Eltron P420 Maintenance Manual

P420

Maintenance Manual

CP PARD RINTER RODUCTS

©2001 Zebra Technologies Corporation

Manual No. 980297-001 Rev. A

FOREWORD

This manual contains service and repair information for P420 Card Printers manufactured

by Zebra Technology Corporation, Camarillo, California. The contents include maintenance,

diagnosis and repair information.

TECHNICAL SUPPORT

For technical support, users should first contact the distributor that originally sold the

product—phone +1 (800) 344 4003 to locate the nearest Eltron Products Distributor. Eltron

Products offers the following:

U.S.A Europe Asia Latin America

Internet

e-mail

Compu

Serve

Phone

FAX

cardsup@eltron.com eurocardsup@eltron.com asiacardsup@eltron.com latincardsup@eltron.com

+805 578 1800 +33 (0) 2 40 09 70 70 +65 73 33 123 +1 847 584 2714

+1 805 579 1808

+44 (0) 1189 895 762

+33 (0) 2 40 09 70 70

http://www.eltron.com

ftp://ftp.eltron.com

102251,1164

+65 73 38 206 +1 847 584 2725

RETURN MATERIALS AUTHORIZATION

Before returning any equipment to Eltron for either in- or out-of-warranty repairs, contact

the Eltron Repair Administration for a Return Materials Authorization (RMA) number. Then

repackage the equipment, if possible using original packing materials, and mark the RMA

number clearly on the outside. Ship the equipment, freight prepaid, to one of the following

addresses:

For USA and Latin America: For Europe, Asia, and Pacific:

Zebra Technologies Corporation Zebra Technologies Corporation

Eltron Card Printer Products Eltron Card Printer Products

1001 Flynn Road Zone Industrielle Rue d’Amsterdam

Camarillo, CA 93012-8706, USA 44370 Varades, France

Phone: +1 (805) 579-1800 Phone: +33 (0) 2 40 09 70 70

FAX: +1 (805) 579-1808 FAX: +33 (0) 2 40 83 47 45

COPYRIGHT NOTICE

This document contains information proprietary to Zebra Technology Corporation. This

document and the information contained within is copyright by Zebra Technology

Corporation and may not be duplicated in full or in part by any person without prior written

approval of Zebra.

While every effort has been made to keep the information contained within current and

accurate as of the date of publication, no guarantee is given or implied that the document is

error-free or that it is accurate with regard to any specification.

iii

This information is not intended as a license to practice or infringe on the patents of this

company or others. Zebra Technology Corporation reserves the right to modify, update or

revise this information at any time without notice.

TRADEMARKS

Eltron is a trademark of Zebra Technology Corporation. All other marks are trademarks or

registered trademarks of their respective holders.

FCC NOTICE:

This equipment has been tested and found to comply with the limits of a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will

not occur in a particular installation. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

CSA NOTICE:

This equipment does not exceed Class A limits per radio noise emissions for digital

apparatus set out in the Radio Interference Regulation of the Canadian Department of

Communications. Operation in a residential area may cause unacceptable interference to

radio and TV reception requiring the owner or operator to take whatever steps are necessary

to correct the interference.

Ce matériel ne dépasse pas les limites de Classe A d’émission de bruits radioélectriques pour

les appareils numériques telles qu’établies par le ministère des Communications du Canada.

L’utilisation faite en milieu résidentiel peut entraîner le brouillage des réceptions radio et

télé, ce qui obligerait le propriétaire ou l’opérateur à prendre les dispositions nécessaires

pour en éliminer les causes.

iv

Table of Contents

CHAPTER 1 GENERAL DESCRIPTION

PRINTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Options · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1-2

Major Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Card Feeder · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1-2

Cleaning Roller · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1-3

Printer · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1-3

Smart Card Docking(Option) · · · · · · · · · · · · · · · · · · · · · · · · · · 1-3

Magnetic Stripe Encoder(Option) · · · · · · · · · · · · · · · · · · · · · · · · 1-4

ABOUT THIS MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

CAUTIONARY NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

PACKAGING CONSIDERATIONS. . . . . . . . . . . . . . . . . . . . . . 1-6

PREPARING A STATIC-SAFE WORK AREA . . . . . . . . . . . . . . . . . 1-6

ENVIRONMENTAL AND SHOCK PROTECTION . . . . . . . . . . . . . . 1-6

CHAPTER 2 INSTALLATION AND OPERATION

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Unpacking · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-2

Tape and PackingRemovals · · · · · · · · · · · · · · · · · · · · · · · · · · 2-3

Card Catcher Installation · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-3

Cleaning Roller CartridgePreparation · · · · · · · · · · · · · · · · · · · · · · 2-4

Cleaning Roller TapeRemoval · · · · · · · · · · · · · · · · · · · · · · · · · 2-4

Cleaning Roller CartridgeInstallation · · · · · · · · · · · · · · · · · · · · · · 2-5

Location Concerns · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-6

Attaching Cables · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-6

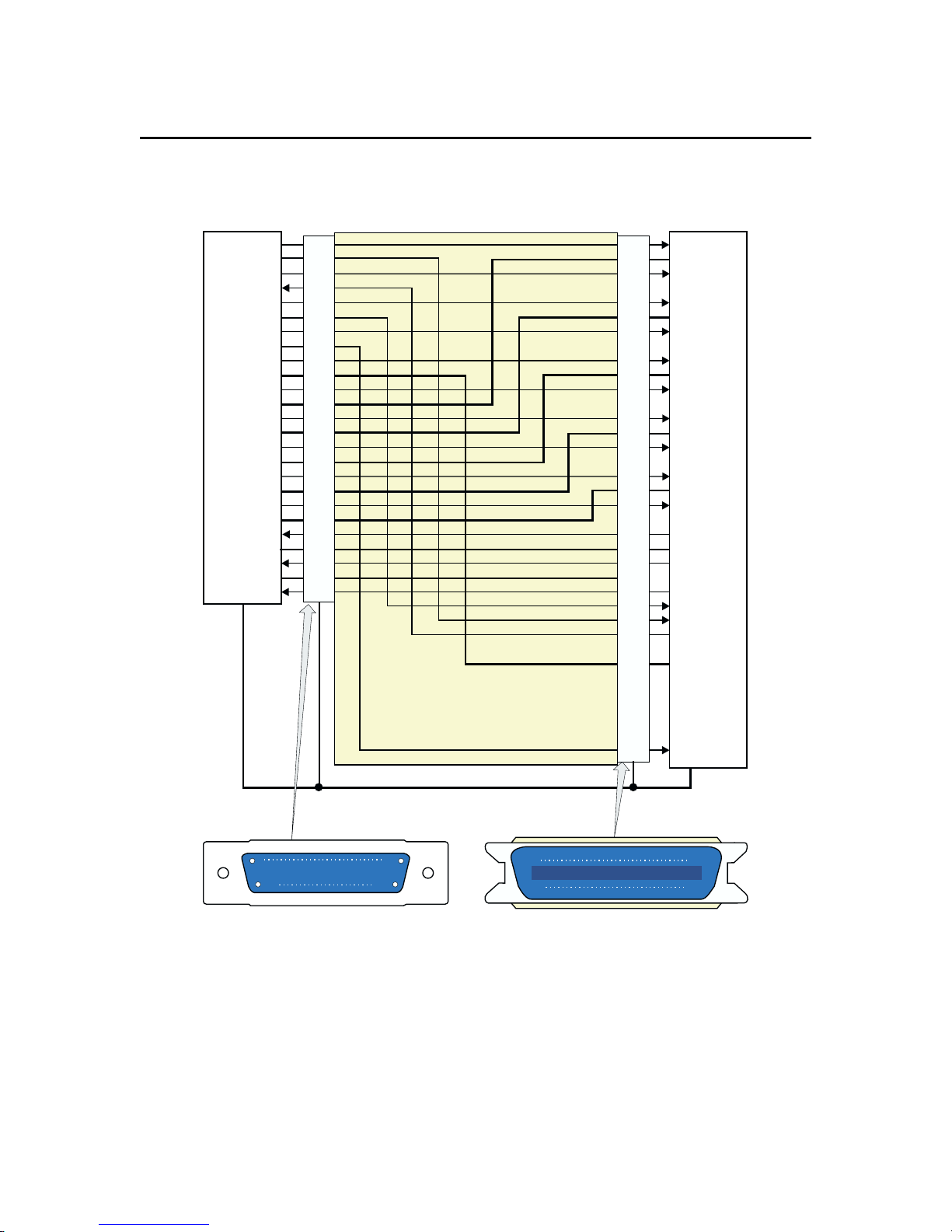

Cable Diagrams· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-7

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Controls and Indicators · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-9

LCD Status Messages · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-10

LCD Alert Messages · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-10

Menu Mode · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-11

Print Head ReleaseandLatch Levers· · · · · · · · · · · · · · · · · · · · · · 2-12

Ribbon Loading · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-13

Card Gate Adjustment · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-14

Loading or EmptyingtheCard InputHopper · · · · · · · · · · · · · · · · · · 2-15

Starting the CleaningCycle · · · · · · · · · · · · · · · · · · · · · · · · · · 2-15

Rejected Card Box· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 2-17

v

CHAPTER 3 THEORY OF OPERATION

COLOR FUNDAMENTALS . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

PRINTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

CARD PATH ELEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

CIRCUITRY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Print Head Circuitry · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3-10

Motor Control Circuitry · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3-12

Status Circuitry · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3-14

Serial and ParallelPortCircuitry · · · · · · · · · · · · · · · · · · · · · · · · 3-16

USB Port Circuitry(Optional) · · · · · · · · · · · · · · · · · · · · · · · · · 3-18

Magnetic Stripe EncoderCircuitry(Option)· · · · · · · · · · · · · · · · · · · 3-19

Smart Card Circuitry(Option) · · · · · · · · · · · · · · · · · · · · · · · · · 3-20

CPU Board PowerCircuitry · · · · · · · · · · · · · · · · · · · · · · · · · · 3-22

Operator Panel Circuitry · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3-22

Card Flip Circuitry · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3-24

CHAPTER 4 TROUBLESHOOTING

DIAGNOSING BASIC PRINTER PROBLEMS . . . . . . . . . . . . . . . . 4-2

DIAGNOSING COMPUTER INTERFACE PROBLEMS . . . . . . . . . . . . 4-4

CHAPTER 5 REPLACEMENT PROCEDURES

REQUIRED TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

PART REPLACEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Rear Case andCoverOpen SensorRemovals · · · · · · · · · · · · · · · · · · 5-2

Front Case Removal · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5-4

Operator Panel PartRemovals · · · · · · · · · · · · · · · · · · · · · · · · · 5-5

Card Feeder RemovalandPart Replacements · · · · · · · · · · · · · · · · · · 5-6

Card Flip RemovalandPart Replacements · · · · · · · · · · · · · · · · · · · 5-8

Printer Removal · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5-14

Power Supply Removal · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5-15

Smart Card PartRemovals(Option) · · · · · · · · · · · · · · · · · · · · · · 5-16

Print Head Replacement · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5-18

Fan Removal · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5-22

Front Belt Removals · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5-23

CPU and EncoderBoardReplacements · · · · · · · · · · · · · · · · · · · · 5-24

Rear Plate Removal · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5-25

Daughter Board Removal · · · · · · · · · · · · · · · · · · · · · · · · · · · 5-26

Ribbon Sensor Removal · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5-27

Flag and HeadLatchSensor BoardReplacement. · · · · · · · · · · · · · · · 5-28

Rear Belt andO-RingRemoval · · · · · · · · · · · · · · · · · · · · · · · · · 5-29

Printer Motor Replacements · · · · · · · · · · · · · · · · · · · · · · · · · · 5-30

Encoder Head Replacement · · · · · · · · · · · · · · · · · · · · · · · · · · 5-32

Ribbon Supply SpindleandClutch Replacements · · · · · · · · · · · · · · · 5-36

Ribbon Take UpSpindleReplacements · · · · · · · · · · · · · · · · · · · · 5-38

vi

CHAPTER 6 MAINTENANCE AND ADJUSTMENTS

CLEANING MATERIALS. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Card Transport, Platen,andCleaning Rollers · · · · · · · · · · · · · · · · · · 6-2

Cleaning the PrintHead· · · · · · · · · · · · · · · · · · · · · · · · · · · · · 6-4

OBTAINING AND INSTALLING FIRMWARE UPDATES . . . . . . . . . . . 6-5

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Stepper Belt Tension · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 6-6

Print Head TiltAdjustments · · · · · · · · · · · · · · · · · · · · · · · · · · 6-10

Print Head PeelBarPosition Adjustment · · · · · · · · · · · · · · · · · · · · 6-13

Image Centering· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 6-14

APPENDIX A TEST SOFTWARE

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Launching the CardPrinterTest Software · · · · · · · · · · · · · · · · · · · · A-2

Changing the COMPort · · · · · · · · · · · · · · · · · · · · · · · · · · · · A-4

Operating in TerminalMode · · · · · · · · · · · · · · · · · · · · · · · · · · A-5

Typical Sub List· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · A-6

Sensor Test Selection · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · A-7

Table of Figures

Figure 2-1. Packaging Materials . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-2. Card Output Hopper. . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-3. Tape and Packing.. . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-4. Cleaning Roller Installation. . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-5. Cleaning Roller Cartridge Preparation.. . . . . . . . . . . . . . 2-4

Figure 2-6. Cleaning Roller Cartridge Installation. . . . . . . . . . . . . . . 2-5

Figure 2-7. Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-8. Cable Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-9. USB Interface.. . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Figure 2-10. Controls and Indicators . . . . . . . . . . . . . . . . . . . . 2-9

Figure 2-11. Menu Mode Selection Diagram. . . . . . . . . . . . . . . . 2-11

Figure 2-12. Print and Lamination Head Latch and Release Levers. . . . . 2-12

Figure 2-13. Ribbon Installation. . . . . . . . . . . . . . . . . . . . . . . 2-13

Figure 2-14. Card Gate Adjustment . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-15. Card Input Hopper Loading. . . . . . . . . . . . . . . . . . 2-15

Figure 2-16. Cleaning Card Installation. . . . . . . . . . . . . . . . . . . 2-16

Figure 2-17. Rejected Card Box. . . . . . . . . . . . . . . . . . . . . . . 2-17

Figure 3-1. Card Path Elements.. . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-2. Printer Module Block Diagram. . . . . . . . . . . . . . . . . . 3-9

vii

Figure 3-3. Print Head Circuitry. . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-4. Motor Control Circuitry. . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-5. Status Circuitry. . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Figure 3-6. Serial and Parallel Port Circuitry. . . . . . . . . . . . . . . . . 3-17

Figure 3-7. USB Port Circuitry.. . . . . . . . . . . . . . . . . . . . . . . 3-18

Figure 3-8. Magnetic Stripe Encoder Elements.. . . . . . . . . . . . . . . 3-19

Figure 3-9. Smart Card Circuitry.. . . . . . . . . . . . . . . . . . . . . . 3-21

Figure 3-10. Printer Power Regulator Circuitry. . . . . . . . . . . . . . . 3-22

Figure 3-11. Operator Panel Circuitry. . . . . . . . . . . . . . . . . . . . 3-23

Figure 3-12. Card Flip Circuitry. . . . . . . . . . . . . . . . . . . . . . . 3-25

Figure 4-1. Problems Duplicated by a Test Print. . . . . . . . . . . . . . . 4-2

Figure 4-2. Interface Diagnostic Flow.. . . . . . . . . . . . . . . . . . . . 4-4

Figure 5-1. Rear Case Fasteners. . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 5-2. Front Case Removal. . . . . . . . . . . . . . . . . . . . . . . 5-4

Figure 5-3. Operator Panel Part Access. . . . . . . . . . . . . . . . . . . . 5-5

Figure 5-4. Card Feeder Replacements. . . . . . . . . . . . . . . . . . . . 5-7

Figure 5-5. Card Flip Card Sensor. . . . . . . . . . . . . . . . . . . . . . 5-8

Figure 5-6. Card Flip Circuit Board. . . . . . . . . . . . . . . . . . . . . . 5-9

Figure 5-7. Card Flip Assembly Removal. . . . . . . . . . . . . . . . . . 5-10

Figure 5-8. Card Flip Stepper Motors. . . . . . . . . . . . . . . . . . . . 5-11

Figure 5-9. Card Flip Pinch Roller. . . . . . . . . . . . . . . . . . . . . . 5-12

Figure 5-10. Card Flip Transport Roller. . . . . . . . . . . . . . . . . . . 5-13

Figure 5-11. Printer Removal. . . . . . . . . . . . . . . . . . . . . . . . 5-14

Figure 5-12. Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Figure 5-13. Smart Card Interface Board. . . . . . . . . . . . . . . . . . 5-16

Figure 5-14. Smart Card Lift Solenoid. . . . . . . . . . . . . . . . . . . . 5-17

Figure 5-15. Smart Card Contact Station. . . . . . . . . . . . . . . . . . 5-17

Figure 5-16. Print Head Upper Fasteners . . . . . . . . . . . . . . . . . 5-18

Figure 5-17. Print Head Ground Lug. . . . . . . . . . . . . . . . . . . . 5-19

Figure 5-18. Print Head Assembly Removal . . . . . . . . . . . . . . . . 5-19

Figure 5-19. Print Head Connectors . . . . . . . . . . . . . . . . . . . . 5-20

Figure 5-20. Properly Positioned Print Head . . . . . . . . . . . . . . . . 5-21

Figure 5-21. Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . 5-22

Figure 5-22. Front Belts. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Figure 5-23. CPU and Encoder Boards. . . . . . . . . . . . . . . . . . . 5-24

Figure 5-24. Rear Plate Removals. . . . . . . . . . . . . . . . . . . . . . 5-25

Figure 5-25. Daughter Board. . . . . . . . . . . . . . . . . . . . . . . . 5-26

Figure 5-26. Ribbon Sensor Removal. . . . . . . . . . . . . . . . . . . . 5-27

Figure 5-27. Flag and Head Latch Sensor Board.. . . . . . . . . . . . . . 5-28

Figure 5-28. Rear Belts and O-Ring. . . . . . . . . . . . . . . . . . . . . 5-29

Figure 5-29. Head Up-Down Motor Removal. . . . . . . . . . . . . . . . 5-30

Figure 5-30. Stepper Motor Removal. . . . . . . . . . . . . . . . . . . . 5-31

Figure 5-31. Ribbon Take-Up Motor Removal.. . . . . . . . . . . . . . . 5-31

Figure 5-32. Encoder Station Shroud. . . . . . . . . . . . . . . . . . . . 5-32

Figure 5-33. Encoder Head (Above-the-Card-Path). . . . . . . . . . . . . 5-32

Figure 5-34. Encoder Station Pressure Roller Rod. . . . . . . . . . . . . . 5-33

viii

Figure 5-35. Encoder Head Pinch Roller Removal.. . . . . . . . . . . . . 5-34

Figure 5-36. Pressure Roller Rod Removal.. . . . . . . . . . . . . . . . . 5-34

Figure 5-37. Encoder Head Fasteners. . . . . . . . . . . . . . . . . . . . 5-35

Figure 5-38. Encoder Head Protective Tape.. . . . . . . . . . . . . . . . 5-35

Figure 5-39. Supply Spindle Assembly . . . . . . . . . . . . . . . . . . . 5-37

Figure 5-40. Ribbon Take Up Spindle . . . . . . . . . . . . . . . . . . . 5-39

Figure 6-1. Cleaning Swabs . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Figure 6-2. Card Transport Rollers. . . . . . . . . . . . . . . . . . . . . . 6-3

Figure 6-3. Print Head Cleaning. . . . . . . . . . . . . . . . . . . . . . . 6-4

Figure 6-4. Stepper Motor Fasteners. . . . . . . . . . . . . . . . . . . . . 6-6

Figure 6-5. Stepper Motor Belt Tensioning Fixture (Part No. 900116-001). . 6-7

Figure 6-6. Stepper Belt Tensioning. . . . . . . . . . . . . . . . . . . . . 6-9

Figure 6-7. Head Alignment Test Cards. . . . . . . . . . . . . . . . . . . 6-10

Figure 6-8. Image Brightness Adjustment. . . . . . . . . . . . . . . . . . 6-11

Figure 6-9. Lower Print Head Fasteners. . . . . . . . . . . . . . . . . . . 6-12

Figure 6-10. Peel Bar Fasteners. . . . . . . . . . . . . . . . . . . . . . . 6-13

ix

x

CHAPTER 1

GENERAL DESCRIPTION

1.1 PRINTER DESCRIPTION

Eltron® Model P420 plastic card printers offer low cost solutions to those that need to

print, encode magnetic stripes, or program smart plastic cards. Eltron offers imaging

ribbon varieties that include dye sublimation color, dye sublimation black, thermal

transfer monochrome in various colors, and scratch-off gray. Dye sublimation ribbons

include panels that support the application of a clear protective varnish.

Standard P420 printers have a Card Feeder, Card-Flip Assembly, and Printer Station,

supporting double-side plastic card printing. Users can set the Card Feeder for the wide

range of plastic card thicknesses offered.

Software support exists for the selection, imaging, and positioning of two internal fonts

and eight bar code formats. This means that the units recognize associated software

commands. Users canavoidusingeither anapplication or the printer driver to imagethese

980297-001 1-1

CHAPTER 1

objects. For those who wish to create card graphics from their software applications, the

units ship withbothWindows 95/98and NT drivers. Both drivers support TrueTypefonts.

1.1.1 Options

Plastic card varieties include Smart Cards and cards with Magnetic Stripes. Because not

everyone may want to use associated capabilities, integration of related hardware is

offered as options. Encoders can place data on either high- or low-coercivity stripes.

1.2 Major Elements

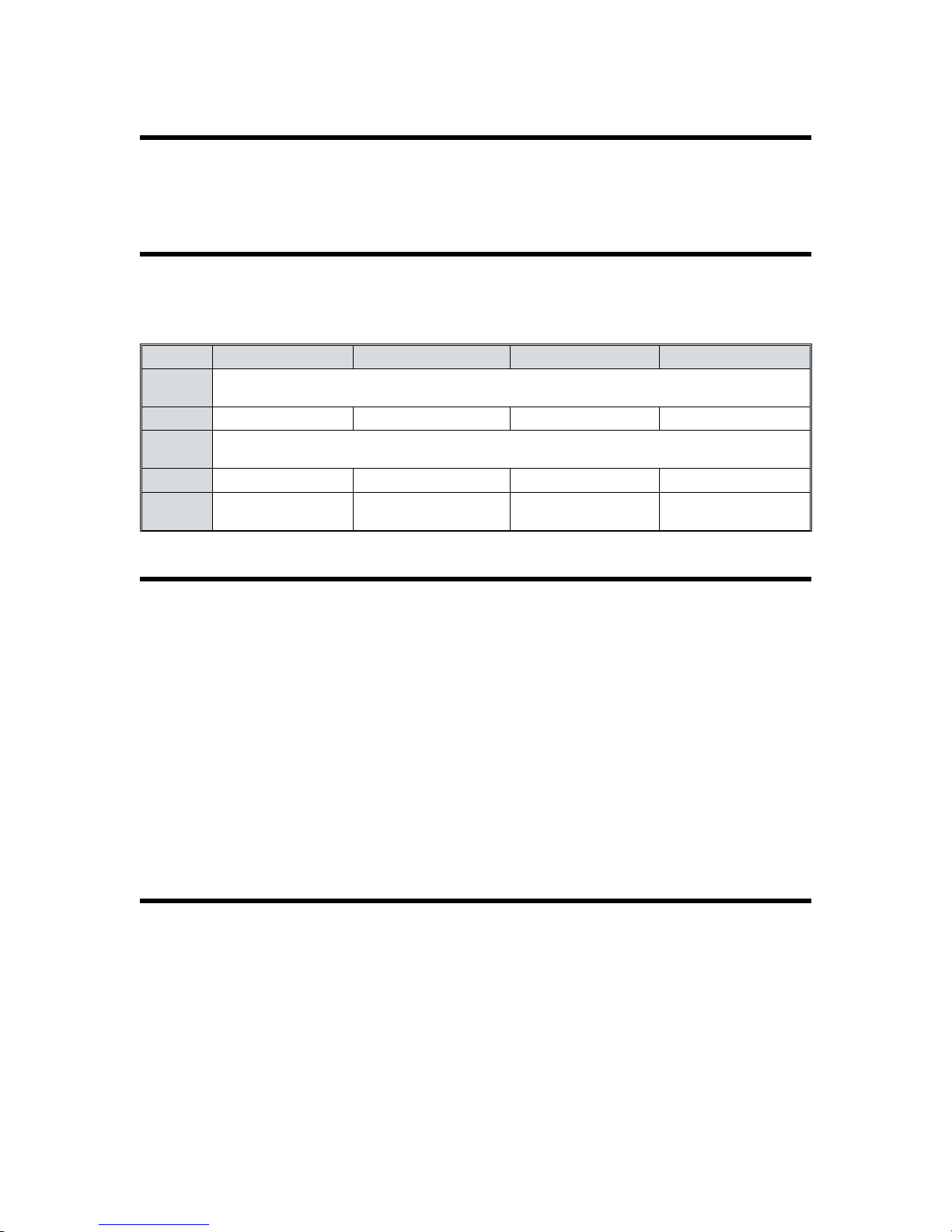

Figure 1-1 shows the Printer assemblies visible with the cover raised.

1.2.1 Card Feeder

With the Card Feeder set for a proper thickness, Cards placed in the Card Input Hopper

enter the printer oneat a time in response toCard Feed Commands. A manualCard Gate

adjustment lets users establish a suitable card thickness setting. Eltron Card Printer

Products offers cards in popular 0.02- and 0.03-inch thicknesses. However, users can

adjust the feeder for other thicknesses as well. The Card Feed Hopper, has an attached

Card Weight that positions itself on top of a stack of cards in the Hopper. This added

1-2 980297-001

CHAPTER 1

weight increases the grip of the card feed rollers and assures reliable card feeds throughout

cartridge-full to cartridge-empty conditions.

1.2.2 Cleaning Roller

Cards transitioning between the Card-Flip and Printer Assemblies travel through a pair of

rollers. Above one of these rollers resides a removable cartridge that contains the Cleaning

Roller. A tacky surface on this roller collects any lint or other loose particles that may

adhere to the underlying rollers due to contact with passing cards. To maintain its ability to

collect particles, users must periodically replace the Cleaning Roller. Users should watch

for evidence of particle buildup on the Cleaning Roller or print anomalies having related

characteristics.

1.2.3 Printer

Card imaging occurs as the cards transition through the Printer Station.For colorimaging,

the cards transition past the Print Head three times. Yellow, magenta, and cyan (YMC)

dyes transfer from ribbon panels onto the cards in amounts controlled by heat produced

by Print Head elements. Each of the 32K color possibilitiesresults from a particular mix of

the YMC dyes. The density of Print Head elements produces images with 300

dot-per-inch (dpi) resolution. One of the commonly used color ribbons also has panels

that can laydownblackmonochrome imagesand a protective clear coating, each duringa

related additional pass across the Print Head.

Whereas the colorpanels of color ribbons laydown dye sublimation dyes, theblack panel

of these same ribbons deposits a thermal transfer resin (Kr) that only images at one heat

setting. While this essentially eliminates resin as a medium for gray scale, a capability

already made available by the YMC panels, resin serves as a particularly good choice for

text and bar codes. By ending the imaging sequence with a clear overlay coating (O),

cards receive added durability and a resistance to fading of the CMY dyes. In summary,

images produced using color ribbons typically have five panels (CMYKrO) and require a

corresponding five passes across the Print Head.

Ribbons also exist insingle-coated and two-panel varieties. Single-coated ribbons deposit

a resin. Users have a choice of many resin colors. Two-panel ribbon varieties have either

black dye (Ks) or Kr panels alternated with panels that lay down clear overlay coatings.

Being a dye, the Ks material supports gray-scale imaging, which offers users an ideal

means of producing black-and-white photo quality images.

While the forgoing describesthe major imaging ribbon types, readersshould check the list

of supplies for other varieties that can serve special imaging needs.

1.2.4 Smart Card Docking (Option)

At a Smart Card Station, located inside the Printer Assembly, Smart Card contacts

connect to a DB-9 connector at the rear of the Printer. This implementation supports the

use of an external Smart Card Programming device. Docking occurs with a card

positioned under the contacts; after which,a solenoid mechanism raises the card to make

the connections.

980297-001 1-3

CHAPTER 1

1.2.5 Magnetic Stripe Encoder (Option)

Printers equipped with Magnetic Stripe Encoders fully support the encoding of cards with

either high or low coercivity magnetic stripes. This includes several encoding formats.

Read-After-Write checking occurs with each encoding to assure a reliable result. After

receipt of related data, encoding of all three tracks occurs in a single pass through the

encoder. Encoding occurs as the cards transition between the Print Station and the Card

Catcher, where the read/write heads and an associated card sensor reside.

The Encoder Head usually resides below the card path in support of a down-facing card

stripe. However, an above-the-card-path option also exists. Although the printer has a

Card Flip, and could, therefore, support Card Input Hopper loadings of either up- or

down-facing stripes, printer efficiency concerns take presidence:

Encoding always occurs first, sothat anyrelated failure produces a card reject without

•

a card print and a related waist of time and ribbon. A required card flip on the way to

the Encoder Head would slow up the process.

• The panel sequence for color ribbon is fixed at YMCKrOand is established duringthe

ribbon manufacturing process. This means that YMC, or color imaging, must occur

first. Imaging always occurs on an up-facing card surface. A card load with the side to

receive color imaging already facing up avoids a card flip between encoding and the

first print sequences.

• Because of the the preceding conditions, those who wish to image color on the side

opposite the stripe are best served by the standard configuration—Encoder Head

placed below the card path, cards placed in the Card Input Hopper with down-facing

stripes.

• In contrast, those who wish to image color on the side with the stripe are best served

with an Encoder Head that resides above the card path. This configuration suits a

Card Input Hopper loaded with up-facing card stripes.

While the forgoing lays the groundwork for imaging using the popular YMCKrO and

YMCKrOKr ribbons, other ribbon types also exist that may not have related concerns.

1.3 ABOUT THIS MANUAL

Eltron Products has directed the Information contained in this manual at returning P420

printer functions to normal operation in the shortest time possible. With this in mind,

service personal should focus on items listed in their recommended spares list. Avoid

lower level replacements whenever possible. Service personnel should keep a log of the

repairs made in support of the concept of continuous product improvement. Chapters

include: General Description, Installation and Operation, Theory of Operation,

Troubleshooting, Part Replacement Procedures, and Maintenance and Adjustments.

Follow the instructions as closely as possible. When unsure of any procedure, please

contact either an Eltron Service Representative (contact Eltron Product Management for

nearest representative) orEltronTechnical Supportat 1-800-344-4003 or 805-578-1800.

Eltron Products stocks all commonly used replacement parts for P420 Printers. For depot

repairs, contact Eltron Sales to place orders and to establish a program for bulk purchases

and credited returns of warranted parts.

1-4 980297-001

1.4 CAUTIONARY NOTES

Exercise reasonable care when servicing P420 printers, as follows:

Other than prescribed operator maintenance, only qualified

personnel should remove the case or otherwise attempt to

repair this equipment. Eltron offers product training to those

wishing to service this equipment.

Servicing personnel must avoid touching exposed circuitry.

Inputs to the Power Supply operate at power line voltages. Any

removal of protective insulation can expose dangerous voltages.

Always remove the power cord while effecting repairs.

During operation, the Print Head operates at an elevated

temperature. Exercise caution when touching parts on or near

this area.

CHAPTER 1

Servicing Personnel should avoid any rough handling of the

Printers or their component parts. The icon to the left also

serves as an indicator alerting conditions of general concern to

users.

An electrostatic discharge (ESD) of energy can damage or

destroy the circuit components inside the Printer. People

acquire such charges while they move around. ESD problems

typically increase with drops in humidity.

Users should not twist the Printer Ribbon Take Up Spindle

manually. Doing so unnecessarily stresses an associated belt.

Any slack left after a ribbon installation gets removed during an

initialization that occurs with the latch-down of the Print Head.

Particle contamination, such as dust, can reduce image quality

and produce excess wear to some printer components. Locate

Printers and print media in areas essentially contamination free.

To avoid fiber deposits, any Cleaning Swabs used must have

foam tips. Also, cleaning solution impurities can leave deposits.

Therefore, only use 99-percent pure or better alcohol.

980297-001 1-5

CHAPTER 1

1.5 PACKAGING CONSIDERATIONS

The factory-supplied shipping carton contains the Printer placed inside a protective ESD

(Electrostatic Discharge) bag and suspended in form-fitting end cushions made from a

foam material. These are the only materials approved for P420 shipments. Any shipping

damage may not be covered by either the product warranty or the carrier if the printer is

shipped with packaging materials that do not meet associated shipping standards. If

necessary, order replacement factory-approved shipping materials from a P420

distributor.

1.6 PREPARING A STATIC-SAFE WORK AREA

To avoid component damage while performing troubleshooting and repair procedures,

service personnel should work in a static-safe area. Items under test should rest on a

properly grounded, conductive, and cushioned mat. Service personnel should wear a

conductive wrist strap. (Most electronic supply stores carry ESD protective devices. For a

local supplier, contact 3M Corporation at 1-800-328-1368 or 512-984-1800.)

1.7 ENVIRONMENTAL AND SHOCK PROTECTION

Avoid extremes of temperature and humidity or mishandling. These conditions can

damage most electronic equipment.

When moving the printer from a cool, dry location to a warmer, more humid location,

allow the printer to temperature stabilize for at least 30 minutes before opening the

protective ESD bag. Otherwise, moisture can condense on the surface of many

components. Moisture can degrade performance or even damage some components.

Avoid rough handling. Careful handling can avoid possible mechanical damage that

might otherwise result from dropping or impacting the printer on a hard surface.

1-6 980297-001

CHAPTER 2

INSTALLATION AND OPERATION

This chapter includes information on the following:

• Unpacking

• Installation

• Controls and Indicators

• Card and Ribbon Loading

Similar descriptions also appear in the associated User’s Guide and other manuals

shipped with the printer. The intent here is to make this manual as complete as possible

with a minimum of references to other manuals. Operations related to software

applications and the Windows Driver do not appear in this manual. Information on the

Test Software appears in Appendix A.

980297-001 2-1

CHAPTER 2

2.1 INSTALLATION

2.1.1 Unpacking

Figure 2-1 shows the carrier-approved packaging materials used for shipping and how

these items fit within inside and outside cartons.

Note that customers should keep these materials on hand for future shipping needs. The

product warranty may not cover a printer damaged during a shipment if the printer is

packaged using unapproved shipping materials. If necessary, users can order

replacements before shipping the Printer.

Figure 2-1. Packaging Materials

2-2 980297-001

CHAPTER 2

2.1.2 Tape and Packing Removals

Figure 2-2 shows the tape and packing material that requires removal prior to printer

operation.

Figure 2-2. Card Output Hopper.

2.1.3 Card Catcher Installation

Figure 2-4 shows the installation of the Card Catcher.

Figure 2-3. Tape and Packing.

980297-001 2-3

CHAPTER 2

2.1.4 Cleaning Roller Cartridge Preparation

Figure 2-4 shows how to install the Cleaning Roller into the Cleaning Roller Cartridge.

Figure 2-4. Cleaning Roller Installation.

2.1.5 Cleaning Roller Tape Removal

Figure 2-5 shows removal of the tape protecting the tacky surface.

Figure 2-5. Cleaning Roller Cartridge Preparation.

2-4 980297-001

2.1.6 Cleaning Roller Cartridge Installation

Figure 2-6 shows where the Cleaning Roller Cartridge fits into the Printer.

CHAPTER 2

Figure 2-6. Cleaning Roller Cartridge Installation.

980297-001 2-5

CHAPTER 2

2.1.7 Location Concerns

Users should avoid dusty locations. Until ready for use, keep ribbon and card media in

their cartons. Select a location that offers easy access to all sides plus an unrestricted air

flow. Avoid locations that experience extremes in temperature and/or humidity.

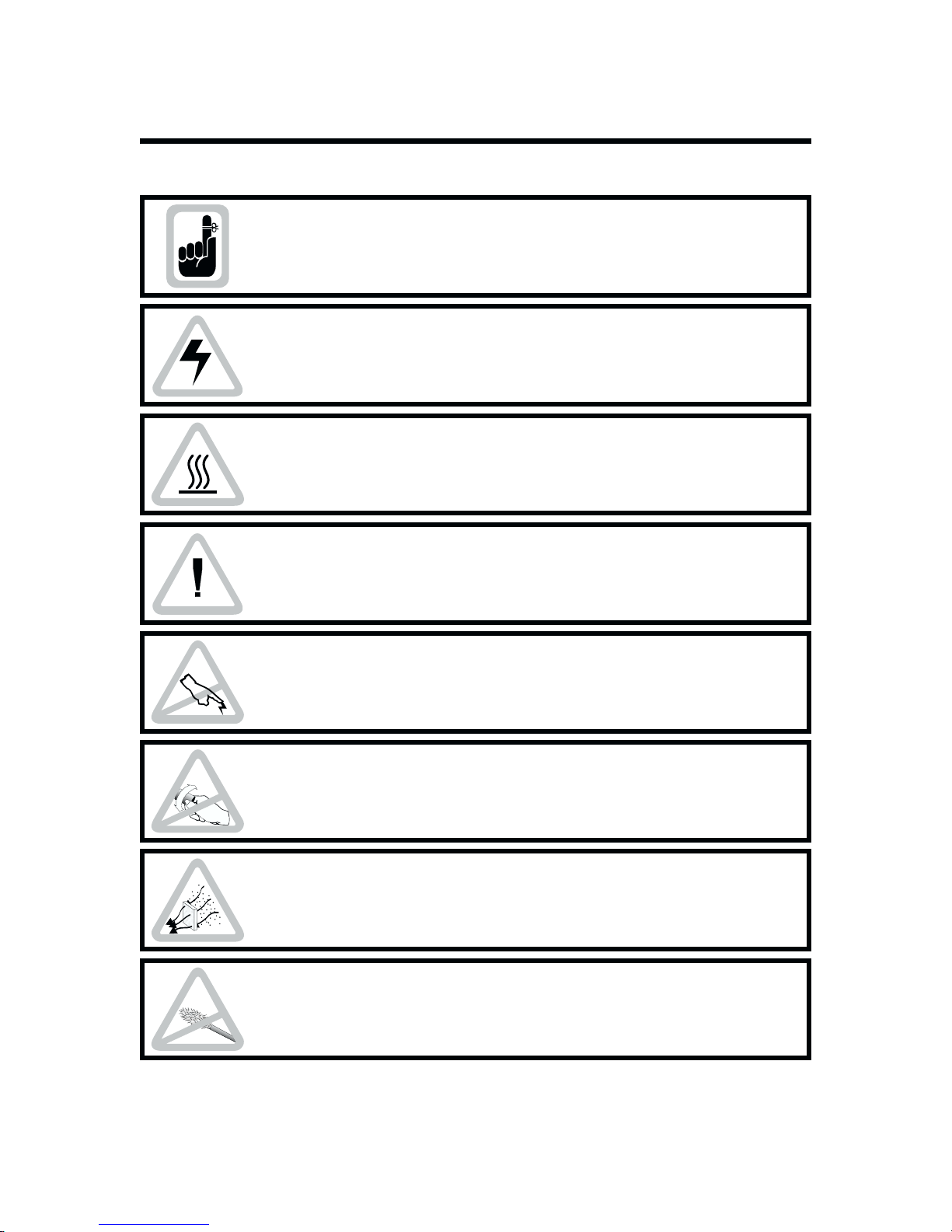

2.1.8 Attaching Cables

Figure 2-7 shows the Rear Panel of a Printer. This panel has the following:

Power ON-OFF Switch

•

Power Connector

•

Computer Interface Connectors (Parallel and USB)

•

Smart Card Connector (Option)

•

The internal power supply automatically adjusts to most of the ac outlet voltages

encountered world wide. Always connect the Power Cable last.

Figure 2-7. Cables.

2-6 980297-001

2.1.9 Cable Diagrams

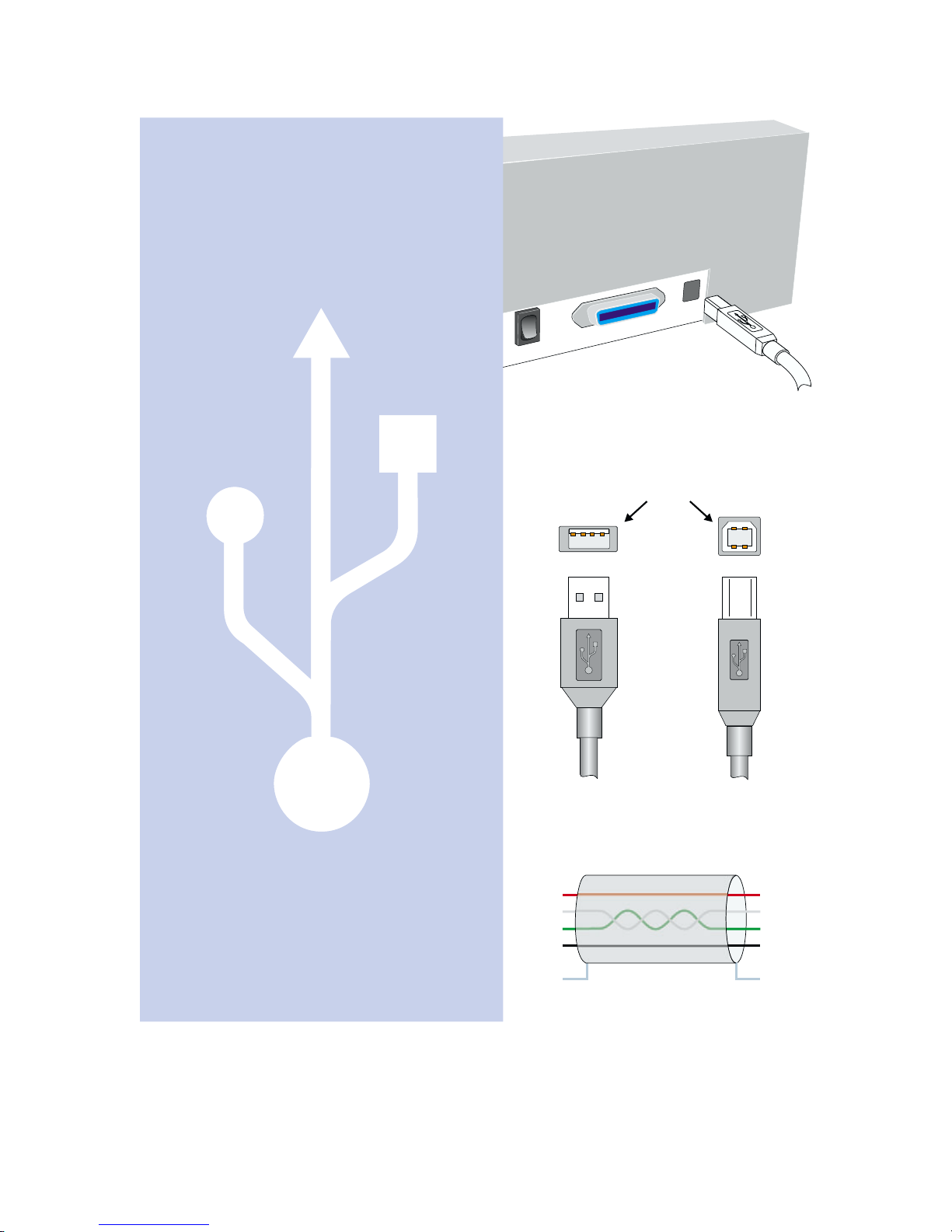

Figures 2-8 and 2-9 show Centronics and USB (Universal Serial Bus) information.

CHAPTER 2

Host

STROBE

AUTO-FEED

DATA 0

ERROR/

DATA 1

INIT

DATA 2

SELECTIN/

DATA 3

GND

DATA 4

GND

DATA 5

GND

DATA 6

GND

DATA 7

GND

ACK/

GND

BUSY

GND

PAPER ERR.

GND

SELECT

DB-25

Pin No.

1

14

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

13

MaleDB-25toMaleCentronics

(Cable)

Centronics

Pin No.

1

19

2

20

3

21

4

22

5

23

6

24

7

25

8

26

9

27

10

28

11

29

12

30

13

31

14

32

15

33

16

34

17

35

18

36

Printer

STROBE/*

GND

P0

GND

P1

GND

P2

GND

P3

GND

P4

GND

P5

GND

P6

GND

P7

GND

ACK/

GND

BUSY

GND

PERROR

N/A

SELECT

INIT/

AUTOFD/*

FAULT/

N/A

GND

N/A

N/A

GND

N/A

N/A

SELECTIN/*

1

14

Figure 2-8. Parallel Cable Wiring.

980297-001 2-7

25

13

SHIELD

Cable Ends

1

19

18

36

CHAPTER 2

USB Concerns

(USB Specification Rev. 2.0)

1. USB-Equipped Host Computers have Hub

connection(s) and software that supports the

connections for up to 127 devices (either USB

Functions or USB Hubs), all hot swapable.

2. Hubs implement one connection path upstream

to, or toward, the Host and typically several Ports

for downstream Functions and/or other Hub

connections. Functions refer to Printers, Mice,

Keyboards, etc.

3. USB Cables e have both A- and B-type

ach

connectors. The A connectors attach to upstream

devices, while the B connectors attach to

downstream devices. Hub loopback connections

(requiring an A-to-A cable) are not allowed.

4. System Software keeps track of the paths and path

parameters both to and from Functions (as Pipes).

System Software does not support more than five

Hubs, not counting the host, along any path.

5. A Pipe can operate at USB High Speed (480Mb/s),

USB Full Speed (12Mb/s), or USB Low Speed (1.5

Mb/s). Functions report needed parameters as part

of setup phases during operations (e.g., following

hot swaps).

6. USB Ports and Cables have a shield and four

conductors—two for data and two that can supply

5 volts to Bus-Powered Devices.

7. It is important to have cables that can support the

bandwidth requirements of a particular path.

Speed

Cables should not be used in paths that can

Low

also operate at High/Full Speeds.

8. Cable designers must meet specified requirements

for data integrity between devices by using

materials for the lengths offered. Extension

suitable

Cables can add factors that breach critical design

elements and should not be used.

VBus1

D+ 2

D- 3

Ground 4

Shield

A

3

4

2

End Views

1

Cable Wiring

B

2

3

1

4

1VBus

2D+

3D4 Ground

Shield

Figure 2-9. USB Interface.

2-8 980297-001

CHAPTER 2

2.2 OPERATION

2.2.1 Controls and Indicators

Figure 2-10 shows the push-buttons, LEDs (Light Emitting Diodes), and LCD (Liquid

Crystal Display) that appear on the front of the Printer. The Power Switch resides on the

rear. Users pressthe Clear Button to indicate completion of an alert response. Users press

the Menu button to enter Menu Mode, after which, the Next and Select (formally Menu

and Clear) buttons serve to navigate and select menu items.

Figure 2-10. Controls and Indicators

980297-001 2-9

CHAPTER 2

2.2.2 LCD Status Messages

LCD Status Messages

(No Operator Response Needed)

Status Condition Reported

INITIALIZING Start-Up Testing in Progress

READY Printer Idle

WAIT TEMPERATURE Print Head Cool Down in Progress

SELF TEST Printing of Test Card in Progress

DOWNLOADING DATA Printer Receiving Data

PRINTING YELLOW Yellow Imaging in Progress

PRINTING MAGENTA Magenta Imaging in Progrress

PRINTING CYAN Cyan Imaging in Progress

PRINTING BLACK Black Imaging in Progress

PRINTING VARNISH Overlay Varnish Application in Progress

PRINT HOLOGRAM Hologram Application in Progress

CLEANING Operator-Initiated Cleaning in Progress

2.2.3 LCD Alert Messages

LCD Alert Messages

(Operator Response Needed)

Operator Action Required*

CLEAN PRINTER Clean Printer and Replace Cleaning Roller at Next Best

Oportunity

CLEAN MAG HEAD Clean Printer Using Cleaning Card at Next Best Oportunity

REMOVE RIBBON During Cleaning, remove Ribbon

OUT OF RIBBON Replace Ribbon

MECHANICAL ERROR Card Transport Problem; Find and Remove Card

OUT OF CARD Refill Card Input Hopper*

ROTATION ERROR Card Flip Problem; Find and Remove Card

COVER OPEN Close Cover

HEAD OPEN Latch Down Print Head

COMMAND ERROR Host Data not Recognized; Re-send*

PARAMETERS ERROR Unsuitable Setup; Check Parameters Selected in Driver*

ENCODING ERROR Stripe Coercivity, Stripe Orientation, or ISO Problem*

READING ERROR Read-after-Write Failure; Verify Suitable Cards or Loading*

REJECT BOX FULL Empty Card Reject Box*

MAGNETIC ERROR Magnetic Stripenot Found; Check Cards or HopperLoading*

*Note: Press Clear upon completion of Operator Action Required.

2-10 980297-001

CHAPTER 2

2.2.4 Menu Mode

Figure 2-11 shows the push button actions necessary to navigate in Menu Mode.

Selections allow users to monitor status, initiate cleaning, and print Test Cards.

READY

After 10 seconds of selection

MENU MODE’S

MAIN MENU

PRINTER INFO

[NEXT] [SELECT]

inactivity, READY returns

automatically

PRINTER

[NEXT]

FIRMWARE

[NEXT]

CARD PRN:

[NEXT]

REJECTED BOX:

[NEXT]

Model Number of

Printer

Firmware Version

Installed

Number of Cards

Printed

Number of Cards in

Reject Box

RIBBON

[NEXT]

OFFSET

[NEXT]

MAG OPTION

[NEXT]

Yxx Mxx Cxx Kxx

[NEXT]

Menu

Next

Ribbon Selection—

Match Driver Selection

w/Physical Ribbon

Origin Offset in

Pixels

Coercivity Setting

HICO, LOCO,

or NONE

xx = YMC Color Intensities and K Contrast

Clear

Select

CLEANING MENU

[NEXT] [SELECT]

SELF TEST MENU

[NEXT] [SELECT]

PRINTER DEFAULTS

[NEXT] [SELECT]

GO TO MAIN MENU

[NEXT] [SELECT]

CLEAN PRINT HEAD

[NEXT] [SELECT]

CLEAN MAG. HEAD

[NEXT] [SELECT]

GO TO MAIN MENU

[NEXT] [SELECT]

Prints a

TEST PATTERN

[NEXT] [SELECT]

PRINT PARAMETERS

[NEXT] [SELECT]

MAG PARAMETERS

[NEXT] [SELECT]

Tes t Ca r d

Prints Card Listing

Printer Parameters

Prints Card Listing

Encoder Parameters

• Remove Ribbon

• Remove Cards

•InsertCleaning

Card in Hopper

Remove Cleaning

Card from Card

Catcher

GO TO MAIN MENU

[NEXT] [SELECT]

Figure 2-11. Menu Mode Selection Diagram.

980297-001 Rev. A 2-11

GO TO MAIN MENU

[NEXT] [SELECT]

CHAPTER 2

2.2.5 Print Head Release and Latch Levers

Figure 2-12 shows the Release and Latch levers for the Print Head. Users open the Cover

and raise the Print Head during manual Cleaning Procedures, removal of card jams, and

ribbon loads.

Figure 2-12. Print and Lamination Head Latch and Release Levers.

2-12 980297-001

CHAPTER 2

2.2.6 Ribbon Loading

Figure 2-13 shows the loading of ribbons. Note that by keeping the Power ON during

Ribbon Loads, a suspended operation resumes automatically with the Print Head

latch-down that completes Ribbon Loading.

Step 1. Remove the ribbon from its packaging and the material holding the supply

and take up rolls together.

Step 2. Unroll enough ribbon from the supply roll to bridge the space between the

supply and take up spindles of the printer.

Step 3. With the Print Head raised, slide the ribbon cores onto the spindles such that

ribbon travels off the top of the supply spindle and onto the top of the take up

spindle. NOTE: Eltron ribbon cores are keyed to assure a proper installation. To

avoid damage to delicate Print Head elements, make sure the dye-coated side of

any ribbons used faces away from the Print Head. Latch down the Print Head.

Do Not Twist

Hot

ESD Sensitive

Figure 2-13. Ribbon Installation.

980297-001 2-13

CHAPTER 2

2.2.7 Card Gate Adjustment

Figure 2-14 shows the Card Gate Adjustment Lever with arrows that show the directions

of travel.

Step 1. Set the Card Gate Thickness Lever to match the thickness of the cards. Note

that lever positions closer to the back of the printer open the Card Feed Gate for

thicker cards. For cards of unknown thicknesses, close the gate, issue a print

command, and gradually open the gate until a feed occurs. Then set the opening

to the closest card thickness as marked on the Card Gate Decal.

Step 2. If during operation cards either fail to feed or multiple card feeds occur, check

the setting of the Card Gate Adjustment Lever. Increase the opening if cards fail to

feed, and decrease the opening if too many cards feed at the same time. Also,

avoid using warped cards or cards with burrs. These card flaws can require Card

Gate openings greater than the one indicated for the card size loaded.

Figure 2-14. Card Gate Adjustment

2-14 980297-001

Loading...

Loading...