Page 1

WORKSHOP MANUAL

Garden Tractor:

EF 95 - EF 105 - EF 125 -

OM 95 - OM 105 - OM 125

Page 2

Workshop manual

2

Page 3

Workshop manual

1 Foreword .................................................................................................................... 5

2 General ....................................................................................................................... 6

2.1 Safety instructions ............................................................................................... 6

3 Maintenance and care ............................................................................................... 7

3.1 Maintenance table .............................................................................................. 7

3.2 Lubricating plan .................................................................................................. 8

3.2.1 Front axle ............................................................................................................... 8

3.2.2 Steering .................................................................................................................. 8

3.2.3 Front and rear wheels ............................................................................................ 8

3.2.4 Tensioning pulley rocker / pivoting and bearing points .......................................... 9

3.3 Oil change .......................................................................................................... 9

3.4 Air filter / spark plug ............................................................................................ 9

3.5 Tyre pressure ..................................................................................................... 10

3.6 Hydrostatic transmission ..................................................................................... 10

3.7 Starter battery (12V / 17 Ah) ............................................................................... 11

3.8 Troubleshooting plan .......................................................................................... 13

3.8.1 Table troubleshooting plan ..................................................................................... 13

3.8.2 Fault display and fault elimination .......................................................................... 15

4 Disassembly............................................................................................................... 18

4.1 Bonnet ................................................................................................................ 18

4.2 Discharge channel .............................................................................................. 18

4.3 Mowing implement .............................................................................................. 19

4.3.1 Disassembling the mowing implement ................................................................... 19

4.3.2 Replacing the blade ............................................................................................... 21

4.3.3 Replacing V-Belt mowing implement ..................................................................... 22

4.3.4 Replacing the bearing (blade change) ................................................................... 26

4.3.5 Replacing the tensioning pulley ............................................................................. 27

4.3.6 Disassembling the blade brake clutch ................................................................... 28

4.3.7 Replacing the mowing implement feeler rollers ..................................................... 28

4.4 Steering .............................................................................................................. 29

4.4.1 Disassembling the steering sector ......................................................................... 29

4.4.2 Disassembling the steering column ....................................................................... 29

4.4.3 Replacing the tie rod .............................................................................................. 30

4.5 Propulsion .......................................................................................................... 30

4.5.1 Removing the floor cover of the vehicle frame ...................................................... 30

3

Page 4

Workshop manual

4.5.2 Removing the propulsion belt ................................................................................. 31

4.5.3 Disassembling tensioning pulleys and idler pulleys ............................................... 34

4.6 Electrical grass catcher emptying ........................................................................ 34

4.7 Electric system .................................................................................................... 35

4.7.1 Replacing headlight bulb ........................................................................................ 35

4.7.2 Starter battery ......................................................................................................... 35

4.7.3 Ignition/starter switch .............................................................................................. 36

4.7.4 Removing the start relay ......................................................................................... 36

4.7.5 Removing the relay ................................................................................................. 36

4.7.6 Fuses ...................................................................................................................... 37

4.7.7 Level buzzer / level switch ...................................................................................... 37

4.7.8 Control panel control elements ............................................................................... 38

4.7.9 Transmission switch ............................................................................................... 40

5 Circuit diagrams ........................................................................................................ 42

5.1 Lawn tractor with rear discharge and electronic system ...................................... 42

5.2 Lawn tractor with rear discharge without electronic system ................................. 44

6 Adjustment work ........................................................................................................ 46

6.1 Mowing implement adjustment ............................................................................ 46

6.2 Grass catcher ...................................................................................................... 47

6.3 Brake adjustment ................................................................................................ 47

6.4 Propulsion pedals................................................................................................ 48

6.5 Fine adjustment of the steering ........................................................................... 49

6.6 Steering sector adjustment .................................................................................. 49

7 Torque setting ............................................................................................................ 50

4

Page 5

Workshop manual

1 Foreword

This handbook contains all the information required for maintenance and repair of Efco and Oleo-Mac lawn tractors.

The individual working processes are explained with comprehensive descriptions and illustrations.

Here, we do not discuss work that can be done without special knowledge (such as changing wheels). During the

disassembly and assembly work, ensure that you follow the instructions for removal/installation.

All the information, illustrations, guidelines and descriptions contained in this document comply with the latest state

of the data that was available for the product at the time of going to press.

Emak reserves the right to make changes, at any time and without prior notice, without obligations of any kind for

the company. The contents of this document may only be reproduced with written approval from Emak.

5

Page 6

2 General

2.1 Safety instructions

Working on the machine does not usually represent a specific hazard. An exception is the work that involves

mechanical components. These activities should be carried out with the caution and attention that is usual

for this type of work.

In addition to observing the usual accident-prevention regulations that are typical for all mechanical

workshops,we recommend:

Carry out maintenance, service and repair work only when the engine is switched off and cool.

Prior to starting work, remove the ignition key and disconnect the negative terminal of the battery.

Wear suitable protective gloves when you handle blades and sheet-metal parts.

Avoid petrol leaking. Wipe up leaked petrol.

Smoking prohibited in the vicinity of engine and tank.

Secure the tractor such that persons cannot be injured from inadvertent actions.

CAUTION!

Workshop manual

Risk of accidents!

Observe the safety instructions in the operating and engine instructions, and the safety

instructions on the unit.

Trailer:

The total weight of a trailer pulled by the tractor should not be higher than 50% of the tractor

weight including driver. For this tractor, the total weight of the trailer should not be higher than

250 kg.

The maximum towed and drawbar load is 40 kg.

6

Page 7

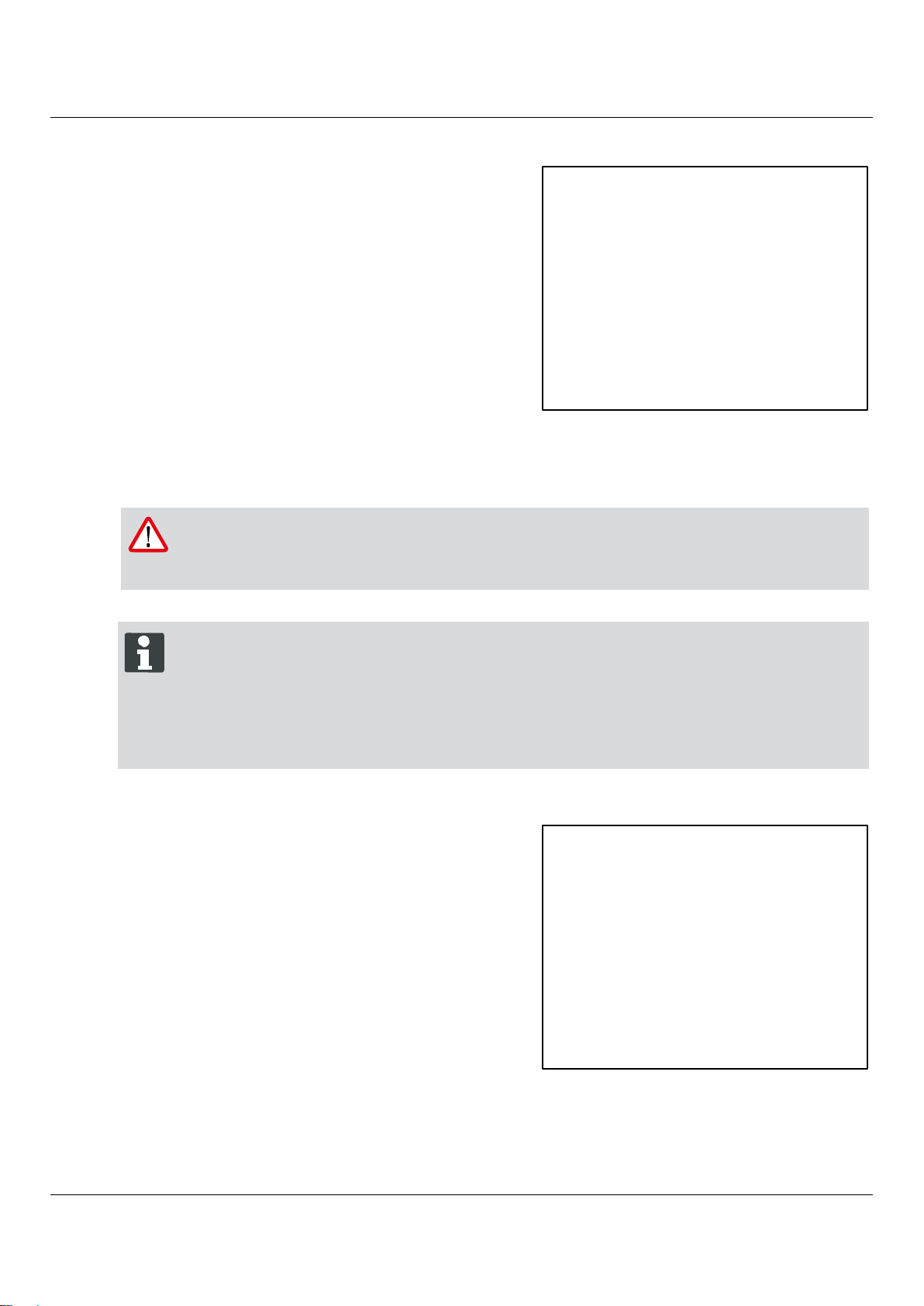

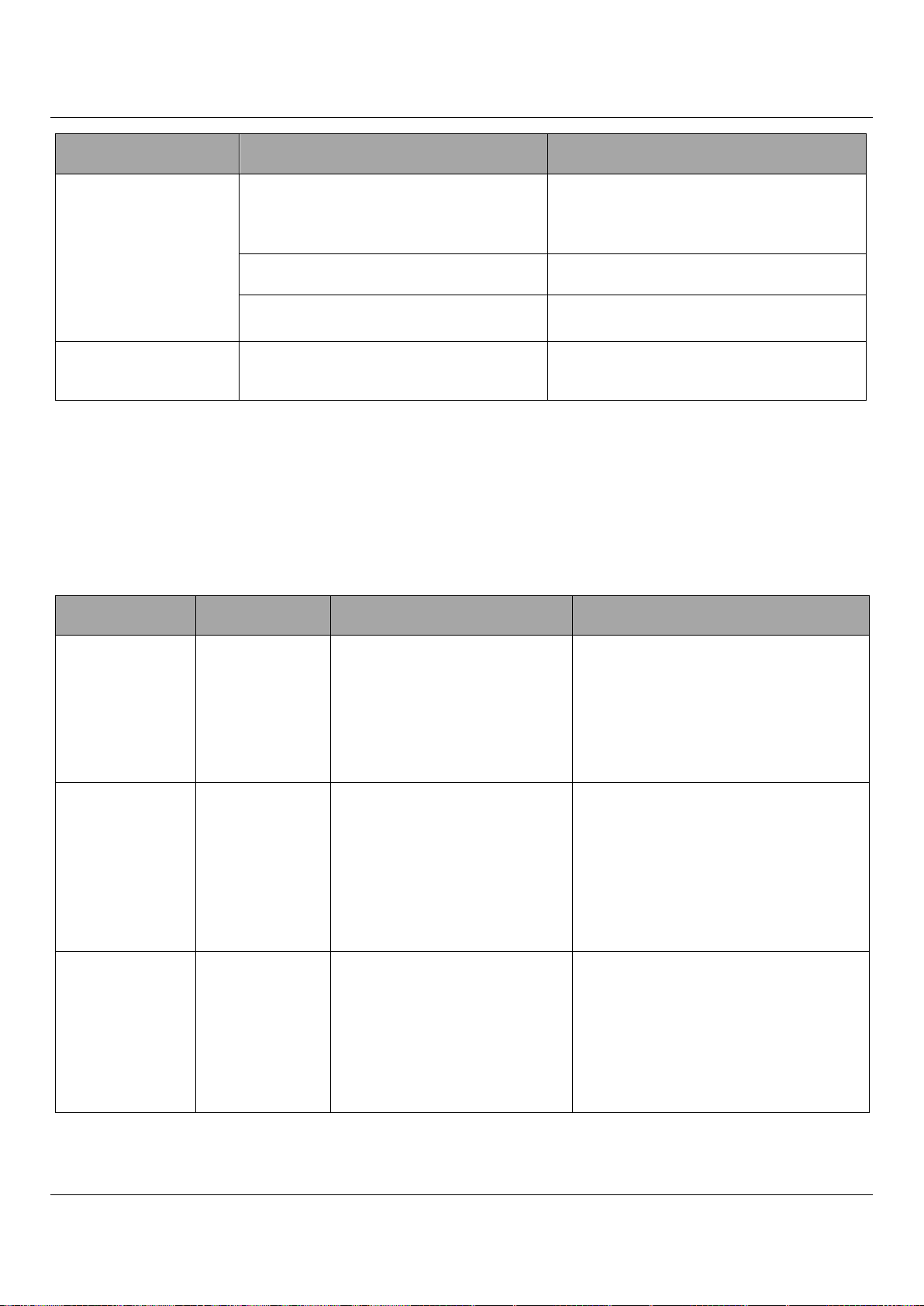

Before

every

use

After the

first 5

operating

hours

Every

10

operating

hours

Every

25

operating

hours

Every

50 operating

hours

or yearly

Every

100

operating

hours

Checking the engine oil level

1)

X X X - -

-

Changing the engine oil

1)

- X - - X

-

Replacing the oil filter (if installed)

1).

- - - - -

X

Cleaning the air filter

1)

- - - X -

-

Replacing the air filter

1)

- - - - X

-

Checking the spark plug

1)

- - - - X

-

Checking the brake

- X X - -

-

Checking the tyre pressure

- X X - -

-

Checking the mowing blade

- X X - -

-

Checking the adjustment of the

mowing implement

- X X - -

-

Checking the hydrostatic transmission

oil level

- - - - X

-

Checking for loose parts

- X X - X

-

Checking V-belt

- - - X -

-

Charging the battery

- - - X X

-

Cleaning the air intake grille on

the engine

- - - - X

-

Removing grass and mowing residues

from the gearbox

- - - X -

-

Cleaning the gearbox cooling fan

- - X - -

-

Lubricating as shown in the lubricating

plan

- - - - X

-

Workshop manual

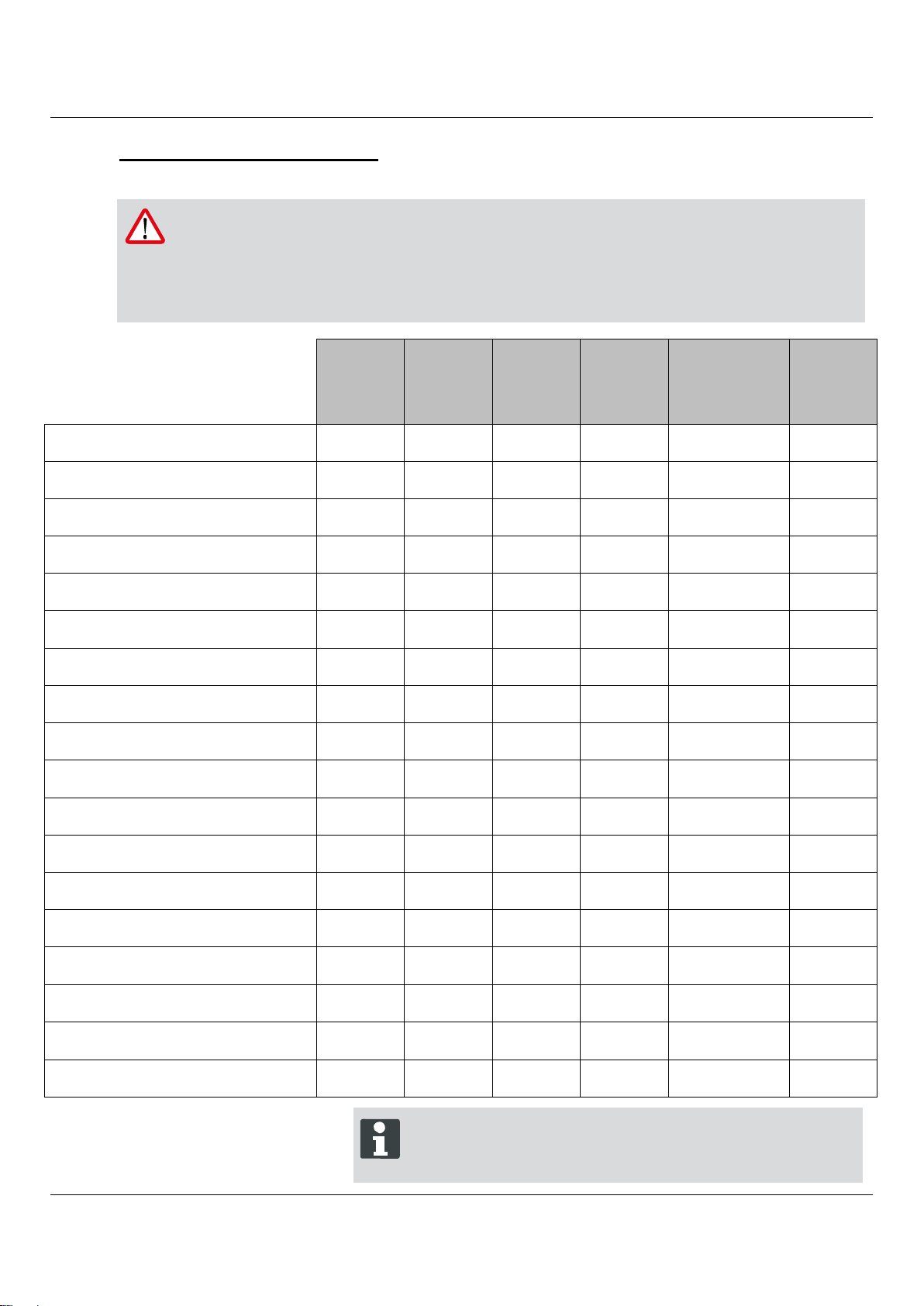

3 Maintenance and care

3.1 Maintenance table

Caution!

Risk of accidents!

Carry out maintenance, service and repair work only when the motor is switched off and cool.

Prior to starting work, remove the ignition key and disconnect the negative terminal of the

battery.

1)

See the operating instructions from

the engine manufacturer

With high stress and at high temperature reducing the

specified maintenance intervals may be necessary.

7

Page 8

3.2 Lubricating plan

3.2.1 Front axle

WARNING!

To ensure the smooth operation of moving parts, we recommend lubricating the following

points every 50 operating hours / once a year.

Lubricate the steering-axle stubs right and left

(lubricating nipples) with multi-purpose grease.

Spray the front axle bearings on the frame with oil.

Lubricate the ball heads with multi-purpose grease.

Remove the ball caps before you start lubrication

(See steering sector disassembly).

Workshop manual

3.2.2 Steering

Grease toothing and bearing surface of the gear

segmentwith multi-purpose grease.

Grease the pinion.

3.2.3 Front and rear wheels

Lubricate roller bearings / hubs with multi-

purpose grease.

Remove the front and rear wheels before you start

lubricating the axles.

Ensure that the driving key is in place when you

install the rear wheels

8

Page 9

Workshop manual

3.2.4 Tensioning pulley rocker / pivoting and bearing points

Tensioning pulley rocker (mowing implement):

Spray pivoting and bearing points with oil.

Pivoting and bearing points:

Spray all pivoting and bearing points and the

pivoting points of the ropes with oil.

3.3 Oil change

CAUTION!

See also operating instructions from the engine manufacturer.

Use an oil drain extension to change oil conveniently.

Have a suitable collecting container ready.

Remove the 19-mm screw plug. Hold the oil drain

extension with a fork spanner to prevent it from

being screwed out of the engine.

CAUTION!

Dispose of the used oil in accordance with

the legal regulations

Never drain used oil into the sewerage

system or the soil.

There are high fines on groundwater

pollution.

You can deliver used oil to any petrol station,

or get the address of a disposal company

from the local authorities.

Alternatively, you can suck off the oil through

the oil filler neck.

3.4 Air filter / spark plug

CAUTION!

See also operating instructions from the engine manufacturer.

9

Page 10

3.5 Tyre pressure

Check the tyre pressure at regular intervals..

Tyre pressure recommended: 0,9 - 1,0 bar

3.6 Hydrostatic transmission

Use a cloth, hand brush, long-handled paintbrush and compressed air to remove dirt and grass residues.

Check the oil level during the yearly service. Top up oil if necessary. (Engine oil 20W50)

Workshop manual

CAUTION!

See also operating instructions from the engine manufacturer.

Start-up after transmission repair

To ensure proper operation and full performance of the transmission, bleed the transmission

before the first start-up of the tractor.

This ensures that all air bubbles are removed that could have formed in the gearbox during the

transport of the tractor.

Procedure

Park the tractor on a level surface and ensure that is

remains in place

Do not apply the parking brake for this process.

Actuate the bypass lever to disengage the transmission.

For 95 - 105 transmission:

Pull out the bypass lever and secure it in the

upper position

10

Page 11

Workshop manual

For 125 transmission:

Push in the bypass lever and secure it in the

upper position

Sit on the operator's seat

Start the engine and set the throttle to medium speed.

The parking brake remains released

Press the forward accelerator pedal (a) for five seconds

Press the rearward accelerator pedal (b) for five

seconds.

Repeat this procedure 3 times.

Set the throttle to idle position.

Set the bypass lever back to drive.

Drive the tractor 1.5 m forward and back. Repeat this

procedure 3 times.

➯ The tractor is now operational

.

3.7 Start battery (12V / 17 Ah)

The starter battery sits under the bonnet.

For winter storage, store the starter battery in a cool and dry place (10°C - 15°C).

Avoid storing the battery at temperatures below freezing point.

Recharging the starter battery during a long storage period is recommended.

CAUTION!

The starter battery should not:

Be stored in the immediate vicinity of a

naked flame

Incinerated

Be put on a radiator

WARNING!

Risk of explosion

Never short-circuit the connection terminals.

Keep the starter battery clean. Wipe it only with a dry cloth.

Do not use water, petrol, thinners or the like for this purpose!

Keep the connection terminals clean and grease them with terminal grease.

11

Page 12

Workshop manual

CAUTION!

Damaging the display

Never disconnect the starter battery while the engine is running.

Never start the tractor with external power supply.

Charging the starter battery

Charging is required:

Prior to storing for the winter break.

During extended standstill of the machine (longer than 3 months).

DANGER!

Risk of explosion!

The charging current of the charger must not be higher than 5 A and e the maximum permitted

charging voltage is 14.4 V.

We recommend charging the maintenance-free and gas-tight starter battery with a

compatible charger.

Charge the starter battery only in a dry room.

Observe the operating instructions for the battery charger.

Remove the ignition key.

Open the engine cover.

CAUTION!

Danger of short circuit!

Ensure that the polarity is correct.

Red terminal = positive pole (+)

Connect the charger terminals to the battery poles.

Connect the charger to the mains, and switch it on.

Black terminal = negative pole (-)

12

Page 13

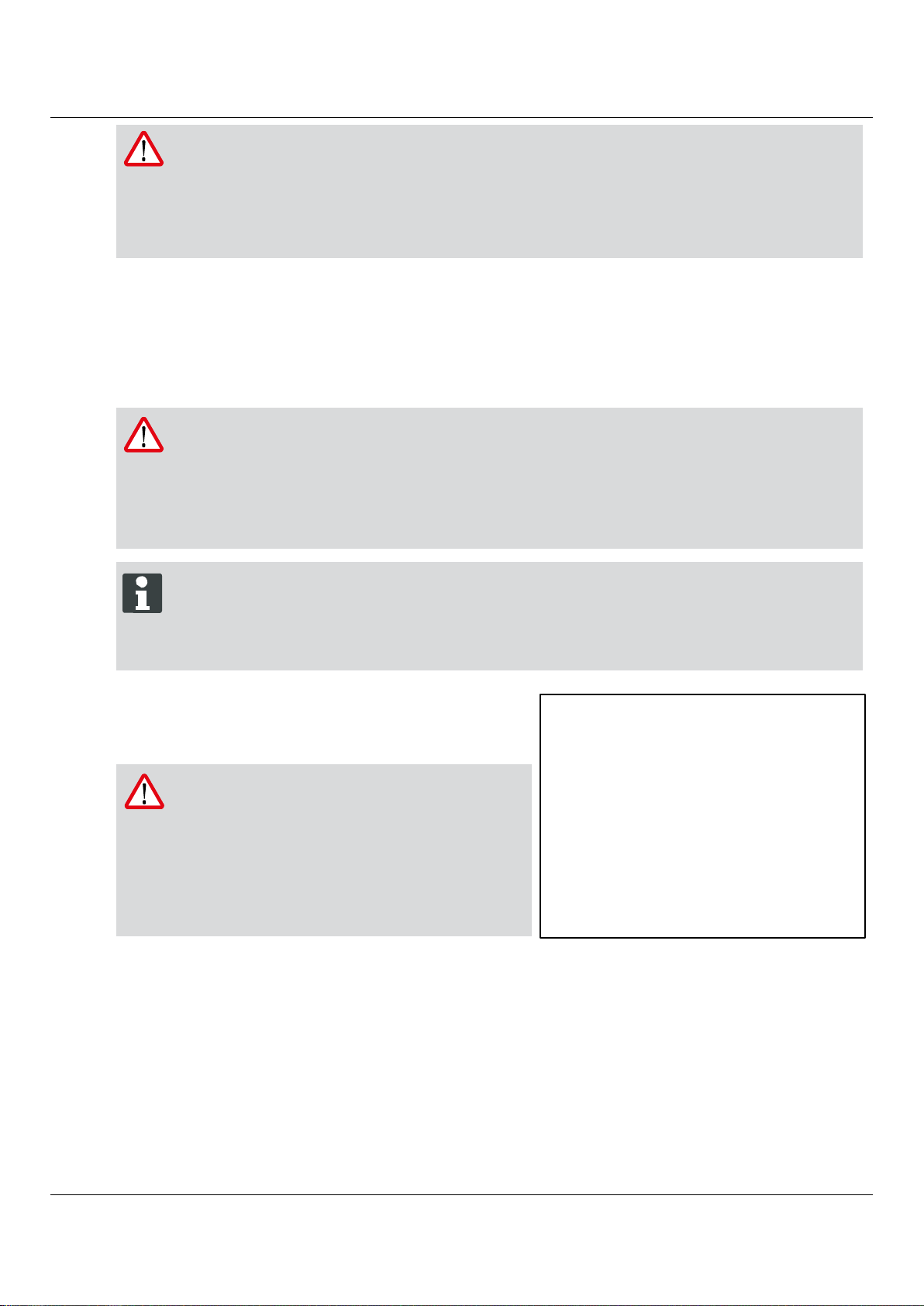

Fault

Possible cause

Rectification

The engine does not start

Lack of fuel

Fill up the tank

Check tank breathing

Fuel filter

1)

Poor quality, contaminated fuel, old fuel in tank

Always use fresh fuel from clean containers.

Maximum storage time 30 days

Clean the carburettor

1)

Air filter plugged

Clean the air filter

1)

No ignition spark

Clean the spark plug

Replace the spark plug if necessary

Check the ignition cables

1)

Check the ignition system

1)

"Engine flooded" after several attempts to start

the engine

Remove the spark plug, dry it, and screw

it back in.

The starter does not

respond

Weak or dead starter battery

Charge the starter battery

Safety switch on operator's seat does not work

Sit properly on the operator's seat.

Replace seat contact switch if necessary.

Safety switch on brake pedal does not work

Press down the brake pedal all the way

Replace the brake contact switch if

necessary.

Safety switch on discharge channel does not

work

The safety switch on the discharge

channel must be actuated when it is

installed properly.

Replace the safety switch if necessary.

Mowing implement engaged

Disengage mowing implement

Fuse (7.5A / 10A) is defective

Check the fuse; replace fuse if necessary

Mowing performance

drops

Grass too long or too wet

Correct cutting height (lower level)

Reverse a short way to make space

Discharge channel/mowing implement

clogged

Clean discharge channel / mowing

implement

WARNINNG!

Risk of accidents!

Shut down the engine

Disconnect the spark plug

connector

Air filter plugged

Clean the air filter 1)

Wrong carburettor setting

Check the setting

1)

Workshop manual

3.8 Troubleshooting plan

3.8.1 Table of troubleshooting plan

13

Page 14

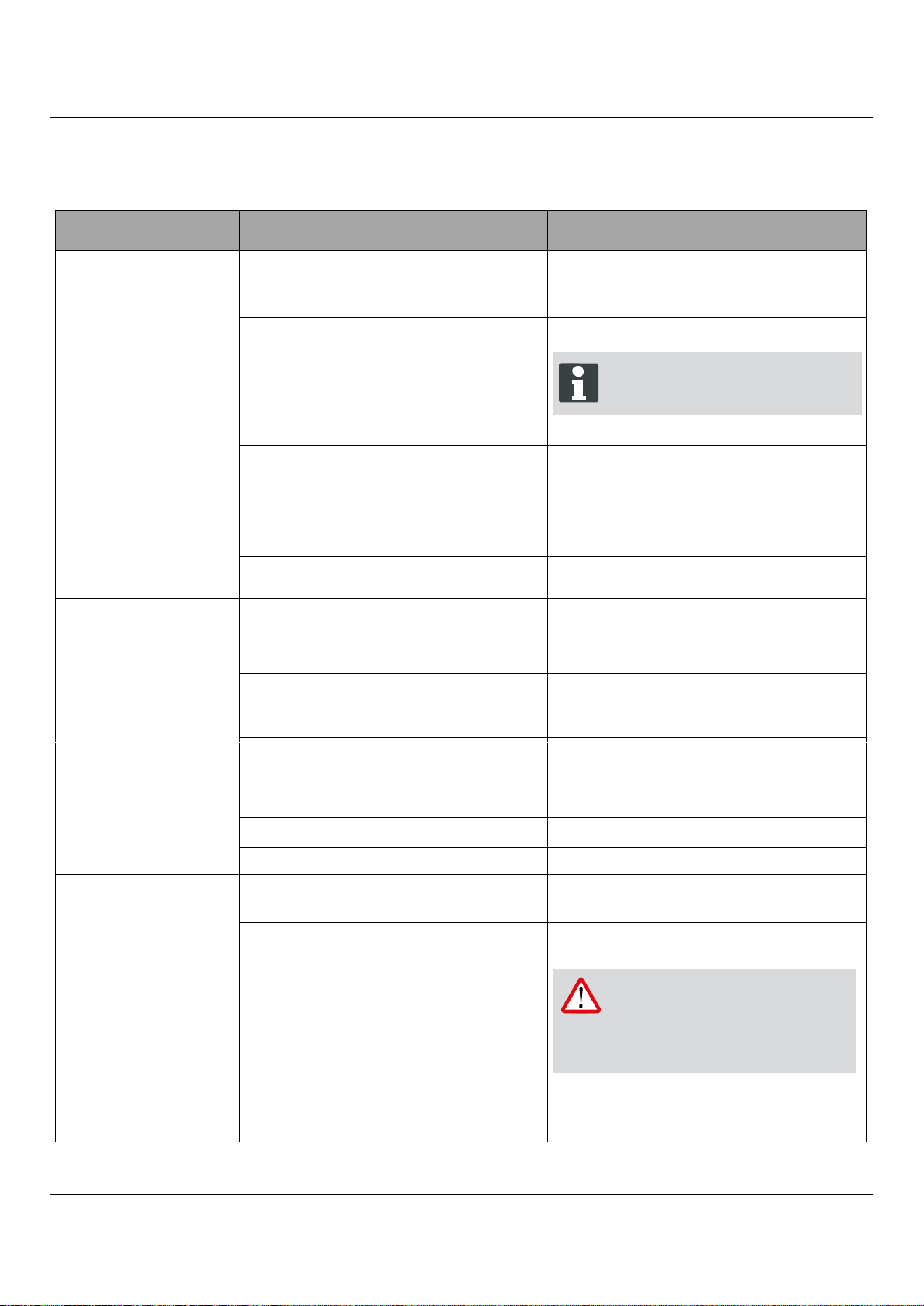

Fault

Possible cause

Rectification

Mowing performance

drops

Blade worn out

Replace the blade (see replacing the blade)

Use only a genuine spare

blade

Driving speed too high

Reduce the driving speed

Power loss

Engine speed (rpm)

Adjust the engine (2850 rpm)

V-belt and pulley defective

Repair and replace

Loose parts

Repair or replace loose parts

Lawn tractor does not

move

No propulsion

Feather key on rear axle not installed

No propulsion - bypass activated

Set bypass lever to operating position

No propulsion - stiff movement of

tensioning rocker

Ease the movement of the tensioning

rocker

Transmission oil level low

Check the transmission oil level; top up if

necessary.2)

Bleed the transmission

2).

Propulsion belt broken.

Replace the propulsion belt

No clean cut / uneven

appearance of the cut

lawn.

Blade worn out, blunt

Replace or regrind the blade (see

replacing the blade)

Use only a genuine spare

blade

Wrong cutting height

Correct the cutting height (lower level)

Engine speed too low

Set the engine speed to MAX (3000 rpm)

Driving speed too high

Reduce the driving speed

Different pressure of the wheel tyres

Correct the tyre pressure

Check the mowing implement adjustment

Grass catcher does not

fill up

Cutting height too low

Correct cutting height

Grass is too wet – it is too heavy to be

transported by the air stream

Allow the lawn to dry before you try again

Blade worn out

Replace or regrind the blade (see replacing

the blade)

Use only a genuine spare

blade

Mowing implement incorrectly adjusted

Adjust the mowing implement

– Front 30 mm

– Rear 40 mm

Workshop manual

14

Page 15

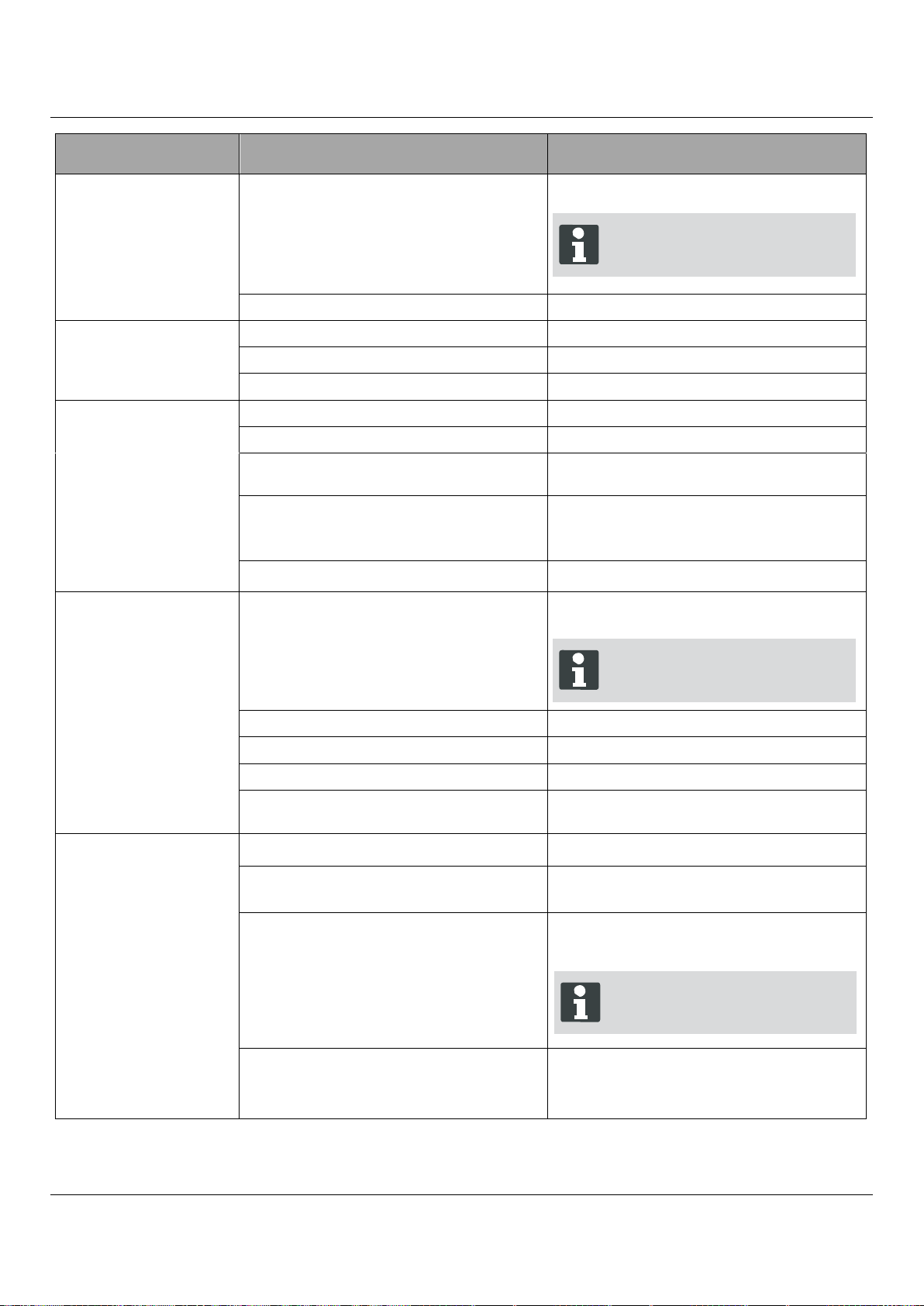

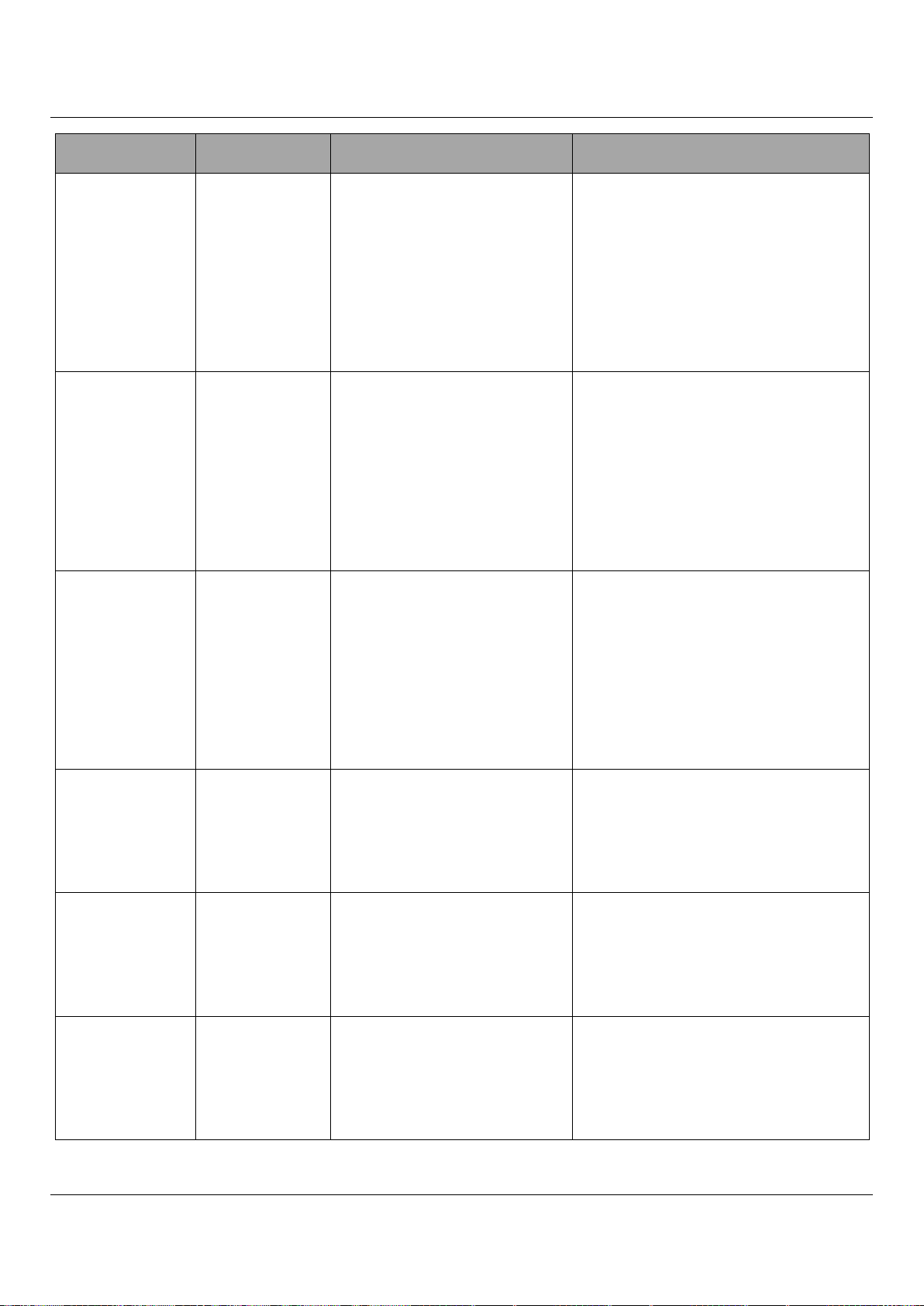

Fault

Possible cause

Rectification

Grass catcher does not

fill up

Grass in lawn too tall

Mow in 2 passes

1 st pass: Maximum cutting height

2 nd pass: Desired cutting height

Fabric bag clogged – does not allow air to

pass

Clean the fabric bag

Discharge channel / mowing implement soiled

- residues of last mowing process

Clean discharge channel / mowing

implement

Level indicator does not

respond / responds

permanently

Mown grass stuck to fill level indicator lever

Remove mown grass from fill level

indicator lever; ensure free lever

movement

Display

Fault

Fault description

Fault elimination

Err 01

Input seat contact

switch

Electronic system detects invalid

status of the seat contact switch

1 Switch the ignition off and back on

(position 2)

2 Sit down and stand up repeatedly

➯ Self-diagnosis; fault can clear

automatically

*

➯ Test / replace a) cable harness, b)

switch, electronic system

Err 02

Input brake

contact switch

Electronic system detects invalid

status of the brake contact switch

1 Switch the ignition off and back on

(position 2)

2 Press and release the brake pedal

several times

➯ Self-diagnosis; fault can clear

automatically

*

➯ Test / replace a) cable harness, b)

switch, electronic system

Err 03

Input mowing

implement switch

Electronic system detects invalid

status of the mowing implement

switch

1 Switch the ignition off and back on

(position 2)

2 Press the mowing implement switch

several times

➯ Self-diagnosis; fault can clear

automatically

*

➯ Test / replace a) cable harness, b)

switch, electronic system

Workshop manual

1)

See the operating instructions from the engine manufacturer

2)

See the operating instructions from the transmission manufacturer

3.8.2 Fault display and fault elimination

15

Page 16

Display

Fault

Fault description

Fault elimination

Err 04

Input grass

catcher contact

switch

Electronic system detects invalid

status of the grass catcher contact

switch

1 Switch the ignition off and back on

(position 2)

2 Open and close the grass catcher

repeatedly

3 Press the grass catcher switch several

times

➯ Self-diagnosis; fault can clear

automatically

*

➯ Test / replace a) cable harness, b)

switch, electronic system

Err 05

Input transmission

switch

Electronic system detects invalid

status of the transmission switch

1 Switch the ignition off and back on

(position 2)

2 Press and release the reverse pedal

several times

3 Press the transmission switch several

times

➯ Self-diagnosis; fault can clear

automatically

*

➯ Test / replace a) cable harness, b)

switch, electronic system

Err 06

Input discharge

channel contact

switch

Electronic system detects invalid

status of the discharge channel

contact switch

1 Switch the ignition off and back on

(position 2)

2 Remove and reinstall the discharge

channel

3 Press the discharge channel contact

switch several times

➯ Self-diagnosis; fault can clear

automatically

*

➯ Test / replace a) cable harness, b)

switch, electronic system

Err 07

Output mowing

implement

Electronic system detects incorrect

status of the mowing implement

output

1 Switch the ignition off and back on

(position 1)

➯ Self-diagnosis; fault can clear

automatically

*

➯ Otherwise, test / replace the

electronic system

Err 08

Output start relay

Electronic system detects incorrect

status of the start relay output

1 Switch the ignition off and back on

(position 1)

➯ Self-diagnosis; fault can clear

automatically

*

➯ Otherwise, test / replace the electronic

system

Err 09

Output engine

solenoid valve

Electronic system detects incorrect

status of the engine solenoid valve

output

1 Switch the ignition off and back on

(position 1)

➯ Self-diagnosis; fault can clear

automatically

*

➯ Otherwise, test / replace the electronic

system

Workshop manual

16

Page 17

Display

Fault

Fault description

Fault elimination

Err 10

Output ignition coil

Electronic system detects incorrect

status of the ignition coil output

1 Switch the ignition off and back on

(position 1)

➯ Self-diagnosis; fault can clear

automatically

*

➯Otherwise, test / replace the electronic

system

Err 11

Output internal

supply voltage

Electronic system detects incorrect

status of the internal supply voltage

output

1 Switch the ignition off and back on

(position 1)

➯ Self-diagnosis; fault can clear

automatically

*

➯ Otherwise, test / replace the electronic

system

Err 12

Output internal

supply

voltage monitoring

system

Electronic system detects

incorrect status of the internal

supply voltage monitoring system

1 Switch the ignition off and back on

(position 1)

➯ Self-diagnosis; fault can clear

automatically

*

➯ Otherwise, test / replace the electronic

system

LED indicator

Fault description

Fault rectification

Only green LED is ON

Normal operation, no fault

There is no fault

Green and red LEDs are

ON

Fault during current operation

Fault rectification according to fault shown on display

Only red LED is ON

Fault during previous operation or

controller fault

Fault rectification according to fault shown on display, or

check/replace electronic system

Workshop manual

* The display goes out for about 4 seconds in this case.

LED behaviour:

The LEDs sit on the display board.

Open the bonnet

Ignition in position 1.

To see the LEDs, look from the left vehicle side of the engine compartment towards the display.

17

Page 18

4 Disassembly

4.1 Bonnet

Open the bonnet.

Disconnect the cables from the light harness to the

headlights.

Remove the C clips (2x) at the bonnet suspensions.

Lightly swing back the bonnet, and pull down in

driving direction left of the bonnet suspension.

Assemble in the reverse sequence.

4.2 Discharge channel

Workshop manual

The discharge channel consists of two telescopic parts.

The lower part is firmly engaged in the mower housing.

The upper part can be pulled out.

Remove the grass catcher

Remove the eye nuts on the left and right of the

discharge channel

Pull out the discharge channel from the rear through

the rear wall.

Assemble in the reverse sequence.

Insert the discharge channel into the rear wall. Ensure

that the upper parts fits neatly into the lower part.

Secure it with the two eye nuts.

18

Page 19

Workshop manual

4.3 Mowing implement

4.3.1 Disassembling the mowing implement

The mowing implement must be removed when the is

used in winter service, and when the V-belt is replaced.

Turn the steering wheel fully to the left.

Remove the grass catcher.

Remove the discharge channel.

Unscrew the cheese-head screw on the channel

holder by 5-6 turns.

Lower the mowing implement to the lowest setting.

Unhook the tension spring on the mowing

implement.

Set the mower implement back up to the top.

19

Page 20

Workshop manual

Swing the locking plate of the V-belt duct forward

(1).

Swing the front part of the V-belt duct down (2).

Lower the mowing implement back down to the

lowest setting.

Remove the V-belt from the pulley of the blade

brake clutch.

Remove the 4 locking pins from the holding clips of

the mowing implement.

Pull off the holding clips over the pins.

Set the mower implement back up to the top.

Pull out the mowing implement from the side.

Incorrect operation in winter service

Install the discharge channel when you use

the tractor in winter service.

20

Page 21

Workshop manual

4.3.2 Replacing the blade

WARNING!

Risk of injuries - cutting

Always wear protective gloves when you handle the blades.

Wear protective goggles when you sharpen the blade.

Unscrew the 17-mm hexagon head screw, and

remove it with serrated lock washer and washer.

Pull off the blade with the blade retainer.

CAUTION!

Balance a reground blade.

Use only genuine spare blades for

replacement.

Assemble in the reverse sequence.

Tightening torque: 65 Nm

A blunt blade has a negative effect on the mowing performance and the appearance of the cut lawn. A poorly balanced

blade causes excessive vibrations during operation. A poorly balanced blade can damage the unit.

Sharpening:

Always sharpen both edges of the blade with a

grinding disc of medium grade.

Always sharpen at the bordered side so that only a

minimum of material is removed.

A blade must be replaced when the wear of the blade

reaches 10 mm.

21

Page 22

Balancing:

Use a suitable measuring instrument to measure the

imbalance. Adjust until the difference between the two

blades is no more than 2 g.

4.3.3 Replacing V-Belt mowing implement – Mowing

implement 95 cm / 105 cm

Disassemble the mowing implement.

Workshop manual

Detach the V-belt duct from the support at the mowing

implement..

Release the 6 hexagon nuts of the mowing implement

cover.

Remove the right V-belt cover from the mowing

implement.

22

Page 23

Workshop manual

Remove the left V-belt cover from the mowing

implement.

Unscrew the screw on the tensioning pulley slightly

until the V-belt can be removed.

Put down the V-belt.

Installing a new V-belt

Guidance and orientation of the V-belt differs

from type to type.

Refer to the information stickers on the mowing

implement.

Place the V-belt around the slightly loosened

tensioning pulley, and screw the pulley back on.

Arrange the V-belt around the rollers in the sequence

(2) / (3) / (4). Ensure that guidance and orientation of

the V-belt are correct.

23

Page 24

Workshop manual

Mowing implement 125 cm

Disassemble the mowing implement.

Detach the V-belt duct from the support at the mowing

implement.

Release the Torx screw (a) and remove the cover (b)

in driving direction right.

Release the Torx screw (c) and remove the cover (d)

in driving direction left.

Release 6 carriage bolts (e), and remove them

together with washers and hexagon nuts.

➯Remove the middle V-belt cover

.

24

Page 25

Workshop manual

Tensioning pulley (g) and idler pulley are installed on the

middle V-belt cover.

Slightly release the hexagon head screw (i) on the

tensioning pulley (g) until you can remove the V-belt (h).

Replacing toothed belt 125 cm

Disassemble the mowing implement. Remove the

V-belt.

Slightly release the hexagon head screws (a) and (b)

underneath the mounting plate (c) until the tensioning

rocker (d) can be moved.

Release the locknut (f) to loosen the adjusting screw (g)

of the tensioning rocker (e).

Release the hexagon head screw (g) and remove it

together with spring washer (h) and washer (i).

Remove the V-belt pulley (j) and (k).

25

Page 26

Workshop manual

Release 2 hexagon head screws (l) to disassemble the

toothed belt guide (m).

Assemble in the reverse sequence.

The distance between toothed belt guide (m)

and toothed belt should be 1 mm all around.

CAUTION!

Adjust the correct tension of the toothed belt.

To a load of 100 N, the toothed belt (1) must not

yield by more than 15 mm.

4.3.4 Replacing the bearing (blade change)

Prerequisites for bearing replacement

1. Disassembling the mowing implement

2. Removing the V-belt

3. Remove the blade together with the blade retainer.

Unscrew the M10 x 1 X 35 (17mm) screw and

remove it together with cup spring and washer.

Pulling off the V-belt pulley

Pull off the pulley driver (1).

Pull off the bearing seal (2).

Remove the O-ring (3).

26

Page 27

Workshop manual

Using a rubber mallet, drive the shaft and the bottom

bearing out of the bearing block.

Remove the top bearing from the bearing block.

Assemble in the reverse sequence.

Tightening torque: 65 Nm

4.3.5 Replacing the tensioning pulley

Disassemble the mowing implement. (See 4.3.1

Disassembling the mowing implement).

Disassemble the V-belt cover (see 4.3.3 Replacing

V-belt mowing implement).

Relieve the tensioning pulley so that the V-belt can be

removed from the tensioning pulley.

Unscrew the hexagon nut (13 mm) and remove it

together with the washer.

The tensioning pulley can be removed

Assemble in the reverse sequence.

Tightening torque: 20 Nm

27

Page 28

4.3.6 Disassembling the blade brake clutch

The blade brake clutch sits underneath the engine.

Disassemble the mowing implement. (See

Disassembling the mowing implement)

Disconnect the connector from the blade brake clutch.

Release the hexagon socket screw 8 mm or 3/8 in.) and

remove it.

Pull the blade brake clutch off the drive shaft.

Assemble in the reverse sequence.

Ensure during assembly that the spring is

installed in the groove of the clutch.

Workshop manual

CAUTION!

Apply thread lock on the fastening screw of the

blade brake clutch.

Tightening torque: 70 Nm

4.3.7 Replacing the mowing implement feeler rollers

Release the hexagon head screw and remove the

feeler roller.

28

Page 29

Workshop manual

4.4 Steering

4.4.1 Disassembling the steering sector

Release the hexagon nut of the tie rod attachment (a).

Release the hexagon nut of the steering sector guide

(b).

Release the hexagon nut of the steering sector axle and

remove the steering sector (c).

Assemble in the reverse sequence.

Tightening torque:

(a) = 45 Nm

(b) = 65 Nm

(c) = 45 Nm

4.4.2 Disassembling the steering column

Disassembling the steering wheel

To remove the cover (a) of the steering wheel, unclip

the hooks at the underside with a suitable tool

(screwdriver), and press them upwards.

Release the hexagon head screw (b) and remove it

together with the cup spring (c) and the washer (d).

Pull the steering wheel (e) off the split sleeve (f).

Remove the split sleeve (f).

Assemble in the reverse sequence.

Use a torque spanner to tighten the hexagon head

screw (b).

Tightening torque: 20 Nm

Removing the steering column

The steering column is removed from the bottom.

Precondition: Steering wheel is removed.

Release the hexagon head screw.

Swing off the steering column support.

29

Page 30

4.4.3 Replacing the tie rod

Pull out the steering column from below.

There are tie rods between the steering sector and the

front wheels, and between the front wheels.

Each side of a tie rod is connected via a ball head with

the steering-axle stub.

Workshop manual

Remove the retaining spring behind the ball head, and

remove the tie rod.

Ensure that the retaining spring sits firmly when

you assemble the unit.

4.5 Propulsion

4.5.1 Removing the floor cover of the vehicle frame

To be able to remove the floor cover, remove the pedal

tops of accelerator (a+b) and brake (c) pedals.

Loosen the cheese-head screws underneath the pedal

tops.

Remove the pedal top.

.

30

Page 31

Workshop manual

Release all 11 screws of the vehicle frame floor cover.

– 3 screws in the right foot area

– 3 screws in the left foot area

– 1 screw in the middle of the floor cover

– 4 screws in the area of the wheelhouse cover

Remove the floor cover of the vehicle frame.

4.5.2 Removing the propulsion belt with 23-in chassis

Detach the spring of the tensioning pulley to relieve the

propulsion V-belt.

Remove the covers (a) of the idler pulleys (b).

Release the hexagon head screw of the idler pulleys (b)

until you can remove the V-belt.

Lift off the safety element at the head of the accelerator

pedal damper and pull the head of the accelerator

pedal damper off the linkage.

31

Page 32

Workshop manual

Using a 17-mm fork spanner, slightly release (1) the

antirotation element (a) and pull it off the blade brake

clutch (c) (2).

Thread the V-belt between antirotation element (a) and

blade brake clutch (c) (3).

This requires the connecting cables of the blade

brake clutch to be disconnected.

Release hexagon head screw (a) and washer of the

propulsion linkage (b) (1).

Swing the propulsion linkage (b) upwards (2).

Remove the V-belt (c) between propulsion linkage (b)

and idler pulley (d) (3).

Release the locking nut (a) (option with cruise control),

and pull off the damper (b).

Release the hexagon nut (c) and pull off the linkage.

Pull off the locking ring (e) (option with cruise control)

and pull off the linkage (f).

Detach the spring (g).

With 20-in chassis

Detach the spring of the tensioning pulley to relieve the

propulsion V-belt.

32

Page 33

Workshop manual

Remove the covers (a) of the idler pulleys (b).

Release the hexagon head screw of the idler pulleys (b)

until you can remove the V-belt.

Lift off the safety element at the head of the accelerator

pedal damper and pull the head of the accelerator pedal

damper off the linkage.

Using a 17-mm fork spanner, slightly release (1) the

antirotation element (a) and pull it off the blade brake

clutch (c).

Thread the V-belt (b) between antirotation element (a)

and blade brake clutch (c).

This requires the connecting cables of the blade

brake clutch to be disconnected.

Release the locking nut (a) and pull off the damper (b).

Pull off the linkage (c).

Detach the spring (d).

Assemble in the reverse sequence.

33

Page 34

Item

Designation:

a

Tensioning pulley (125)

b

Tensioning pulley (95 - 105)

c

Idler pulley

4.5.3 Disassembling tensioning pulleys and idler pulleys

See disassembly / removing propulsion belt

Workshop manual

4.6 Electrical grass catcher emptying

Disassembling the linear cylinder

Disassembly requires the grass catcher to be removed.

Remove the locking rings at the two fastening bolts (b).

Remove the two fastening bolts (b), and remove the

linear cylinders (a).

The linear cylinder (a) is assembled in the reverse

sequence.

34

Page 35

Workshop manual

4.7 Electric system

4.7.1 Replacing headlight bulb

Open the bonnet.

Pull off the lamp socket.

Replace the bulb.

4.7.2 Starter battery

The starter battery sits under the bonnet.

CAUTION!

Damaging the display

Never disconnect the starter battery while the engine is running.

Never start the tractor with external power supply.

WARNING!

Risk of explosion!

To remove the starter battery:

First, disconnect the negative terminal (-) (black or blue

cable).

Next, disconnect the positive terminal (+) (red cable).

Detach the rubber tape.

Lift the battery at the front, and remove it.

Never short-circuit the connection terminals.

35

Page 36

Workshop manual

4.7.3 Ignition/starter switch

Press the clamping springs (b) of the ignition/starter

switch (a), and pull the switch from the top out of the

control panel.

Pull the connector off the switch.

Install in the reverse sequence.

4.7.4 Removing the start relay

CAUTION!

Risk of short-circuit!

Prior to replacing the start relay, disconnect

the battery.

The start relay sits at the right side underneath the tank.

Disconnect the hexagon nuts of the main connections

(2x).

4.7.5 Removing the relay

Disconnect the control connecting cable.

Ensure that the connections sit firmly when

you install the start relay.

(Only in tractors without display)

The relay sits underneath the control panel, next to the

starter battery.

1 2x relay (without electrical grass catcher emptying)

2 3x relay (with electrical emptying of the grass catcher)

See circuit diagram for relay functions.

36

Page 37

Designation

Current in A

Cable harness (without display)

1010

Cable harness (with display)

7,5

Charge

15

Linear cylinder

10

Workshop manual

In the lawn tractors without display, the relay for

electrical grass catcher emptying sits

underneaththe left wheelhouse, next to the linear

cylinder.

4.7.6 Fuses

The fuses sit underneath the control panel, next to the

starter battery.

4.7.7 Level buzzer / level switch

Remove the discharge channel to make it easier to remove the level switch.

Level buzzer

The level buzzer sit underneath the control panel, next to the starter battery.

37

Page 38

Workshop manual

Level shift lever grass catcher

The level shift lever can be removed without a tool

.

Level switch

Remove 2x locking disks

Disconnect the microswitch (a) from the housing.

Assemble in the reverse sequence.

Ensure that the connection assignments are

correct.

125 transmission: Connections 2 and 3

95-105 transmission: Connections 1 and 3

4.7.8 Control panel control elements

Speed control lever

Release screw (a).

Pull off the throttle (b).

Cruise control lever

Release the hexagon socket screw (a).

Remove hexagon socket screw (a) and washer (b).

Pull off the cruise control lever (c).

38

Page 39

Workshop manual

Mowing implement switch

Press the clamping springs of the mowing implement

switch together, and pull the switch from the top out of

the control panel.

Pull the connector off the switch.

Reverse mowing switch (a) / distance sensors (b)

Use the same procedure to remove these two switches.

Pull the switch from the top out of the control panel.

Pull the connector off the switch.

Display

Remove the steering wheel.

Release the Torx screw (a) in the steering wheel

retainer.

Release the Torx screws (b) from below by 2...3 turns

to disconnect the control panel from the body frame.

39

Page 40

Microswitch installation position and connection assignments

95-105

125

Lawn tractors without display

1 Variable

2 Variable

3 Non connected

1 Non connected

Variable

2 Variable

Lawn tractors with display

1 Black

2 Yellow

3 Green/Red

1 Green/Red

2 Yellow

3 Black

Release the 6 cheese-head screws (a) of the display

board (b).

Disconnect the connecting cable (c) of the display film.

Carefully remove the display board (b).

4.3.1 Transmission switch

Transmission switch (b)

The transmission switch (b) sits at the rear of the gearbox

(e).

Release the screw (a) and remove the switch element

(b).

Remove the microswitch from the switch element,

disconnect and replace it.

CAUTION!

Workshop manual

Wrong installation position of the

microswitch.

Observe the installation positions of the

individual transmission types.

The arrow in the following figures (Table

"Microswitch installation position and

connection assignments") shows the

installation position of the microswitch.

40

Page 41

Workshop manual

Transmission switch switching anvil (c)

Release the screw (d) and remove the switching anvil

(c)

41

Page 42

5 Circuit diagrams

5.1 Lawn tractor with rear discharge and electronic system

Workshop manual

42

Page 43

Workshop manual

43

Page 44

5.2 Lawn tractor with rear discharge without electronic system

Workshop manual

44

Page 45

Workshop manual

45

Page 46

6 Adjustment work

6.1 Mowing implement adjustment

Park the lawn tractor on a level surface.

Set the mowing implement to its lowest position.

B

A = mowing implement adjustment front

B = mowing implement adjustment rear

See following steps

A = mowing implement adjustment front (left and right)

Workshop manual

Using two fork spanners, release the locknuts at the

front frame attachment.

Adjust the locknuts equally until the distance of the front

mowing implement at the right and the left is 30 mm at

each side.

Tighten the locknuts.

B = mowing implement adjustment rear (left and right)

Using two fork spanners, release the locknuts at the

rear frame attachment.

Adjust the locknuts equally until the distance of the rear

mowing implement at the right and the left is 40 mm at

each side.

Tighten the locknuts.

Check the front mowing implement adjustment, if

necessary.

46

Page 47

Workshop manual

6.2 Grass catcher

Release the screws (a + c) to adjust the box holding arms

if the gap between box cover (d) and seat console (e) is

not correct.

Release the screws (c) and adjust the supporting rim of

the box cover positively to the seat console (e).

Release the screws (a) and adjust the distance

between the seat console (e) and the first edge of the

box cover (d) to 19 mm.

6.3 Brake adjustment

The brake of a tractor with 95-105 transmission can be

adjusted. The brake linkage is in the vehicle frame in

driving direction right. Merely the discharge channel need

to be removed for adjustment.

Screw the self-locking nut (a) onto the brake linkage

until it is in contact with the spring.

47

Page 48

6.4 Propulsion pedals

The distance between the forward accelerator pedal (a)

and the step plate (c) should be 35 mm ± 1 when the pedal

is not pressed.

Adjusting the accelerator pedal (125)

Release the nuts (d) on the pedal linkage and adjust the

distance of the forward pedal (a).

Workshop manual

Adjusting the accelerator pedal (95-105)

Release the nuts (d) and move the pedal linkage (e).

Tighten the nut (d).

48

Page 49

Workshop manual

6.5 Fine adjustment of the steering

For the fine adjustment of the steering wheel perform the

following setting at the thrust rod (a) front left.

Remove the locking bracket (c) from the ball head (c).

Loosen the locknut (17 mm) (d). Hold the ball head (c)

with pliers.

Lift the thrust rod (a) of the ball head (c).

Rotate the ball head (c) one revolution anticlockwise or

clockwise.

6.6 Steering sector adjustment

Slightly release the hexagon head screw (a) of the

steering sector guide.

While you are pushing the steering sector towards the

steering pinion (b), tighten the hexagon head screw (a).

Tightening torque: 65 Nm

49

Page 50

Object

Tightening

torque

Nm (± 2 Nm)

Comment

Engine

Tighten petrol engine (4x)

25

Oil drain plug

Blade brake clutch

70

Screw lock with Loctite

Transmission

25

First, tighten the transmission screws, then the screws at

the bracing.

Steering

Steering sector guide

25

Grease bearing bush.

Grease the steering sector specifically only at

the bearing surfaces and the teeth.

Steering sector pivot

65

Steering wheel fastening screw

20

Ball head M10 x 1

50

Steering-axle stub clamping lever

20

Mowing implement

Blade

65

Distance blade to lower housing edge 7 ...

max. 12 mm. Blade offset max. 3 mm

Tensioning pulley on rocker

25

Grease the bearing bush of the tensioning

pulley rocker.

The rocker must be able to move smoothly.

Mowing implement V-belt pulley

65

Guide pulleys

45

Mowing implement bearing block

25

Mowing implement suspension

rocker

45

Mowing implement adjustment

front M12

60

Propulsion

Tensioning pulley on the frame

20

7 Torque setting

Workshop manual

50

Page 51

Workshop manual

51

Page 52

Emak S.p.A.

service@emak.it • www.emak.it

Workshop manual

42011 Bagnolo in Piano (RE) Italy

Tel. +39 0522 956611 • Fax +39 0522 951555

52

Loading...

Loading...