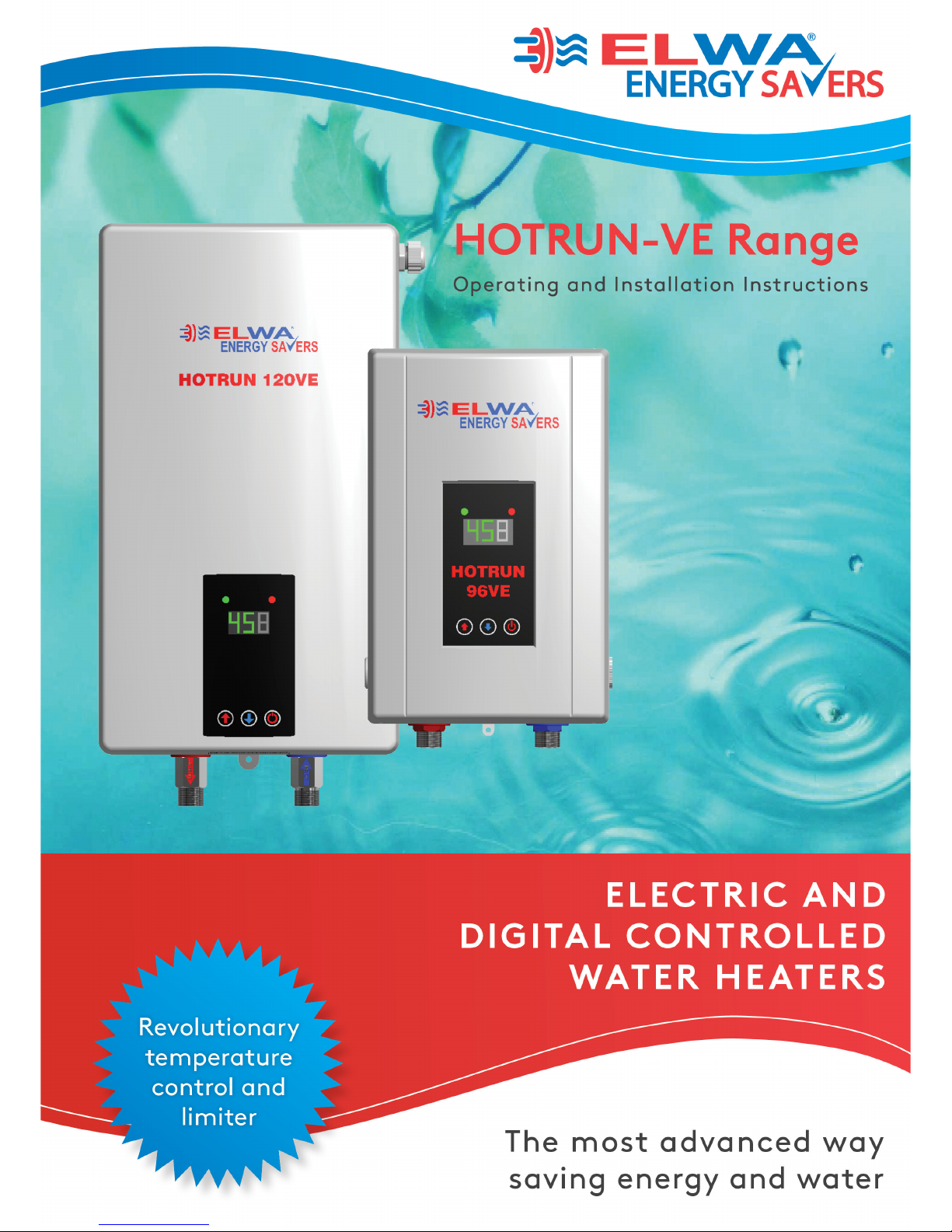

Elwa HOTRUN-VE 38VE, HOTRUN-VE 48VE, HOTRUN-VE 60VE, HOTRUN-VE 75VE, HOTRUN-VE 96VE Operating And Installation Instructions

Contents

General information and safety instructions ……………………………… 3

Mounting instructions ……………………………… 4

Water connections ……………………………… 5

Electrical connection ……………………………… 6

Electrical schematics ……………………………… 7

Control panel ……………………………… 8

Legionella cleaning cycle ……………………………… 9

Maintenance ……………………………… 10

Troubleshooting ……………………………… 10

Terms of warranty ……………………………… 14

Flexible connections ……………………………… 15

Approvals:

IEC/AS/NZS 60335.2.35, Electrical safety, Certificate number 11422CA

AS/NZS 3498 and AS/NZS 3500, Watermark, Certificate number 40034

3

General information

Thank you for choosing an ELWA digital controlled instantaneous water heater.

To ensure your own safety and that of others you need to read these installation and

operating instructions before using this water heater for the first time.

Please keep the instructions and other documentation close to the unit for future reference

Failure to observe this instruction may lead to damage to the water heater.

This product should not be disposed of. ELWA water heaters can always be serviced or repaired

if needed. To prevent possible harm to the environment or human health from uncontrolled waste

disposal, recycle it responsibly to promote the sustainable reuse of material resources.

Plumbing and electrical installation work, commissioning and maintenance of this appliance

should only be undertaken by a qualified tradesperson. Correct and reliable operation of this unit

will only be ensured if original ELWA accessories are used.

This water heater must be connected to a reliable earth connection at all times.

The electrical resistance of the water must be at least >1300 Ω/cm².

Your water supply-company can inform you about the electrical resistance (specific resistance) of

the water in your area. The water heater should not be installed in an area exposed to the risk of

freezing.

Do not operate a HOTRUN in a “dry state”. The electrical power should remain switched

off until the HOTRUN is completely filled with water and all air is released from the

system!

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons with an original approved cord in order to avoid a hazard.

This water heater is manufactured in accordance with applicable safety standards and has been

tested by the relevant authorities. It has been certified to comply with AU and EU standards and

the IEC declaration of electromagnetic conformity.

The exact technical specifications of every water heater is shown on the label of the water heater

This appliance is not intended to be programmed by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

Accessories supplied with every ELWA HOTRUN water heater: wall plugs and screws, two

flexible hoses Watermark approved for hot and cold water connections, three white blanking

grommets

4

The ELWA HOTRUN electric instantaneous water heaters are designed for both point of use

(most efficient and lowest water and energy consumption) and multipoint applications, such as

hand wash basin/shower/kitchen sink(s), in fact all places where instant hot water is required.

The heating of the water is started instantly when sufficient flow is detected by opening a tap or

valve connected to the hot water outlet.

The outlet water temperature depends on the following factors:

- The flow rate through the HOTRUN that is limited by a flow restrictor in the cold water

inlet fitting or if removed can be controlled by a flow valve on the cold water inlet side

- How far the hot water tap is actually opened (or the incoming flow into the HOTRUN

restricted)

- The temperature of incoming cold water

- The mixing of hot- and cold water

The hot water temperature can rise while reducing the flow rate. By closing the hot water tap or

when the flow drops below a minimum flow rate, the heating of the water will stop automatically.

The capacity/performance of the HOTRUN depends on its electrical capacity (kWatt rating).

A temperature rise of 25°C to 30°C can be expected with the standard flow restrictor in the cold

water inlet fitting. An inlet temperature of 25°C can increase the performance by 50% compared

to an inlet temperature of 12°C.

Mounting instructions

1. Mark the position of the plugs or screws according to the positional template, allowing

enough space below and above the water heater (200mm) to open the front cover screws

after installation. The HOTRUN models 38 to 96 can be installed in an over-sink and

under-sink position. As standard, the water heater is supplied for under-sink installation.

To mount in an over-sink position rotate the key-hole bracket on the back plate and the

front cover 180°. The models 120 to 240 can only be installed in over-sink position.

2. Mount the unit using the screws supplied using the positional template.

3. Fit the top screw(s) allowing it to protrude approximately 2-3 mm. Slide the bracket onto

the protruding screw(s).

4. Secure the water heater into position with the screw between the hot and cold water

connections

5

Water connections

1. The HOTRUN-VE range of products need a cold water supply pressure of at least 60kPa.

This 60kPa pressure must remain under full flow conditions. When connecting the

HOTRUN to a low pressure tank/rainwater system without pressure pump, it is unlikely to

switch on in a reliable manner. If unit is supplied by rain water, water must be filtered

before passing the HOTRUN water heater. The minimum supply pressure needs to be

secured at all times or the HOTRUN can fail to switch on.

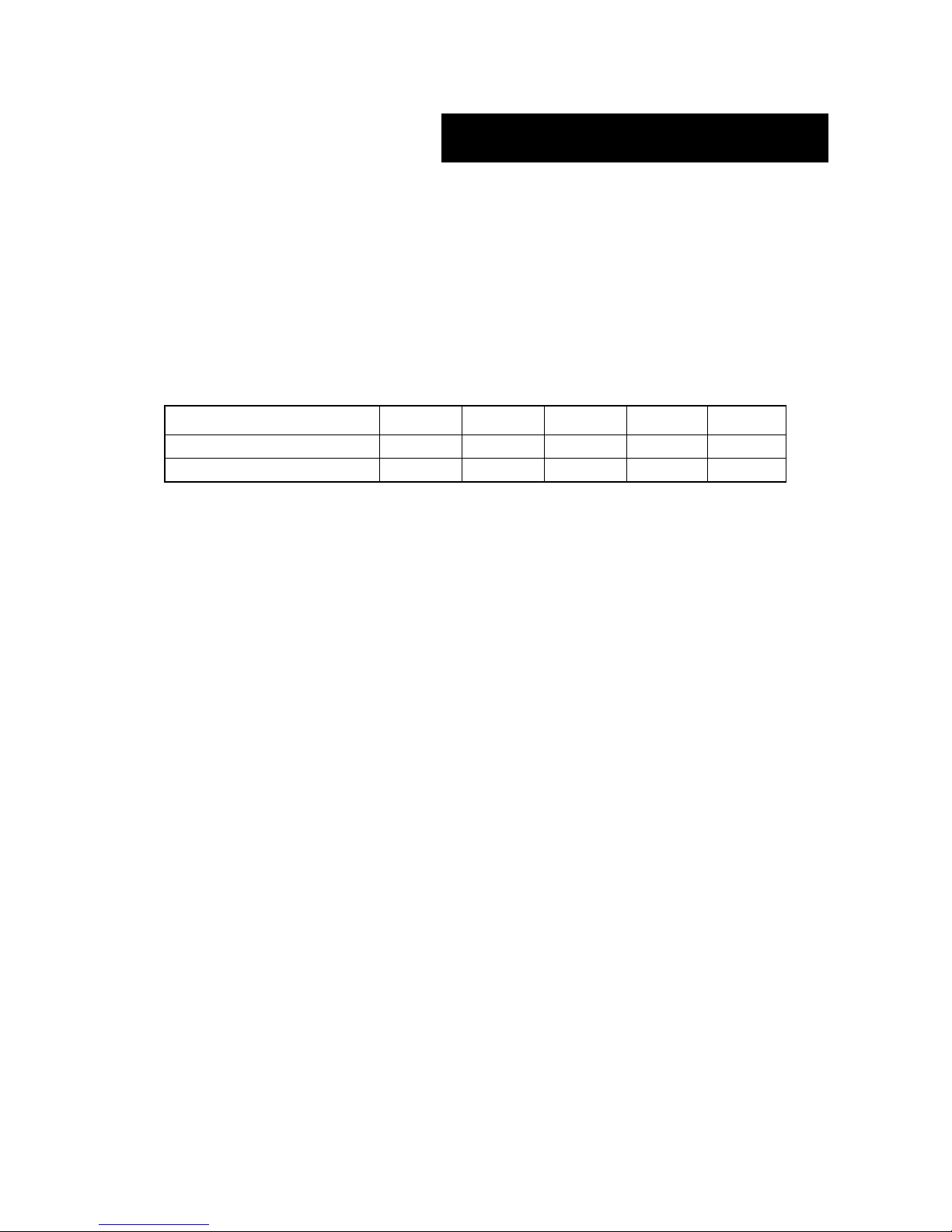

The minimum flow rate to operate the HOTRUN-VE models depends on the model:

2. The maximum inlet water pressure needs to be limited to 600kPa. If it is not guaranteed

the pressure will not exceed 600kPa a pressure limiter of 350kPa or 500kPa needs to be

installed in the total cold water supply to the building or the area where the HOTRUN will

be installed.Take water hammer of flick-mixers into consideration that can cause pressure

boosts, when closing fast, of up to 200kPa on top of the inlet water pressure.

3. Make sure that any flow restrictors in shower heads and aerators in tap outlets installed

after the HOTRUN are not too restrictive, kept clean and make sure these cause minimal

back-pressure to enable the HOTRUN to switch on and off. The outlet back-pressure

needs to be less than the cold water inlet supply pressure, as the cold water can be pushed

back to the HOTRUN when mixing cold water to the hot water and cause the HOTRUN to

switch off. Sometimes a pressure limiter in the total cold water supply needs to be

installed to secure proper performance at all times.

4. Connect the incoming & outgoing water pipe-work to the HOTRUN water connectors

only with the flexible hoses that are supplied with each HOTRUN, unless the water

connections come in from the back through the wall. All HOTRUN fittings and flexible

hoses are Watermark approved and have a flat sealing connection. By using the supplied

flexible hoses you will avoid excessive tension on the HOTRUN fittings. Damaging

internal copper pipework during installation is not covered by warranty.

5. The incoming and outgoing water connections for cold and hot water can't be swapped.

The fitting with the blue marking is for the cold water inlet and the one with the red

marking is for the hot water outlet.

6. Always use a ½˝ BSP (100% bore) ball valve on the cold water supply for service

purposes.

7. Important: After installation open the water tap to flush the device to release all air

from the Heat Exchanger and check all connections. Failing to do so shortens the

life-span of the electric elements. Replacement of elements burning out during

installation is not covered by warranty.

HOTRUN MODEL : 38VE 48VE 60VE 75VE 96VE

Min start-up flow rate: 1.5 l/min 1.8 l/min 2.2 l/min 2.9 l/min 3.8 l/min

Standard delivery flow rate: 2.0 l/min 3.0 l/min 4.0 l/min 5.0 l/min 6.0 l/min

Loading...

Loading...