Page 1

3

2

1

START

SI / YES

STOP

FINE

END

1

PREC.

PREV

2

SUCC.

NEXT

3

OK

3

2

1

1

PREC.

PREV

2

SUCC.

NEXT

3

OK

Installation and operation manual

Video or audio Elvox 2-wire entrance panels with traditional push-buttons

Page 2

DESCRIPTION

Types 12F3 and 12F5 comprise respectively an electronic base unit for the

assembling of two models of entrance panels.

12F3 audio electronic module with conventional push-buttons (single or

double row)

12F5 video electronic module with colour and conventional push-buttons

(single or double row)

To expand the number of calls, requires installation and subsequent programming of additional modules type 12TS (for entrance panels with push-buttons

in single row, from 5 or more calls) or type 12TD (for push-buttons in double

row, from 9 or more calls), see Fig. 11, 12 on page 8.

The abovementioned electronic units are to be used with plates and

components of the 1200 series, separately sold.

Each push-button in the electronic units can generate different call codes with

values from 1 to 200. The entrance panels are designed to operate either

alone or with other entrance panels. In any event one must be set as a Master entrance panel and the others as Slave.

The front of the electronic unit (see Fig. 2, detail A) is fitted with the following

adjustments:

1 Voice line balancing control

2 External volume

3 Internal volume

The entrance panel is equipped with 6 push-buttons for the base programming phase. The base programming of the entrance panel is carried out without installing the front plate, so as to reach all the 6 push-buttons. The

serigraph close to each push-button ease this operation.

For the advanced programming of the entrance panel use the programming

module type 950C or PC Software SaveProg Type 69CD via the interfaces

Type 692I or Type 692I/U.

The volume adjustment may cause the LARSEN effect (whistle); in this event

operate on trimmer 1 (Balance) to avoid the whistle or decrease one or both

volumes (Fig. 2, detail A).

To the audio entrance panels an external camera type CCTV can be connected; in this case it must be programmed as video camera.

The video cameras can be used indifferently either in colour either in B/W installations.

Operating temperature: -10° C ÷ +55° C.

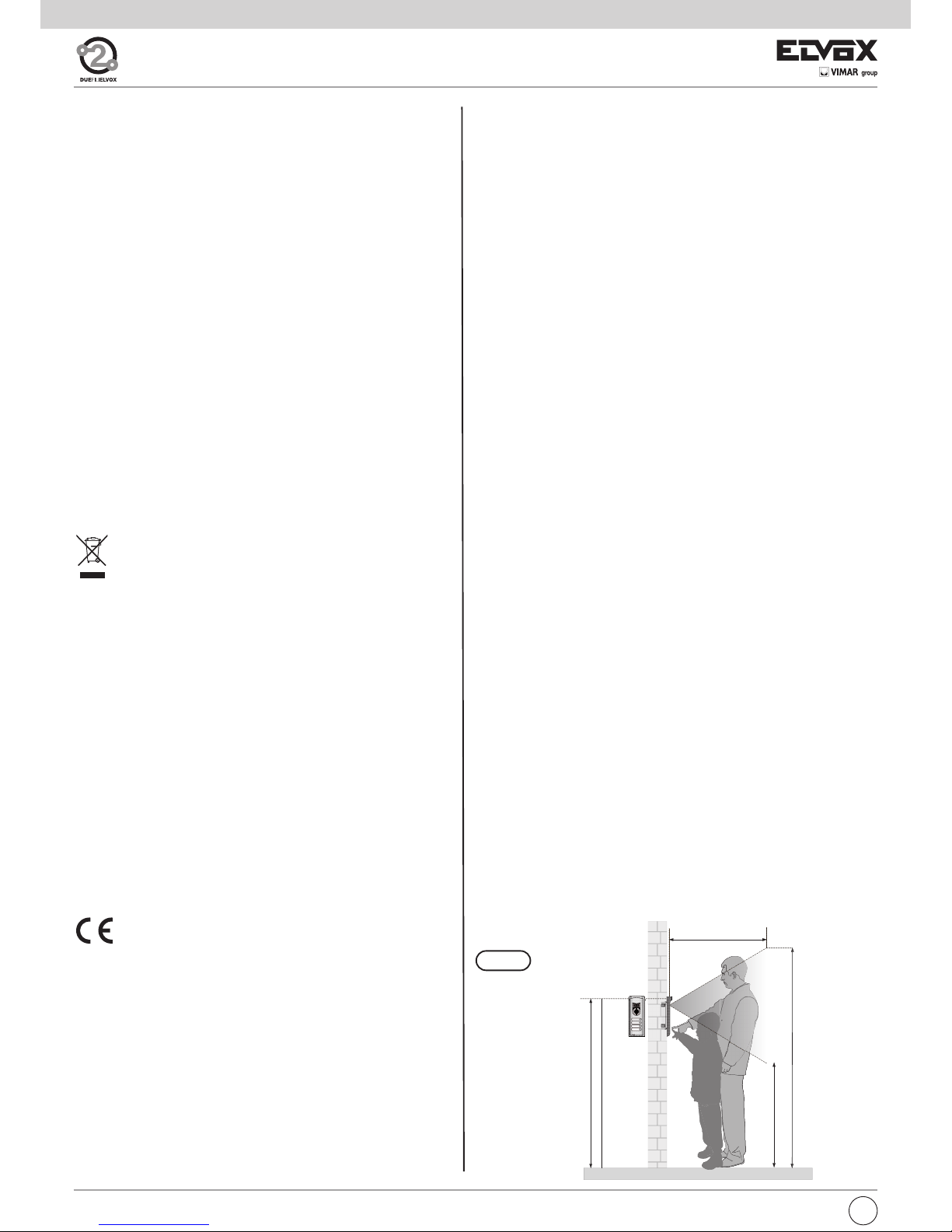

INSTALLATION

The assembling and the installation of the electronic units for the 1200 series

plates require the following phases:

1- Define the plate for the electronic base unit and possible additional plate

(see push-button plates on page: components 4 and 5).

2- Define the back boxes and the frames for the surface wall-mount or

flush-mount installation (see push-button plates on page 6, accessories).

3- Install the flush-mount or surface wall-mount back boxes with the upper

edge at a height of approx. 1,65 m from the ground (Fig. 1).

4- Fix the rainproof covers to the back boxes.

5- Fix the terminal box of the base module to the module holder frame of the

entrance panel.

6- Connect the terminal block to the system as shown in the wiring dia-

gram.

7- Fix the module holder frame.

8- Connect the electronic unit of the base module to the additional modu-

les, if any (extension of the push-button number).

9- Insert the electronic unit and the additional modules in the module hol-

der frames of the entrance panels.

10- Insert the microphone of the electronic base unit in the module holder

frame of the entrance panel (Fig. 9, Part 1).

11- Insert the external plate of the electronic unit in the module holder frame

and the additional entrance panels in the remaining module holder fra-

mes.

12- Close the panel.

2

GB

1,65m

2,04m

1,04m

1m

Fig. 1

SAFETY INSTRUCTIONS FOR INSTALLERS

- Carefully read the instructions on this leaflet: they give important information on the safety, use and maintenance of the installation.

- After removing the packing, check the integrity of the set. Packing

components (plastic bags, expanded polystyrene etc.) are dangerous

for children. Installation must be carried out according to national safety regulations.

- It is convenient to fit close to the supply voltage source a proper bipolar type switch with 3 mm separation (minimum) between contacts.

- Before connecting the set, ensure that the data on the label correspond

to those of the mains.

- Use this set only for the purposes designed, i.e.for electric door-opener systems. Any other use may be dangerous. The manufacturer is

not responsible for damage caused by improper, erroneous or irrational use.

- Before cleaning or maintenance, disconnect the set.

- In case of failure or faulty operation, disconnect the set and do not

open it.

- For repairs apply only to the technical assistance centre authorized by

the manufacturer.

- Safety may be compromised if these instructions are disregarded.

- Do not obstruct opening of ventilation or heat exit slots and do not expose the set to dripping or sprinkling of water.

- Installers must ensure that manuals with the above instructions are left

on connected units after installation, for users' information.

- All items must only be used for the purposes designed.

- The ominipolar switch must be easily accessed.

- WARNING: to avoid the possibility of hurting yourself, this unit must be

fixed to the wall according to the installation instructions.

- This leaflet must always be enclosed with the equipment.

Directive 2002/96/EC (WEEE)

The crossed-out wheelie bin symbol marked on the product indicates that at the end of its useful life, the product must be han-

dled separately from household refuse and must therefore be

assigned to a differentiated collection centre for electrical and electronic

equipment or returned to the dealer upon purchase of a new, equivalent

item of equipment.

The user is responsible for assigning the equipment, at the end of its life,

to the appropriate collection facilities.

Suitable differentiated collection, for the purpose of subsequent recycling

of decommissioned equipment and environmentally compatible treatment and disposal, helps prevent potential negative effects on health and

the environment and promotes the recycling of the materials of which the

product is made. For further details regarding the collection systems available, contact your local waste disposal service or the shop from which

the equipment was purchased.

Risks connected to substances considered as dangerous (WEEE).

According to the WEEE Directive, substances since long usually used on

electric and electronic appliances are considered dangerous for people

and the environment. The adequate differentiated collection for the subsequent dispatch of the appliance for the recycling, treatment and dismantling (compatible with the environment) help to avoid possible

negative effects on the environment and health and promote the recycling of material with which the product is compound.

Product is according to EC Directive 2004/108/EC and following norms.

Page 3

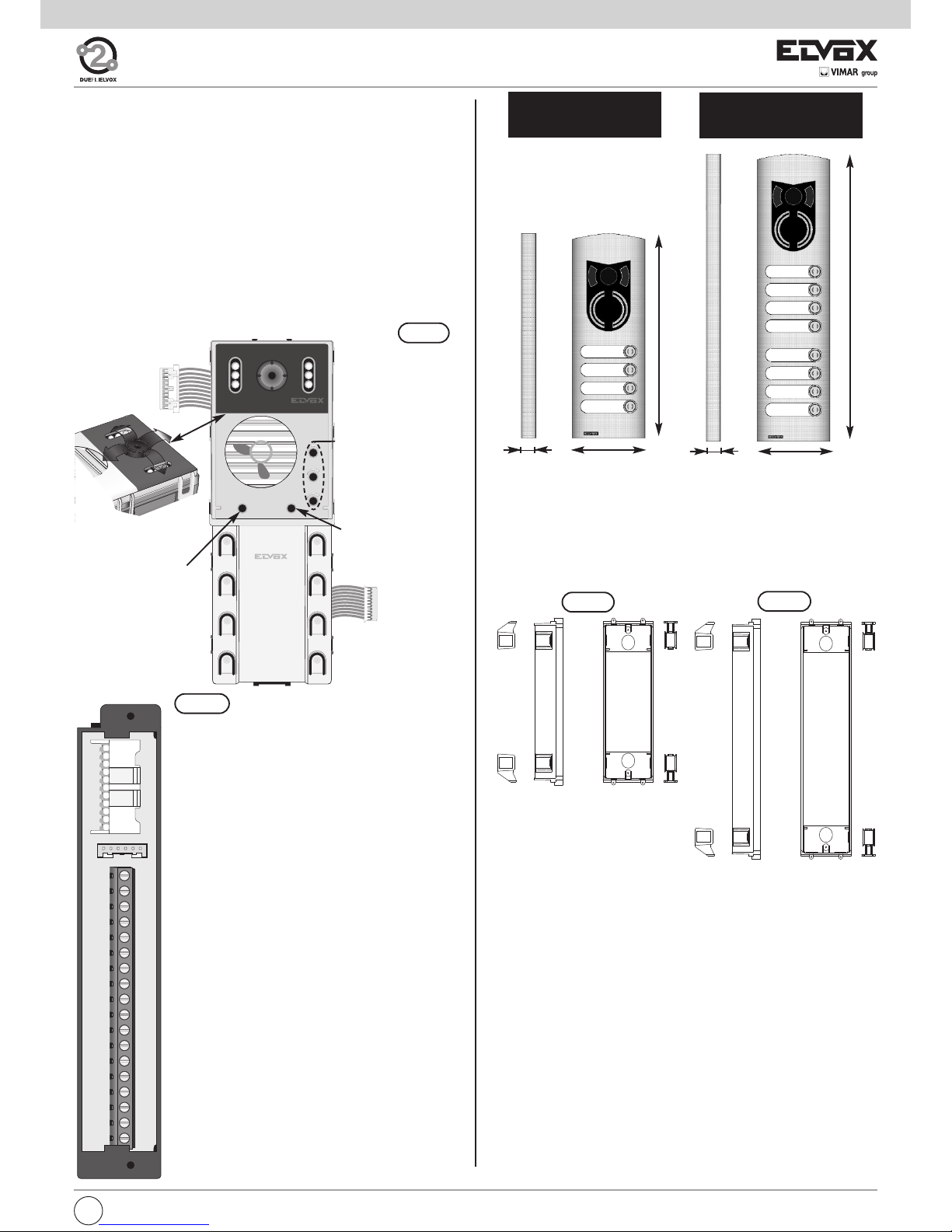

STANDARD MODULES

The standard modules consist of: an electronic unit and a connection terminal block. The electronic unit is equipped with a speech unit, camera (on

video versions), wiring for terminal block connections, wiring for connection of additional modules and 8 call push-buttons, 6 of which are used for

standard programming.

The standard electronic units for colour video panels are equipped with a

camera with the following specifications:

- CCD 1/4" color sensor

- Resolution: 350 linee TV

- Aspheric lens f = 2.7 mm, F = 2.4

- Minimum lighting level 1.0 lux

All cameras can be tilted manually, horizontally and vertically, on removal

of the entrance panel external plate.

Example of standard module with camera.

3

2

1

RST

PRG

4

START

SI / YES

5

STOP

NO

6

FINE

END

1

PREC.

PREV

2

SUCC.

NEXT

3

OK

PRG

CN1) Connector for electronic unit.

CN2) Connector for programmer type 950C.

B2) 2-wire Bus (cable riser).

B1) 2-wire Bus (cable riser).

EXT+) External power supply (+ type 6923).

EXT-) External power supply (- type 6923).

VLED) LED power supply for additional modules.

X) Video input (coaxial core), for external ca-

mera (for type 89F8 only).

M) Video input (coaxial sheath), for external ca-

mera (for type 89F8 only).

PA) Input for door open sensor (with reference to

terminal M).

CA) Door open control (with reference to termi-

nal M).

M) Ground.

S+) 12Vdc lock output (+).

S-) 12Vdc lock output (-).

+12V) +12V output (max 100 mA) with PTC protec-

tion.

-L) External camera pilot, open collector output.

SR) Lock pilot via relay, open collector output.

F2) F2 function pilot via relay, open collector out-

put.

F1) F1 function pilot via relay, open collector out-

put.

M) Ground.

B2

B1

EXT+

EXT-

VLED

M

PA

CA

M

S+

S-

+12V

-L

SR

F2

F1

M

X

B2

B1

EXT+

EXT-

VLED

M

PA

CA

M

S+

S-

+12V

-L

SR

F2

F1

M

X

CN2

CN1

CS2411 250105

Wiring for terminal block

connection

Wiring for connection of additional modules

Controls:

1 - Balance

2 - External volume

3 - Internal volume

Manual horizontal

and vertical tilt

Fig. 3

Reset

)

*

Electronic unit

Fig. 4

Fig. 5

Terminal block

*

The panel supplies a current peak IT> 1A for 10

mS, followed by a hold current I

M

= 200mA for the

entire duration of the lock control (see lock time).

HEIGHT OF 2-MODULE

ENTRANCE PANELS

HEIGHT OF 3-MODULE

ENTRANCE PANELS

Box width 88mm for 1 horizontal module and 50 mm depth.

Type 9092, 9192

For 2 additional modules.

Height: 2 verical modules (248 mm)

Type 9093, 9193

For 3 additional modules.

Height: 3 vertical modules (360 mm)

ACCESSORIES: FLUSH-MOUNTED BACK BOXES

396

100

282

22

100

22

Fig. 2

GB

3

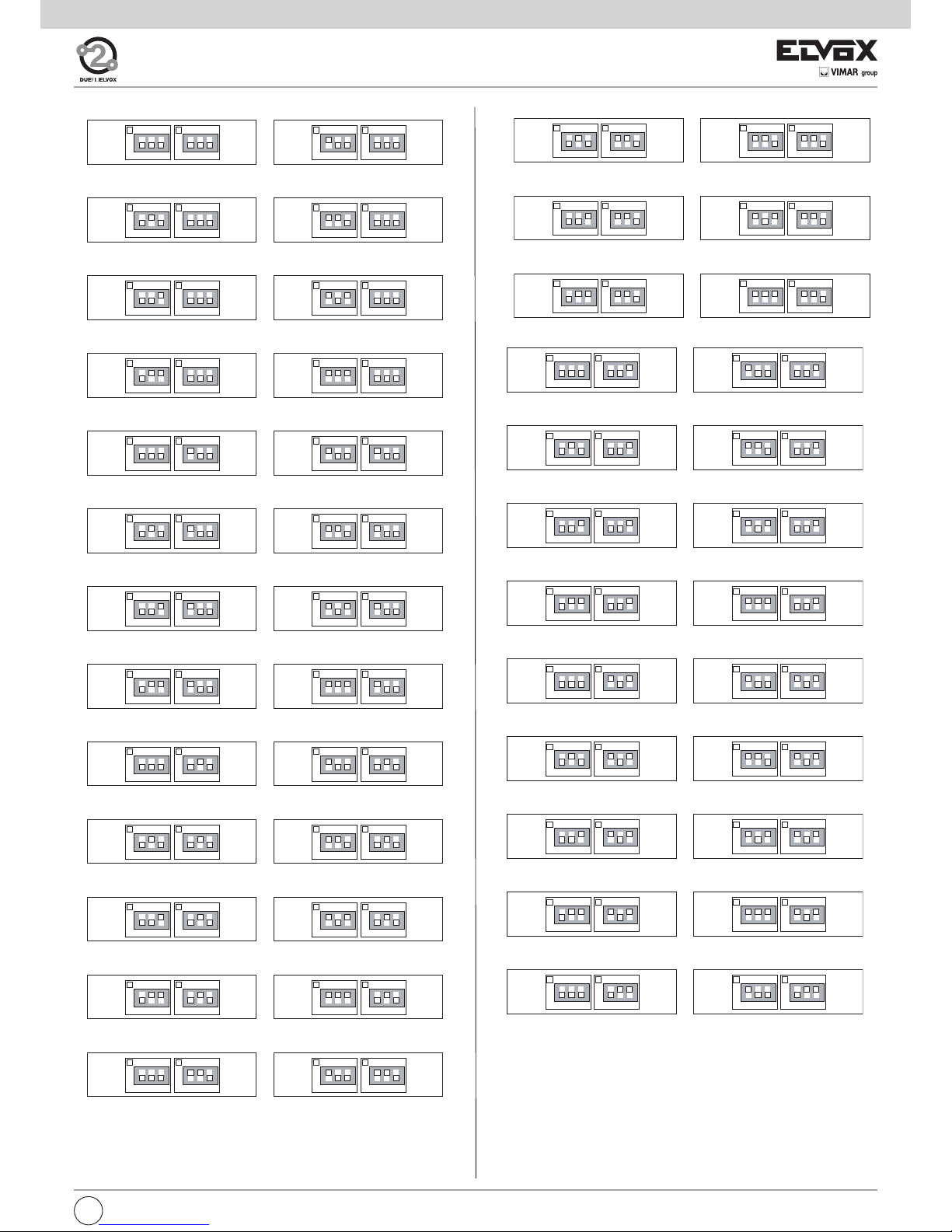

Page 4

Art. 1222/D

Art. 1224/D

Art. 1226/D

Art. 1228/D

Art. 1232/D Art. 1234/D

Art. 1236/D

Art. 1240/D

Art. 1242/D

Art. 1244/D

Art. 1246/D

Art. 12N2/D

Art. 1238/D

Art. 12N4/D Art. 12N6/D

Art. 12N8/D

Art. 12N1 Art. 12N2 Art. 12N3

Art. 1230 Art. 1231 Art. 1232 Art. 1233 Art. 1234

Art. 1235

Art. 1236

Art. 1237

Art. 1220

Art. 1221 Art. 1222 Art. 1223

Art. 12N4

Art. 1224

Art. 1238

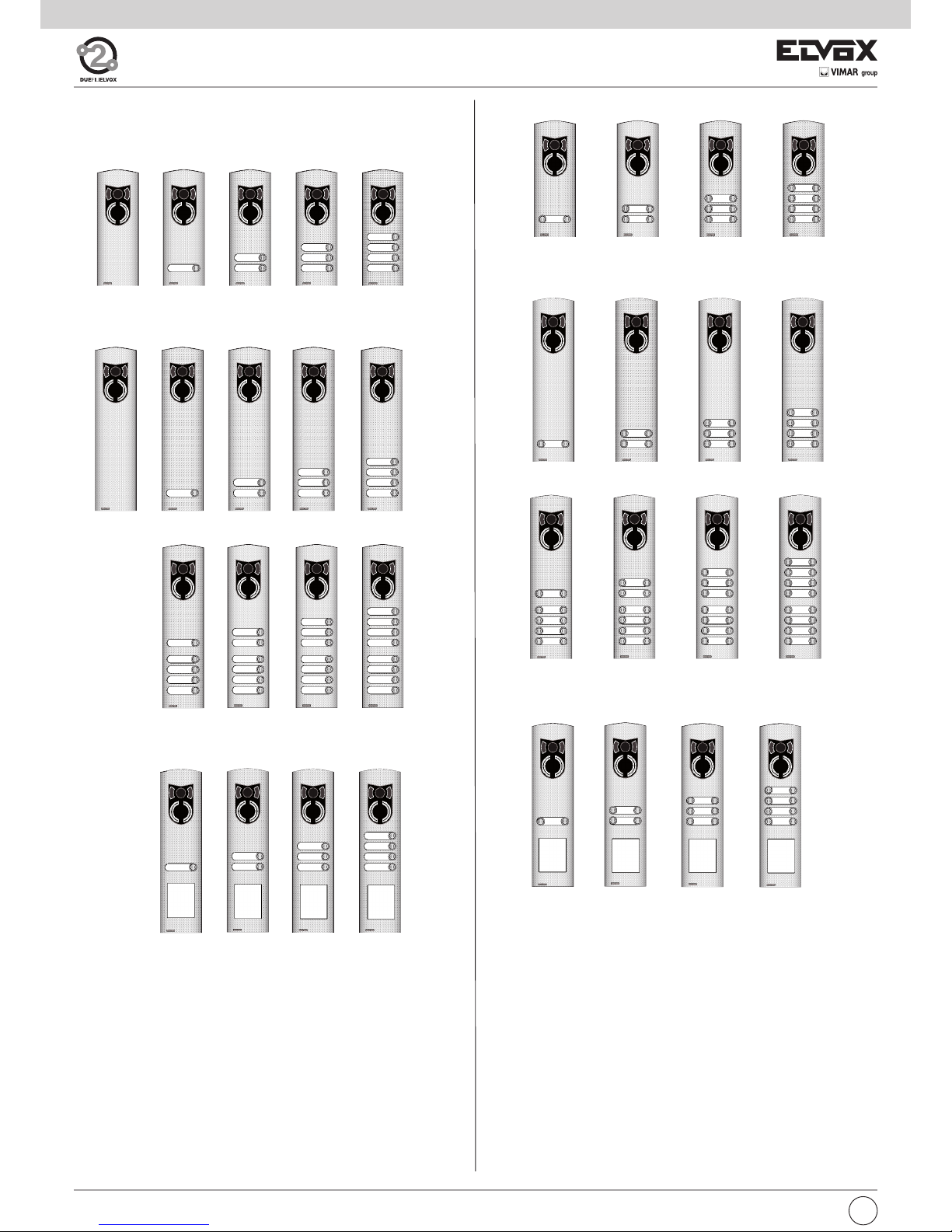

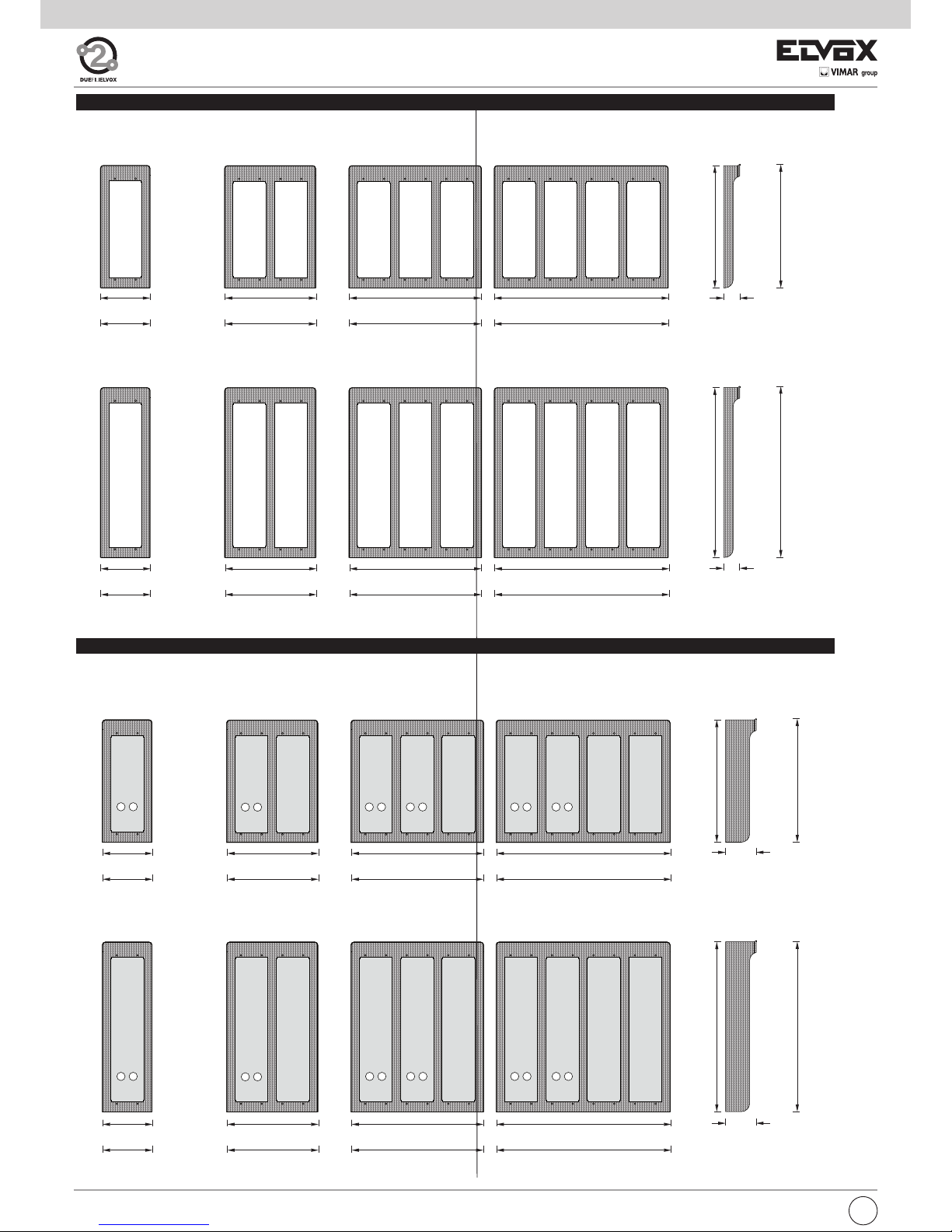

1200 SERIES AUDIO/VIDEO ENTRANCE PANELS

(TWO/THREE MODULES)

- Two-module entrance panels with push-buttons in double row

- Three-module entrance panels with push-buttons in double row

- Three-module entrance panels with push-buttons in double row and

street number holder

- Two-module entrance panels

- Three-module entrance panels

- Three-module entrance panels with street number holder

GB

4

Page 5

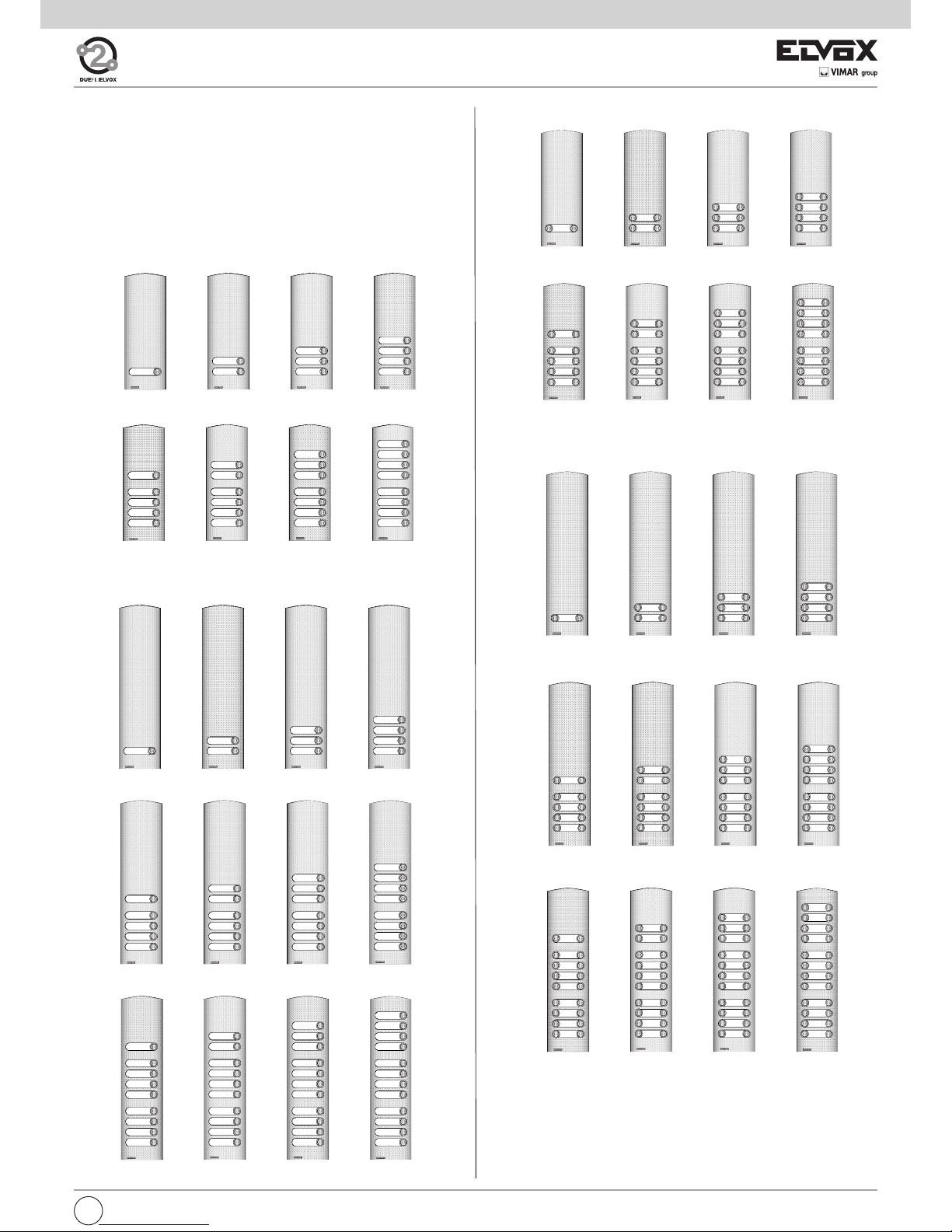

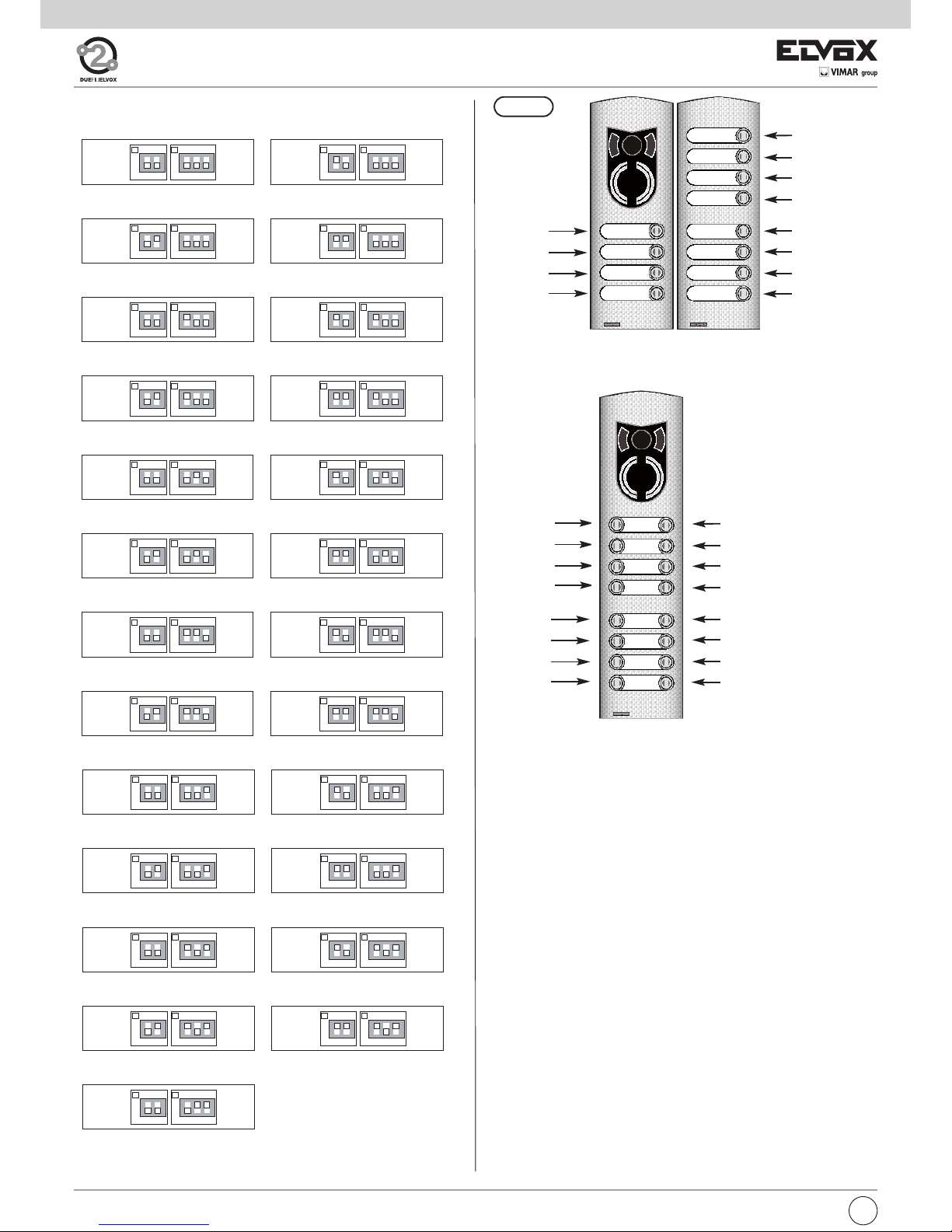

ADDITIONAL ENTRANCE PANELS

The additional entrance panels with traditional type push-buttons are connected to the electronic base units type 12F3 and 12F5 to extend the number of push-buttons. Modules type 12TS (for entrance panels with

push-buttons in single row) or type 12TD (for push-buttons in double row),

which are inserted in the frames under the plates, are connected one after

the other by means of the wiring supplied with the modules. They are then

connected to the standard electronic unit by means of the wiring in the

lower section of the unit Fig .2). Modules type 12TS, 12TD are not supplied as standard with the plates.

Art. 1252/D

Art. 1254/D Art. 1256/D

Art. 1258/D

Art. 1280/D

Art. 1282/D

Art. 1284/D

Art. 1286/D

Art. 1262/D

Art. 1264/D Art. 1266/D

Art. 1268/D

Art. 1270/D

Art. 1272/D Art. 1274/D

Art. 1276/D

Art. 1278/D

Art. 1290/D

Art. 1292/D

Art. 1294/D

Art. 1261

Art. 1262 Art. 1263 Art. 1264

Art. 1265 Art. 1266

Art. 1267 Art. 1268

Art. 1269 Art. 1270 Art. 1271

Art. 1272

Art. 1251

Art. 1252 Art. 1253

Art. 1254

Art. 1255

Art. 1256

Art. 1257 Art. 1258

- Two-module additional entrance panels

- Three-module additional entrance panels

- Three-module entrance panels with push-buttons in double row

- Two-module entrance panels with push-buttons in double row

5

GB

Page 6

1P21 1P22 1P23 1P24

for 1 panel for 2 panels for 3 panels for 4 panels

2 modules high alta 2 moduli 2 modules high 2 modules high

RAINPROOF COVERS

1E21 1E22 1E23 1E24

for 1 panel for 2 panels for 3 panels for 4 panels

2 modules high alta 2 moduli 2 modules high 2 modules high

SURFACE-MOUNTED BOXES WITH RAINPROOF COVER

297

39,5

39,5

412

295

410

74

74

297

412

295

410

124 front side 224 front side 324 front side 424 front side

120 rear side 220 rear side 320 rear side 420 rear side

124 front side 224 front side 324 front side 424 front side

120 rear side 220 rear side 320 rear side 420 rear side

124 front side 224 front side 324 front side 424 front side

120 rear side 220 rear side 320 rear side 420 rear side

124 front side 224 front side 324 front side 424 front side

120 rear side 220 rear side 320 rear side 420 rear side

1E31 1E22 1E23 1E24

for 1 panel for 2 panels for 3 panels for 4 panels

3 modules high 3 modules high 3 modules high 3 modules high

1P31 1P32 1P33 1P34

for 1 panel for 2 panels for 3 panels for 4 panels

3 modules high 3 modules high 3 modules high 3 modules high

GB

6

Page 7

FLUSH-MOUNTED ENTRANCE PANEL INSTALLATION WITH RAINPROOF COVERS.

Assembly of flush-mounted entrance panel requires the use of the flushmounted back boxes type 9092 (9192), 9093 (9193) respectively for 2 or

3 electronic modules mounted vertically (Fig. 4 and 5).

If the entrance panel uses more than one flush-mounted back box, the

rainproof covers must also be used (see push-button plates: accessories

on page 4, series 1Pxx), according to the number of modules fitted vertically or horizontally.

Note: Back boxes type 9092 and 9192 or 9093 and 9193 cannot be matched between them but only between: 9092 with 9092, 9192 with 9192 or

9093 with 9093 and 9193 with 9193.

Warning:during installation of back box type9192 it is necessary to insert

the cover sup-plied in order to avoid possible deformationsof the box itself.

Installation:

- If the installation requires a combination of several back boxes, use the

hooks supplied with the back boxes to secure them together (Fig. 6).

- Install the back box with the upper edge at a height of approx. 1,65 m

from the ground (Fig. 1).

- Fix the terminal block of the electronic unit under the module holder frame

by means of the screws supplied (Fig. 7).

- Fix the rainproof cover to the flush-mounted back box using the screws

supplied (Fig. 7).

- Fix the module holder frames to the frames and the back boxes (Fig. 7).

- Connect the terminal box of the electronic unit to the system.

- Connect the electronic unit to the terminal block by means of the wiring

on the upper section

(Fig. 2).

- Connect the additional entrance panels (Fig. 11), if any.

The connection of more additional modules may require an additional power supply Type 6582 for the LED supply voltage.

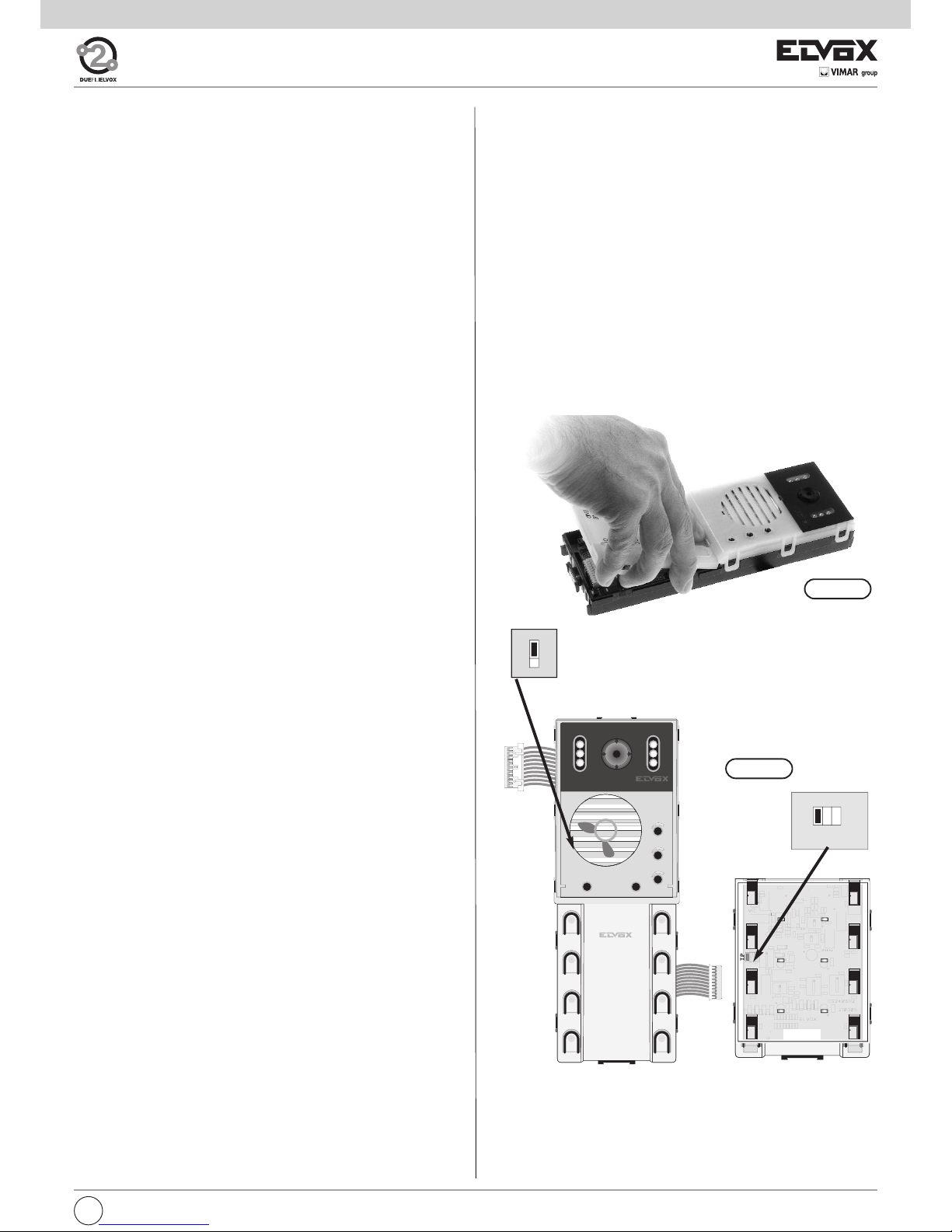

- Insert the electronic unit and the additional modules in the module holder frames. Use the separator supplied with the additional modules to

keep them joined (Fig. 12).

- Insert the microphone in the lower right section of the module holder

frame (Fig. 9 - part. 1).

Pay attention that the microphone cables are inserted in the external

slot of the electronic module (Fig. 9A, 9B).

- If necessary, remove the white cover of push-buttons, of the electronic

unit and of the additional modules.

- Perform the programming phases.

- Reinsert the push-button protection.

- Close the entrance panel, attaching the plate first from the upper section and then securing the lower section by means of the special key on

the head section.

- To remove the name-tag: Press lightly with the fingers to remove the

name-tag placed on the rear section of the push-button plate (Fig. 10).

SURFACE WALL-MOUNTED ENTRANCE PANEL INSTALLATION

Assembly of the surface wall-mounted entrance panel requires the use

of the back boxes series 1Exx.

Installation:

- Fix the electronic unit terminal block under the module holder frame

by using the screw provided (Fig. 8).

- Fix the module holder frames to the frames and back boxes (Fig. 8).

- Connect the terminal block of the electronic unit to the system.

- Connect the electronic unit to the terminal block by means of the

cable present on the upper section (Fig. 2).

- Connect the additional modules, if any (Fig. 11).

The connection of more additional modules may require an additional power supply Type 6582 for the LED supply voltage.

- Insert the electronic unit and the additional modules in the module

holder frames. Use the separator supplied with the additional modules to keep them joined (Fig. 12).

- Insert the microphone in the right lower side of the module holder

frame (Fig. 9 - part. 1).

Pay attention that the microphone cables are inserted in the external

slot of the electronic module (Fig. 9A, 9B).

- If necessary, remove the white cover of push-buttons, of the electro-

nic unit and of the additional modules.

- Perform the programming phases.

- Reinsert the push-button protection.

- Insert the module plates in the modules holder frames (Fig. 8).

- Close the entrance panel, attaching the plate first from the upper sec-

tion and then securing the lower section by means of the special key

on the head section.

- To remove the name-tag: Press lightly with the fingers to remove the

name-tag placed on the rear section of the push-button plate (Fig.

10).

Fig. 6

Fig. 7

Fig. 8

7

GB

Page 8

Fig. 11

Back

Fig. 12

Type 12F3, Type 12F5 Type 12TS o 12TD

Type 12TS in panels with push-buttons in single row (from 5 or more

calls). Type 12TD in panels with push-buttons in double row (from 9 or

more calls).

Fig. 9

part. 1

Fig. 10

Fig. 9A

Fig. 9B

Microphone cable

Electronic unit with module holder frame

Electronic unit without module holder frame

Microphone cable

3

2

1

RST

PRG

4

START

SI / YES

5

STOP

NO

6

FINE

END

1

PREC.

PREV

2

SUCC.

NEXT

3

OK

GB

8

Page 9

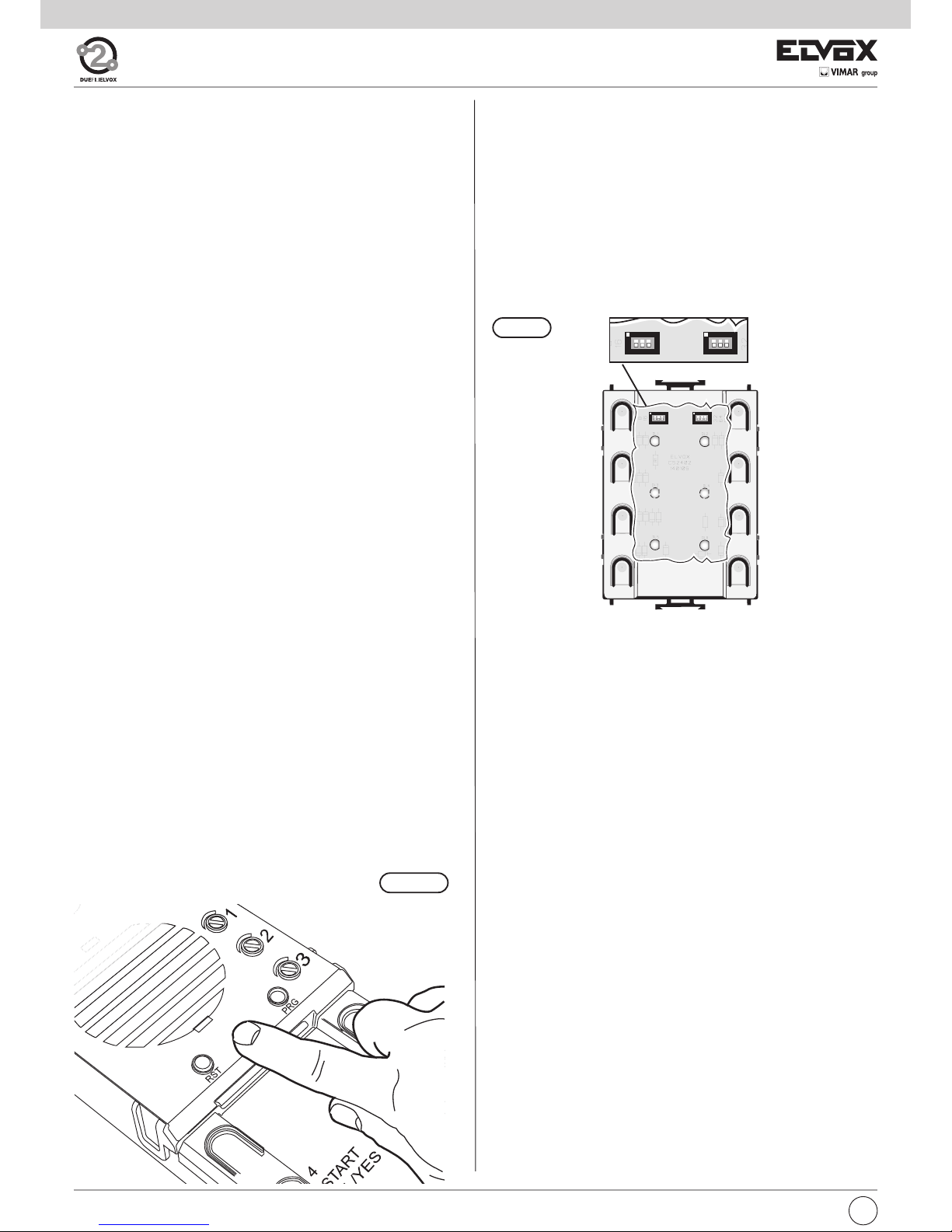

MASTER/SLAVE ASSIGNMENT

(Perform modifications with system switched off)

On systems with more than one panel, a Master panel must be defined

(one only) while the others must be defined as Slave.

This operation is performed by inserting or removing the TP jumper in the

electronic unit below the white cover of the push-buttons. The panel is

supplied as standard with the jumper inserted (Master condition).

Jumper status

TP (inserted) - Master condition.

TP (removed) - Slave condition (to programming)

SV (removed) - always keep without jumper.

SA (inserted) - for audio entrance panels series 12F3

SA (removed) - for video entrance panels 89F5/... or audio

entrance panels 89F3/... but with an

external CCTV camera connected.

Fig. 13A

PATAM ETER S

The panel is supplied already with a standard configuration, to be modified in the case of multiple panels in the same system and if the user wishes to changes the panel operating parameters. There are two parameter

programming levels; one standard and one advanced. Standard programming can be performed directly from the panel keys, while advanced programming requires use of the programmer type 950C or the software

SaveProg Type 69CD for PC by means of interfaces Type 692I or Type

692I/U..

Standard programming parameters:

- Parameter Default value

- Panel ID 1 (Master)

- Reset EEPROM

- Single/Double push-buttons Single row

- Answer time 30 seconds

- Conversation time 120 seconds

- Self-start time 10 seconds

- Lock time 1 second

- F1 time 1 second

- F2 time 1 second

- Panel ringtone repeat Enabled

- Lock block Disabled

- Monitor/interphone ringtone cycles 2

- External volume 15

- Internal volume 3

- Pushbutton remapping Hardware

Parameters for standard and advanced programming with type 950C

or SaveProg:

- Message language Local

- panel ID 1 (Master)

- First key ID 1

- Pushbutton remapping Hardware

- Single/double push-buttons Single row

- Programming password 654321

- Answer time 30 s.

- Conversation time 120 s.

- Self-start time 10 s.

- Lock time 1 s.

- F1 time 1 s.

- F2 time 1 s.

- External volume 15

- Internal volume 3

- Lock block Disabled

- Enablings/Disablings No association

- Panel ringtone repeat Enabled

- Monitor/interphone ringtone cycles 2

- Common locks No association

- F1 common No association

- F2 common No association

- Auto-switching disabling Disabled

- Self-start sequence (Master panel only) No association

- Interphone/Monitor configuration

- Interphone/Monitor function key assignment

- Flag YES / NO

- Function key assignment

o Not Assigned

oIntercommunicating

o Self-Starting

o Auxiliary

o F1 function

o F2 function

o F1 function specific

o F2 function specific

o No Internal Call Ringtone

o No External Call Ringtone

- Call groups (4)

- Associated door call units (4)

- Volume or loudness for 6600 series appliances and derivatives

o Ringtone

o Speakerphone

o External ringtone type

o Brightness (only video door entry units)

o Contrast (only video door entry units)

o Door call ringtone type models Vimar®)

o Intercommunicating ringtone type (only for some models

Vimar®)

- Remote button module configuration.

PRELIMINARY OPERATIONS

Before programming the panels, perform the following preliminary ope-rations:

- Slave panel assignment. On systems with a single panel, this will bedefined Master (default setting). On systems with multiple panels of any

model (alphanumerical, push-buttons), one will be defined Master and

theothers SLAVE.

- Pushbutton hardware programming, for additional modules only.

- Panel ID, entrance panel identification code On systems with multiplepanels, the SLAVE (alphanumerical, push-buttons, outdoor) panels will

be identified with a code.

The panel programming phases use push-buttons on the electronicunit (from 1 to 6); thus performed these operations without closing

thepanel with the front plate.

Fig. 13B

Keep jumper in this position

TP

SV

SA

SV

DL3

DL4

DL5

DL6

1

2

3

4

5

6

SV

TP

SA

3

2

1

RST

PRG

4

START

SI / YES

5

STOP

NO

6

FINE

END

1

PREC.

PREV

2

SUCC.

NEXT

3

OK

9

GB

Page 10

HARDWARE PROGRAMMING OF ADDITIONAL MODULE PUSH-BUTTONS

The dip-switches modify the hardware code of the first pushbutton at the

top right of the module, while the other push-buttons are associated consecutively from top t bottom, right to left (see Tables 1 and 2). Take care not

to overlap the codes of push-buttons on the same panel. When using the

modules with push-buttons in single or double rows the parameter “Single/Double push-buttons” must be programmed according to the type of

module (see standard or advanced programming pages 15 and pages 16).

Fig. 14

PUSHBUTTON HARDWARE PROGRAMMING

(Perform modifications with system switched off)

The hardware programming of push-buttons enables the assignment of a

unique hardware identification code to each pushbutton of the panel. This

operation is indispensable to distinguish each button of the panel and

should only be performed for additional module 805x and 804x. The keys

on the standard modules are already assigned with the numbers from 1 to

8 and the relative hardware programming is not modifiable.

To associate the hardware code use the dip-switches in each additional

module below the white protection of the push-buttons. On 805x series

modules, with push-buttons in single rows, there are 6 dip-switches, while

the 804x series modules, with push-buttons in double rows, there are 5

dip-switches.

ON

123

ON

123

5

6

7

ON

123

ON

123

8

ID ENTRANCE PANEL, IDENTIFICATION PANEL CODE

The identification panel code is required when there is more than one

entrance panel on the installation and only for the panels previously

identified as SLAVE. The operation must be carried out after connecting

all the entrance panels, carrying out the previous operations and powering the installation.

Attention: if the installation power supplies are connected to the elctrical network with more switchers, when switching the installation on, first

power the SLAVE entrance panels and then the MASTER entrance

panel.

Programming may be carried out by means of the programmer type

950C or the PC Software PC SaveProg or by push-buttons from the

entrance panels; if the entrance panel push-buttons are used it is necessary have in the panel a number of push-buttons (different for the physical code) equal to the number of SLAVE entrance panels.

For example:

1) in an installation with 9 entrance panels (1 Master and 8 Slaves) 8 different push-buttons for the 8 entrance panels, provided with the electronic unit.

2) in an installation with 11 entrance panels (1 Master and 10 Slaves) at

least 2 entrance panels out of 11 must be equipped with additional modules to have, besides the 8 standard push-buttons, other 2 pushbttons with different physical codes.

Panel ID programming procedure

Perform the following procedure for each of the SLAVE panels.

- Power up the system. Power first the SLAVE panels followed by the

MASTER panel.

- Wait until the red LEDs indicating ENGAGED/WAIT stop flashing.

- Press and hold the RESET pushbutton (see page 2), of the electronic

unit.

- Press and hold 1st pushbutton at the top right of the electronic unit together with the RESET pushbutton.

- Release the RESET pushbutton while keeping pushbutton (top-right)

for 2 seconds.

- Wait for the panel to emit a high tone from the loudspeaker.

- Enter the Password by pressing the call push-buttons 6 - 5 - 4 - 3 - 2

- 1 in sequence. Each time a pushbutton is pressed, a short “Beep” is

sounded and the output time is renewed (25 seconds), until the next

pushbutton is pressed. The password can only be changed by means

of the programmer type 950C or the PC Software PC SaveProg.

- If the password is correct, the panel emits a high tone of confirmation,

otherwise it emits a low tone and exits the programming phase. The

unit also exits the programming phase when the output time interval

elapses.

- Within 25 seconds, press one of push-buttons to assign the identification code to the SLAVE panel. Pushbutton (top-right) corresponds to

panel 1 SLAVE (ID=2), pushbutton n°2 under n°1 to panel 2 SLAVE

(ID=3) and so on.

If the identification code has already been assigned, the panel emits a long

high tone until another pushbutton is pressed. If the code is available, the

panel emits a low tone and exits the programming phase.

Fig. 13C

Caution!

In order to operate on the programming (PRG) and

Reset push-buttons it is necessary to use the proper

tool usually supplied with the electronic unit.

GB

10

Page 11

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

129 ... 132 133 ... 136

137 ... 140

145 ... 148

153 ... 156

161 ... 164

169 ... 172

177 ... 180

185 ... 188

193 ... 196

141 ... 144

149 ... 152

157 ... 160

165 ... 168

173 ... 176

181 ... 184

189 ... 192

197 ... 200

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

105 ... 108 109 ... 112

113 ... 116 117 ... 120

121 ... 124 125 ... 128

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

ON

123

16

8

4

ON

123

128

64

32

1 ... 4 5 ... 8

9 ... 12

17 ... 20

25 ... 28

33 ... 36

41 ... 44

49 ... 52

57 ... 60

65 ... 68

73 ... 76

81 ... 84

13 ... 16

21 ... 24

29 ... 32

37 ... 40

45 ... 48

53 ... 56

61 ... 64

69 ... 72

77 ... 80

85 ... 88

89 ... 92 93 ... 96

97 ... 100 101 ... 104

Do not use

11

GB

Page 12

ON

12

16

8

ON

12

16

8

ON

12

16

8

ON

12

16

8

ON

123

128

64

32

ON

123

128

64

32

ON

123

128

64

32

ON

123

128

64

32

ON

12

16

8

ON

12

16

8

ON

12

16

8

ON

12

16

8

ON

123

128

64

32

ON

123

128

64

32

ON

123

128

64

32

ON

123

128

64

32

ON

12

16

8

ON

12

16

8

ON

12

16

8

ON

12

16

8

ON

123

128

64

32

ON

123

128

64

32

ON

123

128

64

32

ON

123

128

64

32

ON

12

16

8

ON

12

16

8

ON

12

16

8

ON

12

16

8

ON

123

128

64

32

ON

123

128

64

32

ON

123

128

64

32

ON

123

128

64

32

ON

12

16

8

ON

12

16

8

ON

12

16

8

ON

123

128

64

32

ON

123

128

64

32

ON

123

128

64

32

ON

12

16

8

ON

12

16

8

ON

12

16

8

ON

123

128

64

32

ON

123

128

64

32

ON

123

128

64

32

ON

12

16

8

ON

123

128

64

32

ON

12

16

8

ON

123

128

64

32

ON

12

16

8

ON

123

128

64

32

0 ... 8 9 ... 16

17 ... 24

33 ... 40

49 ... 56

65 ... 72

81 ... 88

97 ... 104

113 ... 120

129 ... 136

145 ... 152

161 ... 168

177 ... 184

25 ... 32

41 ... 48

57 ... 64

73 ... 80

89 ... 96

105 ... 112

121 ... 128

137 ... 144

153 ... 160

169 ... 176

185 ... 192

193 ... 200

Fig. 15

Art. 1224 Art. 1258

1

2

3

4

5

11

10

9

8

7

6

12

Art. 1246/D

1

11

10

9

4

3

2

12

5

15

14

13

8

7

6

16

TABLE 2 - PUSH-BUTTONS IN DOUBLE ROW

Do not use

GB

12

Page 13

LED switched off

LED switchwed on

DL3 DL4

DL5 DL6

SEQUENCE

NEXT

PREVIOUS

NEXT

DL3 DL4

DL5 DL6

PREVIOUS

NEXT

DL3 DL4

DL5 DL6

PREVIOUS

NEXT

DL3 DL4

DL5 DL6

PREVIOUS

NEXT

DL3 DL4

DL5 DL6

PREVIOUS

NEXT

DL3 DL4

DL5 DL6

PREVIOUS

NEXT

OK

END

DL3 DL4

DL5 DL6

PREVIOUS

NEXT

SINGLE/DOUBLE

PUSH-BUTTONS

OK

END

ANSWER

TIME

OK

END

CONVERSATION

TIME

OK

END

SELF-START

TIME

OK

END

LOCK

TIME

OK

END

F1

TIME

OK

RESET

EEPROM

PROGRAMMING

EXIT

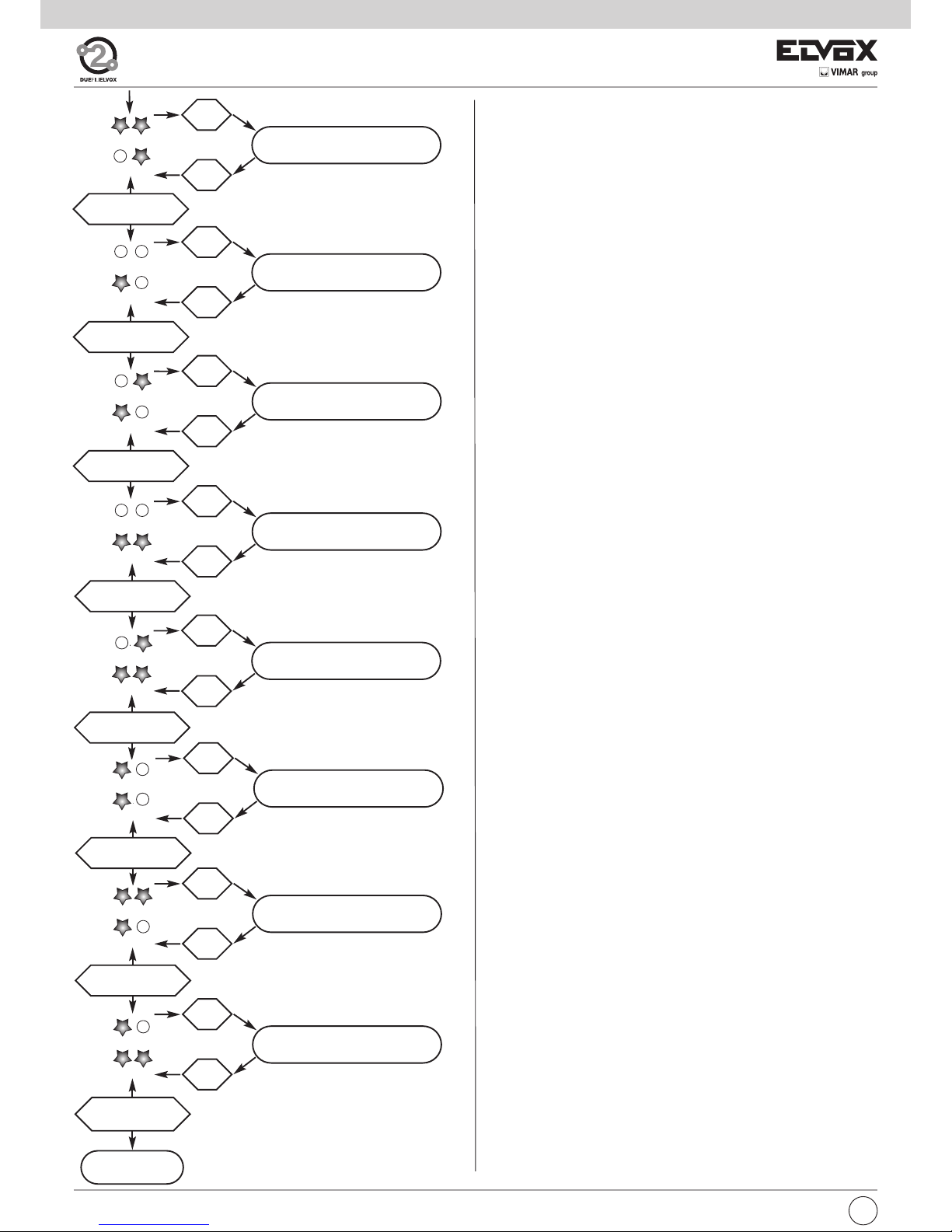

STANDARD PARAMETER PROGRAMMING

Perform the following procedure with the panels powered and after associating the panel ID code. This procedure applies to all panels, Master or

Slave. During programming, the panel is in the engaged status and cannot

be used for normal operation in the system.

For the programming use push-button RPG, 6 push-buttons and 4 green

LEDs present on the electronic unit. In the electronic unit we have in the

whole 8 push-buttons and 6 green LEDs; for the programming the 6 pushbuttons on the lower side and 4 green LEDs on the lower side are used; the

latter serve as indicators for the basic parameter variation. To ease the procedure we call the 4 green LEDs: DL3, DL4, DL5 and DL6.

During programming the 6 push-buttons assume the following functions.

1

PREVIOUS

2

NEXT

3

OK

4

START/YES

5

STOP/NO

6

END

Fig. 15A

Standard programming procedure

- If necessary, press the RESET pushbutton (see par. 2) and wait until the 2

red LEDs stop flashing

- Press the “PRG” push-button and then the push-button on top at the right

hand side and keep them pressed.

- After 2 seconds, the electronic unit emits a high tone for 1 second.

- Enter the Password by pressing the push-buttons 6-5-4-3-2-1 in sequence.

If the password is correct, the 4 LEDs switch off; otherwise it emits a low

tone and exits the programming phase.

- With reference to the following diagram (fig 15B), use the 6 electronic unit

push-buttons to scroll through and modify the parameter values. The

lower 4 LEDs indicate the current function, the push-buttons PREVIOUS

and NEXT select the parameter, the pushbutton OK enters the parameter

editing phase, the pushbutton END exits the parameter editing phase.

The unit also exits the editing phase when the output time interval (30 seconds) elapses, followed by the emission of a low tone for 1 s. The output

time is extended for a further 30 s. when a valid pushbutton is pressed.

For exit from the programming phases, press the RESET pushbutton at any

time.

Fig. 15C

Caution!

In order to operate on the programming (PRG) and Reset push-buttons it

is necessary to use the proper tool usually supplied with the electronic unit.

Fig. 22A

13

GB

Page 14

- RESET EEPROM

Restores all default parameter settings.

On entry to the parameter editing mode, the two red LEDs (DL1 and DL2)

will start to flash 8 times and the panel emits a continuous high tone.

During flashing, press the push-buttons PREVIOUS, OK, STOP in sequence to start deletion of the EEPROM. During deletion, the red LEDs

will start flashing at intervals of 100ms ON / 100ms OFF. On completion

of the deletion process, the panel exits programming mode and the microprocessor is initialised.

- SINGLE/DOUBLE PUSH-BUTTONS

This specifies if the panel push-buttons are in single or double rows.

Default value = push-buttons in single row.

On entry to parameter editing mode, press the pushbutton START/YES

(top left) for single row push-buttons of the pushbutton STOP/NO (middle left) for push-buttons in double rows.

Press the pushbutton END (bottom left) to proceed with the other parameters.

- ANSWER TIME

To be programmed as required. This is the time interval, expressed in

seconds, that the panel waits after a call has been terminated and the

time when the handset of the interphone/monitor is raised. If the handset

is not raised within this time interval, the panel disables the interphone/monitor. If the handset is raised before this interval elapses, the

panel starts to count the conversation time.

Default value = 30 s., minimum value 1 s., maximum value 255 s.

On entry to parameter editing mode, start the count of the time to be

memorised by means of the pushbutton START/YES. To end the count,

press the pushbutton STOP/NO. During the count, the LEDs flash at intervals of 500ms ON/500ms OFF to enable calculation of the time elapsed, 1 flash = 1 s. (e.g. 10 flashes = 10 s.).

Press the pushbutton END to proceed with the other parameters.

- CONVERSATION TIME

To be programmed at user's discretion. This is the time interval, expressed in seconds, that the panel checks, from the time when the handset

is raised after the call. The panel disables the internal unit after this time

interval.Default value = 12 (120 s.), minimum value 10 s., maximum value

2550 s.

On entry to parameter editing mode, start the count of the time to be

memorised by means of the pushbutton START/YES. To end the count,

press the pushbutton STOP/NO. During the count, the LEDs flash at intervals of 500ms ON/500ms OFF to enable calculation of the time elapsed, 1 flash = 1 s. (e.g. 10 flashes = 100 s.).

Press the pushbutton END to proceed with the other parameters.

- SELF-START TIME

To be programmed at the user's discretion. This is the time interval, expressed in seconds, that the panel remains engaged with a monitor/interphone, from activation by means of the self-start function. The

panel disables the internal unit after this time interval.

Default value = 10 s., minimum value 1 s., maximum value 255 s.

On entry to parameter editing mode, start the count of the time to be

memorised by means of the pushbutton START/YES. To end the count,

press the pushbutton STOP/NO. During the count, the LEDs flash at intervals of 500ms ON/500ms OFF to enable calculation of the time elapsed, 1 flash = 1 s. (e.g. 10 flashes = 10 s.).

Press the pushbutton END to proceed with the other parameters.

- LOCK TIME

To be programmed at user's discretion. This is the activation time of

the lock connected between terminals S+ / S- and +12V / SR.

Default value = 1 second, minimum value 0 s., maximum value 5 s.

On entry to parameter editing mode, start the count of the time to be

memorised by means of the pushbutton START/YES. To end the count,

press the pushbutton STOP/NO. During the count, the LEDs flash at

intervals of 500ms ON/500ms OFF to enable calculation of the time

elapsed, 1 flash = 1 s. (e.g. 10 flashes = 10 s.).

Press the pushbutton END to proceed with the other parameters.

To reset the time (0 s.) press the pushbutton STOP/NO in place of the

pushbutton START/YES.

GB

14

DL3 DL4

DL5 DL6

PREVIOUS

NEXT

DL3 DL4

DL5 DL6

PREVIOUS

NEXT

DL3 DL4

DL5 DL6

PREVIOUS

NEXT

DL3 DL4

DL5 DL6

OK

END

F2

TIME

OK

END

REPEAT

PANEL RINGTONE

OK

END

LOCK

BLOCK

OK

END

RINGTONE CYCLES

PREVIOUS

NEXT

DL3 DL4

DL5 DL6

PREVIOUS

NEXT

OK

RESERVED

DL3 DL4

DL5 DL6

OK

END

RESERVED

DL3

DL4

DL6

END

PREVIOUS

NEXT

DL3 DL4

DL5 DL6

PREVIOUS

NEXT

OK

END

PUSHBUTTON

REMAPPING

DL3 DL4

DL5 DL6

OK

END

RESERVED

END

SEQUENCE

PREVIOUS

Page 15

- PUSHBUTTON REMAPPING

Enables modification to the code sent by a pushbutton, regardless of

its physical position assigned with the hardware programming. This

enables use of a pushbutton to call an interphone /monitor that has already been assigned a different code.

Default value = all push-buttons associated with a specific physical

code

On entry to parameter editing mode, the LEDs start flashing; to start

remapping, press the pushbutton START/YES (top left).

After pressing the pushbutton START/YES, press the call pushbutton of

the panel to be remapped. A general call is made from the panel to all

interphones/monitors in the rest condition (not in conversation); the interphones/monitors with handset raised will emit a 3-tone ascending

scale from the loudspeaker.

From this moment the user has a 30-second interval to press, on the interphone/monitor to be associated, the lock push-button.

The panel loudspeaker emits a low tone; this also occurs when the 30second time interval elapses.ù

Press the pushbutton START/YES (top left) to remap other push-buttons or END (bottom left) to proceed with the other parameters.

To restore the default value (Hardware value) of a pushbutton, instead

of pressing START/YES, press STOP/NO and then the pushbutton to

restore the default value and end the procedure.

During this procedure, if the lock pushbutton on the interphone/monitor

concerned is pressed, the panel lock is activated. To eliminate this

event, enable the parameter PANEL BLOCK.

ADVANCED PARAMETER PROGRAMMING

Refer to the instructions for programmer type 950C.

- F1 TIME

To be programmed at user's discretion. This is the activation time of

the device connected between terminals +12V / F1. Default value = 1

second, minimum value 0,5 s., maximum value 255 s.

On entry to parameter editing mode, start the count of the time to be

memorise by means of the pushbutton START/YES. To end the count,

press the pushbutton STOP/NO. During the count, the LEDs flash at

intervals of 500ms ON/500ms OFF to enable calculation of the time

elapsed, 1 flash = 1 s. (e.g. 10 flashes = 10 s.).

Press the pushbutton END to proceed with the other parameters.

To reset the time to 0 (0.5 s.) press the pushbutton STOP/NO in place

of the pushbutton START/YES.

- F2 TIME

To be programmed at user's discretion. This is the activation time of

the device connected between terminals +12V / F2. Default value = 1

second, minimum value 0,5 s., maximum value 255 s.

On entry to parameter editing mode, start the count of the time to be

memorised by means of the pushbutton START/YES. To end the count,

press the pushbutton STOP/NO. During the count, the LEDs flash at

intervals of 500ms ON/500ms OFF to enable calculation of the time

elapsed, 1 flash = 1 s. (e.g. 10 flashes = 10 s.).

Press the pushbutton END to proceed with the other parameters.

To reset the time to 0 (0.5 s.) press the pushbutton STOP/NO in place

of the pushbutton START/YES.

- PANEL RINGTONE ENABLE

To be programmed as required. Enables repetition of the call ringtone

in the loudspeaker of the panel, from the panel where the call is being

made. Default value = enabled

On entry to parameter editing mode, press the pushbutton START/YES

to enable the function, or the pushbutton STOP/NO to disable the function.

Press the pushbutton END (bottom left) to proceed with the other parameters.

- PANEL LOCK BLOCK

To be programmed as required. Activation of the lock block enables

control of the lock only when the panel is in call, conversation or selfstart status. Default value = block disabled

On entry to parameter editing mode, press the pushbutton START/YES

to enable the function, or the pushbutton STOP/NO to disable the function.

Press the pushbutton END (bottom left) to proceed with the other parameters.

- RINGTONE CYCLES

To be programmed at user's discretion. This is the number of times that

the call is repeated in the monitor/interphone when a call pushbutton is

pressed.

Default value = 2 times, minimum value 1, maximum value 20.

On entry to parameter editing mode, start thecount of the cycles to memorised by means of the pushbutton START/YES. To end the count,

press the pushbutton STOP/NO. During the count, the LEDs flash at

intervals of 500ms ON/500ms OFF to enable calculation of the number

of cycles, 1 flash = 1 cycle (e.g. 5 flashes = 5 cycles).

Press the pushbutton END to proceed with the other parameters.

15

GB

Page 16

Table for entrance panels and electronic units for DUE FILI ELVOX (Two Wire Elvox) system

Type of panel

Electronic unit for

1200, 1300 Series

entrance panel

Electronic entrance

panel series 8000

Electronic entrance

panel series PATAVIUM

Electronic entrance

panel series 3300

Electronic entrance

panel series letter box

Alphanumeric audio entrance panel

12F4 89F4 89F4/T 39F4

25F3/8 - 2930

Push-button audio entrance panel

12F3 - 12F3/3

89F3, 89F3/2,

89F3/1, 89F3/0

89F3/T, 89F3/2T,

89F3/1T, 89F3/0T

39F3

25F3/8 - 2930

Alphanumeric video entrance panel

12F7 89F7/C 89F7/CT 39F7

25F3/8 - 2559

Push-button video entrance panel

12F5 -12F5/3

89F5/C, 89F5/C2,

89F5/C1, 89F5/C0

89F5/CT, 89F5/CT2,

89F5/CT1, 89F5/CT0

39F5

25F3/8 - 2559

Conductor section

Terminals Ø up to 10 m Ø up to 50 m Ø up to 100 m Ø up to 300 m

Bus: 1, 2, B1, B2 ( )

0,5 mm

2

0,5 mm

2

0,75 mm

2

1 mm

2

Cable Elvox Type 732H, Type 732I Type 732H, Type 732I Type 732H, Type 732I Type 732H, Type 732I

Electric lock

1,5 mm

2

---

Other: -, +U, +I, -L (#)

1 mm

2

1 mm

2

1,5 mm

2

2,5 mm

2

Video Coaxial cable 75 Ohm type RG59 o RG11 (only for the connection of any external cameras type CCTV)

On Two-Wire installations use cable type 732H or 732I for a maximum distance of 300 metres.

# Additional power supplies (type 6923, 6582, 6982) must be installed as close as possible to the device to which they are to be connected.

BUS TERMINATION FOR ELVOX TWO-WIRE INSTALLATIONS

This note applies to all devices with ELVOX TWO-WIRE technology equipped with “BUS termination connector or dip-switch”, which is identified by the

screen-printed letters “ABC” and marked on the wiring diagrams with

*

.

For correct adaptation of the line, make the setting according to the following rule:

Maintain position “A” if the BUS enters and exits from the device;

Move to position “B” (if Elvox cable) or to position “C” (if CAT5 twisted pair cable) if the BUS line terminates in the device itself.

“A” = NO TERMINATION

“B” = TERMINATION 100 ohm

“C” = TERMINATION 50 ohm

INSTALLATIONS WITH PASSIVE DISTRIBUTOR 692D

(DIN rail version)

ALWAYS use output 1 on distributor type 692D (the only one that has no termination jumper).

For termination of type 692D: If outputs “OUT”, “2”, “3” or “4” are not used, KEEP the jumper on the “TOUT”, “T2”, “T3” or “T4” connector. The default

“TOUT” connector is in the “100” position (Elvox cable), position it to “50” only if using a CAT5 twisted pair cable.

INSTALLATIONS WITH PASSIVE DISTRIBUTOR 692D

(non-DIN rail version)

For termination of type 692D (non-DIN rail version): If the “OUT” output is not used, KEEP the jumper on connector “A”. If the “OUT” output is used, REMOVE the jumper from connector “A”.

INSTALLATIONS WITH ACTIVE DISTRIBUTOR 692D/2.

The termination jumper must be positioned on “B” (for Elvox cable) or on “C” (for CAT5 twisted pair cable) IF AND ONLY IF the BUS terminates at the device itself. It must be left on “A” if effecting entry-exit using terminals 1-2 on 692D/2.

*

GB

16

Page 17

17

B112B2

PRI

EXT+

EXT-

M

PA

X

VLED

B1

B2

S+

S-

F2

F1

SR

-L

+12V

M

M

CA

EXT+

EXT-

M

PA

X

VLED

B1

B2

S+

S-

F2

F1

SR

-L

+12V

M

M

CA

5

2

2

1

4

1

6S

6P

B

A

C

A

C

B

4

5

6S

2

1

6P

1

E+

FP

E-

2

M

CH

+12

B

A

C

4

T2

5

6S

T1

2

1

A

T4

-

+

C

B

VIDEO

T3

6P

1

2

2

2

1

1

12V

CH

B

A

C

FP

M

*

88888888

8

7

R

0

4

1

2

5

9

C

3

6

X

F- Art. 6922

C0

C

P

K

K

K

C

C0

P

L L

X

X

X

X

A1

A3

A2

Mains

K

X

A0

A4

K

X

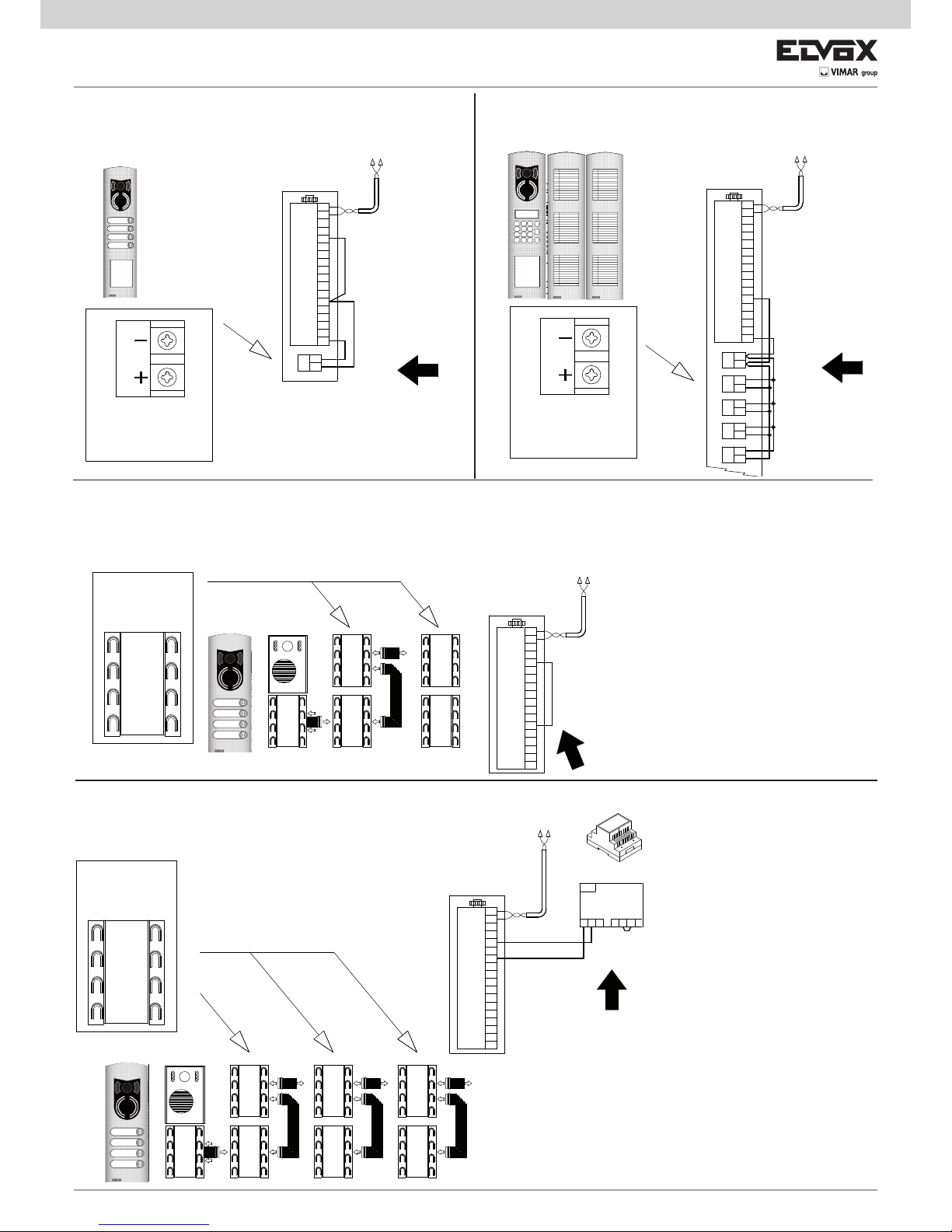

SINGLE AND MULTIPLE RESIDENCE AUDIO DOOR ENTRY SYSTEM WITH INTERPHONES SERIES PETRARCA, 8870, 6600

AND ONE AUDIO ENTRANCE PANEL (REF. SI435).

Interphone

cable riser

A0 - Interphone type 6901, type 6901/D

A1 - Interphone series Petrarca type 6209

A2 - Interphone series 6600

type 6601/AU, 660C/AU, 6701/AU

type 6611/AU, 661C/AU, 6711/AU, type 6xxx/AUF

A3 - Interphone series 8870 type 8879

C - Audio entry panel with push-buttons

C0 - Audio entry panel with alphanumeric display

F - Power supply type 6922

K - Push-button for outdoor call

L - 12 V ~ electric lock

P - Lock release control

X - Cable type 732H, 732I (Two twisted wires)

Page 18

18

VLED

-L

M

F2

F1

SR

CA

S-

+12V

S+

M

M

PA

X

B2

EXT+

EXT-

B1B1

EXT-

EXT+

B2

X

PA

M

M

S+

+12V

S-

CA

SR

F1

F2

M

-L

VLEDVLED

-L

M

F2

F1

SR

CA

S-

+12V

S+

M

M

PA

X

B2

EXT+

EXT-

B1B1

EXT-

EXT+

B2

X

PA

M

M

S+

+12V

S-

CA

SR

F1

F2

M

-L

VLED

5

2

2

1

4

1

6S

6P

B

A

C

A

C

B

4

5

6S

2

1

6P

1

E+

FP

E-

2

M

CH

+12

B

A

C

4

T2

5

6S

T1

2

1

A

T4

-

+

C

B

VIDEO

T3

6P

1

2

B112B2

PRI

2

2

1

1

12V

CH

B

A

C

FP

M

*

88888888

8

7

R

0

4

1

2

5

9

C

3

6

F- Art. 6922

C0

C

P

K

K

K

C

C0

P

L

L

C

P

L

C

P

L

X

X

X

X

X

X

X

A0

A3

A2

Mains

A1

X

K

C

C

K

X

A4

SINGLE AND MULTIPLE RESIDENCE AUDIO DOOR ENTRY SYSTEM WITH INTERPHONES SERIES PETRARCA, 8870,

6600 AND THREE AUDIO ENTRANCE PANELS (REF. SI338).

Interphone cable riser

A0 - Interphone type 6901, type 6901/D

A1 - Interphone series Petrarca type 6209

A2 - Interphone series 6600

type 6601/AU, 660C/AU, 6701/AU

type 6611/AU, 661C/AU, 6711/AU, type 6xxx/AUF

A3 - Interphone series 8870 type 8879

A4 - Interphone series tab type 7509, 7509/D

C - Audio entry panel with push-buttons

C0 - Audio entry panel with alphanumeric display

F - Power supply type 6922

K - Push-button for outdoor call

L - 12 V ~ electric lock

P - Lock release control

X - Cable type 732H, 732I (Two twisted wires)

Page 19

19

SCHEMA SI334

VLED

-L

M

F2

F1

SR

CA

S-

+12V

S+

M

M

PA

X

B2

EXT+

EXT-

B1

VLED

-L

M

F2

F1

SR

CA

S-

+12V

S+

M

M

PA

X

B2

EXT+

EXT-

B1

1

2

BUS D

12

BUS P

2112

B

A

C

D

2

1

1

2

D

C

A

B

2112

BUS P

21

BUS D

B1

EXT-

EXT+

B2

X

PA

M

M

S+

+12V

S-

CA

SR

F1

F2

M

-L

VLED

VLED

-L

M

F2

F1

SR

CA

S-

+12V

S+

M

M

PA

X

B2

EXT+

EXT-

B1

B112B2

PRI

B112B2

PRI

B112B2

PRI

6

3

C

9

5

2

1

4

0

R

7

8

88888888

*

F- Art. 6922

C0

C

P

C0

L

P

L

C

F- Art. 6922

I- Art. 692S

P

L

F- Art. 6922

L

P

C

C

I- Art. 692S

1

2

5

2

2

1

4

1

6S

6P

B

A

C

A

C

B

4

5

6S

2

1

6P

1

E+

FP

E-

2

M

CH

+12

B

A

C

4

T2

5

6S

T1

2

1

A

T4

+

C

B

VIDEO

T3

6P

1

2

2

2

1

1

12V

CH

B

A

C

FP

M

SI334

SI334

C

C

ID=2

ID=3

ID=1

ID=1

ID=2

X

X

X

X

X

X

X

A1

A2

A3

Mains

Mains

Mains

A0

X

X

X

X

X

K

K

K

K

X

A4

K

Cable riser

A0 - Interphone type 6901, type 6901/D

A1 - Interphone series Petrarca type 6209

A2 - Interphone series 6600

type 6601/AU, 660C/AU, 6701/AU

type 6611/AU, 661C/AU, 6711/AU,

type 6xxx/AUF

A3 - Interphone series 8870 type 8879

A4 - Interphone series tab type 7509, 7509/D

C - Audio entry panel with push-buttons

C0 - Audio entry panel with alphanumeric display

F - Power supply type 6922

I - Separator type 692S

K - Push-button for outdoor call

L - 12 V ~ electric lock

P - Lock release control

X - Cable type 732H, 732I (Two twisted wires)

AUDIO DOOR ENTRY SYSTEM FOR BUILDING COMPLEX WITH ONE MAIN ENTRANCE PANEL AND ONE STAIRWAY

PANEL PER APARTMENT BLOCK (REF. si340+si334).

Page 20

20

VLED

-L

M

F2

F1

SR

CA

S-

+12V

S+

M

M

PA

X

B2

EXT+

EXT-

B1B1

EXT-

EXT+

B2

X

PA

M

M

S+

+12V

S-

CA

SR

F1

F2

M

-L

VLEDVLED

-L

M

F2

F1

SR

CA

S-

+12V

S+

M

M

PA

X

B2

EXT+

EXT-

B1

1

2

D

C

A

B

2112

BUS P

B112B2

PRI

21

BUS D

B1

EXT-

EXT+

B2

X

PA

M

M

S+

+12V

S-

CA

SR

F1

F2

M

-L

VLED VLED

-L

M

F2

F1

SR

CA

S-

+12V

S+

M

M

PA

X

B2

EXT+

EXT-

B1 B1

EXT-

EXT+

B2

X

PA

M

M

S+

+12V

S-

CA

SR

F1

F2

M

-L

VLEDVLED

-L

M

F2

F1

SR

CA

S-

+12V

S+

M

M

PA

X

B2

EXT+

EXT-

B1

BUS D

12

PRI

B221B1

BUS P

2112

B

A

C

D

2

1

B112B2

PRI

B1

EXT-

EXT+

B2

X

PA

M

M

S+

+12V

S-

CA

SR

F1

F2

M

-L

VLED

ID = 1 ID = 2

ID = 1 ID = 2 ID = 3

ID = 4 ID = 5 ID = 6 ID = 7

*

88888888

8

7

R

0

4

1

2

5

9

C

3

6

F- Art. 6922

C

P

L

C

I- Art. 692S

SI334

C

P

L

F- Art. 6922

C

P

L

I- Art. 692S

SI334

C

P

L

C

P

L

C

C

P

L

C

P

L

C0

P

L

C0

ID=1

ID=2 ID=3

ID=4

ID=5

ID=6 ID=7

ID=1

ID=2

X

X

X

X

X

X

X

X

X

F- Art. 6922

Mains

Mains

Mains

C

C

C

C

C

AUDIO DOOR ENTRY SYSTEM FOR BUILDING COMPLEX WITH THREE MAIN ENTRANCE PANELS AND TWO STAIRWAY PANELS PER APARTMENT BLOCK (REF. si341+si334).

C - Audio entry panel with push-buttons

C0 - Audio entry panel with alphanumeric display

F - Power supply type 6922

I - Separator type 692S

K - Push-button for outdoor call

L - 12 V ~ electric lock

P - Lock release control

X - Cable type 732H, 732I (Two twisted wires)

Page 21

21

C

A

B

1

E+

FP

E-

2

M

CH

+12

21

12

1

2

5

4

6P

+

-

6S

T1

T2

C

VIDEO

T4

A

B

T3

M

V3

A

C

B

4

12

2

3

1

13

OUT

IN

2A OUT 1A2B 1B

4B3B 4AIN3A

T2

T3 T4

TOUT

100

50

B

A

C

E-

2

2

1

E+

1

12V

CH

FP

M

C

A

B

1

E+

FP

E-

2

M

CH

+12

+I+U-

PRI

1C 2C2B1A 1B2A

2112

C

13

1

3

2

12

4

V3

M

B

C

A

C

A

B

FP

E-

M

1

E+

2

CH

+12

12

IN

21

OUT

2D1D

BA

C

A

B

1

E+

FP

E-

2

M

CH

+12

+I+U-

PRI

B

A

C

E-

2

2

1

E+

1

12V

CH

FP

M

4

T2

5

6S

T1

2

1

A

T4

+

C

B

VIDEO

T3

6P

4

T2

5

6S

T1

2

1

A

T4

+

C

B

VIDEO

T3

6P

1

2

1

E+

FP

E-

2

M

CH

+12

M

V3

A

C

B

4

12

2

3

1

13

B

A

C

C

A

B

+12

CH

M

2

EFP

E+

1

+I+U-

PRI

21

E-

2

2

1

E+

1

12V

CH

B

A

C

FP

M

X

X

X

X

X

X

X

X

X

N- Art. 692D

N2- Art. 692D/2

K

K

K

K

K

K

K

K

K

K

K

B4

B4

B4

B5

B5

B5

B1

B2

B3

B0

B0

B0

B1

B3 B2

B1

B3

B2

G- Art. 6923

G- Art. 6923

G- Art. 6923

*

*

*

*

*

*

*

*

*

*

*

*

*

Mains

Mains

Mains

K

K

*

B6

K

X

B6

K

B6

*

si638

X

Video door entry system cable riser wiring. The

video door entry units (interphones) can be connected to the cable riser in the following ways:

• in-out connection, without the aid of floor distributors;

• connection with passive distributor type 692D;

• connection with active distributor type 692D/2;

• hybrid connection using the above 3 methods.

In a video installation, device termination must be

carried out using the jumpers (ABC) in the device itself. See the notes below for terminating devices at

the cable riser in accordance with the wiring type.

LEGEND:

B0 - Wide Touch series door entry monitor type 7311

B1 - 7200 series door entry monitor type 7211

B2 - 6600 series door entry monitor

type 6621, 662C, 6721

type 6611, 661C, 6711

B3 - 6800 series door entry monitor

type 6801, type 68MV + 68M1

B4 - Petrarca series door entry monitor

type 6029/C + 6209 + 6145

type 6029 + 6209 + 6145

B5 - Giotto series door entry monitor

type 6329, 6329/C

B6- Tab series door entry monitor

type7529, 7529/D

G - Additional power supply unit type 6923

N - Distributor type 692D

K - Door call button

X- Cable type 732H, 732I (Twisted Pair)

Monitor cable riser

Monitor cable riser

Monitor cable riser

*

CONNECTION OF MONITORS WITH AND WITHOUT FLOOR DISTRIBUTOR TYPE 692D AND 692D/2 (REF. si638).

Page 22

22

EXT+

EXT-

M

PA

X

VLED

B1

B2

S+

S-

F2

F1

SR

-L

+12V

M

M

CA

EXT+

EXT-

M

PA

X

VLED

B1

B2

S+

S-

F2

F1

SR

-L

+12V

M

M

CA

B112B2

PRI

4

T2

5

6S

T1

2

1

A

T4

+

C

B

VIDEO

T3

6P

1

2

1

E+

FP

E-

2

M

CH

+12

M

V3

A

C

B

4

12

2

3

1

13

B

A

C

C

A

B

+12

CH

M

2

E-

FP

E+

1

+I+U-

PRI

E-

2

2

1

E+

1

12V

CH

B

A

C

FP

M

3

2

1

6

9

4

5

7

8

R

0

C

X

R

F- Art. 6922

B2

B3

B1

B4

B5

G- Art. 6923

B0

X

X

X

X

X

X

D0

P

L

D0

D

D

L

*

*

*

*

Mains

Mains

STAR

SI / Y

STO

FINE

END

P

K

K

K

K

X

K

B6

*

SINGLE AND MULTIPLE RESIDENCE VIDEO DOOR ENTRY SYSTEM WITH PETRARCA, GIOTTO AND 6600 SERIES VIDEO INTERPHONES AND ONE VIDEO ENTRANCE PANEL (REF. si433).

Monitor cable riser

B0 - Monitor series Wide touch type 7311

B1 - Monitor series 7200 type 7211

B2 - Monitor series 6600

type 6621, 662C, 6721

type 6611, 661C, 6711,

type 6xxx/F

B3 - Monitor series 6800

type 6801, type 68MV + 68M1

B4 - Monitor series Petrarca

type 6029/C + 6209 + 6145

type 6029 + 6209 + 6145

B5 - Monitor series Giotto

type 6329, 6329/C

B6- Tab series door entry monitor

type7529, 7529/D

D - Video entry panel with push-buttons

F - Power supply type 6922

G - Additional power supply type 692S

K - Push-button for outdoor call

L - 12 V ~ electric lock

P - Lock release control

X - Cable type 732H, 732I (Two twisted wires)

Page 23

23

2C 1D 2D1C2B1B2A1A

21122112

+

PRI

B221B1

1C 2C2B1A 1B2A

2112

C

2D1D

BA

1

22

1

2

1

CA

M

M

+12V

-L

SR

F1

F2

S-

S+

B2

B1

VLED

X

PA

M

EXT-

EXT+EXT+

EXT-

M

PA

X

VLED

B1

B2

S+

S-

F2

F1

SR

-L

+12V

M

M

CA CA

M

M

+12V

-L

SR

F1

F2

S-

S+

B2

B1

VLED

X

PA

M

EXT-

EXT+

4

T2

5

6S

T1

2

1

A

T4

-

+

C

B

VIDEO

T3

6P

1

2

1

E+

FP

E-

2

M

CH

+12

M

V3

A

C

B

4

12

2

3

1

13

B

A

C

C

A

B

+12

CH

M

2

EFP

E+

1

+I+U-

PRI

E-

2

2

1

E+

1

12V

CH

B

A

C

FP

M

R

3

2

1

6

9

4

5

7

8

R

0

C

X

R R

D0

P

L

D0

F- Art. 6922

D

P

D

Mains

K

K

N2Art. 692D/2

J- Art. 692C

X

X

X

X

X

X

X

B1

B3

B0

*

*

STA

SI /

STO

FIN

K

L

*

*

K

B2

B6

B4

B5

*

K

*

G- Art. 6923

Mains

P

L

X

X

X

X

X

D

D

STA

SI /

STO

FIN

WIRING DIAGRAM FOR “TWO WIRE ELVOX” VIDEO INTERPHONE INSTALLATIONS WITH TWO OR MORE MONITOR RISERS WITH DISTRIBUTORS TYPE 692D/2 (SI424).

Monitor cable riser

B0 - Monitor series Wide touch type 7311

B1 - Monitor series 7200 type 7211

B2 - Monitor series 6600

type 6621, 662C, 6721

type 6611, 661C, 6711,

type 6xxx/F

B3 - Monitor series 6800

type 6801, type 68MV + 68M1

B4 - Monitor series Petrarca

type 6029/C + 6209 + 6145

type 6029 + 6209 + 6145

B5 - Monitor series Giotto

type 6329, 6329/C

B6- Tab series door entry monitor

type7529, 7529/D

D - Video entry panel with push-buttons

D0 - Video entry panel with alphanumeric display

F - Power supply type 6922

J - Concentrator type 692C

K - Push-button for outdoor call

L - 12 V ~ electric lock

N2 - Active video distributor type 692D/2

P - Lock release control

X - Cable type 732H, 732I (Two twisted wires)

Page 24

24

CA

M

M

+12V

-L

SR

F1

F2

S-

S+

B2

B1

VLED

X

PA

M

EXT-

EXT+

PRI

B221B1

CA

M

M

+12V

-L

SR

F1

F2

S-

S+

B2

B1

VLED

X

PA

M

EXT-

EXT+

MV-+T

-L-+U

PRI

4

T2

5

6S

T1

2

1

A

T4

-

+

C

B

VIDEO

T3

6P

1

2

1

E+

FP

E-

2

M

CH

+12

M

V3

A

C

B

4

12

2

3

1

13

B

A

C

C

A

B

+12

CH

M

2

E-

FP

E+

1

+I+U-

PRI

E-

2

2

1

E+

1

12V

CH

B

A

C

FP

M

88888888

*

8

7

R

0

4

1

2

5

9

C

3

6

K

K

F- Art. 6922

C

P

L

C

C0

P

L

C0

S- Art. 6982

M1

K

Coax 75 ohm

X

X

X

X

X

B4

B5

*

*

*

Mains

Mains

X

G- Art. 6923

Mains

B0

B1

B2

B3

*

K

X

B6

*

K

B0 - Monitor series Wide touch type 7311

B1 - Monitor series 7200 type 7211

B2 - Monitor series 6600

type 6621, 662C, 6721

type 6611, 661C, 6711,

type 6xxx/F

B3 - Monitor series 6800

type 6801, type 68MV + 68M1

B4 - Monitor series Petrarca

type 6029/C + 6209 + 6145

type 6029 + 6209 + 6145

B5 - Monitor series Giotto

type 6329, 6329/C

B6- Tab series door entry monitor

type 7529, 7529/D

C - Audio entry panel with push-buttons

C0 - Audio entry panel with alphanumeric display

F - Power supply type 6922

K - Push-button for outdoor call

L - 12 V ~ electric lock

M1 - 12 V C.C.T.V. external camera

max current 250mA intermittent cycle or

150mA continuous cycle

P - Lock release control

S - Additional power supply type 6982

X - Cable type 732H, 732I (Two twisted wires)

Monitor cable riser

VIDEO ENTRANCE PANEL SYSTEM FOR SINGLE AND TWIN RESIDENCE WITH MONITORS SERIES PETRARCA,

GIOTTO, 6600, ONE ENTRANCE PANEL WITH EXTERNAL CAMERA IN B/W (Ref. SI367).

Page 25

25

EXT+

EXT-

M

PA

X

VLED

B1

B2

S+

S-