emaux NL1200, NL1600, NL1800, NL2300, NL1400 User Manual

...

Thi s man ual pro vid es the nec essar y i nstru ction s to insta ll, use an d mai ntain b obb in woun ded

fil ters. In or der t o o bta in th e bene fits that a re in dicat ed in the c har acter istic s, al l t he instr uctio ns

tha t appea r in this m anual m ust be fo llowe d. This w ill off er a safe a nd long -last ing ins talla tion.

The e quipm ent's s uppli er will p rovid e furth er info rmati on to the u ser whe never i t is need ed.

2. Fi lter' s Chara cteri stics .

The ta nk is made of r esi n o f pol yeste r and gl ass fib er, t ota lly anti corro sive. I nsi de, it con tains

col lecto rs an d dif fuser s mad e of unal ter able plast ic ma teria l (PV C an d A BS), proof agai nst s alt-

2 2

wat er. T hey a re su pplie d for a w orkin g pre ssure of 2.5 kg/ cm to 4 kg /cm and max imum

o

tem perat ure of 43 C. O the r speci ficat ions ca n be supp lied up on requ est.

3 2

Fil trati on ra tes m ay be 20 , 30, 40 an d 50 m /h/ m , depen ding on th e app licat ion a nd the k ind o f

fil trati on elem ents th at have b een sel ected . Rate 50 i s not adv isabl e in publ ic pool s.

1. De scrip tion.

The se fi lters have been desi gne d to provi de wa ter filt ratio n in pools and wat er pa rks, also for all

wat er tre atmen ts th at r equir e the elimi natio n of su spend ed ma tte r usi ng t he pr ope r redu ction of

fil trati on elem ent.

Apa rt from the fi lte r i tself , f iltra tion and de pur ation pr ocess in clude so me poi nts that mu st be

tak en in to ac count as t hey can influ ence the corr ect f ilter oper ation . The se would be c hemic al

wat er trea tment , pump eq uipme nt, pip e segme nts and g enera l hydra ulic de sign.

Whe n pub lic p ool s are conc ern ed, t he cu rrent rule s i n eac h c ountr y sho uld be o bserv ed, a s t he

ins talla tion mu st foll ow them .

The filt ratio n qua lit y dep ends on di ffe rent param eters as d ept h of filtr ation bed, char act erist ics,

qua lity an d grade o f filtr ation m edia, e tc, as we ll as fil trati on rate .

To ch ange sa nd or fil trati on elem ents, p rocee d as foll ows:

·Rem ove top l id.

· Dra in filt er's wa ter and s and thr ough th e lower d raina ge hole .

·If th ere is ro om, san d can be re moved t hroug h the man hole.

·To re fill th e filte r with sa nd, fol low the i nstru ction s given i n start ing.

Thi s fil ter h as be en m anu factu red u sing the b est h igh t echno logy mate ria ls an d man ufact uring

pro cess, g oing th rough s trict q ualit y tests o n mater ials, f inish es and pe rform ance.

All those bum ps, ri ps and bre akage s caus ed by a n in adequ ate us e of the produ ct or b y ig norin g

our r ecomm endat ions ar e not inc luded i n this gu arant ee.

The co rre ct perfo rmanc e o f the filt er's tan k a nd the int ernal co mpone nts is guara nteed fo r 1

yea r.

The se gua rante es inclu de o nly the rep lac ement of def ectiv e p art s. Furth er c harge s, as tho se

wor ks made b y third p artie s, comp ensat ions, e tc, wil l not be ac cepte d by the ma nufac turer .

If the equi pment has bee n st opped dur ing a lo ng p eriod of time , it is advi sable to empt y th e

wat er filt er.

·If th e filte r is situ ated ou tside , it is adv isabl e to pain t it with a s uitab le prod uct eve ry two ye ars.

· In stan dar d fi lters , Pre ssure and tem per ature spe cif icati ons mus t no t be exce eded. Cont act

our t echni cal dep artme nt if you h ave any d oubt ab out the u se of our f ilter .

2

· Du ring the wash ing proce ss, press ure must nev er exce ed 1 kg/ cm for filt ers wit h p lat e wi th

noz zles.

·Opt ional ly, hig h perfo rmanc e filte rs can al so be del ivere d with la teral m anhol e and sig ht glas s,

As we ll as spe cial in ner fin ishes o f high ma inten ance qu ality a nd chem ical re sista nce.

It has to be do ne w it h th e pu mp s to pp ed a nd v al ve s in p os it io n.

Models: NL1200 / NL1400 NL1600 NL1800 NL2000 NL2300 NL2500/ / / / /

INTRODUCTION

SAND FILTER

DESCRIPTION

SPECIFICATIONS

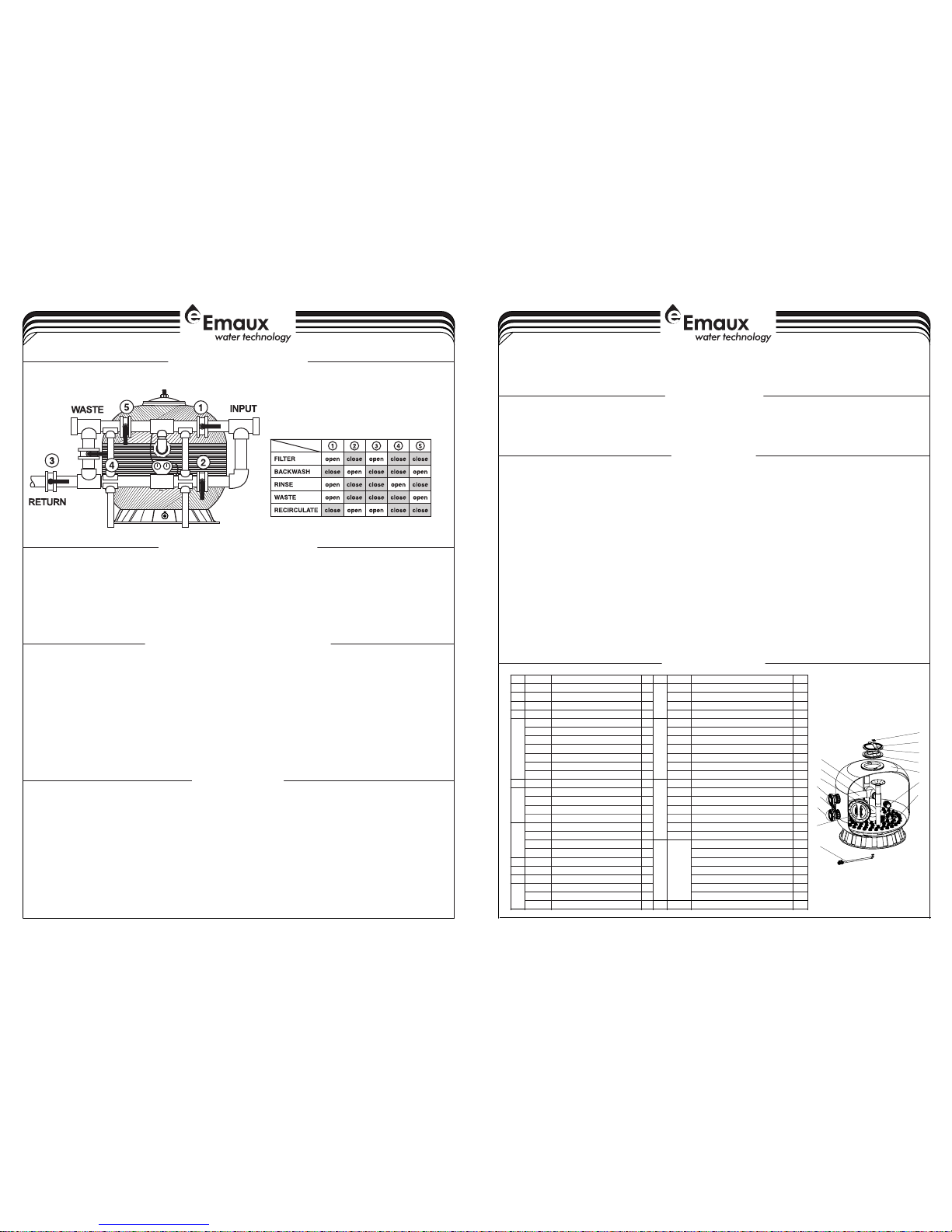

WORKING PROCESS

EMPTYING OF FILTER'S SAND

OTHER RECOMMENDATIONS

GUARANTEE

4-4

1-4

1

2

4

3

6

5

7

8

9

10

11

12

13

14

15

Item

Part No .

Descr iptio n

Qty

Item

Part No .

Descr iptio n

Qty

1

01111 100

Star- Shaped Nut

11289012 821

NL180 0-2. 5/4bar Fi lter Ta nk With B ase

1203042 001

Bow- Shaped Meta l Bar

1

89012 847

NL200 0-2. 5/4bar Fi lter Ta nk With B ase

1302011 155

O-Ri ng for Ma nhole

1

89012 832

NL230 0-2. 5/4bar Fi lter Ta nk With B ase

1401161 006

Manho le189012 833

NL250 0-2. 5/4bar Fi lter Ta nk With B ase

1589012 803

NL120 0-2. 5/4bar Ai r Venti ng Pipe

11389012 804

NL120 0-2. 5/4bar up per fil trati on syst em

1

89012 809

NL140 0-2. 5/4bar Ai r Venti ng Pipe

1

89012 810

NL140 0-2. 5/4bar up per fil trati on syst em

1

89012 814

NL160 0-2. 5/4bar Ai r Venti ng Pipe

1

89012 815

NL160 0-2. 5/4bar up per fil trati on syst em

1

89012 819

NL180 0-2. 5/4bar Ai r Venti ng Pipe

1

89012 823

NL180 0-2. 5/4bar up per fil trati on syst em

1

89012 820

NL200 0-2. 5/4bar Ai r Venti ng Pipe

1

89012 824

NL200 0-2. 5/4bar up per fil trati on syst em

1

89012 830

NL230 0-2. 5/4bar Ai r Venti ng Pipe

1

89012 834

NL230 0-2. 5/4bar up per fil trati on syst em

1

89012 831

NL250 0-2. 5/4bar Ai r Venti ng Pipe

1

89012 835

NL250 0-2. 5/4bar up per fil trati on syst em

1

6

89012 842

Sight G lass

11489012 805

NL120 0-2. 5/4bar lo wer fil trati on syst em

1

7

89012 848

NL120 0-2. 5/4. 0bar Up per fla nge

1

89012 811

NL140 0-2. 5/4bar lo wer fil trati on syst em

1

89012 849

NL140 0/16 00-2 .5/4 bar Upp er flan ge

1

89012 816

NL160 0-2. 5/4bar lo wer fil trati on syst em

1

89012 850

NL180 0/20 00-2 .5/4 bar Upp er flan ge

1

89012 825

NL180 0-2. 5/4bar lo wer fil trati on syst em

1

89012 851

NL230 0/25 00-2 .5/4 bar Upp er flan ge

1

89012 826

NL200 0-2. 5/4bar lo wer fil trati on syst em

1889012 852

NL120 0-2. 5/4b ar lowe r flang e

1

89012 836

NL230 0-2. 5/4bar lo wer fil trati on syst em

1

89012 853

NL140 0/16 00-2 .5/4 bar low er flan ge

1

89012 837

NL250 0-2. 5/4bar lo wer fil trati on syst em

1

89012 854

NL180 0/20 00-2 .5/4 bar low er flan ge

1

15

89012 856

NL120 0-2. 5/4bar No zzles

48

89012 855

NL230 0/25 00-2 .5/4 bar low er flan ge

1

NL140 0-2. 5/4bar No zzles

66

9

89012 843

NL Manh ole Cov er

1

NL160 0-2. 5/4bar No zzles

66

10

89012 857

Dash bo ard1NL180 0-2. 5/4bar No zzles

69

11

89012 858

Nozzl ed late ral

1

NL200 0-2. 5/4bar No zzles

1101289012 808

NL120 0-2. 5/4b ar Filt er Tank W ith Bas e

1

NL230 0-2. 5/4bar No zzles

150

89012 813

NL140 0-2. 5/4b ar Filt er Tank W ith Bas e

1

NL250 0-2. 5/4bar No zzles

195

89012 818

NL160 0-2. 5/4b ar Filt er Tank W ith Bas e

1

EMFI16 05051 0

2-4

3-4

Bef ore fil lin g f ilter s wit h san d or ot her fi ltrat ion ele men ts, it is adv isabl e to ch eck t he in ter nal

col lecto rs to mak e sure th at they h ave not b een dam aged du ring tr anspo rt or ins talla tion.

Aft erwar ds, fi ll the fil ters w ith wa ter and ma ke hyd rau lic te st. Th us, yo u wi ll mak e sure tha t ther e is

no le ak and th at the eq uipme nt work s prope rly.

The n stop t he pump s, ope n ea ch f ilt er's l id ( the fil ter mus t not be emp tied w ith out op eni ng the l id,

as i t coul d co llaps e) and e mpty h alf th e wate r th at eac h fi lter c ont ains. Then, sta rt fil ling t he f ilter

wit h sand o r other fil trati on ele men ts, tak ing in to acco unt th at f irs t of all y ou mus t pu t gra vel up t o

the c ollec tor arm s (10 cm ap prox. )

Thi s mus t be done very care fully in o rder to a voi d any dam age in the lowe r com ponen ts o f t he

fil ter. Wh en the fi lter is b eing fi lled wi th sand , this mu st be car efull y sprea d over th e surfa ce.

Onc e the filt er is fu ll with the filt ratio n ele men ts cl ean t he li d a nd th e i nner par t of the manh ole.

Thi s will pr event a ny debr is and pa rticl es of san d affec ting th e seal of t he join t.

Int roduc e the lid in the m anhol e, le aving it l eve led a nd ce ntere d. Th e l id mu st be supp ort ed by

the h andle , as this w ill avo id that i t could f all int o the tan k and dam age any o f its par ts.

Put t he brid ge in the p ositi on show n and tig hten ma nuall y the whe el.

To ac hieve a pro per sea l, you d o not hav e to tig hte n exces sivel y the wh eel , as thi s cou ld dam age

the l id. The p ressu re itse lf will i mprov e the sea l.

Whe n the filt er is un der pres sure, it is norm al th at wh eel and bri dge r emain sepa rat ed. Y ou mu st

not tight en the wheel again when t he fil ter is under press ure, b ecaus e when the pu mps st op, th e

lid c ould be d amage d or bloc ked.

Onc e the fi lter ha s been c omple tely fi lled w ith wat er, st art t he perf orman ce of in stall ation ,

ven ting man ual ly to e limin ate all the air th at cou ld be insi de the filte r, as the pr ese nce of air

imp airs th e filte r perfo rmanc e.

If a va cuum forms in th e fi lters , it i s nec ess ary to inst all do uble eff ect su ction cups , thes e wil l a lso

act a s autom atic ai r purif iers an d would a void th at the ta nk coul d colla pse.

Aft er this , the fil ter has b een rea dy for wo rking p roces s.

1.1 )

It is a ccept able to p lace th e filte rs unde r the wat er leve l.

Howe ver if vacuu m occu rs in the inst alla tion, suc tion cups mu st be ins talled in th e lids t o avo id th at

dep ressi on coul d colla pse the f ilter 's tank s.

Filt ers must be si tuat ed so that the ir bas es are pe rfectl y leve l and com pletely s uppo rted by the f loor.

The l ocati on must b e of appr opria te size t o allow m ainte nance p eriod ic over hauls a nd othe r

wo rk. Addi tiona lly the room must pro vide a drain to allow , in case of accident , evacuat ion of water

flowi ng from an y tube, filte r, pump, etc. thi s will avoid risk of dama ges in the electr ical i nsta llat ions

(p um ps , electric panels, etc. )

1.2 )

The m anome ter pan el had be en inst alled i n the fil ter. In p ools fi lters , the usu al pres sures w hen the

fil ter is cl ean are :

2

· Inl et pres sure: 0 .8-1 Kg /cm .

2

· Out let pre ssure : 0.4-0 .6 Kg/c m .

2

Whe n the dif feren tial pr essur e betwe en the tw o manom eters i s 1 Kg/cm o r highe r, back wash

mus t be carr ied out .

Fil ters lo catio n.

Man omete rs.

INST AL LATIO N

STARTING

INN ER PART O F

MAN HOLE

HAN DLE

BRI DGE

WHE EL

LID

1) Filter installation

Filters are delivered properly packed and ready in order to

facilitate unloading and transport using fork-lift truck,

crane, etc. It is very important to make sure that the filters

have not suffered bumps during transport.

To obtain a correct filter installation, the following stages must

be observed:

· Install filters in their final location.

· Install correctly the butterfly valves in the filters.

· To connect with the flange of the filter, use PN1.6MPa or

Class E 15bar PVC pipe.

· Install butterfly valves supports and regulate them correctly

(height, etc.)

· Connect butterfly valves with the pipe of the pumps, return

pipes and drain.

· Check the inner parts of each filter (collectors, top

diffusers).

· Fill the filters with water.

· Empty half the water and add the filtration element

(gravel, sand and/or anthracite), etc.

Instrument Panel installation:

· Before running the filter, drill a Φ11.4 diameter hole in the

filter's return pipe and drain that connects to the water

inlet and outlet.(Figure 1, Figure 2)

· Tap a 1/4" thread to the hole with Teflon tape. (Figure 3,

Figure 4)

· Twine the connection head with Teflon tape, fix to 1/4"

thread and connect to the direct head and the valve of

the panel.(Figure 5, Figure 6, Figure 7)

Caution:

· Tap with PN1.6Mpa or Class E 15bar PVC pipe.

Fig ure 1 Fig ure 2

Fig ure 3 Fig ure 4

Fig ure 5 Fig ure 6

Fig ure 7

INL ET

OUT LET

Loading...

Loading...