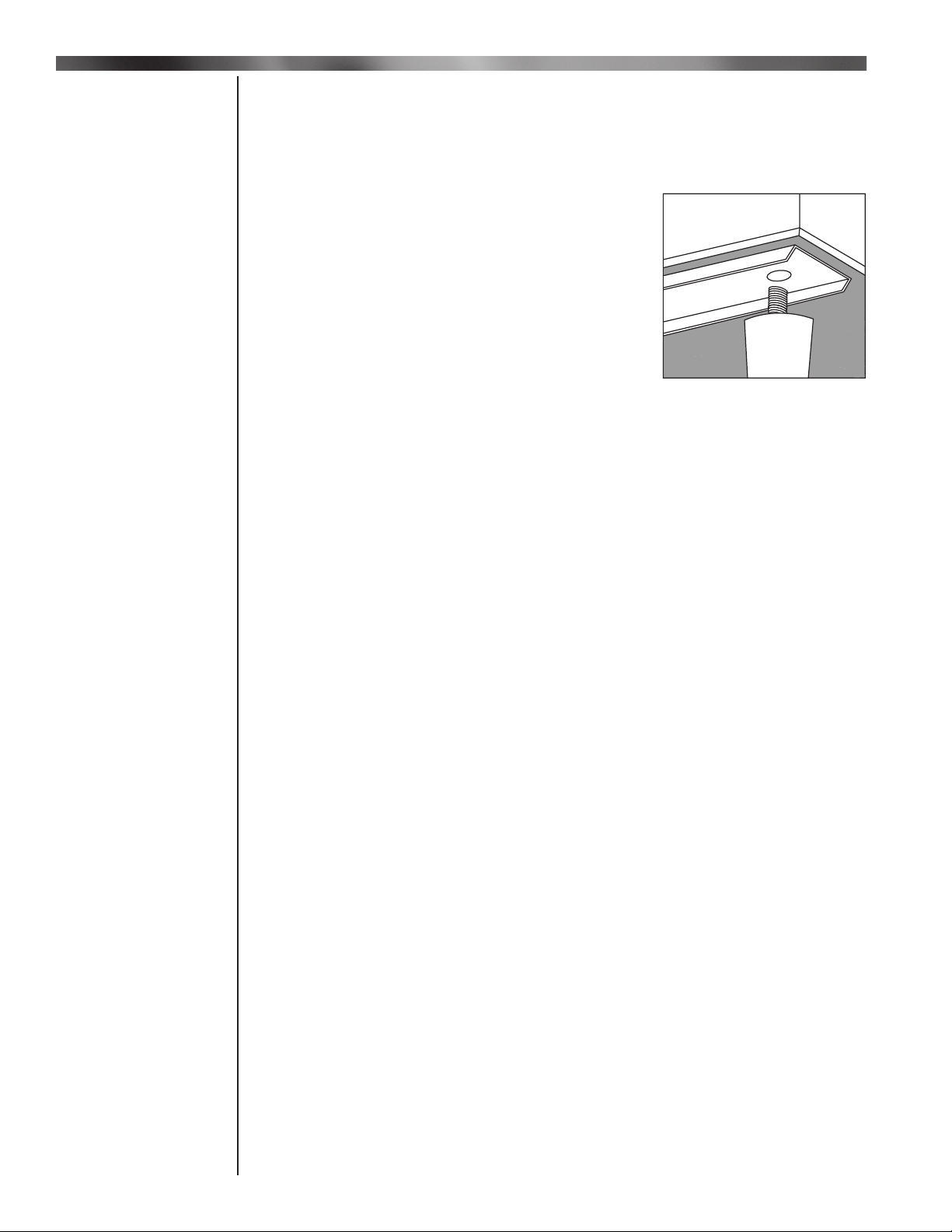

- Remove the leg channels and knobs that are packed in the

broiler (located in the hopper front). The leg channels are two

long pieces of U-shaped steel designed to prevent warping of

the broiler frame when the broiler is moved by sliding on its legs.

See Figure 1

- Prop the broiler up and line up the holes in one of the leg

channels over the holes for the weld nuts on the front end of the

broiler.

- Screw two of the legs provided into the weld nuts to attach the

legs and hold the leg channel in place.

- Repeat procedure for the rear legs.

Figure 1 - Leg Placement

Turn the dial to “HI” and preheat for 20 minutes. Dial down to achieve desired cooking temperature.

______________________________________________

NOTE: Always clean the unit starting at the top and working down. Be sure that the grease hopper

and grease pan are in place before you proceed with any cleaning procedure in order to prevent any

scrapping or grease from dropping into the base and onto electrical wiring and terminal blocks.

FRONT OF BROILER

LEG CHANNEL

LEG

Daily Maintenance

- With normal use of the broiler, deposits build up on the top and bottom of the grate. In order to

assure safe operation, these deposits must be cleaned periodically during the day from both the top

and underside of the grill or grate casting.

a. To clear the top of the casting, scrape each groove with the tip of the scraper provided

until the surfaces are clear.

b. To clear the underside of the casting, insert the scraper head through the slots of the

grill and turn the scraper handle parallel to the grooves. Pulling upward, scrape

deposits from the grill underside. Repeat for each groove.

c. Empty grease pan periodically to avoid messy overfl ow.

______________________________________________

- When broiling is fi nished for the day clean as follows:

a. Clean deposits from the top and bottom of the grate as explained above.

b. Empty the hopper, clean and reinsert hopper.

c. Turn unit to “HI” and leave on for approximately 20 minutes. This will char the

remaining grease on the grill casting.

d. Turn off controls. When grill is cool, scrape the underside again and wire brush the

surface to complete cleaning of the grill.

e. Remove and clean the side splash guards and rear trough. Wash the front and rear

wells and wipe along the sides.

f. Wipe the casting with a dry clean cloth -- do not use water or detergent on the castings.

g. Empty and clean the grease pan.

______________________________________________

2

EmberGlo A Division of Midco International Inc

8471 65

Page 3

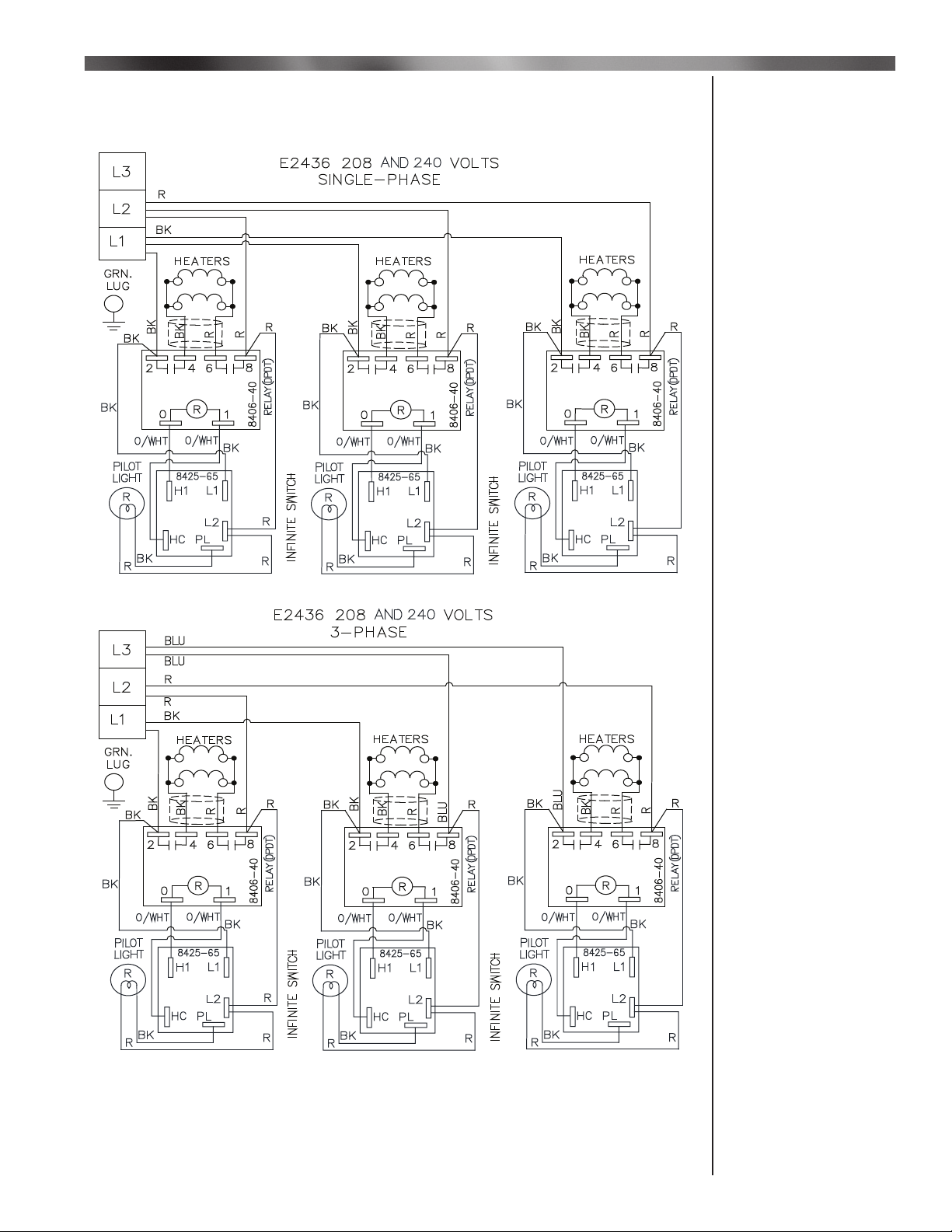

E2436 Electrical Wiring Schematic - 208 & 240 Volt

Schematics

8471 65

Figure 2A - E2436 Schematics for 208 V and 240 V for Single Phase and 3-Phase

EmberGlo A Division of Midco International Inc

3

Page 4

E2436 Electrical Wiring Schematic - 440 & 480 Volt

Schematics Continued

Figure 2B - E2436 Schematics for 440 V and 480 V for 3-Phase

4

EmberGlo A Division of Midco International Inc

8471 65

Page 5

E2436 Exploded View & Parts List

Item Part No. Description Qty

1 1612-90 12″ Grate

2 1609-50 Element w/out Grate 208v 1500w

** 1609-00 Element w/out Grate 240v 1500w 6

** 1609-20 Element w/out Grate 440v 1500w 6

** 1609-30 Element w/out Grate 480v 1500w 6

2A to 2E Repair Assembly - Grate and Element

2A 1612-03 Broiling Grate w/ Element 208v 1500w 6

2B 1612-02 Broiling Grate w/ Element 240v 1500w 6

2C 1612-05 Broiling Grate w/ Element 440v 1500w 6

2D 1612-06 Broiling Grate w/ Element 480v 1500w 6

3 1611-00 Element Clamp 18

4 1711-02 E36 Rear Grease Trough Channel 1

5 1610-00 E Series Right Side Splatter Guard 1

6 8406-40 Switching Relay H-D 3

7 8450-12 6 Inch Leg 4

8 1704-02 E36 Leg Channel 2

9 1604-01 Grease Pan assembly 2

10 1900-03 E36 Control Panel 1

11 1615-00 Red Indicator Light Assembly 3

12 8445-15 Infi nite Knob 3

13A 8425-20 Infi nite Switch

13B 8425-65 Infi nite Switch

14 8408-52 3 Wire Terminal Strip 1

15 4533-22 Emberglo Name Plate 1

w/out Element 3

(shown) 6

(for units built before 2/1/18) 3

(for units built after 2/1/18) 3

Item Part No. Description Qty

16 1610-10 E Series Left Side Splatter Guard 1

17 1900-02 Hopper Kit 1

** Not Shown

1621-00 Grill Scraper 1

1625-04R Relay Repair Kit 1

8447-26 Transformer 1

AVOID ERROR IN PARTS SELECTION. When ordering, use

complete EmberGlo part number and description. Furnish model

number, bill of material number and date code or serial

number from specifi cation plate

1

2

2A

2B

16

17

15

13A

13B

12

2C

2D

3

4

14

5

6

11

8471 65

10

Figure 3 - Exploded View for E2436

EmberGlo A Division of Midco International Inc

89

7

Electric Broiler

Model E2436

5

Page 6

Electric Char Broiler Cooking Guide

... Electric Char-Broiling Grilling Times ...

* Times will vary based upon load size and preference of nished product

ickness Rare Med Well ickness Well

Beef

Filet Mignon, Porterhouse 1″ 8 12 16

T-Bone, Club, Rib 1-1/2″ 12 16 20

Sirloin 2″ 16 22 26

Strip Sirloin 3/4″ 6 8 10

Hamburger,

Ground Chuck, or Round 1/2″ 4 6

Shish Kabobs 1

Skirt Steak 1

″ -- -- 18

″ -- -- 13

8

Poultry

Broiling Chickens 3/4 lb 9

(ready to broil weight for ½ chickens)

Chicken Breasts 1-1/2″ 18

1″ 23

Shellfi sh

Shrimp (Large 12-15/lb) 7

Shrimp Kabobs (Large 12-15/lb) 10

Fish

Fillets (One side without turning) 1/2″ 6

1″ 10

Fish Steaks 1″ 16

1-1/2″ 20

Fish, whole & dressed 3″ 5

Lamb*

Center Cut Loin, Rib 1″ -- 12 18

Sirloin Chops, double Rib 1-1/2″ -- 17 24

English Chops 2″ -- 22 27

Shoulder Chops 1″ -- 12 18

Lamb Riblets 1″ -- 12 18

*These times can be shortened by partial pre, or post cooking

Helpful Hints for the best performance on your Electric EmberGlo Char-Broiler:

Refer to the Electric Char Broiler Cooking Guide brochure - 8474 75E - for more helpful suggestions

Pork

Single Chops 1/2″ -- -- 18

Double Chops 1-1/2″ -- -- 28

Pork Steaks 1″ -- -- 15

Pork Tenderloin 1/2″ -- -- 14

Vegetables

New Red Potatoes (par boiled) 8

Zucchini sliced 1/2″ 6

Corn in husk, silk removed 8 to 10

Eggplant sliced 1/2″ 9 to 11

EmberGlo cooking capacities for electric char broilers were

determined in compliance to UL performance standards.

Hamburgers are to be 30% lean, 4″ diameter x ½″ thick. Only 2

patties are cooked per square foot of grill surface. Burgers are

cooked at maximum temperature.

Production Capacity: E2412 = 60/hr.

E2424 = 120/hr.

E2436 = 180/hr.

1) The temperature at the grill surface, as in all cooking

processes, is most important to the quality of food it produces.

All units will reach proper broiling temperature with a switch

setting of 5 to 5 1/2. This setting will yield between 500° and

550°. The unit will reach broiling temperature in approximately

20 minutes. Any attempt to broil for long periods of time with the

controls above 6 may cause meat to burn. Higher temperatures

allow for rapid cooking times and marked surfaces that some

customers prefer, while low temperatures are for thick cuts of

meat that must cook longer without surface excessive charring.

Extreme grill temperatures should be avoided.

2) Keeping your grates clean after every broil is important. Old

food isn’t seasoning - it’s crud. A clean grate is less likely to be

sticky and will last longer.

6

EmberGlo A Division of Midco International Inc

3) At the end of the day turn unit to “HI” and leave on for

approximately 20 minutes. This will char the remaining grease

on the grill casting. Turn off controls. When grill is cool, scrape

the underside again and wire brush the surface to complete

cleaning of the grill.

4) Always clean the unit starting at the top and working down.

Be sure that the grease hopper and grease pan are in place

before you proceed with any cleaning procedure in order to

prevent any scrapping or grease from dropping into the base

and onto electrical wiring and terminal blocks. Empty grease

pan periodically to avoid messy overfl ow.

5) Wipe the casting with a dry clean cloth -- do not use water

or detergent on the castings.

8471 65

Page 7

Warranty

Warranty

Midco® International Inc Limited Warranty Policy

Exclusions Terms, Customer Requirements and Instructions

All claims should be fi led through Warranty Central.

Call factory for information (773 604 8700)

Only Authorized Service Providers are authorized to provide Limited Warranty service on all EmberGlo

a Division of Midco® International Inc., food equipment as described under and Midco® International

Limited Warranty Policy. A list of providers can be found on our web site: www.emberglo.com

Provisions:

In lieu of an implied warranty, all repairs and replacement parts furnished under our Limited Warranty

shall be f.o.b. point of distribution, but the owner must pay the necessary freight, delivery and labor

costs involved when required. Any Federal, State or Local taxes are also extra. This Limited Warranty

is eff ective for a period of one year from date of installation. EmberGlo

®

Char Broilers and EmberGlo®

Electric Food Preparation Equipment manufactured by Midco International, sold under the EmberGlo

trademark, are guaranteed to be free from defect in material and workmanship under normal use and

service for a period of 1 (one) year after the date of original installation. Midco’s obligation under

this Limited Warranty Policy shall be limited to repairing or replacing, at our option, any part of said

equipment which Midco examination shall disclose to its satisfaction to be thus defective.

Exclusions:

This Limited Warranty Policy does not apply to damages resulting from accident, misuse, abuse

or alteration, nor does it apply to limed steam generators, nor does it apply to any consequential

damages. Most geographical areas require the use of distilled or demineralized water. Tap water is

permissible only with ES Series Steamers. Nor does it apply to Barbriq’s

®

, briquettes, or rods used in

gas broilers. Midco’s obligation will be the replacement of the product or parts removed.

Terms:

Under the terms of this Limited Warranty Policy, models considered portable (devices with cords and

plug caps such as EmberGlo Steamers) must be taken or returned to the nearest service provider,

transportation prepaid, returned transportation collect. Non-portable units with permanent wiring will

be serviced on the customer’s premises. Under these terms, Midco agrees, within the terms of this

Limited Warranty period, to make all repairs at no charge by the authorized service provider. Labor

and mileage charges submitted by any other provider not authorized will be the responsibility of the

customer.

Customer Requirements:

All charges related to repairs made one (1) year after the date of original installation, during the

Limited Warranty period will be the responsibility of the customer. The product registration information

is located on the product I.D. plate.

®

Warranty

,

®

If a part is defective due to workmanship or materials and is removed from the product within

the applicable warranty period and returned to Midco in accordance with the following procedure

described, Midco will, at its option, either repair or replace the part.

Call the factory for Instructions on returned goods.

No equipment may be returned without written authorization from MIDCO. Returned goods

must be shipped prepaid to the factory.

WARNING: Improper installation and use of this product could result in personal or

property injury.

8471 65

EmberGlo A Division of Midco International Inc

7

Page 8

ISO

9001

C

O

M

P

A

N

Y

R

E

G

I

S

T

E

R

E

D

MADE in the USA

As an ISO 9001:2008 certifi ed company, we proudly design, manufacture and assemble our products in Chicago, Illinois, USA.

toll free: 866 705 0515 - tel: 773.604.8700 - fax: 773.604.4070 - web: www.emberglo.com - e-mail: sales@emberglo.com

EmberGlo A Division of Midco International - 4140 West Victoria Street - Chicago, Illinois 60646

318

8471 65

Printed in USA

Loading...

Loading...