Page 1

ELTROPLAN-REVCON

Operating instructions

Power feedback unit

REVCON

SVCS

Power range 7 ... 33kW

Rated voltage 400V

V 2.0 As of 03/10

Page 2

Contents

1 Preface and general information .......................................................................................... 3

1.1 About these Operating Instructions ..................................................................................... 3

1.1.1 Terminology used .......................................................................................................... 3

1.1.2 Type determinator ......................................................................................................... 4

1.2 Scope of delivery ................................................................................................................. 4

1.3 Legal regulations.................................................................................................................. 5

1.4 EC-Directives / Declaration of conformity .......................................................................... 6

1.4.1 What is the purpose of EC-Directives? ......................................................................... 6

1.4.2 What is the meaning of the CE-mark? .......................................................................... 6

1.4.3 EC-Low-Voltage Directive ........................................................................................... 6

1.4.4 EC-Directive Machinery ............................................................................................... 8

2 Safety information ............................................................................................................. 10

2.1 General safety information ................................................................................................ 11

2.2 Safety-responsible persons ................................................................................................ 15

2.3 Usage as directed ............................................................................................................... 15

2.4 Layout of the safety information ....................................................................................... 16

2.5 Residual hazards ................................................................................................................ 16

2.6 General instructions ........................................................................................................... 17

3 Technical data .................................................................................................................... 27

3.1 Characteristics .................................................................................................................... 27

3.2 General data / application conditions................................................................................. 28

3.3 Rated data .......................................................................................................................... 29

3.3.1 Power feedback unit .................................................................................................... 29

3.3.2 Current load ................................................................................................................. 30

3.3.4 Fuses and wire cross sections ...................................................................................... 34

3.3.4.1 Series fuses .............................................................................................................. 34

3.3.4.2 Internal fuses ............................................................................................................ 35

3.3.5 RFI-filter ..................................................................................................................... 36

3.3.6 SKS-module ................................................................................................................ 36

4 Installation ......................................................................................................................... 37

4.1 Mechanical installation ..................................................................................................... 37

4.1.1 Important hints ........................................................................................................... 37

4.2 Dimensions ........................................................................................................................ 38

4.2.1 Power feedback unit .................................................................................................... 38

4.2.2 RFI-filters .................................................................................................................... 41

ELTROPLAN-REVCON page 1

Page 3

Contents

4.3 Electrical installation ......................................................................................................... 43

4.3.1 Operator’s safety ......................................................................................................... 43

4.3.2 Protection of the power feedback unit ........................................................................ 43

4.3.3 Mains types / Mains characteristics ............................................................................ 44

4.3.4 Specifications of the used wires ................................................................................. 44

4.4 Connection ........................................................................................................................ 45

4.4.1 Power connection ....................................................................................................... 45

4.4.1.1 Wiring schematic ..................................................................................................... 47

4.4.2 Fan supply ................................................................................................................... 49

4.4.3 Control wires .............................................................................................................. 49

4.4.4 Control functions ........................................................................................................ 49

4.5 Application example ......................................................................................................... 53

4.6 Installation of a power feedback unit in a CE-typical drive system .................................. 54

4.6.1 Installation .................................................................................................................. 55

4.6.2 Connection of a RFI-filter .......................................................................................... 56

4.6.3 Design of an EMC-conformal cabinet ........................................................................ 57

4.6.4 Remarks ...................................................................................................................... 58

4.6.5 Installation of control wires ........................................................................................ 59

5 Commissioning .................................................................................................................. 60

5.1 First powering up .............................................................................................................. 60

6 Configuration .................................................................................................................... 61

7 Troubleshooting and fault elimination .............................................................................. 64

7.1 LED-messages ................................................................................................................... 65

8 Service ............................................................................................................................... 66

9 Appendix ........................................................................................................................... 67

9.1 Options .............................................................................................................................. 67

9.2 REVCON Product overview ............................................................................................. 69

9.3 Contact .............................................................................................................................. 70

Seite 2 ELTROPLAN-REVCON

Page 4

Preface and general information

1 Preface and general information

1.1 About these Operating Instructions

• These Operating Instructions help you to work properly on and with the

power feedback units REVCON SVCS. They contain safety information

which must be observed and information which are necessary for an undisturbed operation of the units together with the exploitation of all the advantages of the system.

• All persons who work on and with the power feedback units REVCON

SVCS, must have the Operation instructions available and observe all

relevant notes and instruction.

• The Operating Instructions must always be in a complete and perfectly

readable state.

1.1.1 Terminology used

Power feedback unit

For „Power feedback unit REVCON SVCS“ in the following the term

„Power feedback unit“ is used.

Controller

For the frequency inverter which is used together with the power feedback unit

in the following the term „Controller“ is used.

Drive system

For a drive system with power feedback units, controller and other components

of the drive system in the following the term „Drive system“ is used.

ELTROPLAN-REVCON page 3

Page 5

Preface and general information

1.1.2 Type determinator

SVCS 33 - XXX - 1 - 230 V AC

for up to 50% duty cycle

Auxiliary voltage e. g. 230V

Number of fans

Mains voltage e. g. 400 (3 x 400V AC)

max. feedback power e. g.33 (33 kW)

Including SKS-R

SVCS = Power feedback unit

1.2 Scope of delivery

• 1 Power feedback unit REVCON

• 1 Operating Instructions

After receipt of delivery, check immediately whether the scope of supply

matches with the accompanying papers. We do not accept any liability for deficiencies claimed subsequently.

Claim

• visible transport damage immediately to the forwarder .

• visible deficiencies/incompleteness immediately to ELTROPLAN

REVCON.

page 4 ELTROPLAN-REVCON

Page 6

Preface and general information

•

•

1.3 Legal regulations

Labelling Nameplate CE-mark Manufacturer

Power feedback units REVCON SVC are

unequivocally marked by the contents of

Conforms the EC Low

Voltage Directive

the nameplate.

Patent rights

The power feedback unit REVCON

is protected in Germany and Europe by patents :

Patent-No.: DE 3938654C1 and Patent-Nr.: 90123584.6-2207.

Patent infringements become prosecute.

Application

as directed

Power feedback unit REVCON

SVC

• Must only be operated under the conditions prescribed in these instructions.

• Are components

– to feedback electrical energy.

– used for installation into a machine.

– used for assembly together with other components to from a machine.

• Are electric units for the installation into control cabinets or similar enclosed operating hous-

ing.

• Comply with the requirements of he Low-Voltage Directive

• Are not machines for the purpose of the Machinery Directive

• Are not to be used as domestic appliances, but only for industrial purpose.

Drive systems with power feedback unit REVCON

SVC

• Comply with the EMC-Directive if they are installed according to the guidelines of CE-typical

drive systems.

• Can be used

– on public and non-public mains.

– in industrial as well as residential and commercial premises.

• The user is responsible for the compliance of this application with the EC directives .

Liability

The information, data and notes in these Operating Instructions met the state of the art at the

time of printing. Claims referring to power feedback units which have already been supplied

cannot be derived from information, illustrations and descriptions given in these Operation Instructions.

• The specifications, processes and circuitry described in these Operating Instructions are for

guidance only and must be adapted to your own specific application. ELTROPLAN-REVCON

does not take responsibility for the suitability of the process and circuit proposals.

• The indications given in these Operating Instructions describe the features of the product with-

out warranting them.

• ELTROPLAN-REVCON does not accept any liability for damage and operating interference

caused by:

– disregarding these instructions

– unauthorized modifications to the power feedback unit

– operating errors

– improper working on and with the power feedback unit

Warranty

Warranty conditions: see sales and delivery conditions of ELTROPLAN-REVCON GmbH.

• Warranty claims must be made immediately after detecting defects or faults.

• The warranty is void in all cases where liability claims cannot be made.

Disposal Material recycle disposal

Metal

Plastic

l

l

Printed-board assemblies -

ELTROPLAN-

REVCON

Edisonstraße 3

D-59199 Bönen

-

-

l

ELTROPLAN-REVCON page 5

Page 7

Preface and general information

1.4 EC-Directives / Declaration of conformity

1.4.1 What is the purpose of EC-Directives?

The EC-Directives have been drawn up by the European council to define

common technical standards and certification procedures within the European

Community. At the moment there are 21 EC-Directives for product sectors.

The directives are or will be converted in national laws by the member states.

If a certificate is conferred in one member state, it is valid in all other member

states automatically.

The directives only describe the basic standards. The technical details are or

will be described in harmonized European standards.

1.4.2 What is the meaning of the CE-mark?

After an conformity-assessment-procedure the harmony with the standards of

the EC-Directives certified by fixing the CE-mark. Within the EC there are no

trading obstacles for a CE-marked product.

Power feedback units with CE-mark themselves are compliant with the LowVoltage Directive only. . For observing the EMC Directive recommendations

are made.

1.4.3 EC-Low-Voltage Directive

(73/23/EEC)

Modified by: CE – Marking Directive (93/68/EEC)

General:

• The Low-Voltage Directive is valid for all electrical equipment which is

used at a nominal voltage between 50V and 1000V AC and between 75V

and 1500V DC together with customary environment conditions. Excluded

is e.g. the use of electrical equipment in explosive areas and electrical

components of lifts for persons or material.

• Aim of the Low-Voltage Directive is to put only those products into com-

merce which don’t endanger the safety of persons and animals as well as

the preservation of material assets.

page 6 ELTROPLAN-REVCON

Page 8

Preface and general information

EC-declaration of conformity

According to the EC-Low Voltage Directive /73/23/EEC)

Modified by: CE – Marking Directive (93/68/EEC)

The power feedback units REVCON SVC have been developed, designed and

manufactured in accordance with the above mentioned EC-Directive and in

sole responsibility of

ELTROPLAN-REVCON Elektrotechnische Anlagen GmbH,

Edisonstraße 3, D-59199 Bönen

Considered standards:

Standard

DIN VDE 0160 5.88 +A1 / 4.89 +A2 / 10.88

PRDIN EN 50178

Class VDE 0160 / 11.94

DIN VDE 0100 Guidelines for the desing of

EN 50529 IP type of protection

DIN EN 50081 Part 2 3.94 Basic standard noise emission

DIN EN 50082 Part 2 3.85 Basic standard noise emission

Equipement of power installations with

electronic components

power installations

ELTROPLAN-REVCON page 7

Page 9

Preface and general information

1.4.4 EC-Directive Machinery

(89/392/EEC)

Modified by: 1. modification guideline (91/368/EEC)

2. modification guideline (93/44/EEC)

CE – marking guideline (93/68/EEC)

General:

As defined by the machinery guideline a „machine“ is a unit of combined

components or devices, from which at least one has moving parts, and of handling devices, control and energy circuits and so on, which have been combined for a specific application (like treating, moving, processing of a material).

page 8 ELTROPLAN-REVCON

Page 10

Preface and general information

EC-declaration of the manufacturer

In the sense of the EC-Directive Machinery (89/392/EEC)

modified by: 1. Modifying Directive (91/368/EEC)

2. Modifying Directive (93/44/EEC)

CE – Labelling Directive (93/68/EEC)

The power feedback units REVCON SVC have been developed, designed and

manufactured in accordance with the above mentioned EC Directive in exclu-

sive responsibility of

ELTROPLAN-REVCON Elektrotechnische Anlagen GmbH,

Edisonstraße 3, D-59199 Bönen

When installing the machines, commissioning (i.e. the staring of operation as

directed) the power feedback units is prohibited until it is proven that the ma-

chine corresponds to the regulations of the EC Directive 89/392/EEC (Machin-

ery Directive).

ELTROPLAN-REVCON page 9

Page 11

Safety information

2 Safety information

Safety and application notes

for controller

1. General

During operation, power feedback unit may have, according to

their type of protection, live, bare, in some cases also movable or

rotating parts as well as hot surfaces.

Non –authorized removal of required cover, inappropriate use, incorrect installation or operation, creates the risk of severe injury to

persons or damage to material assets.

Further information can be obtained from the documentation.

All operations concerning transport, installation and commissioning as well as maintenance must be carried out by qualified,

skilled personnel (IEC 364 and CENELEC HD 384 or DIN VDE

0100 and IEC-Report 664 or DIN VDE 0110 and national regulations for the preventions of accidents must be observed).

According to this basic safety information qualified skilled personnel are persons who are familiar with the erection, assembly,

commissioning and operation of the product and who have the

qualifications necessary for their occupation .

2. Application as directed

Power feedback units are components which are designed for installation in electrical systems or machinery.

When installing in machines, commissioning of the power feedback unit (i.e. the starting of operation as directed) is prohibited

until it is proven, that the machine corresponds to the regulations

of the EC Directive 83/392/EEC (Machinery Directive); EN

60204 must be observed.

Commissioning (i.e. starting operation as directed) is only allowed

when there is compliance with the EMC-Directive89/336/EEC.

The power feedback units meet the requirements of the LowVoltage Directive 73/23/EEC. The harmonized standards of the

prEN 50178/DIN VDE 0160 series together with EN 604391/DIN VDE 0660 part 500 and EN 60146/DIN VDE 0558 are applicable for the power feedback unit. The technical data and information on the connection conditions must be obtained from the

nameplate and the documentation and must be observed in all

cases.

3. Transport, Storage

Notes on transport, storage and appropriate handling must be observed

The power feedback unit has to protected from inadmissible

stress. In particular during transport and handling no components

are allowed to be bend and / or isolating distances may not be altered. The units are equipped with electrostatic sensitive devices,

which may be damaged by improper handling. Therefore it has to

be avoid to get in contact with electronic components. If electronic components are damaged mechanically the unit must not be

put into operation, as it cannot be ensured, that all relevant standards are observed. Climatic conditions must be observed according to prEN 50178

(to : Low-Voltage Directive 73/23/EEC)

4. Erection

The devices must be erected and cooled according to the regulations of the corresponding documentation.

The power feedback units must be protected from inappropriate

loads. Particularly during transport and handling, components

must not be bent and / or isolating distances must not be changed.

Touching of electronic components and contacts must be avoided.

Power feedback units contain electro-statically sensitive components which can easily be damaged by inappropriate handling.

Electrical components must not be damaged or destroyed mechanically (health risk are possible!).

5. Electrical Connection

When working on live power feedback units, the valid national

regulations for the prevention of accidents (e.g. VBG 4) must be

observed. Before any installation or connection works, the pant

has to be switched off and to be secured properly.

The electrical installation must be carried out according to the appropriate regulations (e.g. cable cross-sections, fuses, PEconnection). More detailed information is included in the documentation. When using the power feedback unit with controllers

without safe separation from the supply line (to VDE 0100) all

control wiring has to be include in further protective measures

(e.g. double insulated or shielded, grounded and insulated) .

Notes concerning the installation in compliance with EMC – such

as screening, grounding, arrangement of filters and laying of cables – are included in the chapter installation of this documentation. These notes must be also observed in all cases for power

feedback units with the CE-mark. The compliance with the required limit values demanded by the EMC legislation is the responsibility of the manufacturer of the system or machine.

6. Operation

Systems where power feedback units are installed, if applicable,

have to be equipped with additional monitoring and protective devices according to the valid safety regulations e.g. law on technical tools, regulations for the prevention of accidents, etc. .

After disconnecting the power feedback unit from the supply voltage, live parts of the power feedback unit and power connections

must not be touched immediately, because of possibly charged

capacitors. For this, observe the corresponding labels on the drive

controllers.

During operation, all covers and doors must be closed.

7. Maintenance and service

The manufacturer’s documentation must be observed.

This safety information must be kept!

The product-specific safety and application notes in

these Operating Instructions must also be observed!

page 10 ELTROPLAN-REVCON

Page 12

Safety information

2.1 General safety information

• These safety regulations are not entitled to completeness. In case of ques-

tions please contact our technicians.

• When commissioning the power feedback units is compliant with the state

of the art. The power feedback unit generally allows safe operation.

• The statements of this manual describe the attributes of the products with-

out guaranteeing them.

• The power feedback unit may expose persons, the power feedback units it-

self and other material to danger, if

– non qualified personal works at and with the power feedback unit.

– The power feedback units is used in opposite to its purpose.

• Power feedback units have to be projected in a way, that they fulfil their

function and don’t expose persons to danger, if they are mounted correctly

and are used in accordance with their purpose. This applies also for the in-

terplay with the whole plant.

• The units, operational data and circuit details described in this manual

have to be understood analogously and have to be checked for transferabil-

ity to each application.

• For the reasons of personal safety, the observance of the EMC-regulations

and for the regular cooling the operation of the device is only allowed

with a closed cover of the housing and with mounted flanges!

•

• Use the drive system only in flawless condition.

•

Modifications of the power feedback units without consultation of a

REVCON-technician are not allowed generally.

ELTROPLAN-REVCON page 11

Page 13

Safety information

•

The warranty given by us expires, if the unit is modified or (even partially)

dismantled or if it is used in contradiction to our instructions.

•

The constructor of the plant, who has to know the technical guidelines,

bears the responsibility for the correct selection and arrangement of the

electrical components.

•

Putting into operation of the power feedback unit is only admissible at

VDE-conform nets of electrical power supply. Non observance may dam-

age the device!

•

In accordance with the corresponding standards and guidelines the opera-

tion on even for a short time over-compensated networks (cosϕ≤1) respec-

tively on un-choked compensation-units is not admissible. If this is done

nevertheless, overvoltages will occur (caused by oscillating currents),

which may damage all connected components, especially electronic units

like controllers and power feedback units.

•

To low powered or unloaded generators and to regulating transformers it is

never allowed to feed back power without a previous consultation of our

application department. Otherwise unintended voltage rises / excess volt-

ages are generated, which may damage or destroy REVCON and com-

bined units!

• Before operating at nets without reference to neutral ground additional

safety measures (e.g. installation of over voltage suppressors like MOV’s)

have to be done. If necessary, please ask for technical support by our tech-

nicians.

• An undisturbed operation of the power feedback unit is only probable, if

the following instructions are observed. If these instructions are not ob-

served, tripping of the unit and damages may occur.

♦ Pay attention to the correct values of mains and DC-bus voltage.

♦ Separate power and control wires (> 15cm)

♦ Use shielded or twisted control wires. Connect both ends of the

shield to ground!

page 12 ELTROPLAN-REVCON

Page 14

Safety information

♦ When using the digital input devices, only use suitable switching de-

vices, whose contacts are able to switch the connected voltages.

♦ Connect the housings of drive, controller and power feedback unit to

ground carefully. Connect shields of power cables to ground at both

ends with as big surface as possible (remove lacquer)!

♦ Connect the cabinet or the plant by a star-shaped network to ground

(ground loops have to be avoided!)

• The power feedback unit has been designed for a fixed connection to

mains only. Especially when using RFI-filter leakage current values>

3,5mA may occur. The cross section of the earthing conductor must be al

least 10mm² copper, or a second conductor has to be connected in parallel

(star shaped grounding network).

• If components are used, which have no electrical separated inputs / outputs

it is necessary to equalize the potentials (e.g. by a equalizing wire). If this

is not observed, these components may be damaged by equalizing currents.

• When carrying out an insulations test in accordance with VDE0100/part

620 the device has to be disconnected to avoid damage to the power semi-

conductors. This procedure corresponds with the standard, as each device

performs a high voltage test in accordance with VDE 0160 (EN 50178) in

the course of final testing after manufacturing.

ELTROPLAN-REVCON page 13

Page 15

Safety information

• A standard fault-current circuit breaker (sensitive on peak currents) is not

allowed to be used as the only protective measure when using controller

and power feedback unit Caused by a DC-component in the mains current

a controller with 3-phase input voltage may prevent a fault-current circuit

breaker from tripping in case of a earth fault. In accordance with VDE

0160 a fault-current circuit breaker is not allowed to be used as the only

protective measure. In dependence on the kind of network (TN, IT, TT)

further protective measures in accordance with VDE 0100 part 410 are

necessary. For a TN-network this may be an over current protection, for a

IT-network a insulation supervision with pulscode-measurment. For all

kind of networks protective insulation (-transformer) may be used, if re-

quired power and length of wires allow that. When selecting a fault current

circuit breaker the following measures have to be considered:

♦ The fault current circuit breaker has to be compliant with the VDE

0664 standard.

♦ The tripping current should be 300mA or more, to prevent a prema-

ture tripping caused by the leakage current of the controller. In de-

pendence on the load, the length of the motor cables and the usage of

a RFI-filter the leakage current may even be much higher.

Faults current circuit breaker, which are sensitive to all kinds of leakage

currents, grant a good protection and are suitable as the only protection

measurement for one ore three phase controllers. The connection instruc-

tions of the manufacturer has to be observed.

page 14 ELTROPLAN-REVCON

Page 16

2.2 Safety-responsible persons

User

• User is any natural or legal entity, who uses the drive system or by whom

order the drive system is used.

• The user respectively his security officer have to grant

– that all relevant regulations, instructions and laws have to be observed

– that only qualified personnel works with or at he drive system

– that the relevant manual is available for the personnel during any works.

– that non-qualified personnel is prohibited to work on the drive system.

Qualified personnel

Qualified personnel are persons who are, based on their education, experience,

instruction and knowledge about standards and guidelines, regulations for the

Safety information

prevention of accidents and the situation in the plant, authorized by the safety

officer of the plant to execute the necessary works and are able to recognize

possible dangers and to avoid them.

(Definition of qualified personnel in accordance with IEC 364)

2.3 Usage as directed

Power feedback units are electrical drive components, which are directed to be

installed in electrical plants or machines. They have to be used only for drive

systems with infinity variable speed controls of 3-phase asynchronous or per-

manent magnet motors. The usage with other electrical loads is not permitted

and may damage the devices. The power feedback unit may only be connected

to symmetrical networks. Non-observance may damage the devices.

ELTROPLAN-REVCON page 15

Page 17

Warning of hazardous

FFFF

STOP

STOP

Safety information

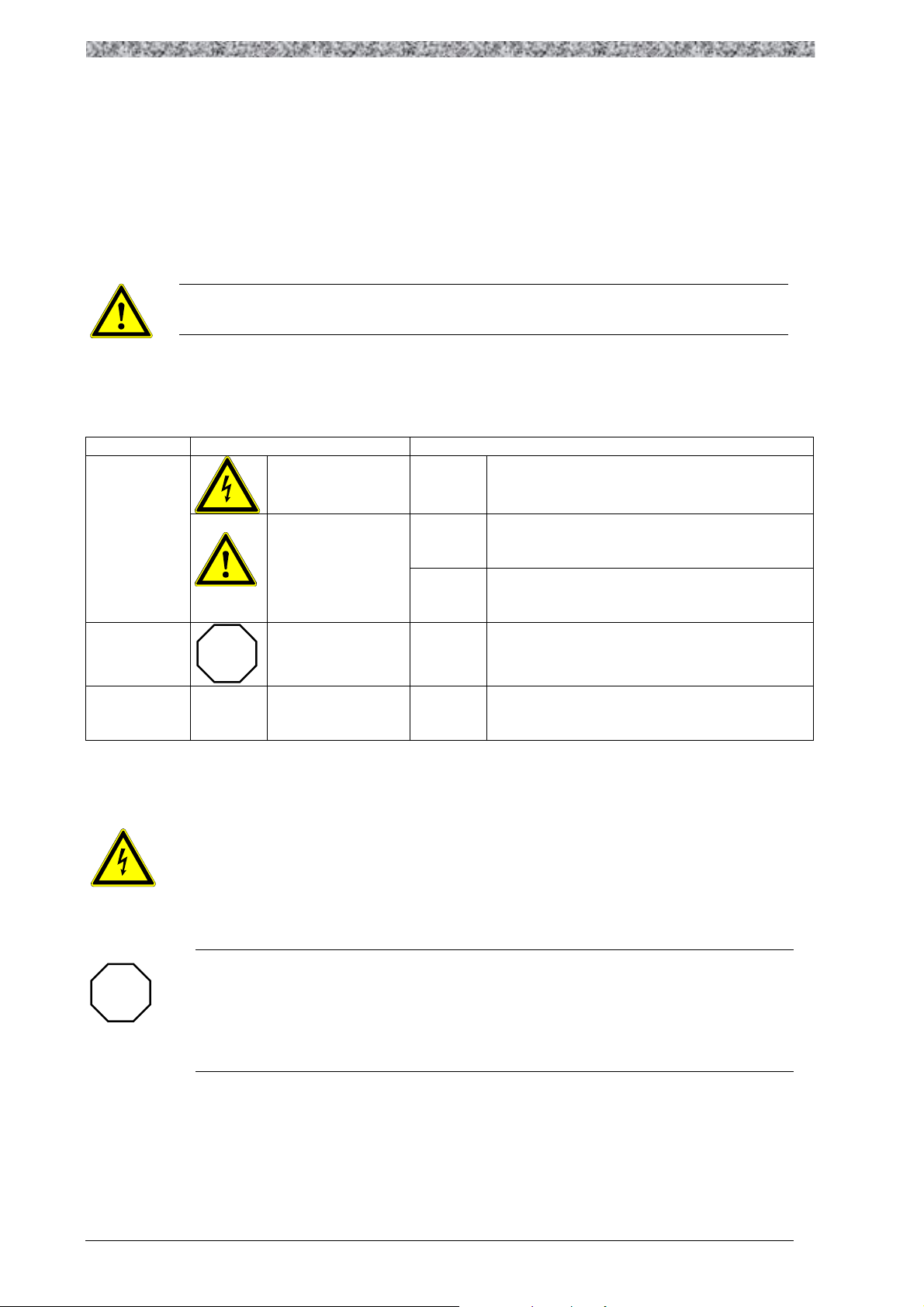

2.4 Layout of the safety information

• All safety notes have a uniform layout:

- The icon characterizes the type of danger.

- The signal word characterizes the severity of danger.

- The note describes the danger and suggests how to avoid the danger.

Signal word

Note

Icons used Signal words

Warning of

danger to

persons

Warning of

danger to material

electrical voltage

Warning of a general

danger

Danger!

Warning!

Caution!

Stop!

Warns of impending danger.

Consequences if disregarded:

Death or very severe injuries.

Warns of potential, very hazardous situation.

Possible consequences if disregarded:

Death or very severe injuries.

Warns of potential, hazardous situation.

Possible consequences if disregarded:

Light or minor injuries.

Warns of potential damage to material.

Possible consequences if disregarded:

Damage of the drive system or its environment.

Other notes

2.5 Residual hazards

Operator’s safety

After mains disconnections, the power terminals + and – remain live for

several minutes.

Protection of the device

Cyclic connection and disconnection of the supply voltage at terminals L1, L2

und L3, may overload the internal input current limitation:

Allow at least 1 minute between disconnection and reconnection.

Note!

This note designates general, useful notes.

If you observe it, handling of the power feedback

unit / drive system is made easier.

page 16 ELTROPLAN-REVCON

Page 18

2.6 General instructions

By these information to erectors and users of a plant hints on properties and

directions concerning the power feedback unit are given. These hints are not

entitled to completeness.

Special features in comparison towards a chopper

Unlike a braking resistor a power feedback device isn't a constant sink, but it's

dependent on the momentary characteristics of the supplying net. Commutation

brake downs and voltage-flicker in the net have an considerable effect to the

backward current of the device. In case of a short time voltage brake down the

Safety information

backward current has to rise correspondingly to feedback the demanded power-

amount. Does the level of the supply voltage sink for a longer time, the maxi-

mum feedback power is reduced.

If only one phase fails, the device is able to work on, but the current in the two

remaining conductors will rise up to 150% of the normal level.

ELTROPLAN-REVCON page 17

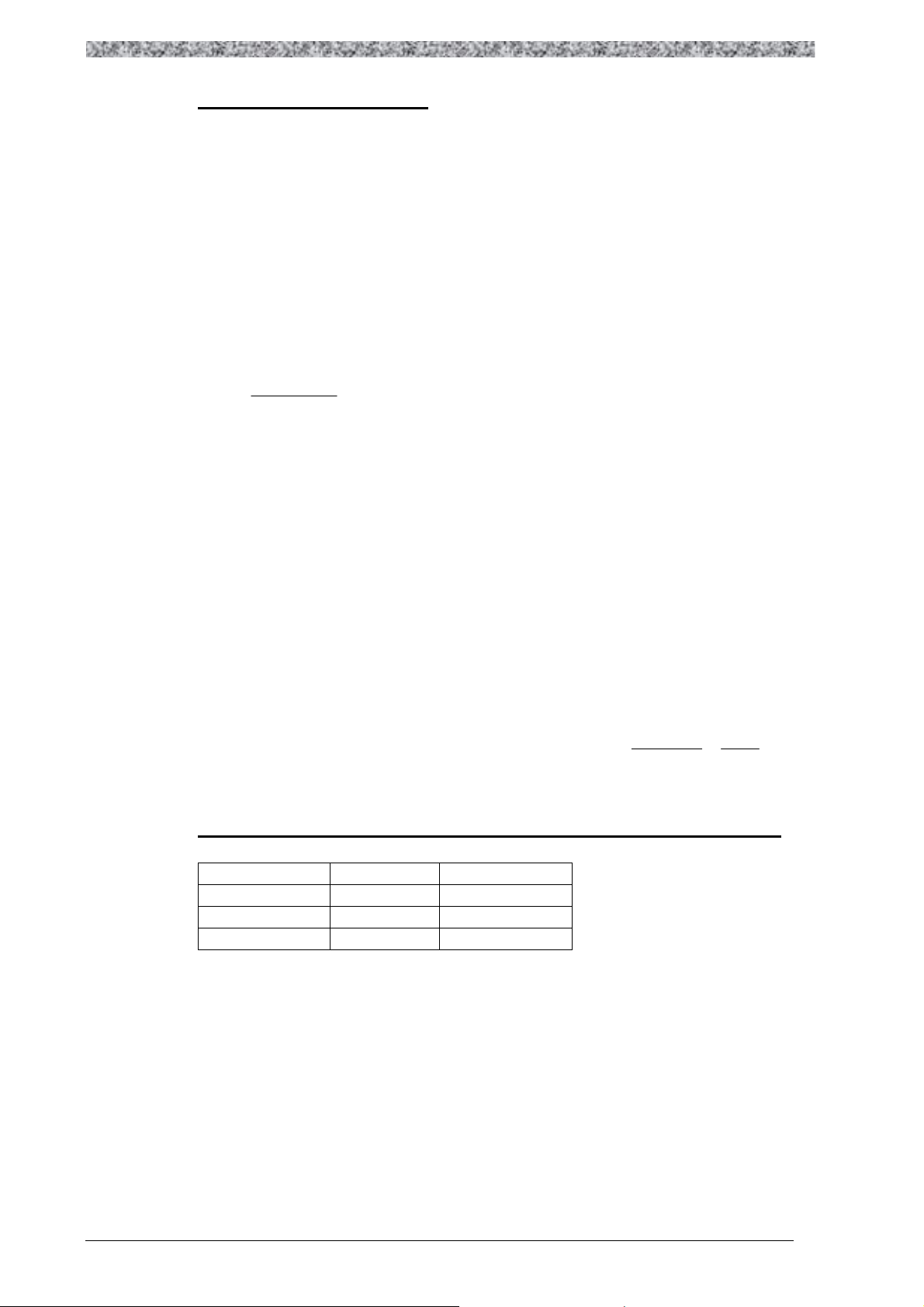

Page 19

(

)

i

REVCON

®

-

type

Power

DC-

capacitance

SVC

7-

45kW

100µF

70-

135kW

200µF

160-200kW

420µF

Safety information

Length of the DC-connection

The maximum inductivity of the DC-connection between output B6 bridge of

the inverter and the power feedback device mustn't exceed a certain level, as

this inductivity inducts an additional voltage to the DC-bus, when the IGBT’s

are switched off . To avoid an overload to the components of the power feed-

back unit, this additional voltage must not exceed 100V. Resulting from this

and other relevant characteristics of the power feedback unit (DC-capacity and

absolute maximum value of the grid current) the maximum inductivity

L

=

max

or equal than the sum of the DC-bus inductivity of the frequency inverter and

the conductor inductivity of the DC connection. The DC-bus inductivity of the

2

UC

∆⋅

GL

2

ˆ

can be calculated. This inductivity always has to be higher

frequency inverter has only to be considered, if it is placed between the inverter

B6 bridge and the power feed-back unit. The cables, which are normally used

for power applications, have an inductance per unit length of about 0,6µ H/m. If

the values of the input capacitance C, the during power backfeeding maximum

allowed rise of the DC-voltage ∆UGL =100V, the top level of the AC-current of

the device (=2xI

DC-bus ´choke L

be calculated with the following equation:

), the inductance per unit length L´ and the inductance of the

eff

are known the maximum longitude of the conductors can

ZKD

2

UC

l

max

∆⋅

=

2

ˆ

Li

⋅

L

ZKDGL

−

′

′

L

Typical capacitance of the DC-connection inside the power feedback unit :

Table 2.6.1

Example:

C=200µF, ∆UGL=100V, i=271A, a=80mm, r=8,5mm, µ0=1,257.10-6 H/m ⇒

l

=26m

max

For longer DC-Bus-wires additional capacitors have to be installed (please get

in contact with our application-department if the occasion arrises).

page 18 ELTROPLAN-REVCON

Page 20

Safety information

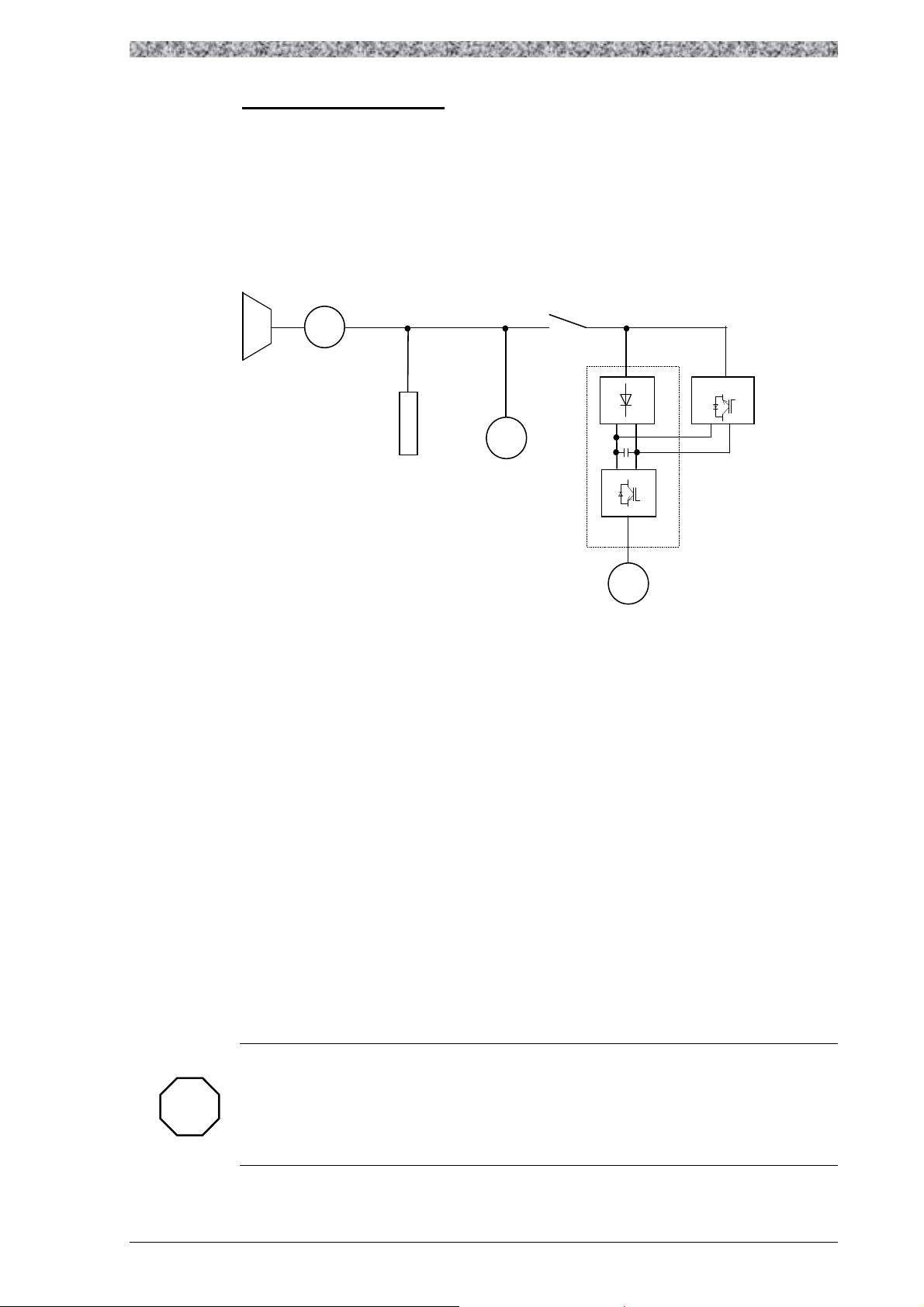

REVCON

0,4kV

G

STOP

Operation on a generator

The usage of a power feedback unit within an island network (e.g. with an

diesel generator) is possible, but there are restrictive regulations concerning the

power limits.

100kVA

R

20kW

M

20kW

FU

M

Figure 2.6.1

Within a network, that is assembled like in figure 2.6.1, there are two addi-

tional restrictions: First the power of the motor connected to the inverter must

be lower than half of the nominal power of the generator. Second the total

amount of the power of the two other loads must be more than double of the

backfeed-power.

If these conditions aren't checked up a change from motory to generatory op-

eration may result in load shocks. These shocks are too dynamic for the voltage

regulator of the generator. The regulator reacts with an overshoot and as a re-

sult of this with an over voltage within the island network.

STOP!

Over voltages may cause serious damages to the connected frequency in-

verter and /or to the power feedback unit and to the other loads.

ELTROPLAN-REVCON page 19

Page 21

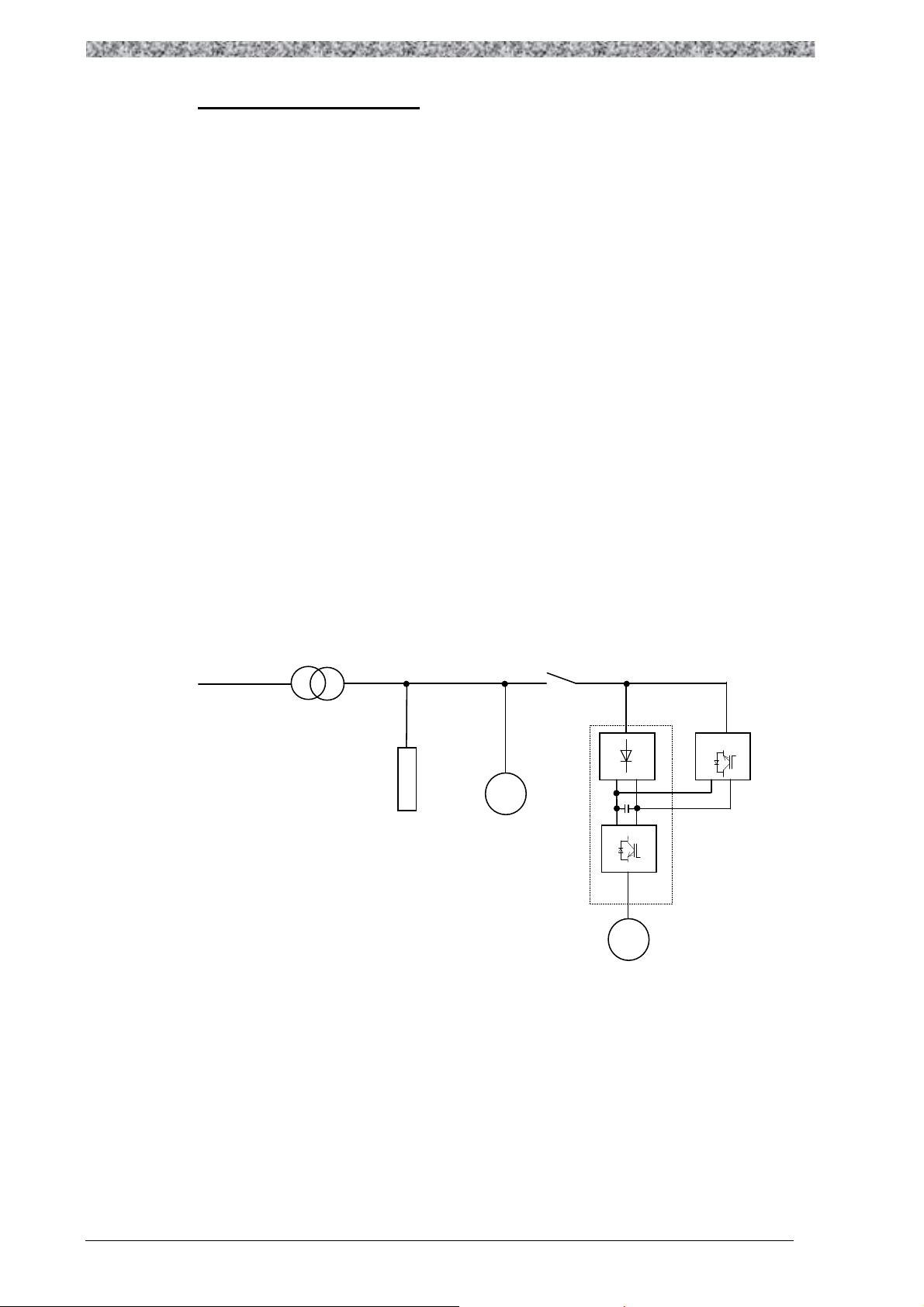

REVCON

Safety information

Operation on a transformer

If only a few loads operate within a network section the connected transformer

must be able to transport the in this section not used power back to the next

voltage level without producing a not allowed voltage increase inside the sec-

tion. Therefore the nominal power of the transformer has to be one and a half

higher than the backfed power out of the section, so that also the harmonic and

reactive components of the current can be transmitted. In the network section

displayed in figure 2.6.2 these conditions are checked up, even if the other

loads are switched off.

Is the backfed power in the order of the nominal power of the transformer, it's

impedance voltage has to be small enough (max. 6%) to limit the voltage in-

crease in the section.

The operation of the power feedback unit in combination with an adjusting

transformer (e.g. in the case of a braked slip-ring induction motor) is only al-

lowed, if the quotient ratio of feedback-power and nominal power is much

smaller than one

10kV

100kVA

Tr

0,4kV

20kW

R

M

20kW

M

FU

60kW

Figure 2.6.2

page 20 ELTROPLAN-REVCON

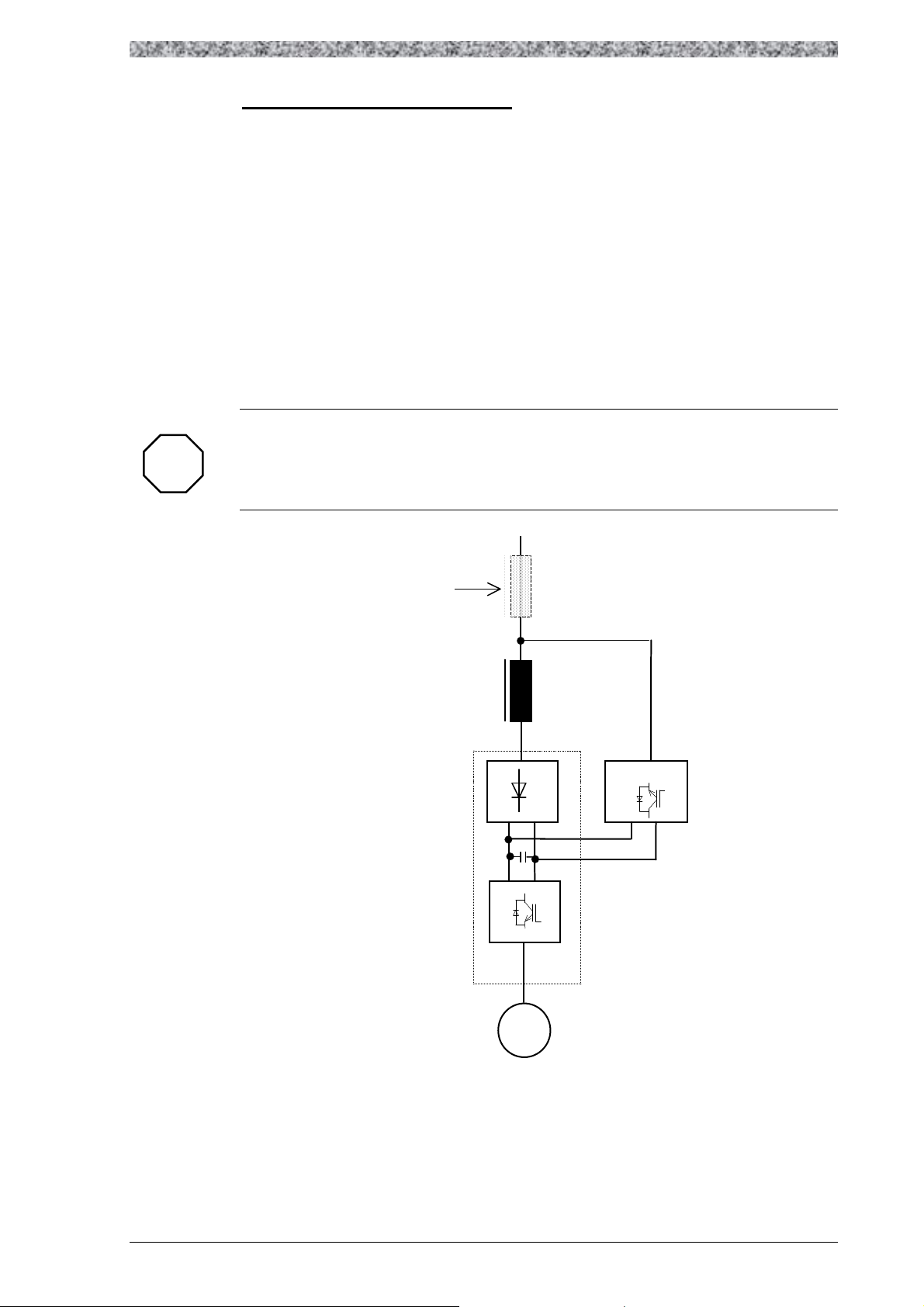

Page 22

Safety information

REVCON

Not allowed!

STOP

Placing of the commutation choke

If the frequency converter is connected to an external commutation choke, the

connection of the power feedback unit has to be done at it's network terminals

(figure 2.6.3). Is the connection done at the load terminals of the commutation

choke it's inductivity prevents the synchronising to the supplying net and the

induction voltage of the choke when it is switched of under load may result in

damages to the power feedback device.

STOP!

Over voltages may cause serious damages to the connected frequency in-

verter and /or to the power feedback unit and to the other loads.

Figure 2.6.3

FU

M

60kW

The same things apply to the also non-admissible pre-connection of further

commutation chokes.

ELTROPLAN-REVCON page 21

Page 23

∆U ∆U ∆U ∆U ∆U ∆U ∆

U

I

REVCON

Safety information

Line and contact resistances

The values of current carrying capacity of conductors refer to the most often

used copper conductors. Concerning to it's higher specific resistance

aluminium conductors must have greater dimensions.

Regardless of which conducting materials is used, the contact terminals of the

conductors have to be low resistive and their number has to be reduced to the

necessary minimum.

Too much or too high resistive terminals may result in a unsafe voltage magni-

fication during the power feedback operation.

Supplying

network

Figure 2.6.4

FU

M

Proceeding from a stable network with e.g. 400V nominal voltage and a back-

ward current of 80A, at a bad made terminal of 100mW a voltage of 8V is

dropped (A good made terminal has got a resistance of ca 1 mW.). During

backfeed operation at seven serial terminals at the net switch there results an

voltage of 456V.

page 22 ELTROPLAN-REVCON

Page 24

STOP

Safety information

STOP!

Over voltages may cause serious damages to the connected frequency in-

verter and /or to the power feedback unit and to the other loads.

Current capacity of copper conductors for frequency inverters and power

feedback operation

conductor cross section

(mm²) per phase

conductor radius

(mm)

fuse

(A)

max. permanent

current (A)

16 2,3 63 46

25 2,8 80 59

35 3,3 100 73

50 4,0 125 90

70 4,7 160 106

95 5,5 200 140

120 6,2 250 206

185 7,7 315 250

2x120 2x6,2 400 300

2x150 2x6,9 500 390

2x185 2x7,7 630 485

3x185 3x7,7 800 570

3x240 3x8,7 1000 740

4x240 4x8,7 1250 920

These values are based on a cable length of 100m and a maximum voltage drop of 5V..

Table 2.6.2

ELTROPLAN-REVCON page 23

Page 25

Supplying network

false

REVCON

Safety information

Connection of further loads

The connection of further loads ( e.g. cabinet ventilation or climatisation)

parallel to the frequency inverter / power feedback unit at a common circuit

breaker like in figure 2.6.5 is not allowed. If it's done nevertheless, in case of

tripping of the circuit breaker the connection to the network ( energy sink and

synchronising element for the power feedback unit) misses. The IGBT's now

switch the DC-voltage directly to the other loads. The resulting nearly rectan-

gular "net"-voltage drives a current through the loads, which level and form

depends on their impedance. Is the power consumption of the loads to small,

the DC-voltage and also the output voltage of the power feedback unit rises

during the backfeed operation. This increased voltage may damage all con-

nected components.

Figure 2.6.5

wrong

FU

M

60kW

M

page 24 ELTROPLAN-REVCON

Page 26

Safety information

Supplying network

REVCON

FFFF

STOP

STOP!

Over voltages may cause serious damages to the connected controller and

/or to the power feedback unit and to the other loads.

Figure 2.6.6

M

FU

FU

M

M

FU

60kW

TIP!

Same things apply to the structure like in figure 2.6.6. Even in this case it is

necessary to place a circuit breaker in each backfeeding current circuit.

ELTROPLAN-REVCON page 25

Page 27

Safety information

Unchoked compensation plants and resonance rise

Compensation plants are used in the centre of the power supply of a company.

Disturbances or damages at these plants have effects on the power supply and

may result in interrupted production processes.

Although this is no longer state of the art, many compensation plants are in op-

eration without any choking. The problems which result from a usage of such

an unchoked compensation plant are manifold:

- direct resonance

- resonance rise

- switching transients or

- impairments of centralized ripple systems

The fact, that a company produces back effects to the power supply is not the

only reason for the creation of resonance. Decisive for the risk, to generate a

resonance is the compensation power at the medium voltage transformer. The

higher this power is, the higher is the risk of resonance. The second important

factor is the harmonic load of the medium voltage level. This harmonic load is

transmitted via the transformer and causes effects on the low voltage level.

Most often the limits were exceeded for the 5th harmonic component.

page 26 ELTROPLAN-REVCON

Page 28

3 Technical data

3.1 Characteristics

• Small compact housing

• Braking power of controller is fed back into mains

• Power range 4kW to 350KW

• Up to 4 units can be paralleled (more on request)

• DC-bus coupling of several controllers possible

• IGBT power modules with high efficiency and high service reliability

• Self synchronising

• Overload protection during backfeeding operation

• Supervision of mains voltage, phase sequence and temperature

Technical data

• High efficiency

• High dynamic braking processes are possible

• User-friendly commissioning – no adjustment necessary

• Including buit in harmonic filter SKS-R

ELTROPLAN-REVCON page 27

Page 29

Technical data

3.2 General data / application conditions

Area Values

Permissible temperature range* During transport of the unit: -25°C...+70°C (to VDE 0160)

During storage of the unit: -25°C...+55°C (to VDE 0160)

During operation of the unit: 5°C... +40°C without power derating

40°C...+55°C with power derating

Humidity class* Humidity class F without condensation ( 5% - 85% relative humidity)

Installation height h*

H ≤ 1000 m a.m.s.l. without power derating

1000 m a.m.s.l. < h 4000 m a.m.s.l. with power derating

Air pressure* 86kPa – 106kPa to VDE0875 part 11 and prEN55082

Degree of pollution VDE 0110 Part 2 degree 2

Noise immunity EN 61000-4-4 degree 4

EN 61000-4-2 degree 3

EN 50082-2 criterion A

Insulation strength Overvoltage category III according to VDE 0110

Packaging DIN 55468 for transport packaging materials

Type of protection IP 20

Approvals CE: Low-Voltage Directive

*climatic conditions according to class 3K3 (EN 50178 Part 6.1)

page 28 ELTROPLAN-REVCON

Page 30

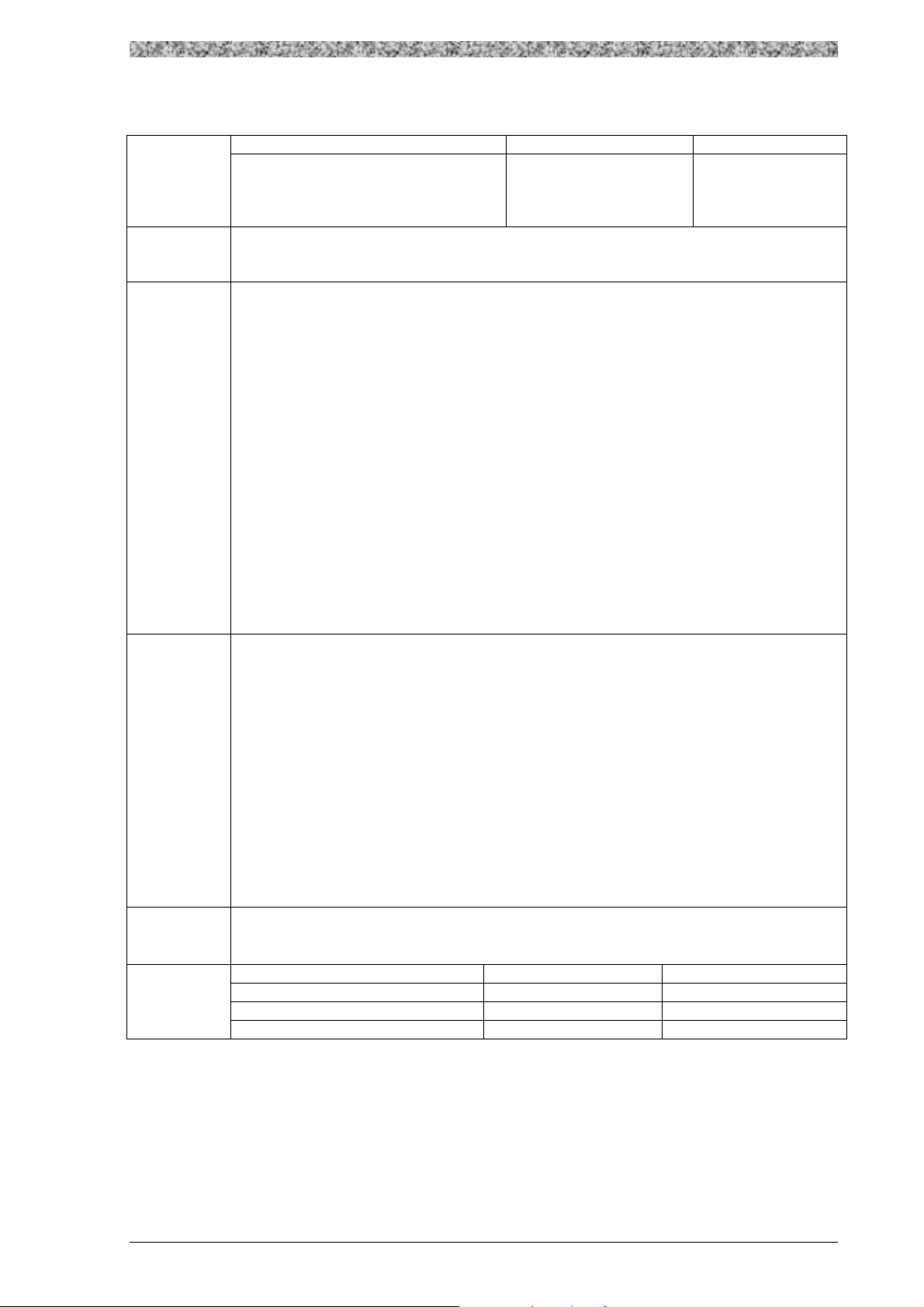

3.3 Rated data

3.3.1 Power feedback unit

REVCON type

Nominal range of the

interlinked mains voltage

Tolerance of the

interlinked mains voltage

Mains frequency

Overload capability

SVC(S) 400V

UN[V]

UN[V]

fN[Hz]

Technical data

380 ≤ UN ≤ 415

342 ≤ UN ≤ 456

50 ± 2 %

ca. 1,2 x Irms (dynamic)

Efficiency

Power factor*3

Total harmonic distortion*

3

η[%]

cosϕ

THDI

Ca. 96 % (4 % therm. losses)

∼ 1

< 16%

[%]

*1 need of airflow

m³ / h

a) SVCS 7-400, 13-400, 22-400, : 200

b) SVCS 33-400 : 350

Power derating

[%/K]

[%/m]

40°C < Ta < 55°C ⇒ 3%/K

1000m a.m.s.l.< h ≤4000m a.m.s.l. ⇒ 5%/1000m

Table 3.3.1.1

*1 depending on the size of the unit ( nominal power and nominal voltage)

2

*

3

*

alternative case-type with minor changed dimensions

at nominal current

ELTROPLAN-REVCON page 29

Page 31

FFFF

Technical data

3.3.2 Current load

Nominal voltage 400V

AC

REVCON ® - Typ

SVCS 7-400-1-0 11 A 13 A

SVCS 13-400-1-0 20 A 24 A

SVCS 22-400-1-0 32 A 38 A

SVCS 33-400-1-0 48 A 58 A

Table 3.3.2.1

max. current I

rms

NOTE!

To calculate the correct value of regenerating power it is necessary to note, that

the real momentary regenerating power is dependent on the real existing main

circuit voltage at any time. To calculate the regenerative power the following

DC

max. current I

formula should be used:

P = U

eff

· I

· √3 · cosϕϕϕϕ (during regenerative operation : cosϕ = 1)

eff

The maximum possible regenerative power is calculated based on the momen-

tary rms mains voltage and the maximum rms current of the respective device.

Example:

Model SVC(S) 45 with rated feedback power of 45kW , maximum rated rms

current 65A (refer to technical data), nominal mesh voltage rating e.g. 400V.

From that results: P=400V x 65A x √3=45033W, that’s about 45,0kW

If the momentary rms mains voltage is only 395V or even lower for a short

time, the maximum possible regenerative power is reduced as well:

P = 395V x·65A x √3 = 44470W, that’s about 44,5kW.

page 30 ELTROPLAN-REVCON

Page 32

Technical data

3.3.3 Allowed operating data with max. braking power

− Devices of product line REVCON® SVCS 7-XXX-1-... without forced cooling have an al-

lowed operating duration of 100%.

− Devices of product line REVCON® SVCS 13-XXX-1-... without forced cooling have an

allowed operating duration of 50% (referring to a cycle time of 10 min.). With forced cool-

ing they have an allowed operating duration of 100%.

− Devices of product line REVCON® SVCS 22-XXX-1-... with forced cooling have an al-

lowed switch on duration time of 50% (referring to a cycle time of 10 min.).

− For the devices from product line REVCON® SVCS 33-XXX-1-... the following thermal

limited load graphs are valid.

ELTROPLAN-REVCON page 31

Page 33

REVCON

Technical data

3.3.3.1 Thermal limited load graphs

By means of these thermal limited load graphs you can find out the max. switch-on-time depending on the needed braking power. The curves are valid for a max. cooling air temperature

of 35°C (95°F).

Example of an application:

10

min

braking

time

100 % constant power: 26 kW

9

8

7

SV(C

45-XXX-1-...

))))

33 kW

6

5

4

2

3

1

2

1

2

0

0 1 2 3 4 5 6 7 8 9 10 11

Diagram

3.3.3.1.1

1

intermission time

45 kW

min

Example : necessary braking power : 33 kW

braking duration : 2 min.

time between two brakes : 5 min.

Evaluation: In this case the point of intersection of braking time and intermission time is

below

the thermal limited power graph in the allowed area (with forced cooling).

Remark: Without forced cooling, the intermission time is 8 minutes.

Example : necessary braking power : 45 kW

braking duration : 3 min.

time between two brakes : 3 min.

Evaluation: In this case the point of intersection of braking time and intermission time is

above

the thermal limited power graph. That means this operation cycle is not allowed.

Remark: In case of an intermission time of e.g. 3,5 min. this operation cycle would be

allowed again.

page 32 ELTROPLAN-REVCON

Page 34

Thermal limited load graphs:

REVCON

SV(C) 33-XXX-1-...

Technical data

10

min

100 % constant power with fan: 21,5 kW

9

braking

time

8

7

6

5

4

3

2

1

0

0 1 2 3 4 5 6 7 8 9 10 11

Diagram 3.3.3.1.2

27 kW with fan

33 kW with fan

27 kW without fan

33 kW without fan

intermission time

min

ELTROPLAN-REVCON page 33

Page 35

SVCS

7-

400-1-0 Siba 50 179 06 20A 660V 10*38mm

CS M5

25mm²

SVCS

13-

400-1-0 Siba 50 124 06 30A 690 V 14x51mm

CS M6

35mm²

SVCS

22-

400-1-0 Siba 50 124 06 50A 690 V 14x51mm

CS M6

35mm²

SVCS

33-

400-1-0 Siba 50 140 06 80A 690 V 22x58mm

CS M6

35mm²

Technical data

3.3.4 Fuses and wire cross sections

The power feedback unit is connected to mains supply via the terminals L1-L3 at the

commutation choke and PE at the heatsink. Mains fuses must be designed according to the

current load capacity of the supply wire.

3.3.4.1 Series fuses

Semiconductor fuses have to be connected in series with the power feedback unit as following

tables (refer to figure 4.4.1.1.1 position 1). The listed manufacturer is recommended, but natu-

rally also comparative fuses of other manufacturer (e.g. Jean Müller, Ferraz, Bussmann) are

suitable.

REVCON ® - type

max. fuse AC

Table 3.3.4.1.1

ES ≅ end sleeve for strands

CS ≅ cable socket with drill hole for M6 / M8 / M10

* at the copper lug of the commutation choke.

** at the fuse holder respective disconnector

Connection terminal and max.

cross section of the supply line *

page 34 ELTROPLAN-REVCON

Page 36

Technical data

SVCS

7-

400-1-0 Siba 50 124 06

2

0A 690 V 14x51mm

ES 10mm²

SVCS

13-

400-1-0 Siba 50 124 06 50A 690 V 14x51mm

ES 10mm²

SVCS

22-

400-1-0 Siba 50 140 06 63A 690 V 22x58mm

ES 35mm²

SVCS

33-

400-1-0 Siba 50 140 06 80A 690 V 22x58mm

ES 35mm²

STOP

3.3.4.2 Internal fuses

The power feedback unit is equipped with semiconductor fuses according to the following ta-

bles (refer to figure 4.4.1.1.1. position 7). The listed manufacturer is recommended, but natu-

rally also comparative fuses of other manufacturer (e.g. Jean Müller, Ferraz, Bussmann) are

suitable.

Table 3.3.4.2.2

REVCON ® - type

Stop!

If semiconductor fuses (figure 4.4.1.1.1 position 1 and 7) trip, please get in

contact with ELTROPLAN-REVCON immediately, as possibly further protec-

tive measures have tripped. If internal fuses are exchanged, please verify, that

only the original types are used for replacement.

Warning!

Before replacing a fuse, switch off all voltages!

DC-fuses

(use fast acting semiconductor fuses only)

Connection terminal and max. cross

section of the supply line **

ELTROPLAN-REVCON page 35

Page 37

Technical data

3.3.5 RFI-filter

To observe the EMC-rules. In accordance with figure 4.4.1.1.1 a radio fre-

quency interferences filter class A can be preconceived to the REVCON unit.

In tables 3.3.5.1 to 3.3.5.5 the power feedback units are assigned to the corre-

sponding RFI-filter types.

REVCON ® - type

SVC(S) 7-400-1-0 RF-SVC 7-400 1

SVC(S) 13-400-1-0 RF-SVC 13-400 1

SVC(S) 22-400-1-0 RF-SVC 22-400 1

SVC(S) 33-400-1-0 RF-SVC 33-400 1

Table 3.3.5.1

Order designation for filter

Case type

3.3.6 SKS-module

To decrease the low frequency harmonic back effects to mains a filter module

REVCON SKS-R is built into the power feedback unit .

page 36 ELTROPLAN-REVCON

Page 38

4 Installation

4.1 Mechanical installation

4.1.1 Important hints

• Use the power feedback units as build-in devices only!

• Observe free spaces!

- Several power feedback units in one cabinet may be installed next to

each other without spacing.

- Keep a horizontal distance of at least 70mm to other components and to

the cabinet walls.

Installation

- Keep a vertical distance of at least 150mm to other components and to

the cabinet walls.

• Ensure that there are no obstacles in the way of the cooling air input and output.

• If the cooling air is polluted (dust, dirt swirl, grease, aggressive gas ) so that the

function of the power feedback unit may be impeded

- Take sufficient countermeasures, e.g. separate cooling air, mounting of

air filters, periodical cleaning.

• Do not exceed the ambient temperature permissible during operation.

Provided mounting position

The power feedback unit has been designed for vertical wall mounting (± 15°)

only. Mounting is allowed only on a flat surface without using any kind of spac-

ers. This kind of mounting is necessary to guarantee the right way for the cooling

air. A power loss of 3 % from the max. nominal power rating has to be calculated.

Air-temperature may not exceed 40 °C near the unit. Air-in- and air-out-openings

at the top and the bottom of the unit may not be concealed by installation materials

such as cable ducts or other equipment. Keep a distance of min. 15 cm to the air-

in- and air-out-openings and a distance of min. 7 cm to beside mounted parts or

cabinet-walls.

ELTROPLAN-REVCON page 37

Page 39

Installation

4.2 Dimensions

4.2.1 Power feedback unit

REVCON ®

Type

SVCS 7-400-1-0 500 - 245 272 315 - 260 80 -- -- 25

SVCS 13-400-1-0 500 - 245 272 315 - 260 80 -- -- 30

SVCS 22-400-1-0 500 - 245 272 315 - 260 80 -- -- 35

SVCS 33-400-1-0 700 - 245 272 315 - 260 80 -- -- 40

Table 4.2.1.2

.

H

(mm)

H1

(mm)

H2

(mm)

B

(mm)

B1

(mm)

T

(mm)

T1

(mm)

e

(mm)

f1

(mm)

f2

(mm)

f3

(mm)

weight

(kg)

page 38 ELTROPLAN-REVCON

Page 40

4.2.1.1 Dimension diagrams

1. SVCS 7-400-... to SVCS 22-400...

Installation

ELTROPLAN-REVCON page 39

Page 41

Installation

2. SVCS 33-400-...

f2

Cooling airflow out

f2

Cooling airflow in

REVCON

H

7

f1

all cableinputs from bottom

B

B

f

1

T

e

1

page 40 ELTROPLAN-REVCON

Page 42

Installation

4.2.2 RFI-filters

The radio interference filter of case-type 1 and 2 are mounted in footprint-housings, which

could be placed between cabinet-wall and power feedback unit.

The radio interference filter of case-type 3 and 4 are mounted in housings, which should be

placed beside the power feedback unit.

The power feedback units were fixed with screws M6 , the RFI-filter with screws M8.

4.2.2.1 Dimension diagrams

1. Diagram Case 1

ELTROPLAN-REVCON page 41

Page 43

Installation

2. Diagram Case 2

3. Diagram Case 3

page 42 ELTROPLAN-REVCON

Page 44

4.3 Electrical installation

STOP

4.3.1 Operator’s safety

Danger!

After mains disconnection, the DC-bus terminals of the power feedback unit

remain live for several minutes! The exact time, till this voltage has decreased

to a not dangerous value is dependent on the used controller and has to run

down before any service operations or similar activities are started.

The exact values have to be cross checked with the documentation of the con-

troller.

Installation

Replace defective fuses by the regular types (chapter 3.3.3.2) only and without

any live voltage.

4.3.2 Protection of the power feedback unit

Stop!

The power feedback units contain electrostatic sensitive devices (ESSD).

During working at the terminals the personnel has to observe the rules of the

international standard IEC 747-1 chapter 9. Basically before starting the works

the personnel has to free itself from electrostatic voltages:

Discharge yourself by touching the PE-screw of the housing or another

grounded surface in the cabinet.

ELTROPLAN-REVCON page 43

Page 45

Installation

4.3.3 Mains types / Mains characteristics

Observe the restrictions in accordance to the respective mains type!

If you want to run power feedback units at mains types, which are not listed in

the table below please consult our technicians.

VDE conformal

mains type

With grounded star point

Operation of the

power feedback unit

Allowed

With isolated star point After consulting the manufacturer and

possible modification of the unit allowed

With grounded active wire After consulting the manufacturer allowed

Table 4.3.3.1

4.3.4 Specifications of the used wires

• The used wires have to be compliant with the specifications on site ( e.g.

UL or UL-c)

• The regulations about the minimum cross section of PE-wires have to be

observed!

• The effectiveness of a screened wire is dependant on

Remark

Observe the technical

data of the unit

- a good screen connection

- a low screening impedance:

Use screens tin- or nickel-plated copper screens only!

- the swamp factor of the screen mesh:

at least 70% to 80% with a swamp angle of 90°

• Protect the mains wires of the power feedback unit with the provided wire

protection fuses.

page 44 ELTROPLAN-REVCON

Page 46

4.4 Connection

STOP

After removing the lateral screws and the cover of the housing the connection

terminals are accessible. The wires should be passed through the metal glands

in the flange sheet.

Stop!

When picking up the cover don’t damage the wires, which lead to the display!

4.4.1 Power connection

Fusing (also refer to chapter 3.3.4)

Installation

• The specifications of chapter 3.3.4 (fuses and wire cross sections) are rec-

ommendations and refer to the operation

– in cabinets and machines

– installation in cable ducts

– max. ambient temperature +40°C.

• When choosing the cross section of the wire the voltage drop under load

should be considered (refer to chapter 3.4)

• Protection of the wires at mains side (L1, L2, L3):

– by commercial wire protection fuses.

– fuses have to be compliant with the relevant standards on site.

– rated voltage of the fuses have to be compliant with the voltage on site.

• Protection of the power feedback unit at mains side (L1, L2, L3):

– by commercial semiconductor fuses.

– fuses have to be compliant with the relevant standards on site.

– rated voltage of the fuses have to be compliant with the voltage on site.

• Protection of the power feedback unit at DC side (+UG, -UG):

– fuses are part of the power feedback unit (refer to chapter 3.3.4.2).

The erector/user of the plant bears the responsibility for the observance of

further relevant standards (e.g.: VDE 0113, VDE 0289 and so on).

ELTROPLAN-REVCON page 45

Page 47

FFFF

Installation

Connection

• All connections should be as short and low-impedance as possible.

• For the observance of the EMC-guideline (in accordance to actual stan-

dards like VDE 0160 and EN 50178) screened wires have to be used.

• Connect the mains supply wires at the terminals L1, L2, L3 (at the mains

choke) of the power feedback unit. Only three phase connection is allowed.

• A defined phase sequence (clockwise rotation field) must be observed at

the main circuit connection of the power unit. The power feedback unit is

equipped with a phase-sequence control unit. In case of an incorrect rota-

tion field an error message is displayed via LED as follows: "rotation field

failure" or "phase failure". In this case two phases, connected to the power

unit, have to be exchanged.

• Connect the earthing wire of the supply cables to the earthing screw of the

power feedback unit.

• The wires for the DC-bus coupling between controller and power feedback

unit have to be connected to the DC-fuse holder. It is absolutely necessary

to observe the correct polarity.

Tipp!

Interchanging of + (PLUS) and – (MINUS) avoids the correct function of the

power feedback unit.

page 46 ELTROPLAN-REVCON

Page 48

4.4.1.1 Wiring schematic

Controller

radio inter

-

ference filter

3

PE U V W

L1 L2 L3

c

ontrol

8 11 12

X2

X2

1

operation

+24 V

-

OFF

RESET

7

4

5

8

PE

N

L3

230V

L1

N

L1

L2

1

2

3

Installation

6

1

N

PE

L1 L2 L3

+

REVCON SVCS...(type)

- -

Error

2

relay

4

ext.

+

M

~

Figure 4.4.1.1.1 Wiring schematic of the power feedback unit REVCON SVC(S) and one ore more

Remark:

This is an wiring example. Special features of a application (e.g. installation of a PLC) may

require modifications of the wiring of the terminals X2.1 ... X2.12 .

ELTROPLAN-REVCON page 47

controllers

Page 49

Installation

Legend for figure 4.4.1.1.1 (REVCON

SVCS)

1. Fusing in accordance with controller manual.

2. It is not allowed to connect any other devices except the frequency inverter and the

power feedback unit behind the main magnetic switch.

Danger

If this is not observed, you take the risk that, in the case of switching off the

mains during feed back the power, the voltage in that sector may rise up to a

dangerous level. This may destroy the connected devices and perhaps also the

inverter and/or the power feedback unit. To avoid such situation, the power

feedback unit is equipped with an overvoltage switch off, but nevertheless this

hint should be observed!

3. Fusing in accordance with power feedback unit manual. This may be left our, if at

position 1 semiconductor fuses or full range fuses are used and if after 1 the cross

section of the wires is not reduced.

4. Cross section in accordance with the relevant VDE-rules.

5. Fusing (230 V supply, <2A current input) in accordance with DIN VDE 0298 or

short circuit proof wiring.

6. Design of the mains choke in accordance with controller manual (possibly not

applicable, if already installed inside the controller).

7. At these terminals one ore more controllers (even with different power ratings)

may be attached, like it shown in figure 4.5.1. Even if several controllers are at-

tached, the wires have to be as short and low impedance as possible!

8. The „ON“ or „RESET“ signal may be initiated via terminals 9 and 10 or 11 and 12:

Terminals 9 and 10: potential free contact (short time contact)

Terminals 11 and 12: positive pulse (12-24 V DC); practicable e.g. via PLC

(terminal 11 +, terminal 12 -).

page 48 ELTROPLAN-REVCON

Page 50

Installation

4.4.2 Fan supply

Some power feedback units are equipped with two terminals (blue terminal =

neutral [N] , grey fuse terminal = phase [L]) for the supply of the internal

fan(s). The fuse inside the fuse terminal is installed for internal wire protection

and of the following type 2A medium 500V 5x30mm.

4.4.3 Control wires

• Connect the control wires to the terminal row X2 at the control board of

the power feedback unit.

• Don’t parallel control wires to interfering power wires.

• Connect the screening of the control wires with an as big as possible sur-

face to the metal cable glands of the flange.

4.4.4 Control functions

The control terminal strip is placed on the control board and is indicated with

X2. It is fitted with a plug-in device for easy handling (see figure 4.4.4.2).

The control board must always be designed for the respective main circuit volt-

age. Therefore the main circuit voltage (230 V, 380 V - 415 V, 440 V - 480 V,

500 V or 690 V) must be declared with every order. This is also necessary for a

possible exchange of the device.

From the control terminal strip the operating condition or rather the collective

error can be connected to extern. There is also the possibility to execute the ex-

ternal reset or the switch-functions and to connect them with the controller or

the PLC.

ELTROPLAN-REVCON page 49

Page 51

X1

X2 X4

X3 X5

X5

X8

Installation

Space diagram of the control board REV 1.4.X

J4

terminal X3

connection to

driver board

terminal X5, X8

option

TR1

TR6

L4

TR4

J5 J3

J6

REVCO N

V. 1.4.3

J7

J8

TR2

J1

LD5

LD3

LD4

LD2

LD1

TR3

TR5

terminal X1

synchronisation to

mains supply

Figure 4.4.4.1

page 50 ELTROPLAN-REVCON

terminal X2

terminal X4

connection to

type of

control board

(example)

signalling board

LED-messages

green: operation

1. red: phase failure

2. red: U

orange: overtemperature

yellow: collective error

/ overcurrent

CE

ext. messages

and controlling

Page 52

Terminal usage:

8

external

OFF

ON/RESET

terminal 5 and 6 intern connected

to the temperature supervision

collective error

relay

X2

1

2

3

4

5

6

7

Installation

9

10

11

12

Figure 4.4.4.2

Terminals 1-4 (refer to figure 4.4.4.2)

These terminals are contacted to two potential free (SELV) relay contacts (one

NOC and one NCC) with a maximum current load of 5 A AC or 3 A DC. It is

not allowed to connect other voltage types than SELV!

In figure 4.4.4.2 the relay is displayed in rest position.

The relay toggles, if:

+

-

ELTROPLAN-REVCON page 51

1.) power supply is o.k.,

2.) no error present,

and after perhaps an ON-signal has been released.

If an OFF-signal has been released, an collective error is display as the relay

toggles.

Page 53

Installation

Terminals 5 and 6

These terminals are already used for the internal temperature supervision of the

heat sink.

Terminals 7 and 8

(use screened wires only, max length)

OFF-signal

These terminals may be used for an external OFF-signal (NOC, short time

contact) to stop the power feedback unit.

Note!

The OFF-signal stops the backfeeding immediately. If this is done in regen

mode, the controller would trip because of too high DC-bus voltage right

afterwards.

Terminal 11 and 12

(used screened wires only)

These terminals may be used for an external ON-signal (external voltage 12 –

24V DC [e.g. from PLC], short time pulse) to start / reset the power feedback

unit.

(connect „Plus“ to terminal 11, „Minus“ to terminal 12)

page 52 ELTROPLAN-REVCON

Page 54

4.5 Application example

Installation

figure 4.5.1

Within greater plants several power feedback units may be coupled. Figure

4.5.1 shows an example of a windage plant with some possible combinations.

The operation of several inverters at one common DC-bus allows to reduce the

amount of power feedback units. On the other hand several power feedback

units may be coupled to transmit more power. It's also possible to drive several

motors at one inverter, as they react, seen from the DC-bus (and that's, what the

power feedback unit sees), like one big motor.

To proportion such a plant it is important to look at the worst case. The maxi-

mum feedback power of the power feedback unit has to be higher as or , at a

minimum, equal to the total amount of the braking power of the connected mo-

tors.

ELTROPLAN-REVCON page 53

Page 55

•

•

•

•

•

Installation

4.6 Installation of a power feedback unit in a

CE-typical drive system

General

Assembly

Filters

Screening

Earthing

The user is responsible for the compliance of his application with the EC directives.

- If you observe the following measure you can be sure that the drive system will not

cause any power-feedback-unit-caused EMC problems, i.e. comply with the EMC

Directive when running the machine.

- If devices which do not comply with the CE requirement concerning noise immunity

EN 500082-2 are operated close to the power feedback unit, these devices may be interfered electromagnetically by the power feedback units.

Connect the power feedback unit and the RFI-filter to the grounded mounting plate with a

wire of large cross section as possible:

– Mounting plates with conductive surfaces (zinc-coated or stainless steel) allow per-

manent contact.

– Varnished boards should not be used for installation in accordance with EMC.

• If you use several mounting plates:

– Connect as much surface of the mounting plates as possible (e.g. with copper bands)

• Ensure the separation of power and control cables.

• Cable guides as close as possible to the reference potential. Unguided cables have the same

effect as aerials.

Use RFI filters which are assigned to the power feedback unit.

RFI filters reduce impermissible high frequency interference to a permissible value.

Metallic cable glands ensure a big-surface connection between screen and housing

• If the screened wire are interrupted at relays or terminals:

- Connect the screens of the wires with a big surface to the mounting plate.

• If the mains wires between RFI-filter and power feedback unit are longer than 300mm:

- Use screened mains wires

- Connect the screen direct at the controller / power feedback unit and at the RFI-filter to

the mounting plate.

• Screen the control wires:

- Connect the screens on the shortest possible way to their terminals.

All metallic conduction components (power feedback unit, controller,

RFI-filter) have to be connected to one common earthing point (PE-bus bar).

• Observe the in the safety guidelines defined minimum cross sections:

- For EMC not the cross section, but the surface of a wire and the contact to the mount-

ing plate is important for the function.

page 54 ELTROPLAN-REVCON

Page 56

Installation

Power feedback units are electrical units for usage in industrial and commercial

plants. In accordance with the EMC guideline 89/336/EEC it is not obligate to

mark these units, as in the sense of the EMC guideline and the EMC law they

are components to be mounted by an competent electromechanical engineer

and cannot be used stand alone. The proof of the observance of the protective

aims of the EMC guideline has to be carried out by the erector / user of the ma-

chine / plant. If the by ELTROPLAN-REVCON released RFI-filters are used

and the following measures and installation guidelines are observed, the adher-

ence to the prescribed data is cleared.

In combination with the related RFI-filter the power feedback unit has been de-

signed for the usage in ambients of the limit class „A“ („B“ on request).

Definition in accordance with basic standard:

• EN50081-2 for emission

• EN50082-2 for immision

4.6.1 Installation

Appropriate design of pant and cabinet.

To avoid noise incoupling lay

a) mains/supply wires

b) motor wires of controllers / servo amplifiers

c) control- and data wires (small voltage range < 48 V)

with a distance of at least 15 cm between each other.

To obtain low resistive HF-connections, grounding, screening and other metal-

lic connections (e. g. mounting plates, mounted units) have to be done with a as

big as possible surface to metallic ground. Use grounding and potential equali-

sation wires with as big cross section as possible (min. 10mm²) or thick

grounding tapes.

ELTROPLAN-REVCON page 55

Page 57

Installation

Use copper or tinned copper screened wires only, as steel screened wires are

not suitable for high frequency applications. Connect the screen with metal

clamps or metal glands to the equalisation bars or PE-connections. Don’t

elonger the screen with single wires!

If external RFI-filters are use, these have to be mounted not more than 30cm

away from the noise source and with a very good, low resistive based contact.

Inductive switching units (relay, magnetic contactor and so on) have to be

equipped with varistors, RC-circuits or suppressor diodes always.

All connections have to be as short as possible and must lay as close to the