Troubleshooting

Guide

EmberGlo Model AR60

EmberGlo

A Division of Midco International Inc.

4140 West Victoria Street

Chicago, Illinois 60646

tel 773.604.8700

fax 773.604.4070

web www.emberglo.com

Quality Designed for Proven Performance

WARNING:

Unplug power supply cord before removing top

and back. Procedures described in this booklet are

to be done with unit disconnected from power source.

PRINTED IN U.S.A.

1098

8471-08

Operation overview

Operational guidelines 1

Problems

Unit will not heat up and light is out 1

Unit will not heat up and light is on 1

Unit heats up but does not steam—

water system problem 2

Unit Heats up but does not steam—

generator problem 3 & 4

Unit steams but food is wet or soggy 4

Unit steams but very slowly 4

Schematic drawings

AR60 Internal Wiring 4

AR60 Exploded View 5

Replacement parts

AR60 Parts and Hardware List 6

Contents

EmberGlo Model AR60

Operational Guidelines

For maximum performance of Model AR60 the following

recommendations should be followed.

1. Use distilled water only.

Most areas of the country require use of room temperature

distilled water otherwise the generator will become clogged

with mineral deposits. Do not use cleaners, de-limers or other

chemicals in the steamer.

2. Keep water pan clean.

Food particles and debris will restrict or stop the amount of

water reaching the generator. A strainer inside pump inlet tube

will collect any foreign matter and should be checked periodically

to see if water supply is being kept clean.

3. Allow steamer to heat up for 20 minutes before using.

This helps reduce condensate and poor performance.

4. Keep drawer closed when not in use.

This keeps the food pan hot and reduces condensation in the

steam chamber.

5. Avoid over-pumping.

The steamer is designed to steam once every 20 seconds.

Constant pumping more frequently than this will reduce

the performance or even cause generator flooding.

1

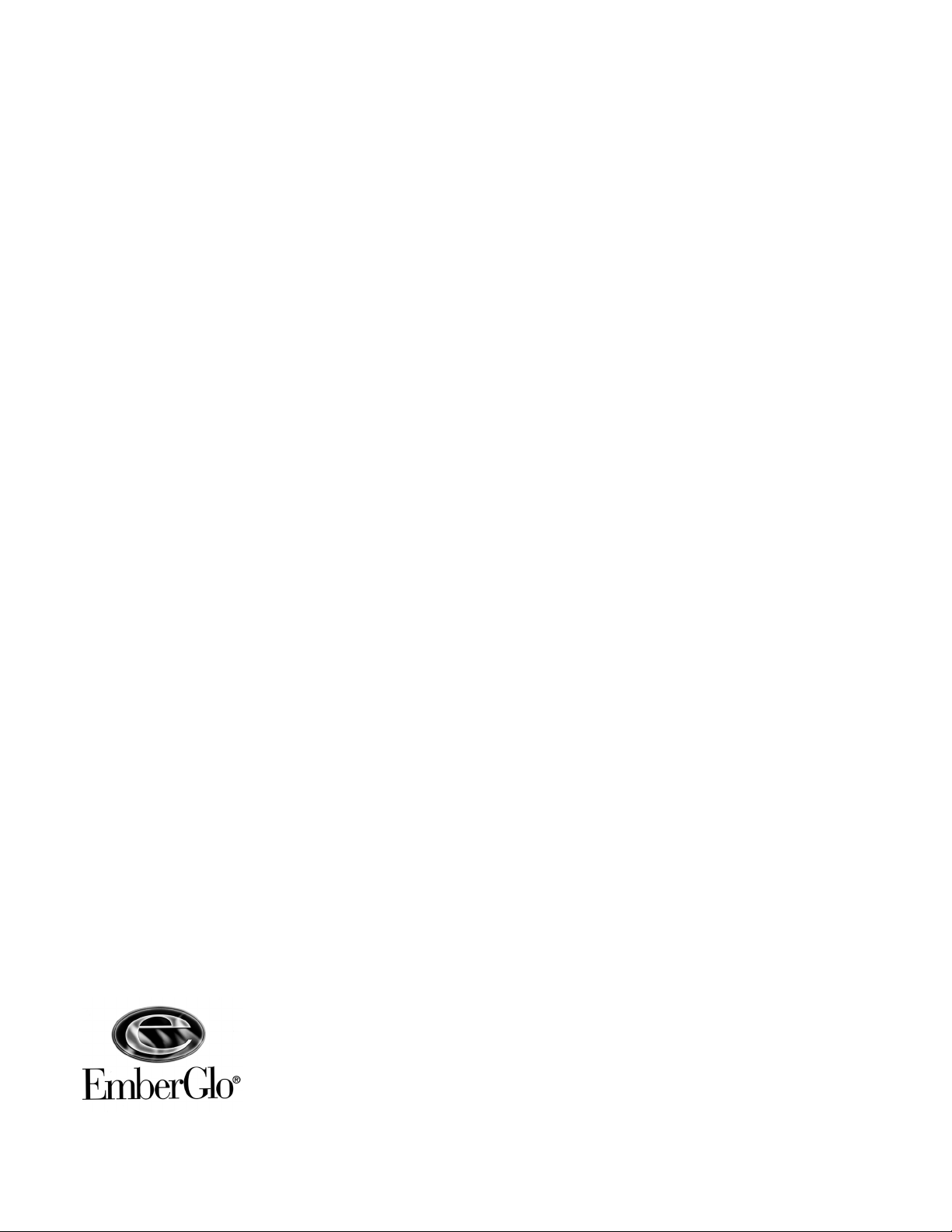

Unit Will Not Heat Up and Light Is Out

(See Figure 1)

1. Unit is unplugged.

Plug unit in.

2. No power to outlet.

Check voltage at outlet. It should be 115-120 volts.

If there is no voltage, then problem is in building circuit.

3. Defective switch.

Check continuity through switch. If there is no continuity,

then replace switch.

4. Loose or broken wire.

Check continuity from cord plug to switch, from switch to

thermostat, from thermostat to element, from element back

to plug. Tighten loose screws or replace defective cord or wire.

Be sure white (neutral) is connected to non-switched terminal

of power switch.

Figure 1

Unit Will Not Heat Up and Light Is On

1. Defective thermostat.

Check continuity across thermostat when unit is off and at room

temperature. If there is no continuity, then replace thermostat.

Thermostat is normally closed and opens at 350°F. Thermostat is not

repairable.

2. Defective generator element.

Check continuity at element terminals. An ohmmeter check

across element terminals should read about 10 Ω. If no continuity,

then replace generator.

3. Loose or broken wire.

Check continuity between switch and thermostat and thermostat

and element. Tighten screws or replace open wire.

(See Figure 2).

Figure 2

2

Unit Heats Up But Does Not Steam—

Water System Problem

1. No water in pan or water below inlet tube.

Fill water pan to about 1/4" of top of water pan baffles. The water

pan will comfortably hold about 3

1

/4quarts of water. This is enough

water to operate the steamer constantly at maximum capacity for

about two hours.

(See Figure 3).

Figure 3

Figure 5

Figure 4

2

4

3

2. Crank or linkage defective or disengaged.

(See Figure 4).

Remove top and rear panels, then operate pump handle and observe

pump shaft at rear of unit. Pump shaft should move about

7

/8" as

handle is depressed. Spring should return handle to upright position.

Replace defective or worn parts

or reconnect disengaged parts.

3. Clogged pump strainer.

Loosen inlet check nut and remove strainer. Clean strainer

and reassemble.

4. Leak in pump tube assembly.

Remove pump tube assembly and look for cracks or holes in plastic

tube. Replace if defective.

(Note: The open end of dip tube spring hook must be at

bottom of water pan.)

5. Defective pump.

(See Figure 5)

The pump is constructed with ball and spring check valves.

The valves may be inspected by removing pump from machine

and then disassembling valves. Look for broken springs, damaged

balls and damaged or worn seats. Sometimes just a tiny particle

on the ball seat can cause problems. Clean seats, replace defective

parts and reassemble.

(Note: Do not over tighten fittings. They should be just tight

enough to prevent leaking.)

• Test by assembling pump tube assembly to pump and immersing

end of plastic tube in water. Pull pump shaft out. Push pump shaft in

and a stream of water should shoot out of outlet fitting several feet.

Try pump several times in this manner to make sure it performs well.

If it does not, then replace entire pump (pump piston and cups are

not replaceable).

3

Figure 6

Unit Heats Up But Does Not Steam—

Generator Problem

(See Figure 6)

• If, after checking all preceding items, nothing wrong is found,

then disconnect the riser tube at the generator fitting and operate

the pump. A stream of water should shoot out of riser tube about

ten to fifteen feet.

• If it does not, then remove riser tube and check for blockage.

If riser tube is open, then recheck items on preceding pages. Water

must shoot out of riser tube before proceeding.

• If water shoots out of riser tube, but unit does not steam,

then check for blockage of steam holes at generator clean out.

Remove cover and gasket (replace old gasket with a new gasket

before reassembling). Center hole usually clogs first because

it is smaller.

(See Figure 7.)

6. Center hole cleaning.

Clean center hole with 7/64diameter drill and two side holes with a

3

/16diameter drill.

(See Figure 7.)

• If unit still does not steam, then generator is probably "limed"

and must be disassembled and cleaned.

(See Figure 8).

• To clean generator, first remove generator and discharge plate

from unit. Separate generator from discharge plate and clean "lime"

from generator cavity, holes, and distribution grooves.

(See Figure 8).

7. Steam hole cleaning.

Clean twelve steam holes in discharge plate. Remove loose "lime"

from discharge plate.

8. Discharge plate care.

Do not scrape away all "lime" from center of discharge plate.

A thin coat of "lime" promotes steaming. Polishing discharge plate

may reduce steaming.

Figure 7

• To reseal generator, first place discharge plate on steamer so that

the twelve steam holes line up with the twelve round holes in steam

chamber. From inside of steam chamber, insert two carriage bolts in

opposite corners and through discharge plate. Tape the bolts in place

from inside steam chamber.

Figure 8

Figure 9

9. Reassemble generator.

(See Figure 9).

Apply a

1

/16" to 1/8" diameter bead of RTV silicone sealant around

cavity in generator as shown. Use your finger to smooth out

the silicone, otherwise the generator will not seal properly.

Dow Corning 732 or GE 159 silicones are acceptable. The silicone

must be good to 450°F. Do not apply too much silicone because

it may block steam holes. Then put generator on steamer and

reassemble. Tighten generator nuts to fifty to sixty in/lbs. Allow

RTV to cure for about twenty-four hours before using steamer.

(Generator Gasket (5602-00) can be used instead of resealing with

RTV sealant. It requires no additional silicone and allows immediate

use of steamer since no cure time is needed).

• Check overheat indicator label on clean out cover to see if unit

has overheated. If triangle on Celsidot 450°F label has turned black,

unit has reached at least 450°F. Thermostat should be replaced.

4

Unit Steams But Unit Is Wet or Soggy

1. Check for excessive steam.

Excessive pumping may flood the generator and cause water to

"blow through" onto food. Steamer is designed to be pumped at

twenty second intervals. It is acceptable to operate pump once,

then wait a couple of seconds and operate again. More frequent

pumping than this may result in "wet" food.

2. Check food pan for water.

Operate pump once, without any food in food pan, then open food

drawer to look for water puddles. If you see one or two puddles of

water in the food pan and can see water run out of the steam hole

in the steam chamber then the generator is probably defective. Refer

to pages 3 and 4 to reseal generator.

Unit Steams But Very Slowly

1. Check water delivery system.

First check for a problem in the water delivery system. Review pages

2 and 3. If no water system delivery problems are found, then the

generator may be partially clogged. Pages 3 and 4 discuss steps to

check and reseal generator.

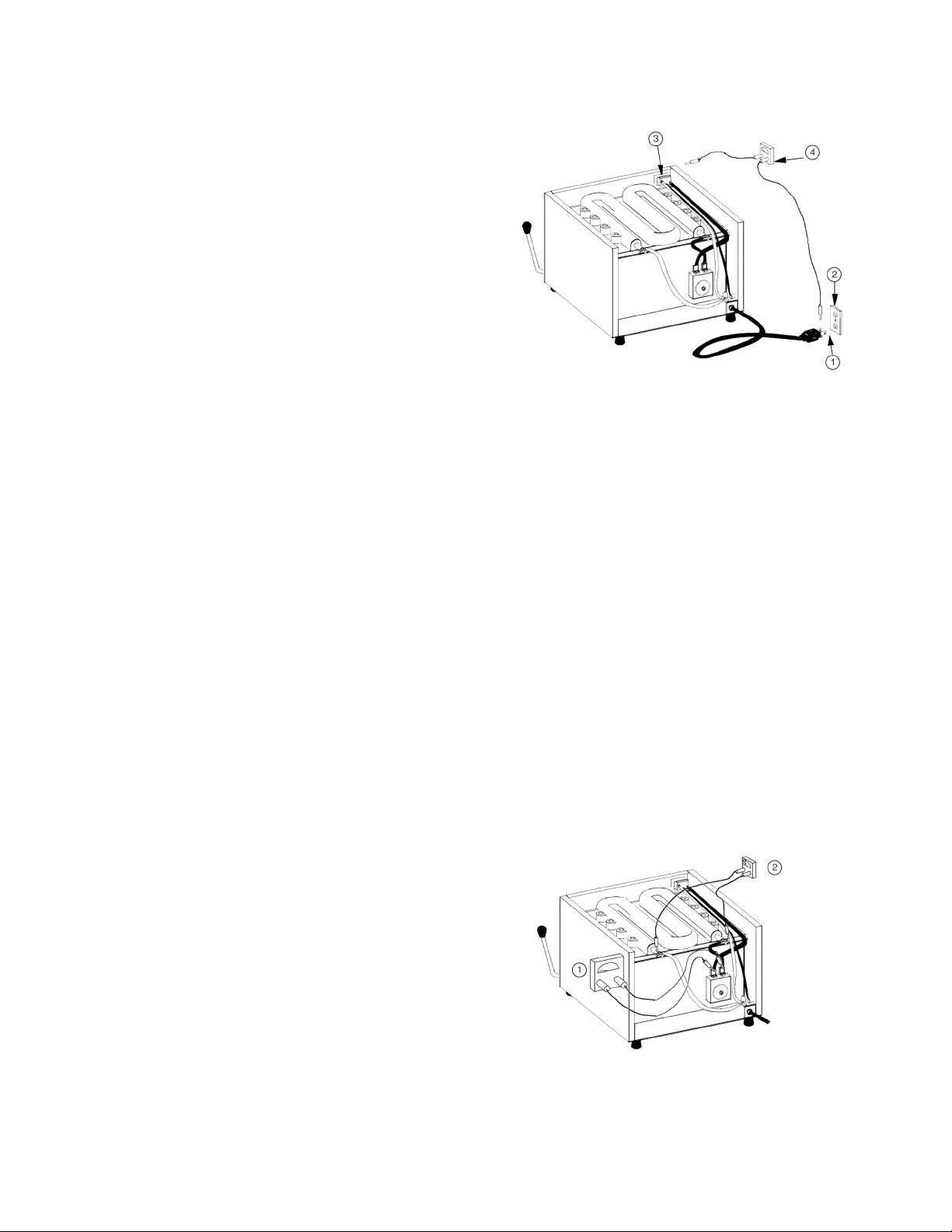

Internal Wiring of

EmberGlo Model AR60

All wiring is 16GA nickel plated copper

with silicone insulation and glass braid 200°C.

(See Figure 10 for wire locations.)

Figure 10

Model AR60 Exploded View

5

120V 12.5A 1500W

AR60 Replacement Parts List

PART NUMBER DESCRIPTION

1 1694-00 Caution Label

2 2618-00 Cord Set

3 5686-00 Water Pan Baffle (2-Required)

4 2625-30 Pump Spring

5 5601-40 Generator Insulation

6 5602-20 Clean Out Cover Gasket

7 5601-90 Clean Out Cover

8 5604-35 Dip Tube Spring Assembly

9 5604-83 Spacer

10 5682-00 Slide Channel Rivetment

11 5682-50 Food Pan Grid

12 5688-00 Water Pan Weldment

13 5676-50 Cabinet Top

14 5615-02 Pump Handle

15 5616-90 Strain Relief

16 5622-00 Steam Range Nameplate

17 5683-50 Food Pan 4" Deep

18 2608-10 Discharge Plate

19 5655-00 120V Generator

20 5685-00 Steam Chamber Weldment

21 5691-00 Steam Chamber Bottom Rivetment

22 5686-50 Food Drawer Rivetment

23 5687-00 Door Liner/Gusset Weldment

24 5617-90 Crank

25 5680-50 Rear Leg

26 5660-00 Pump/Check Valves

27 5617-20 Pump Chassis

28 5677-00 Cabinet Back

29 5678-50 Upper Switch Panel

30 5678-00 Food Door

31 5660-80 Left Cabinet Side

32 5660-81 Right Cabinet Side

33 5693-00 Riser Tube

34 5693-10 Dip Tube Assembly

35 5661-30 Bulb Clamp

36 5661-40 Heyco Mount

37 5661-50 Upper Switch Panel Spacer

38 5661-70 Left Water Pan Support

39 5661-71 Right Water Pan Support

40 5661-80 Rear Foot

41 5661-90 Steam Deflector

42 2636-10 Pump Rod End

43 5663-10 Slide Channel Stop

44 5663-90 Food Drawer Nut Plate (2-Required)

45 8423-14 Toggle Switch

46 8452-08 Thermostat

47 8445-00 Ball Knob

48 8445-01 Water Pan Knob

49 8445-04 Black Vinyl Grip Handle

50 8450-11

3

/32x 5/8Woodruff Key

51 8450-19

3

/8Nyliner

PART NUMBER DESCRIPTION

52 8450-25 Socket Tip (4-Required)

53 8451-36 10-24 x 1

1

/2Stainless Steel Carriage Bolt

(16-Required)

54 8451-44 Strainer

55 5617-80 Foot/Bolt

56 5655-20 Crank Stop Post

57 8480-17 74B Wire Nut (2-Required)

58 8483-00

1

/8M x 1/4T Compression El

59 8496-11

1

/8Brass Pipe Plug

60 6-32 x

1

/8Slotted Round Head Zinc Plated

(2-Required)

61 6-32 x 1 Slotted Oval Head Nickel Plated (2-Required)

62 6-32 Hex Nut Zinc Plated (2-Required)

63 No. 6 Split Lockwasher Stainless Steel (2-Required)

64 No. 8 x

3

/8Phillips Round Washer Head

65 10-24 x

3

/8Slotted Round Head Stainless Steel

(13-Required)

66 10-32 x

1

/4Slotted Pan Head Stainless Steel

(2-Required)

67 10-24 Hex Nut Zinc Plated (23-Required)

68 No. 10 Flat Washer Zinc Plated (16-Required)

69 10-24 x

7

/8Slotted Round Head Stainless Steal

(2-Required)

70 No. 10 Split Lockwasher Stainless Steel (16-Required)

71 10-24 x

1

/4Slotted Pan Head Stainless Steel

72 10-32 x 3/8 Phillips Truss Head Stainless Steel

(4-Required)

73 2626-00 Check Valve Pin

74 Pump End Clip

75

1

/8x 1 Cotter Pin Zinc Plated

76

1

/2-20 Pal Nut 1220 Zinc Plated

77

5

/16-24 Hex Jam Nut

78 Pump Shoulder Bolt

The Following Kits Are Available

2608-80 (16) 8451-36 Stainless Steel Carriage Bolts

with nuts and washers

5602-00 Generator Gasket

5604-35 (1) 5604-30 Dip Tube Spring Assembly with nut

5615-10 (1) 5615-02 Pump Handle with 8450-19 Nyliner,

8450-11 Woodruff Key and

1

/8x 1 cotter pin

5627-20 (1) 5601-90 Clean Out Cover, (2) 5602-20 Clean Out

Cover Gasket with (2) 10-24 x

3

/8slotted round head

screws, (2) No. 10 split lockwashers and Celsidot label

5652-70 (1) 8543-13 Wire Assembly Black, (1) 8543-14 Wire

Assembly Black, (1) 8551-17 Wire Set White, (1)

8551-18 Wire Set Black, (1) 8551-20 Wire Set White

Loading...

Loading...