Page 1

User’s Guide

P500 and P600

1997 Eltron International Inc.

User’s Manual No. 980179-001 Rev. A

Page 2

Page 3

FOREWORD

This manualcontains installation and operation information for the Privilege Series card printers

manufactured by EltronInternational Incorporated, Simi Valley, California.

RETURN MATERIALS AUTHORIZATION

Before returning any equipment to Eltronfor in-warranty or out-of-warranty repair, contact RepairAdministrationfora Return MaterialsAuthorization(RMA)number.Repacktheequipment in

the originalpacking material and mark the RMA number clearly on theoutside. Ship theequipment, freight prepaid,to the address listed below:

Eltron Repair Administration, USA

41 Moreland Road

Simi Valley, CA. 93065

Phone: +1 (805) 579-1800

FAX: +1 (805) 579-1808

Label Printers: Card Printers:

Eltron International, Europe Eltron International, Europe

Eltron House Zone Indutrielle, Rue d'Amsterdam

Molly Millars Lane 44370 Varades, France

Wokingham RG41 2QZ England Phone: +33 (0) 240 097 070

Phone: +44 (0) 1189 770 300 FAX: +33 (0) 240 834 745

FAX: +44 (0) 1189 895 762

COPYRIGHT NOTICE

This document containsinformation proprietaryto EltronInternational Incorporated.This document and the information contained within is copyrighted by Eltron International Incorporated

and maynot be duplicated in fullor in partby any person without written approval from Eltron.

While every effort has beenmade tokeep theinformation containedwithin currentand accurate

as ofthe date of publication, no guarantee isgiven or impliedthat the document is error-free or

thatitisaccurate with regard toanyspecification.Eltronreservestherightto make changes,forthe

purpose of productimprovement, at any time.

TRADEMARKS

Privilege, Privilege P500 and Privilege P600 are service marks. PrivilegeCard is a trademarkof

PrivilegeCard,S. A., asubsidiaryofEltronInternationalIncorporatedand Eltron isatrademarkof

Eltron International Incorporated.Windows andMS-DOS areregistered trademarksof Microsoft

Corp. All othermarks are trademarks or registered trademarks of their respective holders.

980179-001 Rev. A iii

Page 4

WARRANTY INFORMATION

We Need To Hear From You!

To Establish Your Warranty Period And Provide Access To Technical Support,

Send Us Your Product Registration Card Today!

Eltronwarrantsthemechanism, control electronicsandpowersupply,undernormaluse and service, to be free from defects inmaterial andworkmanship fora periodof twelve(12) monthsfrom

the dateof purchaseby theend user.Eltron warrants the print headand Laminatorhead, under

normal useand service,to befree from defects in materialand workmanshipfor a period of one

yearor 40,000passes(whichever occursfirst)from thedateof purchasebythe enduser.Proof of

purchaseor productregistrationisrequired. Ifproofof purchase orproductregistration cannot be

established,shipment datetothe originalbuyer(dealer ordistributor)will beusedto establishthe

warranty period.

Failureto exercise cautiontoprotect the equipmentfromelectrostatic dischargedamage,adverse

temperatureandhumidityconditions or physicalabusemayvoidthewarranty.Failure to useonly

Eltron approved media may void the warranty. Eltron will, at it’s option, repair or replace the

equipment or any parts which are determined to be defective within this warranty period, and

which are returnedto Eltron F.O.B. factory of origin.

The warranty set forth above is exclusive and no other warranty, whether written or oral, is expressed or implied. Eltron specifically disclaims the implied warranties of merchantability and fitness for aparticular purpose.

FCC NOTICE:

This equipment hasbeen tested and foundto comply with the limits of a Class B digital device,

pursuant to Part15 ofthe FCC Rules.These limitsare designedtoprovide reasonableprotection

against harmful interferencewhen theequipment isoperated in acommercial environment.This

equipment generates, uses and can radiateradio frequencyenergy and,if notinstalled andused

in accordance with the instructions, may cause harmful interference to radio communications.

However, there isno guaranteethat interference willnot occurin aparticularinstallation. Operationof thisequipmentin aresidentialarea islikelyto causeharmfulinterference inwhichcase the

user will berequired to correct the interference at his own expense.

INDUSTRY CANADA NOTICE:

This device complieswith Industry Canada ICS-003 class B requirements.

Cet equipement estconforme a l’ICS-003 classe B de la norm Industrielle Canadian

iv 980179-001 Rev. A

Page 5

Icon Descriptions

Indicatesamechanicalhazard,suchas one associated with moving parts, capable of resulting in equipment damage or personal injury.

Indicates an electrical hazard, such as an exposedvoltagepoint, capableofcausing electrical shock and personal injury if touched.

Indicates information of particular interest that

requires consideration in the associated context.

Indicatesapartthatcan operate at anelevated

temperature capable of causing pain or a burn

if touched.

Indicates an area where an electrostatic discharge (ESD) can cause component damage.

Use a grounding wrist band.

Indicatesthatfiberdeposits from fibrouscleaning materials (e.g., cotton swabs) can reduce

print quality.

Indicates that exposure to dust and other airborne particles can contaminate the printer

and reduce print quality.

Indicates that except for card and ribbon loading and maintenance, the cover must remain

closed.

980179-001 Rev. A v

Page 6

ELTRON INTERNATIONAL, INC.

declaresthat the

déclareque le

bescheinigt,daß dasGerät

declaraque el

dichiarache

P500 Card Printer

P600 Card Printer

isin conformancewiththe requirements oftheEuropean CouncilDirectiveslistedbelow:

estconforme auxspécificationsdes directives del'UnionEuropéenne ci-dessous:

dernachstehend angeführtenDirektivendes EuropäischenRats:

cumple

conlos requisitosdelas Directivas delConsejoEuropeo, segúnlalista siguiente:

èconforme allespecifichedelle sequenti direttivedell’UnioneEuropea:

89/336/EEC EMC Directive

92/31/EE EMC Directive

73/23/EEC Low Voltage Directive

Onthe approximationofthe lawsof MemberStatesrelating toElectromagneticCompatibility andProductSafety.

Baséessur lalégislation desEtatsmembres relativeà lacompatibilitéélectromagnétique età lasécurité desproduits.

Ü

berdie AnnäherungderGesetze der Mitgliedsstaateninbezug aufelektromagnetischeVerträglichkeit und

Basadoen

laaproximación delas leyesdelos PaísesMiembros respectoala Compatibilidadelectromagnética

Basatesulla legislazionedeglistati membrirelativa allacompatibilitáelettromagnetica ealla securezza deiprodotti.

Thisdeclaration isbasedupon compliance oftheproduct tothefollowingstandards:

Cettedéclaration reposesurla conformité duproduitaux normessuivantes:

DieseErklärung basiertdarauf,daß das Produktdenfolgenden Normen entspricht:

Estadeclaración sebasaen el cumplimientodelproducto conlassiguientes normas:

Questadichiarazione sibasasulla conformitá delprodottoalle normesequenti:

Produktsicherheitentspricht.

ylas Medidasdeseguridad relativasal producto.

EN 55022-A, CISPR 22RF Emissions Control

EN 500082-1 IEC 801Immunity to Electromagnetic Dicturbances

EN 60950 IEC 950 Product Safety

vi 980179-001 Rev. A

HughGagnier, President

ELTRONINTERNATIONAL, Inc.

41Moreland Road

SimiValley, CA93065-1692 U.S.A.

Page 7

Table of Contents

Getting Started .......................1

Introduction ..........................1

Unpacking Privilege Card Printers ...............4

Check List ...........................5

Installation ...........................7

Upgrading to Expanded Memory ...............13

Expanded Memory Board Installation .............15

Operation ..........................17

Major Components ......................17

Controls & Indicators .....................18

Ribbon Preparation ......................20

Ribbon Loading ........................21

Handling the Media ......................25

Card Gate Adjustment .....................26

Printer Access and Usage ...................30

Printing ............................31

Adjustments ..........................32

Physical Processes .......................33

Cleaning The Printer......................37

Cleaning Stationary Card Path Items .............40

Cleaning the Card-Feed Roller.................41

Cleaning the Upper and Lower Cleaning Rollers........42

Print Head Cleaning ......................44

Cleaning the Transport and Platen Rollers ...........45

Cleaning Laminator Rollers ..................49

Magnetic Card Stripe Encoder ................51

Introduction ..........................51

Media Loading Orientation ..................52

Ensuring Data Reliability....................52

Encoding ...........................53

When to Clean the Encoder ..................55

Cleaning the Encoder .....................55

Adjustments ..........................55

Smart Card Contact Station .................57

Introduction ..........................57

Media Loading Orientation ..................58

Adjustments ..........................58

Smart Card Chip Interface ...................59

Media Jams ..........................60

980179-001 Rev. A vii

Page 8

Appendix A

Trouble Shooting ......................61

Other Support Resources ...................64

Parallel Interface Cable Wiring.................65

Supported Card Media and Ribbon ..............65

Printer Features and Options .................68

Appendix B

Supplies and Accessories ..................71

Accessories ..........................71

Print Ribbons .........................72

Special Ribbons ........................72

Card Media ..........................73

Miscellaneous Supplies ....................73

Installable Options .......................73

Appendix C

Windows Card Printer Driver ................75

Installation of Printer Drivers..................75

Using the Windows 95 Driver .................83

Using The Windows 3.1 Driver ................92

Glossary ...........................101

viii 980179-001 Rev. A

Page 9

Getting Started

Eltron

Privilege Multiple-

Station Card Printers

Thissectioncontainsinformation ontheinstallation of Eltron’s P500 and P600 Privilege

Multiple-Station card printers.

Introduction Eltron’s Privilege Series card printers offer a

low cost, high quality solution to those requiring computer-controlled printing and encoding of credit card style plastic cards. Card

applications include personalized identification, access control, visitor, membership, promotion and luggage card, badges and tags.

1

980179-001 Rev. A 1

Page 10

Getting Started

Features

• 300 dots-per-inch print resolution for crisp,

clear printing.

• High resolution color dye sublimation technology supporting 32.7K colors for photo

quality imaging, along with:

Monochrome thermal transfer technology

for solid imaging of Bar Codes, Text and

Graphic Objects, each producable from

command parameters, making related bit

map downloads unnecessary.

• A Bar Code command thatcanproduceencodedcardprinting inanyof 10 residentbar

codeformats,and aTextcommand thatcan

produce text using 2 resident fonts.

• A 3-Track Magnetic Stripe Encoder option

that writes and then read-verifies data,

supporting cards with high- or lowcoercivity magnetic stripes. P500s can have

either up- or down-facing stripe encoders.

• P500s have Windows™ design and print

user software and a Windows™ printer control driver that supports True Type fonts.

• Efficiently designed to fit in minimum footprint,with asee-through coverthat offersusers a view of the process while offering

protection from exposure to environmental

contaminants.

• Produces duplex (two-sided) Prints on either plain or preprinted plastic card materials.

2

980179-001 Rev. A

Page 11

Getting Started

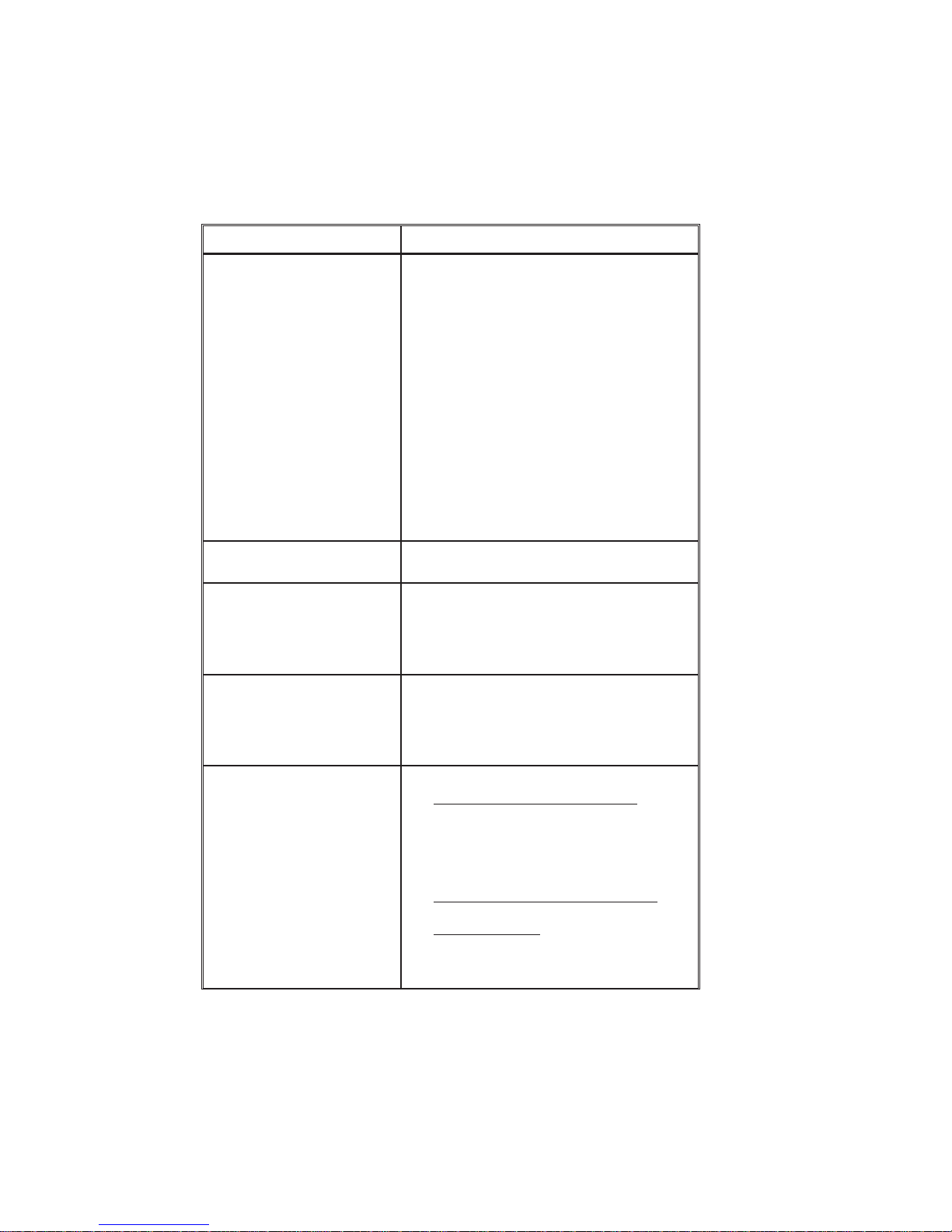

Models All printers have parallel printer ports. P500s

Include WindCard™ Classic Software. Printers

may be ordered in any of the following standard configurations:

Model No. Description

P500CF

120385-001

P600

120284-001

Option

No.’s

104525-001 •

104674-001 • •

104674-002 • •

104674-003 • •

104674-004 • •

300020-001 120V

300020-002 230V

Color Printer withLaminator

Multiple Station ColorPrinter

Options

Expanded Mem-

ory (P500)

Low Coercivity

Encoder

High Coercivity

Encoder

Encodes Down-

facing Stripe

Encodes Up-

facing Stripe

Power Cord

980179-001 Rev. A 3

Page 12

Getting Started

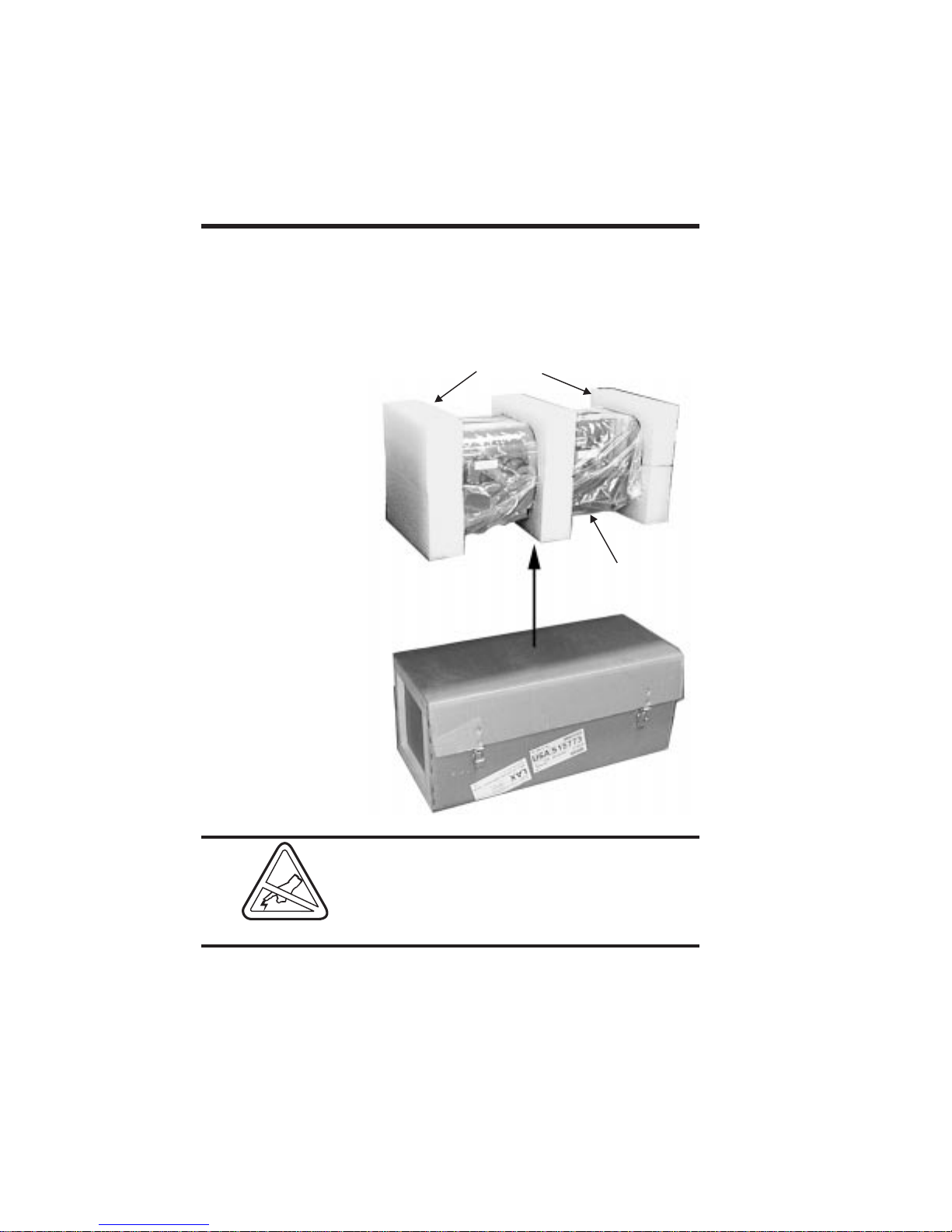

Unpacking

Privilege Card

Printers

Packing Materials

Supply Kit:

Supply Kit:

• Printer Cable

• Printer Cable

• Power Cord

• Power Cord

• Manuals

• Manuals

• Card Weight

• Card Weight

• Card Catcher

• Card Catcher

• Software (P500)

• Software (P500)

Printers ship in a carton and protective bag.

Keep all packing material in case the need to

move or reship the printer arises.Avoidtouchingtheelectricalconnectorstoprevent electrostatic discharge damage while setting up the

printer.

Foam End

Foam End

Cushons

Cushons

Printer in

Printer in

Shipping Bag

Shipping Bag

4

Thedischargeof electrostaticenergythat accumulates on the surface of the human body or

other surfaces can damage or destroy the

print head or other electronic components

used in this device.

980179-001 Rev. A

Page 13

Getting Started

When unpacking the Privilege card printer

(and card media), be aware that a clean and

nearly dust free environment is required for

properoperation andstorage.Theprintquality

can be effected by dust, body oils and acids

(i.e., finger prints) and exposure to other foreignmaterialsduringunpacking orhandlingof

the printer and media.

Check List Your PrivilegeCard Printershipswiththeitems

listed below:

• Printer (Check for proper Model):

• Interface Cable

• Power Cord

980179-001 Rev. A 5

Page 14

Getting Started

• Card Feeder Weight

• Card Catcher

• Manuals:

- Printer User’s Guide

• Software

• CD-ROM

- WindCard Software

- Windows Driver(s)

Ifanyitems aremissing,contact yourdealerfor

replacement parts.

6

980179-001 Rev. A

Page 15

Getting Started

Cardmedia,ribbon, andsuppliesare available

from yourEltrondistributororcallELTRONat

(800) 344-4003 for the distributor nearest

you.Refer toAppendixBforcompletesupplies

ordering information.

Installation The following sections serve as a guide to

printer,WindCard™software,andWindows™

card printer driver installations.

Step Ê

Unpacking

Step Ë

Attach Power

Figure 1-1

Printer

Rear Panel

With help from another person, remove the

printer from the carton and protective plastic

bag.

AC power supplied to Privilege card printers

must be current limited to 16-amps or less using an associated circuit breaker or other such

electrical device.

Place the printer in a clean, dust free loca-

tion that allows easy access to all sides of the

printer. Never operate the printer while it rests

on a side or upside down.

Set the AC power switch to the OFF (0) position.

980179-001 Rev. A 7

AC Power Switch:

AC Power Switch:

1 = ON

1 = ON

O = OFF

O = OFF

Page 16

Getting Started

Power Switch

Connection

Figure 1-2

Positions

Switch OFF Switch ON

Never operate the printer in a location where

the operator, computer, or printer can get wet.

Personal injury could result.

Attach the AC power cord to the AC power receptacle in the rear of the printer.

Figure 1-3

Power

Attach the AC power cord to a grounded electricaloutlet ofthe propervoltageandplugtype.

Figure 1-4

AC Outlet

Connection

8

980179-001 Rev. A

Page 17

Getting Started

Step Ì

Attach Interface

Cable

Figure 1-5

Interface

Cable

Attachandsecurethesupplied DB-25 (female)

to DB-25 (male) parallel printer cable between

the parallel port of the host computer and the

parallel interface connector on the back of the

printer.

Interface

Interface

Cable

Cable

Secure

Secure

Connector

Connector

Intermittent or unpredictable operationmay

occur from unsecured connectors.

See Appendixes A and B for cable specifications and ordering information.

Step Í

Applying Power

Setthepowerswitchto ON (1). Notethatmessagesappearon the LCDscreensasthe printer

cycles through the power-on sequence. Also

note that READY appears at the end of the sequence. If theseeventseitherfailtooccuror an

ERROR message appears instead of READY,

refer to Appendix A - Trouble Shooting.

980179-001 Rev. A 9

Page 18

Getting Started

Step Î

Windows™ 3.1

Software

Installation

Startthehostcomputer.AfterDOShasloaded,

start Windows™. Insert the WindCard™ diskette into a floppy disk drive. From the Windows™ Program Manager‘s File pull-down

menu, select R

un....

Enter A:SETUP (or B:SETUP if you placed

the diskette in drive B). Press the Enter key.

10

Follow the installation instructions on the

screen to install the software.

Refer to Section 2, Operation, for information

on loading cards and ribbons and for initializing the printer for operation.

980179-001 Rev. A

Page 19

Getting Started

See Appendix C for loading WindCard™ software into other operating platforms and the

Windows™ Printer Driver file.

980179-001 Rev. A 11

Page 20

Getting Started

12 980179-001 Rev. A

Page 21

Getting Started

Upgrading to

Expanded Memory

Users can field upgrade P500 printers to include ExpandedMemory.P600salreadyhave

thismemory.Onlythe CPUboardofModule 1

(the Print Station board) exhibits improved

performance with the Expanded Memory installed. The Memory Extension Board plugs

intotheCPU boardof Module 1. Accesstothis

board requires removal of the rearprintercase

assembly.

Avoid unnecessary risks! Removal of the

RearCase ofthe printerexposes CircuitBoards

thatcontainalithium batteries. These batteries

operate for long periods of time and, replacements may never become necessary. Anyone

replacing these batteries subjects his or herself

to the following risk:

WARNING:

• A Danger of Explosion exists if a

battery is incorrectly replaced.

• Replace only with the same or

equivalent type recommended by the

manufacturer.

• Dispose of used batteries according

to the manufacturer’s instructions.

980179-001 Rev. A 13

Case removal exposes circuit points that, if

touched with power on, can present a hazard.

Therefore, never remove any case

component without first unplugging the

Power Cord.

Page 22

Getting Started

Case Removal

Step ¶

Figure 1-6

Screws Holding Rear

Case

Case Removal

Step ·

Using a one-millimeter Allen wrench, remove

the two screws holding the top of the case.

Then, using amediumPhillipsscrewdriver,remove the eight screws that secure the back of

the case.

Remove Allen

Remove Allen

Screws

Screws

Remove

Remove

Philips

Philips

Screws

Screws

Without letting the rear case move backward

fromitspositionwhilesecured, lifttherear case

straight up. Wires attached to the switches and

LCDs restrict how far the rear case can separate from the printer. Therefore, after freeing

therearcasefrom the printer,resttherear case

at a position that does not stress the wires.

Figure 1-7

Rear Case Removed

14

980179-001 Rev. A

Page 23

Getting Started

Case Removal

Step 3

Figure 1-8

Bracket Removal

Expanded Memory

Board Installation

Removal of the upper Phillips screws frees a

bracket. First note the proper position of this

bracket, and then remove the bracket. If

replaced improperly, the rear case screws cannot be refastened.

The addition of an Expanded Memory board

in Module 1 of a P500 allows the host computer to download all image data in a continuous stream, instead of the single color

downloadsfollowed byassociated printingthat

occur without this addition. Multiple-card

printing occurs much faster with this option installed. Rear case removal gives access for this

upgrade.

980179-001 Rev. A 15

Before touching any of the circuit components

on either the printer or the Expanded Memory

board,be sureto dischargeany staticchargeby

touching the metal chassis. Better yet, wear a

grounding wrist band.

Page 24

Getting Started

Installing the

Memory Board

Step ¶

Figure 1-9

Expanded Memory

Installation

Plug the Expanded Memory Board into the

two connectors on the upper right section of

theCPU boardof Module1. Matchtheconnectorssuchthat the ExpandedMemoryboardremains confined within the boundaries of the

CPU board, not oriented to extend over the

edge.

Installing the

Memory Board

Step ·

16

Replacethebracketand printer casebyreversing the steps performed during their removal.

980179-001 Rev. A

Page 25

2

Operation

This section contains information on the operation of the Privilege card printer.

Major

Components

Figure 2-1 shows a P600 Card Printer. Note

that both models have similar

appearances—except,the P500hasaLaminatorwhere theP600 hasasecondPrintStation.

Card-Feed

Figure 2-1

Card-Flip

Major Components

Card

Card

Catcher

Catcher

Print or

Print or

Lamination

Lamination

Station

Station

980179-001 Rev. A 17

Card-Feed

Hopper

Hopper

Print

Print

Station

Station

Page 26

Operation

Controls &

Indicators

The Power

Switch

Figure 2-2

Printer Controls

and Indicators

All the card printer controls and indicators, except for the power switch, reside on the top of

the printer.

The POWER SWITCH is located on back

panel of the printer. Placing the switch in the

ON (1) position applies power to the printer.

Placingtheswitchin the OFF(0)positionturns

off the printer. See Figures 1-1 and 1-2 in Section 1.

The POWER SWITCH also works in conjunction with the Panel Button. See the

Panel Button on the following pages.

Module-2 LCD

Module-2 LCD

and Button

and Button

Module-1 LCD

Module-1 LCD

and Button

and Button

18 980179-001 Rev. A

The following LCD messages can appear:

Page 27

Operation

REPORTING LCD

LCD MESSAGES DESCRIPTIONS

Module 1 Print

Station

Module 2 Print

Station (P600)

INITIALIZING Printer Initializing • • •

WARMING UP P500 Laminator Wait •

READY Ready to Print • • •

PRINTING Printing in Progress • •

LAMINATING Lamination in Progress •

OUT OF RIBBON New Ribbon Required • • •

OUT OF CARD More Cards Required • • •

COMMAND ERROR Command/Parameter Error • • •

MECHANICAL ERROR Mechanical Problem • • •

ENCODING ERROR Read Verify Error • •

READING ERROR Error Reading Mag.Stripe • •

ROTATION ERROR Card-Flip Error •

TEMPERATURE ERROR Laminator Temp. Wait •

COVER OPEN To Proceed, Close Cover • • •

Module 2 Lami-

nation Station

980179-001 Rev. A 19

See Appendix A for troubleshooting tips.

Page 28

Operation

Ribbon

Preparation

Figure 2-3

Ribbon and

Empty Core

Ribbon

Preparation

Step 1

Ribbon

Preparation

Step 2

Both the Print Stations and the P500 Lamination Station require the same pre-installation

ribbon preparations. To prepare a ribbon, the

taped end must be refastened to an empty

core. Eltron recommends the following:

Lamination

Print

Place both the ribbon and an empty core on

end, next to one another, and touching. For

Lamination ribbons, the notched end of the

empty core must face up.

Untape the end that fastens the ribbon end to

the roll while leaving the tape attached on the

supply side.

20

Ribbon

Preparation

Step 3

Figure 2-4

Ribbon

Preparation

Unwind enough ribbon to reach the empty

coreandtapetheend down. If boththeribbon

rollandthe emptycoreare kept touchingwhile

the tape is refastened, ribbon should be centered on thecore.Animproperlypreparedribboncanresultin wrinkling in theprinterduring

ribbon advances.

980179-001 Rev. A

Page 29

Operation

Ribbon

Preparation

Wind one or two turns of ribbon onto the ribbon core.

Step 4

Ribbon Loading Ribbon loading involves the placement of the

prepared ribbon onto the Supply and Take-up

spindles.Similarprocedures applytoPrint Stations and Laminators, as follows:

Ribbon Loading

Lift open the cover.

Step 1

Figure 2-5

Raising the Cover

Ribbon Loading

Step 2

Press down on the Print/Lamination Head Release Latch to raise the Print Head. The Print

Head springs upward when released.

Press Here

Figure 2-6

Raising the Print

Press Here

to Raise

to Raise

Print Head

Print Head

Head

980179-001 Rev. A 21

Page 30

Operation

DO NOT TOUCH the Print Head or nearby

electronic components. Discharged electrostatic energy from a person’s body or from

equipment can damage or destroy print heads

and other printer components.

Atthis pointconsider interruptingribbon installation to perform a cleaning, as described further on in this section. At the very least, wash

off any buildup on the Cleaning Rollers.

Ribbon Loading

Step 3

Using a prepared ribbon, unroll a comfortable

amount from the supply side to span the distance between the Supply and Take Up spindles. Then, at the same time, slide the Supply

and Take Up Cores onto their respective spindles.

Make suretopushbothfullyontothespindles.

Also make very sure that the ribbon comes off

ofthetop oftheSupply Spindleandfeeds onto

the top of the Take Up Spindle.

Note that for proper seating the take-up

cores of Lamination Ribbons have a slot

that must align with a screw on the takeup spindle.

Take extra care when installing a Print Station

ribbon. Printing with a reversed ribbon can

damage the Print Head or make an extensive

cleaning necessary.

22

980179-001 Rev. A

Page 31

Figure 2-7

Laminator Take Up

Ribbon Core

Alignment

Align Notch with

Align Notch with

Spindle Screw

Spindle Screw

Operation

Ribbon Loading

Step 4

Figure 2-8

Ribbon Path

Push down the Latch-Down lever until an

audible click occurs at the latched-down

position.

Supply

Supply

Take Up

Take Up

Spindle

Spindle

Spindle

Spindle

980179-001 Rev. A 23

Page 32

Operation

Figure 2-9

Latching Down

Print Head

Press Here to

Press Here to

Latch Down

Latch Down

Print Head

Print Head

24 980179-001 Rev. A

Page 33

Operation

Ribbon Loading

Step 5

Initialize ribbon—after changing or replacing

ribbons or following a Mechanical Error. Use

the button closest to the Station getting new

ribbon or reporting an error. To initialize:

Color Ribbon-Press andholdthe PanelButton until ribbon advances. Ribbon should stop

with the Print Head between a clear and a yellow panel.

Black Plus Overlay Ribbon - Press and

hold the Panel Button until the ribbon advances.The ribbonshould stopwith anoverlay

panel centered at the print head.

Monochrome Ribbon - No initialization required.

Hologram Ribbon - No initialization required for ribbons that have no hologram

placement requirements and no index marks.

P500 Lamination Ribbon - Press and hold

the left panel button until ribbon advances.

Only ribbons with die-cut panels require Initialization. Ribbon should stop with a black indexmarklocated totheright oftheLamination

Head.

980179-001 Rev. A 25

Handling

the Media

Maintain a clean and nearly dust free environment in media storage areas. Dust, body oils

and acids (e.g., finger prints) and other foreign

materials encountered while unpacking or

handling of the printer and media can have an

adverse affect on card images.

Page 34

Operation

Cards just removed from the media packaging

typically have accumulated an electrostatic

charge. Electrostatic charges can cause cards

to stick together, making card feeds difficult.

Card shuffling can reduce some of this adhesive force. However, avoid bending the card

mediaortouchingthecard surfacesthat willreceive images.

DO NOT set unprinted cards on dust or lint

carrying surfaces, i.e., table tops, cloth, computers, etc..

DO NOT place media with magnetic stripes

on or near magnetic sources, such as: monitors, non-electronic phones, paper clip holders, speakers, etc.

26

Card Gate

Adjustment

The Card Gate serves to meter card feeds so

that onlyonecardfeedsata time. If more than

one card feeds, a card jam occurs. Each card

thickness requires a different Card Gate opening. Never intermix cards with different thickness in the Card Feed Hopper. Only use

0.030-mil cards in P500s

980179-001 Rev. A

Page 35

Figure 2-10

Card Hopper

Card

Card

Weight

Weight

Cards

Card Gate

Card Gate

Adjustment

Adjustment

Card Feed

Card Feed

Rollers

Rollers

Operation

Card Feed

Card Feed

Opening

Opening

Prevent Media Jams!

Adjusting the Card Feeder is critical for proper

mechanical operation of the printer.

980179-001 Rev. A 27

Page 36

Operation

Card Gate

Adjustment and

Media Loading

Step 1

Figure 2-11

Card Gate

Adjustment

Placeasinglecard of the desiredthicknessinto

theCardFeeder. OpentheCardGate(turn the

gate adjustment knob clockwise) until the end

of the card can fit under the gate.

Gate too High

Gate too Low

28

Gate About Right

980179-001 Rev. A

Page 37

Operation

Card Gate

Adjustment and

Media Loading

Step 2

Card Gate

Adjustment and

Media Loading

Step 3

Card Gate

Adjustment and

Media Loading

Step 4

With asinglecardendjustunderthe gate, turn

theadjustment knobcounterclockwisetolower

the gate to the point the gate just contacts the

card. Note that any further lowering pivots the

otherendofthecard off of the rightfeedroller.

Turn the knob clockwise a quarter turn to add

some space between the gate and the card.

Placeasecondcardon top of the first.Without

bending or deforming the cards, try to slide

both cards through the gate, If only the lower

card fits, the adjustment should suffice. If both

cards fit under the gate, either lower the gate

slightly or repeat the previous steps.

Add cards of the same thickness to the Card

Feed hopper sufficient for the printing needs

and place the Card Weight on top of the stack.

During the first few print cycles, watch for card

jams or feed failures. Alternately, send a Card

Feed command to check for proper feeds, as

follows:

From the Windows Driver (See Appendix C),

type:

ME↵

where:

↵ = Enter

From WindCard (See WindCard manual), Select Printer Tools. In the Printer Tools dialog

box Enter:

ME↵

980179-001 Rev. A 29

Page 38

Operation

Printer

Access and

Usage

The printer requires at least three (3) inches of

free space around all sides for access to printer

controls, card input, and card output.

Do Not Operate Printer with Cover

Open.

To maintain a clean printing environment and

to prevent ESD damage, keep the cover of the

printer closed except during maintenance and

media loading procedures. An interlock prevents card flips with the cover open.

With a fixed amount of space available, the

maximum number of cards the Card Feed

hopper can hold varies as a function of card

thickness, as follows:

• 100 of the 30-mil (0.762 mm) cards

• 150 of the 20-mil (0.508 mm) cards

Note that P500s can only laminate 30-mil

cards.

30

980179-001 Rev. A

Page 39

The Card Catcher tray begins spilling cards

onto the surface below after collecting the following:

• 50 of the 30-mil (0.762 mm) cards

• 75 of the 20-mil (0.508 mm) cards

Figure 2-12

Card Catcher

Tray

Printing When theribbonandcardmedia areloadedas

previously described, and the printer power is

on, the card printer is ready to print.

Operation

Printing requires the WindCard™software, (a

Windows™softwareprogram),theWindows™

printer driver, or direct printer command level

programming through the printer interface.

980179-001 Rev. A 31

Page 40

Operation

Printing a Test

Card

Figure 2-13

Color Printer

Test Card

The printerprintsaTestCardiftheRight

(Module 1) Panel Button is pressed and

held in while printer power is turned on. The

button can be released when SELF TEST appears on the LCD. Remember to synchronize

the ribbon for any color printing.

P500s print and then laminate. The informa-

tionthatappearsonthe cardappliesto Module

1.P600sprintonbothsides—eachmoduleimages a different surface. Module 1 information

appears on one side, and Module 2 information appears on the other.

P500 Print Sta-

P500 Print Sta-

tion Test Card

tion Test Card

P500 Lamination

P500 Lamination

Station Test Card

Station Test Card

P600 Station

P600 Station

Test Card

Test Card

Adjustments The card printers have no user adjustable fea-

32

tures except for the card gate adjustment, see

preceding pages.

980179-001 Rev. A

Page 41

Operation

Protect Your Factory Warranty!

Neglect in performing recommended cleaning

procedures canvoidyourwarranty,ascanimproper packaging and shipping.

Other than the recommended cleaning procedures described in this manual, only allow

Eltronfactoryauthorizedtechnicians to service

Privilege printers.

NEVER loosen,tighten,adjust,bend, etc. any

part or cable inside the printer.

The only user adjustable features of the Privilegecardprinters are madeinsoftware (orprogramming) and the card feeder gate

adjustment.

Physical Processes A sensor signals when the feederrollersdeliver

a card to the card transport rollers. Cleaning

Rollers remove dust or lint, and transport rollers accurately position the cards for printing,

lamination (P500), Smart Card Contact Station docking (optional), and magnetic stripe

encoding (also optional).

980179-001 Rev. A 33

The print and laminator head(s) lower to the

surface of the card for printing or lamination.

Printing occurs with ribbon movement and

card movement synchronized. After the completion of operations at one station, cards

moveon tothe nextstation.Cardsejectafterall

specified card operations have occurred.

Page 42

Operation

Color Dye

Sublimation

Gray-Scale Dye

Sublimation

Resin Thermal

Transfer

Color imaging involves three passes of cards

underaprinthead.Yellow, magenta,and cyan

dyes diffusefromcorrespondingribbonpanels

onto the cards in measured quantities for each

dotofa300dpi matrix. Each ribbonpanelcan

produce 32 dye densities on a dot-by-dot basis. Therefore, the range of colors for each dot

is 32.7K.

Gray scale imaging involves a single pass of

cards under the print head. Measured quantities of black dye diffuse from the ribbon onto

the cards on a dot-by-dot basis. Each card dot

can have 32 different densities.

Monochrome ribbons and the monochrome

panels of multiple-panelribbonsproducesolid

imaging by transferring a very durable resin

material onto cards. Resin either transfers or

not on a dot-by-dot basis. Unlike dye sublimation,noin-betweenconditionsexisttoproduce

a gray scale within each dot. Particularly Bar

Codes,but alsoText, Lines,and Rectanglesoften get composed using solid images. Also

Thermal Transfer ribbons come in a variety of

colors other than black. However, bar code

readers need black bar codes.

Overlay Varnish

Thermal Transfer

34

Ribbons with Dye Sublimation panel(s) typically also have an Overlay Varnish Thermal

Transfer panel. These include YMCKrO,

YMCKrOKr, and KsO ribbons. Both color and

gray-scale dyes fade withexposuretoultravioletradiation.Acoating of overlayvarnishgives

images a much longer life. Notably, only dye

sublimation images require this protection.

Resin images hold their color without the protection of overlay varnish. P500 Overlaminate

ribbons with die-cut patches or transfer mate-

980179-001 Rev. A

Page 43

Operation

rial also deposit a card coating that adds ultraviolet protection and an even longer card life

than overlay varnish.

Print Sequence For P500 printers without Expanded Memory,

the typical print sequence for YMCKrO Ribbons proceeds as follows:

• Printerribbonsynchronizes totheyellow(Y)

ribbon panel prior to printing. If not, press

the RESET button to re-synchronize.

• Card-feed rollers deliver a card to the transport rollers, which accurately position cards

for all subsequent printer operations.

• Data for Yellow (Y) imaging downloads.

• Yellow Printing occurs.

• Card moves back, and ribbon advances to

next panel.

• Download, print, return card, and synchronize steps occur for ribbon panels Magenta

(M), Cyan (C), Black Resin and Overlay.

• For duplex (two-sided) card printing, cards

move to the card-flip, where the lower side

transfers to an up-facing side. P500 cards

return againtothe print headofthefirst station for a repeat of the imaging sequence.

Often, only black resin (say for a bar code)

gets applied on the second side. The

YMCKrOKr ribbon offers an economical

choice for those with this requirement.

• After imaging, P500s send the cards to the

Laminator station through the Card-Flip.

There, either a diecutpatchoralamination

material is applied to the up-facing side.

P500s only support single-side lamination

using the included software. However, the

980179-001 Rev. A 35

Page 44

Operation

Card-Flip can present either side to the

Laminator.

• When these processes end, along with any

Smart Card programming or Magnetic

Stripe encoding, a card ejects.

Data downloading is the only difference between a P500 with Expanded Memory and

one without. The extra memory makes possiblereceptionofanuninterruptedstring of data

commands prior to any imaging. With all necessary data resident in printer memory, imagingspeedincreases.Asignificant improvement

occurs for multiple copy printing.

Becauseoftheirdualprintstations,P600soffer

a great deal of versatility in choosing their operations. Users should explore the possibilities

by selecting the command sequence that best

suits their requirements. After mapping out

planned imaging, decide which ribbons best

suit these requirements. Then, decide where

the ribbons should be installed for best performance. Finally, refer to the Programmer’s

manual for commands that implement the desired operation. Remember to integrate any

Smart Card docking or magnetic stripe encoding into the command sequence.

36

980179-001 Rev. A

Page 45

Operation

Cleaning The

Printer

For quality card images keep the printer dust

and lint free. Any particles left on mechanisms

inthecardpathcan migrate onto cardsandinterfere with both YMC dye sublimation and

resin thermal transfer. These ribbon materials

cannot penetrate particles left on the cards.

Thefrequencyofcleaning requiredvaries,depending on the print environment and the usage.

Never use a shop air compressor to blow

away particles in the printer. Air compres-

sors can contain rust-inhibiting oil and may

have ineffective moisture traps. Oil and moisture adversely affect print quality, and when

sprayed,mayspreadcontaminatesthroughout

the printer.

Also canned air requires a very careful usage.

Avoid directing an air stream in a way that

distributesparticlesfromareas having asignificant particle contamination.

Anyvacuum usedmusthaveitsoutflowwellfiltered and directed away from the printer.

Never attempt to vacuum particles off of the

PrintHead,asdamage to delicateimagingelements can result.

980179-001 Rev. A 37

Page 46

Operation

Eltron offers the following items for cleaning

the printer:

• Disposable, Clean Non-fibrous (foam)

swabs with alcohol filled handle for head

cleaning and suitable for roller cleaning

• An alcohol filled, felt pen suitable for roller

cleaning

Bend to Break

Bend to Break

and Release Fluid

and Release Fluid

• A Cleaning Kit comprised of a spray can of

alcoholand apackage ofcleaning cardssuitable for a general cleaning but required for

Magnetic Encoder head cleaning.

38

Cleaningproductsfor the Privilegecardprinter

areavailabledirectlyfrom your Eltrondistributor or call Eltron at (800) 344-4003 for the

distributor nearest you.

980179-001 Rev. A

Page 47

Operation

Alternate cleaning materials can include the

following:

• Foam swabs (never use cotton or any other

fibrous material.)

• 99% pure or better Isopropyl Alcohol for

moistening swabs

• Clean Running Water (Used for Upper

Cleaning Roller only).

Card Path

Elements

Figure 2-14

Media Path

The following figure shows the elements in the

cardpaththatrequire a periodic cleaning.Procedures follow for the following items:

• Card Guides, Smart Card Contact Station,

and Magnetic Encoder Read-Write heads.

• Card Feed Roller

• Cleaning Rollers

• Print Head

• Transport and Platen Rollers

Card Input Hopper

Card Feed

Cleaning

Rollers

Ribbon

Supply

Rollers

Card-Flip

Assembly

Magnetic

Encoder

(Option)

To Module 2

Card Flip

Card

Path

Shroud

Card

Catcher

Ribbon

Take Up

Transport

and Platen

Rollers

Print Head

PeelBar

Smart Card

Station

(Option)

Module 1

Laminator (P500) or

Print Station (P600)

980179-001 Rev. A 39

Card

Cooling

(P500)

Head Up/Down

Cam (2 places)

Module 2

Card-

Flip

Rollers

Page 48

Operation

When To Clean Cleaning frequency varies with different envi-

ronments. Typically, cleanings that follow ribbon depletion keep the card printer operating

properly. Ifnot,considereitheranotherprinter

location or a more frequent cleaning.

Cleaning

Stationary Card

Path Items

Using the

Cleaning Kit

Step 1

Using the

Cleaning Kit

Step 2

Using the

Cleaning Kit

Step 3

Using the

Cleaning Kit

Step 4

Items in the card path that cannot be reached

directly require a cleaning using the alcoholmoistened cards of the Cleaning Kit. Encoder

Read-Writeheads requirethis kindofcleaning.

Remove the ribbon from both the Supply and

Take Up spindles. See Ribbon Loading in this

section.

Moisten a Cleaning Card by spraying with alcohol. Saturate the card, but if alcohol drips

from the card, blot away the excess.

Place the moistened Cleaning Card in the InputTray,topped withthecard weight.Ifnecessary, adjust the Card Gate for the card

thickness. (Since this procedure calls for only

one card, you can open the gate as much as

you like.)

Send the Cleaning Card through the printer

several times without enabling printing. Dependingon thesetup, useoneofthefollowing:

40

Where:

= Space

↵ = Enter

EntryiseitherviaWindCard™ (see manual) or

The Windows Driver (see Appendix C).

980179-001 Rev. A

Page 49

Operation

The following command shuttles a Cleaning

Card from the Input Hopper to the Card

Catcher:

ME↵

For best results, shuttle a card five or more

times.

Cleaning the

Card-Feed Roller

Cleaning the

Feeder Rollers

Step 1

Cleaning the

Feeder Rollers

Step 2

Figure 2-15

Card-Feed Rollers

CardFeedRollersthatfail to grip thecardscan

impede the even delivery of cards to the transport rollers. To clean the Card-Feed Rollers,

proceed as follows:

Remove any cards from the Card Hopper.

Clean the rollers using a Swab or Cleaning

Pen. To gain access to initially unexposed areas, cycle the roller by applying the printer

power while holding the Panel Button on for

three (3) seconds (see Test Card sequence in

preceding description) Let the roller air dry for

two (2) or more minutes.

Card-Fee d

Card-Fee d

Rollers

Rollers

980179-001 Rev. A 41

Page 50

Operation

Cleaning the

Upper and Lower

Cleaning Rollers

Cleaning the

Cleaning Rollers

Step 1

Figure 2-16

Upper Cleaning

Roller

Upper

Upper

Cleaning

Cleaning

Roller

Roller

Spring

Spring

Clip

Clip

These rollers receive cards fed from the Input

Hopper and Card Flip. The upper roller has a

coating that collects any loose particles on the

surface of cards. Note that these rollers exist in

Module 1 just after the Card Feed Hopper and

in Module 2 just after the Card Flip.

Remove any cards from the printer. Open the

printer cover. To free an Upper Cleaning

Roller, gently pull the Spring Clip clear of the

Upper Cleaning Roller pin. Then, remove the

Upper Cleaning Roller.

Cleaning the

Cleaning Rollers

Step 2

42

Clean the Upper Cleaning rollers with running

water. Then allow the rollers to air dry without

resting the rubberized part on a surface.

980179-001 Rev. A

Page 51

Operation

Cleaning the

Cleaning Rollers

Step 3

Figure 2-17

Lower Cleaning

Roller

Cleaning the

Cleaning Rollers

Step 4

Use a swab or cleaning pen on the Lower

Cleaning Rollers. Cycle the rollers by applying

the printer power while holding the Panel Button on for three (3) seconds to expose initially

unexposed areas. This is the Test Card sequence described in Controls and Indicators,

Section 2.

Reinstall the Upper Cleaning Roller. First slide

the shaft pin into the hole in the chassis opposite the Spring Tab.

DO NOT

touchtherollersurfacethat contacts

the media.

Snaptheoppositeshaftpinoftherollerinto the

hole on the Spring Tab.

Without touching the body of the roller, make

suretherollerlocksin place.Toavoidcontamination, always hold the roller by the metal

ends.

980179-001 Rev. A 43

Page 52

Operation

Print Head

Cleaning

Print Head

Cleaning

Step 1

During printing, the ribbon(s) isolate the Print

Head(s) from the cards. Therefore, the ribbon

has the greatest influence on Print Head contamination. An improperly installed ribbon,

with thedyeandresincoatingsfacing the Print

Head can cause permanent damage. No

amount of cleaning can remove dye or resin

fused onto delicate Print Head elements.

Turn the printer power OFF. Open the cover,

raise the print head, and remove the ribbon

from both spindles. See Ribbon Loading, in

this Section.

The print head should only be cleaned with a

solution of 99% pure Isopropyl Alcohol and a

clean non-fibrous (foam) swab.

Avoid touching the Print Head elements. The

release of Static charges can damage the Print

Head elements and Internal circuits.

44 980179-001 Rev. A

Page 53

Operation

Print Head

Cleaning

Step 2

Figure 2-18

Cleaning

Print Head

Gently rub an alcohol-moistened swab across

the print head from the front to the back of the

printer. Do Not Soak the Print Head.

Allowtheprintheadto dryfor 2minutesbefore

reloading the ribbon and core.

Initiate a Test Card sequence. See Printing a

Test Card in this section.

Cleaning the

Transport and

Platen Rollers

Cleaning Platen

and Transport

Rollers

Step 1

980179-001 Rev. A 45

Along with the Cleaning Rollers, these rollers

movethecardsbetween the InputHopperand

CardCatcher.ExceptforthePlaten, these rollers operate in pairs—a lower drive roller and

an upper pinch roller that holds cards against

the drive roller.

Open the Cover, and unlatch and raise the

Print andLaminationHeads,Removeanyribbon. Note that all associated instructions appear in previous descriptions.

Page 54

Operation

Cleaning Platen

and Transport

Rollers

Step 2

Figure 2-19

Encoder Shroud

Shroud

Shroud

Fasteners

Fasteners

Remove the Shrouds that cover the associated

transport rollers. Note that two screws hold

each Shroud in place.

In the following steps, cycle the rollers to reach

initially unexposed areas by applying the

printer power while holding the Panel Button

pressed for three (3) seconds. This is the Test

CardsequencedescribedinControls and Indicators in this section.

46

In the following steps, avoid touching the Print

Head. A static discharge can damage delicate

PrintHead elementsas wellasinternalcircuits.

980179-001 Rev. A

Page 55

Operation

Cleaning Platen

and Transport

Rollers

Step Ì

Figure 2-20

Encoder Transport

Rollers

Encoder

Encoder

Rollers

Rollers

Cleaning Platen

and Transport

Rollers

Step Í

Using an alcohol-moistened Swab or a Felt

Pen, clean the two sets of rollers exposed with

removal of the Shrouds. Note that these appear under both Shrouds in P600s.

Using an alcohol-moistened Swab, clean the

Cooling Station Roller (P500 only).

Figure 2-21

Cooling Station

Rollers

Cooling

Cooling

Station

Station

Rollers

Rollers

980179-001 Rev. A 47

Page 56

Operation

Cleaning Platen

and Transport

Rollers Step Î

Figure 2-22

Platen Roller

Cleaning Platen

and Transport

Rollers

Step Ï

Using an alcohol-moistened Swab, clean the

Platen Roller.

Using an alcohol-moistened Swab, clean the

roller pair under the Print Head

Figure 2-23

Print Station Rollers

Print

Print

Station

Station

Rollers

Rollers

48

980179-001 Rev. A

Page 57

Operation

Cleaning Platen

and Transport

Rollers

Step Ð

Figure 2-24

Card-Flip Rollers

Card-Flip

Card-Flip

Rollers

Rollers

Cleaning Platen

and Transport

Rollers

Step Ñ

Using an Alcohol-moistened Swab, clean the

Card-Flip Rollers.

Replace the Encoder Shroud (see Step 2), install,Ribbon,placecardsin theInputTray,and

print some Test Cards. Inspect the cards for

Print Anomalies. If Anomalies appear, refer to

Appendix A, Troubleshooting.

Cleaning

Laminator Rollers

Cleaning

Laminator Rollers

Step Ê

980179-001 Rev. A 49

The Lamination head has two rollers—an upper heated roller and a lower pressure roller.

Turn off power, open the cover, and unlatch

andraisetheLaminator head. Thisissimilarto

the Ribbon Loading described in Section 1.

Page 58

Operation

Afterturningoffpower,waitaboutfiveminutes

before cleaning the Laminator rollers. The upper Laminator roller generates a substantial

amount of heat with power switched on.

Cleaning

Laminator Rollers

Step Ë

Figure 2-25

Laminator Rollers

Upper Roller

Lower Rolle r

Using an alcohol-moistened swab, clean both

Laminator rollers. The upper roller can be

turned manually to reach initially unexposed

areas. The lower roller can be turned using the

sameprocedure thatproduces testcards. (Turn

on power while hold in the Laminator button

for three seconds) Immediately turn off power

to avoid heating the upper roller.

50

980179-001 Rev. A

Page 59

3

Magnetic Card Stripe Encoder

This section has information on the additional

operation and maintenance requirements of

an Eltron Privilege Series card printer with an

optionalMagneticCardStripeEncoder. Eltron

offers models for recording on either low- or

high-coercivity magnetic card stripes.

Introduction The general operation of a printer with an en-

coder option nearly duplicates that of models

without this option. P600 Encoders can reside

ineitherModule1orModule2, justpastaPrint

Station. P500 Encoders always reside in Module 1. Encoder installations exist for either upor down-facing magneticstripesinbothP500s

and P600s.

Only use cards with flush magnetic stripes.

Never use pasted-on stripes.

980179-001 Rev. A 51

Page 60

Magnetic Card Stripe Encoder

Media Loading

Orientation

Figure 3-1

Magnetic Stripe

Position

PrinterswithMagneticEncoderscan havetheir

read/write heads positioned either above or

below the path traveled by the cards. All

configurations must have the magnetic stripes

placed closest to the rear of the printer. However, check the configuration to determine

whether the magnetic stripe should face up or

face down. Improper hopper loads produce

read errors.

Position Stripe

Position Stripe

Toward Back

Toward Back

(and typically facing

(and typically facing

down, but check

down, but check

configuration)

configuration)

Ensuring Data

Reliability

52

A read verify pass is always performed on all

encoded cards to guarantee data integrity.

Either Software (WindCard™) or command

programming controls the Write and Readverify data processes.

980179-001 Rev. A

Page 61

Magnetic Card Stripe Encoder

Encoding With data downloaded, printers with Magnetic

Encoders can encode all three magnetic stripe

tracks simultaneously. Encoders also support

nonstandard track densities and bits per track.

Aftersettingread/writeparameters,downloads

to track buffers occurs, as follows:

where:

= Escape

= Space

↵ = Return

&Btrack#data↵

Initiationofsimultaneousthree-trackmagnetic

stripe encoding then occurs, as follows:

&E*↵

AProgrammer’s manualdescribes allthe com-

mands including those related to the Encoder

(see Appendix B).

The following shows three examples that enter

data. initiate encoding, and set up read/write

parameters that can be sent from either the

Windows™ driver or directly using DOS (e.g.,

COPYfilenameLPT1)orviaa TextEditor and

itsPrint facility(with PrivilegeDriverselected):

Example 1. Download Data and Encode Card:

Direct Control Windows Driver

&B1JOHN DOE↵ ~C0&B 1 JOHNDOE

&B2555-46-5389↵ ~C0&B 2 555 465389

&B34789↵ ~C0&B 3 4789

&E*↵ ~C0&E*

980179-001 Rev. A 53

Page 62

Magnetic Card Stripe Encoder

Example 2. Set Read/Write Parameters, Enter Data, Encode

Stripe, and Eject:

Command Result

&D175↵ Sets track-1density to 75 bpi

&D375↵ Sets track-3density to 75 bpi

&CDEW1a3↵ Sets to encode track 1 with5-bit

&CDER1q3↵ Sets toread 5-bit characters on track

&B112345↵ Enters 12345 intrack-1 buffer

&B254321↵ Enters 54321 intrack-2 buffer

&B309876↵ Enters 09876 intrack-3 buffer

&E*↵

ME↵ Ejects card fromprinter

characters

1

Encodes three tracksusing buffer

data, and positionscard for printing

Example 3. Reset to ANSI/ISO:

Command Result

&CDEW1A↵ Resets track-1 encodesto ANSI/ISO

&CDER1Q↵ Resets track-1 reads for ANSI/ISO

&CDEW2B↵ Resets track-2 encodesto ANSI/ISO

&CDER2R↵ Resets track-2 reads for ANSI/ISO

&CDEW3C↵ Resets track-3encodes to ANSI/ISO

&CDER3S↵ Resets track-3 readsfor ANSI/ISO

std.

std.

std.

std.

std.

std.

54 980179-001 Rev. A

Page 63

Magnetic Card Stripe Encoder

When to Clean

the Encoder

Cleaning the

Encoder

The Read/Write Head and drive rollers of the

Encoder require a periodic cleaning to maintain error-free encoding.

The encoder should be cleaned when:

• A “General Cleaning” is performed on the

printer.

• The printer’s Drive Rollers are cleaned.

• Write and Read verify process has failed on

morethanonecard. See AppendixA,Trouble Shooting.

Turn OFF printer power.

Remove all card media and both the Supply

andTakeUpspools fromtherespectiveribbon

spindles.

Use the Cleaning Kit procedure described in

Section 2.

Adjustments Privilege card printers with Magnetic Card

Stripe Encoders have no related user adjustments.

980179-001 Rev. A 55

Page 64

Magnetic Card Stripe Encoder

Protect Your Factory Warranty!

Neglect in performing recommended cleaning

procedures can lead to problems not covered

in the warranty.

Other than the recommended cleaning procedures described in this manual, only allow Eltron factory authorized technicians to service

these printers

NEVER loosen,tighten,adjust,bend, etc. any

part or cable inside of the printer.

The only user adjustable features of the Privilegecardprinters are madeinsoftware (orprogramming) and the card feeder gate

adjustment.

56 980179-001 Rev. A

Page 65

4

Smart Card Contact Station

This section contains information on the additional operations of card printers with Smart

Card contact stations.

Introduction Smart Cards (ISO7816) have built-in microcir-

cuits. Card memory can store fingerprints,

voice recognition patterns, medical records

and other such data. Printers can have docking

stations installed that can interface with Smart

Card circuits. Smart Card programming hardwareconnectstoaDB-9 connector on the rear

panel. Configurations with this option respond

to commands that position the cards at the

docking station, as follows:

980179-001 Rev. A 57

Command

MS

OS value

Allotherprinter operations remainthesame as

those for other Privilege models.

Result

Moves card to Contact

Station

introduces offset of

value dots from Station default (96)

Page 66

Smart Card Contact Station

Do not position printing over Smart Card contacts.

Media Loading

Orientation

Figure 4-1

Card Contact

Position

Orient the cardswiththeSmartCardChipfacing up and such that the edge closest to the

contacts feeds first.

Up-Facing

Up-Facing

Chip Contacts

Chip Contacts

Adjustments No adjustments exist for Privilege printers with

58

Smart Card programming stations other than

theCardFeederGateAdjustment described in

section 2.

980179-001 Rev. A

Page 67

Smart Card Contact Station

Protect Your Factory Warranty!

Neglect in performing recommended cleaning

procedures canvoidyourwarranty,ascanimproper packaging and shipping.

Other than the recommended cleaning procedures described in this manual, only allow

Eltronfactoryauthorizedtechnicians to service

these printers.

NEVER loosen,tighten,adjust,bend, etc. any

part or cable inside of the printer.

The only user adjustable features of these card

printers are made in software (or programming)andthecardfeeder gateadjustment(see

Section 2).

Smart Card

Chip Interface

When a command to the parallel printer interface sends a card to the Smart Card Programming station, the printer connects the Smart

Card Chip contacts to the female DB-9 connector on the rear of the printer. An attached

external Smart Card Programmer uses the

DB-9 as an interface to Smart Card chip connections.

Figure 4-2

Host Computer

Smart Card

Smart Card

Contacts Interface

980179-001 Rev. A 59

Smart Card

Contact

Contact

Interface

Interface

Host Computer

Interface

Interface

Page 68

Smart Card Contact Station

DB-9 Pins

Smart Card

Contact Points

1 C1 (Vcc)

2 C2 (Reset)

3

C3 (Clock)

4 C4 (RFU)

5 C5 (GND)

6 C6 (Vpp)

7 C7 (I/O)

8 C8 (RFU)

9

(GND when chip is at station)

Media Jams Always remove the bottom card of a two-card

jam first. Never pull the top card out of the

printer. Instead, sequence the printer power

with only the top card remaining (the last card

toentertheprintpath). Remove all othercards

from the path and card feeder.

60

Damagemay occurto thecontacts attheSmart

Card chip programmer station if the top (last)

card is not ejected by the printer.

980179-001 Rev. A

Page 69

Common Printing

Problems Trouble

Shooting Guide

Problem Solution or Reason

Appendix A

Trouble Shooting

The following lists some common issues that

can confront users experiencing problems

when using Eltron Privilege Series card

printers.

No messages appear on LCD.

An LCD indicates WAIT

TEMPERATURE

Printing appears faded or exhibits poor quality.

Parallel “Scratch Lines”, missing image parts

1. Power Switch OFF (O position)

to ON (1 position).

2. Power Not connected

the Printer to the outlet power.

3. Tripped Breaker

panel supplying power outlet.

1. Too Cold

Head has not yet stabilized within proper

operating range.

2. Too Hot

Head has exceeded a proper operating

temperature—typically due to high volume

printing.

1. Clean the print head.

2. Adjust the contrast and intensity in software

or with programming.

3. Verify value of related Print Head Resistance does not apply to current print head.

Print a Test Card, and compare value with

label on related print head.

1. Check ribbon

2. Clean Print Head

3. Call technical support

: Associated Print or Lamination

: Associated Print or Lamination

: Check AC cord from

: Check the Fuse/Breaker

: Set switch

980179-001 Rev. A 61

Page 70

Appendix A

Problem Solution or Reason

An LCD indicates

COMMAND ERROR

An LCD indicates

OUT OF RIBBON

Cards are present, but LCD indicates

OUT OF CARD

An LCD indicates

READING ERROR

An LCD indicates

MECHANICAL ERROR

Errors Using Windows Driver:

1. Printer Command Coding Error:

Clear command error by pressing related

Panel Button.

2. Ribbon Error:

Press Panel button; note card ejects, if present, and ribbon re synchronizes

3. Feeder Error (empty):

Press Panel Button; note that last command

repeats using another card.

4. Magnetic Stripe Write Error:

Press Panel Button; note that card ejects

and command repeats with another card

5. Other Errors:

Press Panel Button; note that any card

present ejects and error indications cease

6. Check the programming command syntax.

1. Replace used ribbon.

2. Check for broken ribbon

Card Feed Problem:

1. Card Gate adjusted too low

2. Card Weight not in place.

3. Cards or Card-Feed rollers contaminated

with oily deposit and require cleaning

Encoder Command Coding Error:

1. Verify command syntax

2. Call technical support

3. Check card Hopper for proper stripe

position

Mechanical Error:

1. Card Jam - Nonmagnetic Encoder

Open cover, remove related upper cleaning

roller, empty feeder, pull jammed cards out.

Replace upper cleaning roller and run Test

Card

RESET. Cycle power off and on.

2. Card Jam - Magnetic Encoder Models

See Section 3, Clearing Media Jams.

3. Card Not Feeding

printer. Release Print Head latch and run

Test Card

RESET, Cycle power off and on.

completely through

:

:

62 980179-001 Rev. A

Page 71

Problem Solution or Reason

Appendix A

LCD indicates

COVER OPEN

Printer cuts (melts) through the

transferribbon.The ribbonisadvancing at the same rate as the

card media.

Ribbon breaks during resynchronization of the color ribbon panel.

Voids on printed card, varies

from panel to panel.

Voids on printed card, same for

all card panels

Close the cover so that card flips can occur

1. Reinstall the ribbon.

2. Synchronize the ribbon panels by pressing

the related Panel button until the ribbon

starts advancing.

3. Verify proper (or default) print settings in

software.

4. Verify the proper ribbon/panel combination

are selected in the software or programming sent to the printer.

5. Verify that the print heat (resistor) is set to

the correct level in the WindCard software,

Windows color printer driver or by programming commands sent to the printer.

Print a Test Card and note the resistance/heat setting. Verify the card values

match those that appear on the print head

label. (See following illustration.)

1. Raise the related Print Head and synchronize the ribbon. The previous print process

may have been interrupted during the print

process.

1. Clean the Cleaning Roller

2. Complete all cleaning procedures

1. Check Card surfaces for smoothness,

flatness or edge burrs If necessary, get new

cards.

2. Use approved media.

980179-001 Rev. A 63

Print Head

Print Head

Label

Label

Page 72

Appendix A

Other Support

Resources

First attempt a repair using the forgoing table,

Then, if necessary, contact the dealer that sold

you the printer.

Eltron International also offers a variety of information and user support services, as follows:

• Internet:

http://www.eltron.com

ftp://ftp.eltron.com

e-mail:

Label Printers: techsup@eltron.com

Card Printers: privsup@eltron.com

Europe: eurosup@eltron.com

Singapore: asiasup@eltron.com

Latin America: latinsup@eltron.com

• BBS: +1 (805) 579-3445

TheBBSsupports dataratesup to 28.8BPS

with No Parity, 8 data bits, and 1 stop bit

(n,8,1). Communications software should

haveanANSITerminalMode (not MS Windows Terminal) such as Q-Modem.

64

• CompuServe e-mail: 102251,1164

• Customer Service: +1 (800) 344-4003

For the name of a dealer in your area.

• Technical Support FAX:

U.S.A.: +1 (805) 579-1808

Asia: +65 73 38 206

Europe: +44 (0) 1189 895 762

Latin America: +1 (847) 584 2725

For your assistance and support with Eltron

printers and software.

980179-001 Rev. A

Page 73

Appendix A

Parallel Interface

Cable Wiring

The following diagram shows the cable wiring

required to use the printer’s parallel interface.

HOST

STROBE

DATA 0

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

ACK/

BUSY

PAPERERR.

READY

INIT

ERROR/

N/A

N/A

N/A

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

DB-25

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

DB-25

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

PRINTER

STROBE

DATA 0

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

ACK/

BUSY

PAPERERR.

READY

INIT

ERROR/

N/A

N/A

N/A

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

Female DB-25 to Male DB-25

Supported Card

Media and Ribbon

Thecardprinterssupportawidevariety ofcard

media and ribbon types. The card media

should be matched to the ribbon type to avoid

ribbon burning, sticking and to achieve proper

dye sublimation. For optimum performance

and printer (Print Head) life

, always use Eltron

approved card media and ribbons.

980179-001 Rev. A 65

Page 74

Appendix A

Card Media

CR-80 credit card style cards (ISO 7810)

made of PVC (recommended) or Polyester

ABScardmaterials.Somecard manufacturing

processes use a thin, clear over-lamination.

Magnetic (Mag.) Stripe Card (ISO 7811)

Smart Card with ISO 7816 Chip, With AF-

NOR Chip, or a combination of the Magnetic

Stripeononesideandoneof theChipversions

on the other side.

Ribbons Eltron Privilegecardprintersrequire Eltron ap-

proved ribbons. Eltron’s resin thermal transfer

and die sublimation media are specifically designed for Privilege card printers. (See Appendix B.)

Thermal Transfer (Resin) -Allprintstations

can use Thermal Transfer ribbon. Resin offers

more durability than dye sublimation, with

greaterresistancetoscratchesand UV-induced

fading.

66

DyeSublimation- Printingrequiresdye sublimation ribbons with either black orCyan(C),

Magenta(M)andYellow (Y)panels.Theseribbons have Overlay varnish panels to add UV

protection and durability. Color ribbons have

blackthermaltransferresin panels forbarcode

and other solid imaging.

980179-001 Rev. A

Page 75

Appendix A

Radius 0.125 in (3.18mm)

3.375 in ± 0.010 in

(85.72mm ± 0.25mm)

Card Dimensions

2.125 in

± 0.002 in

(53.98mm

± 0.05mm)

Thickness

0.009 in to 0.034 in

(0.23mm to 0.84mm)

Magnetic Stripe Dimensions

0.218 in (5.54mm) Max.

0.623 in

(15.82mm) Min.

0.000 in to 0.115 in

(0.00mm to 2.92mm)

0.000 in to 0.115 in

(0.00mm to 2.92mm)

Smart Card Chip

0.221 in (5.62mm)max. gap

0.01 in

(2.54mm)

Min. gap

(8.25mm)

980179-001 Rev. A 67

C1

0.395 in

0.210 in

(3.54mm)

No-print Area

0.790 in

21.87mm

0.782 in (19.87mm)Min.

0.403 in (10.25mm)Max.

0.631 in

(7.54mm)

0.218 in (5.54mm)Max.

0.623 in (15.82mm)Min.

C1 - VCC(Supply Voltage)

C2 - RST(Reset Signal)

C1

C4

C3 - CLK(Clock)

C5

C4 - RFU

C5 - GND(Logic Ground)

C6 - VPP(Programming Voltage)

C8

C7 - I/O(Data Input/Output)

C8 - RFU

Page 76

Appendix A

Printer Features

and Options

The Privilege card printer series are part of Eltron’s personal and industrial printer family. A

Privilege card printer prints on standard credit

card size cards. These color printers can produce images using either dye sublimation

and/orthermaltransfer(monochrome)modes.

This list only serves as a reference. Consult the

latest Data Sheet.

PRIVILEGE SERIES CARD PRINTERS

Print Resolution

• 300 dots per inch (11.8 dot per millimeter)

Printing Technology

• Monochrome - Thermal Transfer

• Color - Dye Sublimation

Print Time

• Typically3secondspercard(monochrome)

• Typically 45 seconds per card (color)

Print Speed

• 0.5 ips

Font Support

• Arial 22 Bold and Arial 28 Normal

• True Type fonts with the WindCard™ or

Windows™ compatible printer driver to access Windows™ resident fonts.

Bar Code Symbologies

• Code 39 (3 of 9)

• Interleaved 2 of 5 (I-2/5)

• Standard 2 of 5 (2/5)

• EAN 8

• EAN 13

• UPC A

• MONARCH

• Code 128 subsets B with or without Check

Digit

• Code 128 Subset C with or without Check

Digit

68

980179-001 Rev. A

Page 77

Appendix A

Card Types - ISO Format

• CR-80 - ISO 7810

• Option; Magnetic Stripe - ISO 7811

• Option: Smart Card - ISO 7816

• PVC (recommended), PVC w/Polyester

core, ABS card materials

Magnetic Encoding - Option

• 3 tracks

• 3 Media Recording Densities:

Low Coercivity, 300 Oersteds

Medium Coercivity, 2750 Oersteds

High Coercivity, 4,000 Oersteds

• Supports recording formats: ITA, ABA and

Thrift.

Smart Card - Option

• Supports ISO 7816 Smart Card standards

Card Dimensions

• Thickness -

Monochrome - 10 mil to 40 mil

(0.254 mm to 0.762 mm)

Color - 20 mil to 30 mil

(0.508 mm to 0.762 mm)

• Standard Card Thickness:

0.020" (0.508 mm)

0.024" (0.610 mm)

0.030" (0.762 mm)

• Width - 3.375" (85.6 mm) typical

• Length - 2.125" (53.98 mm) typical

Card Feeder

• Stacks up to 150, 20 mil cards

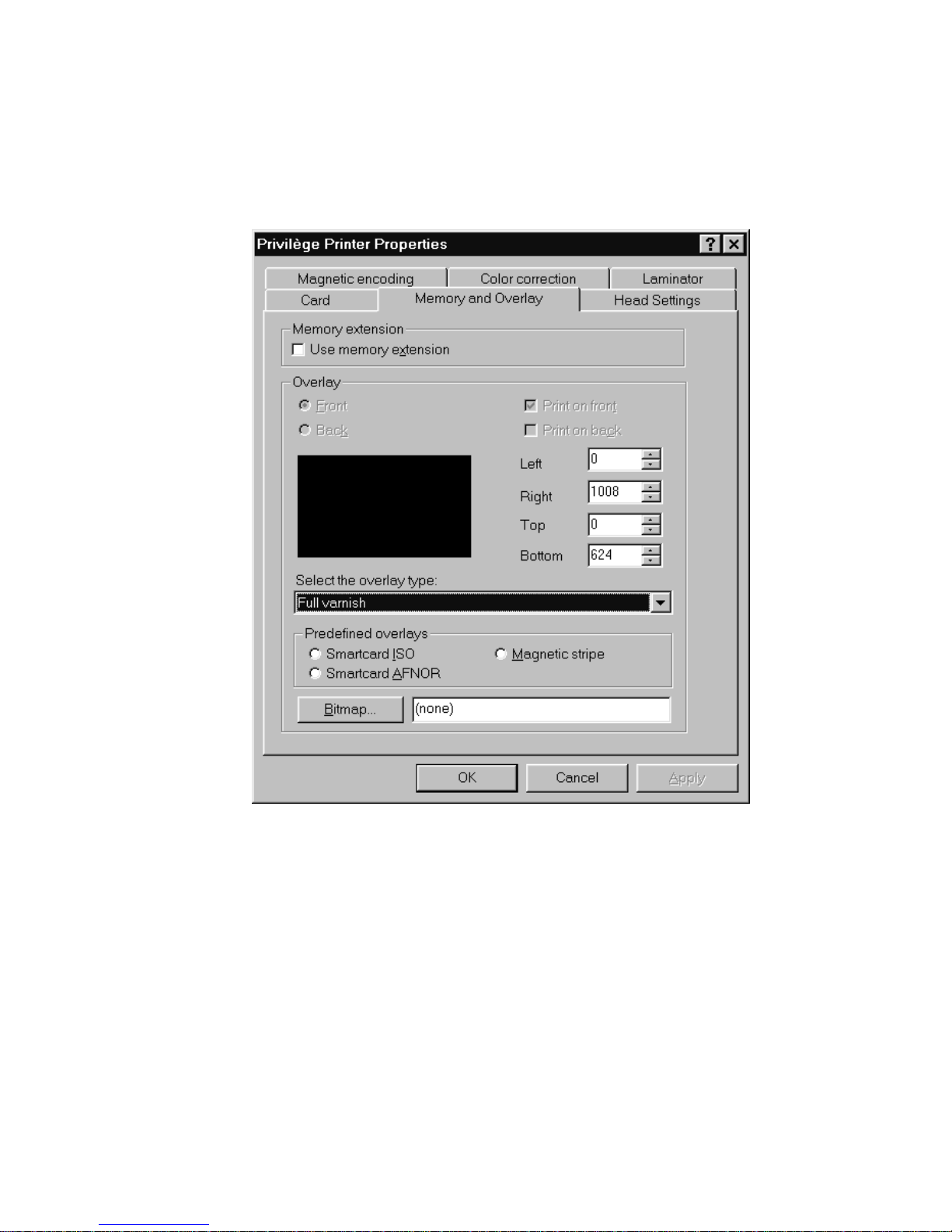

• Stacks up to 100, 30 mil cards