Page 1

Installer manual

SL24.W

Control panel for sliding gates 24 Vdc

Page 2

SL24.W

Contents: Page

Product features ................................................................................................................................................. 1

System type ........................................................................................................................................................ 2

Description of the terminal blocks....................................................................................................................... 2

Power supply connection.................................................................................................................................... 3

Connecting accessories ..................................................................................................................................... 3

Programming the control panel .......................................................................................................................... 6

Diagnostics ......................................................................................................................................................... 18

Updating rmware .............................................................................................................................................. 19

Control panel behaviour when loading settings .................................................................................................. 19

Control panel connection from Smartphone/Tablet ............................................................................................ 20

2

EN

Page 3

SL24.W

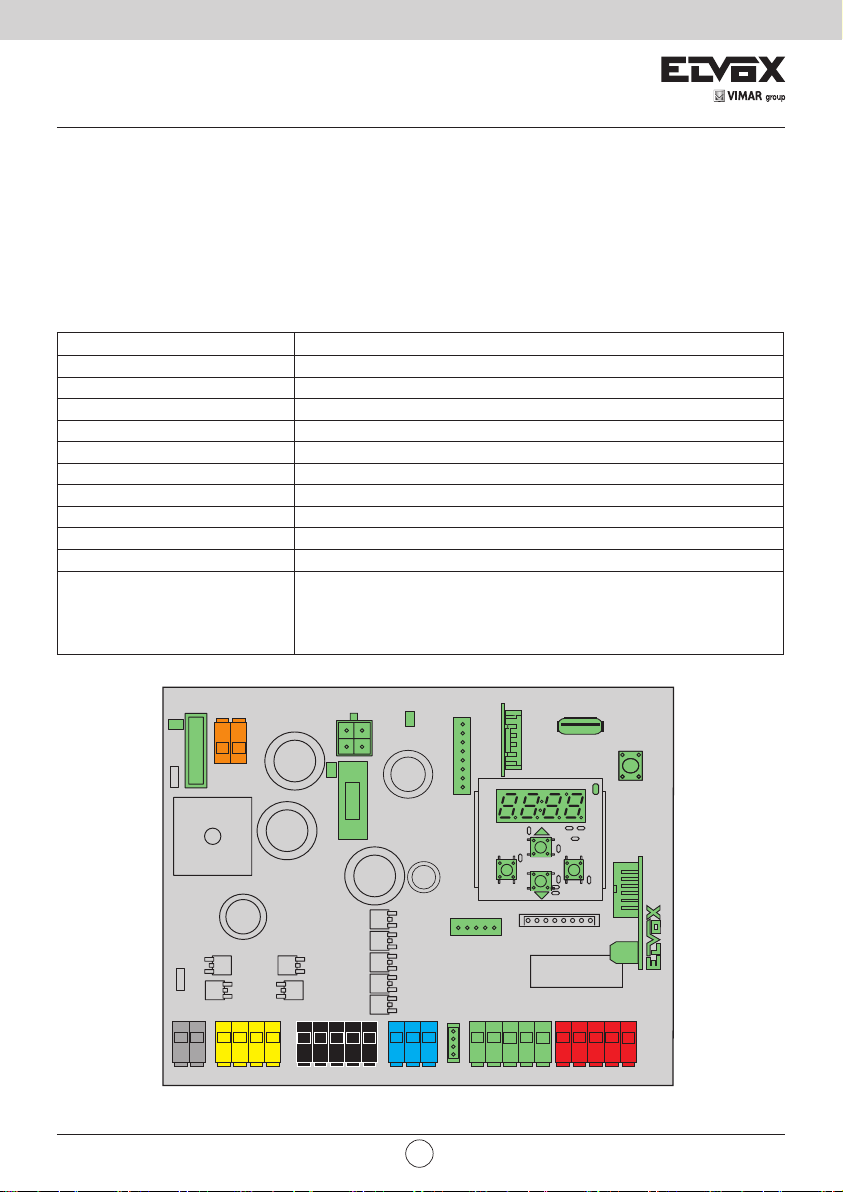

1 - Product features:

Control panel for gear motors for 24Vdc sliding gates. The control panel:

- is equipped with an integrated 433 MHz rolling code or xed code receiver, storing up to 4032 codes

- is equipped with W-Fi connection and programming via Smartphone and Tablet using the EMC.W module and the

Wi-Gate app is equipped with a back-lit display for programming and diagnostics

- is used to customise all gate movement control parameters (speed and slowdown spaces, motor force, obstacle

sensitivity, reaction to obstacles, acceleration and deceleration ramps...)

- is equipped with fully congurable inputs and outputs

- is used to lock the control panel and receiver settings with a 4 digit password protection

Technical data:

Power supply 24 Vac

Motor supply voltage 24 V DC

Maximum motor power 150 W

Flashing light output 24 V DC 35 W max

Accessories power supply 24 V DC 500 mA

Receiver memory 4032 Elvox rolling codes

Receiver frequency 433 MHz

Remote controls code Rolling code or xed

Fuse F1 ATO line protection 15 A

Fuse F2 Accessories protection 5x20 mm F 3.15A

Operating temperature -10 to +50°C

MEM for memory module MEM.W connection (included)

Ports

RADIO for radio module 433RAD.W connection (included)

USB for rmware updating

CNX1 for Wi-Fi EMC.W module connection

CNX2 for opposing leaf module connection

VIMAR group

T1 T2

SEC

DL4

T2T1

VR3

F1

PT1

FSC1

MOT PS

21 22 0 1 1 2

21 22 0112

BAT

DL3

AUX LSW ENC ACT SAF

10 11 0

10 11 0

PWR

F2

99 31 32 C3C499 S1 S2 S3

99 31 32 C3 99 S1 S2 S3

MEM

CNX1

PROGRAM. MENU'

ESC OK

CNX2

C1C299

C1C299

EN

CNP1

SL24.W

C4

USB

PP

DL1

RADIO

S4A1 A2

S4A1 A2

1

Page 4

SL24.W

T2T1

BAT

F1

SEC

VR3

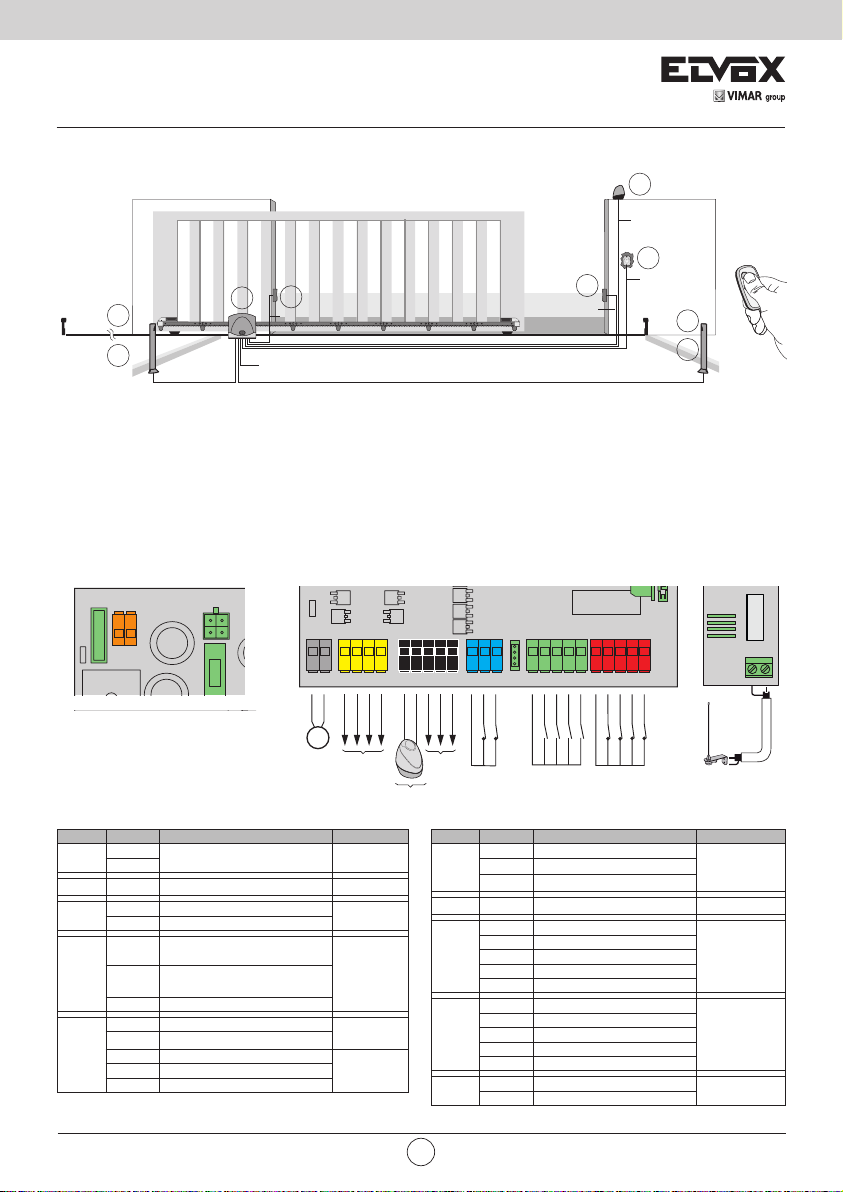

2 - System type:

For the sizing of the cable routing, the required cross-sections of the cables are shown below.

F

A

G

2x0.5 mm

Legend

A. Gear motor

B. Rack

C. External photocells

D. Flashing light

E. Selector

F. Internal photocells

G. Photocell posts

3 - Description of the terminal block

SEC

T2T1

VR3

F1

BAT

2

3x1.5 mm2 (230 Vac)

C

2

4x0.5 mm

FSC1

MOT PS

21 22 0 1 1 2

21 22 0112

OPEN M1

CLOSE M1

M1

24 V-

24 V+

500 mA max

2

4x0.5 mm

AUX LSW ENC ACT SAF

99 31 32 C3C499 S1 S2 S3

99 31 32 C3 99 S1 S2 S3

24 V-

COM

A1 24 V+

A2 24 V+

BLINK 24 V+

500 mA max

24 V+

24 V+ TEST

35 W max

10 11 0

10 11 0 A1 A2

BLINK 24 V-

2x0.5 mm

C1C299

C1C299

COM

C

2

SL24.W

C4

COM

D

4x0.5 mm

E

3x0.5 mm

S4A1 A2

S4

2

2

F

G

433RAD.W

ANT

- ANT

Block Terminal Description Rated data

T1

SEC

BAT - Battery pack rapid coupling

MOT

PS

Secondary transformer 24 Vac

T2

21 Opening motor (white)

22 Closing motor (brown)

Accessory power supply

0

negative

Accessory power supply

positive

2 Accessories positive checked

10 Flashing light negative 24 V DC

11 Flashing light positive

AUX

0 Accessories negative

A1 Congurable output 1 positive

A2 Congurable output 2 positive

2

24 V DC

150 W

24 V DC

500 mA1

35 W

24 V DC

500 mA

Block Terminal Description Rated data

99 Inputs common (blue)

31 Limit switch 1 (brown)

LSW

32 Limit switch 2 (black)

ENC - Motor encoder

99 Control common

C1 Congurable control 1

ACT

C2 Congurable control 2

C3 Congurable control 3

C4 Congurable control 4

99 Safety device common

S1 Congurable safety device 1

PS

S2 Congurable safety device 2

S3 Congurable safety device 3

S4 Congurable safety device 4

ANT Aerial signal

ANT

- Aerial earth

EN

N.C.

N.O.

N.C.

Page 5

SL24.W

(230 Vac) 5x20mm T 2A

ACT

COM

C1=1 (P.P.)

C2=2 (PED)

C3

C4

C1C299

ACT

COM COM

N.O. N.O.

N.C. N.C.

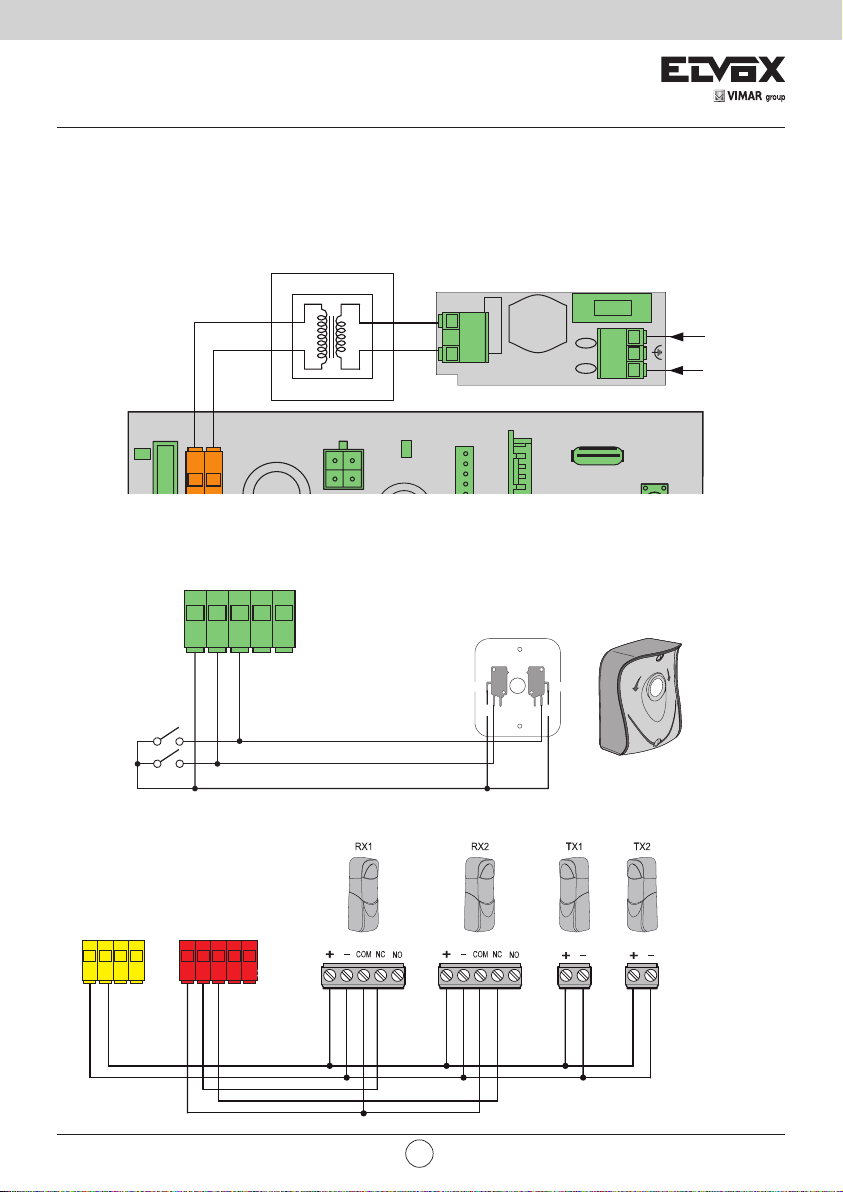

4 - Power supply connection

The control panel is powered at the SEC terminal with 24Vac and must be connected to the secondary terminal of a

transformer for powering from the mains electricity. The transformer is supplied with the gear motor or control cabinet

the control is tted in and the secondary is pre-wired to the control panel. The primary terminal on the transformer is

already wired to the mains lter, also supplied with the gear motor or the control cabinet, for connecting the mains lter

to the mains electricity refer to the image below:

(120 Vac) 5x20mm T 4A

LN

FA

L

230 Vac

120 Vac

N

T2

T1

SEC

DL4

T2T1

3

5 - Connecting accessories

5.1 - Key switch and control device

C3

C1

99

C2

COM

Pedestrian

Step by step

5.2 - Key switch and control device

PS

0 1 1 2

24 V-

24 V+

99

COM

C1=1 (P.P.)

SAF

S1 S2 S3

S2=2 (PH)

S1=1 (PHC)

C2=2 (PED)

S4

C4

BAT

PWR

MEM

CNX1

COM COM

N.C. N.C.

N.O. N.O.

USB

VIMAR group

EN

3

Page 6

SL24.W

24 V-

99 S1 S2 S3

S4

SAF

COM

24 V-

24 V+

S1=1 (PHC)

S2=2 (PH)

0 1 1 2

PS

COM

C1=1 (P.P.)

C2=2 (PED)

C3

C4

C1C299

ACT

COM COM

N.O. N.O.

N.C. N.C.

COM

99 S1 S2 S3

S4

SAF

COM

S1=4 (BAR)

S2=5 (8k2)

SAF

COM

S1=6 (STP

N.C.8K2 (8.2 KΩ)

5.3 - Photocells and photocells in closing with photo-test on

5.4 - Sensitive edge

S1 S2 S3

99

S1=4 (BAR)

5.5 - Stop push button

PS

0 1 1 2

24 V+

SAF

S4

S2=5 (8k2)

24 V+ TEST

SAF

99 S1 S2 S3

COM

S2=8 (PHT)

S1=7 (PTCH)

S4

N.C.8K2 (8.2 KΩ)

4

99 S1 S2 S3

)

S4

EN

Page 7

SL24.W

AUX LSW ENC ACT SAF

AUX LSW ENC ACT SAF

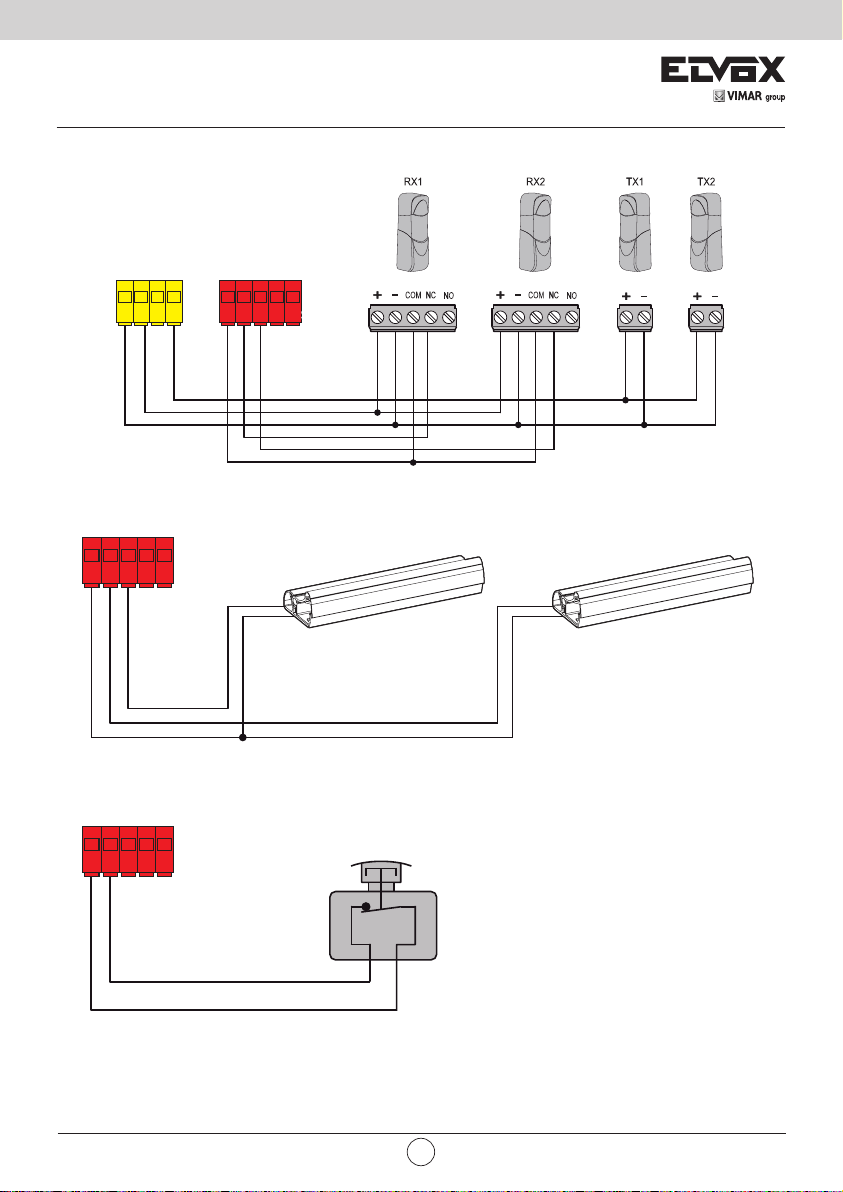

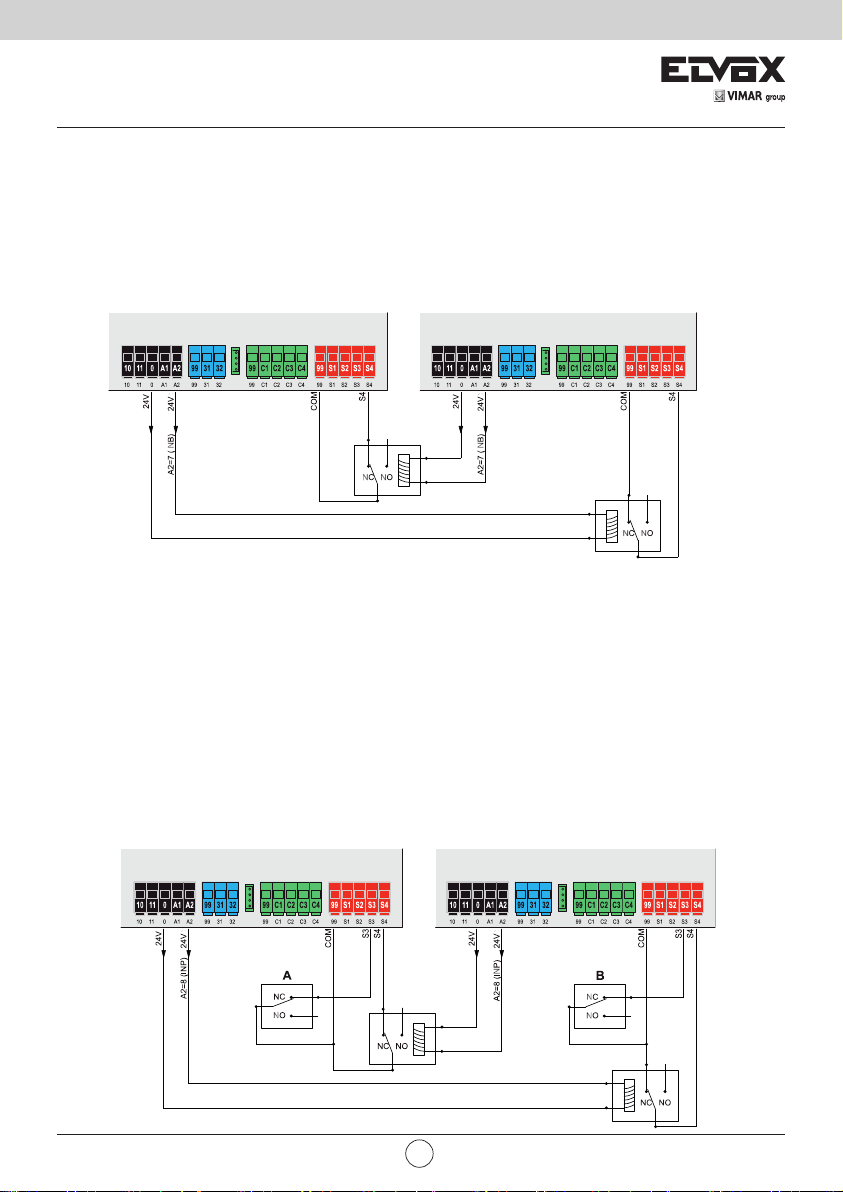

5.6 - Connecting two control panels in interlocking mode, output A2 = 7 (INB)

The interlocking connection involves 2 gates operating according to the following method:

- gate 1 opens only if gate 2 is closed

- gate 2 opens only if gate 1 is closed

When this mode is on, the safety input S4 is automatically congured without the installer selecting it as

an interlock input (checking that the other gate is closed). The two control panels operating in interlocking

mode must be connected by interposing 2 relays as shown in the gure:

AUX LSW ENC ACT SAF

AUX LSW ENC ACT SAF

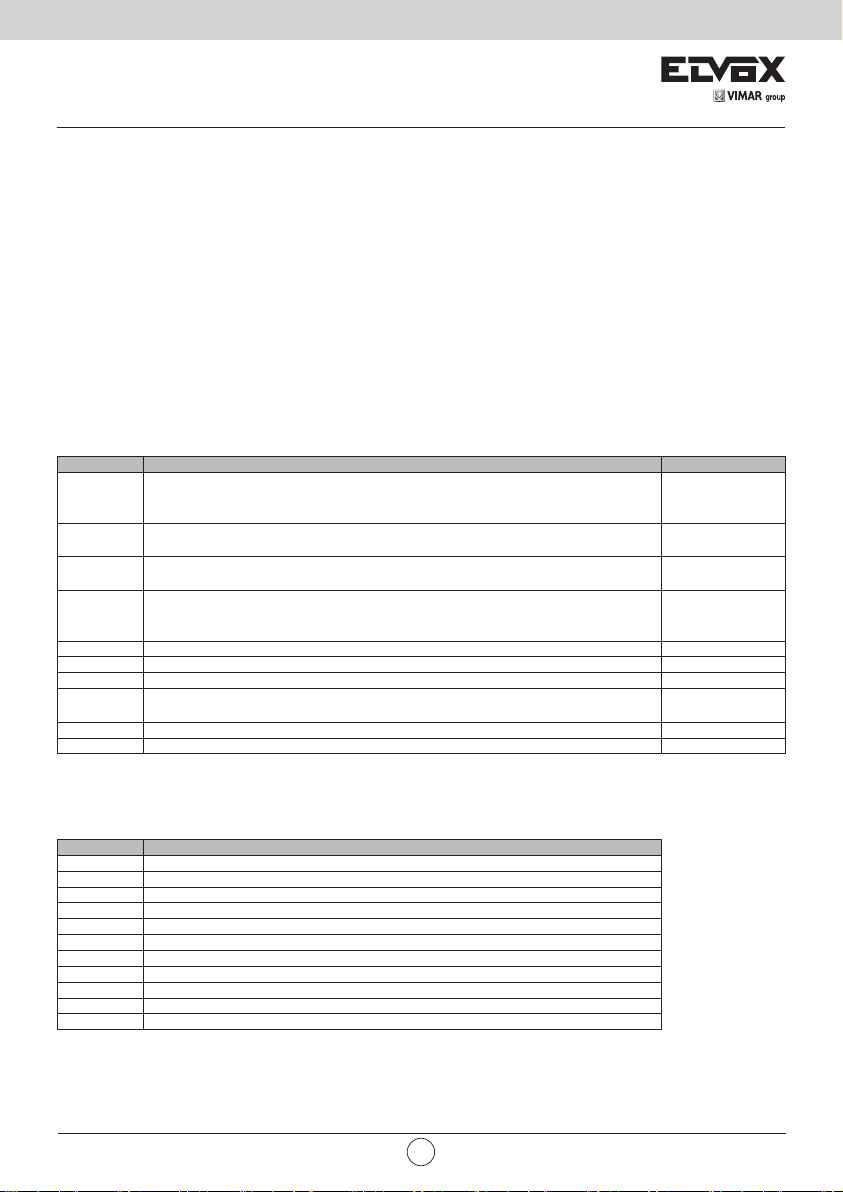

5.7 - Connecting two control panels in interlocking mode with presence, output A2 = 8 (INP)

The interlocking connection with consent to opening from presence signal involves 2 gates operating

according to the following method:

- gate 1 opens only if gate 2 is closed

- gate 2 opens only if gate 1 is closed

- gate 1 opens only if there is a presence signal

- gate 2 opens only if there is a presence signal

When this mode is on, the safety input S4 is automatically congured without the installer selecting it as

an interlock input (checks the state of closure of the other gate) and the safety input S3 is congured

automatically as the presence input. The two control panels operating in interlocking mode must be connected by interposing 2 relays and using accessories which send the presence signals to the control

panels (e.g. magnetic coils A and B) as shown in the gure:

AUX LSW ENC ACT SAF

AUX LSW ENC ACT SAF

VIMAR group

EN

5

Page 8

SL24.W

6 - Control panel programming:

6.1 - Preliminary operations

To function correctly, the control panel requires some minimum and essential settings. There are two:

- Setting the motor type.

In its default conguration, the control panel is not associated to any type of motor. The type of motor associated to the

control panel must be set.

- Gate travel calibration

The control panel must know some physical parameters of the gate in order to function correctly. The operation allowing

the control panel to know these physical gate parameters is called travel calibration. If this is not done, the control panel

may not perform slowdowns or detect obstacles correctly.

6.2 - Using the display

The control panel is programmed using the display and the navigation buttons on board or via Smartphone/Tablet (see

paragraph "Wi-Fi connection to Smartphone/Tablet"). The control panel settings are shown on the display and can be

edited using the menu navigation buttons as shown in the following table:

Buttons Function Pressure length

OK

▲

▼

ESC

▲+▼ Resetting the card 3 s

▲+ OK Opening control 1 s

▼+ OK Closing control 1 s

ESC + OK

ESC + OK When the board is switched on the Firmware updating mode starts 3 s

PP Step-step control Instantaneous

Switching on the display

Sub-menu entry

Conrm value change and return to menu

Scroll up

Increase parameter value

Scroll down

Reduce parameter value

Exit the menu

Cancel value change and return to menu

Switching o the display

Display test (switches on each segment of the display and points individually in

sequence)

Instantaneous

Instantaneous

Instantaneous

Instantaneous

3 s

6.3 - Menu

The control panel programming is organised into menus and sub-menus used to access and edit the parameters and

logics of the control panel. The control panel is equipped with the following rst-level menus:

Menu Description

MOT Motor parameters setup

LRNT Travel calibration procedure run menu

TRV Travel parameter settings menu

OUT Auxiliary output conguration menu

IN Input conguration menu

LGC Operating logic settings menu

RAD Remote control management menu

STAT Diagnostic and reporting menu

EXP Expansion board management menu

LOAD Default value restore menu

PASS Protection level settings menu

All sub-menus are described in the following table

6

EN

Page 9

SL24.W

Motor parameters

Type of gear motor used

O1

OFF Not set

1 Acto 600D (ESM2)

Type of position control

Automatically set with the choice of gear motor. You are advised not to change the setting

given by the type of gear motor.

O2

2 Virtual encoder: the control panel calculates the gate position using the electric motor operat-

3 Encoder for Acto 600D (ESM2)

MOT

Type of limit switch on opening

Automatically set with the choice of gear motor. You are advised not to change the setting

given by the type of gear motor.

OFF No limit switch on opening: the electric motor stops at the end of the working time

O3

1 Stop limit switch on opening: the limit switch stops the motor

2 Limit switch in proximity opening: the limit switch allows the manoeuvre to continue at the

Type of limit switch on closing

Automatically set with the choice of gear motor. You are advised not to change the setting

given by the type of gear motor.

OFF No limit switch on closing: the electric motor stops at the end of the working time

O4

1 Stop limit switch on closing: the limit switch stops the motor

2 Limit switch in proximity closing: the limit switch allows the manoeuvre to continue at the

Gate travel calibration

Rapid travel calibration.

The calibration is done fully automatically and sets:

- The slowdown in opening at 20% of the total travel

- The slowdown in closing at 20% of the total travel

- Pedestrian opening at 30% of the total travel

Pressing button

LRNE

- PP Wait for start of calibration procedure

PP CL 1 When button pressed: closing and search for closing limit switch

- OP 1 Opening travel measurement

- CL 1 Closing travel measurement

- OPC1 Opening current curve reading

- CLC1 Closing current curve reading

- END End of procedure

Advanced travel calibration.

The calibration allows the installer to choose:

LRNT

- Slowdown position in opening

- Slowdown position in closing

- Pedestrian opening position

Pressing button

- PP Wait for start of calibration procedure

PP CL 1 When button pressed: closing and search for closing limit switch

PP OP 1

LRNA

- OP 1

PP CL 1

- CL 1 Continuation of opening and slowdown speed up to closing limit switch

PP OPED

- CPED Leaf closing from pedestrian opening position

- OPC1 Opening current reading

- CLC1 Closing current reading

- END End of procedure

ing parameters

approach speed set until it detects the mechanical stop

approach speed set until it detects the mechanical stop

Msg on

display

Msg on

display

Phase description

Phase description

Start opening. When button pressed: slowdown start position on opening setting

Continuation of opening and slowdown speed up to opening limit

switch

Start closing. When button pressed: slowdown start position on closing

setting

Start pedestrian opening. When button pressed: pedestrian opening

position setting

Default

1

Default

3

Default

1

Default

1

VIMAR group

EN

7

Page 10

SL24.W

Self-calibration

If the gate travel parameter is changed, there is no need for the installer to run new calibrations, however, when changing the travel parameters, the control panel needs to learn the current curve again, thus disabling the obstacle detection

only during the self-calibration manoeuvre.

Self-calibration is appropriately signalled:

- on the control panel display by the code AT

- by the light ashing at twice the normal frequency

The events generating self-calibration are:

- change in parameters: T24, T26, T28, T30, T32, T34, T40

- loading of settings from a MEM.W memory card

- reset/import of settings from the Wi-Gate app

Gate travel parameters

TRV

Motor force (%).

Sets the value of the force given to the motor to push the leaf

T1

1 Minimum force

100 Maximum force

Direction.

Sets the motor direction

1 Left gear motor (the gate seen from the side where the gear motor is installed opens

T4

2 Right gear motor (the gate seen from the side where the gear motor is installed opens

Choice of intervention method for obstacle detection

1 Overcurrent or leaf stopped: the obstacle is detected when the current threshold or the

T7

2 Leaf stopped: the obstacle is detected only when the leaf slows down excessively

3 Overcurrent: the obstacle is detected when the current threshold is exceeded

4 Overcurrent and leaf stopped: the obstacle is detected when the current threshold and

Motor obstacle detection time on opening

Time after which the current threshold or the encoder threshold trigger the obstacle detection

on opening (adjustable at intervals of 100 ms)

T8

10 100 ms (minimum time)

60 600 ms (maximum time)

Motor obstacle detection time on closing

Time after which the current threshold or the encoder threshold trigger the obstacle detection

on closing (adjustable at intervals of 100 ms)

T9

10 100 ms (minimum time)

60 600 ms (maximum time)

Polling time

Time during which the motor pushes with maximum force to move the leaf (adjustable at

intervals of 0.5 s)

T12

0.5 0.5 s (minimum time)

5.0 5.0 s (maximum time)

Pedestrian opening position (% of total opening travel)

T13

10 Minimum position

100 Maximum position

Disengagement space on obstacle

(inversion distance following the detection of an obstacle)

OFF Not disengaged, stops only

T14

1 Minimum inversion

10 Maximum inversion

towards the left)

towards the right)

encoder slowdown threshold is exceeded

the encoder slowdown threshold are exceeded at the same time

Default

50

Default

1

Default

1

Default

20

Default

20

Default

2.0

Default

30

Default

5

8

EN

Page 11

SL24.W

T15

T17

T24

T26

T28

TRV

T30

T32

T34

T36

T38

T40

Motor stop approach force reduction distance

Indicates the distance from the mechanical stop starting from which the motor force is

reduced by half (used to adjust the impact of the leaf on the mechanical stop).

This happens only when the control panel works with encoder and proximity limit switch or

without limit switch.

OFF Force reduction o

10 Minimum force reduction distance

100 Maximum force reduction distance

Easy release

Disengagement time after manoeuvre to reduce the motor pressure on the mechanical stop

(adjustable at intervals of 100 ms)

OFF No disengagement

10 100 ms (minimum disengaging)

50 500 ms (maximum disengaging)

Normal motor speed when opening

1 minimum speed

100 maximum speed

Normal motor speed when closing

1 minimum speed

100 maximum speed

Motor slowdown speed when opening

1 minimum speed

100 maximum speed

Motor slowdown speed when closing

1 minimum speed

100 maximum speed

Motor slowdown distance when opening

% of travel or total work time done at slowdown speed

0 No slowdown

100 Slowdown for the whole distance

Motor slowdown distance when closing

% of travel or total work time done at slowdown speed

0 No slowdown

100 Slowdown for the whole distance

Motor acceleration time when opening

Time during which the motor accelerates to reach the normal opening speed (adjustable at

intervals of 0.1 s)

0 Maximum acceleration (0 s to reach normal speed)

2.0 Minimum acceleration (2.0 s to reach normal speed)

Motor acceleration time when closing

Time during which the motor accelerates to reach the normal closing speed (adjustable at

intervals of 0.1 s)

0 Maximum acceleration (0 s to reach normal speed)

2.0 Minimum acceleration (2.0 s to reach normal speed)

Motor deceleration ramp

Deceleration ramp between normal motor speed and slowdown speed

0 Steep ramp (maximum deceleration)

100 Low ramp (minimum deceleration)

Default

OFF

Default

OFF

Default

90

Default

90

Default

30

Default

30

Default

20

Default

20

Default

0.5

Default

0.5

Default

30

VIMAR group

EN

9

Page 12

SL24.W

Auxiliary output conguration

Terminal A1 output type

OFF Output o

Gate open warning light (SCA)

1

Operation as per SCA parameter setting

Auxiliary Radio output (RAU)

2

Operation as per RAU parameter setting

Courtesy light (LCO)

3

A1

OUT

A2

RAU

RAUT

On during leaf movement and for the amount of time after the leaf stopping set in parameter

LCO

Zone light (LZO)

4

On during leaf movement

Gate left open (OAB)

5

On if the gate remains open for a time longer than that dened by the open gate alarm logic

(L16)

Maintenance (MAN)

6

Output o when the number of maintenance signalling manoeuvres (MNPS) is reached in the

diagnostics section

Terminal A2 output type

OFF Output o

Gate open warning light (SCA)

1

Operation as per SCA parameter setting

Auxiliary Radio output (RAU)

2

Operation as per RAU parameter setting

Courtesy light (LCO)

3

On during leaf movement and for the amount of time after the leaf stopping set in parameter

LCO

Zone light (LZO)

4

On during leaf movement

Gate left open (OAB)

5

On if the gate remains open for a time longer than that dened by the open gate alarm logic

(L16)

Maintenance (MAN)

6

Output o when the number of maintenance signalling manoeuvres (MNPS) is reached in the

diagnostics section

Synchronization output, compass type interlock (INB)

7

Automatically congures input S4 as synchronization input without any choice by the user.

The control panel consents to the gate opening only if the other gate is in the closed position

Synchronization output, compass type interlock (INP) with presence signal.

Automatically congures input S4 as synchronization input and S3 as presence input without

8

any choice by the user.

The control panel consents to the gate opening only if the other gate is in the closed position

and the presence input is occupied

Auxiliary Radio Output Conguration

1 Impulsive: the output is active for 1 s following the RAU command from the remote control

Timed: the output is active for the time set in the RAUT parameter following the RAU command

2

from the remote control

3 Bistable: the output works in Step-Step ON/OFF mode

RAU output timing

1 1 s (minimum time)

600 600 s (maximum time)

Default

1

Default

2

Default

1

Default

1

10

EN

Page 13

SL24.W

LCO

OUT

SCA

Input conguration

IN

C(X)

Courtesy light timer

1 1 s (minimum time)

300 300 s (maximum time)

SCA output operating mode

Gate closed: o

1

Gate open: on xed

Gate closed: o

Gate moving: intermittent

2

Gate open: on xed

Indeterminate position: intermittent pause of 1 s every 5

Gate closed: o

Gate opening slow intermittent

3

Gate open on xed

Gate closing intermittent

Indeterminate position: intermittent pause of 1s every 5

Gate stopped on xed

4

Gate moving o

Gate closed o

5

Gate moving on xed

C1/C2/C3/C4 command input

Step-step (PP)

The step-step control:

- with the gate stopped and closed, opens the gate

1

- in opening, stops or closes the gate according to the step-step logic setting (L10)

- with the gate stopped after opening, closes the gate

- in closing, stops or opens the gate according to the step-step logic setting (L10)

- with the gate stopped after closing, opens the gate

Pedestrian (PED)

Opens the gate to the pedestrian position

2

It acts like a step-step if the command is given with the gate beyond the pedestrian position

Open (OPEN)

The open command:

- with the gate stopped and closed, opens the gate

3

- in opening is ignored

- with the gate open, resets the pause time

- with the gate stopped, opens the gate

- in closing, opens the gate

Close (CLS)

The close command:

- with the gate stopped and closed, is ignored

4

- in opening, closes the gate

- with the gate stopped, closes the gate

- in closing is ignored

Timer (TIM)

The timer command:

5

- when closed, opens the gate and keeps it open as long as the contact remains

closed

- when the contact is released it closes the gate

Pedestrian Timer (TIMP)

6

Has the same function as the timer command but on the pedestrian position

Default

120

Default

1

Default C1

Default C2

Default C3

Default C4

VIMAR group

EN

11

Page 14

SL24.W

IN S(X)

S1/S2/S3/S4 safety input

OFF O Default S3/S4

Photocell closing (PHC)

The closing photocell:

- with the gate stopped, allows the gate to open

1

- in opening does not intervene

- with the gate open, does not allow it to close and when released will reset the

pause time

- in closing, reopens the gate immediately

Photocell (PH)

The photocell:

- with the gate stopped, does not allow the gate to open

2

- during opening stops the movement and when released proceeds with opening

- with the gate open, does not allow it to close and when released will reset the

pause time

- in closing stops the movement and when released reopens the gate

Opening photocell (PHO)

The opening photocell:

- with the gate stopped, allows the gate to open

3

- in opening, recloses it completely

- with the gate open, allows it to close and does not reset the pause time

- in closing does not intervene

Sensitive edge with NC clean contact (BAR)

- with the gate stopped, does not allow the gate to open

- in opening disengages

4

- with the gate open, does not allow it to close and when released will reset the

pause time

- in closing disengages

8.2 KΩ balanced sensitive edge (8K2)

5

Same behaviour as the NC sensitive edge

Stop (STP)

6

- stops the gate

Interrupts the automatic closing as per the logic stop setting from stop (L12)

Photocell closing checked (PHC)

7

As per closing photocell but with check

Photocell checked (PHT)

8

As per photocell but with check

Photocell opening checked (PHC)

9

As per opening photocell but with check

NC sensitive edge checked (BART)

10

As per KΩ NC sensitive edge but with check

8.2 KΩ balanced sensitive edge checked (8K2T)

11

As per 8.2 KΩ sensitive edge but with check

Default S1

Default S2

12

EN

Page 15

SL24.W

Control panel logic settings

Automatic closing

L1

OFF Automatic closing o

ON Automatic closing on

Pause time

L2

1 1 s (minimum time)

180 180 s (maximum time)

Pedestrian pause time

L3

1 1 s (minimum time)

180 180 s (maximum time)

State on power up

CL

L4

OP

LGC

Apartment block

OFF Apartment block function o

L5

1 Ignores closing and stop commands in opening

2 Ignores closing and stop commands in opening and in pause

3 Ignores closing and stop commands in opening, in pause and in closing

Rapid closing

OFF Rapid closing function o

1 Rapid closing in gate mode:

L6

2 Rapid closing in barrier mode:

Clearance time (adjustable at intervals of 1 s)

Time after which the gate closes again if the rapid closing (L6) is on

L7

1 Minimum clearance time

10 Maximum clearance time

Default

ON

Default

30

Default

20

Default

Gate in closed position:

The rst step-step command opens the gate.

Gate in open position:

The rst step-step command closes the gate. If automatic closing is on, after the pause time

the gate closes

The control panel starts to count the clearance time (L7) from when the closing photocell is

released, when the clearance time expires it closes again.

The control panel starts to count the clearance time (L7) from when the closing photocell is

released, when the clearance time expires it closes again. If the closing photocell is occupied

again, it does not command it to reopen but to stop. When released again it continues with

closing. The closing photocell returns to normal operating after complete closure

OP

Default

OFF

Default

OFF

Default

2

VIMAR group

EN

13

Page 16

SL24.W

LGC

Pre-ash

Flashing time of the ashing light before the gate starts to move

OFF Pre-ash disabled

L8

3 3 s pre-ash

4 4 s pre-ash

5 5 s pre-ash

Manned

OFF Manned function o

1 Step-step command disabled, remote controls not working. The control panel accepts only

L9

L10

L11

L12

L14

L15

L16

open and close commands

2 Emergency manned. In normal standard operating conditions, with the safety devices occu-

pied it works as manned.

Step by step

2 Step-step command operates in 2 steps: open, close, open...

3 Step-step command operates in 3 steps: open, stop, close, open...

4 Step-step command operates in 4 steps: open, stop, close, stop, open...

Stop from step-step

OFF Automatic closing disabled when a stop command from step-step is given

ON Automatic closing not disabled when a stop command from step-step is given

Stop from stop

OFF Automatic closing disabled when a stop command from stop is given

ON Automatic closing not disabled when a stop command from stop is given

Operation in battery

1 Standard operation

2 Normal operation with ashing light disabled

3 After a re-open command it stays open

4 When the main power supply is cut o it opens and remains open

Economy

OFF Standard operation

1 Economy operation on. With the gate closed, it switches o the accessory power supply on

outputs 1 and 2. The outputs are powered again following a new command.

Gate blocked open indicator

Number of minutes after which, with the gate partially or totally open, whatever the set

pause time, an alarm signal is sent (on the display and output congured as OAB)

OFF Indicator disabled

3 Minimum interval

60 Maximum interval

Default

OFF

Default

OFF

Default

4

Default

ON

Default

ON

Default

1

Default

OFF

Default

30

14

EN

Page 17

SL24.W

Remote control management

Saving a button as step-step

oooo Waiting for code

PP

1001 Remote control 1 saved as step-step

1055 Remote control 55 saved as step-step

Saving a button as open

oooo Waiting for code

OPEN

2001 Remote control 1 saved as open

2055 Remote control 55 saved as open

Saving a button as pedestrian

oooo Waiting for code

PED

3001 Remote control 1 saved as pedestrian

3055 Remote control 55 saved as pedestrian

Saving a button as Auxiliary Radio Output activation

oooo Waiting for code

RAU

4001 Remote control 1 saved as Auxiliary Radio Output

4055 Remote control 55 saved as Auxiliary Radio Output

Saving a button as close

oooo Waiting for code

CLS

5001 Remote control 1 saved as close

5055 Remote control 55 saved as close

Saving a button as stop

oooo Waiting for code

STP

6001 Remote control 1 saved as stop

6055 Remote control 55 saved as stop

Saving a button as Courtesy light on

oooo Waiting for code

LCO

7001 Remote control 1 saved as Courtesy light on

RAD

7055 Remote control 55 saved as Courtesy light on

Control of remote control memory position

oooo Waiting for code

5001 Remote control button 1 saved as close

CTRL

7099 Remote control button 99 saved as Courtesy light on

-030 Remote control button 30 not in memory

---- Remote control not in memory

Remote control programming

OFF Remote programming of remote controls o

1 Remote programming of remote controls on:

RE

Total receiver memory deletion

ERSA

oooo Signals the deletion of the receiver memory on the display

Deletion of single remote control from its position in the memory

ERS1

X Use buttons ▲▼ to select the number of the remote control to delete

Deletion of single remote control from the remote control code

ERSR

oooo Waiting for code

Default

1

used to programme remote controls from a remote control already in the memory, using

the following procedure:

-press buttons 1 and 2 on the remote control already in the memory at the same time

-press the button on the remote control already in the memory to copy on the new remote

control

-press the button on the new remote control on which to copy the button just pressed on

the remote control already in the memory

Note: the button on the new remote control just saved inherits the function assigned to the

button on the remote control already in the memory

Press OK for 5 s

Press OK to conrm

Deleting remote control

VIMAR group

EN

15

Page 18

SL24.W

Diagnostics and reporting

ALM

ALMA

MNPC

MNPS

MNPA

MNPE

MNTC

STAT

LIFE

PONC

PONE

RSTC

RSTE

TL

INF

Alarm log reading

0 Most recent alarm

10 Oldest alarm

Error signals

1 Only on display

2 On display and maintenance output

Reading of number of manoeuvres since last maintenance

002 First 3 digits of the number of manoeuvres since last maintenance

3256 Last 4 digits of the number of manoeuvres since last maintenance

In the case described above, the gate has carried out 23,256 manoeuvres since the last maintenance

Number of manoeuvres since last maintenance

Number of manoeuvres generating a maintenance signal (in thousands of manoeuvres)

OFF Maintenance signalling o

1 1,000 manoeuvres (minimum interval)

300 300,000 manoeuvres (maximum interval)

Maintenance signalling

1 Signalling only on display

2 Signalling on display and maintenance output (MAN)

3 Signalling on display and ashing light (rapid ashing at end of manoeuvre)

4 Signalling on display, ashing light (rapid ashing at end of manoeuvre) and mainte-

Reset manoeuvres since last maintenance counter

oooo Waiting press OK for 5 s to reset the counter to 0

Total manoeuvres counter

012 First 3 digits of the number of manoeuvres since last maintenance

5874 Last 4 digits of the number of manoeuvres since last maintenance

In the case described above, the gate has carried out 125,874 manoeuvres in total

Life counter (days of activity of the control panel)

584 Reading of the number of days of activity of the control panel

In the case described above, the control panel was active for 584 days

Number of control panel power-ups counter

2547 Reading of the number of control panel power-ups

In the example shown above, the control panel was powered up 2547 times (it could indicate a

poor quality mains electricity, with frequent power cuts)

Reset number of control panel power-ups counter

oooo Waiting press OK for 5 s to reset the counter to 0

Number of self-reset counter

1123 Reading of the number of control panel self-resets

A self-reset is a reset of the microswitch by the control panel for safety reasons. Typically the control panel goes to self-reset when the minimum microswitch voltage threshold has been reached.

An excessive number of self-resets could indicate a poor quality power supply, subject to strong

voltage uctuation.

Reset number of self-reset counter

oooo Waiting press OK for 5 s to reset the counter to 0

Installer telephone settings and display

Press OK briey to view the saved number (use buttons ▲▼ to scroll)

3334 First 4 digits of the installer number

2548 Next 4 digits of the installer number

32 Last 2 digits of the installer number

In the example shown above the installer telephone number is: 3334254832

Press OK for 5 s to enter the number edit mode. Use buttons ▲▼ to change the value, OK to

conrm the number, use ESC to return to the previous digit, underscore “_” indicates a space

Control panel info display

SL24.W Control panel name

1.13 Control panel rmware version

Default

1

Default

OFF

Default

1

nance output (MAN)

16

EN

Page 19

SL24.W

Connection module

CNX1

EXP

CNX2

LOAD

Connection module on CNX1 connector

OFF No module connected

1 Wi-Fi module EMC.W connected

Connection module on CNX2 connector

OFF No module connected

1 Opposing leaf module EMC.DU connected. Control panel functioning as MASTER

2 Opposing leaf module EMC.DU connected. Control panel functioning as SLAVE

Restore default values and loading from memory card

Loading the default values

oooo Waiting press OK for 5 s to load the default values.

Note:

DEF

Loading the default values then requires the travel to be calibrated again, LRNT ashes on the

display until (rapid or advanced) calibration is done.

Loading the programming from memory card

oooo Waiting press OK for 5 s to load the values from memory card.

MEM

DONE Loading from memory card completed OK

EMEM Loading from memory card error (e.g. no card)

Control panel protection level settings

Programming block not authorised

OFF No protection

1 Protection of menus MOT, LRNT, TRV, OUT, IN, LGC, STAT, EXP, LOAD

2 Protection of menu RAD

PASS

Protection from connection via smartphone (it is not possible to connect to the control panel from a

3

smartphone)

Protection of menus MOT, LRNT, TRV, OUT, IN, LGC, STAT, EXP, LOAD and connection from

4

smartphone)

5 Protection of menu RAD and connection from smartphone)

6 Complete control panel protection

Default

1

Default

OFF

Default

OFF

Note:

- The password must be entered in the control panel each time you wish to access a protected menu.

If the password entered is incorrect access to the menu is denied.

- A new password must be saved in the control panel each time you change the protection level from OFF to any one

of the 6 protected levels. The new password must be entered twice, the second time to conrm it has been entered

correctly.

- Use buttons ▲▼ to change the password digits and OK to conrm and move to the next digit

VIMAR group

EN

17

Page 20

SL24.W

7 - Diagnostics:

7.1 - Signalling

Signalling indications are shown on the display for events of interest to the installer concerning normal and anomalous

operation. They appear on the display when the associated event occurs. These indications may signal a failure if some

of the system components are not working (e.g. photocells).

The following table gives the list of indications shown to the installer:

Signal Description

C1 Contact closed on command C1 input

C2 Contact closed on command C2 input

C3 Contact closed on command C3 input

C4 Contact closed on command C4 input

S1 Contact open on safety device S1 input

S2 Contact open on safety device S2 input

S3 Contact open on safety device S3 input

S4 Contact open on safety device S4 input

FO1 Opening limit switch position reached

FC1 Closing limit switch position reached

OBO Obstacle detected on opening

OBC Obstacle detected on closing

AF1 Motor in stop approach force reduction interval

MSO1 Mechanical stop reached in opening

MSC1 Mechanical stop reached in closing

BATT

BT- Battery almost at (indication shown only when the gate is stopped)

BT-- Battery totally at (indication shown only when the gate is stopped)

RX Radio command received from saved remote control or from App

NX Radio command received from unsaved remote control button

RD Rolling/xed code decoding o

OAB Gate left open

AT Gate in self-calibration

7.2 - Alarms

Alarms are generally indications on the display of operating failures which prevent the automation system from work-

ing. They appear on the display when the associated event occurs. The alarms generally signal wiring errors, but may

also indicate control panel or gear motor failures.

The following table gives the list of alarms shown to the installer:

Alarm Description

XXXX Reset card

MNP Manoeuvre interval since last maintenance reached alarm

F0 Error motor not selected

F1 Motor cables inverted error

F3 Reversed limit switch error

F4 Both open limit switch alarm

F5 Opening limit switch malfunction error

F6 Closing limit switch malfunction error

F9 Communication error with expansion card

F10 Error alarm motor not connected

F12 Encoder error alarm

F14 Microswitch undervoltage (check power supply and outputs)

F15 Safety test 1 failed

F16 Safety test 2 failed

F17 Safety test 3 failed

F18 Safety test 4 failed

F19 Manoeuvre length/timeout alarm

F21 Mosfet short alarm

F23 Blocked rotor alarm

F25 Overlapping leaf in closing alarm

F26 5th obstacle in closing alarm

F27 Overcurrent alarm

F29 Radio memory full alarm

F30 Faulty radio memory alarm

F31 Short ashing alarm

F32 Gate open light short alarm

F33 No memory card alarm

F34 FW checksum alarm

F36 Board temperature alarm

18

Operation with battery.

When this message is displayed it is followed by an indication of the battery operating voltage, e.g.

24.5V

EN

Page 21

SL24.W

8 - Updating Firmware:

The control panel is equipped with a USB port that is used to update the control panel Firmware or the Wi-Fi EMC.W

communication module Firmware

Caution:

If the rmware updating procedure is not carried out properly it may damage the control panel or the Wi-Fi communication module, make sure not to interrupt the mains power supply during the update.

To perform the Firmware Update, consult the instructions provided with the Firmware

9 - Control panel behaviour when loading settings:

On full uploading of the settings, some parameters are loaded, others maintained and others again are reset.

According to the type of loading, it may be necessary to calibrate the gate travel again.

To know which parameters the control panel loads, which are maintained and which are reset, refer to the table below:

Action Data Control panel behaviour

RESET

(control panel reboot)

Firmware Updating

LOAD MEM

(loading from memory

card)

Reset/Import control

panel data from WiGate app

LOAD DEF

(loading default values)

ERSA

(deletion of receiver

memory)

Fixed counters

Resettable counters

Motor parameters

Gate travel data

Installer settings

Password

Remote controls

Fixed counters

Resettable counters

Motor parameters

Gate travel data

Installer settings

Password

Remote controls

Fixed counters

Resettable counters

Motor parameters Importing data from a MEM.W memory card

Gate travel data Self-calibration on rst manoeuvre

Installer settings

Remote controls

Fixed counters

Resettable counters

Motor parameters Importing data from Wi-Gate app

Gate travel data Self-calibration on rst manoeuvre

Installer settings Importing data from Wi-Gate app

Password

Remote controls

Fixed counters

Motor parameters

Gate travel data Travel data reset, new LRNE or LRNA calibration required

Installer settings

Password

Remote controls No variation

Fixed counters

Resettable counters

Motor parameters

Gate travel data

Installer settings

Password

Remote controls Complete deletion

No variation

No variation

No variation

Importing data from a MEM.W memory cardPassword

No variation

No variation

No variationResettable counters

Restored to DEFAULT

No variation

VIMAR group

EN

19

Page 22

SL24.W

Fixed counters

Resettable counters

Reset/Import receiving

data from Wi-Gate app

10 - Control panel connection from Smartphone/Tablet:

The control panel may be programmed directly from a Smartphone/Tablet without having to interact with the control

panel display or buttons.

Requirements for establishing the connection

- an SL24.W or SW24.W control panel

- an EMC.W Wi-Fi connection module

- an Android device with at least version 4.4 or iOS minimum version 8.0 with the Wi-Gate app installed (download-

able from Google Play or App Store)

- Service access credentials (supplied by Vimar Spa)

To enable the connection check that the EMC.W module is connected to the CNX1 connector and that the parameter

EXP-> CNX1 is set to 1.

Follow the instructions given in the EMC.W module instructions to establish the connection.

Using the Wi-Gate app all the congurations which can be done using the control panel buttons can also be done from

the Smartphone, which however uses full descriptions to make the meaning of the parameters immediately understand-

able.

In addition to connection to the control panel for more immediate and easy conguration, the Wi-Gate app can be used

to save/restore the control panel conguration data on/from a Cloud-based database which can be managed from the

Web portal by accessing the page:

http://wi-gate.vimar.cloud

The installation database management web portal access credentials are the ones used to access the Wi-Gate app.

Here it is possible to manage the records of the saved installations and the access authorisations for the collaborators

of the account holder.

Note: the conguration data of the saved control panels and receivers are not visible from the web interface, they are

physically saved on the cloud but can be retrieved from the cloud and exported onto the control panels only using the

Wi-Gate app.

Motor parameters

Gate travel data

Installer settings

Password

Remote controls Import of remote control list from Wi-Gate app

No variation

20

EN

Page 23

SL24.W

EC DECLARATION OF CONFORMITY

(Declaration of incorporation of partly completed machinery annex IIB 2006/42/EC

No.: ZDT00744.00

The undersigned, representing the following manufacturer Vimar SpA Viale Vicenza 14,

36063 Marostica VI Italy

declares under his own responsibility that the products

Electronic control unit

Trade mark

Elvox SL24.W

Elvox SW24.W

* See www.vimar.com for the full description of the products.

when installed with the appropriate accessories and/or enclosures for devices are in conformity with the provisions of

the following EU directive(s) (including all applicable amendments)

Machinery Directive 2006/42/CE EN 60335-2-103 (2015)

LV Directive 2014/35/EU

R&TTE Directive 1999/5/CE EN 301 489-3 (2013), EN 301 489-17 (2012) EN 300 220-2 (2012),

EN 300 328 (2015)

EMC Directive 2014/30/EU EN 61000-6-2 (2007), EN 61000-6-3 (2007) + A11 (2011)

Further hereby declares that the product must not be put into service until the final machinery into which it is to be

incorporated has been declared in conformity with the provisions of Directive 2006/42/EC, where appropriate.

Declares that the relevant technical documentation is compiled by Vimar SpA and in accordance with part B of Annex

VII of Directive 2006/42/EC and the following essential requirements of this Directive are applied and fulfilled:

1.1.1, 1.1.2, 1.1.3, 1.1.5, 1.1.6, 1.2.1, 1.2.2, 1.2.6, 1.3.1, 1.3.2, 1.3.3, 1.3.4, 1.3.7, 1.3.8, 1.3.9, 1.4.1, 1.4.2, 1.5.1, 1.5.2,

1.5.4, 1.5.5, 1.5.6, 1.5.7, 1.5.8, 1.5.9, 1.6.1, 1.6.2, 1.7.1, 1.7.2, 1.7.3, 1.7.4.

I undertake to make available, in response to a reasoned request by the national authorities, any further supporting

product documents they require.

Type ref.

Cat. ref. Description EN *

SL24.W Control card Wi-Fi 24V sliding gates

SW24.W Control card Wi-Fi 24Vswing gates

Marostica, 6/3/2017 The Managing Director

Note: The contents of this declaration correspond to what declared in the last revision of the ocial declaration available before printing

this manual. The text herein has been re-edited for editorial purposes. A copy of the original declaration can be requested to Vimar SpA

VIMAR group

EN

21

Page 24

SL24.W installer EN 02 1708

Viale Vicenza 14

36063 Marostica VI - Italy

www.vimar.com

Loading...

Loading...