Page 1

Strata

Thermal Printers

User’s Manual

©1999 Zebra Technologies Corporation

User’s Manual No. 980181-001 Rev. C

Page 2

Page 3

FOREWORD

This manual provides installation and operation information for the Eltron Strata LP (LP2684) and

Strata TLP (TLP2684) printers, manufactured by Zebra Technologies Corporation, Camarillo,

California.

COPYRIGHT NOTICE

This document contains information proprietary to Zebra Technologies Corporation. This docu

ment and the information contained within iscopyrightedbyZebraTechnologiesCorporationand

may not be duplicated in full or in part by any person without written approval from Zebra. While

every effort has been made to keeptheinformationcontainedwithincurrentandaccurate as of the

date of publication, no guarantee is given or implied that the document is error-free or that it is accurate with regard to any specification. Zebra reserves the righttomakechanges,forthepurposeof

product improvement, at any time.

TRADEMARKS

Strata, Strata LP , Strata TLP,LP2684andTLP2684areservicemarksandEltron is atrademark of

Zebra Technologies Corporation. Windows and MS-DOS are registered trademarks of Microsoft

Corp. All other marks are trademarks or registered trademarks of their respective holders.

FCC NOTICE:

This equipment has been tested and found to comply with the limits of aClass A digital device, pur

suant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses andcan radiateradio frequency energyand, ifnot installed andused in

accordance with theinstructions, maycause harmfulinterference to radio communications. How

ever, there is no guarantee that interference will not occur in a particular installation. Operation of

this equipment in a residential area islikely to cause harmful interference inwhich case the user will

be required to correct the interference at his own expense.

-

-

-

INDUSTRY CANADA NOTICE:

This device complies with Industry Canada ICS-003 class A requirements.

Cet equipement est conforme a l’ICS-003 classe A de la norm Industrielle Canadian

980181-001 Rev.C

iii

Page 4

WARRANTY INFORMATION

We Need To Hear From You!

To Establish Your Warranty Period And Provide Access To Technical Support,

Send Us Your Product Registration Card Today!

Zebra warrants the mechanism, control electronics and power supply, under normal use and ser

vice, to be free from defects in material and workmanship for a period of twelve (12) months from

the date of purchaseby theend user.Zebra warrants theprint head,under normaluse andservice,

to be free from defects in material and workmanship for a period of ninety (90) days or 30KM of

printing (whichever occurs first) from the date of purchase by the end user. Proof of purchase or

product registration is required. If proof of purchase or product registration cannot be established,

shipment date to the original buyer (dealeror distributor) will be used to establish the warranty pe

riod.

Failure to exercise caution to protect the equipment from electrostatic discharge damage, adverse

temperature and humidityconditions or physical abuse may void the warranty.Failure to use only

Zebra approved media mayvoid thewarranty. Zebrawill, atits option,repair orreplace theequip

ment or any parts which are determinedto be defective within this warranty period, and which are

returned to Zebra F.O.B. factory of origin.

The warranty set forth above is exclusive and no other warranty, whether written or oral, is expressed or implied. Zebra specifically disclaims the implied warranties of merchantability and fitness for a particular purpose.

RETURN MATERIALS AUTHORIZATION

Before returning any equipment to Zebra for in warranty or out of warranty repair, contact Repair

Administration for a Return Materials Authorization (RMA) number. Repack the equipment in the

original packing material and mark the RMA number clearly on the outside. Ship the equipment,

freight prepaid, to the address listed below:

-

-

-

Zebra Repair Administration, USA

Label Printers: Card Printers:

Zebra International, Europe Zebra International, Europe

Eltron House Zone Indutrielle, Rue d'Amsterdam

Molly Millars Lane 44370 Varades, France

Wokingham RG41 2QZ England Phone: +33 (0) 240 097 070

Phone: +44 (0) 1189 770 300 FAX: +33 (0) 240 834 745

FAX: +44 (0) 1189 895 762

iv 980181-001 Rev.C

1001 Flynn Road

Camarillo, CA. 93012

Phone: +1 (805) 579-1800

FAX: +1 (805) 579-1808

Page 5

Table of Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking Your Printer . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . 8

The FEED Control . . . . . . . . . . . . . . . . . . . . . . . 10

The STATUS Indicator. . . . . . . . . . . . . . . . . . . . . 12

Loading Labels

or Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Loading Transfer Ribbons . . . . . . . . . . . . . . . . . . . 25

Removing A Partially Used Transfer Ribbon . . . . . . . . . . 31

Top Of Form Sensing . . . . . . . . . . . . . . . . . . . . . 32

Using AutoSense. . . . . . . . . . . . . . . . . . . . . . . . 33

Cleaning Your Printer . . . . . . . . . . . . . . . . . . . . . 35

Cleaning the Print Head . . . . . . . . . . . . . . . . . . . . 36

Cleaning Under the Sensor Bracket . . . . . . . . . . . . . . 37

Using the Label Dispenser . . . . . . . . . . . . . . . . . . . 38

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 41

Where to Start . . . . . . . . . . . . . . . . . . . . . . . . . 41

Other Support Resources . . . . . . . . . . . . . . . . . . . 44

Serial Interface Communication Configuration. . . . . . . . . 45

Serial Interface Cable Wiring. . . . . . . . . . . . . . . . . . 45

Tag Media Sensing . . . . . . . . . . . . . . . . . . . . . . 46

Printer Features . . . . . . . . . . . . . . . . . . . . . . . 47

Supplies and Accessories . . . . . . . . . . . . . . . . . . 53

Using the Media Cutter . . . . . . . . . . . . . . . . . . . 57

980181-001 Rev.C v

Page 6

General Cautions and Warnings

These pages describe general safety and maintenance warnings and cautions for the printer.

They are referenced throughout the manual. The manual may also include other warnings and

cautions not displayed here.

Warning - Shock Hazard

The printer should never be operated in a location where it can

get wet. Personal injury could result.

Warnung - Stromschlaggefahr - Der Drucker sollte nie an

feuchten Standorten in Betrieb genommen werden. Es besteht

erhöhte Verletzungs und Unfallgefahr.

Warning - Static Discharge

The discharge of electrostatic energy that accumulates on the

surface of the human body or other surfaces can damage or

destroy the print head or electronic components used in this

device. DO NOT TOUCH the print head or the electronic

components under the print head assembly.

Caution - Printer Setup & Handling

1)When installing or modifying the printer setup or

configuration, ALWAYS TURN POWER OFF Before:

A) Connecting any cables.

B) Performing any cleaning or maintenance operations.

C) Moving the printer.

2) Damage to the printer interface connector, accessories or

enclosure may result from placing the printer on it’s front bezel

or backside during unpacking or handling.

vi 980181-001 Rev.C

Page 7

Media Cautions & Tips

1) Always use high quality Eltron approved labels and tags.

Eltron approved supplies can be ordered from your ELTRON

dealer. For the name of a dealer in your area, call Eltron

Customer Service at one ofthe numbers listed onthe back page

of this manual.

2) If poor quality, adhesive backed labels are used, that DO

NOT lay flat on the backing liner, the exposed edges may stick

to the label guides and rollers inside the printer, causing the

label to peel off from the liner and jam the printer.

3) DO NOT use non-Eltron transfer ribbon. Permanent damage

to the print head may result if a non-Eltron ribbon is used.

Non-Eltron ribbons maybe wound incorrectly for the printer or

contain chemicals that may damage the print head.

4) IMPORTANT - If a transfer ribbon is installed incorrectly by

the operator, damage to the print head may result.

5) DO NOT use a ribbon when printing with direct thermal

media.

Media Reload Tip

If you should run outof labels or ribbonwhile printing, DO NOT

turn the power switch OFF (0) while reloading or data loss may

occur. The printer will automatically resume printing when a

new label or ribbon roll is loaded.

Print Mode Control (TLP2684)

The printer is reconfigured for direct thermal (or thermal

transfer) printing with the “O” command for the Strata TLP

thermal transfer printer. See the EPL2 programmer's manual

for details.

Print Quality Tip

Print density (darkness) is affected by the heat energy (density

setting) applied and by the print speed. Changing both Print

Speed and Density may be required to achieve the desired

results.

980181-001 Rev.C

vii

Page 8

viii 980181-001 Rev.C

Page 9

Installation

1

Installation

This section provides information on the

installation of the printer and software.

Introduction The Strata printer models are low cost, manu-

facturing oriented, thermal desktop printers.

The Strata LP is a direct thermal printer. The

Strata TLP is a thermal transfer and direct thermal printer. The printers have been specifically

designed for printing large labels, hazardous

material labels, small signs, fan-fold media, and

shipping and receiving labels while operating in

office to industrial environments.

The printer features sturdy construction, a small

footprint, a heavy-duty motor, and sharp, reli

able printing up to 8.5 inches (216 mm) wide.

The print head resolution of a Strata printer is

203 dpi (8 dots/mm).

The printer can print letter (8.5”x 11”) and A4

(210mm x 297mm) sizes. Print forms up to 8.5

inches (216 mm) wide and 22 inches (558.8

mm) long or two times A4 (210mm x 594mm)

size with optional memory added.

-

980181-001 Rev.C 1

Page 10

Installation

User Documentation

&Software

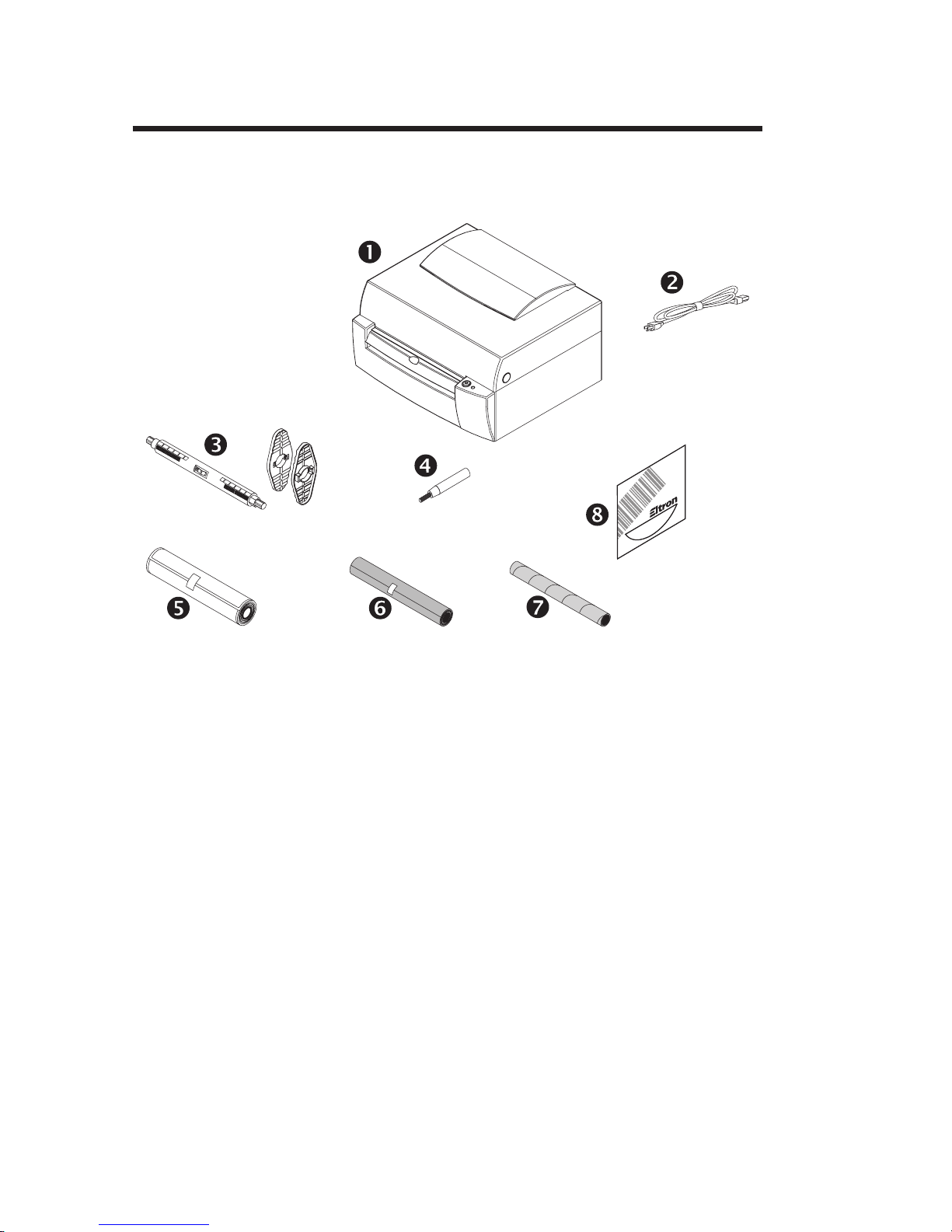

Unpacking Your

Printer

Open the shipping carton and remove the

printer and its accessories.

Check List

2

Printer

1

Power Cord

2

Media Holder and Retainers

3

Cleaning Pen (for print head)

4

Sample Label Roll

5

Sample Transfer Ribbon Roll (TLP only)

6

Ribbon Core (TLP only)

7

Software and Documentation CD

8

980181-001 Rev.C

Page 11

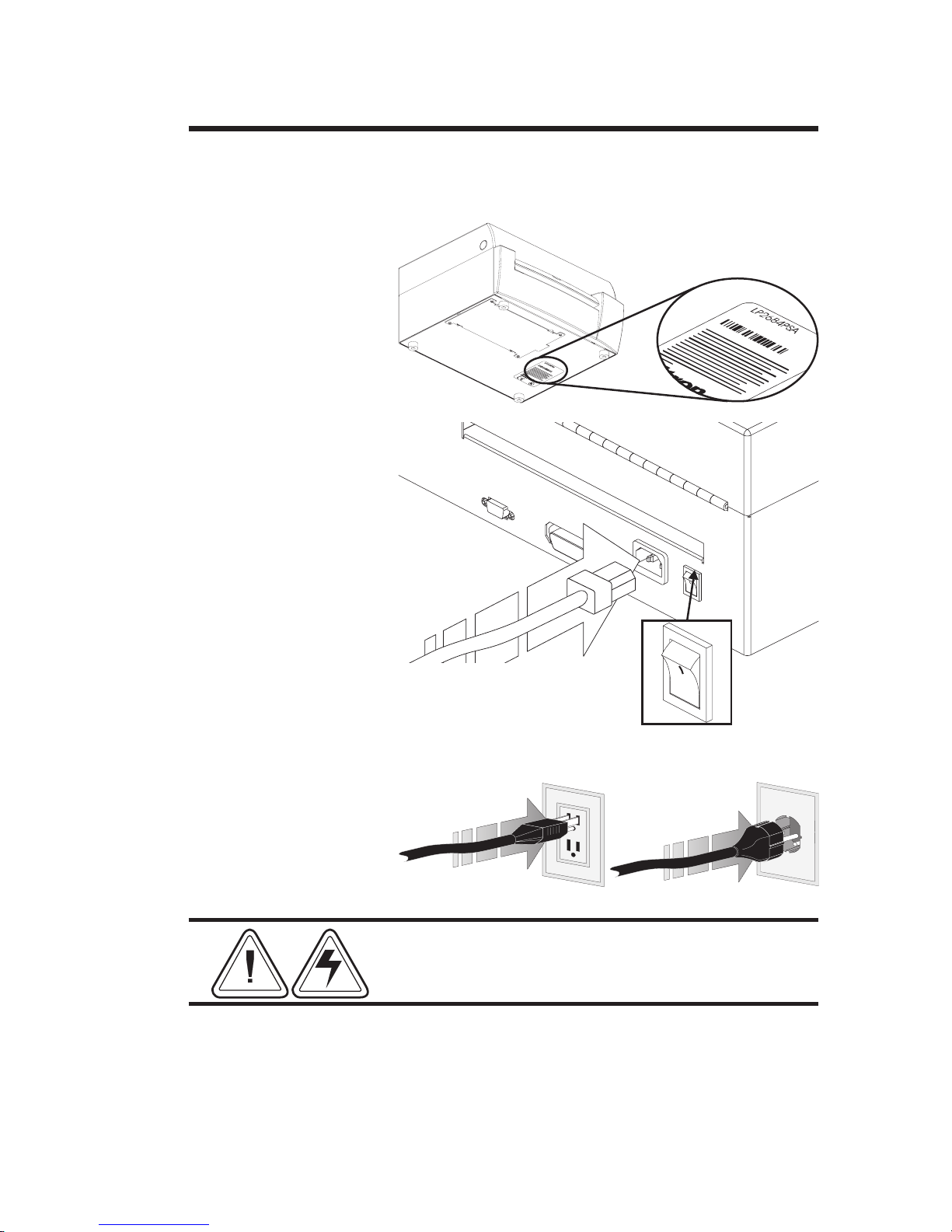

Installation

Part No.: 120XXX-XXX

Serial No.:XXXXXXXX

Input Power:115VAC 6.3A 50/60Hz

Installation The following steps will guide you through the

installation of the printer and software.

Step ➊

Attach Power

Check Voltage

Pa

S

rtN

eri

a

o

lNo.

.:120

In

pu

tP

:X

X

o

X

XX-

we

X

X

X

r:

XX

XX

11

XX

5

V

AC6

.

3A50

/

60

H

z

O

O

O = Off

See Warnings - Page vi

980181-001 Rev.C 3

Page 12

Installation

Step ➋ Attach

Interface Cable

Parallel Interface

Serial Interface

For additional information on serial cable wir

-

ing, refer to Appendix A.

4

980181-001 Rev.C

Page 13

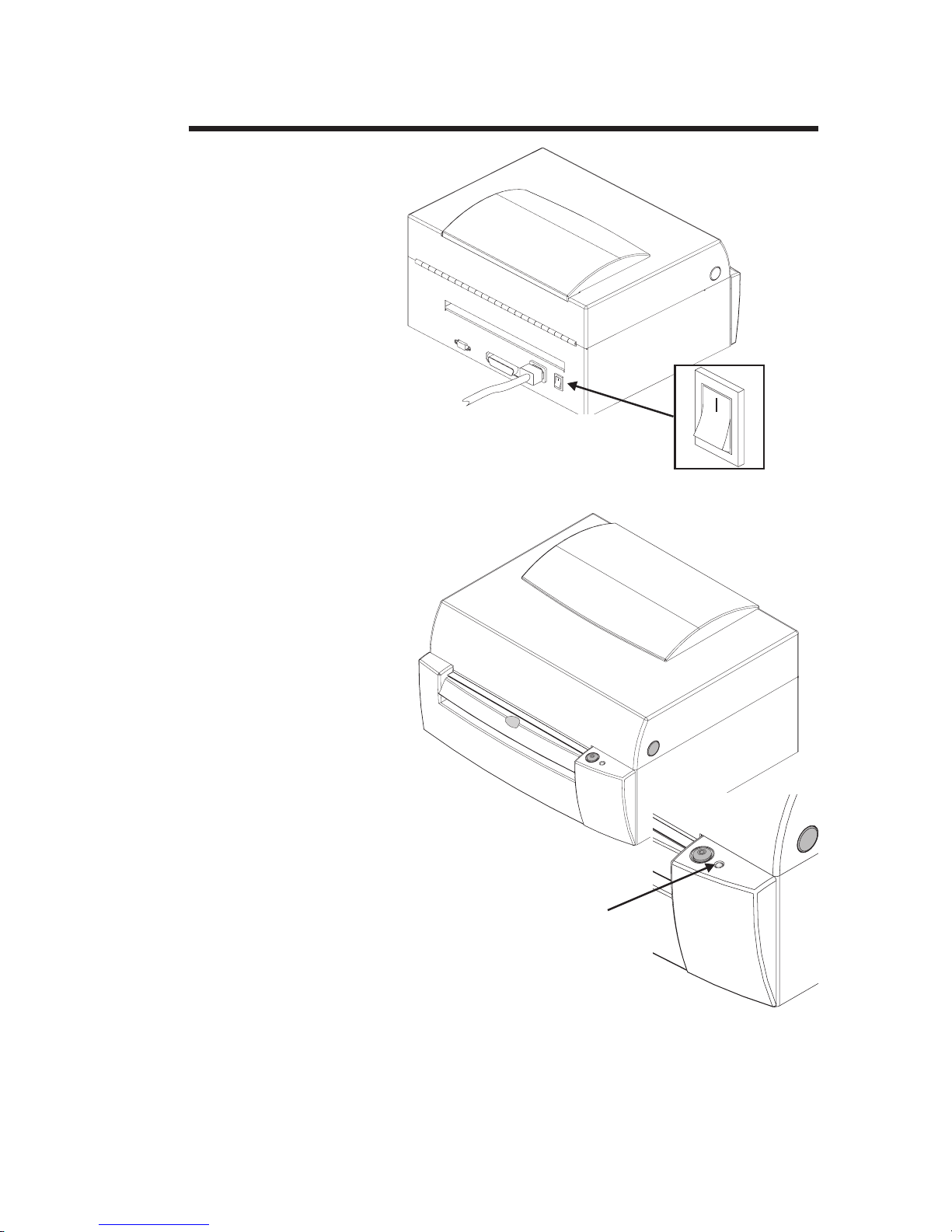

Step ➌ Apply

Power

Installation

O

O

I = On

980181-001 Rev.C 5

On

If the indicator fails to light, refer to

Appendix A - Troubleshooting.

Page 14

Installation

Step ➍ Install

Software

Start your computer. Follow the installation

instructions on the disk label to install the

software.

Refer to Section 2 - Operation, for information

on loading labels and using your printer.

6

980181-001 Rev.C

Page 15

2

Operation

This section provides information on the operation of the printers.

All user control (and adjustment) printer

features are identified by green parts.

980181-001 Rev.C 7

Page 16

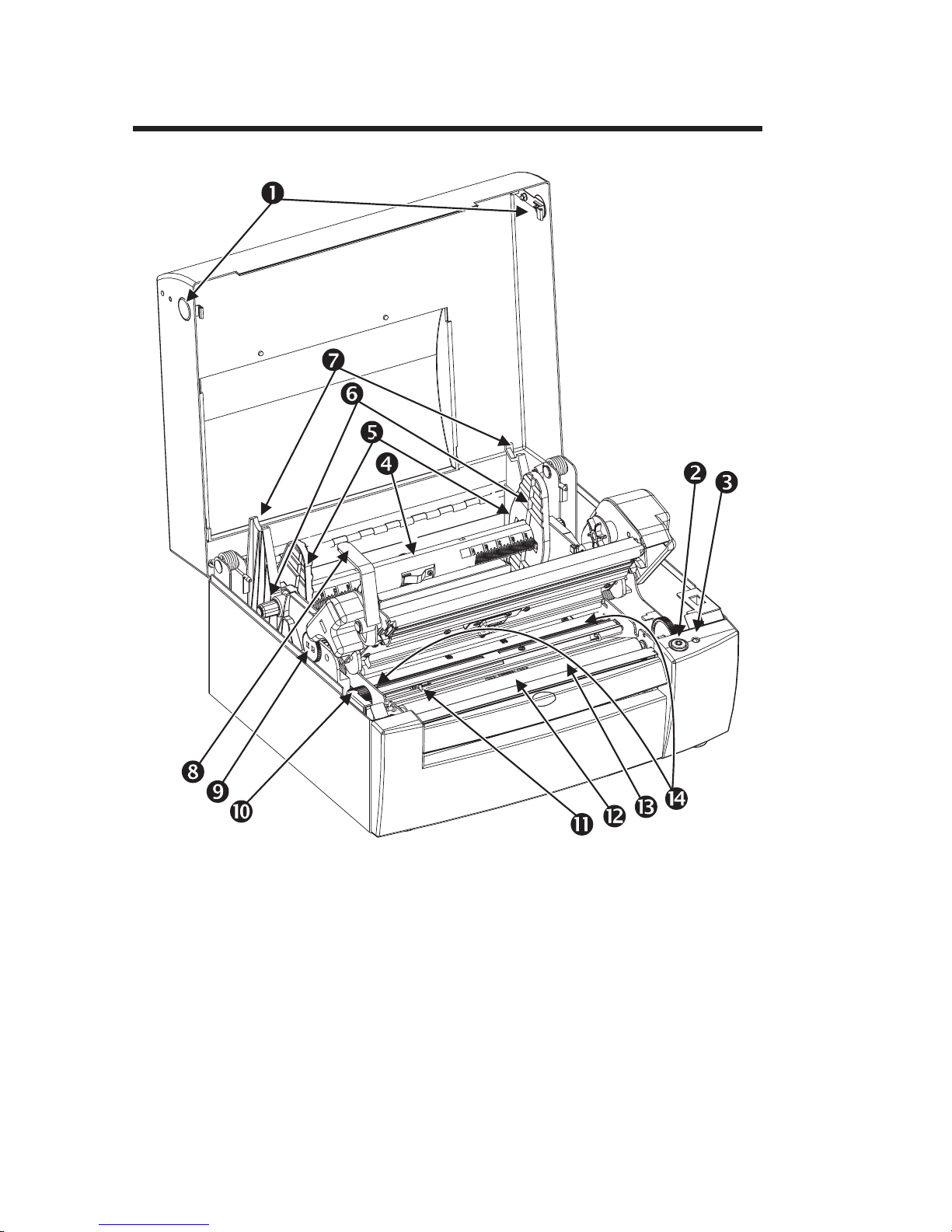

Operation

Your Printer

Cover Release Buttons 8 Carriage Lock/Release Lever

1

Feed Button

2

3 Status Indicator : Transmissive (Gap) Sensor

4 Media Roll Holder Adjustment Gear

5 Media Roll Retainers ; Transmissive (Gap) Sensor

6 Lower Media Stand Position Indicator

(Printing Position) < Reflective (Black Mark) Sensor

7 Upper Media Stand = Platen Roller

(Loading Position) > Media Guides

8 980181-001 Rev.C

Media Guide Adjustment Gear

9

Page 17

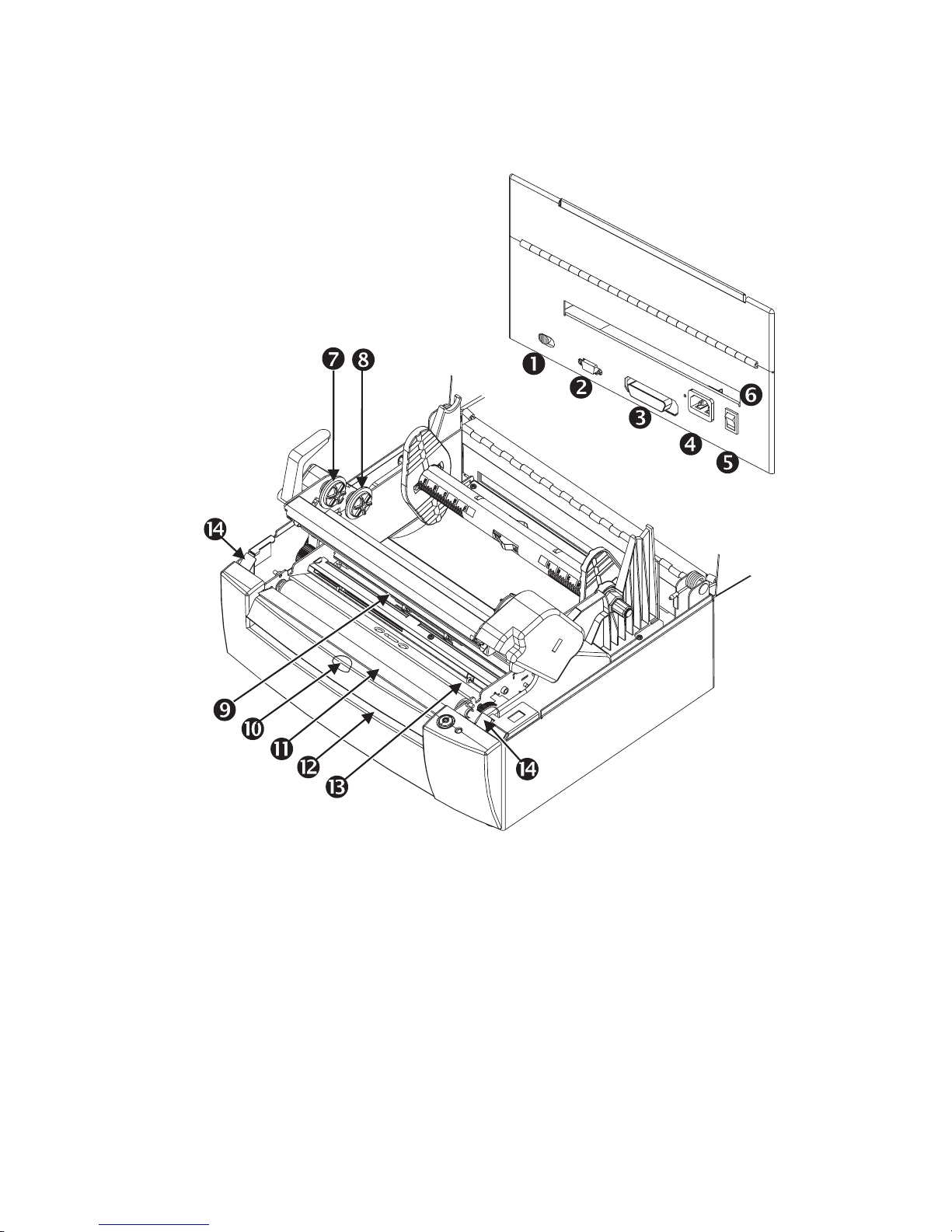

Operation

1 Batch/Dispense Select Switch 8 Ribbon Supply Spindle

2 Serial Interface 9 Ribbon Sensor

3 Parallel Interface : Label-Taken Sensor

4 Power Cord Receptacle ; Dispenser Bar

5 On/Off Switch < Label Liner Exit

6 Fan-Fold Media Entry = Release for Transmissive (Gap)

7 Ribbon Take-up Spindle Sensor Guide Bar Bracket

980181-001 Rev.C 9

Page 18

Operation

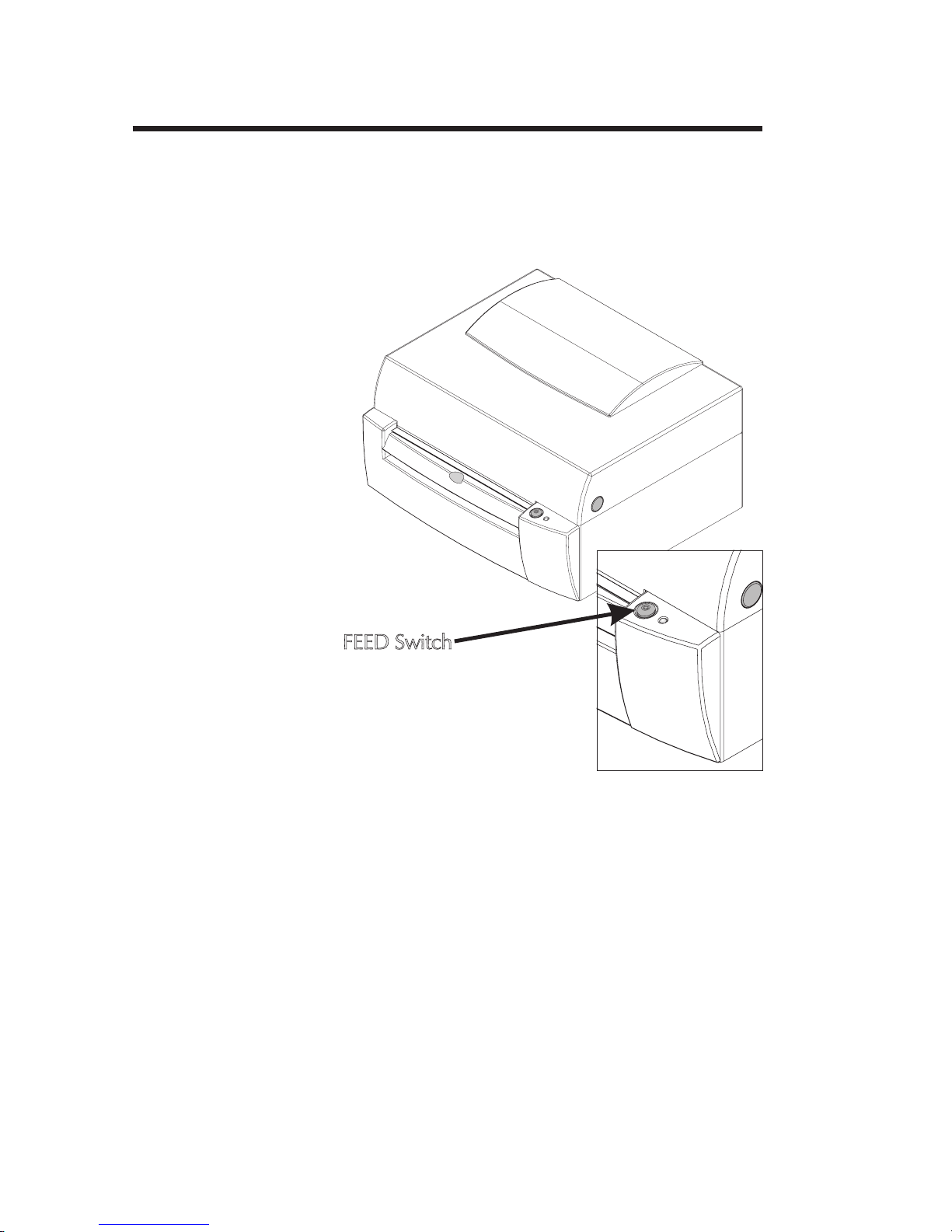

The FEED Control The FEED button controls specific printer

functions: feeding media (labels, tags or

continuous media), loading media, pausing

printing, and initiating AutoSense (Dump

Mode).

10

Use the FEED control button in normal opera

tion by tapping or holding the button.

•

Tapping the FEED Button with labels

loaded will cause the paper to advance to the

top of the next label. This action is referred to

as a “Form Feed”.

•

While Printing, Tapping the FEED Button

will pause batch printing (at the next label

gap) with indicator green flashing red. Press

ing the FEED Button again will resume print

ing with the next label in the batch process.

980181-001 Rev.C

-

-

-

Page 19

Operation

Holding the FEED button down will cause

•

the printer to continuously Form Feed until

the button is released. The printer will feed

the media until the next top of form is

reached.

Holding the FEED button without media

•

loaded will cause the printer to continuously

(line) feed until the button is released or me

dia is detected. This is useful when reloading

media in the printer and is also known as

“Power Media Loading”.

Holding the FEED button down while pow

•

ering up the printer with media loaded will

cause the printer to enter the AutoSense

mode. See AutoSense on page 33 for important details.

-

-

Always run the AutoSense procedure when

loading new batch or type of media. Media from

the same manufacturing lot and having

identical dimensions do not need to have the

AutoSense procedure run every time new

media is loaded.

The Form Feed length is set by printer

programming (Q) command in EPL2

programming language or the AutoSense

feature, an automatic label and gap length

sensing operation. See AutoSense, page 33.

Continuous media with no label gaps,

containing black marks or notch holes, require

programming to set the form length and feed

distance.

980181-001 Rev.C 11

Page 20

Operation

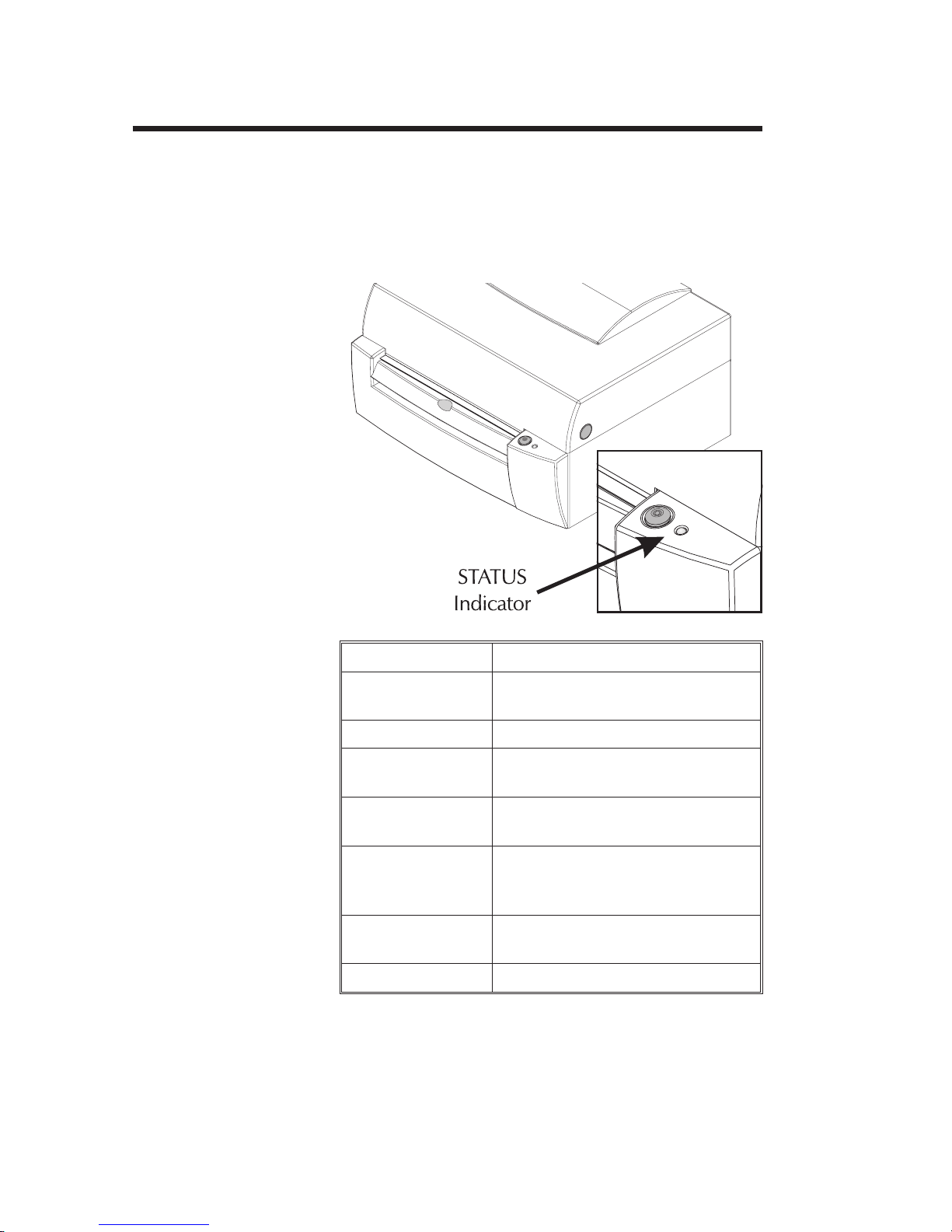

The STATUS

Indicator

The STATUS indicator is a power and status in

dicator. When the printer power is first switched

ON (1), the STATUS indicator will glow

GREEN, indicating that the printer is ready for

operation.

-

Indicator Color Meaning

GREEN

GREEN Blinking

GREEN with RED

Blinking Twice

AMBER

RED

RED

Flashing

DARK

1) Power ON, ready for use.

2) Printing, operation normal.

Interface Activity

Printer PAUSED

(during a batch print operation)

1) Command Error condition

2) Command Syntax Error

1) Media Out (printing)

2) Ribbon Out (printing)

3) Power-up failure

Print Carriage Open

Power OFF.

Refer to Appendix A for additional information

on troubleshooting error conditions.

12

980181-001 Rev.C

Page 21

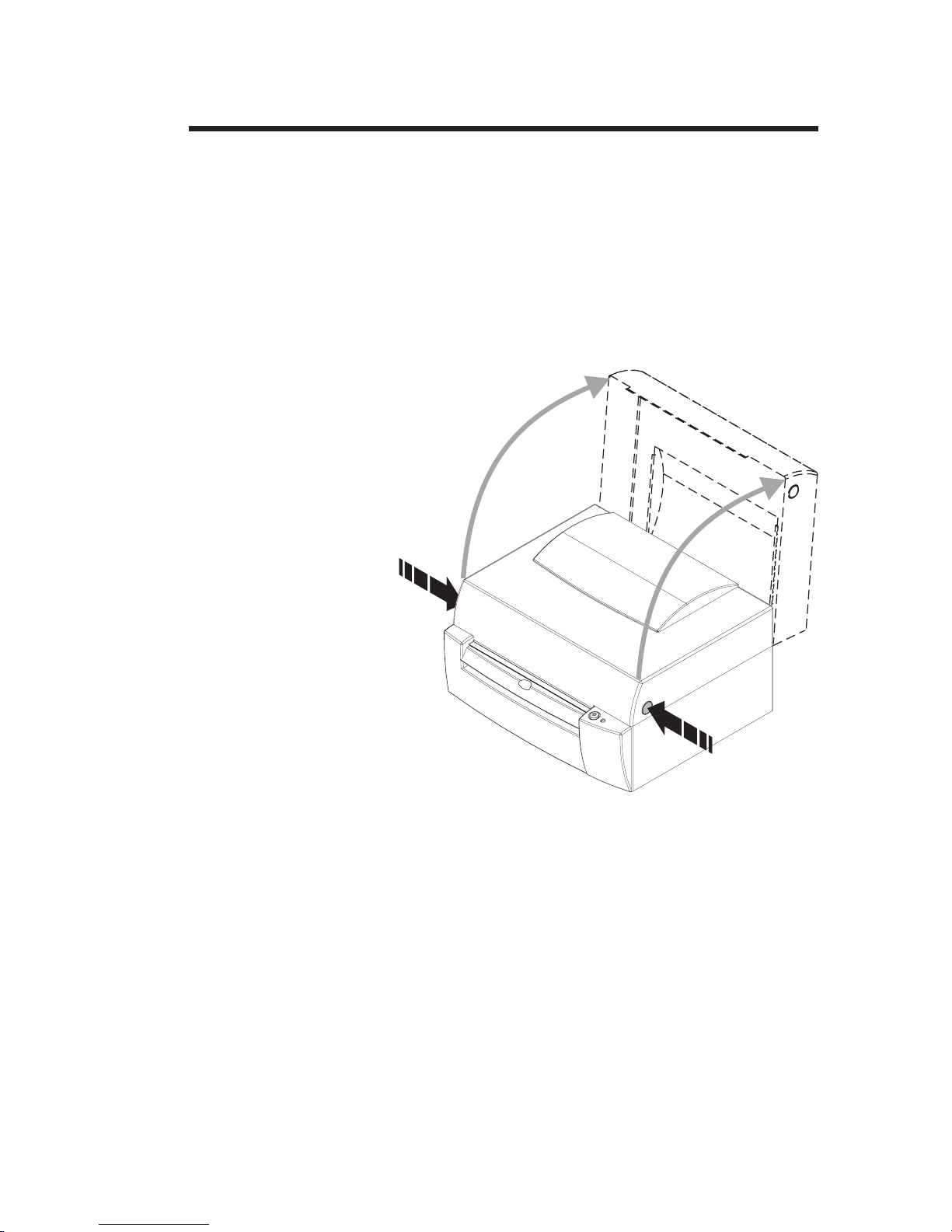

Operation

Loading Labels

or Tags

Step 1 Open the printer. Press the two green release

Your printer can print on adhesive backed la

bels, non-adhesive tags or continuous media

(typically paper). The printer is capable of using

media on a roll or fan fold media.

buttons on the sides of the printer to open the

cover.

-

980181-001 Rev.C 13

Page 22

Operation

Step 2 Place the roll of media on the media holder

tube. The media holder tube is directional and

will not work properly if installed incorrectly.

The media holder is keyed with a hex to be

mounted on the right side of the printer when

installed.

14

CORRECT INCORRECT

980181-001 Rev.C

Page 23

Operation

Step 3 Center the media roll on the holder. If the media

roll is narrow, then the media roll holders can be

added to prevent loose (uneven) pack of the

media on the roll.

Media Retainers (optional)

980181-001 Rev.C 15

90°

90°

Page 24

Operation

Step 4 Set the media and roll holder on the upper me

dia stand for loading.

-

16

980181-001 Rev.C

Page 25

Operation

Step 5 Turn the media guide adjustment wheel to

wards the rear of the printer to open the media

guides.

-

Open the media guides until they are widerthan

the media.

Media

Guides

980181-001 Rev.C 17

Page 26

Operation

Step 6 Open the print head carriage with the release

lever. Pull forward and then up.

Release Lever

18

980181-001 Rev.C

Page 27

Operation

Step 7 Insert the loose end of the media roll between

the media guides and under the guide bar

bracket that holds the transmissive (gap) sensor.

Continue feeding the media under the print

head carriage until it exits out the front of the

printer.

980181-001 Rev.C 19

Page 28

Operation

Step 8 Turn the green media guide adjustment wheel

towards the front of the printer until the label

guides match the width of the media.

20

980181-001 Rev.C

Page 29

Operation

Step 9 Move the media roll to the lower media stand

for printing.

980181-001 Rev.C 21

Page 30

Operation

Sensor

Position

Step 10 When using the transmissive (gap) sensor for

top of form (label) sensing, verify that the sen

sor is positioned at minimum

centered over a tag hole. See Top of Form

Sensing, page 32, for more details on sensor

operation.

Adjustment

Wheel

label gap point or

-

Sensor

Position

Marker

Turn the sensor’s adjustment wheel towards the

rear of the printer to move it into the middle.

Turn it towards the front of the printer to move it

out to the media edge. Do not position the sen

sor at the edge of media.

Center the transmissive (gap) sensor for most

labels and always center it for continuous

media.

-

22

980181-001 Rev.C

Page 31

Operation

Step 11 Close and lock the print head carriage. Push the

print head carriage down to close and then push

the lever back to lock.

Turn on the printer power. Tap the FEED control until the STATUS indicator glows GREEN.

980181-001 Rev.C 23

Page 32

Operation

Step 12 Set label detection parameters for media:

Use the AutoSense procedure for first time

•

use of new media to set the transmissive

(gap) sensor.

Use the AutoSense procedure for detection

•

of label and gap lengths.

Use EPL2 programming (Q) command to

•

set form length (and gap) as well as media de

tection and control method for sensing label

gap, black mark or continuous (unmarked)

media.

Windows Users!

Use Settings / Printers on the Start Menu of

Windows 95 or Windows NT versions 3.51 &

4.0 to select the label size that matches the labels

loaded in the printer.

-

24

980181-001 Rev.C

Page 33

Operation

Loading Transfer

Ribbons

Transfer ribbons are used when printing on

thermal transfer media such as adhesive labels

or non-adhesive tags. Thermal transfer ribbons

are available in general purpose wax (blue

leader), general purpose wax-resin (silver

leader) and polyester resin (gold leader).

Take-Up

Spindles

Supply

Spindles

Tracking

Bar

The print head carriage in a thermal transfer

printer includes these functional features:

•

Ribbon Take-Up Spindles (forward pair)

Pulls ribbon over the print head.

•

Ribbon Supply Spindles (back pair)

Provides back tension to stop wrinkles.

•

Ribbon Tracking Bar (in back of print head

carriage). Automatically tracks ribbon ten

sion (equalizes) across the ribbon’s width.

-

980181-001 Rev.C 25

Page 34

Operation

Step ➊ Install an empty ribbon core onto the front rib

bon (take-up) spindle pair. Push the core onto

the left side ribbon (takeup) spindle. Rotate the

core on thespindle until thenotches on theright

side of the core match-up with the long spokes

on the right side ribbon (take-up) spindle.

-

26

Notch

Long Spoke

980181-001 Rev.C

Page 35

Operation

Step ➋ Loosen the ribbon leader that secures the lead

ing end of the transfer ribbon roll. Fold the rib

bon leader over and attach it to the under side

of the ribbon leader.

-

-

980181-001 Rev.C 27

Notch

Page 36

Operation

Step ➌ Install the ribbon roll onto the rear ribbon

(supply) spindle pair so that the ribbon feeds

from the top of the roll toward the back of the

printer. The ribbon roll installs the same as the

ribbon (take-up) core.

Wrap the ribbon around the print carriage,

aound the ribbon tracking bar and above the

media guide bracket.

Caution:

The ribbon doesnot follow the same path as the

labels. The ribbon threads above the brackets

that hold the media guides and transmissive

(gap) sensor guide bar.

28

980181-001 Rev.C

Page 37

Operation

Step ➍ Hold open the print carriage to pull the ribbon

through towards the front of the print carriage

and up to the empty take-up core. Center the

ribbon on ribbon core. Attach the ribbon to the

core with the adhesive strip on the leader or

with tape.

980181-001 Rev.C 29

Page 38

Operation

Step ➎ Rotate the ribbon take-up core a minimum one

full revolution (from the top to the back of the

printer) to remove most of the slack from the rib

bon. Verify that the ribbon is wrapping straight

on the ribbon core.

After the media is loaded, hold the ribbon snug

and close theprint head. See label and tag (me

dia) loading, page 13.

Press the FEED button (with the printer power

on) to condition the ribbon. This is to remove

the slack and wrinkles in the ribbon. Repeat un

til the slack is removed. Verify that the ribbon is

wrapping straight on the ribbon core.

-

-

-

30

980181-001 Rev.C

Page 39

Operation

Removing A

Partially Used

Transfer Ribbon

Step ➊ Open the print carriage to release ribbon ten

A partially used transfer ribbon can be removed

by following the steps below.

The unused portion of partially used transfer

ribbons can be reloaded using the normal rib

bon loading procedure.

sion. Using scissors, cut the transfer ribbon just

below the take-up roll.

-

-

Step ➋ Remove the supply roll and tape the end to

Step ➌ Remove the take-up roll.

980181-001 Rev.C 31

prevent it from unwrapping.

Discard used ribbon off the take-up core. Save

the empty take-up core for when you load

ribbon again.

Page 40

Operation

Top Of Form

Sensing

To accommodate different media and media

dimensions, your printer is equipped with sen

sors capable of detecting the top of form for la

bels or tags. Two methods are used by the

printer for top of form sensing: gap sensing and

black mark sensing.

Gap Sensing The gap sensing feature depends on the ability

of the movable transmissive (gap) sensor to

“see through” the label liner between labels.

Label and label backing liner opacity vary due

to manufacturing differences in label stock. The

sensor may have difficulty distinguishing the

difference between labels and the liner and may

require the user to AutoSense the media. Gap

sensing is standard on all printers and the sensitivity is set with the AutoSense feature.

-

-

Black Mark

Sensing

The black mark sensing feature depends on the

printer’s fixed position, reflective (black mark)

sensor. The sensor is in the middle of the media

path. The black mark sensor is used with special

labels that have a black mark printed on the back

of the label liner or tag between each label ortag.

Black mark sensing is standard on all printers.

Continuous Media If the media is continuous (fax or plain paper)

with no marks notches or gaps, then the top of

form and form length must be set by program

ming. The transmissive sensor senses media

out. For proper operation, the printer needs to

measure the length of the form.

See the Q command in the EPL2 programming

manual for setting the form length of continuous

media with no label gaps, black line mark or

notch hole.

-

32

980181-001 Rev.C

Page 41

Operation

Using AutoSense The AutoSense feature sets sensitivity of the

transmissive sensor and measures and stores

the form (label) andgap lengths. To activate the

AutoSense feature:

Step 1 Set the power switch to the OFF (0) position.

Step 2 Load labels into the printer (do not use the dis

Step 3 Press and hold the FEED Control button while

Dump Mode

-

penser).

placing the power switch in the ON (1) position.

The STATUS Indicator light will blink. Release

the FEED Control when the printer starts feeding labels and the indicator turns solid green. Do

not hold the FEED Control button more than 5

seconds.

The printer will advance 3-4 labels while performing the adjustment. When the adjustment

is complete, a status summary label will be

printed and the printer will be placed in Diag-

nostic Dump mode.

Sample Printout

980181-001 Rev.C 33

Page 42

Operation

Step 4 Tap the FEED Control once to switch the printer

back to normal operation.

If the indicator light turns AMBER or RED, refer

to Appendix A for troubleshooting information.

34

980181-001 Rev.C

Page 43

Operation

Cleaning Your

Printer

You have easy access to all of the printer’s me

dia path areas to allow for cleaning and clearing

of media jams. You can clean the sensor areas,

print head, platen roller and areas adjacent to

the media path surfaces.

Warning -Shock Hazard - See page vi.

Always turn the printer off before cleaning.

Warnung - Elektrische Gefahr - Zuerst

abschalten dur Drucker. Säubern Sie jetzt den

Drucker.

Use a brush or vacuum to clean the media path

(except the print head). If necessary, use a

lint-free cloth very lightly

moistened with water

to clean the platen. Let the platen dry before

loading labels.

-

Warning - Static Discharge - See page vi.

Never touch the print head. Always clean the

print head with a cleaning pen (to protect the

print head from static discharge and fibers).

If a label has become jammed in the printer,

remove the label and any adhesive residue,

immediately. Adhesive may spread through out

the printer’s media path if not completely

removed. Many adhesives are permanent and

have short “set” times.

980181-001 Rev.C 35

Page 44

Operation

Cleaning the

Print Head

Step 1 Open the printer and the print head carriage.

Step 2 Gently rub the cleaning pen across the dark

As you use your printer, the print head may be

come contaminated resulting in poor print qual

ity. Whenever new labels are loaded into the

printer, the print head should be cleaned with a

cleaning pen.

area of the print head.

-

-

Clean Print Head

Allow the print head to dry for 1 minute before

loading labels.

Do not touch the cleaning pen to the platen

roller. If necessary, gently wipe the platen roller

with a dry, lint-free cloth.

36

980181-001 Rev.C

Page 45

Operation

Cleaning Under

the Sensor Bracket

Step 1 Open the print head carriage.

Step 2 Open the sensor bracket. Pull the slide lock to

The transmissive (gap) sensor guide bar bracket

can pivot up for easy cleaning.

the left and lift the front of the bracket up.

Transmissive (Gap)

Sensor Bracket

Step 3 Clean the metal part of the bracket, only. The

Step 4 Swing the sensor bracket down to close. The

Slide Lock

sensor is recessed to protect it from labels and

adhesive.

Clean the clear sensor window below the sensor

bracket. Do not use abrasive cleaning materials.

Only use water on a lint free, clean, damp cloth

lightly moistened. Let dry. Verify that the

very

window is clear of streaks and clouding.

slide lock will automatically lock when in posi

tion.

Close the print carriage.

-

980181-001 Rev.C 37

Page 46

Operation

Using the Label

Dispenser

Step 1 Push the switch to the peel position.

Printers with the label dispenser function (indi

cated by a T after the model number) can dis

pense a single label that is already peeled away

from the liner. Before performing these steps,

load a media roll (refer to page 12 ifnecessary).

-

-

38

Step 2 Open the print head and lift the dispenser bar.

980181-001 Rev.C

Page 47

Operation

Step 3 Remove a few labels. Push a corner of the liner

behind the gray roller and through the slot.

Step 4 Remove slack by pulling the liner.

980181-001 Rev.C 39

Page 48

Operation

Step 5 Close the dispenser bar and print head. Tighten

the liner against the dispenser bar.

Adjust the media guides (refer to page 19).

Step 6 Send your print job. The printer dispenses one

label and waits for you to take it before printing

the next label. You must remove each printed

label before the next label prints.

40

980181-001 Rev.C

Page 49

Troubleshooting

Appendix A

Troubleshooting

This section addresses the most common issues

you may face with operation and configuration

of the printer.

Where to Start The first troubleshooting reference source is the

Common Problems Troubleshooting table on

the following page.

980181-001 Rev.C 41

Page 50

Troubleshooting

Common Printing Problems

Troubleshooting Guide

Problem Solution or Reason

STATUS indicator

does not light GREEN

when power switch is

turned to the ON (1)

position.

1. Check power connections from the printer to

the outlet.

With the STATUS

indicator light GREEN,

the printer appears to

be working, but

nothing is printed.

Printing is faded or

poor quality.

Printing stops and the

STATUS indicator

lights RED.

1. Verify that the labels are the correct type.

2. Check the roll and verify that the print surface

faces up for (direct thermal) printing.

3. Check that the transfer ribbon is correctly

routed and has the ink side out (TLP only).

1. Clean the print head with cleaning pen.

2. Adjust print speed/darkness in software or

with programming.

3. Check the roll and verify that the media print

surface is facing up.

4. Verify that the correct combination thermal

transfer ribbon and media are in use.

1. Possible problem sensing labels with transmissive (gap) sensor. Perform AutoSense adjustment. Align the transmissive (gap) sensor

position, see page 22.

2. Possible problem with label media.

a) Gap between the bottom of a label and the

top of the next label should be at least 1/16".

b) For tags, see Tag Media Sensing, page 46.

c) Use only Eltron approved labels and tags.

3. Possible label jam.

4. Check that the media is correctly routed.

5. Possible software/programming problem.

a) Check the printer memory configuration.

b) Refer to the EPL2 Programming manual

for the correct data syntax.

6. Transmissive sensor is dirty. Clean media

path.

42 980181-001 Rev.C

Page 51

Problem Solution or Reason

1. Check for Out-of-Media condition or missing

labels in the middle of a roll.

2. Check for Out-of-Ribbon condition or dam

age or previous use of ribbon in middle of the

roll.

3. Check that the ribbon and label media are

correctly routed.

Status Indicator is RED

4. When direct thermal printing, verify that the

programmed mode (or printer driver) is set for

direct thermal printing. See the programmer’s

manual for details.

5. Transmissive sensor is dirty. Clean media

path.

6. Verify that the print head carriage is closed

and latched.

Troubleshooting

-

980181-001 Rev.C 43

Page 52

Troubleshooting

Other Support

Resources

The first troubleshooting reference source is the

table on the previous page. Next, contact the

dealer where you purchased your printer.

Zebra Technologies also provides a variety of

information and user support services:

Internet:

•

Web Address: http://www.eltron.com

ftp: //ftp.eltron.com

e-mail:

Label Printers: techsup@eltron.com

Card Printers: privsup@eltron.com

Europe: eurosup@eltron.com

Singapore: asiasup@eltron.com

Latin America: latinsup@eltron.com

• CompuServe e-mail: 102251,1164

• Customer Service: +1 (805) 579 1800

For the name of a dealer in your area.

• Technical Support FAX:

USA: +1 (805) 579 1808

Asia: +65 84 20 366

Northern Europe: +44 (0) 1189 895 762

Southern Europe: +33 (0) 240 097 070

Latin America: +1 (847) 584 2725

For your assistance and support with Eltron

printers and software.

44

980181-001 Rev.C

Page 53

Troubleshooting

Serial Interface

Communication

Configuration

Serial Interface

Cable Wiring

The printer’s serial port is configured with the

Y command for the printer. See the EPL2 pro

grammer's manual for details.

The printer’s serial port default configuration is:

9600 baud

8 bit data

1 stop bit

No parity

The figure below displays the cable wiring re

quired to use the printer’s serial interface

DB-9

Pin #

N/C

RxD

TxD

DTR

GND

DSR

RTS

CTS

RI

DB-9

Pin #

11

22

33

44

55

66

77

88

99

PrinterHost

+5 Volts*

TxD

RxD

N/C

GND

RDY

N/C

RDY

N/C

-

-

Female DB-9 to Male DB-9

DB-25

Pin #

N/C

RxD

TxD

DTR

GND

DSR

RTS

CTS

RI

Female DB-25 to Male DB-9

*+5 volts at 150 mA for external device (e.g. KDU or scanner)

980181-001 Rev.C 45

DB-9

Pin #

18

23

32

420

57

66

74

85

922

PrinterHost

+5 Volts*

TxD

RxD

N/C

GND

RDY

N/C

RDY

N/C

Page 54

Troubleshooting

Tag Media Sensing The printer uses a moveable sensor to detect in

dex holes/notches in tag stock. The sensor can

move from a center tag notch to a notch on the

out side edge of tag stock as wide as 8.5 inches

(216mm) wide.

D

C

Print

Direction

B

A

Left Side

Edge of Tag

Stock Media

The dimensions show the position acceptable

position range of the “Notch” (hole) on tag

stock for the printer and the gap sensor’s adjustment range.

Tag

Tear-away

C

L

-

46 980181-001 Rev.C

Dimension Min. Max. Nominal

A

B

C

D

Maximum Media Width

With Roll Holders - 8.5” (216mm)

Without Roll Holders - 8.75” (222mm)

.236”

(6mm)

.079”

(2mm)

Sensor Adjustment Range (Left Side):

From Center of Media to 4.3”(109mm)

.250”

(6.35mm)

—

.512”

(13mm)

——

.512”

(13mm)

.118”

(3mm)

Page 55

Printer Features

Appendix B

Printer Features

Features The printer has many time saving, user friendly,

design features. Some of these printer features

are listed below:

• Anti-jam, straight through media path

• Sturdy, clam shell case with force balanced

lid and locking latch for safer handling

• Internal label roll holder

• 5 printer resident fonts

•

Over 20 bar codes, including 2 dimensional

bar codes PDF-417 and MaxiCode

•

Batch or on-demand printer operation

•

Double buffered label formatting for “onthe-fly” label printing

•

Power media loading

•

Flip-up print head carriage and label sensor

assemblies for fast, easy cleaning.

•

Center aligned label printing and adjustment.

980181-001 Rev.C 47

•

RS232C serial and Centronics parallel ports

Page 56

Printer Features

Flash memory makes firmware updates easy

•

and seamless

Firmware Options

Hardware Options

Create-A-Label Tools for Windows

•

®

Software

Windows Drivers (Windows

•

Windows® 95, and Windows

®

®

3.1X,

NT 3.51 &

4.0)

Snap’N’Lock front bezel for easy access

•

Flash memory expandable to 1 megabyte.

•

SRAM memory expandable to 1 megabyte.

•

• Real Time and Date Clock

• Asian character sets

(Chinese, Japanese or Korean).

• Factory installed Dispenser with label presen-

tation sensor.

Accessories

General

Specifications

• Factory installed label and tag Cutter.

• Keyboard Display Unit (KDU) for a

stand alone printing solution.

•

TwinAX Converter

•

Create-A-Label 3 for Windows

•

512KB Flash and 512KB SRAM standard

•

Downloadable firmware capability

•

Moveable see-through and center justified

black mark sensor for die-cut labels and tags

•

AutoSense automatic label sensor adjust

ment

•

Internal label roll holder

•

Rear-feed slot for fan-fold or roll label stock

-

48

980181-001 Rev.C

Page 57

Printer Features

Easy-to-load label and ribbon path

•

Easy-to-use EPL2 command language

•

Prints text, graphics and bar codes in four di

•

rections: 0°, 90°, 80° and 270°

Graphics, line and box drawing features,

•

PCX bit map supported

Label back feed for maximum label usage

•

printing

Diagnostics and configuration print out and

•

ASCII dump

Double buffering for faster throughput

•

-

Software and

Drivers

Printing

Bar Codes

• Create-A-Label Tools for Windows™

• Drivers available for Windows 3.xx™, Win-

dows 95™, NT 3.51 and NT 4.0

• Direct thermal (LP) and thermal transfer

(TLP) printing

• Maximum print speed 4" (102mm) per

second

•

203 dpi (8 dots/mm) print resolution

•

Maximum print width 8.5" (216mm)

•

Maximum print length 11" (A4) standard, 22"

(2 x A4) optional

•

Minimum print length .5" (12.7mm)

With optional cutter 1.25” (31.75mm)

•

Code 39

980181-001 Rev.C 49

•

Code 93

•

Code 128 UCC (Serial Shipping Container

Code)

Page 58

Printer Features

Code 128 Autoselect

•

CodaBar

•

UCC/EAN-128

•

Interleaved 2 of 5

•

UPC-A, UPC-E, 2 & 5 digit add on

•

EAN-8, EAN-13, 2 & 5 digit add on

•

POSTNET

•

MaxiCode

•

PDF-417

•

• German Postal Code

• Bar codes with or without human readable

text

Standard Fonts

Media Sensing

• Bar codes can be printed in four directions 0°,

90°, 180° and 270°

• International character sets standard

• Five alpha-numeric fonts from .049"

(1.25mm) to .23" (5.84mm) high

•

All fonts expandable vertically and horizon

tally up to 8x

•

Fonts can be printed in four directions 0°,

90°, 180° and 270°

•

Smooth soft fonts can be downloaded from

Create-A-Label Tools for Windows™ and

Create-A-Label 3 for Windows™

•

Moveable see-through sensor for die-cut la

bels and tags

-

-

50

•

Reflective sensor for use with black stripe

marks

980181-001 Rev.C

Page 59

Printer Features

Media

Type: roll-fed, die-cut, continuous or fan-

•

fold labels, tags or tickets

Materials: thermal transfer or thermal sensi

•

tive papers

Maximum media width: 8.75" (222.3mm)

•

Minimum media width: 4" (102mm)

•

Maximum media length: 11" (279mm) stan

•

dard, 22" (559mm) optional with maximum

print width set. Note: The actual print length

is dependent upon the programmed print

(image) width and the maximum length will

increase as the print area is narrowed.

• Minimum media length: .5" (12.7mm)

With optional cutter: 1.25” (31.75mm)

• Media thickness (w/ liner): .003" (.08mm) to

.0075" (.19mm)

-

-

Ribbons

Communications

Interface

• Internal supply roll capacity: 5" (127mm)

O.D.

• Wax, Wax/Resin and Resin

•

Standard widths: 4.33" (110mm), 5"

(127mm), 6" (152mm), 6.5" (165mm), 7"

(178mm) and 8.66" (220mm)

•

Standard length: 6.142" (156m), on a 1"

(25mm) I.D. Core

•

RS232C

•

Centronics parallel

•

Xon/Xoff, hardware handshaking

•

Programmable 7 or 8 bit data length, 1 or 2

stop bits, selectable parity

•

4,800 to 38,400 baud rates

980181-001 Rev.C 51

Page 60

Printer Features

Mechanical

Electrical

Environmental

Width: 13.6" (344mm)

•

Depth: 11.9" (305mm)

•

Height: 8.1" (204mm)

•

Weight: 21.0lbs. (9.5kg)

•

Voltage: 115V/60 Hz, 230V/50 Hz

•

Complies with FCC Class B and CE require

•

ments; Built to UL, CUL and TUV require

ments.

Operating temperature: 40°F to 104°F (5°C

•

to 40°C)

• Storage Temperature: -40°F to 140°F (-40°C

to 60°C)

• Operating Humidity: 10% to 80% non-

condensing

-

-

• Storage Humidity: 10% to 90% non-

condensing

• Ventilation: Free air

52

980181-001 Rev.C

Page 61

Supplies and Accessories

Appendix C

Supplies and Accessories

Accessories available for theStrata™ printer are

listed below. Always refer to the ELTRON part

number when placing an order. For the name

of an Eltron brand dealer in your area, call:

1(800) 344-4003 or the nearest Zebra Technologies office (located on the back of this

manual).

Description Part Number

Parallel Interface Cable, 6’

Parallel Interface Cable, 10’

Serial Interface Cable, 6’ (DB-9 to DB-9)

Serial Interface Cable, 10’ (DB-9 to DB-9)

Serial Interface Cable, 6’ (DB-25 to DB-9)

KDU (Keyboard Display Unit)

Windows Printer Driver

Create-A-Label 3 for Windows

User’s Manual (this Manual)

Programmer’s Manual

300016-006

300016-010

300017-006

300017-010

300018-006

120180-001

105501-003

105524-001

980181-001

980009-001

980181-001 Rev.C 53

Page 62

Supplies and Accessories

Typical Applications

Features

Ribbon

Shipping

Inventory Tracking

Low cost

Ease of use

Low Environmental Durability

Not Used

Limited Label Life

Shipping

Inventory Tracking

Product Labeling

Compliance Labeling

Will fade and/or discolor when

exposed to heat, sunlight, and

chemicals.

Lowest cost thermal transfer

combination

Most commonly used

Low environmental durability

Wax

Low abrasion resistance

Longer life than direct thermal

Media (Stock)

Paper Label

Ta g

Synthetic Label

54 980181-001 Rev.C

Paper Label

Ta g

Direct Thermal

Thermal Transfer

Page 63

Supplies and Accessories

Typical Applications

Features

Ribbon

Retail applications where labels are

handled

Excellent for most applications

Compliance Labeling

Better environmental durability.

Better abrasion resistance than

wax

More expensive than wax

General

Purpose Resin

High temperature environments

Medical applications

Outdoor environments

Environments with chemicals

Good aesthetic appearance

High environmental durability

High physical durability

Excellent aesthetic appearance

Most expensive label/tag

Hard Resin

Compliance labeling

combination

Media (Stock)

980181-001 Rev.C 55

Paper Label

Ta g

Synthetic Label

Synthetic Label

Thermal Transfer

Page 64

Supplies and Accessories

56 980181-001 Rev.C

Page 65

Appendix D

Using the Media Cutter

Printers with the cutter option have a bezel with

a motorized blade. Printers with cutterscan dispense a single form that is automatically cut

from the media roll.

980181-001 Rev.C 57

Page 66

Using the Media Cutter

Guidelines Use the cutter to cut through continuous paper

Specifications Cutter warranty 90 days

from rolls and liner between labels.

You can switch between cutting and feeding by

using the OC command. You can set form

length and gap distances by using the Q com

mand. Refer to the EPL2 programmer’s man

ual for complete programming information.

Keep the cutter dry. Never use any solutions or

solvents to clean the blade. If there is a jam, fol

low the steps for Clearing the Cutter.

Blade life 500,000 cuts

-

-

-

Media types Direct thermal paper

Paper label liner

Tag stock

MaximumThickness 0.0075 in. (0.191mm)

Density 150 g/m

2

Width 4.00 - 8.75 in.

(101.6 - 222.25 mm)

Minimum length

using cutter 1.25 in. (31.8 mm)

58

980181-001 Rev.C

Page 67

Using the Media Cutter

Clearing the

Cutter

Step 1—Prepare

the Printer

If the media is crooked, a jam can occur. The

only tool required to clear a jam is a pair of small

tweezers.

Turn the printer off.

Unplug the power cord and interface cable.

980181-001 Rev.C 59

Page 68

Step 2—Clear

the Jam

Use tweezers to removemedia from the internal

blade areas.

If the jam is inside the cutter, detach the cutter

assembly from the printer. Press both bezel releases and pull the cutter up and forward.

60

Lay the cutter flat. Leave cables, retainers and

wires connected. Do not pull or strain any con

nections.

If you cannot remove the jammed media, call

for service.

980181-001 Rev.C

-

Page 69

Using the Media Cutter

Step 3—Replace

the Cutter

Align the left edges of the bezel and printer.

Connect the bezel by snapping down into place.

Step 4—Check

the Cutter

Connect the power cord and interface cable.

Turn the printer on. Tap the Feed button. The

printer should feed one label then cut the liner.

980181-001 Rev.C 61

Page 70

World Wide Offices:

Zebra Technologies Corporation

Eltron Products

1001 Flynn Road

Camarillo, CA 93012-8706 USA

Phone: +1 (805) 579 1800

FAX: +1 (805) 579 1808

e-mail: sales@eltron.com

Zebra Technologies, Europe

Eltron House

Molly Millars Lane

Wokingham, RG41 2QZ England

Phone: +44 (0) 1189 770 300

FAX: +44 (0) 1189 895 762

e-mail: eurosales@eltron.com

Zebra Technologies, France

50 rue Marcel Dassault

92100 Boulogne-Billancourt

France

Phone: +33 1 55 20 93 93

FAX: +33 1 55 20 93 99

e-mail: eurosales@eltron.com

Zebra Technologies, Latin America

836 Arlington Heights Rd. #357

Elk Grove, IL 60007

Phone: +1 (847) 584 2714

FAX: +1 (847) 584 2725

e-mail: latinsales@eltron.com

Zebra Technologies, Asia Pacific Headquarters

1 Sims Lane #06-11

Singapore 387355

Phone: +65 84 20 322

FAX: +65 84 20 366

e-mail: asiasales@eltron.com

980181- 001C

Products

Loading...

Loading...