Page 1

WORKSHOP MANUAL

63,4 cm³ chainsaws

Page 2

General failures’ analysis

63,4 cm³ chainsaws

Page 3

General failures’ analysis

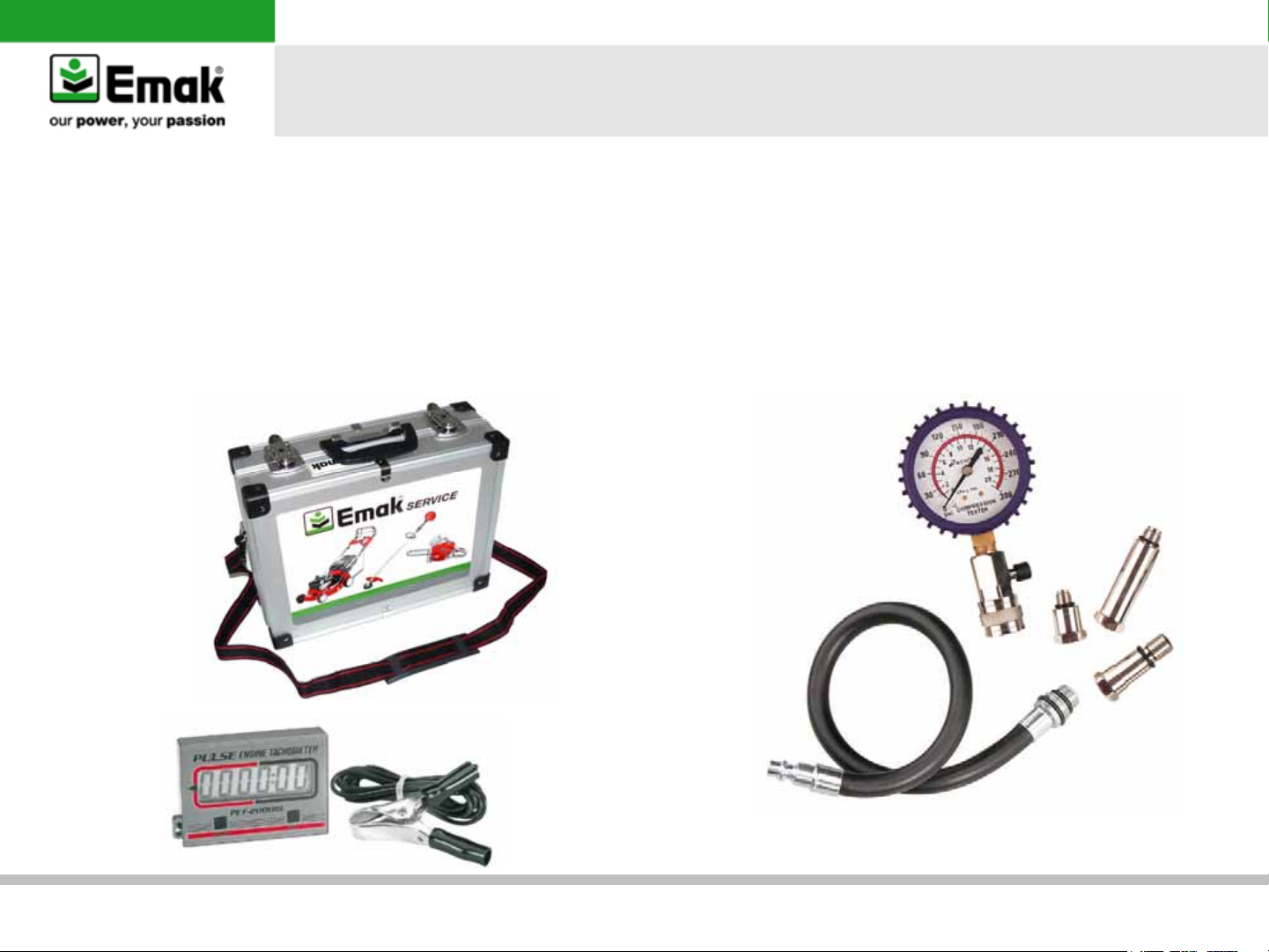

Suggested tools

I. Emak tool kit

II. Compression tester: to check thermal group

III. Electronic tachometer: for 2 and 4 stroke engines, measurement range from 100 to 30,000 RPM

I.

III.

p/n 3055125

p/n 001000785

63,4 cm³ chainsaws

II.

p/n 001000392A

Page 4

Index

General failures’ analysis

1) Performance

a) Compression test

b) Cylinder and piston inspection

c) Decompressor inspection

d) Cooling system cleaning

e) Muffler inspection

2) Fuel system

a) Fuel and fuel filter inspection

b) Fuel system test

c) Tank breather inspection

d) Engine seal test

e) Manifold inspection

3) Ignition system

a) Starter housing inspection

b) Spark plug inspection

c) Spark test

d) Flywheel-coil air gap inspection

e) Flywheel key inspection

4) Oil pump, bar and shock absorber

a) Oil tank breather inspection

b) Oil filter inspection

c) Sprocket/power mate ring inspection

d) Oil pump inspection

e) Chain brake inspection

f) Lubrication and bar maintenance

g) Shock absorber replacement

5) Tuning

a) Air filter inspection

b) Needle valve inspection

c) Carburetor inspection

d) Suggested tools for carburetion setting

e) Carburetion tuning

6) Tightening torques

7) Trouble shooting

a) The engine does not start

b) Low performance

c) Additional problems

63,4 cm³ chainsaws

Page 5

1) Performance

General failures’ analysis

a) Compression test

b) Cylinder and piston inspection

c) Decompressor inspection

d) Cooling system cleaning

e) Muffler inspection

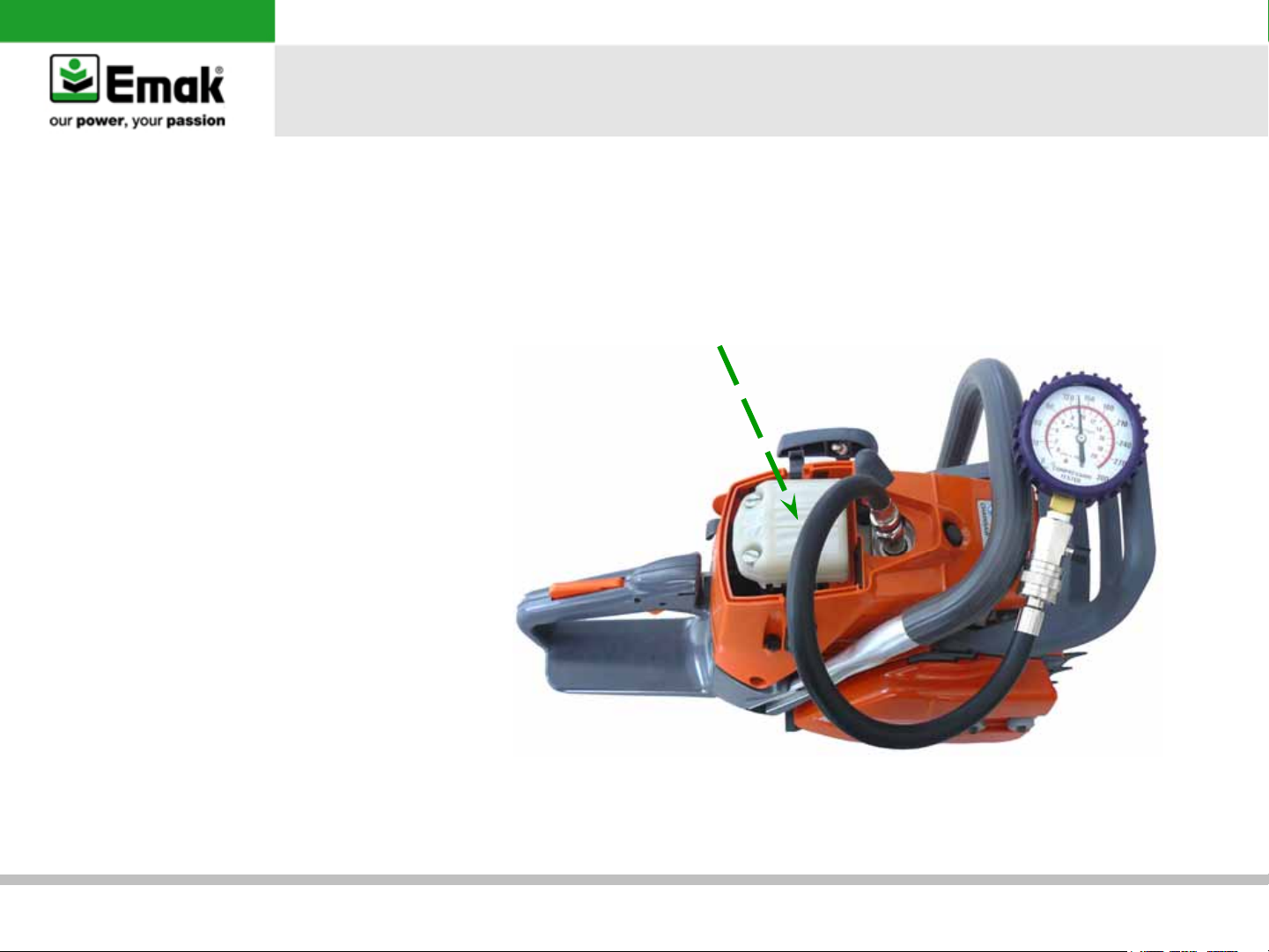

a) Compression test

• Apply the Emak compression

tester (I) on cylinder. Pull

energetically the rope 10

times

• Verify that the compression

value in not less than 8 bar –

130 psi

• If the value in higher than

8 bar – 130 psi, start

inspection c), if lower, carry

on with inspection b)

I

p/n 001000392A

63,4 cm³ chainsaws

Page 6

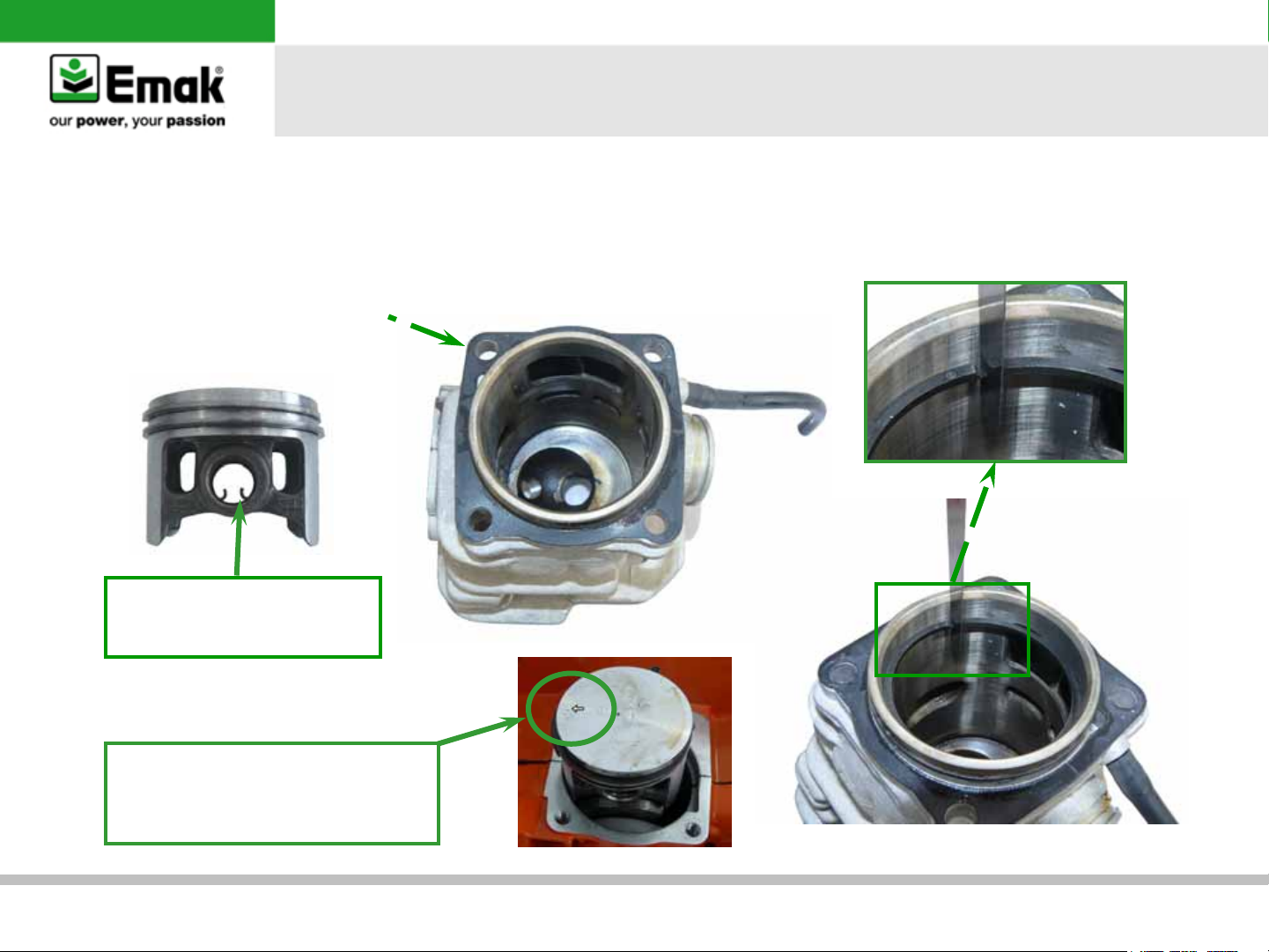

b) Cylinder and piston inspection

• Verify the diamond scoring on piston and the nickel-lining on cylinder. Replace if necessary

• Verify the piston rings wear using feeler gauge (gap max 1,0 mm)

Tightening torque cylinder-screws

1,2 Kgm (106,20 in lb) + Loctite 243

Warning: during assembly

make sure the circlip has

the feet pointing up

General failures’ analysis

Warning:

The arrow on the top of the

cylinder points towards the

exhaust port.

63,4 cm³ chainsaws

Page 7

General failures’ analysis

c) Decompressor inspection

Verify that the decompressor and the decompression hole on the cylinder is not closed to carbon deposits.

Clean and/or replace if necessary.

63,4 cm³ chainsaws

Page 8

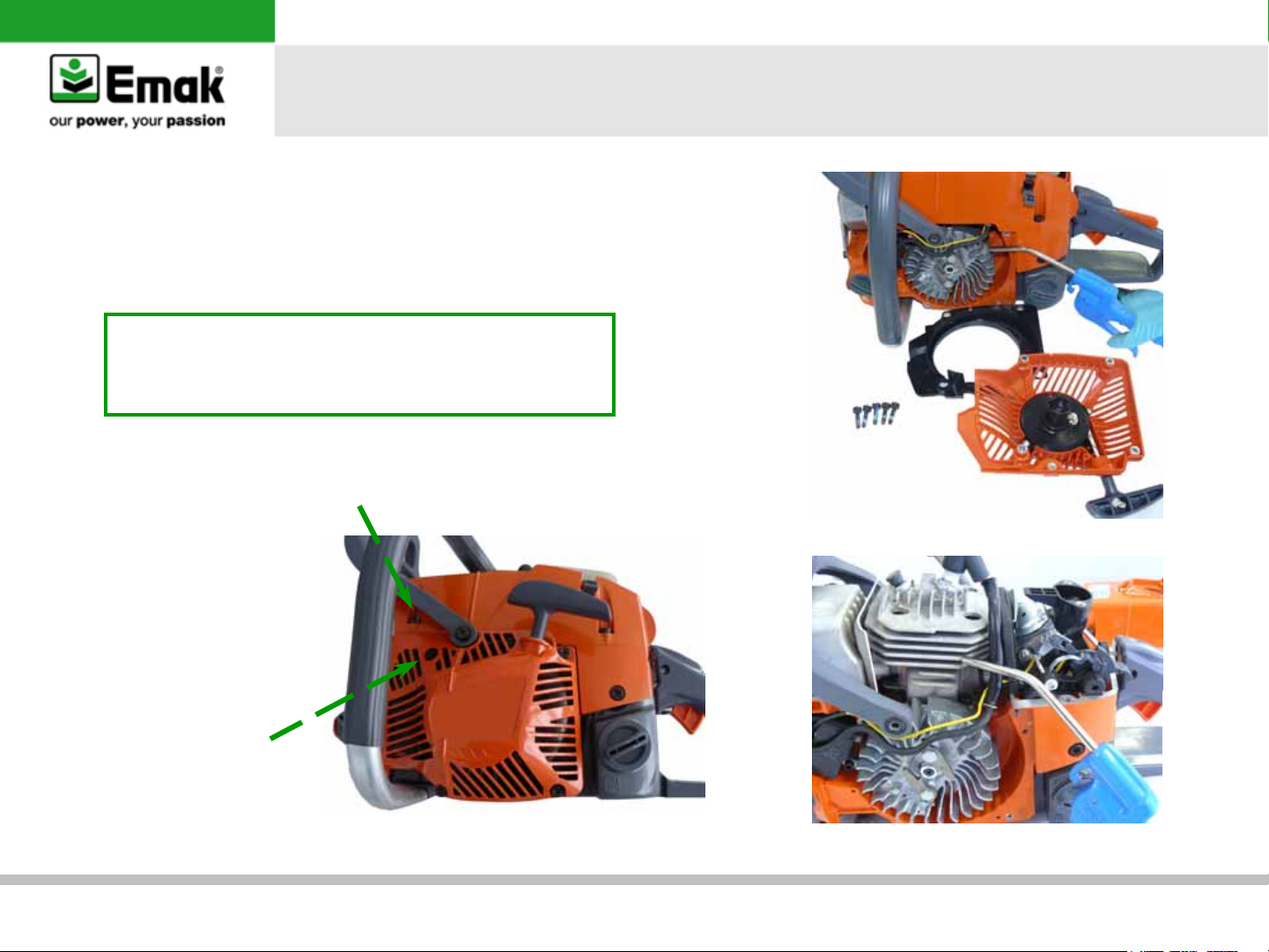

d) Cooling system cleaning

Blow, with compressed air, cylinder fins, starter

case and flywheel

Important:

•Clean weekly the cooling system. For heavy

duty work, clean it every day

• Use Loctite 243 to tighten plastic component

Tightening toque cover-basement

0,4 kgm (35,4 in lb) + Loctite 243

General failures’ analysis

Tightening torque

Cover

0,4 kgm (35,4 in lb)

+ Loctite 243

63,4 cm³ chainsaws

Page 9

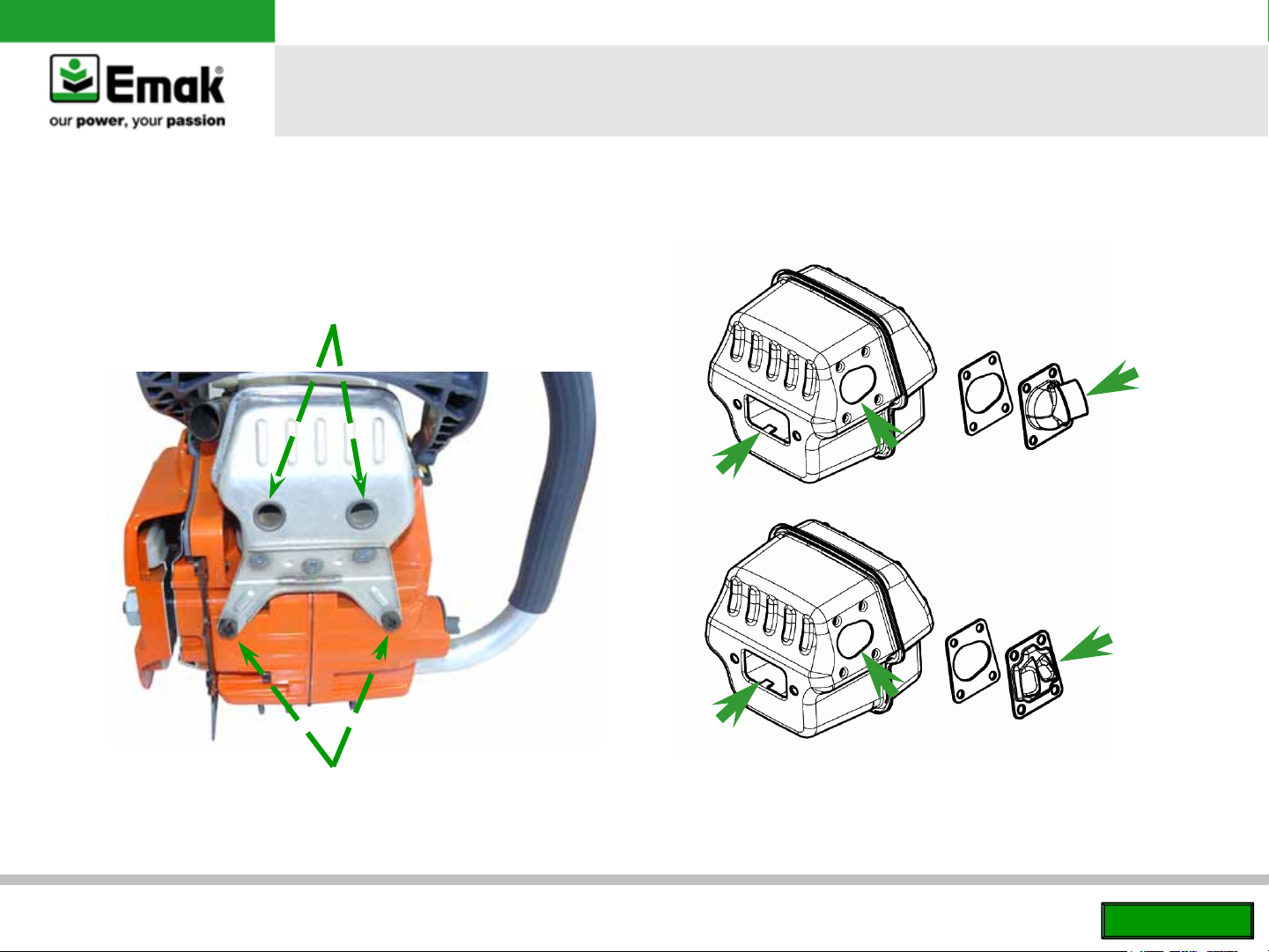

e) Muffler inspection

If the muffler is blocked or damaged, clean or

replace it

Tightening torque muffler-cylinder

1,0 kgm (88,5 in lb) + Loctite 243

General failures’ analysis

Tightening torque cover muffler-basement

0,6 kgm (52,1 in lb) + Loctite 243

63,4 cm³ chainsaws

Back to index

Page 10

2) Fuel system

a) Fuel and fuel filter inspection

b) Fuel system test

c) Tank breather inspection

d) Engine seal test

e) Manifold inspection

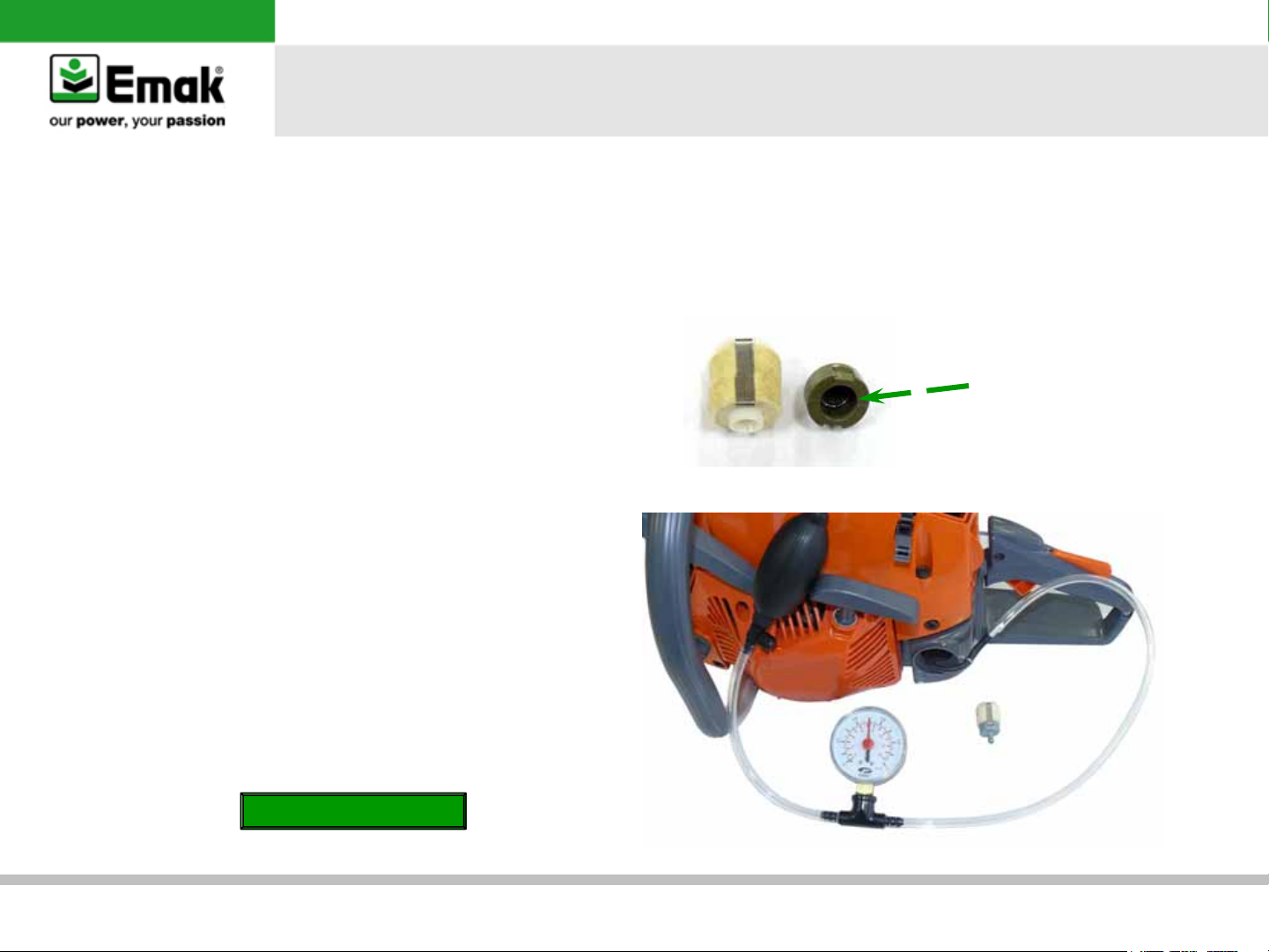

a) Fuel and fuel filter inspection

• Verify fuel quality odor

• Dismount and check periodically the fuel filter

and the sintered internal filter. In case of dirt or

oxidation, replace it

General failures’ analysis

Sintered

internal

filter

b) Fuel system test

• Apply the pressure gauge at the fuel line. Check

any possible leakage at 0,5 bar

• If the pressure is not stable, it may indicate

worn fuel system or loose at the carburetor

parts

Go to

Carburetor inspection

63,4 cm³ chainsaws

Page 11

General failures’ analysis

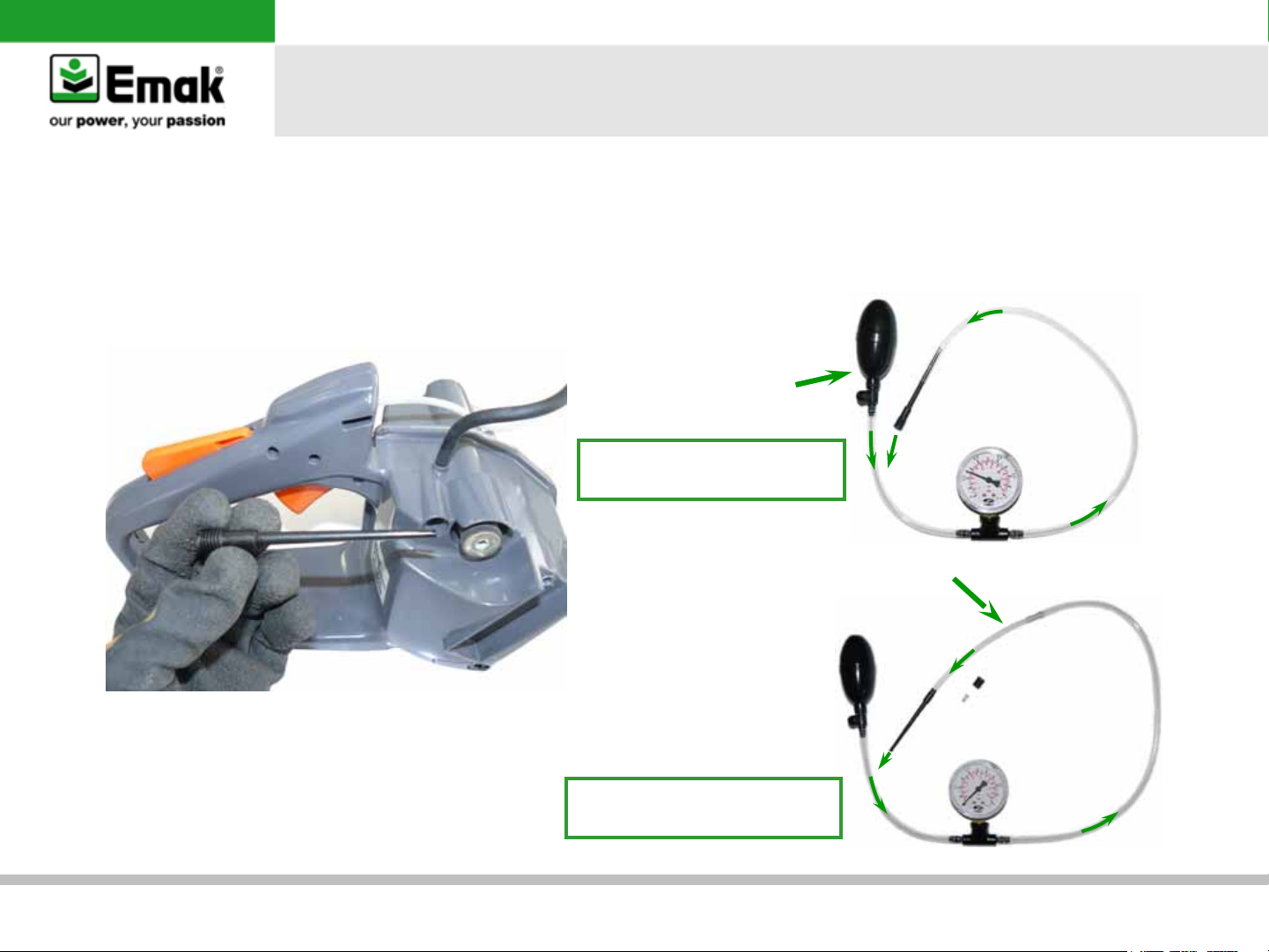

c) Tank breather inspection

• Dismount the breather and check the components

• Apply the pressure gauge (I), supplied with Emak tool kit, at the breather valve and verify the correct

working in both ways. To check the inlet direction use the adaptor (II), supplied with the pressure gauge’s

box, as shown on the photo. Replace or clean if necessary

I

p/n 1043900

Breather sealing test:

0,2 – 0,3 bar

II

Breathing system test:

0,00 bar

63,4 cm³ chainsaws

Page 12

d) Engine seal test

• Remove air filter, cover, air filter support,

carburetor and muffler. Cover the intake side

with insulator and exhaust side using the

special flanges supplied with Emak tool kit (I

and II). Tap the impulse’s tube with a cap (III)

and replace the decompressor with a special

cap (IV)

General failures’ analysis

• The pressure has to remain stable at 0,5 bar. If

the engine looses pressure, find the leakage and

fix it. Repeat seal test

IV

III

I

p/n 001000368B

III

p/n 001000005A

63,4 cm³ chainsaws

Page 13

General failures’ analysis

e) Manifold inspection

Check the manifold for wear. Verify that the manifold’s rubber is not deteriorated or hardened and check that

there are no cuts or holes. Replace if necessary

63,4 cm³ chainsaws

Back to index

Page 14

3) Ignition system

a) Check housing inspection

b) Spark plug inspection

c) Spark test

d) Flywheel-coil air gap inspection

e) Flywheel key way inspection

a) Starter housing inspection

Remove housing. Inspect parts for wear. If

necessary clean or replace

General failures’ analysis

Wind the spring 7 times

ø 4,0 x 1035 mm

Important: grease moving parts

63,4 cm³ chainsaws

Page 15

General failures’ analysis

b) Spark plug inspection

Remove the spark plug and check the gap

between the electrodes (0,5 mm)

(0,5 mm)

c) Spark test

• Fit the tester (I) between spark plug and spark

plug cap. Pull the rope and verify the current

• Replace the spark plug if necessary

• Check the two wires, ignition coil and switch

I

p/n 001000515R

63,4 cm³ chainsaws

Page 16

General failures’ analysis

d) Flywheel-coil air gap inspection

• Check the air gap using the shim (II-0,3 mm)

• Adjust if not correct

Tightening torque coil-screws

0,35 kgm (30,98 in lb) + Loctite 243

e) Flywheel key way inspection

• Remove flywheel with corrector tool (III)

• Inspect key way’s condition and position. If

II

cod. 001000004

necessary, replace or adjust

III

cod. 001000782

Tightening torque flywheel-nut

2 kgm (177,0 in lb)

63,4 cm³ chainsaws

Back to index

Page 17

General failures’ analysis

4) Oil pump, bar and shock absorber

a) Oil tank breather inspection

b) Oil filter inspection

c) Sprocket/power mate ring inspection

d) Oil pump inspection

e) Chain brake inspection

f) Lubrication and bar maintenance

g) Shock absorber replacement

a) Oil tank breather inspection

• Clean with compressed air

• Verify the quality of the bar and chain oil

b) Oil filter inspection

Check the oil filter. If it is dirty, clean it

Tightening torque crankcase-screws

0,8 kgm (69,44 in lb)

+ Loctite 243

Make sure that the

height of the oil tank

breather is 1 mm lower

than bar face

63,4 cm³ chainsaws

Page 18

c) Sprocket/power mate ring inspection

Check the sprocket/power mate ring wear

periodically. Replacement is suggested every

100 hrs or before

General failures’ analysis

OK REPLACE

Attention: When reassembling the clutch make

sure that the worm gear drive spring (I) lodges

into the clutch drum correctly (II)

I

Attention: always replace the snap ring after

removing.

63,4 cm³ chainsaws

II

Page 19

c) Oil pump inspection

• Insert the piston stop (I) in the spark plug hole and remove the clutch

• Remove the oil pump, check the pump and worm gear

I

p/n 001000684

General failures’ analysis

Tightening torque clutch

4,5 kgm (398,3 in lb)

+ Loctite 270

Important: If the gear inside the pump is hard to turn, disassemble all components and clean them using Emak

detergent

63,4 cm³ chainsaws

Page 20

e) Chain brake inspection

Check the brake band for wear. This must be changed if the wear limit is less than 0,6 mm

General failures’ analysis

63,4 cm³ chainsaws

Page 21

f) Lubrication and bar maintenance

• Lubricate the sprocket nose

• Keep the rail and the lubrication holes cleaned

• Check the parallelism of the guide bar and for sharp metal edges

• Turn the bar every 8 hrs to grant uniform wear

The angled

lubrijet oilway

hole must be

cleaned

E

S

A

E

R

G

General failures’ analysis

63,4 cm³ chainsaws

Page 22

g) Shock absorber replacement

• Control the AV mounts for wear or damage (A).

Change when necessary

• In case of wear or breakage replace the parts with

special tool (I), supplied with Emak tool kit, as in

photo

I

p/n 001000680A

General failures’ analysis

A

A

63,4 cm³ chainsaws

Page 23

Substitute spring AV mounts

• Check for wear or damage of the AV mounts exchange if necessary.

Substitute spring AV mounts:

– loosen the spring support (C)

– insert the screwdriver and loosen the spring.

General failures’ analysis

C

B

Important: Make sure when assembling

the springs fit correctly into the crankcase

(B), as shown in photo

63,4 cm³ chainsaws

Page 24

Substitute AV mounts on inlet flange

• Control the wear and damage and exchange if necessary.

General failures’ analysis

63,4 cm³ chainsaws

Back to index

Page 25

5) Tuning

a) Air filter inspection

b) Needle valve inspection

c) Carburetor inspection

d) Suggested tools for carburetion setting

e) Carburetor tuning

a) Air filter inspection

• Clean with Emak detergent, rinse with water and

blow with compressed air in the opposite direction

of the normal air flow

• Replace the filter when damaged

0,45 kgm (39,83 in lb)

General failures’ analysis

Tightening torque

carburetor-screws

+ Loctite 243

63,4 cm³ chainsaws

Page 26

General failures’ analysis

b) Needle valve inspection

Check the right position of the valve using a

caliper. Adjust if necessary

Needle

c) Carburetor inspection

Check and clean all components (diaphragm,

needle, filter). Use the repair kit to replace worn

components. If the carburetor is oxidized, replace

it

OK REPLACE

63,4 cm³ chainsaws

Back to fuel system

Page 27

d) Suggested tools for carburetion setting (Euro 0)

Special screwdriver (I) to adjust the jets: for adjustment the jets “L” e “H”

General failures’ analysis

p/n 001001070R

63,4 cm³ chainsaws

I

Page 28

Suggested tools for carburetion setting (Euro 1)

Special screwdriver (I) to adjust the jets: for adjustment the jets “L” e “H”

General failures’ analysis

I

p/n 3055130

63,4 cm³ chainsaws

Insert the special screwdriver

(as shown on the photo) and

adjust the jets

Page 29

General failures’ analysis

e) Carburetor tuning

Correct tuning of the EURO 0 and EURO 1 (direttiva 97/68/CE + 2002/88/CE).

The jets have the following factory registration: L=1; H=1

When, following a repair or engine overhaul, you are obliged to re-tune the carburetor to its’ original setting

Idling adjustment (L)

1. Start the unit and warm up for 60 seconds. If the engine stop, readjust T screw

2. Close the L jet until the maximum number of rpm is reached (stop rotating the jet before the rpms drop or

the unit stalls);

3. Adjust the T screw until the unit reaches an idle rpm between: 3700 and 4100 RPM

4. Open the jet L until the rpm go from 3700/4100 to 2700/3100 RPM

Maximum adjustment (H)

5. Adjustment of the jet H for wide open throttle operation whit bar (standard 20” - 51 cm) and chain until the

unit reaches an maximum rpm between: 11800 RPM and 12800 RMP

63,4 cm³ chainsaws

Torna a indiceBack to index

Page 30

General failures’ analysis

0,4 –

35,4 *

2 - 177

0,7 –

61,95

6) Tightening torques

0,35 – 30,98 *

0,1 -

8,85 *

0,1 –

8,85 *

0,6 –

52,1 *

0,35 – 30,98 *

Tightening torques

(kgm) – (in lb) / lubrication

* = Loctite 243

▲ = Loctite 270

G = Grease

O = Oil

2 -

177

O

1,2 –

106,2 *

1,4 –

123,9

63,4 cm³ chainsaws

Page 31

0,4 –

35,4 *

General failures’ analysis

1 – 88,5 *

0,6 – 52,1 *

Euro 1

0,3 – 26,55

Euro 0

0,15 – 13,28

0,4 – 35,4

0,45 –

39,83 *

0,17 – 15,04

63,4 cm³ chainsaws

0,1 – 8,85

Tightening torques

(kgm) – (in lb) / lubrication

* = Loctite 243

▲ = Loctite 270

G = Grease

O = Oil

Page 32

0,8 – 70,8 *

General failures’ analysis

0,8 –

70,8*

0,5 – 44,25 *

0,1 –

8,85

0,4 – 35,4 *

0,4 – 35,4 *

0,4 – 35,4 *

63,4 cm³ chainsaws

0,3 – 26,55 *

0,4 – 35,4 *

0,5 – 44,25 *

0,1 – 8,85

0,8 –

70,8 *

0,45 –

39,83*

Tightening torques

(kgm) – (in lb) / lubrication

* = Loctite 243

▲ = Loctite 270

G = Grease

O = Oil

0,45 –

39,83*

Page 33

0,4 –

35,4 *

0,3 – 26,55 *

4,5 – 398,3 ▲

General failures’ analysis

0,45 –

39,83 *

0,15 –

13,28 *

0,3 –

26,55 *

Tightening torques

(kgm) – (in lb) / lubrication

* = Loctite 243

▲ = Loctite 270

G = Grease

O = Oil

0,35 –

30,98 *

0,3 – 26,55 *

63,4 cm³ chainsaws

0,35 – 30,98 * 1,2 – 106,2

Back to index

Page 34

General failures’ analysis

7) Trouble shooting: ENGINE DOES NOT START

1. The engine does not

turn over

2. There is no

compression

3. No spark

4. Fuel does not reach

the carburetor, the

machine stops after 5

minutes

1.a Starter assy defect or

broken starter rope

1.b Internal damage

2.a Spark plug looses

2.b Piston ring, cylinder and

piston worn

3.a Ignition switch is in “OFF”

position

3.b Ignition system defected

3.c Broken spark plug or

wrong type

4.a Fuel filter or breather

blocked

4.b Fuel system is leaking air

4.c Wet spark plug, flooded

cylinder

RemediesCausesSymptoms

1.a Check starter assy or starter rope

replacement

1.b Check thermal group and replace

worn components

2.a Tighten spark plug. Compression

test

2.b Replace worn or damaged parts.

Compression test

3.a Switch “ON” and restart

3.b Inspect and/or replace

3.c Replace the spark plug

4.a Clean or replace

4.b Tightness test on fuel system

4.c Carburetor inspection (point 5.c).

Take off spark plug, rotate the engine,

blow inside cylinder passing through

spark plug hole, dry the spark plug

and restart

Go to

Section 3

Section 1

Section 1

Section 1

Section 3

Section 3

Section 2

Section 2

Section 5

5. Wrong carburetion

setting or erratic

throttle response

5.a Air filter dirty

5.b Wrong L and H setting

5.c Carburetor problems

5.d Manifold problems

63,4 cm³ chainsaws

5.a Clean or replace

5.b Adjust the carburetion according

the above

5.c Carburetor inspection

5.d Manifold tightness

Section 5

Section 5

Section 5

Section 2

Page 35

General failures’ analysis

Trouble shooting: LOW PERFORMANCE

1. Engine

overheating

2. Engine

performance is

not stable

1.a Carburetor mixture too lean

1.b Air leaking in the engine or in

fuel system

1.c Wrong oil-fuel ratio

1.d Fan, starter housing, cylinder

fins dirty or damage

1.e Carbon deposit on piston

2.a Dirty air filter

2.b Loose spark plug or damaged

2.c Water in the fuel

2.d Seizure

RemediesCausesSymptoms

1.a Set the carburetor

1.b Find air leaking and eliminate it

1.c Replace with fresh fuel and right

oil ratio

1.d Clean or replace it

1.e Eliminate deposit

2.a Clean or replace

2.b Tighten or replace

2.c Clean the carburetor and replace

fuel

2.d Replace the components

Go to

Section 5

Section 1

Section 2

Section 1

Section 1

Section 5

Section 3

Section 5

Section 1

2.e Faulty carburetor or diaphragm

63,4 cm³ chainsaws

2.e Check and replace

Section 5

Page 36

General failures’ analysis

Trouble shooting: ADDITIONAL PROBLEMS

1. The chain does not

work correctly or does not

rotate

1.a Bended or worn bar

1.b Lubrication system blocked

1.c Worn sprocket

1.d The chain is not sharp

1.e Chain to tight

RemediesCausesSymptoms

1.a Replace or maintain

1.b Clean or replace

1.c Replace sprocket

1.d Sharpen the chain

1.e Correct tension/assembly

bar and chain

Go to

Section 4

Section 4

Section 4

Owner’s

manual

Owner’s

manual

63,4 cm³ chainsaws

Back to index

Loading...

Loading...