Page 1

3M MAXSecure

Printer Module

Maintenance Manual

Manual No. 980286-001 Rev. A

Page 2

Page 3

FOREWORD

This manual contains service and repair information for 3M MAXSecure Printer Modules manufactured by the

3M Corporation,St. Paul, Minnesota. The contents include maintenance, diagnosis and repair information.

TECHNICAL SUPPORT

For technical support, users should first contact the distributor that originally sold the product—phone +1 (800)

344 4003 to locate the nearest 3M Distributor.

COPYRIGHT NOTICE

This document contains information proprietary to 3M Corporation. This document and the information

contained within is copyright by 3M Corporation and may not be duplicated in full or in part by any person

without prior written approval of 3M..

While every effort has been made to keep the information contained within current and accurate as of the date of

publication, no guarantee is given or implied that the document is error-free or that it is accurate with regard to

any specification.

This information is not intended as a license to practice or infringe on the patents of this company or others. 3M

Corporation reserves the right to modify, update or revise this information at any time without notice.

TRADEMARKS

3M MAXSecure is a service mark, and 3M is a registered trademark of 3M Corporation. All other marks are

trademarks or registered trademarks of their respective holders.

FCC NOTICE:

This equipment has been tested and found to comply with the limits of a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at their own expense.

CSA NOTICE:

This equipment does not exceed Class A limits per radio noise emissions for digital apparatus set out in the Radio

Interference Regulation of the Canadian Department of Communications. Operation in a residential area may

cause unacceptable interference to radio and TV reception requiring the owner or operator to take whatever

steps are necessary to correct the interference.

Ce matériel ne dépasse pas les limites de Classe A d’émission de bruits radioélectriques pour les appareils

numériques telles qu’établies par le ministère des Communications du Canada. L’exploitation faite en milieu

résidentiel peut entraîner le brouillage des réceptions radio et télé, ce qui obligerait le propriétaire ou l’opérateur

à prendre les dispositions nécessaires pour en éliminer les causes.

iiiiii

Page 4

Page 5

TABLE OF CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

1.1 PRINTER MODULE DESCRIPTION ..................1-1

1.1.1 Clear CardMaterial Feed, Shear,and Flip-Over ··············1-3

1.1.2 Print Station ·······························1-3

1.1.3 White CardFeeder Station ························1-4

1.1.4 Card AssemblerStation··························1-5

1.2 OPTIONS AND ACCESSORIES ....................1-5

1.3ABOUTTHISMANUAL........................1-5

1.4 CAUTIONARY NOTES.........................1-6

1.5 PACKAGING CONSIDERATIONS ...................1-9

1.6 PREPARING A STATIC-SAFE WORK AREA...............1-9

1.7 ENVIRONMENTAL AND SHOCK PROTECTION . . . ........1-9

CHAPTER 2 INSTALLATION AND OPERATION

2.1 INSTALLATION ............................2-2

2.1.1 Unpacking ································2-2

2.1.2 Location Concerns ····························2-3

2.1.3 Adding theLaminator and DieCutter ···················2-3

2.1.4 Attaching Cables ·····························2-4

2.1.5 Cable Diagrams ·····························2-5

2.2 OPERATION..............................2-6

2.2.1 Controls andIndicators ··························2-6

2.2.2 LCD MessagesRelated to PrinterModule ·················2-7

2.2.3 LCD MessagesRelated to LaminatorModule ···············2-7

2.2.4 LCD MessagesRelated to EncoderModule ················2-8

2.2.5 LCD MessagesRelated to Adjustments,Testing, and MicrocodeDownloads 2-8

2.2.6 LCD MessagesRelated to Cleaning ····················2-8

2.2.7 Print HeadLatch and ReleaseLevers ···················2-9

2.2.8 Ribbon Installation ···························2-10

2.2.9 Card Media ·······························2-11

2.2.10 Clear CardMaterial Loads ·······················2-11

2.2.11 White CardFeeder Loading ······················2-12

2.2.12 Two- versesThree-Layer Selection ···················2-13

CHAPTER 3 THEORY OF OPERATION

3.1 COLOR FUNDAMENTALS ......................3-1

3.2 PRINTER INTRODUCTION ......................3-5

3.3 CIRCUITRY ..............................3-8

Page 6

CHAPTER 4 TROUBLESHOOTING

4.1 DIAGNOSING BASIC PRINTER PROBLEMS ..............4-2

4.2 DIAGNOSING COMPUTER INTERFACE PROBLEMS .........4-5

CHAPTER 5 REPLACEMENT PROCEDURES

5.1 REQUIRED TOOLS ..........................5-2

5.2 PART REPLACEMENTS ........................5-3

5.2.1 Case Removal ······························5-3

5.2.2 White CardFeeder Station Removal ···················5-4

5.2.3 White CardFeeder Station Replacements ·················5-5

5.2.4 Upper ClearCard Station Removal ····················5-6

5.2.5 Upper ClearCard Station ComponentReplacements ···········5-7

5.2.6 Lower ClearCard Station Removal ····················5-8

5.2.7 Lower ClearCard Station Components ··················5-9

5.2.8 Card AssemblyStation Removal·····················5-10

5.2.9 Card AssemblyStation Component Replacements············5-11

5.2.10 Print HeadReplacement ························5-12

5.2.11 Fan Replacement ···························5-17

5.2.12 Ribbon SensorReplacement ······················5-18

5.2.13 Cleaning RollerSpring Clip Replacement················5-19

5.2.14 Front BeltRemovals ··························5-20

5.2.15 Printer StationRemoval ························5-21

5.2.16 Printer StationMotors and RearBelts and Sensors ···········5-22

5.2.17 Ribbon SupplySpindle and ClutchReplacements ···········5-24

5.2.18 Ribbon TakeUp Spindle Replacements ················5-26

5.2.19 Print StationCard Sensor ·······················5-28

5.2.20 CPU Boardand Socketed ICRemovals·················5-29

5.2.21 Extension PCBACircuit Board andSocketed IC Replacements ·····5-30

5.2.22 Clear CardStation Controller BoardReplacements ···········5-31

5.2.23 Power SupplyReplacements ······················5-32

5.2.24 Operator PanelReplacement ·····················5-33

CHAPTER 6 MAINTENANCE AND ADJUSTMENTS

6.1 CLEANING MATERIALS ........................6-2

6.2 CLEANING ..............................6-2

6.2.1 Print HeadCleaning ···························6-3

6.2.2 Replacing CleaningRoller Sheath ·····················6-4

6.2.3 Cleaning Card-Feedand Card-Transport Rollers ·············6-5

6.3 ADJUSTMENTS ............................6-6

6.3.1 Print HeadResistance ··························6-6

6.3.2 Peel BarAdjustment ···························6-6

6.3.3 Image Centering ·····························6-8

6.3.4 Pressure RollerPosition ·························6-10

6.3.5 Stepper BeltTension Adjustment ····················6-11

6.3.6 Front BeltTension Adjustments ·····················6-14

iv

Page 7

APPENDIX A TEST SOFTWARE

A.1 INSTALLATION ............................A-1

A.2 OPERATION .............................A-1

A.2.1 Launching theCard Printer TestSoftware ················A-2

A.2.2 Changing theCOM Port ·························A-3

A.2.3 Operating inTerminal Mode ·······················A-4

A.2.4 Typical SubList ·····························A-5

A.2.5 Typical PotAdjustment Selection ·····················A-6

A.2.6 Downloading Firmware ·························A-7

TABLE OF FIGURES

Figure 2-1. Packaging Materials .......................2-2

Figure 2-2. Laminator Installation.......................2-3

Figure 2-3. Cables. .............................2-4

Figure 2-4. Cable Wiring. ..........................2-5

Figure 2-5. Printer Controls and Indicators. .................2-6

Figure 2-6. Print Head Latch and Release Levers. ..............2-9

Figure 2-7. Ribbon Installation. ......................2-10

Figure 2-8. Clear Card Material Loads....................2-11

Figure 2-9. White Card Hopper Loading. .................2-12

Figure 2-10. Card Layer Selection Lever...................2-13

Figure 3-1. 3M MAXSecure Card Path. ...................3-7

Figure 3-2. Block Diagram. .........................3-9

Figure 4-1. Problems Duplicated by a Test Print. ..............4-2

Figure 4-2. Interface Diagnostic Flow. ....................4-5

Figure 5-1. Case Fasteners. .........................5-3

Figure 5-2. White Card Feed Station Removal. ...............5-4

Figure 5-3. White Card Feeder Components. ................5-5

Figure 5-4. Upper Clear Card Station Removal. ...............5-6

Figure 5-5. Upper Clear Card Station Replaceable Components. ......5-7

Figure 5-6. Lower Clear Card Station. ....................5-8

Figure 5-7. Lower Clear Card Station Components. .............5-9

Figure 5-8. Card Assembly Station Removal. ................5-10

Figure 5-9. Card Assembly Station Components...............5-11

Figure 5-10. Print Head Upper Fastener Removal. .............5-12

Figure 5-11. Print Head Assembly Fasteners.................5-13

Figure 5-12. Print Head Assembly Parts. ..................5-14

Figure 5-13. Print Head Connectors.....................5-15

Figure 5-14. Properly positioned Print Head. ...............5-16

Figure 5-15. Fan Replacement. ......................5-17

Figure 5-16. Ribbon Sensor. ........................5-18

Figure 5-17. Cleaning Roller Spring Clip...................5-19

v

Page 8

Figure 5-18. Front Belt Removals. .....................5-20

Figure 5-19. Printer Station Removal. ...................5-21

Figure 5-20. Printer Station Rear Parts....................5-23

Figure 5-21. Supply Spindle Assembly....................5-25

Figure 5-22. Ribbon Take Up Spindle. ...................5-27

Figure 5-23. Printer Station Card Sensor...................5-28

Figure 5-24. CPU Board...........................5-29

Figure 5-25. Extension PCBA. .......................5-30

Figure 5-26. Clear Card Station Controller Board. .............5-31

Figure 5-27. Power Supply Removal. ...................5-32

Figure 5-28. Operator Panel Board Removal. ...............5-33

Figure 6-1. Cleaning Materials........................6-2

Figure 6-2. Print Head Cleaning. ......................6-3

Figure 6-3. Changing the Upper Cleaning Roller ..............6-4

Figure 6-4. Card Transport Rollers. .....................6-5

Figure 6-5. Peel Bar Fasteners. .......................6-7

Figure 6-6. Lower Clear Card Feeder Pressure Roller Adjustment. .....6-10

Figure 6-7. Stepper Motor Fasteners. ...................6-11

Figure 6-8. Stepper Motor Belt Tensioning Fixture..............6-12

Figure 6-9. Stepper Belt Tensioning. ....................6-13

Figure 6-10. Front Belt Tension Adjustments. ...............6-14

vi

Page 9

CHAPTER 1

GENERAL DESCRIPTION

1.1 PRINTER MODULE DESCRIPTION

3M MAXSecure Printer Modules can operate as stand-alone card imaging devices or, as shown

above, become part of a larger system that can also include a 3M Lamination and Die Cutter

Module. 3M MAXSecure can also include a Magnetic Stripe Encoder Module (not shown).

3M MAXSecure can produce either two- or three-layer cards composed of either a Clear Card

and a White Card or a white card sandwiched between two Clear Cards. Clear Card imaging

occurs first. A Clear Card can receive full color CMY (cyan, magenta, yellow) and/or black resin

imaging. Imaging on the White Card can occur next. The White Card can receive Kr (Black

Resin) monochrome images. A second Clear Card serves to prolong card life and protect any

image placed on the White Card. Notably, an image placed on the White Card ends up on the

side opposite the Clear Card image. Security imprints appear on the side of the White Cards that

980286-001 Rev. A 1-1

Page 10

CHAPTER 1

GENERAL DESCRIPTION

receive no image by the Printer Module. On the finished cards, however, these images underlie

the Clear Card image.

After imaging, the Printer Module assembles and delivers a Clear and White Card to the

Laminator and Die Cutter Module. For three-layer cards, a second Clear Card follows. An

attached Laminator and Die Cutter Module fuses the Clear and White Card material and die

cuts the result to a standard credit/debit/etc card size.

Because the image on the Clear Card faces the White Card, scratches and ultraviolet radiation

have little affect on this image. Resin images offer substantial resistance to wear factors without

needing added protection, but for three-layer cards, an additional Clear Card maximizes wear

resistance. These features result in cards that can accept a fair amount of abuse and, with

reasonable treatment, can remain in service for 10 years.

Figure 1-1 shows the Printer Module assemblies visible with the cover raised.

Figure 1-1. Major Assemblies

1-2

980286-001 Rev. A

Page 11

CHAPTER 1

GENERAL DESCRIPTION

1.1.1 Clear Card Material Feed, Shear, and Flip-Over

The upper part of this assembly contains a motor and a shear. The middle part has two

sensors—one for signaling the shear point and another to sense splices. The lower part

implements flip-overs of a second Clear Card.

All three parts of the assembly have rollers that move the material, due either to a manual

advance or by a motor powered drive roller. Clear Card material feeds off of a roll and into a slot

in the top of this assembly and then down vertical card guides.

The motor moves card-sized segments beyond the shear. A shear occurs when an associated

sensor detects material. As more media enters the upper part, the sheared segment enters either

the flip-over or the horizontal card guides. The assembly ultimately delivers Clear Cards to the

horizontal drive rollers.

Only one Clear Card surface has a bonding agent. So that the bonding material on the second

Clear Card can face the White Card, a solenoid-operated gate directs Clear Cards for a flip-over

before directing their entry into the horizontal guides.

Rolls of Clear Card material contain splices that require operator removals. A sensor in the

guides detects the splices, which results in related LCD messages to the operator.

1.1.2 Print Station

The printer first receives a Clear Card segment. Associated color imaging results from multiple

passes across the Print Head. Because the imaging occurs on the side opposite the viewed side,

Clear Cards receive mirrored images.

A motor-driven cam controls the position of the Print Head. Imaging occurs with a card and the

ribbon sandwiched between the lowered Print Head and the platen roller below. Card

transports not related to imaging occur with the Print Head raised sufficiently to allow freer

movement of cards, typically at faster rates.

Ribbon, having dye- and sometimes resin-coated panels, feeds from the supply to the take-up

spindles. During imaging, the coated side contacts the card, and the non-coated side contacts

the Print Head. Incremental ribbon advances accompany associated incremental advances of a

card across the Print Head. Card increments correspond to 300 dpi (dots-per-inch) image

resolution, which duplicates the density of elements across the Print Head.

Each dot imaged occurs from a ribbon dye transfer due to heat produced by an associated Print

Head element. For color, each element can produce 32 different heat levels, which correspond

to 32 different dye densities. When dots get superimposed on other dots to produce a

YMC-blended color, 32K combinations become possible. This imaging process is typically

called Dye Sublimation.

Resin imaging occurs at only one dot density. Resin, while excellent for bar codes and other solid

imaging, only responds well when transferred using a single temperature. An associated Print

Head element is either fully on or completely off. Solid imaging occurs for all internally

generated bar codes, text, and graphic elements. Users wishing to produce gradients of gray

while using resin imaging must resort to dithering and deliver an associated bit map. Because

980286-001 Rev. A 1-3

Page 12

CHAPTER 1

GENERAL DESCRIPTION

dithering creates a pixel (picture element) using a small dot matrix, reduced picture resolution

results. This resin imaging process is called Thermal Transfer. In contrast, users can create 32

levels of gray using YMC blends without loosing any image resolution.

By the time a card is fully imaged, a whole set of ribbon panels is used. Users can obtain ribbon

media in several configurations, each offering a cost optimization for a particular set of card

design requirements. For example, YMC ribbons cover the need for only Clear Card color

imaging without resin. The need for YMCKr ribbons occurs when resin imaging, of say bar

codes, must alsoappear, YMCKrKr ribbons serve those instances when black resin imaging must

occur on both the Clear and White cards.

After completion of the Clear Card imagingand the card moves to the Card Assembler Station, a

White Card feed occurs. The feed injects the White Card directly into the horizontal card guides.

White Cards can only receive black resinimages. Also, as stated previously, imaging depends on

a remaining unused Kr ribbon panel. A second Clear Card, when used, receives no image.

A standard feature of all 3M Card printers lets users print bar-codes using any of the 10

printer-resident formats. An associated image results from entry of a single command line,

where a related set of parameters precedes the data. Data refers to the alphanumeric string that a

bar code reader decodes when scanning the card. Associated parameters format the bar code,

specify size and position, and determine whether or not an associated text string appears under

the bar code.

Sensors in the Printer assembly include one that detects incremental advances of the ribbon,

one that detects the presence of a card entering the horizontal card guides,and one that finds the

yellow ribbon panel following an operator initialization. All synchronized card and ribbon

movement within the Printer Station depends on these sensors. Two microswitches form

sensors that signalwhen the PrintHead has reachedan either fullyup or fullydown position.

Motors in the Printer assembly include a stepper for precise control of card positioning in the

card path and dc motors to advance ribbon and raise and lower the Print Head.

1.1.3 White Card Feeder Station

This assembly delivers White Cards placed in the Feeder to the horizontal card guides of the

Printer assembly. Included are a dc motor that powers two feed rollers and a Card Gate that lets

only one card feed at a time. White Card thickness for two-layer cards measures 0.022 inches,

while those used for three-layer cards measures 0.015 inches.

Cards easily pass through a gate opening one and one-half times the card thickness without

allowing multiple feeds or rubbing against the upper restraint. When cards fail to feed, a user

typically finds acard with excessivewarping. The frontpanel LCD indicatesOUT OF CARDSif a

card fails to appear at the Printer assembly before a related time out occurs.

1-4

980286-001 Rev. A

Page 13

CHAPTER 1

GENERAL DESCRIPTION

1.1.4 Card Assembler Station

After imaging, a Clear and a White Card come together in the Card Assembler. The card path

deepens here, so that a White Card can rest on top of a Clear Card. The assembly includes a

motor, a solenoid, and two sensors. After these card components come to rest in this assembly,

as signaled by the lower of the two sensors, the solenoid-coupled roller raises to push the cards

against the motor-powered drive roller. The powered roller then delivers these two layers to the

exit opening of the Printer Module. An attached Laminator and Die Cutter Module would sense

this event and draw the cards into its card path. The upper sensor signals the presence of cards at

the output. Until these cards are taken away, no new cards should enter for card assembly. An

attached Laminator and Die Cutter Module waits for a second Clear Card, in instances where

the Layer Lever is set to 3 Layer.

The sensors can detect two error conditions. The CLEAR AT EXIT error signals that a second

Clear Card has entered the assembly instead of the expected White Card. The WHITE AT EXIT

error signals that a second White Card has entered the assembly prior to removal of a previously

assembled set.

1.2 OPTIONS AND ACCESSORIES

A Full Complement of Card and Ribbon Supplies—distributors of 3M Products stock these

items in order to assure that 3M MAXSecure users can obtain supplies that consistently produce

the best possible results.

1.3 ABOUT THIS MANUAL

3M Products has directed the Information contained in this manual at returning Printer module

functions to normal operation in the shortest time possible. With this in mind, service personal

should focus on items listed in the recommended spares list. Avoid lower level replacements

whenever possible. Service personnel should keep a log of the repairs made in support of the

concept of continuous product improvement. Chapters include: General Description,

Installation and Operation, Theory of Operation, Troubleshooting, Part Replacement

Procedures, and Maintenance and Adjustments. Appendix A describes software developed for

testing 3M MAXSecure printers.

Follow the instructions as closely as possible. When unsure of any procedure, please contact

either a 3M Products Service Representative (contact 3M Product Management for nearest

representative) or 3M Products Technical Support at 1-800-344-4003 or 805-578-1800.

3M Products stocks all commonly used replacement parts for 3M MAXSecure printers. A list of

the recommended spares appears in this Chapter. For depot repairs, contact 3M Product Sales

to place orders and to establish a program for bulk purchases and credited returns of warranted

parts.

980286-001 Rev. A 1-5

Page 14

CHAPTER 1

GENERAL DESCRIPTION

1.4 CAUTIONARY NOTES

Exercise reasonable care when servicing the printer, as follows:

Other than prescribed operator maintenance, only qualified personnel

should remove the case or otherwise attempt to repair this equipment. 3M

Products offers training to those wishing to service this equipment.

Servicing personnel must avoid touching exposed circuitry. Inputs to the

Power Supply operate at power line voltages. Any removal of protective

insulation can expose dangerous voltages. Always remove the power cord

when effecting repairs.

During printing, the Print Head operates at an elevated temperature.

Exercise caution when touching the parts on or near these areas.

Servicing Personnel should avoid any rough handling of the printer or its

component parts. The Print Head in particular requires careful handling.

Never lower the Print Head onto any object other than the card and

ribbon media.

An electrostatic discharge (ESD) of energy can damage or destroy the print

head and other electronic Printer Module components. People can acquire

such charges while moving around. ESD problems increase as the

humidity drops.

Users should not twist the Ribbon Take Up spindle manually. Doing so

unnecessary stresses the associated belt. Any slack left after a ribbon

installation gets removed during the initialization produced by pressing the

panel button.

To avoid deposits, clean only with fiber free Cleaning Swabs and

99-percent or better pure alcohol.

1-6

980286-001 Rev. A

Page 15

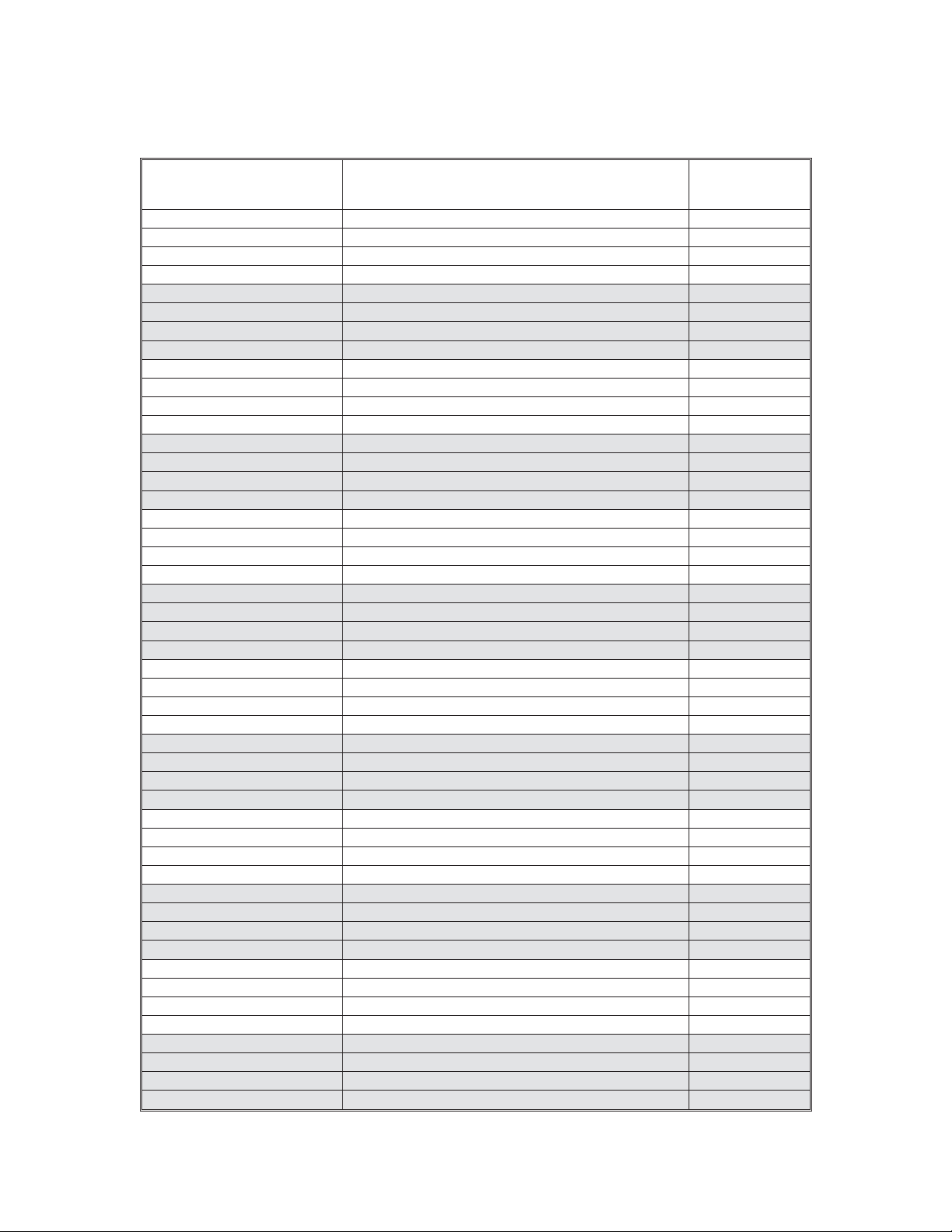

Part Replacement Spares

CHAPTER 1

GENERAL DESCRIPTION

Recommended Quantity

(Per 100 Printers)

A/R

5

5

5

5

5

5

10

1

3

1

1

9

A/R

A/R

A/R

A/R

A/R

2

2

1

A/R

2

2

2

1

2

15

10

2

5

1

2

1

2

10

2

2

2

2

2

5

2

2

2

5

10

2

Item Part No.

Lock Set for Enclosure

Kit, Print Engine

Kit, White Card Feeder

Kit, Clear Material Cutter

Kit, Clear White Material Entry Assembly

Kit, Printer Exit

Kit, Electronics, Printer

Kit, Roller, Card Feeder

Kit, Power Supply Fuse (Set of 10)

Kit, Main Circuit Board, Printer

Kit, Head Up/Down Sensor Switch

Kit, Cleaning Roller Clip

Kit Pressure Roller (Set of 5)

Kit, M4 x 8, Flat Head Phillips Screws (Set of 100)

Kit, M4 x 8, Pan Head Phillips Screws (Set of 100)

Kit, Printer Enclosure (Light Gray)

Kit, Printer Enclosure (Dark Gray)

Kit, Rubber Foot, Base

Kit, Printer Input/Output Extension Board

Kit, Printer AC Power and Filter

Kit, AC Power Switch (Set of 5)

Kit, Forcep, Curved

Kit, Solenoid

Kit, Ribbon Sensor

Kit, Ribbon Spindles

Kit, Clear Material Shear

Kit, Clutch Assembly

Kit, Exit Pressure Roller Assembly

Kit, Upper Cleaning Roller

Kit, Power Supply Assembly 120/240 Auto Ranging

Kit, DC Motor

Kit, Stepper Driver IC (L6219 at U12)

Kit, Flag Sensor

Kit, DC Motor Driver IC

Kit, Cleaning Roller Bearing

Kit, Ribbon Take Up O-Ring Belt

Kit, Rear Main Drive 0.08P, 40Deg, 63T

Kit, Belt, 0.080P, 40Deg, 88T x 3(1/8)

Kit, Belt, 0.080P, 40Deg, 63T x 3(1/8) (Set of 5)

Kit, Front Right Encoder Roller Drive, Belt 50T x 3 (1/8)

Kit, Front Left Encoder Roller Drive, Belt 95T x 3 (1/8)

Kit, Cam, Printhead Lift

Kit, PCBA, LCD Display

Kit, Timing Belt, 105T x 1/8 (Feeder)

Kit, Fan, Print Head

Kit, Stepper Motor

Kit, Replacement Print Head—Style 2

Kit, Knob, Max

105901-067

105901-203

105901-205

105901-207

105901-208

105901-063

105901-233

105901-226

105901-013

105901-218

105901-018

105901-019

105901-029

105901-032

105901-033

105901-211

105901-212

105901-037

105901-042

105901-050

105901-051

105901-052

105901-055

105901-057

105901-058

105901-231

105901-241

105909-005

105909-010

105909-020

105909-021

105909-024

105909-026

105909-028

105909-033

105909-038

105909-040

105909-043

105909-044

105909-045

105909-046

105909-058

105909-089

105909-098

105909-099

105901-230

105909-112

105901-087

980286-001 Rev. A 1-7

Page 16

CHAPTER 1

GENERAL DESCRIPTION

Spare Accessories

Recommended

Quantity

(Per 100 Printers)

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

10

A/R

A/R

A/R

Kit, Cleaning Core

Interface Cable

Power Cord (Domestic)

Power Cord (Europe)

Kit, Feeder, Weight

Kit, Cleaning Card

User’s Guide

Windows Drivers (NT and 95)

Kit, Cleaning Swab

Kit, Ribbon Take Up Core

Kit, Cleaning Core Spindle Assembly

Kit, Foam and Box (Printer or Laminator)

Kit, Maintenance Manual

Item Part No.

105901-001

300055-001

300020-001

300020-002

105901-036

105901-056

980279-001

105901-047

105909-057

105909-035

105901-061

105901-054

105901-227

1-8 980286-001 Rev. A

Page 17

CHAPTER 1

GENERAL DESCRIPTION

1.5 PACKAGING CONSIDERATIONS

The factory cartons include a printer placed inside a protective ESD (Electrostatic Discharge)

bag and suitable form-fitting foam cushions. Testingof this packaging hasconfirmed its ability to

withstand the forces required by equipment transporters. If any other shipping materials are

used, related shipping damage may not be covered by the warranty. If necessary, order

replacement factory-approved shipping materials from a 3M MAXSecure distributor.

1.6 PREPARING A STATIC-SAFE WORK AREA

To avoid component damage while performing troubleshooting and repair procedures, service

personnel should prepare a static-safe working area. This area should include a properly

grounded, conductive, cushioned mat to rest the Printer Module on and a conductive wrist strap

to ground the servicing technician. (Most electronic supply stores carry ESD protective devices.

For a local supplier, contact 3M Corporation at 1-800-328-1368 or 512-984-1800).

1.7 ENVIRONMENTAL AND SHOCK PROTECTION

Avoid extremes of temperature and humidity or mishandling. These conditions can damage

most electronic equipment.

When moving the printer from a cool, dry location to a warmer, more humid location, allow the

printer to temperature stabilize for at least 30 minutes before opening the protective ESD bag.

Otherwise, moisture can condense on the surface of many components. Moisture can degrade

performance or even damage some components.

Avoid rough handling. Careful handling can avoid possible mechanical damage that might

otherwise result from dropping or impacting the printer on a hard surface.

980286-001 Rev. A 1-9

Page 18

CHAPTER 1

GENERAL DESCRIPTION

1-10 980286-001 Rev. A

Page 19

CHAPTER 2

INSTALLATION AND OPERATION

This chapter includes information on the following:

• Unpacking

• Attaching a Laminator and Die Cutter

• Printer Module Cables

•

Printer Controls and Indicators

•

Ribbon Installation

•

Clear Card Installation

•

White Card Installation

Similar descriptions also appear in the associated User’s Guide and other manuals shipped with

the printer. The intent here is to make this manual as complete as possible for the targeted

service provider. Operations related to software applications and the Windows Driver do not

appear in thismanual. Installation andoperation of theTest Software appearsin Appendix A.

980286-001 Rev. A 2-1

Page 20

CHAPTER 2

INSTALLATION AND OPERATION

2.1 INSTALLATION

2.1.1 Unpacking

Figure 2-1 shows the packaging materials used to ship the Printer Module.

Note that customers should keep these materials on hand forfuture shipping needs. The product

warranty may not cover a printer damaged during shipment using other shipping materials. If

necessary, users should order replacements before shipping the Printer Module.

Figure 2-1. Packaging Materials

2-2

980286-001 Rev. A

Page 21

CHAPTER 2

INSTALLATION AND OPERATION

2.1.2 Location Concerns

Users should avoidlocations with heavy concentrations of airborne contaminates. Until ready to

use, keep Clear Card material and White Cards in their cartons. Such care also applies to

Cleaning Roller Sheaths. Handle all ribbon and card media in a way that avoids contamination.

Fingerprints and other such contaminants can lower image quality. Select a location that offers

easy access to all sides and unrestricted air flow for ventilation. Avoid locations that experience

extremes in temperature and/or humidity.

2.1.3 Adding the Laminator and Die Cutter

Figure 2-2 shows how the Printer Module and Laminator and Die Cutter fasten together.

CAUTION: To avoid damage, separate the Modules prior to any move to a new location.

Step 1. As shown, align the left side of the Printer Module with he right side of the

Laminator and Die Cutter Module.

Step 2. Lift the Laminator and Die Cutter Module to engage the hooks with the Printer

Module slots. Make sure that the pin on the Laminator Module aligns with the slot

in the Printer Module.

Figure 2-2. Laminator Installation.

980286-001 Rev. A 2-3

Page 22

CHAPTER 2

With ferrites at each end.

INSTALLATION AND OPERATION

2.1.4 Attaching Cables

Figure 2-3 shows the Rear Panel of the Printer Module. This panel has the following:

Power ON-OFF Switch

•

Power Connector

•

Parallel Port DB-25 Connector (e.g., LPTx)

•

Module Interconnect DB-9 Connector

•

Figure 2-3 shows the cables to the host computer and the cable that interconnects the Printer

Module to a Laminator and Die Cutter Module. The internal power supply automatically adjusts

to most of the outlet voltages encountered world wide. Always connect the Power Cable last.

Figure 2-3. Cables.

2-4

980286-001 Rev. A

Page 23

2.1.5 Cable Diagrams

Figure 2-4 shows the cable wiring.

CHAPTER 2

INSTALLATION AND OPERATION

HOST

STROBE

DATA 0

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

ACK/

BUSY

PAPER ERR.

READY

INIT

ERROR/

N/A

N/A

N/A

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

DB-25

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

DB-25

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

PRINTER

MODULE

STROBE

DATA 0

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

ACK/

BUSY

PAPER ERR.

READY

INIT

ERROR/

N/A

N/A

N/A

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

Female DB-25 to Male DB-25

PRINTER

MODULE

N/A

RxD

TxD

DTR

GND

DSR

RTS

CTS

RI

DB-9

Pin #

1

2

3

4

5

6

7

8

9

DB-9

Pin #

1

2

3

4

5

6

7

8

9

LAMINATE

MODULE

N/A

RxD

TxD

DTR

GND

DSR

RTS

CTS

RI

Female DB-9 to Male DB-9

Figure 2-4. Cable Wiring.

980286-001 Rev. A 2-5

Page 24

CHAPTER 2

INSTALLATION AND OPERATION

2.2 OPERATION

2.2.1 Controls and Indicators

Figure 2-4 shows the Push Button and LCD (liquidcrystal display) that appear on thefront of the

Printer Module as well as the rear-panel-mounted Power Switch. As shown, the LCD

communicates operational status to users.

After ribbon installation, users press and hold the Panel Button for about three seconds or until

hearing the ribbon begin to advance. This initialization positions a yellow panel for subsequent

printing. Users also press and can immediately release the button to proceed after correcting an

error condition. For example, the system can sense a card jam and suspend operation but

cannot sense the removal and discarding of the offending card. Until a user presses the Panel

Button, system operation remains suspended and waits for this signal to resume.

The Panel Button can also initiate Test Prints. To initiate a Test Print, hold the Panel Button

pressed while turning power on. Resulting Test Prints contain information on the configuration

of the associated printer. Test Prints also offer an easy-to-obtain printer output for servicing

personnel that wish to see image anomalies or the effect produced by a printer adjustment.

Figure 2-5. Printer Controls and Indicators.

2-6

980286-001 Rev. A

Page 25

CHAPTER 2

INSTALLATION AND OPERATION

2.2.2 LCD Messages Related to Printer Module

LCD Message Description

INITIALIZING Power-On Initialization in progress

READY Ready to Receive Commands

PRINTING Printer Busy

CLEAR FEEDER ERR No Response from Clear Card Feeder During Power-ON Checks

WAIT TEMPERATURE Print Head Cool-Down in Progress

REMOVE SPLICE Clear Card Splice Detected—Removal at Card Assembly Station Required

OUT OF CLEAR Install Clear Card Roll

OUT OF WHITE More White Cards Required

OUT OF RIBBON New Ribbon Required

SELECT WHITE Wrong Layer Selection for White Cards in Hopper

CLEAR AT EXIT Attempt to Place 2nd Clear in Exit

WHITE AT EXIT Attempt to Place 2nd White in Exit

EXIT FAILURE Error Sending Cards to Laminator

MECHANICAL ERR Card Jam Sensed

DOWNLOADING Printer Receiving Data

CLEAR TURN ERROR Error During Flip-Over of Third Layer

CUTTER ERROR Error at Clear Card Cutter

CLEAR AT ENTRY Remove Clear at Cleaning Roller

WHITE AT ENTRY Remove White Card at Cleaning Roller

SELF TEST Test Print in Process

2.2.3 LCD Messages Related to Laminator Module

LCD Message Description

WARMING UP Printer Waiting for Laminator

LAMINATOR BUSY Printer Waiting for Laminator

WAIT LAMINATOR Error Reprint Wait–Laminate Finishing

LAMINATOR ERR Error During Lamination

980286-001 Rev. A 2-7

Page 26

CHAPTER 2

INSTALLATION AND OPERATION

2.2.4 LCD Messages Related to Encoder Module

LCD Message Description

ENCODER BUSY Encoder is Busy; Printer Waiting to Send Card

ENCODING ERR Error During Encoding

WAIT ENCODER Error Reprint Wait–Encoder Finishing

CARD ENCODER A Card is in the Encoder

NO CARD ENCODER No Cards in Encoder

MAGNETIC ERROR Communications Error Between Printer and Encoder

CLEAN MAG HEAD Clean Magnetic Encoder

2.2.5 LCD Messages Related to Adjustments, Testing, and Microcode Downloads

LCD Message Description

COMMAND ERROR Command Not Recognized by Printer

PARAMETERS ERROR Command Received has Imporper Parameters

REMOVE CLEAR Can appear During Improper Sensor Adjustment

ERR NO SPLICE Cannot Detect Splices due to Sensor Adjustment

NO ACCESS Printer Password Required for Command Sent

FLASH ERROR Error Detected During Firmware Download

KEY TO EXIT Offers Exit Opportunity During Testing—Press Button

2.2.6 LCD Messages Related to Cleaning

LCD Message Description

CLEANING PRINTER Time to Clean Printer—Press Panel Button when Ready to Begin

REMOVE RIBBON Remove the Ribbon Before Continuing

REMOVE CARD Cleaning Card at Exit Requires Removal

NO CLEANING CARD Place New Cleaning Card at Clear Material Load Point

REMOVE CLEAR Remove Cleaning Card

CLEANING CUTTER

A Clear Card Shear Cleaning/Sharpening Sequence is Running (Follows Splice

Removal After OUT OF CLEAR Message)

2-8 980286-001 Rev. A

Page 27

CHAPTER 2

INSTALLATION AND OPERATION

2.2.7 Print Head Latch and Release Levers

Figure 2-6 shows the Latch and Release levers for the Print Head. Users open the Cover and

raise the Print Head for Cleaning Procedures and Ribbon Loading. The Print Head and Cover

must both remain down for card imaging and other printer operations.

Users should keep the cover closed as much as possible to reduce the exposure of internal

components to airborne contaminants. Any contaminants that find their way onto cards

traveling along the card path have a good chance of adversely affecting print quality.

Figure 2-6. Print Head Latch and Release Levers.

980286-001 Rev. A 2-9

Page 28

CHAPTER 2

INSTALLATION AND OPERATION

2.2.8 Ribbon Installation

Refer to Figure 2-7, and proceed as follows:

Step 1. Open the Cover, raise the Print Head, and remove any ribbon and ribbon core

still remaining in the printer.

Step 2. To prepare a new ribbon for installation, undo the tape keeping the ribbon

from unraveling. Then, rest both the ribbon and an empty core on end, on a flat

surface, and touching. Tape the loose ribbon end onto the empty core, and wind

some ribbon onto the core. For extra cores, order Part Number 105909-035. Users

needing to switch back and forth between different kinds of ribbons will need more

than the spare shipped with the printer.

Step 3. Push a prepared ribbon and ribbon core onto the supply and takeup spindles,

respectively. Note that the ribbon feeds off the top of the Supply Spindle and onto

the top of the Take-Up Spindle. This is very important. Damage to the Print Head

can occur if the ribbon side with dye ever contacts the Print Head. Therefore, be

very sure to install the ribbon properly.

Step 4. Latch down the Print Head, and close the printer cover.

Step 5. Remove any unfinished card from the exit mechanism.

Step 6. Press the Panel Button to initialize.

Do Not Twist

Figure 2-7. Ribbon Installation.

2-10

Hot

ESD Sensitive

980286-001 Rev. A

Page 29

INSTALLATION AND OPERATION

2.2.9 Card Media

3M Products offers the following Card media:

Description Part Number

Kit containing Clear Card roll and White Cards for 2-Layers

Kit containing Clear Card roll and White Cards for 3-Layers

104523-055

104523-060

2.2.10 Clear Card Material Loads

Refer to Figure 2-8, and proceed as follows:

Step 1. Place a roll of Clear Card Material onto the holder such that the loose end

feeds from the bottom of the roll.

Step 2. With power on, feed the loose end through the two sets of guide rollers and

then into the top of the Clear Card Feed Station. When sensed, the Printer Module

automatically advances the material to a point below the Shear.

CHAPTER 2

Figure 2-8. Clear Card Material Loads.

980286-001 Rev. A 2-11

Page 30

CHAPTER 2

INSTALLATION AND OPERATION

2.2.11 White Card Feeder Loading

Refer to Figure 2-9, and proceed as follows:

Step 1. Park the Card Weight at the top of the White Card Feeder.

Step 2. Place cards in the Input Tray. Note that cards can stick together for various

reasons, and users should effect a shuffle-like action on the stack prior to placing

cards into the White Card Feeder. Note that Magnetic Stripes, if present, should

face up and be nearer the back of the Feeder than the front. Preprinted Secure

Card imaging must face down.

Step 3. Place the Card Weight on top of the cards. Note that the Card Weight

increases the gripping of the Card Feed Rollers. Also, note that any accumulation

of contaminants on the Card Feed Rollers can lead to card feed slippage. Clean the

Card Feed Rollers when signaled by the LCD or after experiencing card feed

failures.

Figure 2-9. White Card Hopper Loading.

2-12

980286-001 Rev. A

Page 31

CHAPTER 2

INSTALLATION AND OPERATION

2.2.12 Two- verses Three-Layer Selection

Figure 2-10 shows the lever that sets the Printer Module for either two- or three-layer operation.

Be sure that the lever setting matches with the card thickness selected for use, as follows:

2-Layer Setting requires 0.022-inch card thicknesses.

•

3-Layer Setting requires 0.015-inch card thicknesses.

•

Figure 2-10. Card Layer Selection Lever.

980286-001 Rev. A 2-13

Page 32

CHAPTER 2

INSTALLATION AND OPERATION

2-14 980286-001 Rev. A

Page 33

CHAPTER 3

THEORY OF OPERATION

This chapter includes three major topics:

• Color Fundamentals

• Printer Module Card Path Elements

• Circuit Description

3.1 COLOR FUNDAMENTALS

Color refers to the hues seen in the visual spectrum. This spectrum consists of all the colors seen

in a rainbow or by the dispersal of white light through a prism. The extremes of this spectrum are

red (the longest wavelength perceivable) and violet (the shortest wavelength perceivable). The

remaining orange, yellow, green, etc., shades lie between the red and violet extremes.

Spectrums above and below the visual are called ultra violet and infrared, respectively.

Saturated colors are colors in their purest state. This means they contain no white (as in pastels)

or black (contrast reduction) components. A so-called trained observer can discern about 450

pure shades. If these colors are diluted by black, the ability to discern shades diminishes.

However, white dilution increases the number of colors discernible.

980286-001 Rev. A 3-1

Page 34

CHAPTER 3

THEORY OF OPERATION

When computers get involved in the color process such things as memory capacity and data

3

compression become factors. Fifteen-bit color yields 32x10

each pixel in the desired image. Twenty-four bit color yields 16x10

9

yields 4x10

shades. Note that the memory required for images expands substantially with the

shades and a requires 15-bits for

6

shades. Thirty-two bit color

number of shades. Compression attempts to reduce the memory requirements. Some

compression schemes only attempt to identify repeating colors. Others, such as JPEG, can treat

various amounts of change as if they were the same repeating colors. Carried to an extreme, a

posterized result would occur, and the color changes would step unnaturally.

In the color printing process, particular shades of color derive by mixing quantities of the basic

colors cyan, magenta, yellow, and sometimes black (usually referred to as CMY or

CMYK—where K designates black). When users choose some other color definition from their

application—e.g., hue saturation intensity (HSI) or red green blue (RGB)—a conversion to

CMY/CMYK must take place to support a printer. Mixing occurs at the level of each pixel. Pixels

serve as the basic elements of images. Pixels can comprise either one dot (the smallest printable

element) or a small matrix of dots, depending on the methodology used to form the images.

Offset printing and Dye Sublimation can produce a substantial range of colors within just one

dot. Color Monitors produce their range of colors using a red, green, and blue (RGB) three-dot

matrix. Scanners and digital cameras employ charge-coupled devices (CCDs) that deliver RGB

outputs.

Thermal Transfer and most Ink Jet printers produce their range of colors using larger dot

matrixes—typically up to four-by-four or equivalent dots—where each dot color can be a

fundamental (CMY), or the combination of fundamentals (RGB and black). Therefore, these

particular devices limit their dot colors to cyan, magenta, yellow, red, green, blue, black, and the

media color (usually white). The color perceived results from the optical mixing of the eight

possible color components contained in the matrix.

With eight dot colors possible, a four-by-four dot matrix can produce in excess of 4 billion

8

)

combinations ((4x4

). However, as long as the color components remain the same, the dots in

a matrix can be shuffled into any pattern without changing the color perceived. For example, a

matrix containing all-white dots except for one red dot produces the same shade of pink no

matter where in the matrix the red dot lies. Therefore, a matrix containing n dots can produce

each color in n different ways. Thismakes a four-by-four matrix capable of producing more than

8

268 million different shades ((4 x 4)

/16 + white). For monochrome printing, which is the only

matrix-based printing that users might want to apply to a 3M MAXSecure printer, this same

2

)

matrix can produce 16 different gray shades plus white ((4x4

/16 + white).

Mixing of dot colors in Offset Printing and Dye Sublimation occurs by controlling the amount of

each dye or ink that gets applied to each dot. Mixing in monitors occurs from control of beam

intensity, with three beams acting on the individual phosphors applied to CRTs (cathode ray

tubes).

Of all thesemethods, Dye Sublimationproduces the best quality printouts, because as is the case

for all 3M MAXSecure printers, each dot can have the full range of 15-bit color (32K shades) at

full 300 dpi resolution. In fact, even with resolutions equal, Dye Sublimation still has an

advantage over offset printing. Dye Sublimation creates a dot color by varying the density of the

CMY dyes. Offset printing creates a dot color by varying the diameter of the CMYK ink dots,

3-2

980286-001 Rev. A

Page 35

CHAPTER 3

THEORY OF OPERATION

which can make individual dots more observable and subject to moiré pattern generation. With

Dye Sublimation, users achieve essentially the continuous-tone quality of photographs.

Moiré patterns can become a factor when users generate either print files or hard copy

separations for offset printing. Users should ask the people that do their offset printing which

separation angles best reduce these patterns before risking a distorted result. Many applications

offer Print dialog options for these settings.

All the non Dye Sublimation print methods work because people perceive individual dot colors

only to the point the dots remain individually discernible. At sizes or distances where individual

dots cannot be seen, optical mixing occurs. To see individual dot intensities or colors, view the

monitor or printed page using an eye loupe or other such magnifier. Not all images require high

dot densities. The need for high dot density decreases as the viewing distance increases. For

example, a large roadside sign may require separations screened at only four lines-per-inch.

Note that press men use lines per inch, because of the screens used to vary dot size, and

computer users use dots per inch, but both refer to picture resolution.

Because a monitor and a printer produce color using different methods, users can expect

somewhat different results. A monitor uses an additive process, meaning a particular color

derives from intensity control. For example, a color moves toward the green by intensifying

excitation of green phosphors. Printed images, on the other hand, use a subtractive process.

These images display their color through reflected light—unlike monitors, which become a light

source created by excitation of phosphors. To create a particular printed color, the process must

subtract (that is, filter out and not reflect) the spectrum parts of the source illumination that do

not contribute to the color desired.

The light reflected off of the surface of a white card passes through the colored dyes deposited on

the surface of the card, both going and coming. The dyes used to form printed images serve as

filters of light that would otherwise reflect off of what is typically a white print media. In printed

images, complete filtration (or what serves as the maximum subtraction capability), results in

black. The absence of filtration results in the media color. In monitors, maximum beam

intensities (maximum additions) result in white, and minimum intensities produce black.

Because light reflected from print media depends on ambient lighting, users may get darker

images from a printer than they see on a monitor, particularly a monitor with a high intensity

setting.

Print illumination (generally from room or outdoor lighting) affects color for all printed images.

When a light source emits less in certain parts of the visual spectrum, a print illuminated by this

source by necessity reflects less of the associated colors. This is true even though the

corresponding light reflecting capability remains inherent in the print. Imagine, for example, the

effect of placing a color filter in front of a light source. Only the visual spectrum parts passed by

this filter reaches the print. Viewers can sometimes see subtle effects of this by observing the

same print under sunlight, incandescent lights, and fluorescent lights.

Sunlight radiates fairly evenly over the entire visual spectrum, having only a slight increase at the

center. Incandescent lights radiate far more on the red side than on the blue side of the visual

spectrum. Fluorescent lights radiate differently depending on their phosphor blends. Such

classifications as “Cool Light” and “Warm Light” refer to blue-rich and red-rich enhancements,

respectively.

980286-001 Rev. A 3-3

Page 36

CHAPTER 3

THEORY OF OPERATION

When close concern for color is important in displaying prints, users should find a similar

ambient setting for a color check. If a color is closely related to identifying a printed feature, users

may find themselves dealing with this level of concern, with skin tones typically offering the

greatest challenge. However, most applications tend to require a less critical evaluation. Usually,

what looks good in one setting tends also to look good in another setting, despite any subtle

differences in ambient lighting.

In scientific terms, the question “How white is my source?” is resolved by a side-by-side

comparison between a source in question and a heated black body radiator. The term “black

body” refers to a material that produces no color other than that which results from heating.

Imagine such a material first appearing reddish and then gradually appearing white hot followed

by bluish white as its temperature increases. These are the whites to which comparisons are

made. In the Graphic Arts industry, the following standards for white exist:

Region Black Body Temperature

US. 5000°K

Europe 6500°K

Note that a color image created for a U.S. print media will appear different when printed on a

European print media. Any white media used will have measurable color spectrum

characteristics that can accent or attenuate particular colors. Consider, for example, what might

happen to an image printed on a media having a bluish tinge.

Color is very much a function of the device either sensing or producing the color. A computer

monitor, for example,can produce very bright images, typically brighter than those produced by

a television set. A television set typically can produce a broader range of colors than can a

monitor. Television manufactures emphasize color range over brightness; monitor

manufacturers emphasize brightness over color range. While the forgoing compromises

generally hold true, each device manufacturer, in fact, takes a different perspective when

deciding which formulations to use in the red, green, and blue CRT phosphors.

Further complications arise with the addition of a color scanner to a system. These devices also

differ between manufacturers. WYSIWYG (what you see is what you get) from scanner to

monitor to printer gets complicated because of different device color ranges (Gamuts) and by

the different color systems used. A printed color outside the range of a scanner cannot make it to

a monitor. Users that attempt to use a computer application to edit an image received from a

scanner may add colors beyond the range of their printer. Notably, some applications issue

gamut warnings. Both monitors and scanners use the RGB system, while color printers use the

CMY/CMYK system.

An important concern is how a device handles colors beyond its range. If a device just

substituted the best color available, objects filled with blends, starting from inside the gamut and

ending at some point beyond the gamut, would loose their desired appearance. For example,

an object blending from say an orange to a red beyond the red range would abruptly stop

blending at the point the device could no longer produce a deeper shade of red. The remaining

blend would then have the same color. Some devices avoid this effect by compressing (re

mapping) the gamut. While compression maintains the desired effect, too much compression

produces posterizing. When this occurs, color changes appear unnaturally abrupt in some parts

of the image.

3-4

980286-001 Rev. A

Page 37

CHAPTER 3

THEORY OF OPERATION

3.2 PRINTER INTRODUCTION

3M MAXSecure color imaging requires three passes of a Clear Card media across the Print

Head. Clear Card media shuttles back and forth across the print head during this process. The

ribbon feeds between the image head and the card media and during printing advances from its

supply to its take-up reels in step with the advancing print media.

Heat, when generated at an image head element, transfers ribbon dye in a measured quantity

onto the print media. In color printing, the ribbon advances from one color panel to the next

between each imaging pass. A card exits to the Card Assembler following the last pass.

Monochrome printing for each black resin image requires additional passes.

3M MAXSecure printers employ an image head with a single row of 672 print head elements,

300 to the inch. Note that the capability for card coverage exceeds the needs of a standard card

size by 0.115 inch, or about 34 dots. This excess supports both programmable centering and full

bleed imaging. Each element can generate 32 different heat levels for color and a single heat

level for monochrome.

Figure 3-1 shows two views of a 3M MAXSecure Printer Module. Refer to the upper view for

components that transport the card and ribbon media and the labeling of major components.

Refer to the lower view for elements that sense media positions.

Motors and Solenoids

Printer Stations have two dc motors: one for the ribbon take up, and another to drive the cam

that raises and lowers the print head. For the required imaging precision, a stepper motor drives

the rollers that transport card media. A dc motor in the White Card Feeder and a steppper motor

in the Clear Card Feeder insert related card media. Another dc motor in the Card Assembler

station delivers card components to the exit slot.

Timing belts couple the upper two sets of rollers in the Upper Clear Card Feed and Shear

Station, including the related Manual Advance Knob. Timing belts also couple the two rollers in

the White Card Feed Station. Also note that the Printer Station stepper powers a set of rollers in

the Lower Clear Card Feed and Shear Station. An associated timing belt extends stepper drive

across the two stations.

A solenoid exists in the Card Assembler. When this solenoid releases, card components raise to

engage the upper roller, where dc motor drive can transport cards to the exit slot. At this point,

cards await theirremoval, either manuallyor by anattached Laminator andDie Cutter Module.

An additional solenoid in the Clear Card and Shear Station directs Clear Cards either directly to

the horizontal card guides or to the lower section for a flip-over. The second Clear Card of a

three-layer card transitions through the lower section.

980286-001 Rev. A 3-5

Page 38

CHAPTER 3

THEORY OF OPERATION

Sensors

During a print cycle, LED-Photo transistor sensors monitor the positions of the cards and the

advance of the ribbon. Note that two types exist—a beam interrupt type and a beam reflection

type. Switch sensors also exist that operate off of the cam that raises and lowers the Print Head.

These switches sense completion of head-up and head-down transitions.

Two ribbon sensors exist. One ribbon sensor can receive a beam reflection through the yellow

ribbon panels. Users can initialize the ribbon to these positions by pressing the Panel button.

This ribbon panel sensor also senses out-of-ribbon conditions. Operating in association with the

Flag sensor, the need for ribbon advance corrections is sensed. The number of flag slots counted

verses the sensing of the yellow panel for each colorimage produced serves as the basis forthese

corrections. As more ribbon accumulates on the Take Up spindle, a reduction in the amount of

take up occurs to keep line advances sufficiently even.

Three sensors exist in the Clear Card Feed and Shear Station—two sense reflections off of the

Clear Card material and one senses transmissions through the Clear Card material. Properly

setup, the transmission sensor can signal the presence of a splice. The reflection sensor signals

when a shear should occur to produces a card segment. The upper reflection sensing sensor

signals the presence (or absence) of Clear Card material in the card path.

Two more reflective sensors appear in the lower part of the Clear Card and Shear Station. The

upper-most sensor signals the need to switch from Clear Card Station drive to Printer Station

drive. The lower-most sensor signals the need to reverse Printer Station drive. As this drive

continues, the Clear Card enters the horizontal card path with its bonding agent facing down.

Note that the previous Clear Card entered the horizontal card path with its bonding agent facing

up, and a White Card entered between the two Clear Cards with its security imprints facing

down.

Two Card Assembly Station sensors exist—an upper beam interrupt type and a lower beam

reflection type. The upper sensor indicates when cards appear at the output slot. The lower

sensor produces a reflective signal that indicates the presence of a White Card. These sensors

can also signal errors caused by too many cards in the Card Assembly Station.

3-6

980286-001 Rev. A

Page 39

Manual

Advance Knob

Clear Card Feed

Rollers

Card

Path

Exit

Solenoid

CARD ASSEMBLER

STATION

Ribbon

Take Up

Stepper-Driven

Transport Rollers

Print Head

PRINTER

STATION

Ribbon

Supply

Platen

Roller

Print Head

Up/Down

Cam

Clear Card

Shear

Cleaning

Roller

Clear

Card

Material

Sensor

CLEAR CARD FEED

AND SHEAR STATION

Card Path

Solenoid

Clear Card

Flip-Over

Card Path

White Card

Feeder Rollers

WHITE CARD

FEED STATION

Select

Flag

Sensor

Head Up/Dn

Switch

Sensors

Input

Sensor

Cut

Sensor

Clear Reverse

Top Sensor

Clear Reverse

Bottom Sensor

Splice

Sensor

Card at

Output

Sensor

Card(s) in

Assembler

Sensor

Ribbon

Sensor

Figure 3-1. 3M MAXSecure Card Path.

980286-001 Rev. A 3-7

Page 40

CHAPTER 3

THEORY OF OPERATION

3.3 CIRCUITRY

As shown in Figure 3-2, the printer has the following circuits:

Print Head Circuitry

•

Motor Control Circuitry

•

Status Circuitry

•

Host and Module Interconnect Ports

•

Operator Panel Circuitry

•

If possible, spend some time with this figure. The intent is to offer another perspective to

descriptions given in other parts of the manual.

Printer Modules havethree printed circuit boards—a Main CPU board, an Extension board, and

a second Processor board that controls Clear Material feeds. The figure depicts soldered-in

circuit blocks without shading. The lighter shading indicates socketed ICs. The darker shading

indicates external assemblies connected to the circuit boards by cabling.

The Microcontroller determines all operations through data and address busses and control

signals. Flash memory contains the associated micro-code. Note also that the Address bus

primarily serves transfers involving the Flash and DRAM chips. Most other data transfers occur

with a chip enable or other Microcontroller signal.

Two types of status are collected—sensor and parameter. Analog comparators receive inputs

from the LED-Photo transistor detectors. The D/A Converter allows the Microcontroller to

trigger an integration signal sent to the comparators placed on the Extension board.

Comparators operate using single-slope integration as a basis for checking sensor levels.

Single-slope integration times the interval between the start of a sawtooth wave and the point an

analog comparator switches state.

Motors exist in two types—dc, and stepper. The solenoid and all dc motors, including the one in

the Shear, receive 24-volt dc power. This same supply powers a dc-to-dc converter that delivers

5-volt power to the remaining circuitry.

Print data, still in compressed bit-map form, enters the RAM. After reception, the Microcontroller

sends the data to the Print Head Drive circuitry. Decompression occurs after the Microcontroller

retrieves data and before its delivery to the Print Head Drive circuitry.

Word-by-word, the data shifts into the 672 print head registers that feed theelements of the print

head. Print Head registers receive the data in two serial streams from the Print Head Drive

circuitry. For Clear Card color printing, the Microcontroller loads the 672 registers five times,

each time followed by a different pulse width that enables delivery of data to the Print Head

elements. Each pulse width produces a different heat for those elements that have received an

active data bit. Each element can, therefore, deposit up to 32 different dye densities on a card for

each of the ribbon panel colors. When expanded to include all ribbon panels, 32K possibilities

exist. This process continues for each line of imaging and through all panels of the installed color

ribbon. In contrast, monochrome imaging only employs one pulse width per line of imaging.

3-8

980286-001 Rev. A

Page 41

Operator Control

and Display

MICROCONTROLLER

CHAPTER 3

THEORY OF OPERATION

Clock

(32 MHz)

LCD

Messages

DB-9 (Encod.)

DB-9 (Lam.)

DB-25

Head Up

Head Down

Print Head

Voltage

Vdd

Print Head

Thermistor

Initialize and

Error Clear

Serial Port Driver

(Module

Parallel

Port

Register

Status

• Card

• Ribbon

• Flag

• Head

Parameter

Status

Data Bus

(16-bits)

Control

Signals

Address

Bus

Stepper

Print

Head

Drive

Printer

Drive

DC

Motor

Drive

FLASH

DRAM

PHASE1

PHASE2

PHASE3

PHASE4

Print

Head

Assembly

Printer

Stepper

White

Feed

Head

Up/Dn

Ribbon

CLEAR FEED PCBA

Status

• Clear Loaded

• Cut Clear

• Splice

EXTENSION PCBA

Status

• Clear Rev. Top

• Clear Rev.

Bottom

• 2-Layer

• 3-Layer

• Clear Out

• White Out

Printer

Stepper

Drive

Microcontroller

Control

Registers

D/A

Converter

(REF.)

PHASE1

PHASE2

PHASE3

PHASE4

dc Motor

and

Solenoid

Drive

Clear

Stepper

Path Sel.

Solenoid

Shear

Exit

Feed

Exit

Solenoid

Figure 3-2. Block Diagram.

980286-001 Rev. A 3-9

Page 42

CHAPTER 3

THEORY OF OPERATION

A Parallel cable extends the data bus of the Main CPU board to the Extension board.

Centronics™ (i.e., LPTx) port signals from the Main CPU board serve as a Host I/O. A serial

(RS-232C) port interconnects the Printer Module with a Laminator and Die Cutter Module.

Another serial port interconnects the Printer Module with the Encoder Module. An associated

Receiver/Transmitter IC contains a charge pump, so that serial signals can have ±10-volt

swings.

A serial data line and an associated clock line transfers data to the Clear Card Controller. After

reception of commands from the CPU Board Controller, this controller opperates indepently to

control the feeding of Clear Card Material. The material feeds through control of a stepper

motor. Card path selection occurs through control of a solenoid. Signaling key points in the feed

process are the Clear Loaded, Cut Clear, and Splice sensors. A single line back to the CPU

Board Controller signals completion of an operation.

The Microcontroller monitors the Card Sensor during card feeds. Once a card reaches the Card

Sensor, the Stepper Motor takes over card positioning control. Pulses sent to the Stepper

produce accurate bi-directional step increments that position the cards for printing and delivery

to the Card Assembler Station.

Users press the button on the front of the printer to advance a multiple-panel ribbon to the point

imaging can begin. The Ribbon Sensor produces a signal at the yellow panel in support of this

positioning.

Printing requires an advancing ribbon and a Print Head lowered to the surface of the card, both

resulting from associated dc-motor drives. The motor that lowers and raises the Print Head

drives a cam that works against a spring-loaded Print Head. Limit switches indicate the Head Up

and Head Down conditions. During printing, the spring maintains the required downward

pressure of the Print Head on the ribbon and card.

3-10

980286-001 Rev. A

Page 43

CHAPTER 4

TROUBLESHOOTING

Typically, troubleshooting begins with an attempt to relate a problem to an associated

component or system function. In this phase, servicing personnel may attempt to duplicate the

problem and then use various means to test for a malfunction or improper system setup.

This chapter hopes to aid in this process by presenting Flow diagrams that lead to some areas

related to an observed problem. Those with replacement components on hand can often speed

up the repair process by swapping related components. This process either narrows the

possibilities or eliminates the problem. Trial-and-error works particularly well with easily

accessible components, such as those accessible by opening the cover or removing the rear

case.

Only a symptom-related list of possibilities appears. When the suggestions presented fail to

effect a repair, CPU and Extension Board replacements, if not prescribed, should nevertheless

be tried. Also, check for broken or disconnected cables and any loss of either ac or dc power.

Beyond this, 3M Products offers Technical Support and factory repair as options.

980286-001 Rev. A 4-1

Page 44

CHAPTER 4

TROUBLESHOOTING

4.1 DIAGNOSING BASIC PRINTER PROBLEMS

Figure 4-1 shows a diagnostic flow diagram designed to reproduce problems related to card

images and card transports. Two tables follow that offer associated details and section

references.

Diagnosing Basic

Printer Step 1

Turn Power On

Check for Print

Anomalies

LOOK FOR:

No Image

Faint Image

Artifacts

Horizontal Line(s)

Vertical Lines

Sticking Ribbon

Washout

Ribbon Sheared

Image Off Center

CMYK Not Aligned

Abrupt Color Change

LCD

Message

Appears?

Ye s

Cycle Power

With Panel

Button Pressed

Test Card

Emerges?

No

NoYe s

Check Power,

Fuse, Cord, etc.

Check Card

LOOK FOR:

No Clear Card Feed

No Shear

No White Card Feed

Multiple Card Jam

Partial Wht. Card Feed

Stall at Cleaning Roller

Stall Past Platen Roller

Transport

Path

Figure 4-1. Problems Duplicated by a Test Print.

4-2

980286-001 Rev. A

Page 45

Problems Associated with Print Anomalies

Symptom Possible Causes

No Image

Faint Image

Artifacts Particles on Feed or Transport Rollers

Horizontal Lines Dirty or Damaged Print Head Element

Multiple

Evenly-Spaced

Horizontal Lines

Vertical Lines Stepper Transport Belts Too Tight

Sticking Ribbon Peel Bar Adjustment

Washout Peel Bar Adjustment

Sheared Ribbon Image Not Centered

Image Off Center X- and Y-Offset Values

CMYK Not

Aligned

Abrupt Color

Change

CPU Board

Head Up/Dn Motor

Switch Sensors

Low Print Head Voltage

Dirty Print Head

CPU Board Print Head Registers

Erratic Card Feed due to Belt Tension

or dirty rollers

Initialization

Flag Sensor

Clutch Pads

Ribbon Take-Up Motor/O-Ring

CHAPTER 4

TROUBLESHOOTING

References

Adjustment

or Cleaning

6.2.1

6.2.3

6.2.1 5.2.10

6.3.5

6.3.2

6.3.2

6.3.3

6.3.3

6.3.5, 6.3.6

6.2.3

Replace-

ment

5.2.20

5.2.16

5.2.16

5.2.23

5.2.20

2.2.1

5.2.16

5.2.17

5.2.16

980286-001 Rev. A 4-3

Page 46

CHAPTER 4

TROUBLESHOOTING

Problems Associated with Card Transport Failures

Symptom Possible Causes

Clear Card Material Not Below Shear

No Clear Card

Feed

No Cut and Clear

Card Material

Feeds Past Cut

Point

No White Card

Feed

Multiple Card Jam

Partial Card Feed

Stall at Cleaning

Roller

Stall in Printer

Station

LED Indicates SPLICE

Clear Card Feed Station Rollers Dirty

Clear Card Feed Motor, Belt, or pulleys

Clear Station PCBA or IC

Lower Clear Card Feed Station Sensor

Card Weight Not on Card Stack

Warped White Card

Dirty Card Feed Roller

Card-Feed Motor

Card-Feed Belt

Layer Lever Set for 3-Layers

Card Sensor

Card Sensor Adjustment

Layer Lever Set for 2-Layers

Card Weight Not in Place

Rear Stepper Motor or a Transport Belt

Card Sensor

Broken Belt or Slipping Pulley

Card Sensor

Cleaning Roller not or improperly Installed

Card Transport Belt

References

Adjustment

or Cleaning

2.2.10

2.2.2

6.2.3

2.2.11

6.2.3

2.2.12

Appendix A

2.2.12

2.2.11

6.3.5

6.3.5, 6.3.6

6.2.2

Replacement

5.2.6, 5.2.7

5.2.22

5.2.7

5.2.3

5.2.3

5.2.16

5.2.19

5.2.14, 5.2.16

5.2.19

5.2.13

5.2.14, 5.2.16

4-4 980286-001 Rev. A

Page 47

CHAPTER 4

TROUBLESHOOTING

4.2 DIAGNOSING COMPUTER INTERFACE PROBLEMS

Figure 4-2 shows a flow diagram that checks the interface to the computer. For additional

information, see:

Cabling—

•

Theory—

•

Replacements—

•

Diagnosing Interface

Connect Printer to PC,

Prepare Printer with

Ribbon and Cards, and

Tu rn Po we r On

Issue Commands

Using Either:

WindCard

·

Windows Driver

·

Test Software

·

Printer

Responds?

Repair/Replace:

I/O Cable

·

CPU Bd. Cable

·

CPU Bd.

Ÿ