Page 1

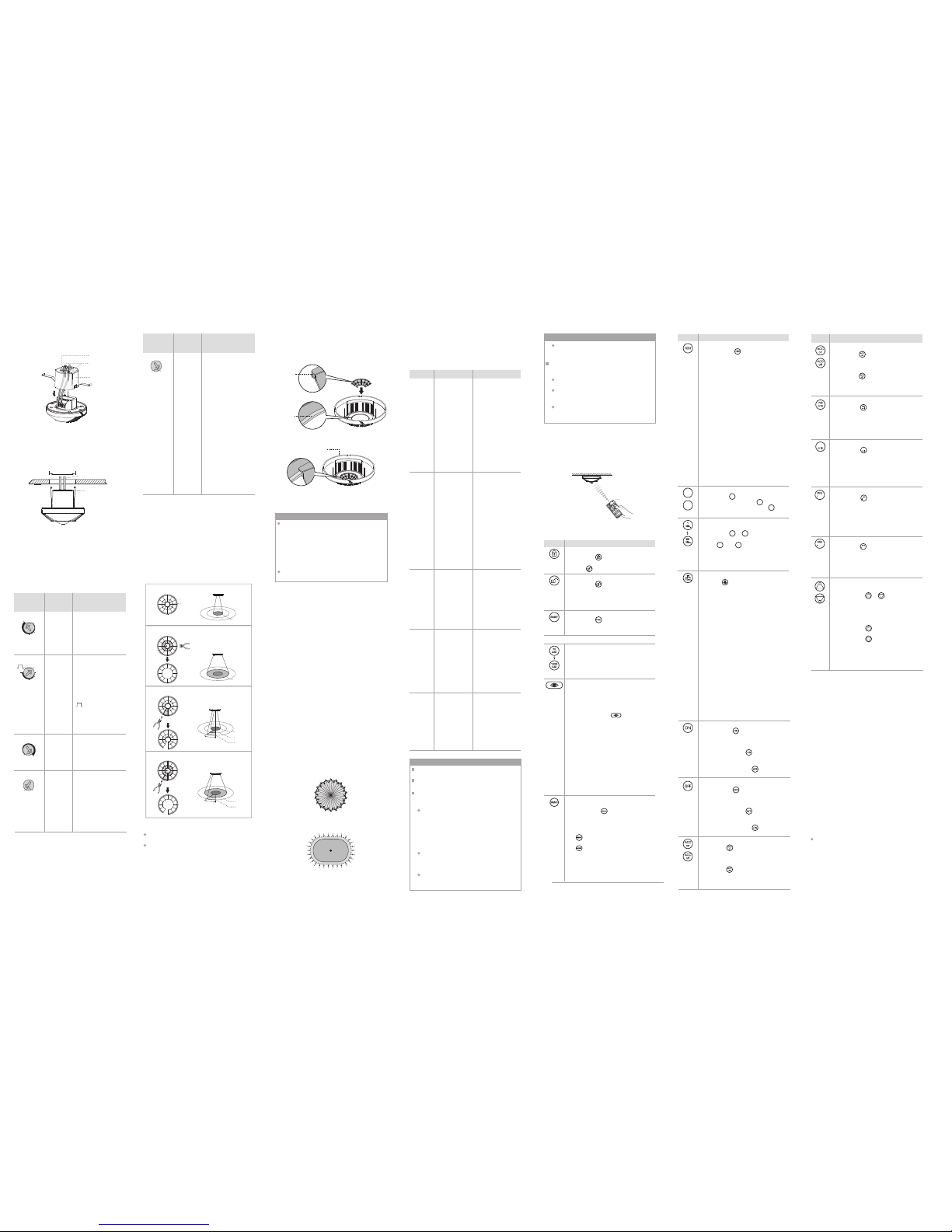

FIG.5-A

PIR Minor Motion

PIR Major Motion

Ultrasonic Minor

Motion

Ultrasonic Major

Motion

FIG.4-B

Open office

14m

8m

3.1.3 Examples of application

3.1.3.1 Ultrasonic sensor is less affected by humidity

which is more suitable for using in the moisty

environment (See FIG.5-A).

FIG.5-D

The shelves of

The cabinet. The stalls of

3.1.3.2 Ultrasonic sensor detects occupant based on

the Doppler Effect and it does not need to

“see” directly the movement of occupant. In

other words, it is able to detect the movement

happened behind the obstacles (See FIG.5-B

& FIG.5-C & FIG.5-D).

FIG.5-E

FIG.5-F FIG.5-G

3.1.3.3 Ultrasonic sensor is high sensitive in detecting

small movement, such as a minor motion of

typing, hand waving, door opening, etc. (See

FIG.5-E & FIG.5-F & FIG.5-G):

Light keeps off when

no movement is

detected.

Typing, light keeps

on.

Open the door,

light turns on.

3.1.4 Helpful tips for installation

Since the detector is in response to temperature,

airflow and wind change, please avoid the following

conditions:

Avoid aiming the detector toward the objects which

may be swayed in the wind, such as curtain, tall

plants, miniature garden, etc. (See FIG.6-A).

Avoid aiming the detector toward the objects

whose surfaces are highly reflective, such as

mirror, monitor, etc. (See FIG.6-A).

It is better to locate the detector at least 2m away

from the glass gate or window for avoiding

nuisance triggering because the shaking of glass

could trigger the ultrasonic sensor (See FIG.6-D).

FIG.5-H FIG.5-I

FIG.5-J

3.1.3.4 Since ultrasonic sensor is high sensitive to the

small motion and does not require a direct

view between the sensor and the movement,

therefore, it is optimum for using in the spaces

where frequently has less or small motion

taken place, such as a conference room, an

open plan office with partitions, a library, etc.

(See FIG.5-H & FIG.5-I & FIG.5-J).

D2 D1 N

N

L

Load

Power box

L

M/S R

Push button

(N.O.)

Manual

switch

Jumper

FIG.7

D2 D1 N LLN

N

L

Load

Power box

Power box

N

L

M/S R

S S

Push

button

(N.O.)

Master Slave

FIG.8

3.2.1.2 Master / slave operation (See FIG.8).

Jumper

It is better to locate the detector at least 2m away

from the source of airflow such as doorway, vents

and air conditioning, etc. (See FIG.6-B & FIG.6-C &

FIG.6-E). If airflow causes the detector false

triggering, set ACC knob to ON position. After that,

if the false triggering still exists, lower the ultrasonic

sensitivity or select a more suitable location.

The distance between two detectors must be at

least 2m to avoid interference (See FIG.6-F).

The direction of the ultrasonic sensor should aim to

the main detection area to obtain the best coverage

(See FIG.3).

FIG.6-E

>

2m

FIG.6-F

>

2m

FIG.6-D

>2m

Air

duct

3.2 Wiring

3.2.1 For lighting (With jumper wire on D1 & L

terminals).

3.2.1.1 One detector controls one load (See FIG.7).

FIG.6-BFIG.6-A FIG.6-C

Push button

(N.O.)

Push

button

(N.O.)

D2 D1 N

Power box

L

M/S R

Jumper

N

L

Ein

t

←

Staircase timer

Load

FIG.9

3.2.1.3 One detector controls staircase timer (Set

time knob to ) (See FIG.9).

1s.

3.2.2 For HVAC (Remove jumper wire on D1 & L

terminals) (See FIG.10).

D2 D1 N

N

L

Load

Power box

L

M/S R

Push button

(N.O.)

FIG.10

AC/DC

......

Presence Detector

PMUSC

INSTRUCTION MANUAL

TECHNICAL SPECIFICATIONS

ACC on / ACC

off Switch

Adjustable from approx. 5sec to

30min, Test &

Adjustable from approx. 10Lux to

1000Lux

Select “ON” for activating or select

“OFF” for deactivating air current

compensation function

1s.

Auto Off Time

Adjustment

Lux

Adjustment

230V~±10% 50/60HzRated

Voltage

PIR + US, PIR only, US only, PIR

or US

PIR: 360

o

circular, adjustable up

to Φ8m

US: 360

o

, adjustable up to 10m x

16m, it’s an oval shape

0

o

C to +45oC

Detection

Range

(H=2.5m)

Triggering

Method

selection

ClassⅡ, IP20

Operating

Temperature

Environmental

Protection

1

1

1

PACKAGE CONTENTS

22

Lens

shield

Detector

Pattern

Item

Quantity

Manual

Pattern

Quantity

1

Item

Junction

box JB-46

Accessories for optional purchase

2 PRODUCT DESCRIPTION

2.1 Features

The Dual-Technology presence detector PMUSC

integrates advanced PIR and Ultrasonic technologies

in one unit. The combination of these technologies

helps to eliminate false triggering problems even in

difficult applications. It is suitable for indoor

application which is ideal for using in home, openplan office, multi-stall public restroom, conference

room, under-ground parking lots, classroom, library,

etc.

4

Nondropping

screw

Φ3 x 18mm

US only or PIR/US:

When there is high level of minor motion or obstacle

(furniture or partitions) existing in the monitored

space, or it is a multi-stall space. For example, a

multi-stall public restroom, an office with partitions,

etc.

PIR+US:

If the precise detection is necessary, choose this

triggering method which can reduce the false

triggering problem. For example, a classroom, an

open-plan office, etc.

Triggering mode application examples:

With its knobs and IR remote controller, the time,

ultrasonic sensor sensitivity, Lux, ACC (air current

compensation) function and PIR/US triggering

method can be adjusted as user desired to match

different application requirements and energy saving

for switching light on and off.

2.2 Additional functions

2.2.1 Function of terminal R

Connect terminal R with push button (N.O. type) to

manually control the load’s on / off. When the load is

off, press (>1sec) the push button (N.O. type) to

manually switch the load on. The load keeps on if the

movement is detected constantly. The load can be

automatically switched off if no movement is detected

and the delay time has expired, or by pressing the

push button again. When the load is off, the movement cannot trigger the load on, and the detector will

return to the previous mode until detecting the last

movement and the delay time has expired. Refer to

FIG.7 for wiring connection.

PIR only:

If the monitored space is free of obstacle or has

high level of airflow or the detection area is needed

to be well specified. For example, a small-scale

office with air-conditioning, a small conference

room, etc.

FIG.1

2.2.2 Function of master / slave

14m

8m

20%

overlap

2.2.2.1 Compatible with slave detector to achieve

this function. PMUSC can connect up to

10pcs slave detector which has the same

detection range as PMUSCt o enlarge the

detection range. Under this mode, load and

LED perform according to the setting of the

master detector (PMUSC). Slave detector

works as a movement register to send signal

to master detector.

2.3 Dimension:

PMUSC: Φ111.5 x 67mm (See FIG.2-A)

2.2.3 Advance switching off function

To enhance energy savings, the detector is able to

turn off the controlled load prior to the set delay off

time if it detected the passing through occupant.

When the load is off, once the detector is triggered,

the load will keep on. If no movement is detected

again during 30sec to 3min, the load will on for

2.5min, and then off, even the time setting value is

more than 3min.

FIG.2-A

Φ111.5

52

67

JB-46: Φ111.5 x 35mm (See FIG.2-D)

FIG.2-C

FIG.2-B

FIG.2-D

FIG.2-E

35

Φ111.5

Φ111.5

72

Φ111.5

43.5

90

SP-96: 62.5 x 50mm (See FIG.2-B)

Detector with power box cap SP-96 for flush

mount:

Φ111.5 x 90mm

(See FIG.2-C)

Detector with junction box JB-46 for surface

mount: Φ111.5 x 72mm

(See FIG.2-E)

50

62.5

3 INSTALLATION AND

WIRING

Please disconnect power completely and read the

entire instruction manual carefully before

installation.

3.1 Select a proper location

FIG.3

Side view

US 16m

PIR 8m

2.5m

PIR Minor Motion

PIR Major Motion

Ultrasonic Minor Motion

Ultrasonic Major Motion

3.1.1 The recommended installation height of this

detector is 2 - 3m, and 2.5m is the optimal

mounting height. The detection range of PIR

sensor can reach up to Φ8m, and ultrasonic

sensor is an oval shape of 8m x 10m with small

movement (i.e. hand wave), and an oval shape

of 10m x 16m with large movement (i.e. walk).

The detection angle is 360° for both PIR and

ultrasonic sensors (See FIG.3).

Top view

US 10m

US 8m

360°

PIR

Φ4m

PIR

Φ8m

US 10m

US 16m

12m

7.5m

Classroom

Conference room

10m

8m

FIG.4-A

Dual-technology detector is capable of detecting

occupant without directly seeing the moving person

due to the high sensitivity of ultrasonic sensor.

Ceiling mount will give an overall view of the entire

room, and the detector should be mounted in the

center of the room so that the detector can detect

movement from anywhere of the monitored space.

If you choose the PIR technology (PIR+US or PIR

only) as triggering method, the detector should be

located where the PIR sensor is able to see the

occupant.

In order to ensure good reliability of PIR sensor, an

overlapping area is need to be considered while

installing several sensors in a space.

3.1.2 Location of dual-technology detector (See

FIG.4-A & FIG.4-B).

CAUTION!

Switches complying with this standard are

suitable for use at ambient temperature not

normally exceeding 25°C, but occasionally

reaching 35°C.

A circuit breaker (250VAC, 10A) type C according

to EN60898-1 shall be installed in the fixed wiring

for protection.

Do not mount on conductive surface.

Do not open the enclosure frequently.

Turn off power when change the light sources.

Bulb burn of certain brands would cause high inrush current which might damage the unit

permanently.

Installation and assembly of electrical

equipment must be carried out by skilled

person. Contact a qualified electrician

in the event of fault down.

Screw

Φ

3 x

14mm

2

Wood

screw

Φ

4

x 25.4mm

Pattern

Quantity

11

Item

PMUSIR

IR remote

controller

Power box cap

SP-96

+

U

LT

+

U

L

T

Time1

Time2

ON

ACC

OFF

ACC

PIR

/US

PIR

only

US

only

PIR

+US

IR-11T

Lux

Load (L )

Max. 10A (cosφ=1) for 250VAC

Max. 3A (cosφ=0.4) for 250VAC

Max. 5A for 30VDC

For lighting (with jumper wire):

For HVAC (remove jumper wire):

12 x (2 x 18W)

7 x (2 x 36W)

5 x (2 x 58W)

Energy saving Lamp: Max. 600VA /

400W (include

CFL and PL

lamp)

<

<

<

Incandescent Lamp: Max. 2000W

AC halogen Lamp : Max. 1000W

LV halogen Lamp : Max. 1000VA

(600W)

Fluorescent Lamp : Max. 900VA /

100μF

25 x (1 x 18W);

15 x (1 x 36W);

10 x (1 x 58W);

3.3.1.4 Assemble the detector with power box, then

fix them with two screws (See FIG.11).

3.3.1.5 Put on the decorative frame and restore the

power supply.

3.3.1.2 Pull out cables from European standard

junction box (See FIG.12), then strip off 6 8mm of cable sheathing for wiring, and refer

to the wiring diagrams for correct cable

connections (See FIG.7 - FIG.10).

FIG.12

mm8 - 6

3.3.1.3 Fit the power box into European standard

junction box then screw them with two screws

(See FIG.13).

FIG.13

3.3.1 Flush mount with European standard junction

box

3.3.1.1 Take off the decorative frame (See FIG.11).

FIG.11

Non-dropping

screw

Power box

Detector head

Decorative

frame

3.3 Installation Procedure

NOTE

The direction of the ultrasonic sensor should aim to

the main detection area to achieve the best

detection coverage when detector is flush mounted

with European standard junction box, and the fixing

plate can be adjusted 45°.

2.2.2.2 2.5mm

2

power cables for D1, D2, L, N

connection, and 1.5mm2 for master and slave

connection. Refer to FIG.8 for wiring

connection.

2.2.2.3 To get complete coverage in an open office

area, install multi slave detectors with approx.

20% overlap ultrasonic detection range to

adjacent ones (See FIG.1).

Dual-Technology

FIG.5-B FIG.5-C

W

RH % OK

RH %

OK

Dual-Technology

Presence Detector

PMUSC

3.3.2 Surface mount

3.3.2.1 There are 7 pairs of fixing holes with various

distances from 41mm to 85mm on the bottom

cover of the combined junction box JB-46

which can be selected for different mounting

applications (See FIG.14-A). To select two

same figures on both ends for the

corresponding fixing distance (See FIG.14-B).

FIG.14-A

80

80

8

5

8

5

7

0

7

0

6

0

6

0

63

63

53

53

41

41

80

80

8

5

85

7

0

70

60

6

0

63

63

53

53

41

41

A

B

Fixing holes

Fixing holes

FIG.16

80

85

70

60

63

53

41

80

85

70

6

0

63

53

41

FIG.17

Nondropping

screw

Nondropping

screw

3.3.2.4 Insert four non-dropping screws to the

corresponding screw holes on detector’s fixing

plate. Afterwards, those four screws will not

drop off to provide convenient subsequent

installation (See FIG.17).

3.3.2.5 Refer the FIG.11 to assemble the detector

head with the power box, and then refer to

the wiring diagrams (See FIG.7 - FIG.10) for

correct cable connections.

3.3.2.6 Put on the decorative frame and restore

power supply.

3.3.3 Flush mount

3.3.3.1 To install detector, please drill a hole with

diameter of 65mm on ceiling board and keep

the power cable outside. Please strip off 6 8mm of cable sheathing for wiring (See

FIG.18).

FIG.18

NO. A B

The distance

between A and B

1

2

3

4

5

6

7

41

53

60

63

70

80

85

41

53

60

63

70

80

85

41mm

53mm

60mm

63mm

70mm

80mm

85mm

FIG.14-B

FIG.15

3.3.2.2 To feed power cables through the side of

junction box, please use the cutting pliers to

break the side cable entry knockouts, then

insert cables into junction box and feed

through it. Please strip off 6 - 8mm of cable

sheathing for wiring (See FIG.15).

3.3.2.3 Choose two proper knockouts to fix the

junction box JB-46 on the surface of ceiling

board with two wood screws (See FIG.16).

30 - 35mm

6 - 8mm

Φ=65mm

30 - 35mm

6 - 8mm

Cable entry

knockout

Drill a hole with

Φ =65mm on the

ceiling

Page 2

Green

LED does

not turn

on

1. Ultrasonic

sensor is not

chose as the

triggering

method (US

only; PIR/US;

PIR+US).

2. Exceed the

valid detection

range.

1. Choose ultrasonic

sensor as the

triggering method.

2. The movement

should be in the

valid detection

range (10m x 16m).

Nuisance

triggering

There are heat

sources, airflow,

highly reflective

objects or any

objects which

may be swayed

in the wind within

the detection

coverage.

Avoid aiming the

detector toward any

heat sources, such as

air conditioning,

electric fans, heaters

or any highly reflective

surfaces. Make sure

there are no swaying

objects within the

detection coverage.

Lighting

device

does not

turn off

1. Auto off delay

time is set too

long.

2. Detector is

nuisance

triggered.

3. Incorrect

wiring.

1. Set auto off delay

time to a shorter

time and check if

the load is switched

off or not according

to the preset off

delay time.

2. Keep the objects

which may cause

nuisance triggering

away from detection

coverage to avoid

activating detector

while doing the test.

3. Refer to wiring

diagrams (See

FIG.7 - FIG.10).

Red LED

does not

turn on

1. PIR sensor is

not chose as

the triggering

method (PIR

only; PIR/US;

PIR+US).

2. Exceed the

valid detection

range.

1. Choose PIR sensor

as the triggering

method.

2. The movement

should be in the

valid detection

range (Φ8m).

5

TROUBLE SHOOTING

Problem

Possible cause

Suggested solution

When PMUSC works abnormally, please check

assumptive problems and suggested solutions in

following table that will hopefully to solve your

problems.

Lighting

device

does not

turn on

1. Power does

not switch on.

2. Incorrect

wiring.

3. The ambient

light level is

too high.

4. Malfunctioned

load.

1. Switch on the

power.

2. Refer to wiring

diagrams (See

FIG.7 - FIG.10) and

check if the load is

malfunctioned.

3. Set Lux value

above the ambient

light level then

trigger the detector

and check if the

load is switched on

or not.

4. Replace the

disabled load with

a new one.

6 OPTIONAL ACCESSORY

FIG.24

PMUSIR

+

ULT

+

ULT

Time1

Time2

ON

ACC

OFF

ACC

PIR

/US

PIR

only

US

only

PIR

+US

IR-11T

Lux

NOTE

Wire connections in reverse in between N and

L will cause lower sensitivity of ultrasonic

sensor.

The following conditions may cause lower

sensitivity of PIR sensor:

On very foggy days, the sensitivity may be less

due to moisture collecting on the lens.

On very hot days, the sensitivity will be lower

as high ambient temperature can be close to

body temperature.

On very cold days when wearing heavy

clothing, and especially if the facial area is

covered, maybe appear less sensitive.

The Effects to PIR sensitivity:

NOTE

Do not attempt to open or repair the unit without

qualified electrician while it is malfunctioned.

Cleaning: Wipe with dry cloth only. Soap or

rough cloth may damage the detector lens.

The following conditions may cause lower

sensitivity or false triggering of ultrasonic sensor:

Set ACC knob to ON: The airflow will cause

false trigger to ultrasonic sensor. To reduce

the possibility of false trigger, the dual

technology sensor is designed with air current

compensation (ACC) function which is able to

reduce the sensitivity of ultrasonic sensor

approx. 10% ~ 40% varied with the strength of

airflow.

Ultrasonic sensitivity will be affected by the

materials such as carpet, sound absorbable

cotton, curtain, etc. since they are sound wave

absorber.

Low ambient temperature might slightly

decrease ultrasonic sensitivity and also reduce

the detection range.

The Effects to ultrasonic sensitivity:

All rig hts res erved . No repro ducti on, copy, o r

transmission of this priduct may be made without

writing permission.

1. Pressing “ ” button to activate the air

current compensation function which is

confirmed by the green LED keeping on

for 5sec.

2. Pressing “ ” button to deactivate the

air current compensation function which

is confirmed by the green LED flashing

for 5sec.

ACC on/off control function

1. By pressing “ ” button, load will be

switched off 8hrs, it is confirmed by

flashing of detector’s LEDs.

2. Exit off mode and return to Auto mode

either by pressing “ ” again or to re supply power to detector after it is off.

3. Load (for lighting control) can be lead to

on mode by pressing “ ” button under

off mode.

Load off

1. Press “ ” button to enter into short

impulse mode, both LED and load are

controlled by Lux under this mode.

2. If the triggering method is “PIR+US”:

Both PIR and ultrasonic sensors are

triggered, the load and LEDs will be on

for 1sec, and then off. The next trigger ing should be 9sec interval.

3. If the triggering method is “PIR/US”:

Either PIR or ultrasonic sensor is

triggered, the corresponding LED and

load will be on for 1sec, and then off.

The next triggering should be 9sec

interval.

4. If the triggering method is “PIR only”:

Only PIR sensor is triggered, the red

LED and load will be on for 1sec, and

then off. The next triggering should be

9sec interval.

5. If the triggering method is “US only”:

Only ultrasonic sensor is triggered, the

green LED and load will be on for 1sec,

and then off. The next triggering should

be 9sec interval.

6. LoadⅡhas no reaction in short impulse

mode.

Short impulse mode

1. By pressing “ ” button, load will be

switched on 8hrs, it is confirmed by

flashing of detector’s LEDs.

2. Exit on mode and return to Auto mode

either by pressing “ ” again or to re supply power to detector after it is off.

3. Load (for lighting control) can be lead to

off mode by pressing “ ” button under

on mode.

Load on

4.3.5 To repeat above mentioned procedures to

adjust the settings of detector either by knobs

or IR remote controller and conduct the walk

test until the detector’s detection coverage

meets your demand.

FIG.23-A

FIG.23-B

Walk type for PIR sensor

Walk type for ultrasonic sensor

4.2.3 Fixing lens shield: There is a circular groove on

the back of the decorative frame and the lens

shield is designed with a circular hook. By

coupling the hook into the groove, the lens

shield is fixed (See FIG.22-A & FIG.22-B).

FIG.22-A

FIG.22-B

Decorative frame

Circular

groove

Circular

hook

NOTE

4.3 Walk test (uncontrolled by Lux)

It takes approx. 30sec for detector to warm up

with load on after power is initially supplied or

resupplied after power failure, then the detector

enters into normal operation to carry out a walk

test. During which, red and green LEDs will

permanent on for 30sec if no IR setting value is

stored in detector. Reversely, the red and green

LEDs will flash for 30sec if any setting value has

been stored in the detector.

Re-supplied after power failure, detector works

according to the previous settings.

The purpose of conducting the walk test is to check

whether the triggering method (PIR, ultrasonic) is set

correctly or not and to adjust the detection coverage.

Procedures of conducting the walk test (Lux controller

is disabled):

4.3.1 Set the time knob to “Test” position.

4.3.2 Adjust the position of meter knob for matching

the sensitivity of ultrasonic sensor as you

desired. The detection coverage of PIR sensor

can be adjusted by using the lens shield.

4.3.3 Set the ACC knob to OFF position.

4.3.4 Select the desired trigger method (i.e. PIR+US,

PIR only, US only or PIR/US).

Step 1: Switch on the power supply and it takes

approx. 30sec for detector to warm up with

load and LED on for 30sec, afterwards they

will turn off.

Step 2: To walk within the desired detection coverage

of detector (Refer to FIG.23-A & FIG.23-B).

Step 3: When its PIR sensor is triggered by move ment, the red LED turns on for 2sec, then

turns off; when its ultrasonic sensor is

triggered by movement, the green LED turns

on for 2sec then turns off. When choosing

PIR+US as triggering method, both red and

green LEDs will turn on for 2sec then turn off

if both sensors have been triggered by move ment.

6.1 It is recommended warmly to purchase our high

quality IR remote controller PMUSIR for easy

convenient and safe operation on PMUSC.

Button Function

US

US

1. By pressing “ ” “ ” buttons to set

the sensitivity of ultrasonic sensor. Each

time the user presses the button, the

sensitivity of ultrasonic sensor would

increase or decrease 10% with

indication of green LED flashing.

2. By pressing “ ” button to increase the

sensitivity of ultrasonic sensor.

3. By pressing “ ” button to decrease

the sensitivity of ultrasonic sensor.

4. When the sensitivity of ultrasonic sensor

is at its highest or lowest level which is

confirmed by green LED keeping on for

approx. 2sec.

Sensitivity adjustment of Ultrasonic

sensor

US

US

US

US

US

By pressing “ ” button, the detector is

set to activate its load on only when the

ultrasonic sensor of it detects the movement, and the green LED will flash to

confirm the successful setting of this

mode. To exit this mode by selecting other

mode.

Ultrasonic only function

US

1. Pressing “ ” button to activate the air

current compensation function which is

confirmed by the green LED keeping on

for 5sec.

2. Pressing “ ” button to deactivate the

air current compensation function which

is confirmed by the green LED flashing

for 5sec.

ACC on/off control function

PIR only function

By pressing “ ” button, the detector is

set to activate its load on only when the

PIR sensor of it detects the movement,

and the red LED will flash to confirm the

successful setting of this mode. To exit this

mode by selecting other mode.

US

By Pressing “ ” button, the detector is

set to activate its load on when either PIR

sensor or ultrasonic sensor is triggered by

movement. When PIR is triggered, the red

LED will flash; when ultrasonic sensor is

triggered, the green LED will flash. To exit

this mode by selecting other mode.

PIR or Ultrasonic mode

US

US

By pressing “ ” button, the detector is

set to activate its load on when both PIR

sensor and ultrasonic sensor detect the

movement, and both red and green LEDs

will flash. To exit this mode by selecting

other mode.

PIR & Ultrasonic mode

US

Button Function

Time setting for Time / Time1 or

Time2

By pressing “ ” “ ” to select the load

desired to set the delay off time value.

Either “ ” or “ ” is pressed, LED

flashes 2sec, and then press the corresponding time value button to set it, which

is confirmed by 2sec flashing of

detector’s LED.

Time1

Time1

Time2

Time2

1. By pressing “ ” button to enter into

test mode. Both load and LEDs are

uncontrolled by Lux value.

2. If the triggering method is “PIR+US”:

Both PIR and ultrasonic sensors are

triggered, the load and LEDs will be on

for 2sec, and then off. The next trigger ing should be 2sec interval.

3. If the triggering method is “PIR/US”:

Either PIR or ultrasonic sensor is

triggered, the corresponding LED and

load will be on for 2sec, and then off.

The next triggering should be 2sec

interval.

4. If the triggering method is “PIR only”:

Only when PIR sensor is triggered, the

red LED and load will be on for 2sec,

and then off. The next triggering

should be 2sec interval.

5. If the triggering method is “US only”:

Only when ultrasonic sensor is

triggered, the green LED and load will

be on for 2sec, and then off. The next

triggering should be 2sec interval.

6. LoadⅡhas no reaction in test mode.

Test mode

Time2

Time1

Select load for time setting

By pressing “ ” to set the delay off

time value of loadⅠ, and “ ” to set the

delay off time value of loadⅡ. “ ” is

invalid if the detector has only one load.

Time2

Time2

Time1

Load for lighting control (Relay)

Lux value adjustments for lighting

control

By pressing corresponding button, the

selected light level threshold for

switching on the connected load can be

set.

By pressing “ ” button,PMUSIR is

unlocked; thereafter it can be used to make

settings. The PMUSIR will lock

auto-matically if there is no operation occurred

in 2min counting from the last operation.

By pressing “ ” button,PMUSIR can be

locked and no adjustments are workable

(except “ ” button).

Lock PMUSIR

Button Function

Unlock PMUSIR

Reset

By pressing “ ” button, detector is

controlled by potentiometers, and it can

delete all the MEMO data.

Automatic read-in of actual light

level function for lighting control

Actual light level can be read-in as

threshold for switching the corresponding light if the provided Lux values do

not match user's requirement. The steps

are as below: Push “ ” button till

detector's red and green LEDs flashing

to enter into learning mode, learning

time is 10sec. Then the ambient light

level is read in confirmed by LED on to

indicate IR learning successfully. Then it

returns to Auto mode. If the ambient

light level is out of the range of 5 1000Lux, detector will learn for 10sec,

then LEDs flash quickly for 5sec to

indicate IR learning unsuccessfully, but

below Lux value will be stored: 1000Lux

if the actual light level is above 1000Lux,

and 5Lux if the actual light level is below

5Lux.

1. By pressing “ ” button, both loads

and detector's LEDs have no reaction

if no settings are stored in PMUSIR.

2. When time of Time1, Time2 and Lux

are set by PMUSIR already, press

“ ” button more than 3sec to store

the settings successfully. By pressing

“ ” button less than 1sec, the stored

settings can be duplicated to a new

detector.

3. Remove the battery more than 5sec,

all the settings will be deleted. It needs

to be reset after replacing the battery.

Store and duplicate the values of

Time1, Time2, and Lux set by PMUSIR

6.2 Push button function:

Due to our policy of continuous improvement we

reserve the right to change specification without

prior notice.

Errors and omissions excepted. These instructions

have been carefully checked prior to publication.

However, no responsibility can be accepted by

E-Matic for any misinterpretation of these instructions.

E-Matic Energy Management Solutions

Distributed by: Challenger Security Products

10 Sandersons Way,

Blackpool, FY4 4NB

Tel: 01253 791888, Fax: 01253 791887

Email: enquiries.ematic@adivision.co.uk

www.e-matic.co.uk

Ematic_PMUSC_Instructions_Rev01

4.2 Usage of lens shield for PIR sensor

4.2.1 PMUSC has provided 2 lens shields for masking

the undesired detection area of PIR sens or.

One lens shield has 2 layers with 6 small units

each, and 30° of detection angle can be covered

by each unit. For example, to inst all the detector

at the height of 2.5m, the detection range ca n

reach to 2m diameter if the complete lens shield

has been used; and up to 6m diameter i f only

the A layer of lens shield has been used ( See

FIG.21-A & FIG.21-B).

4.2.2 After user choosing the desired dete ction area,

the needless lens shield should be removed

(See FIG.21-C).

Φ2m

A

B

FIG.21

30°

Φ6m

Φ8m

The shadow part of the lens shields in the FIG.21-A

& FIG.21-B & FIG.21-C is needed to be cut off.

The ultrasonic sensor is unaffected by the lens

shield.

Knob

(Ex-factory

setting)

Function Knob setting

4 OPERATION AND

FUNCTION

4.1 Setting of Lux, Time, Meter, ACC and

PIR/US knobs

Lux

1000

300

10

100

Set the

light value

for

switching

on load

Range: Approx. 10Lux

to 1000Lux

User can set the knob

according to their

requirement for

application. The marked

values are for reference

only.

Time

15m

5m

5s

30m

Test

1s.

Range: Approx. 5sec to

30min

Test: Test mode (Load

and red and/or

green LED will

2sec on, 2sec off).

Test mode is

uncontrolled by

Lux.

: Short impulse

mode for staircase

timer switch control

(Load and red and

/ or green LED will

1sec on, 9sec off).

1s.

Set delay

off time

Set the

sensitivity

of

ultrasonic

sensor

“

-” = Min. (Approx. an

oval shape of 2m x

3m).

“+” = Max. (Approx. an

oval shape of 10m

x 16m).

Meter

4x6m

7x8m

+

-

3.3.3.2 Break the two rubber gask ets on the power

box cap with screwdriver, then put the power

cable through them (See FIG.19).

FIG.19

Cable entry

P

ower box cap

Non-dropping

screw

Rubber gasket

3.3.3.3 Refer to wiring diagrams for correct cable

connections, then cover the power box cap

back and screw it tightly.

FIG.20

3.3.3.5 Switch on the power supply.

Φ=65mm

Power cable

Spring clips

ACC

OFF ON

Reduce

the false

trigger

problem

caused by

airflow.

ON : Activate the ACC

function.

OFF: Deactivate the

ACC function.

Remark: Under ACC ON

status, the

detection

coverage of

ultrasonic

sensor will be

reduced.

Knob

(Ex-factory

setting)

Function Knob setting

PIR only US only

PIR/US PIR+US

Select

triggering

method

PIR/ US: Load will turn on

when either PIR

or ultrasonic

sensor is

triggered.

PIR+US: Load will turn

on when both

PIR and

ultrasonic

sensors are

triggered, and

after the load is

on, either PIR

or ultrasonic

sensor detects

movement, the

load keeps on.

PIR only:Load will turn

on only when

PIR sensor is

triggered.

US only: Load will turn

on only when

ultrasonic

sensor is

triggered.

The whole lens shield is used.

Φ6m

30°

Φ6m

Φ8m

Φ2m

A layer of the lens shield is used.

Part of the lens shield is used.

Part of the lens shield is used.

3.3.3.4 Insert detector’s two spring clips into the

drilled hole, then push it upwards (See

FIG.20).

Loading...

Loading...