Page 1

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Operating instructions filter module REVCON® RHF

Power range 4 ... 440kW

Nominal voltage 380V, 400V, 460V

500V, 600V, 690V

Issue 17/03

Page 2

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Contents

1 Important information .................................................................................. 3

1.1 About the operating instructions ..................................................................................... 3

1.2 Uses terms and definitions ............................................................................................... 3

1.3 SI units and symbols.......................................................................................................... 4

1.4 Unit designation ................................................................................................................ 5

1.5 Legal regulations ............................................................................................................... 6

1.6 Scope of supply ................................................................................................................. 7

2 Safety instructions ........................................................................................ 8

2.1 Layout of the safety instructions ...................................................................................... 9

2.2 General safety guidelines................................................................................................ 10

2.3 For the safety responsible persons ................................................................................. 12

2.4 Specification of the used wires ....................................................................................... 13

2.5 Remaining danger ........................................................................................................... 13

3 Introduction into the subject harmonics ......................................................14

3.1 The effect of harmonics in a power distribution system ................................................ 14

3.2 The negative effect of harmonics is twofold .................................................................. 15

3.3 Harmonic limitation standards and requirements ......................................................... 15

3.4 Harmonic Mitigation ....................................................................................................... 19

4 Introduction into the subject filter modules.................................................20

4.1 Function principle REVCON RHF ..................................................................................... 20

4.2 Harmonic line filter for frequency converters ................................................................ 25

5 EU- directives / Declaration of conformity ...................................................27

5.1 What is the purpose of EU-directives? ........................................................................... 27

5.2 What is the meaning of the CE- marking? ...................................................................... 27

5.3 EG-directive low voltage ................................................................................................. 27

5.4 Standards and permission .............................................................................................. 28

6 Selection of the right filter module and technical data .................................29

6.1 Calculation ...................................................................................................................... 29

6.2 Worked sample ............................................................................................................... 30

6.3 Characteristics ................................................................................................................. 31

6.4 General Data / Operation conditions ............................................................................. 32

6.5 Rating values ................................................................................................................... 34

6.6 Item numbers and ampacity RHF ................................................................................... 35

6.7 Cable cross section .......................................................................................................... 39

6.8 General information ....................................................................................................... 39

6.9 Electrical operating conditions RHF ................................................................................ 40

6.10 Allocation of the fans ...................................................................................................... 47

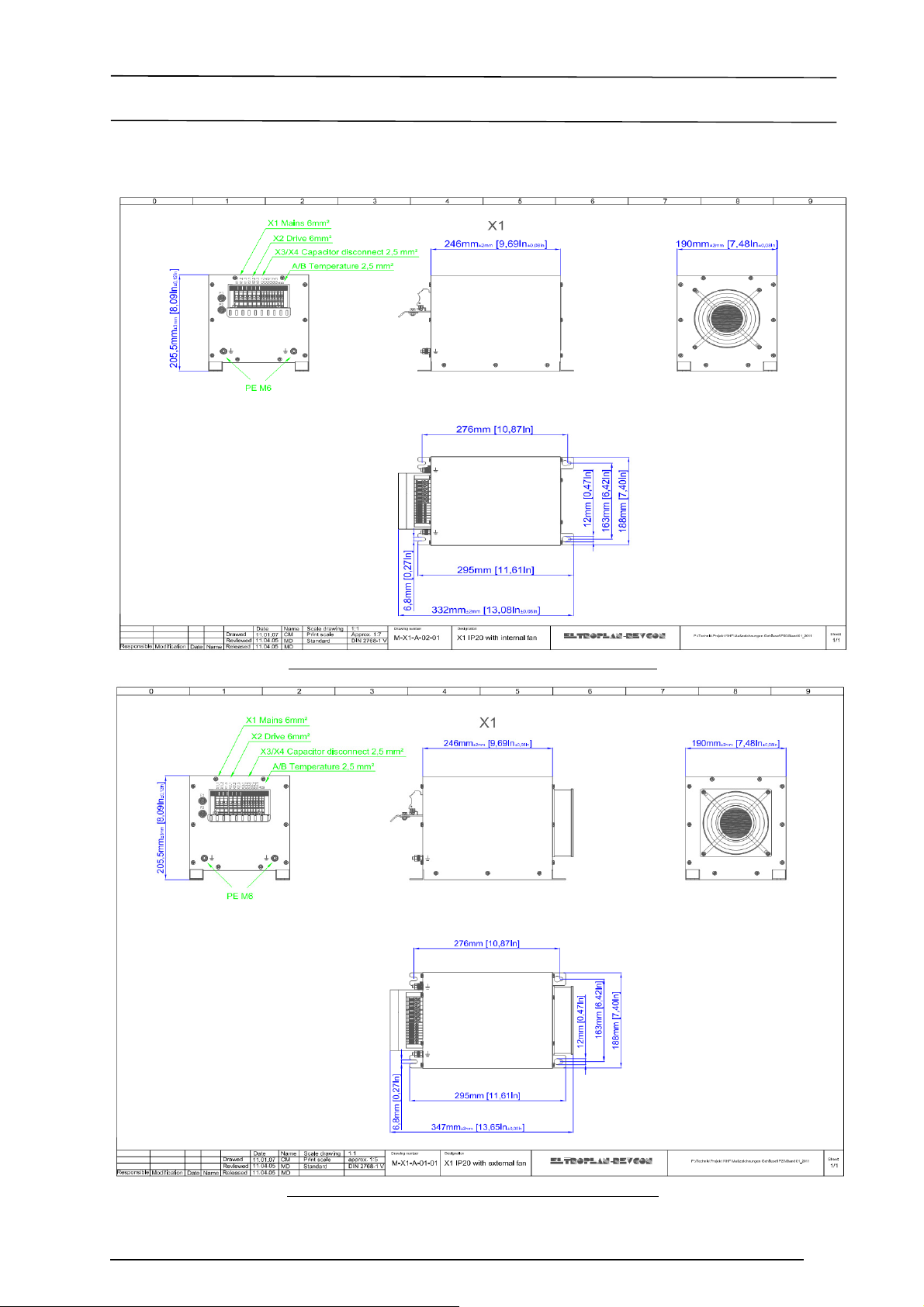

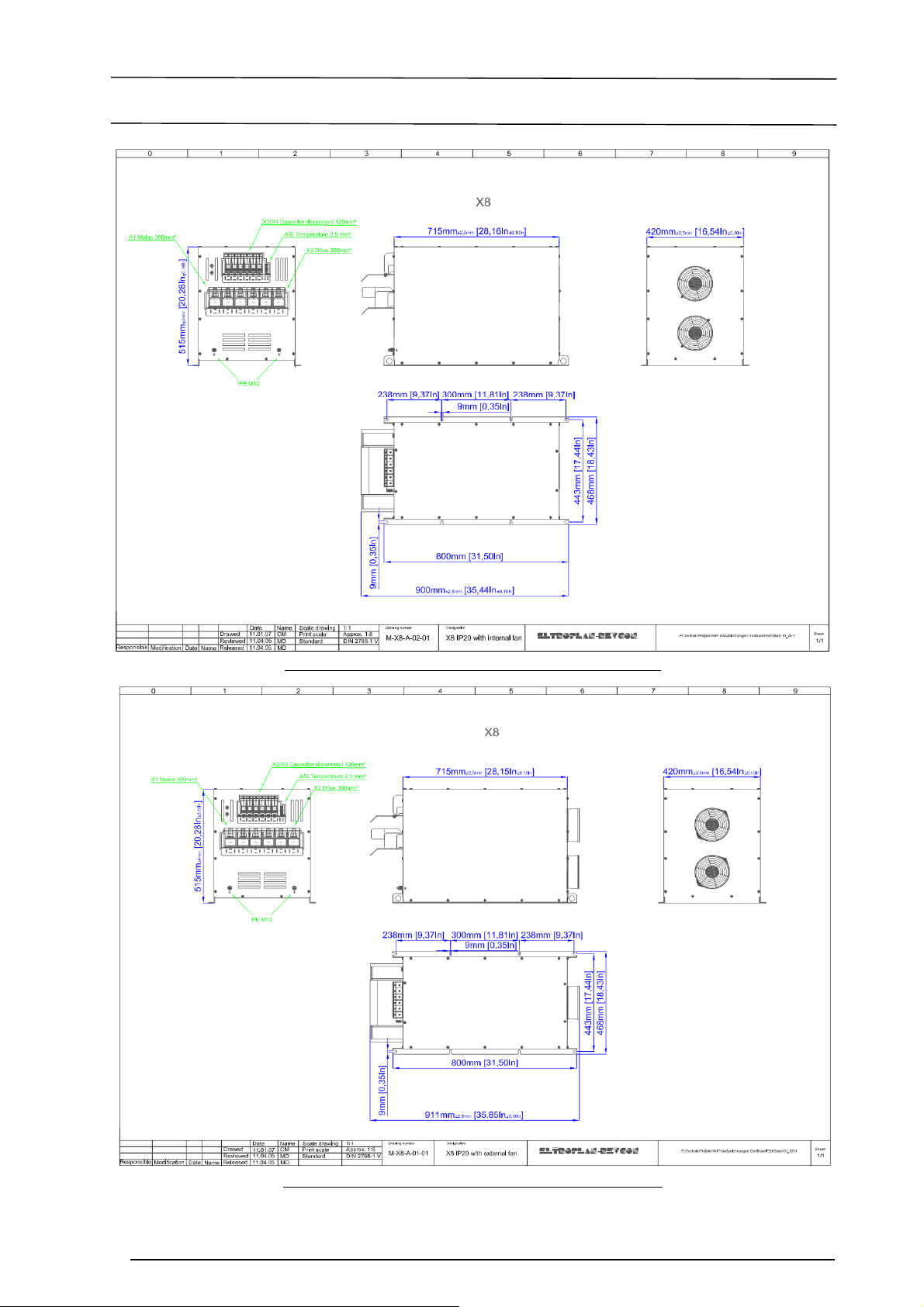

6.11 Dimension diagrams ....................................................................................................... 53

7 Installation ..................................................................................................61

7.1 Mechanical installation ................................................................................................... 61

Operating instructions RHF

1

Page 3

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Contents

7.2 International protection rating ....................................................................................... 62

7.3 Specified mounting position ........................................................................................... 63

7.4 The air ventilation ........................................................................................................... 64

8 Electrical installation ....................................................................................65

8.1 Network configuration / Net conditions ......................................................................... 65

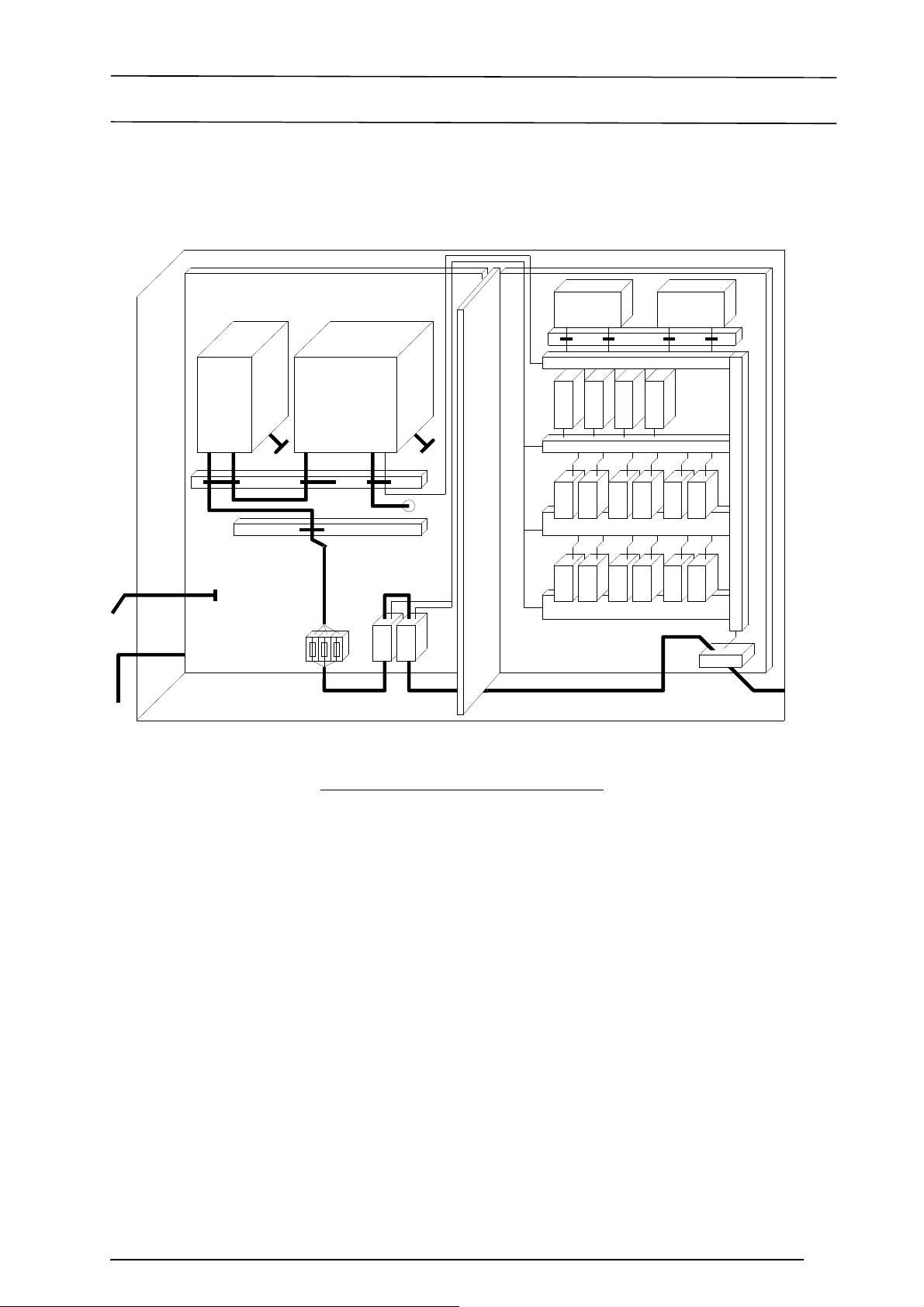

8.2 Operation principle RHF .................................................................................................. 66

8.3 Wiring diagram RHF ......................................................................................................... 67

8.4 Line connection ................................................................................................................ 70

8.5 Fuses ................................................................................................................................ 71

8.6 Installation in a CE- typical drive system ......................................................................... 73

8.7 Installation ....................................................................................................................... 74

8.8 Installation of a EMC- conform electrical enclosure ....................................................... 75

8.9 Note ................................................................................................................................. 76

9 Commissioning .............................................................................................77

9.1 First switching-on ............................................................................................................ 77

10 Capacitor disconnection..............................................................................78

11 Option Nema 1- enclosure ..........................................................................81

12 REVCON® product overview ........................................................................85

13 Contact ........................................................................................................86

14 Index and directory .....................................................................................87

14.1 List of figures ................................................................................................................... 88

14.2 List of tables .................................................................................................................... 89

2

Operating instructions RHF

Page 4

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Important information

1 Important information

1.1 About the operating instructions

• These present operating instructions are the translation of the original instructions,

which were composed in the official EU language German.

• These operating instructions shall ensure safe operation of and with the filter mod-

ule REVCON RHF. They contain security advices which must be observed and

information which is necessary for an undisturbed operation of the units and for

the exploitation of all advantages of the system.

• All persons who work on and with the filter module REVCON RHF must have ac-

cessible the operating instructions, or the equal chapters of the operating instructions for other with this option equipped REVCON

sons must follow the relevant notes and designations.

• The operating instructions must be complete and perfectly legible.

1.2 Uses terms and definitions

Filter module

For “Filter module REVCON RHF“ the term “Filter module“ is used in the following chapters, if the designation refers to all types (A, B).

For different characteristics, the complete marking (for example RHF-A) is used.

Drive system control

For the frequency convert which is used together with the filter module,

the term “Controller” is used.

Drive system

For a drive system with filter modules, controller and other components of the

drive system in the following the term “Drive system“ is used.

products available. All per-

Operating instructions RHF

3

Page 5

Prefix

Symbol

Prefix

Symbol

24

–1

21

–2

18

–3

15

–6

12

–9

9

–12

6

–15

3

–18

2

–21

1

–24

M,N

M,N

M,N

M,N

RMS

FC,L

Important information

1.3 SI units and symbols

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

10

10

10

10

10

10

10

10

10

10

Yotta Y 10

Zetta Z 10

Exa E 10

Peta P 10

Tera T 10

Giga G 10

Mega M 10

Kilo k 10

Hecto h 10

Deca da 10

Measure Name

Ampere A

Speed n

Farad F

Frequency f

Degree Celsius °C

Gramm g

Henry H

Hertz Hz

Magnetic flux density T

Meter m

Minute min

Newton meter Nm

Second s

Thermodynamic temperature K

Volt V

Resistor, electrical Ω

Real power W

Efficiency factor η

Deci d

Centi c

Milli m

Micro µ

Nano n

Pico p

Femto f

Atto a

Zepto z

Yocto y

Measure Name

Electromagnetic compatibility EMV

Direct current DC

Motor nominal frequency f

Motor power rating P

Motor nominal voltage U

Motor nominal current I

Nominal current RHF module I

Power input current I

Revolutions per minute min-1

Alternating current AC

4

Operating instructions RHF

Page 6

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Important information

1.4 Unit designation

RHF - Y 30 - XXX – XX – XX

Protection category

Frequency

Connection voltage e.g.: 400 (3 x 400V AC)

Nominal current of the filter module

A=THDI ≤ 16% (at THD U ≤ 2%)

B=THDI ≤ 10% (at THD U ≤ 2%)

RHF=REVCON filter module

Example: Nameplate RHF-A 72-400-50-20-A:

REVCON

Serien-Nr. / Serial no. 08/10 RHF-A 72-111

Artikel-Nr. /Article no. 25010007

Type / Type RHF-A 50- 400-50-20-A

Spannung / Voltage 3 x 400 VAC/50Hz

I

72 A

eff.

I

108 A

eff max.

Umgebungstemp. / Ambient Temp. Max 45°C

Schutzart / Protection IP 20

geprüft / tested ________________

ELTROPLAN-REVCON GmbH Made in Germany

Figure 1: The REVCON® RHF nameplate

®

Operating instructions RHF

5

Page 7

Marking

Name plate

CE-

marking

Manufacturer

Trade mark

Intended use

Liability

Warranty

Disposal

Material

Recycl

ing Disposal

Important information

1.5 Legal regulations

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

rights

Filter modules REVCON RHF are

clearly marked by the content of the

nameplate

The filter module REVCON RHF is protected in the Federal Republic of Germany by utility patents.

Patent-Nr.: DE 3938654C1 und Patent-Nr.: 90123584.6-2207. Violation of this utility patent and

the verbalized trade mark rights will be prosecuted criminally.

Filter module REVCON RHF

• only to use under the terms of this operating instructions and the required operational conditions

• are components

– to reduce the harmonic distortions of the electrical network by specific B6 rectifiers and inverters

– to fit in a machine

– to assembly with other components to a machine together

• are electric equipment to assembly in a electrical enclosure or similar

• locked up operations rooms

• conform to the protection requirements of the EG directive “low-voltage “

• are no machines in terms of the EG directive “machines“

• are no household appliances, but components which are determined only for the further applica-

tion in commercial use

Drive system with filter module REVCON RHF

• conform to the EG directive “Electromagnetic Compatibility“, if they are installed by the specifications of the CE-typical drive control system

• are applicable

– in the public electrical network and closed electrical networks.

– in the industrial sector and in living areas as well as in business units.

The responsibility for the compliancy of the EG directive with the machine application is one for

the user.

Conformable

to EG directive “low-voltage“

ELTROPLAN-REVCON

Edisonstraße 3

D-59199 Bönen

• The indicated information, technical data and notes in this operating instruction were updated at

the time of the printing. No demands for changing a delivered filter module can be asserted by

the information, figures and descriptions of these operating instructions.

• The represented process engineering notes in this operating instructions and circuit details are

suggestions, which transferability on the respective application must be verified. For the suitability of the specified procedures and circuit suggestions accepts the ELTROPLAN-REVCON

GmbH no guarantee.

• The data in these operating instructions describe the characteristic of the products without ensuring them.

• No Liability will be taken over for damages and malfunctions which result by:

– disregard of the operating instructions

– arbitrary changes on the filter module

– operating errors

– improper works on and with the inverter

• Warranty conditions: Look at the sales - and delivery conditions of the

ELTROPLAN-REVCON GmbH.

• Immediately announce guarantee claims after the discovery of defects or faults

• The warranty expires in all cases, in which even no liability claims can be asserted.

Metal

Plastic

-

-

6

Operating instructions RHF

Page 8

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Important information

1.6 Scope of supply

• 1 filter module RHF

• 1 operating instructions

– After receipt of the delivery verify immediately, if the scope of supply corre-

spond to the shipping documents. We make no warranty for later complained

defects

– Complain

• visible damages in transit immediately at the deliverer

• visible defects / incompleteness immediately at ELTROPLAN REVCON

Operating instructions RHF

7

Page 9

1.

4.

Safety instructions

2 Safety instructions

Safety- and application instructions

for propulsion converters

(in conformity with low- voltage directive 2006/95/EG)

General

During the operation filter modules can own according to their

protection class live, blank and if necessary even movable

parts, as well as hot surfaces.

The hazard of severe person or property damage exists at not

permissible removal of the required coverage, at inadmissible

application, at false Installation or operation.

Further information can be learned from the documentation.

All works for transport for installation and commissioning as

well as maintenance has to be done by specialized staff (IEC

60364 or CENELEC HD 384 or DIN VDE 0100 und IECReport 664 or DIN VDE 0110 and observe national accident

prevention regulations).

Specialized staffs in terms of these fundamental safety instructions are persons who are acquainted with installation,

assembly, commissioning and operation of the product and

who dispose through their work of the corresponding Qualifications.

2.

Conventional application

Filter modules are components that are conventional for the

installation in electrical systems or machines.

At the installation in machines is the start-up of the filter modules (the start of the conventional operation) prohibited until it

is determined that the machine complies with the regulations

of the EG directive 2006/42/EG (Machine directive); EN

60204 is to observe.

The start-up (the start of the conventional operation) is only

allowed under compliance of the EMC-directive. The filter

modules comply with the requirement of the low- voltage directive 2006/95/EG. The technical Data and also the data of

the connecting conditions have to be taken from the nameplate and the documentation and they have to be necessarily

observed.

3.

Transport, storage

Notes on transport, storage and appropriate handling must be

observed

At non-observance any warranty expires.

The power feedback unit has to be protected from inadmissible

stress.

The transport is only valid in original packaging and in the

thereon by pictograms marked transport position.

In particular during transport and handling no components are

allowed to be bent and / or isolating distances may not be altered. The units are equipped with electrostatic sensitive devices, which may be damaged by improper handling. Therefore it has to be avoided to get in contact with electronic components. If electronic components are damaged mechanically

the unit must not be put into operation, as it cannot be ensured, that all relevant standards are observed. Climatic conditions must be observed according to prEN 50178.

These safety instructions have to be kept!

Observe also the product specific safety- and application notes of these operating instructions!

ELTROPLAN - REVCON

Assembly

The Assembly and cooling of the devices must occur accordingly the instructions of the respective documentation.

The filter modules have to be protected of not permissible

stress. Particularly at transport und handling no components must have to be bent and / or insulation distances being changed. The touch of electric components and contacts is therefore to avoid. Electric components must not be

mechanical damaged or destroyed. (Under conditions

health hazards!).

At mechanical defects at electric and other components it is

not allowed to start up the device, because a compliance of

applied standards is not longer guaranteed.

5.

Electrical connection

At live-line working on filter modules apply national accident

prevention regulations (VBG 4) must be observed. Before

any installation- and connection works the system must be

operated on dead voltage and accordingly must be secured.

The electric installation must be performed according to the

respective instructions (e.g. cable cross- section, fuses,

connection to the protective conductor). At usage of the filter module with drive system control without a safe disconnect from the supplying circuit (according to VDE 0100) all

control cables must be included in additional protective

measures (e.g. double insulated or shielded, grounded and

insulated).

Notes for the EMV-conform installation – like shielding,

grounding, arrangements of filter modules and the installing

of conductors – are located in the chapter “Installation of

these operating instructions”. These notes must even be

observed at CE-marked propulsion converters. The compliance of the required limit values by the EMV- legislation is

up to the responsibility of the manufacturer of the system or

the machine.

6.

Operation

After disconnect of the filter modules of the supply voltage,

it is not allowed to touch live-line device parts and line connections because possibly charged capacitors must not be

touched immediately.

During the operation all covers and doors must be closed.

7.

Service and Maintenance

The operation of the manufacturer must be observed.

Elektrotechnische Anlagen GmbH

8

Operating instructions RHF

Page 10

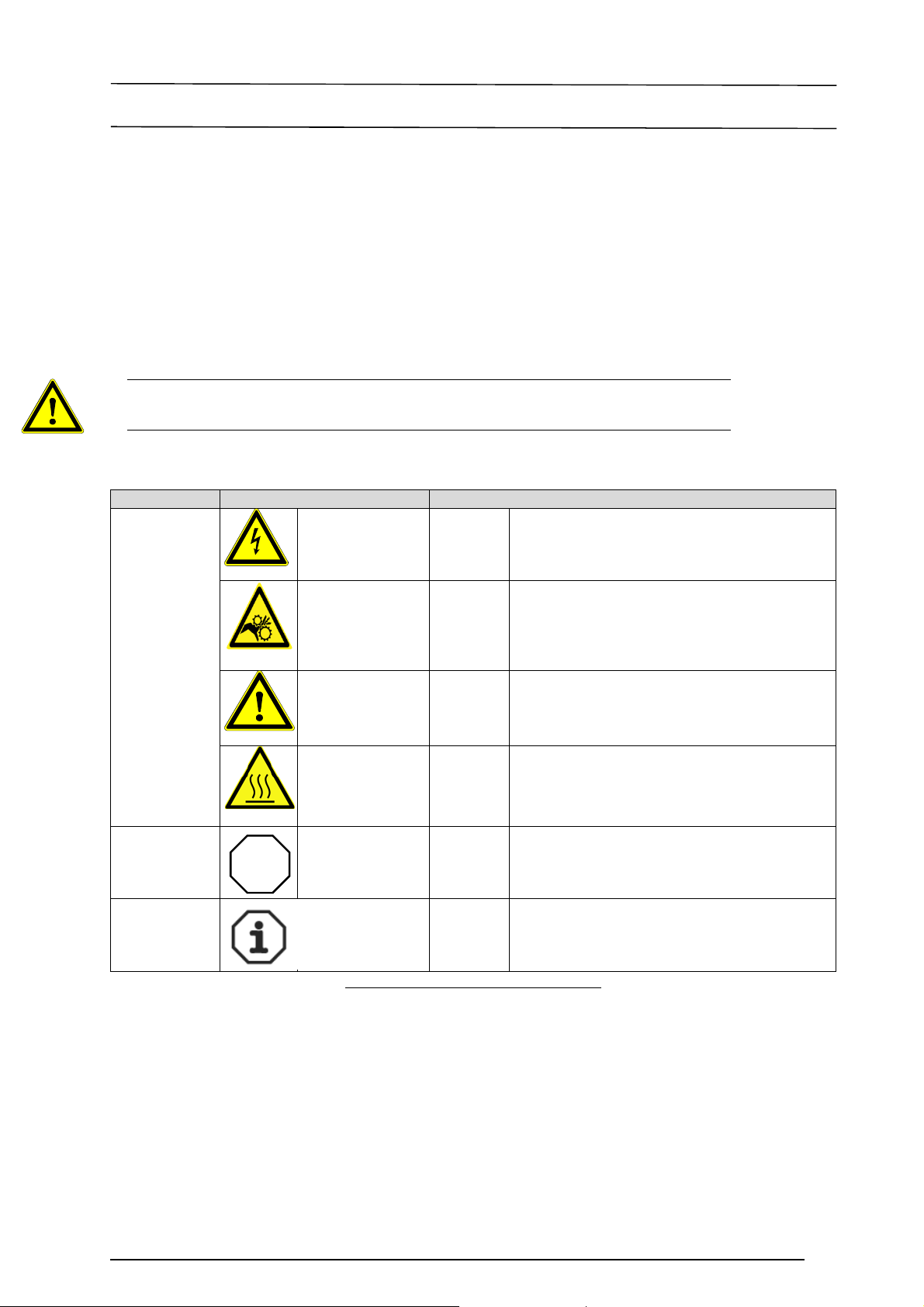

Used pictograms

Signal words

Warn

ing of

Danger

!

Warn

ing!

Caution

!

Warn

i

ng!

Warn

ing of

Stop!

Useful

info

r-

Note

!

STOP

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Safety instructions

2.1 Layout of the safety instructions

All safety instructions are built uniformly:

• The pictogram marks the type of danger.

• The signal word marks the severity of danger.

• The legend marks the danger and gives notes, how to avoid the danger.

Signal word

Legend

injury to

persons

property

damages

mation and

application

notes

Imminent danger

by current

Warning of an

imminent danger

Dangerous

situation

Warning of hot

surface

Harmful situation

Information

Table 1: Layout of the safety instructions

Warns of an immediately imminent Danger.

Consequences by disregard:

Death or severe injuries

Warns of a possible, very danger

situation.

Possible consequences by disregard:

Death or severe injuries

Warns of a possible, dangerous situation.

Possible consequences by disregard:

Minor or small injuries

Warns of touching a hot surface.

Possible consequences by disregard:

Burnings

Warns of possible property damages.

Possible consequences by disregard:

Damage of the drive system or its surroundings

Marks a generally, useful note, tip.

If you follow it, you make the handling of the

filter module easier

Operating instructions RHF

9

Page 11

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Safety instructions

2.2 General safety guidelines

• These safety guidelines make no demand to be complete.

• In case of questions and problems please confer with a technician of our compa-

ny.

• The filter module complies with the state of technology at date of delivery and is

considered as reliable basically.

• The data of these operation instructions describe the characteristics of the prod-

ucts, without assuring them.

• The filter module may cause danger of risk for persons, the filter module itself

and for other material assets, if

non qualified staff are working on and with the filter module

-the filter module is used improperly

• The Filter modules must be planned and commissioned so that they fulfil their in-

tended function in a proper installation, at intended use and at error-free operation and cause no danger for persons. This is valid even for their interaction with

the complete plant.

• The represented procedural notes and circuit details in these operation instruc-

tions have to be understood analogously and have to be verified to assign ability

to the current application.

• Operate the drive system only at perfect status.

• Changes to or modifications of the filter module are fundamentally prohibited.

They require in any event the confer with a technician of our company

• The granted guarantee from us expires, if the device is changed or (even partly)

dismantled, or if it is deployed in contradiction to our instruction.

• The installer of the plant must know the technical rules and guidelines and is re-

sponsible for the correct selection and arrangement of the electrical equipment .

• The operation of the filter module is only permitted on standard conform grids of

the electrical energy supply! Disregard can lead to reduction of the filter effect

and possibly to destruction of the filter module.

10

Operating instructions RHF

Page 12

STOP

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Safety instructions

• According to the corresponding standards and guidelines is the operation even at

for a short time overcompensated grids (cos

plants without chokes is not permitted, because the otherwise caused by oscillation recurrent surges can damage all connected loads, particularly electronic

equipment for example drive controller and power feedback units .

Stop!

An undisturbed and safe operation of the filter module is only to expect under the ob-

servance of the following connection instructions.

At deviations of these guidelines in individual case malfunctions and damages could occur:

– Observe the grid voltage.

– Run power- and control lines separated (> 15cm)

– Use shielded / twisted control lines only

– Run the shielding riveted to PE!

– Ground the enclosure of drive, drive control, power feedback unit and filter mod-

ule safe. Connect Shielding of power lines riveted and extensive (Remove the

lacquer)!

– Ground the electrical enclosure or the plant to main ground star point sigmoid

(necessarily avoid ground loops!)

– The filter module is only determined for a solid connection, because particularly

at the application of interference filter leakage current of 3,5 mA appear. The protective earth conductor must average minimum 10 mm² copper, or one second

conductor must be ran electrical parallel to Ground (grounded neutral point sigmoid).

ϕ ≤

1) respectively at compensation

Operating instructions RHF

11

Page 13

STOP

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Safety instructions

2.3 For the safety responsible persons

Operator

• Operator is every natural or legal person, which uses the drive system or in which

order the drive system is used.

• The operator respectively his safety representative must assure:

-That all relevant instructions, notes and laws will be abided

-That only qualified staff works on and with the drive system

-That the staff has the operating instructions at all respective works availably

-That non qualified staff must not work on and with the drive system .

Qualified staff

Stop!

Qualified staff means persons, that are entitled (by the safety responsible) due to their

training, experience, education, their knowledge in relevant norms, directives, accident

directives and operation conditions to execute the necessary works and to recognize

possible danger and to avoid it. (Definition of qualified staff IEC 364)

12

Operating instructions RHF

Page 14

STOP

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Safety instructions

2.4 Specification of the used wires

• The used wires must conform to the required specification on site

• The regulations about the minimum cross- section of PE-conductors must be ob-

served.

Connection:

• The connection has to be done by the terminals X1.1-X1.3 and X2.1-X2.3

• The temperature monitoring must be connected with the terminals A/B of the filter

module with the pulse stop of the converter.

Stop!

If this connection is not made at all or at least analogously (for example via an PLC),

the filter module may be damaged at constant overload operation.

Caution!

If this connection is not made at all or at least analogously (for example via na PLC)

and the installation instructions (chapter 8) are not observed, this may lead to a ther-

mal overload of the filter module and possibly to a smoke emission and/or a fire.

2.5 Remaining danger

Danger!

After switching off the electrical network, all connections could lead a dangerous con-

tact voltage for up to 10 minutes!

Operating instructions RHF

13

Page 15

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

3 Introduction into the subject harmonics

3.1 The effect of harmonics in a power distribution system

In figure 2 a transformer is connected on the primary side to a common point of cou-

pling PCC1 on the medium voltage supply. The transformer has an impedance ZT und

supplies a number of loads.

At a common coupling point PCCP2 all loads are connected. Each load is connected

through wires that have the corresponding impedances Z1, Z2 und Z3:

Figure 2: The effects of harmonics

Harmonic currents drawn by non-linear loads cause distortion of the voltage because

of the voltage drop on the impedances of the distribution system. Higher impedances

result in higher levels of voltage distortion.

Current distortion relates to the device performance and it relates to the individual

load. Voltage distortion relates to system performance .It is not possible to determine

the voltage distortion in the PCC knowing only the load’s harmonic performance .

14

Operating instructions RHF

Page 16

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

The configuration of the distribution system and the relevant impedances must be

known to calculate the distortion in the PCC.

A commonly used term to describe the impedance of a grid is the short circuit ra-

tio Rsce, defined as the ratio between the short circuit apparent power of the

supply at the PCC (Ssc) and the rated apparent power of the load (S

with

and

3.2 The negative effect of harmonics is twofold

• Harmonic currents contribute to system losses (power cable, transformer etc.)

• Harmonic voltage distortion causes disturbances to other loads and increase

losses in other loads

3.3 Harmonic limitation standards and requirements

The requirements for harmonic limitation are:

equ

).

• Application specific requirements

• Requirements from standards that have to be observed

The application specific requirements are related to a specific installation with

technical reasons for limiting the harmonics.

For example: A 250kVA transformer is connected with two 110kW motors. One is

connected direct and the other motor is supplied by a frequency converter.

If the other motor should also be supplied by a frequency converter, the trans-

former will, in this case, sized too small.

If the system should be retrofitted without changing the transformer, the harmonic

distortion caused by two drives must be mitigated using RHF filters.

Operating instructions RHF

15

Page 17

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

There are various harmonic mitigation standards, regulations and recommenda-

tions. Different standards are applied in different geographical areas and indus-

tries. The following standards that are applicable will be specified:

• IEC/EN 61000-3-2

• IEC/EN 61000-3-12

• IEC/EN 61000-3-4

• IEC 61000-2-2

• IEC 61000-2-4

• IEEE 519

• G5/4

IEC 61000-3-2:

The scope of IEC 61000-3-2 is equipment connected to the public low-voltage

distribution system with an input current up to and including 16 A per phase. Four

emission classes are defined: Class A through D.

IEC 61000-3-12:

The scope of IEC 61000-3-12 is equipment connected to the public low-voltage

distribution system having an input current between 16A and 75A.

The emission limits are currently only for 230/400V 50Hz systems and limits for

other systems will be added in the future. The emission limits that apply for drives

are given in Table 4 in the standard. There are requirements for individual har-

monics (5th, 7th, 11th, and 13th) and for THD and PWHD.

16

Operating instructions RHF

Page 18

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

IEC 61000-3-4:

Limits, Limitation of emission of harmonic currents in low-voltage power supply

systems for equipment with rated current greater than 16A.

The IEC 61000-3-12 supersedes IEC 61000-3-4 for currents up to 75A. Therefore

the scope of IEC 61000-3-4 is equipment with rated current greater than 75A con-

nected to the public low voltage distribution system. It has the status of a Tech-

nical report and should not be seen as an international standard.

A three-stage assessment procedure is described for the connection of equip-

ment to the public supply and equipment above 75A is limited to stage 3 connec-

tion based on the load's agreed power. The supply authority may accept the con-

nection of the equipment on the basis of the agreed active power of the load's in-

stallation and local requirements of the power supply authority apply. The manu-

facturer shall provide individual harmonics and the values for THD and PWHD.

IEC 61000-2-2 and IEC 61000-2-4: The IEC 61000-2-2 and IEC 61000-2-4 are

standards that stipulate compatibility levels for low-frequency conducted disturb-

ances in public low-voltage supply systems (IEC 61000-2-2) and industrial plants

(IEC 61000-2-4).

These low-frequency disturbances include harmonics, but are not limited to har-

monics.

The values prescribed in these standards should be taken into consideration

when planning installations. In some situations the harmonic compatibility levels

cannot be observed in installations with frequency converters and harmonic miti-

gation is needed.

IEEE519,:

IEEE519 establishes goals for the design of electrical systems that include both

linear and nonlinear loads. Waveform distortion goals are established and the in-

terface between sources and loads is described as point of common coupling

(PCC).

Operating instructions RHF

17

Page 19

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

IEEE519 is a system standard that aims the control of the voltage distortion at the

PCC to a THD of 5% and limits the maximum individual frequency voltage har-

monic to 3%. The development of harmonic current limits aims the limitation of

harmonic injection from individual customers so they will not cause unacceptable

voltage distortion levels and the limitation of the overall harmonic distortion of the

system voltage supplied by the utility.

The current distortion limits are given in Table 10.3 in the standard and depend on

the ratio ISC/IL where ISC is the short circuit current at the utility PCC and IL is the

maximum demand load current.

The limits are given for individual harmonics up to the 35th and total demand dis-

tortion (TDD). Please note that these limits apply at the PCC to the utility. While

requiring individual loads to comply with these limits also ensures the compliance

at the PCC, this is rarely the most economic solution, being unnecessarily ex-

pensive. The most effective way to meet the harmonic distortion requirements is

to mitigate at the individual loads and measure at the PCC.

If in a specific application it is required that the individual drive should comply with

the IEEE519 current distortion limits, an AHF can be employed to meet these lim-

its.

G5/4, Engineering recommendation, planning levels for harmonic voltage

distortion and the connection of nonlinear equipment to transmission sys-

tems and distribution networks in the United Kingdom:

G5/4 sets the Planning levels for harmonic voltage distortion to be used in the pro-

cess of connecting non-linear equipment. A process for establishing individual cus-

tomer emission-limits based on these planning levels is described.

G5/4 is a system level standard. For 400V the voltage THD planning level is 5%

at the PCC. Limits for odd and even harmonics in 400V systems are given in Ta-

ble 2 in the standard. An assessment procedure for the connection of non-linear

equipment is described. The procedure follows three stages, aiming to balance

the level of detail required by the assessment process with the degree of risk that

the connection of particular equipment will result in unacceptable voltage har-

monic distortion

.

A RHF-filter should be employed to meet the requirements of G5/4.

18

Operating instructions RHF

Page 20

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

3.4 Harmonic Mitigation

To mitigate the harmonics caused by the frequency converter 6-pulse rectifier

several solutions exist and they all have their advantages and disadvantages. The

choice of the right solution depends on several factors:

• The grid (background distortion, mains unbalance, resonance and type of

supply – transformer / generator)

• Application (load profile, number of loads and load size)

• Local / national requirements/regulations (IEEE519, IEC, G5/4, etc.)

• Total cost of ownership (initial cost, efficiency, maintenance, etc.)

IEC standards are harmonized by various countries or supranational organiza-

tions. All above mentioned IEC standards are harmonized in the European Union

with the prefix “EN”.

For example the European EN 61000-3-2 is the same as IEC 61000-3-2. The situ-

ation is similar in Australia and New Zealand, with the prefixes AS/NZS.

Harmonic solutions can be divided into two main categories: Passive and active

were the passive solutions consist of capacitors, inductors or a combination of

the two in different arrangements.

The simplest solution is to add inductors/reactors of typically 3% to 5% in front of

the frequency converter. This added inductance reduces the amount of harmonic

currents produced by the drive.

More advanced passive solutions combine capacitors and inductors in trap ar-

rangement specially tuned to eliminate harmonics starting from e.g. the 5th har-

monic.

Operating instructions RHF

19

Page 21

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

4 Introduction into the subject filter modules

4.1 Function principle REVCON RHF

The REVCON RHF consists of a main inductor L0 and a two-stage absorption cir-

cuit with the inductance L1 and L2 and the capacitors C1 and C2.

The absorption circuit eliminates harmonics starting at the fifth order and is specif-

ic for the designed supply frequency.

The filter performance in terms of THDI varies as a function of the load.

Figure 3: Function principle RHF

The REVCON RHF is available in two variants for two performance levels: RHF-B with

5% THDI (total current harmonic distortion) and RHF-A with 10% THDI. The strategy

behind the two levels is to offer a performance similar to 12 pulse rectifiers with the

RHF-A and a performance similar to 18 pulse rectifiers with RHF-B.

The filter performance in terms of THDI varies as a function of the load. At nominal

load the performance of the filter should be equal or better than 10% THDI for RHF-A

and 5% THDI for RHF-B.

At partial load the THDI has higher values. However, the absolute value of the har-

monic current is lower at partial loads, even if the THDI has a higher value. Conse-

quently, the negative effect of the harmonics at partial loads will be lower than at full

load. All THDI values are typical values and must be verified in accordance to chapter

3.1 .

20

Operating instructions RHF

Page 22

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

For example:

An 18.5kW drive is installed on a 400V/50Hz grid with a 35A RHF-A (type code

RHF-A-35-400-50-20-A).

The following values are measured for different load currents, using a harmonic

analyzer:

IN RMS [A]

9,60 9,59 5,45

15,24 15,09 13,78

20,54 20,08 12,46

25,17 25,00 11,56

30,27 30,10 10,50

35,20 34,03 9,95

* Calculated values

16,0

14,0

12,0

10,0

Fundamental current 50 Hz

I1 RMS [A]

Table 2: Measurement RHF-A 35-400-50-20-A

RHF-A 35-400-50-20-A

THDI [%]

Total harmonic current

Ih RMS [A]*

0,52

2,07

2,50

2,89

3,15

3,39

4

3,5

3

2,5

h

8,0

THDI [%]

6,0

4,0

2,0

0,0

5,00 10,00 15,00 20,00 25,00 30,00 35,00

I

[A]

Mains

Table 3: Diagram RHF-A 35-400-50-20-A

THDI [%]

Total harmonic current Ih

2

1,5

1

0,5

0

Total harmonic current I

Operating instructions RHF

21

Page 23

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

It can be observed that at partial load 15A, the THDI is approximately 14%, com-

pared to 10% at the nominal load of 34A. On the other hand, the total harmonic

current is only 2.07A at 15A line current against 3.39A harmonic current at 34A

line current. Therefore is the THDI only a relative indicator of the harmonic perfor-

mance. The harmonic distortion of the voltage will be less at partial load than at

nominal load. Factors such as background distortion and grid unbalance can affect

the performance of RHF- filter. The specific figures are different from filter to filter

and the graphs below show typical performance characteristics.

Background distortion: The design of the filters aims to achieve 10% respectively

5% THDI levels with a background distortion of THDU = 2%. Practical measure-

ments on typical grid conditions in installations with frequency converters show

that often the performance of the filter is slightly better with a 2% background dis-

tortion.

The complexity of the grid conditions and the different specific harmonics cannot

allow a general rule about the performance on a distorted grid. Therefore the

worst-case performance is chosen to consider characteristics with the background

distortion:

RHF-B

25

THDU 0%

20

THDU 2%

15

THDU 5%

10

THDI average [%]

5

0

0 10 20 40 60 80 100

Load [%]

Table 4: Diagram RHF-B

22

Operating instructions RHF

Page 24

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

RHF-A

60

50

40

30

THDI [%]

20

10

0

0 10 20 40 60 80 100

Load [%]

THDU 0%

THDU 2%

THDU 5%

Table 5: Diagram RHF-A

The Performance at 10% THDU has not been plotted. The filters have been tested

and can operate at 10% THDU but the filter performance can no longer be guaran-

teed. The filter performance also deteriorates with the unbalance of the supply.

The typical performance is shown in the graphs below:

RHF-B

14

12

10

8

6

THDI average [%]

4

2

0

0 10 20 40 60 80 100

Load [%]

Table 6: Diagram RHF-B

0% Unbalance

1% Unbalance

2% Unbalance

3% Unbalance

Operating instructions RHF

23

Page 25

Introduction

25

20

15

THDI [%]

10

5

0

0 10 20 40 60 80 100

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

RHF-A

Load [%]

Table 7: Diagram RHF-A

0% Unbalance

1% Unbalance

2% Unbalance

3% Unbalance

24

Operating instructions RHF

Page 26

®

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

4.2 Harmonic line filter for frequency converters

Passive harmonic compensation of the input current of the frequency converter:

The harmonic line filter is used to reduce the circuit harmonic distortions of non

linear loads, which are supplied with uncontrolled B6- bridge rectifiers, how for

example frequency converters. At the REVCON® RHF it is about a passive filter

module.

It is not aligned to single frequencies how a absorption circuit, but works how a

Band- stop filter that attenuates strong all low harmonic oscillations approx. until

the fiftieth.

For comparison are in the following chart the circuit harmonic distortions of some

potential circuits in principle represented by means of the THDI (total harmonic

distortion of current) at the rated point of the rectifier:

Rectifier with

Rectifier without

chokes

4% uk

without

chokes

Rectifier

with RHF- A

Rectifier

with RHF- B

80 % 40 % < 16 % < 10 % < 10 % < 5 %

The passive harmonic Rectifier REVCON

RHF features an effective, inexpensive

and very efficient (η = 99,5%) means, to reduce network loads with harmonics.

Figure 4 shows the typical current waveform of a B6 bridge without RHF module:

Rectifier with RHF- A

and link choke

Rectifier with

RHF-B and link

choke

Operating instructions RHF

Figure 4: The Current waveform without RHF module

25

Page 27

Fourier analysis of mains

currents

Harmonic component

o

nent

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Introduction

Figure 5 shows the typical current waveform of a B6 bridge with RHF module:

Figure 5: The Current waveform with RHF module

Figure 6 shows the Fourier analysis of the grid current by comparison:

Abbildung 3.1.3: Fourieranalyse der Netzströme im Vergleich

30

25

20

15

10

5

0

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49

Without RHF

With RHF

Figure 6: The Fourier analysis of the grid current

26

Operating instructions RHF

Page 28

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

5 EU- directives / Declaration of conformity

5.1 What is the purpose of EU-directives?

The EU-directives are composed by the European Council and are used as definitions of common technical requirements and certification procedures inside the

European Community. At the moment there are 30 EU-directives for different sections. The standards are or will be converted by the respective member states in

national laws. An in a member state issued certificate is automatically valid without

more testing in all other member states.

The directive- texts restrict on the formulation of the essentially requirement.

The technical details are or will be defined in European harmonized standards.

5.2 What is the meaning of the CE- marking?

After an already made Conformity valuation method the accordance with the requirements of the EU- directives will be confirmed by the mounting of a CEmarking. Within the EU there are no trade barriers for a CE-marked product.

Filter modules with CE-marking comply independently, exclusively the low voltagestandard. The filter modules are considered as inherently benign and therefore

out of the scope of the EMC-standard (EMC directive 2014/30/EU).

5.3 EG-directive low voltage

Low voltage-directive (2014/35/EU)

General:

• The low voltage-directive is valid for all electrical devices to use at a nominal voltage between 50V and 1000V alternating voltage and between 75V and 1500V direct voltage and at usual environmental condition. Expected is for example the usage of electrical devices in explosive atmosphere and electrical parts of personand freight elevator.

• Protection target of the low voltage-directive is to put only such electrical devices

on the market, which do not endanger the safety of humans or animals and the

conservation of material assets.

EG- directives

Operating instructions RHF

27

Page 29

ELTROPLAN - REVCON

EG- directives

5.4 Standards and permission

IEC/EN 61000-3-2 RHF

IEC/EN 61000-3-12 RHF

IEC/EN 61000-3-4 RHF

IEC/EN 61000-2-2 RHF

IEC/EN 61000-2-4 RHF

IEEE 519 RHF

G5/4 RHF

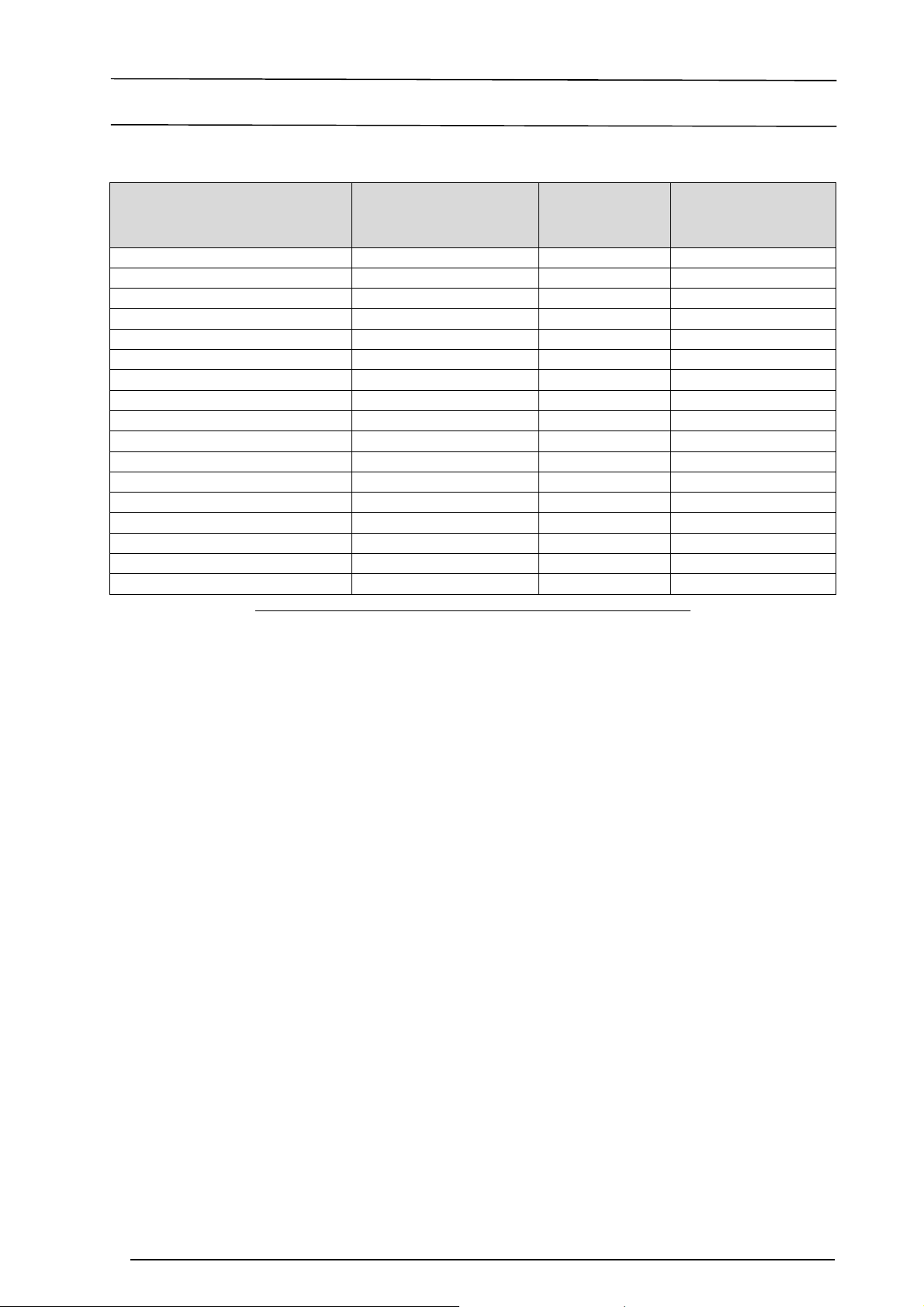

Standard Range

Elektrotechnische Anlagen GmbH

Power Conversion Equipment - UL 508C

Industrial Control Equipment - CSA-C22.2 No. 14

Table 8: Standards and permission

RHF (460V, 600V)

RHF (460V, 600V)

28

Operating instructions RHF

Page 30

STOP

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Technical data and dimension diagrams

6 Selection of the right filter module and technical data

To reach optimal performance of the filter module and to operate it durable optimal, the filter module must be sized so that it fits to the load defined by the line input current of the frequency converter

=> I

FC,L

This is the input current of the frequency converter, not to be confused with the

classification of the frequency converter which is the output(motor) current of the

frequency converter.

6.1 Calculation

The line input current I

current I

and cos φ. Both data are to be found for example on the name plate of

M,N

can be calculated with the data of the motor, nominal

FC,L

the motor.

In the case that the nominal motor voltage, U

age UL, the calculated current I

must be corrected with the ratio between these

FC,L

is unequal to the actual line volt-

M,N

voltages and with the following equation:

The equation is:

! !!

The chosen RHF filter module must have an equal nominal current I

RMS

, which

complies with the line input current of the frequency converter or which is larger.

"

#

Do not oversize the RHF. The best harmonic performance is obtained at nominal filter load.

Using an oversized filter will most likely result in worse THDI performance.

If several frequency converters are operated on the same filter module, the RHF

filter module must be dimensioned with the sum of the calculated line input currents.

Stop!

If the RHF module is sized for a specified load and the motor is exchanged or modified

afterwards, the current must be calculated again to prevent an overload of the filter

module.

Operating instructions RHF

29

Page 31

RHF

ELTROPLAN - REVCON

Technical data and dimension diagrams

6.2 Worked sample

The following data are known:

System line voltage UL 400 V

Motor power nameplate PM 90 kW

Efficiency of the motor ηM 0,96

Efficiency of the frequency converter ηFC 0,97

Efficiency of the RHF module η

The maximum line current I

"$

"$

In this case 144 A must be chosen.

Note!

-**. &' *)/ *)0 *)1

can be calculated by the following equation:

RMS

&'

-2'34

"

%

)*+,

0,98

"(

Elektrotechnische Anlagen GmbH

The true nominal current depends on the actual load; therefore it is lower than the

nominal Data most often.

30

Operating instructions RHF

Page 32

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Technical data and dimension diagrams

6.3 Characteristics

• Small compact size

• Reduction of the THDI to ≤ 15% (10%) at type RHF-A (RHF-B)

• Optional THDI = 5% (depends on the application)

• Power range 4kW to 440KW

• High Efficiency

• User-friendly commissioning, because no programming or setting necessary

Note:

1. The reduction of the low- frequency circuit harmonic distortions on the speci-

fied THD I data implies, that the total harmonic distortion of the unaffected line

voltage THD U smaller than 2%. Under this requirement the THD I improve of

the line current of the drive controller with the filter module REVCON® RHF

A/B to typically ≤15%. When these requirements are not or only partially complied, it still implies a significant reduction of the harmonic components, but

under conditions the specified THD I-data will be not achieved.

2. Under den same conditions the THD I improves the main current of the drive

control with the filter module REVCON® RHF-B to typically ≤10%.

3. With the filter module a more better filter effect can be achieved, if the drive

control is equipped with a link choke, which inductance complies to a net-

sided choking of approx. 4%. At this Configuration THD I-data result of

<10% at otherwise same requirements as beneath 1 respectively of <5% at

otherwise the same requirements as beneath 2.

Operating instructions RHF

31

Page 33

Range

Data

ELTROPLAN - REVCON

Technical data and dimension diagrams

6.4 General Data / Operation conditions

Elektrotechnische Anlagen GmbH

Valid temperature

range*

Stress of humidity* Humidity class F without condensation (5% - 85% relatively humidity)

Environment:

Resonance search

Environment:

Sine vibration test

Altitude of side h*

Air pressure* According to EN50178 (86kPa – 106kPa during operation)

Degree of pollution Stress of humidity 2 following VDE 0110 part 2

Insulation stability Overvoltage category III following VDE 0110

Package DIN 55468 for transport package materials

At transport of the device: -25°C...+70°C (following DIN EN 50178)

At storage of the device: -25°C...+55°C (following DIN EN 50178)

At operation of the device: -20°C...+45°C without power reduction

45°C...+60°C with power reduction

Base standard: DIN EN 60068-2-6

Test specification: 5 Hz,150 Hz, 3 directions (0,5 g, 0,1 g, 0,5 g)

Base standard: DIN EN 60068-2-6

Test specification: (5 Hz-13,2 Hz)-150 Hz

2 mm peak to peak 0,7 g

h ≤ 1000 m üNN without power reduction

1000 m üNN < h 4000 m üNN with power reduction

Transport:

Random vibration test

Transport:

Mechanical shock test

Protection class IP 20 (at RHF and external power choke IP 00)

Approvals CE: Low- voltage directive

*Climatic terms following class 3K3 (EN 50178 part 6.1)

Base standard: DIN EN 60068-2-64

Base standard: DIN EN 30786-2

Base standard: DIN EN 60068-2-27

Base standard: DIN EN 30786-2

Table 9: General Data / Operation conditions

32

Operating instructions RHF

Page 34

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Technical data and dimension diagrams

Figure 7 shows the Power reduction in dependence of the ambient temperature:

Belastung in %

110

100

90

80

70

60

40 45 50 55 60

Umgebungstemperatur in °C

Figure 7: Power reduction in dependence of the ambient temperature

Operating instructions RHF

33

Page 35

ELTROPLAN - REVCON

Technical data and dimension diagrams

6.5 Rating values

Device series

Nominal range of

the line-to-line line

voltage

Tolerance of the

line-to-line line

voltage

Power frequency

Overload ability

UN[V]

UN[V]

fN[Hz]

RHF

380V

380

342 ≤ UN ≤

418

60 ± 2 % 50 ± 2 % 60 ± 2 % 50 ± 2 %

RHF

400V

380 ≤ UN ≤

415

342 ≤ UN ≤

456

Elektrotechnische Anlagen GmbH

RHF

460V

440 ≤ UN ≤

480

396 ≤ UN ≤

528

1,5

RHF

500V

500

450 ≤ UN

≤ 550

RHF

600V

600

540 ≤ UN

≤ 660

60 ± 2 % 50 ± 2 %

RHF

690V

690

540 ≤ UN

≤ 759

* Efficiency

** THD I

cos ϕ

* Cooling air

requirement

Power reduction

* Depended on the device type and design

** At observation of the following connecting conditions: THD U < 2%, standard con formable electrical networks

η[%]

[%]

m³ / h

[%/K]

[%/m]

at 75% IN 0,85 cap.

at 100% IN 0,99 cap.

at 150% IN 1,0 cap.

a) Installation size X1-X2: 200 m³ / h

b) Installation size X3-X6: 350 m³ / h

c) Installation size X7-X8: 700 m³ / h

1000m üNN < h ≤4000m üNN ⇒ 5%/1000m

Table 10: Rating values

ca. 98,5-99,5

5-16

See figure 7

34

Operating instructions RHF

Page 36

Current I

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Technical data and dimension diagrams

6.6 Item numbers and ampacity RHF

The indicated current values advert to the line current of the drive control and not

on the branch current of the filter module itself!

Nominal voltage 380V 60Hz

REVCON® - type

RHF- A/B 10-380-60-20 A 25010040 / 25020040

RHF- A/B 14-380-60-20 A 25010041 / 25020041

RHF- A/B 22-380-60-20 A 25010042 / 25020042

RHF- A/B 29-380-60-20 A 25010043 / 25020043

RHF- A/B 35-380-60-20 A 25010044 / 25020044

RHF- A/B 43-380-60-20 A 25010045 / 25020045

RHF- A/B 58-380-60-20 A 25010046 / 25020046

RHF- A/B 72-380-60-20 A 25010047 / 25020047

RHF- A/B 86-380-60-20 A 25010048 / 25020048

RHF- A/B 101-380-60-20 A 25010049 / 25020049

RHF- A/B 144-380-60-20 A 25010050 / 25020050

RHF- A/B 180-380-60-20 A 25010051 / 25020051

RHF- A/B 217-380-60-20 A 25010052 / 25020052

RHF- A/B 252-380-60-20 A 25010053 / 25020053

RHF- A/B 304-380-60-20 A 25010054 / 25020054

RHF- A/B 325-380-60-20 A 25010055 / 25020055

RHF- A/B 380-380-60-20 A 25010056 / 25020056

RHF- A/B 433-380-60-20 A 25010057 / 25020057

Table 11: Item numbers and Ampacity at nominal voltage 380V 60Hz

Item number

RHF-A / RHF-B

Current I

RMS

100% [A] AC

10 15,0

14 21,0

22 33,0

29 43,5

35 52,5

43 64,5

58 87,0

72 108,0

86 129,0

101 151,5

144 216,0

180 270,0

217 325,5

252 378,0

304 456,0

325 487,5

380 570,0

433 649,5

RMS

150% [A] AC

1 min in 10 min

Operating instructions RHF

35

Page 37

Current I

Current I

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Technical data and dimension diagrams

Nominal voltage 400V 50Hz

REVCON® - type

RHF- A/B 6-400-50-20 A 25010018 / 25020018 6 9,0

RHF- A/B 10-400-50-20 A 25010000 / 25020000 10 15,0

RHF- A/B 14-400-50-20 A 25010001 / 25020001 14 21,0

RHF- A/B 22-400-50-20 A 25010002 / 25020002

RHF- A/B 29-400-50-20 A 25010003 / 25020003

RHF- A/B 35-400-50-20 A 25010004 / 25020004

RHF- A/B 43-400-50-20 A 25010005 / 25020005

RHF- A/B 58-400-50-20 A 25010006 / 25020006

RHF- A/B 72-400-50-20 A 25010007 / 25020007

RHF- A/B 86-400-50-20 A 25010008 / 25020008

RHF- A/B 101-400-50-20 A 25010009 / 25020009 101 151,5

RHF- A/B 144-400-50-20 A 25010010 / 25020010 144 216,0

RHF- A/B 180-400-50-20 A 25010011 / 25020011 180 270,0

RHF- A/B 217-400-50-20 A 25010012 / 25020012 217 325,5

RHF- A/B 252-400-50-20 A 25010013 / 25020013 252 378,0

RHF- A/B 304-400-50-20 A 25010014 / 25020014 304 456,0

RHF- A/B 325-400-50-20 A 25010015 / 25020015 325 487,5

RHF- A/B 380-400-50-20 A 25010016 / 25020016 380 570,0

RHF- A/B 433-400-50-20 A 25010017 / 25020017 433 649,5

Table 12: Item numbers and Ampacity at nominal voltage 400V 50Hz

Item number

RHF-A / RHF-B

Current I

100% [A] AC

RMS

22 33,0

29 43,5

35 52,5

43 64,5

58 87,0

72 108,0

86 129,0

150% [A] AC

1 min in 10 min

RMS

Nominal voltage 460V 60Hz

REVCON® - type

RHF- A/B 10-460-60-20 A 25010020 / 25020020 10 15,0

RHF- A/B 14-460-60-20 A 25010021 / 25020021 14 21,0

RHF- A/B 19-460-60-20 A 25010022 / 25020022

RHF- A/B 25-460-60-20 A 25010023 / 25020023

RHF- A/B 31-460-60-20 A 25010024 / 25020024

RHF- A/B 36-460-60-20 A 25010025 / 25020025

RHF- A/B 48-460-60-20 A 25010026 / 25020026

RHF- A/B 60-460-60-20 A 25010027 / 25020027

RHF- A/B 73-460-60-20 A 25010028 / 25020028

RHF- A/B 95-460-60-20 A 25010029 / 25020029 95 142,5

RHF- A/B 118-460-60-20 A 25010030 / 25020030 118 177,0

RHF- A/B 154-460-60-20 A 25010031 / 25020031 154 231,0

RHF- A/B 183-460-60-20 A 25010032 / 25020032 183 274,5

RHF- A/B 231-460-60-20 A 25010033 / 25020033 231 346,5

RHF- A/B 291-460-60-20 A 25010034 / 25020034 291 436,5

RHF- A/B 355-460-60-20 A 25010035 / 25020035 355 532,5

RHF- A/B 380-460-60-20 A 25010036 / 25020036 380 570,0

RHF- A/B 436-460-60-20 A 25010037 / 25020037 436 654,0

Table 13: Item numbers and Ampacity at nominal voltage 460V 60Hz

Item number

RHF-A / RHF-B

Current I

100% [A] AC

19 29,0

25 37,5

31 46,5

36 54,0

48 72,0

60 90,0

73 109,5

RMS

150% [A] AC

1 min in 10 min

RMS

36

Operating instructions RHF

Page 38

Current I

Current I

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Technical data and dimension diagrams

Nominal voltage 500V 50Hz

REVCON® - type

RHF- A/B 15-500-50-20 A 25010080 / 25020080 15 22,5

RHF- A/B 20-500-50-20 A 25010081 / 25020081 20 30,0

RHF- A/B 24-500-50-20 A 25010082 / 25020082

RHF- A/B 29-500-50-20 A 25010083 / 25020083

RHF- A/B 36-500-50-20 A 25010084 / 25020084

RHF- A/B 50-500-50-20 A 25010085 / 25020085

RHF- A/B 58-500-50-20 A 25010086 / 25020086

RHF- A/B 77-500-50-20 A 25010087 / 25020087

RHF- A/B 87-500-50-20 A 25010088 / 25020088

RHF- A/B 109-500-50-20 A 25010089 / 25020089 109 163,5

RHF- A/B 128-500-50-20 A 25010090 / 25020090 128 192,0

RHF- A/B 155-500-50-20 A 25010091 / 25020091 155 232,5

RHF- A/B 197-500-50-20 A 25010092 / 25020092 197 295,5

RHF- A/B 240-500-50-20 A 25010093 / 25020093 240 360,0

RHF- A/B 296-500-50-20 A 25010094 / 25020094 296 444,0

RHF- A 366-500-50-20 A 25010095 366 549,0

RHF- A 395-500-50-20 A 25010096 395 592,5

Table 14: Item numbers and Ampacity at nominal voltage 500V 50Hz

Item number

RHF-A / RHF-B

Current I

100% [A] AC

RMS

150% [A] AC

1 min in 10 min

24 36,0

29 43,5

36 54,0

50 75,0

58 87,0

77 115,5

87 130,5

RMS

Nominal voltage 600V 60Hz

REVCON® - type

RHF- A/B 15-600-60-20 A 25010100 / 25020100 15 22,5

RHF- A/B 20-600-60-20 A 25010101 / 25020101 20 30,0

RHF- A/B 24-600-60-20 A 25010102 / 25020102

RHF- A/B 29-600-60-20 A 25010103 / 25020103

RHF- A/B 36-600-60-20 A 25010104 / 25020104

RHF- A/B 50-600-60-20 A 25010105 / 25020105

RHF- A/B 58-600-60-20 A 25010106 / 25020106

RHF- A/B 77-600-60-20 A 25010107 / 25020107

RHF- A/B 87-600-60-20 A 25010108 / 25020108

RHF- A/B 109-600-60-20 A 25010109 / 25020109 109 163,5

RHF- A/B 128-600-60-20 A 25010110 / 25020110 128 192,0

RHF- A/B 155-600-60-20 A 25010111 / 25020111 155 232,5

RHF- A/B 197-600-60-20 A 25010112 / 25020112 197 295,5

RHF- A/B 240-600-60-20 A 25010113 / 25020113 240 360,0

RHF- A/B 296-600-60-20 A 25010114 / 25020114 296 444,0

RHF- A 366-600-60-20 A 25010115 366 549,0

RHF- A 395-600-60-20 A 25010116 395 592,5

Table 15: Item numbers and Ampacity at nominal voltage 600V 60Hz

Item number

RHF-A / RHF-B

Current I

100% [A] AC

24 36,0

29 43,5

36 54,0

50 75,0

58 87,0

77 115,5

87 130,5

RMS

150% [A] AC

1 min in 10 min

RMS

Operating instructions RHF

37

Page 39

Current I

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Technical data and dimension diagrams

Nominal voltage 690V 50Hz

REVCON® - type

RHF- A/B 15-690-50-20 A 25010060 / 25020060 15 22,5

RHF- A/B 20-690-50-20 A 25010061 / 25020061 20 30,0

RHF- A/B 24-690-50-20 A 25010062 / 25020062

RHF- A/B 29-690-50-20 A 25010063 / 25020063

RHF- A/B 36-690-50-20 A 25010064 / 25020064

RHF- A/B 50-690-50-20 A 25010065 / 25020065

RHF- A/B 58-690-50-20 A 25010066 / 25020066

RHF- A/B 77-690-50-20 A 25010067 / 25020067

RHF- A/B 87-690-50-20 A 25010068 / 25020068

RHF- A/B 109-690-50-20 A 25010069 / 25020069 109 163,5

RHF- A/B 128-690-50-20 A 25010070 / 25020070 128 192,0

RHF- A/B 155-690-50-20 A 25010071 / 25020071 155 232,5

RHF- A/B 197-690-50-20 A 25010072 / 25020072 197 295,5

RHF- A/B 240-690-50-20 A 25010073 / 25020073 240 360,0

RHF- A/B 296-690-50-20 A 25010074 / 25020074 296 444,0

RHF- A 366-690-50-20 A 25010075 366 549,0

RHF- A 395-690-50-20 A 25010076 395 592,5

Table 16: Item numbers and Ampacity at nominal voltage 690V 50Hz

Item number

RHF-A / RHF-B

Current I

100% [A] AC

RMS

24 36,0

29 43,5

36 54,0

50 69,0

58 87,0

77 115,5

87 130,5

150% [A] AC

1 min in 10 min

RMS

38

Operating instructions RHF

Page 40

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Technical data and dimension diagrams

6.7 Cable cross section

When wiring a RHF-filter module the drive system should be wired with the same

cross section as without filter module.

6.8 General information

With this information the installers and users of a plant should be given information

on special characteristics and rules in terms on a filter module.

With this information no demand of completeness will be raised.

Compensation plants without chokes and resonance danger

Compensation plants are used in centre of the power supplies of companies. Disturbances or damages at these plants can affect to the power supplies of the company and cause expensive losses of production.

In fact today therr are still many compensation plants without chokes used although the actual guidelines are in conflict with this fact.. The problems, which can

occur in connection with a compensation plant without chokes, are manifold:

- Direct Resonance

- Resonance lifting

- Switching transients or

- Impairment of ripple control transmission

Rising of resonances is not determined whether an operation itself causes harmonic distortions. Decisive for the risk to encounter a resonance is the compensation power at the transformer. The risk of a resonance will rise together with the

compensation power and is influenced by the harmonic load of the medium voltage level, which is transmitted by the transformer and effects the low-voltage level.

Limit exceeding, caused by resonance lifting, may particularly bedetected especially for the 5th harmonic.

Operating instructions RHF

39

Page 41

Cable

ELTROPLAN - REVCON

Technical data and dimension diagrams

6.9 Electrical operating conditions RHF

Nominal voltage 380V 60Hz

Elektrotechnische Anlagen GmbH

REVCON® - type

RHF-A-

10-380-60-20 A X1 13,5 1,6 M6 0,5-10 CS

14-380-60-20 A X1 16,3 1,6 M6 0,5-10 CS

22-380-60-20 A X2 22 1,6 M6 0,5-10 CS

29-380-60-20 A X2 25 2,4 M8 1,5-25 CS

35-380-60-20 A X3 33 2,4 M8 1,5-25 CS

43-380-60-20 A X3 37 2,4 M8 1,5-25 CS

58-380-60-20 A X3 38 4.5 M8 2,5-50 CS

72-380-60-20 A X4 43 4,5 M8 2,5-50 CS

86-380-60-20 A X4 55 6,0 M8 10-70 CS

101-380-60-20 A X5 62 6,0 M8 10-70 CS

144-380-60-20 A X5 74 12,0 M8 2,5-95 CL M8

180-380-60-20 A X6 85 12,0 M8 2,5-95 CL M8

217-380-60-20 A X6 102 60,0 M12 25-300 CL M16

252-380-60-20 A X7 117 60,0 M12 25-300 CL M16

304-380-60-20 A X7 136 60,0 M12 25-300 CL M16

325-380-60-20 A X7 162 60,0 M12 25-300 CL M16

380-380-60-20 A X7 172 60,0 M12 25-300 CL M16

433-380-60-20 A X8 203 60,0 M12 25-300 CL M16

Configuration

filter module

Table 17: Electrical operating conditions 380V 60Hz RHF-A

Weight

[kg]

Torque*

Clamps X1+X2

[Nm]

Grounding

cross

section

[mm²]

Cable Lug**

Nominal voltage 380V 60Hz

Cable Lug**

Cable

cross

section

[mm²]

REVCON® - type

RHF-B-

10-380-60-20 A X1 18 1,6 M6 0,5-10 CS

14-380-60-20 A X1 20,0 1,6 M6 0,5-10 CS

22-380-60-20 A X2 30 1,6 M6 0,5-10 CS

29-380-60-20 A X3 34 2,4 M8 1,5-25 CS

35-380-60-20 A X3 52 2,4 M8 1,5-25 CS

43-380-60-20 A X3 53 2,4 M8 1,5-25 CS

58-380-60-20 A X4 57 4.5 M8 2,5-50 CS

72-380-60-20 A X4 75 4,5 M8 2,5-50 CS

86-380-60-20 A X5 97 6,0 M8 10-70 CS

101-380-60-20 A X5 104 6,0 M8 10-70 CS

144-380-60-20 A X6 106 12,0 M8 2,5-95 CL M8

180-380-60-20 A X6 126 12,0 M8 2,5-95 CL M8

217-380-60-20 A X7 135 60,0 M12 25-300 CL M16

252-380-60-20 A X7 170 60,0 M12 25-300 CL M16

304-380-60-20 A X7 206 60,0 M12 25-300 CL M16

325-380-60-20 A X7 229 60,0 M12 25-300 CL M16

380-380-60-20 A X7 265 60,0 M12 25-300 CL M16

433-380-60-20 A X8 270 60,0 M12 25-300 CL M16

Configuration

filter module

Table 18: Electrical operating conditions 380V 60Hz RHF-B

Weight

[kg]

Torque*

Clamps X1+X2

[Nm]

Grounding

* Locking torque of the electrical network and converter terminal clamp

** CS ≙ Cable end sleeve, CL ≙ Cable lug

40

Operating instructions RHF

Page 42

Cable

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Technical data and dimension diagrams

Nominal voltage 400V 50Hz

Clamps X1+X2

Torque*

[Nm]

Grounding

cross

section

[mm²]

Cable Lug**

REVCON® - type

RHF-A-

6-400-50-20 A X1 13,5 1,6 M6 0,5-10 CS

10-400-50-20 A X1 13,5 1,6 M6 0,5-10 CS

14-400-50-20 A X2 16,3 1,6 M6 0,5-10 CS

22-400-50-20 A X2 22 1,6 M6 0,5-10 CS

29-400-50-20 A X3 33 2,4 M8 1,5-25 CS

35-400-50-20 A X3 37 2,4 M8 1,5-25 CS

43-400-50-20 A X3 39 2,4 M8 1,5-25 CS

58-400-50-20 A X4 44 4.5 M8 2,5-50 CS

72-400-50-20 A X4 56 4,5 M8 2,5-50 CS

86-400-50-20 A X5 62 6,0 M8 10-70 CS

101-400-50-20 A X5 74 6,0 M8 10-70 CS

144-400-50-20 A X6 85 12,0 M8 2,5-95 CL M8

180-400-50-20 A X6 102 12,0 M8 2,5-95 CL M8

217-400-50-20 A X7 119 60,0 M12 25-300 CL M16

252-400-50-20 A X7 136 60,0 M12 25-300 CL M16

304-400-50-20 A X7 142 60,0 M12 25-300 CL M16

325-400-50-20 A X7 147 60,0 M12 25-300 CL M16

380-400-50-20 A X7 172 60,0 M12 25-300 CL M16

433-400-50-20 A X8 205 60,0 M12 25-300 CL M16

Configuration

filter module

Table 19: Electrical operating conditions 400V 50Hz RHF-A

Weight

[kg]

Nominal voltage 400V 50Hz

REVCON® - type

RHF-B-

6-400-50-20 A X1 13,5 1,6 M6 0,5-10 CS

10-400-50-20 A X1 18 1,6 M6 0,5-10 CS

14-400-50-20 A X1 20 1,6 M6 0,5-10 CS

22-400-50-20 A X2 30 1,6 M6 0,5-10 CS

29-400-50-20 A X3 52 2,4 M8 1,5-25 CS

35-400-50-20 A X3 53 2,4 M8 1,5-25 CS

43-400-50-20 A X3 58 2,4 M8 1,5-25 CS

58-400-50-20 A X4 76 4.5 M8 2,5-50 CS

72-400-50-20 A X4 98 4,5 M8 2,5-50 CS

86-400-50-20 A X5 104 6,0 M8 10-70 CS

101-400-50-20 A X5 106 6,0 M8 10-70 CS

144-400-50-20 A X6 126 12,0 M8 2,5-95 CL M8

180-400-50-20 A X6 135 12,0 M8 2,5-95 CL M8

217-400-50-20 A X7 172 60,0 M12 25-300 CL M16

252-400-50-20 A X7 206 60,0 M12 25-300 CL M16

304-400-50-20 A X8 221 60,0 M12 25-300 CL M16

325-400-50-20 A X8 230 60,0 M12 25-300 CL M16

380-400-50-20 A X8 265 60,0 M12 25-300 CL M16

433-400-50-20 A X8 272 60,0 M12 25-300 CL M16

Configuration

filter module

Table 20: Electrical operating conditions 400V 50Hz RHF-B

Weight

[kg]

Torque*

Clamps X1+X2

[Nm]

Grounding

Cable

cross

section

[mm²]

Cable Lug**

* Locking torque of the electrical network and converter terminal clamp

** CS ≙ Cable end sleeve, CL ≙ Cable lug

Operating instructions RHF

41

Page 43

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Technical data and dimension diagrams

Nominal voltage 460V 60Hz

REVCON® - type

RHF-A-

10-460-60-20 A X1 13,5 1,6 M6 0,5-10 CS

14-460-60-20 A X1 16,3 1,6 M6 0,5-10 CS

19-460-60-20 A X2 22 1,6 M6 0,5-10 CS

25-460-60-20 A X2 25 1,6 M6 0,5-10 CS

31-460-60-20 A X3 33 2,4 M8 1,5-25 CS

36-460-60-20 A X3 37 2,4 M8 1,5-25 CS

48-460-60-20 A X3 38 2,4 M8 1,5-25 CS

60-460-60-20 A X4 43 4,5 M8 2,5-50 CS

73-460-60-20 A X4 55 4,5 M8 2,5-50 CS

95-460-60-20 A X5 62 6,0 M8 10-70 CS

118-460-60-20 A X5 74 6,0 M8 10-70 CS

154-460-60-20 A X6 85 12,0 M8 2,5-95 CL M8

183-460-60-20 A X6 102 12,0 M8 2,5-95 CL M8

231-460-60-20 A X7 117 60,0 M12 25-300 CL M16

291-460-60-20 A X7 136 60,0 M12 25-300 CL M16

355-460-60-20 A X7 162 60,0 M12 25-300 CL M16

380-460-60-20 A X7 172 60,0 M12 25-300 CL M16

436-460-60-20 A X8 203 60,0 M12 25-300 CL M16

Configuration

filter module

Table 21: Electrical operating conditions 460V 60Hz RHF-A

Weight

[kg]

Torque*

[Nm]

Clamps X1+X2

Grounding

Cable

cross

section

[mm²]

Cable Lug**

Nominal voltage 460V 60Hz

section

Cable

cross

[mm²]

Cable Lug**

REVCON® - type

RHF-B-

10-460-60-20 A X1 18 1,6 M6 0,5-10 CS

14-460-60-20 A X1 20 1,6 M6 0,5-10 CS

19-460-60-20 A X2 30 1,6 M6 0,5-10 CS

25-460-60-20 A X2 34 1,6 M6 0,5-10 CS

31-460-60-20 A X3 52 2,4 M8 1,5-25 CS

36-460-60-20 A X3 53 2,4 M8 1,5-25 CS

48-460-60-20 A X3 57 2,4 M8 1,5-25 CS

60-460-60-20 A X4 75 4,5 M8 2,5-50 CS

73-460-60-20 A X4 97 4,5 M8 2,5-50 CS

95-460-60-20 A X5 104 6,0 M8 10-70 CS

118-460-60-20 A X5 106 6,0 M8 10-70 CL M8

154-460-60-20 A X6 126 12,0 M8 2,5-95 CL M8

183-460-60-20 A X6 135 12,0 M8 2,5-95 CL M16

231-460-60-20 A X7 170 60,0 M12 25-300 CL M16

291-460-60-20 A X7 206 60,0 M12 25-300 CL M16

355-460-60-20 A X8 229 60,0 M12 25-300 CL M16

380-460-60-20 A X8 265 60,0 M12 25-300 CL M16

436-460-60-20 A X8 270 60,0 M12 25-300 CL M16

Configuration

filter module

Table 22: Electrical operating conditions 460V 60Hz RHF-B

Weight

[kg]

Torque*

[Nm]

Clamps X1+X2

Grounding

* Locking torque of the electrical network and converter terminal clamp

** CS ≙ Cable end sleeve, CL ≙ Cable lug

42

Operating instructions RHF

Page 44

Cable

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Technical data and dimension diagrams

Nominal voltage 500V 50Hz

Cable

cross

section

[mm²]

Cable Lug**

Clamps X1+X2

Torque*

[Nm]

Grounding

REVCON® - type

RHF-A-

15-500-50-20 A X3 12 2,4 M8 1,5-25 CS

20-500-50-20 A X3 13 2,4 M8 1,5-25 CS

24-500-50-20 A X3 22 2,4 M8 1,5-25 CS

29-500-50-20 A X4 36 4,5 M8 2,5-50 CS

36-500-50-20 A X4 40 4,5 M8 2,5-50 CS

50-500-50-20 A X5 42 6,0 M8 10-70 CS

58-500-50-20 A X5 52 6,0 M8 10-70 CS

77-500-50-20 A X6 56 12,0 M8 2,5-95 CL M8

87-500-50-20 A X6 62 12,0 M8 2,5-95 CL M8

109-500-50-20 A X6 74 12,0 M8 2,5-95 CL M8