emaux SS Installation & Operating Instructions Manual

INSTALLATION

Only qualified, licensed personnel should install pump and wiring.

IMPORTANT ELECTRICAL

Electrical Contractors Please Note: EMAUX pumps must be wired to th e

main power supply through an approved and correctly rated contactor.

Pump Mount Must:

Be solid Level Rigid Vibration Free.

Allow for gate valves in suction and discharge piping.

Have adequate floor drainage to prevent flooding.

Be protected from excess moisture.

All adequate access for servicing pump and piping.

NOTICE:

Pump suction and discharge connections have moulded in thread stops, DO NOT try to screw

pipe in be yond these stops.

Allow use of shor t, direc t suctio n pipe. ( To reduce fri ction lo sses & do n’t i nstall t he p ump a t

m ore t han 3 M g eometrical height from water lev el)

EMPU 1001181 3

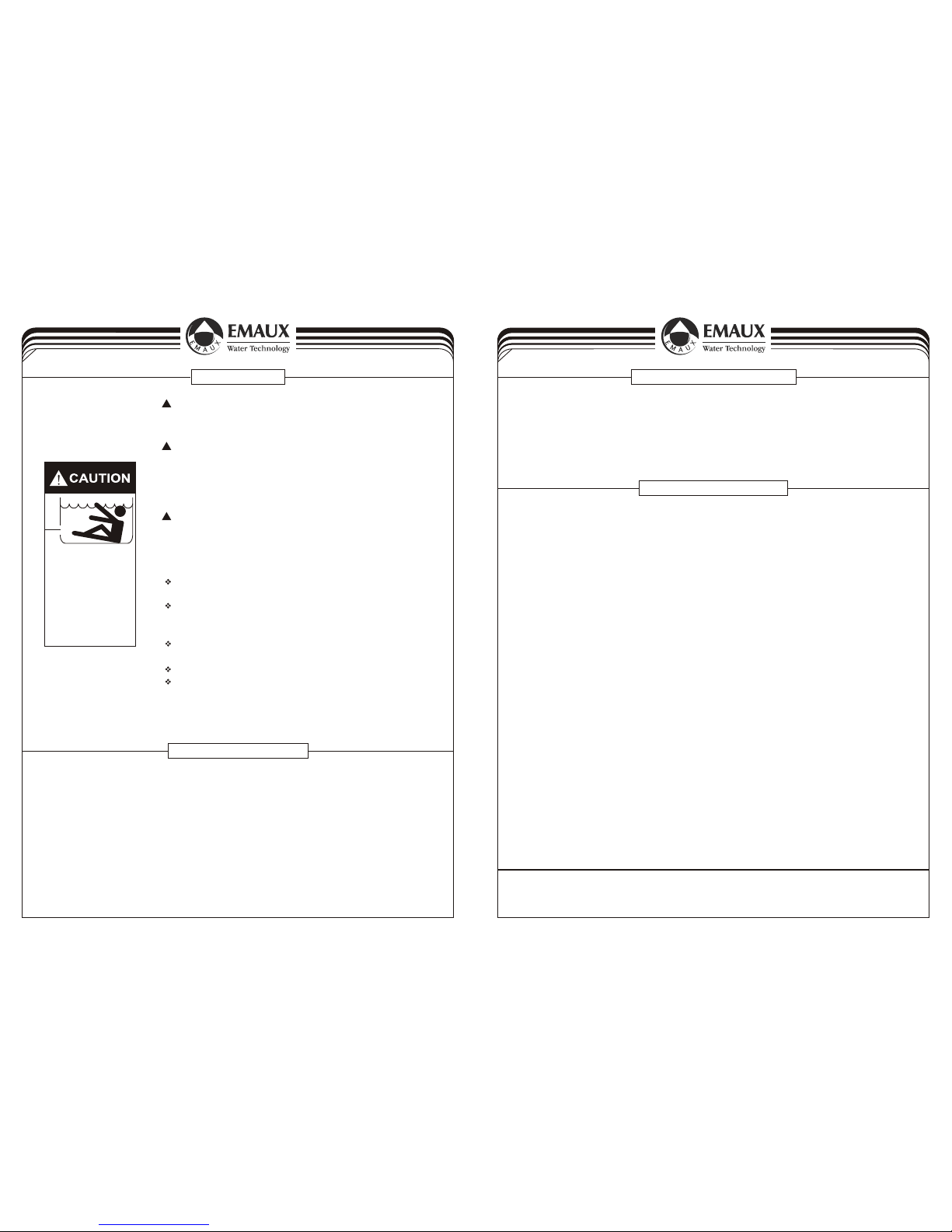

SS Pool & Spa Pump

Installation & Operating Instructions

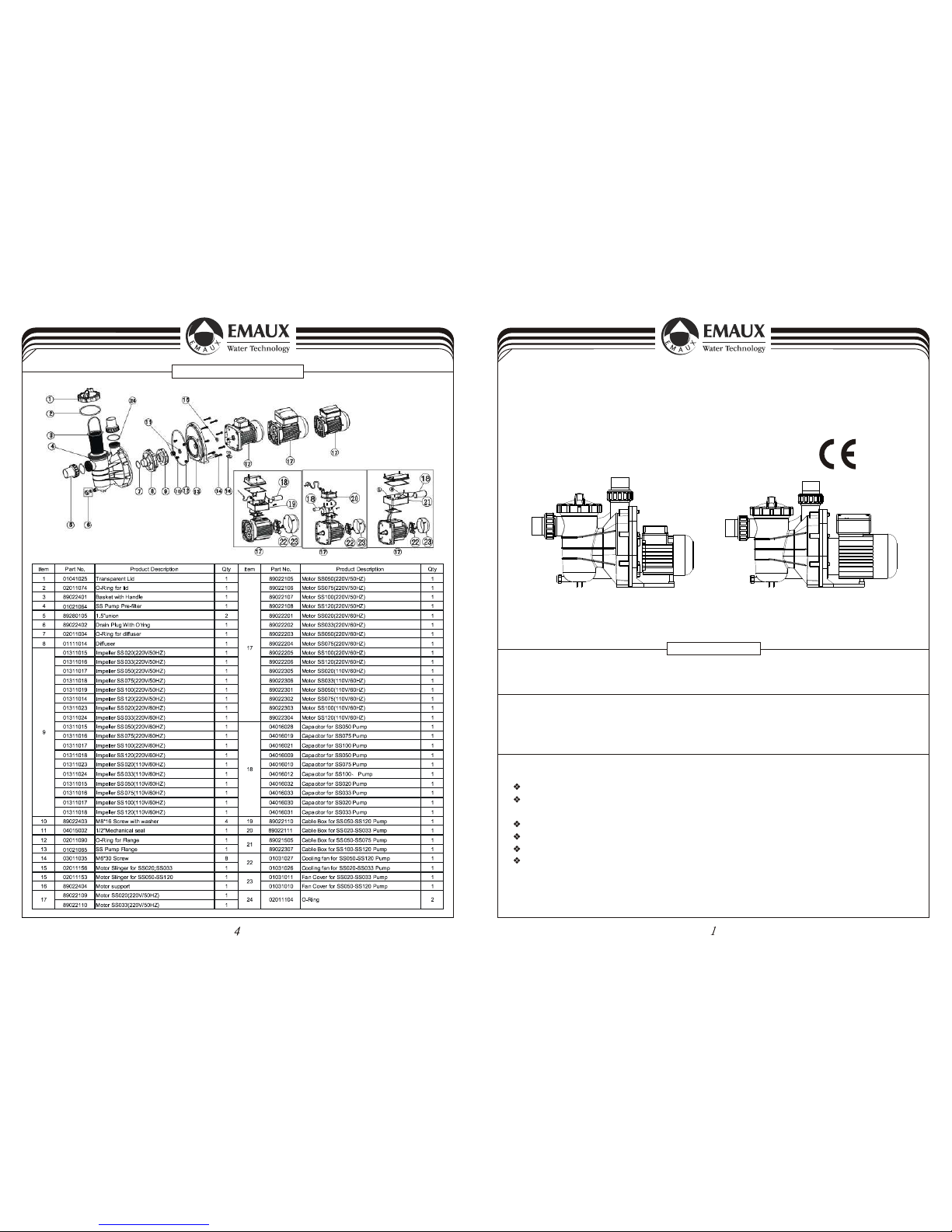

PUMP PARTS FOR SS

2

NEVER run pump dry! Running pump dry may damage seals,

causing leakage and flooding! Fill pump with water before

starting motor.

Before removing lid:

STOP PUMP before proceeding.

CLOSE GATE VALVES in suction and discharge pipes.

RELEASE ALL PRESSURE from pump and piping system.

NEVER tighten or loosen screws while pump is operation.

Do not block pump suction! To do so with body may cause severe or fatal

injury. Ch ild ren u sing pool must ALWAYS hav e cl ose a du lt

Supervision!

Priming Pump:

Release all air from filter a nd piping system: see filter owner

manual.

In a flooded suction system (water source higher than pump),

pump will prime itself when s uction an d discharge valves are

opened.

If pump is not in a flooded suction system, unscrew and remove

trap cover; fill trap and pump with wat er.

Clean and inspect Ring; re-install on trap cover.

Replace trap cover on trap; turn clockwise to tighten cover.

NOTICE: Tighten trap cover by hand only.

Pump should prime now. Priming time will depend on vertical

length of suction lift and horizontal length of suction piping.

OPERATION

!

Hazardous suction.

Can trap hair or

body part, causing

severe injury or

death.

Do not block

suction.

1.

2.

3.

4.

5.

6.

The only ro utine m ainten ance nee ded is ins pection /cleaning of tra p bask et. Debris or tra sh that

collects in basket, will choke off water flow through the pump. Follow instructions below to clean trap:

Stop pump, close gate valve in suction and discharge, and release all pressure from system before

proceeding.

Unscrew trap lid (turn counterclockwise).

Remove strainer basket and clean. Be sure all holes in basket are clear,flush basket with water and

replace in trap with large opening at pipe connection port (between ribs provided). If basket is

replaced backwards cover will not fit on trap body.

Clean and inspect lid Ring; reinstall on trap cover.

Clean Ring groove on trap body and Replace lid. To help keep lid from sticking, tighten hand tight

only.

Prime pump (see priming instructions above)

!

!

!

Routine Maintenance

33

MOT OR DO ES NO T START

1. Di sco nn ect s wi tch o r cir cu it br ea ker i n

of f p os ition

2. Fu ses b lown or ther ma l o ve rload o pen

3. Lo cke d motor s haft

4. Mo tor w indin gs burn ed ou t

5. De fec ti ve st ar ting sw itc h insid e singl

ph as e m ot or

6. Di sco nn ected o r def ec tiv e wirin g

7. Lo w v ol tage

PUM P D OE S NOT REAC H FUL L S PE ED

1. Lo w v ol tage

2. Pu mp co nnect ed for wr ong v oltag e

MOT OR OV ERHEATS ( pr otect or tr ip s)

1. Lo w v ol tage

2. Mo tor w indin gs conn ec ted f or wr on g

vo lt age o n dua l volta ge mo de l

3. In ade qu ate v en tilat io n

PUM P D EL IVERS N O WATER

1. Pu mp is not pr imed

2. Cl ose d valve i n suc ti on or d isc ha rge

li ne

3. Le aka ge or a ir into s uct io n sys te m

4. Im pel le r clo gg ed

LEA KA GE OF WATE R AT SHA FT

1. Sh aft s eal r eq uires r epl ac ement

Re fe r al l s ervic e t o your lo cal ag ent or de aler a s h is k no wl edg e o f your eq uip me nt mak es

him th e ve st quali fi ed sou rc e of in forma ti on. Or de r al l r ep air pa rts th ro ugh yo ur dea le r. Gi ve

the fo llo wi ng inf or matio n w hen or de rin g r epair pa rts :

1. Un it n am eplat e d ata or se ria l n umber on label .

2. De scr ip tion o f p art.

LOW PU MP C APAC ITY

1. Valve in suc ti on or d is charg e l ine pa rt ly

cl os ed

2. S uc tio n o r disc ha rge li ne par tl y p lug ge d

3. S uc tio n o r disc ha rge li ne too sm al l

4. P lu gge d b asket in skimm er or h ai r and

li nt str ai ner

5. D ir ty f il ter

6. I mp ell er clogg ed

HIG H P UMP PRESS UR E

1. D is cha rg e valv e o r inle t f itt in gs clo se d

to o m uch

2. R et urn li nes to o s mall

3. D ir ty f il ters

NOI SY P UM P AND MO TOR

1. P lu gge d b asket in skimm er or h ai r in li nt

st ra ine r

2. W orn mo tor be ar ings

3. Valve in suc ti on lin e p artly cl ose d

4. S uc tio n l ine pa rt ly plu gg ed

5. Vacuu m h ose pl ug ged or too sm al l

6. P um p no t s uppor te d prop er ly

AIR BU BBL ES AT I NLET F ITT IN GS

1. L eakage o f air into suct ion line at

conn ections or va lve s tem

2. C ov er g as ket of ha ir and li nt s tr ainer

ne ed s cl ea ning

3. L ow wat er level in pool

SERVICE & REPAIR PARTS

TROUBLE SHOOTING

NO TE : If th e reco mm endat io ns i n t he tro ub le sho ot ing po rtion of this m an ual do not

sol ve you r p artic ul ar pro bl em( s) , p lea se conta ct you r l oc al d ea ler fo r s erv ic e.

Loading...

Loading...