emaux ST Series, STA Series Instructions Manual

Before installation, be sure to read all instructions and warnings carefully.

Refer to product data plate(s) for additional operating instruction and specifications.

INSPECTION

Examine the equipment when received. Notify your dealer or carrier of any damage or

missing parts. Verify that equipment is of size and model specified.

When installing and using this electrical equipment, basic safety precautions should

always be followed, including the following:

1) READ AND FOLLOW ALL INSTRUCTIONS.

2) WARNING - To reduce risk of injury, do not permit children to use this product unless they

are closely supervised at all times.

3) WARNING - (For cord & plug connected units) risk of electric shock. Connect only to a

grounding type receptacle protected by a ground-fault circuit-interrupter(GFCI).

Contact a qualified electrician if you cannot verify that the receptacle is protected by a

GFCI.

4) WARNING - (For cord & plug connected units). To reduce the risk of electric shock,

replace damaged cord immediately.

5) WARNING - (For cord & plug connected units). To reduce the risk of electric shock do not

use an extension cord to connect unit to electric supply; Provide a properly located

outlet.

6) WARNING - (For hot tub and spa pumps). Do not install within an outer enclosure or

beneath the skirt of the hot tub or spa, unless so marked.

7) SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

EMPU16 02275 5

ST & ST Series PumpA

14

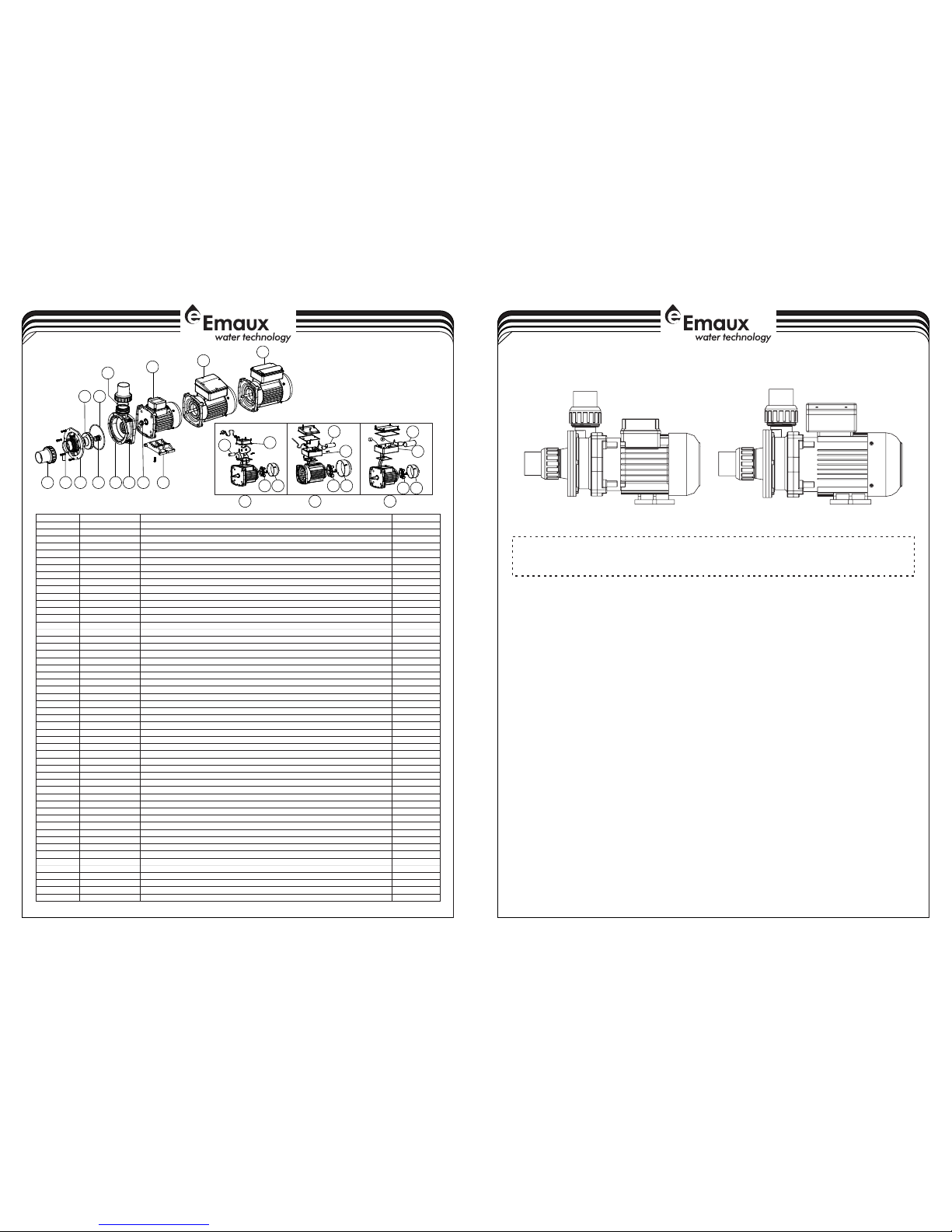

PUMP PAR TS FO R S T

Key No.

Part No .

Descr iptio n

Qty

1*

89280 105

1.5"u nion (B lack/ W hite Co lour)

2

2

89022 103

M5*16 S crew fo r pump fr ont wit h Washe r

6

3

01021 046

ST SD Pum p Body Co ver

1

4

02011 076

O-Rin g for Pum p Body

1

5

01311 015

Impel ler SD0 20/SD 50/SQ 20/SQ 50/SS 20/SS 50/ST 20/ST 50

1501311 016

Impel ler SD3 3/SD7 5/SQ3 3/SQ7 5/SS3 3/SS7 5/ST3 3/ST7 5

1

5

01311 017

Impel ler SD0 50/SD 100/S Q050/ SQ100 /SS05 0/SS1 00/ST 050

1

5

01311 018

Impel ler SD0 75/SD 120/S Q075/ SQ120 /SS07 5/SS1 20/ST 075

1

5

01311 019

Impel ler SD1 00/SQ 100/S S100/ ST100 (220V /50HZ )

1

5

01311 014

Impel ler SS1 20(22 0V/50 HZ)

1

5

01311 023

Impel ler SD0 20/SQ 020/S S020/ ST020 (220V ,110V /60HZ )

1501311 024

Impel ler SD0 33/SQ 033/S S033/ ST033 (220V ,110V /60HZ )

1

6

04015 033

1/2" Me chani cal Sea l

1

7

01021 024

SD SQ ST Pu mp Body

1

8

89022 104

M8 x 25 Scr ew with W asher f or Moto r

4902011 156

Motor S linge r

1

10

89022 109

Motor S D020/ SQ020 /SS02 0/ST0 20(22 0V/50 HZ)

1

10

89022 110

Motor S D033 (2 20V/5 0Hz)

1

10

89022 105

Motor S D050/ SQ050 /SS05 0/ST0 50(22 0V/50 HZ)

11089022 106

Motor S D075/ SQ075 /SS07 5/ST0 75(22 0V/50 HZ)

11089022 107

Motor S D100/ SQ100 /SS10 0/ST1 00(22 0V/50 HZ)

1

10

89022 108

Motor S D120/ SQ120 /SS12 0/ST1 20(22 0V/50 HZ)

11089022 201

Motor S D/SQ/ SS/ST 020(2 20V/6 0HZ)

1

10

89022 202

Motor S D/SQ/ SS/ST 033(2 20V/6 0HZ)

1

10

89022 203

Motor S D/SQ/ SS/ST 050(2 20V/6 0HZ)

1

10

89022 204

Motor S D/SQ/ SS/ST 075(2 20V/6 0HZ)

1

10

89022 205

Motor S D/SQ/ SS/ST 100(2 20V/6 0HZ)

1

10

89022 206

Motor S D/SQ/ SS/ST 120(2 20V/6 0HZ)

1

10

89022 305

Motor S D/SQ/ SS/ST 020(1 10V/6 0HZ)

1

10

89022 306

Motor S D/SQ/ SS/ST 033(1 10V/6 0HZ)

1

10

89022 301

Motor S D/SQ/ SS/ST 050(1 10V/6 0HZ)

1

10

89022 302

Motor S D/SQ/ SS/ST 075(1 10V/6 0HZ)

1

10

89022 303

Motor S D/SQ/ SS/ST 100(1 10V/6 0HZ)

1

10

89022 304

Motor S D/SQ/ SS/ST 120(1 10V/6 0HZ)

1

11

89022 101

Base wi th M5 x 20 Sc rew

1

12

04016 028

Capac itor fo r SS/SD /SQ/S T050 Pu mp 110V

1

12

04016 019

Capac itor fo r SC050 & S S/SD/ SQ/ST 075 Pum p 110V

1

12

04016 021

Capac itor fo r SC075 & S S/SD/ SQ/ST 100-1 24 Pump 1 10V

1

12

04016 009

Capac itor fo r SS/SD /SQ/S P/ST0 50 Pump

1

12

04016 010

Capac itor fo r SS/SD /SQ/S P/ST0 75 & SC05 0 Pump

1

12

04016 012

Capac itor fo r SS/SD /SQ/S P/ST1 00-12 0

11204016 032

Capac itor fo r SS/SD /SQ/S T020 Pu mp 110V

1

12

04016 033

Capac itor fo r SS/SD /SQ/S T033 Pu mp 110V

1

12

04016 030

Capac itor fo r SS/SD /SQ/S T020 AM U020P /TP(5 0/60H z)

1

12

04016 031

Capac itor fo r SS/SD /SQ/S T033 Pu mp

1

13

89022 111

Cable B ox for SQ /ST/S D020- 033, SS 020-S S030 Pu mp

1

14

89022 112

Cable B ox for SD ,SQ,S P,ST0 50-12 0 Pump

1

15

89021 505

Cable B ox for ST 050-S T075 Pu mp (110 V/60H Z)

1

16

01031 027

Cooli ng fan fo r SS/SD /SQ/S T050- SS/SD /SQ/S T120 Pu mp

11601031 026

Cooli ng fan fo r SS/SD /SQ/S T020- SS/SD /SQ/S T030 Pu mp

1

17

01031 011

Fan Cov er for SS /SD/S Q/ST0 20-SS /SD/S Q/ST0 30 Pump

1

17

01031 010

Fan Cov er for SQ /SP/S S/SD/ ST050 -SQ/S P/SS/ SD/ST 120

1

18

02011 104

O-Rin g for 1.5 " Union

2

Notes :1* 892 80105 B is 1.5" union i n Black C olour

1* 8928 0105W i s 1.5"u nion in W hite Co lour

1 2

3

4

5

678 9

11

18

10

10

10

13

10

12

16

17

12

14

16

17

10

16

17

15

12

10

220 V 50HZ 220 V 50HZ 110V 6 0HZ

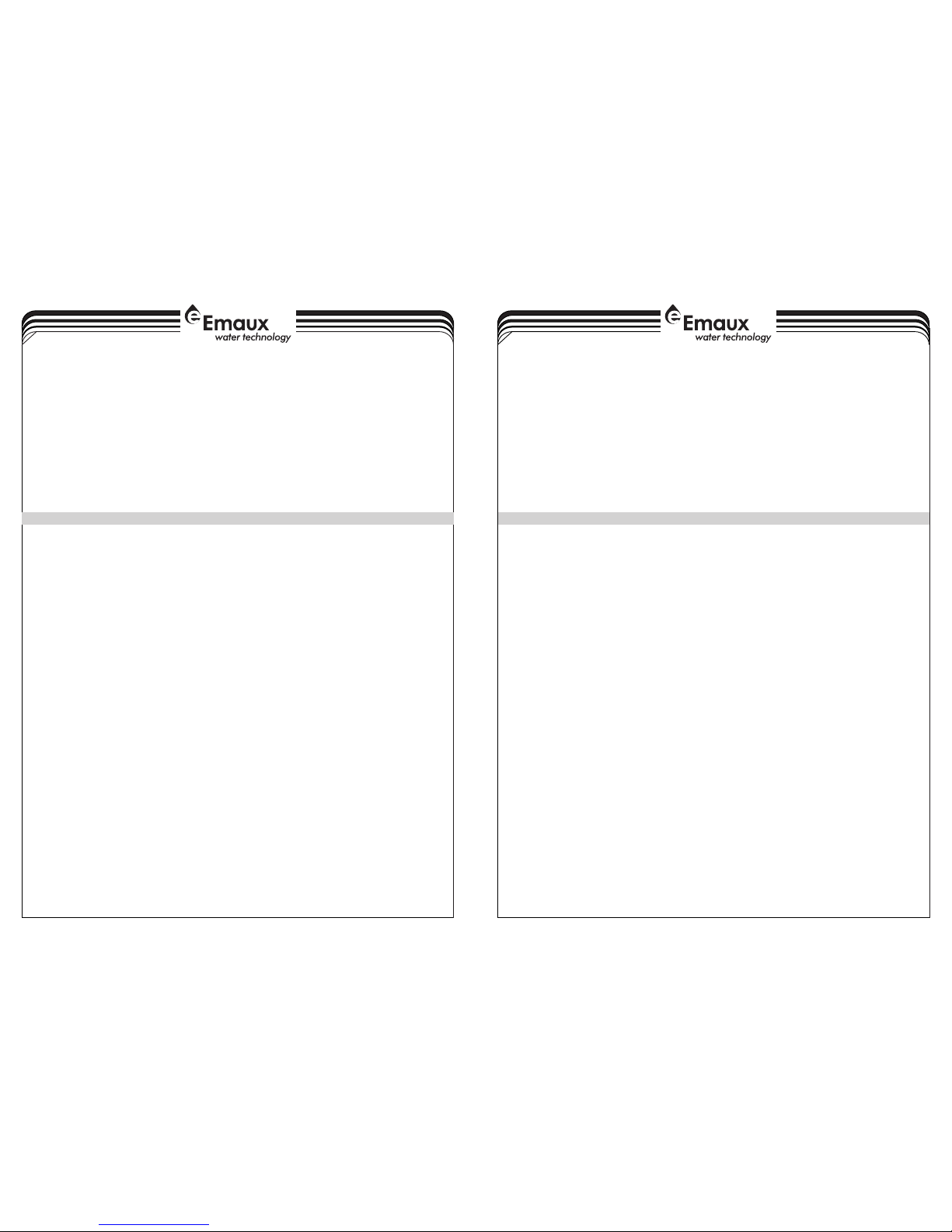

Locate pump as close to pool/spa as possible, preferably in a dry, well ventilated area

away from direct sunlight. It should be on a hard, level surface. Give consideration to:

1) Drainage -away from pump

2) Ventilation of pump motor

3) Access for future servicing and winterizing

4) Protection from the elements

Pumps without strainer bodies are designed for flooded suction (all suction fittings and

suction piping below water level) and will not self-prime. Consequently, the pump must be

installed at an elevation that is below water level when pool or spa is filled.

GENERAL PLUMBING

Rigid or flexible PVC pipe can be used. Pipe ends should be clean and free of any flash

caused by the cutting operation. Be sure that the proper solvent is used on type of pipe

specified.

Caution: We recommend that consider climatic conditions when applying adhesives,

make the adhesive action of certain glues less effective. Check the manufacturer's

instructions.

Refer to information on motor nameplate for electrical service data. All motors should

have fused disconnect switch or circuit breaker. Be sure wire size is sufficient for pump hp

and distance from power source. Wiring should be done in accordance with applicable

codes by a competent electrician.

Do not operate pump until it has been primed as water acts to cool and lubricate the seal.

For pumps without strainer bodies and located above water, close suction line valve and

fill pump with water in order to prime. If no flow is observed in five minutes, stop the motor

and re-prime. If the pump fails to operate, check for air leaks. Refer to trouble shooting

section.

Suction pipe should be as large or large than discharge pipe avoid using a suction pipe

smaller than pump connection.

Keep the piping as straight and short as possible, and of suitable size. Avoid connecting an

elbow directly into the pump inlet(use a length of straight pipe to allow a proper entry for

the water).arrange horizontal runs to slope upward to the pump to prevent high spots that

could form air pockets. Support the piping independently so that it places no strain on the

pump. Keep as much of the suction line as possible below the water level to reduce

priming time.

FOR SOLVENT WELD CONNECTION

ELECTRICAL DATA

PUMP START UP

PUMP PLUMBING

TROUBLE SHOOTING

1) Motors are self-lubricating no lubrication required.

2) Shaft seals may become worn and must be replaced if leakage is observed.

NOTE: If the recommendations in the trouble shooting portion of this manual do not solve

your particular problem(s), please contact your local dealer for service.

Refer all service to your local dealer as his knowledge of your equipment makes him the

vest qualified source of information. Order all repair parts through your dealer. Give the

following information when ordering repair parts:

1) Unit nameplate data.

2) Description of part.

SERVICE & REPAIR PARTS

Motor does not start

1) Disconnect switch or circuit breaker in

off position

2) Fuses blown or thermal overload open

3) Locked motor shaft

4) Motor windings burned out

5) Defective starting switch inside sing

phase motor

6) Disconnected or defective wiring

7) Low voltage

Low pump capacity

1) Suction or discharge line partly

plugged

2) Suction or discharge line too small

3) Pump running at reduced speed

4) Impeller clogged

Pump delivers no water

1) Pump is not primed

2) Leakage or air into suction system

3) Impeller clogged

Noisy pump and motor

1) Worn motor bearings

2) Suction line partly plugged

Leakage of water at shaft

Shaft seal requires replacement

High pump pressure

Return lines too small

Pump does not reach full speed

1) Low voltage.

2) Pump connected for wrong voltage.

Motor overheats

1) Low voltage

2) Inadequate ventilation

Air bubbl es a t i nle t fitt ing s

1 Leaka ge o f air i nto su cti on lin e at

conn ectio ns o r v alv e stem

2 Low water lev el in d rai n o f ba th

)

)

INSTALLATION LOCATION

PUMP MAINTENANCE

32

Loading...

Loading...