ID 2021 2.0 July 2018

User Manual QT250 and QT800

with Dual CAN and Failsafe options

Table 1: Document history for User Manual QT250 and QT800

Document

ID

Revision

Author

Changes

Approved

by

Date

2021

1.0

SKO

Based on 1372 with

adjustments.

Updated version

with Failsafe option

May 2018

2021

2.0

SKO

Added information

on Dual CAN

July 2018

Copyright © 2018, Eltorque AS

This document is submitted in confidence and contains proprietary information which shall not be

reproduced or transferred to others for the purpose, tender or any other intensions without written

permission of Eltorque AS

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 3 of 86

Table of Contents

Chapter 1 Introduction ............................................................................................................................................................... 7

1.1 System Overview ........................................................................................... 7

1.2 Description .................................................................................................... 8

1.3 Features ......................................................................................................... 9

1.4 Area of use .................................................................................................... 9

1.5 Technical support information .................................................................. 10

1.6 Reader groups ............................................................................................. 10

1.7 Notation used in this manual ..................................................................... 10

1.8 Related documentation .............................................................................. 11

1.9 Disclaimer .................................................................................................... 11

1.10 Terms and abbreviations ............................................................................ 11

1.11 About this user manual .............................................................................. 13

Chapter 2 HSE Information.................................................................................................................................................... 15

2.1 Care and cleaning of actuator .................................................................... 15

2.2 Disposal and waste handling ..................................................................... 15

Chapter 3 Product Description ........................................................................................................................................... 17

3.1 QT250 and QT800 actuators ..................................................................... 17

3.2 Actuator control system examples ............................................................ 18

3.3 Technical specification ............................................................................... 19

3.4 Actuator components ................................................................................. 21

3.4.1 QT250 Actuator --------------------------------------------------------------------- 21

3.4.2 QT800 Actuator --------------------------------------------------------------------- 21

3.5 Communication interface box ................................................................... 22

3.6 Labelling ...................................................................................................... 22

3.7 Cabling ......................................................................................................... 23

3.8 Storage ......................................................................................................... 23

3.9 Engineering information ............................................................................. 24

3.9.1 Power circuit design --------------------------------------------------------------- 24

3.9.2 Duty performance ------------------------------------------------------------------ 24

3.9.3 Endurance ------------------------------------------------------------------------------ 25

3.9.4 Shielding considerations -------------------------------------------------------- 25

3.9.5 Communication interface considerations ------------------------------- 25

3.9.6 Installations with Eltorque Hybrid Marine Cable --------------------- 27

3.9.7 Orientation ----------------------------------------------------------------------------- 28

3.9.8 Space requirements ---------------------------------------------------------------- 28

3.9.9 Mounting -------------------------------------------------------------------------------- 31

3.9.10 Additional information adaption actuator/valve --------------------- 31

3.9.11 Torque considerations for valve and actuator ------------------------- 31

3.9.12 Closing time --------------------------------------------------------------------------- 31

3.9.13 Configuration ------------------------------------------------------------------------- 32

Chapter 4 Mounting and Installation .............................................................................................................................. 33

4.1 Mounting the actuator on the valve .......................................................... 33

4.2 Mounting procedure QT250 and QT800 ................................................... 33

4.3 Valve flange fastening holes ...................................................................... 34

4.4 Cable connection overview ......................................................................... 35

Table of Contents

Page 4 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

4.5 Cable glands ................................................................................................ 36

4.6 Power supply connection............................................................................ 37

4.7 Grounding (earthing) .................................................................................. 39

4.8 Communication connection interfaces ...................................................... 39

4.8.1 Connection procedure ------------------------------------------------------------ 39

4.8.2 CANopen interface connection ----------------------------------------------- 39

4.8.3 Digital interface connection --------------------------------------------------- 41

4.8.4 Analog interface connections ------------------------------------------------- 42

Chapter 5 Operation .................................................................................................................................................................. 43

5.1 Manual operation ........................................................................................ 43

5.2 Error alarms and error handling ................................................................ 44

5.2.1 GENERAL alarm ---------------------------------------------------------------------- 44

5.2.2 POSITION UNDEFINED alarm --------------------------------------------------- 44

5.2.3 TEMPERATURE alarm -------------------------------------------------------------- 45

5.2.4 TORQUE alarm ------------------------------------------------------------------------ 45

5.3 Troubleshooting .......................................................................................... 46

Chapter 6 Maintenance ............................................................................................................................................................ 49

6.1 Maintenance overview ................................................................................ 49

6.2 Inspection .................................................................................................... 49

6.3 Tightening of bolts ..................................................................................... 49

6.4 Lubrication................................................................................................... 49

6.5 Care and cleaning of anodizing ................................................................. 49

Chapter 7 Technical Details.................................................................................................................................................. 51

7.1 Surface treatment ....................................................................................... 51

7.2 Communication interface ........................................................................... 51

7.2.1 CANopen interface ----------------------------------------------------------------- 51

7.2.2 Digital interface ---------------------------------------------------------------------- 51

7.2.3 Analog interface --------------------------------------------------------------------- 53

Chapter 8 Ordering Information and Recommended Spare Parts ................................................................ 55

Dual CAN Option .................................................................................................................................................. 59

A.1 Terms and abbreviations ............................................................................ 59

A.2 Product description ..................................................................................... 59

A.2.i. Differences from standard to Dual CAN actuator -------------------- 60

A.3 Actuator control system examples ............................................................ 60

A.4 Engineering information ............................................................................. 61

A.4.i. Cabling considerations ----------------------------------------------------------- 61

A.5 Mounting and installation .......................................................................... 61

A.6 Operation ..................................................................................................... 62

A.7 Ordering information .................................................................................. 62

A.8 Technical details ......................................................................................... 63

A.8.i. Dual CAN ------------------------------------------------------------------------------- 63

Failsafe Option ...................................................................................................................................................... 65

B.1 Terms and abbreviations ............................................................................ 66

B.2 Disposal and waste handling ..................................................................... 66

B.3 Product Description .................................................................................... 66

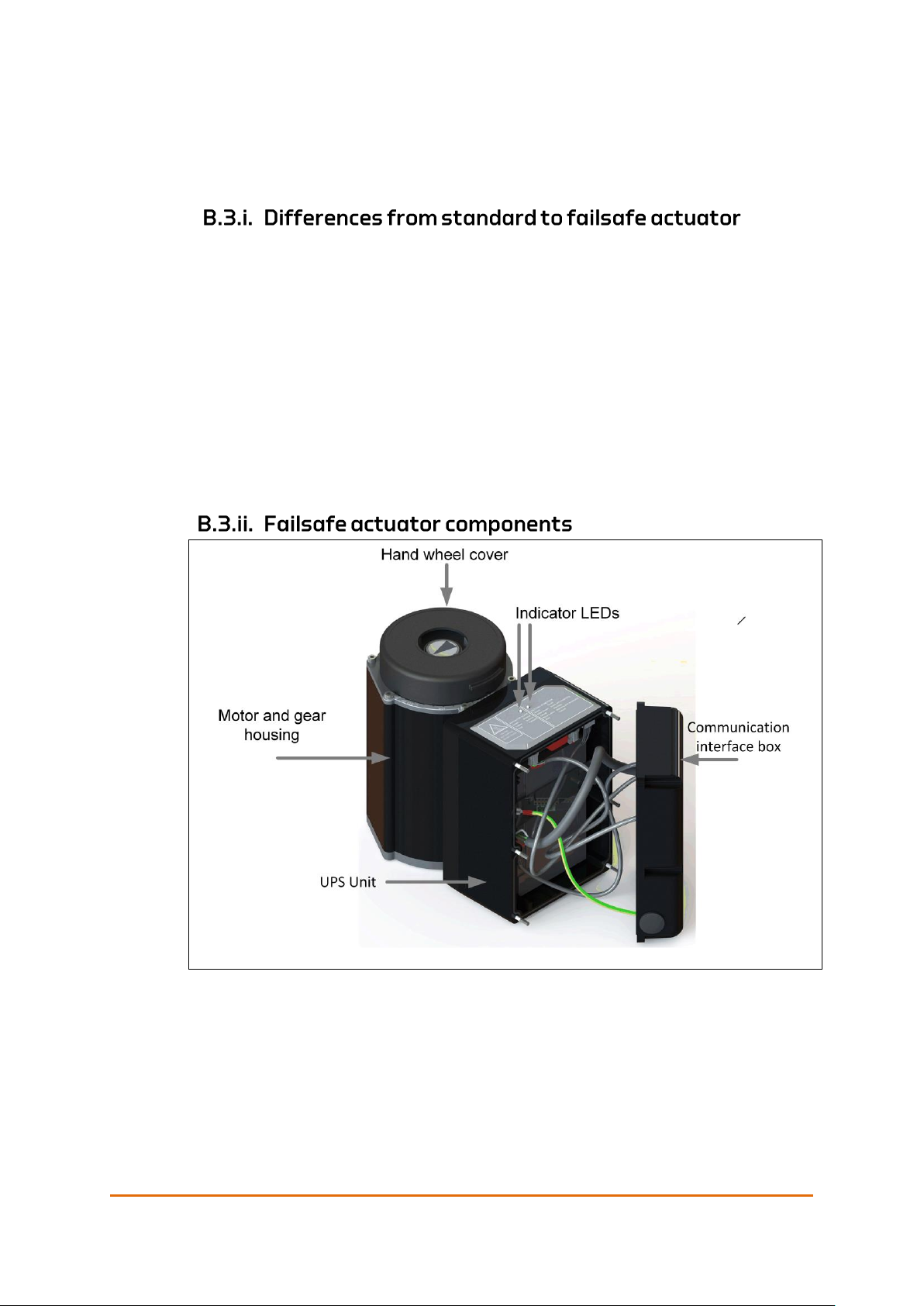

B.3.i. Differences from standard to failsafe actuator ----------------------- 67

B.3.ii. Failsafe actuator components ------------------------------------------------- 67

B.4 Planning ....................................................................................................... 68

B.4.i. Installation plan --------------------------------------------------------------------- 68

Table of Contents

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 5 of 86

B.4.ii. Maintenance plan ------------------------------------------------------------------- 68

B.4.iii. Storage ----------------------------------------------------------------------------------- 68

B.4.iv. Battery charge ------------------------------------------------------------------------ 69

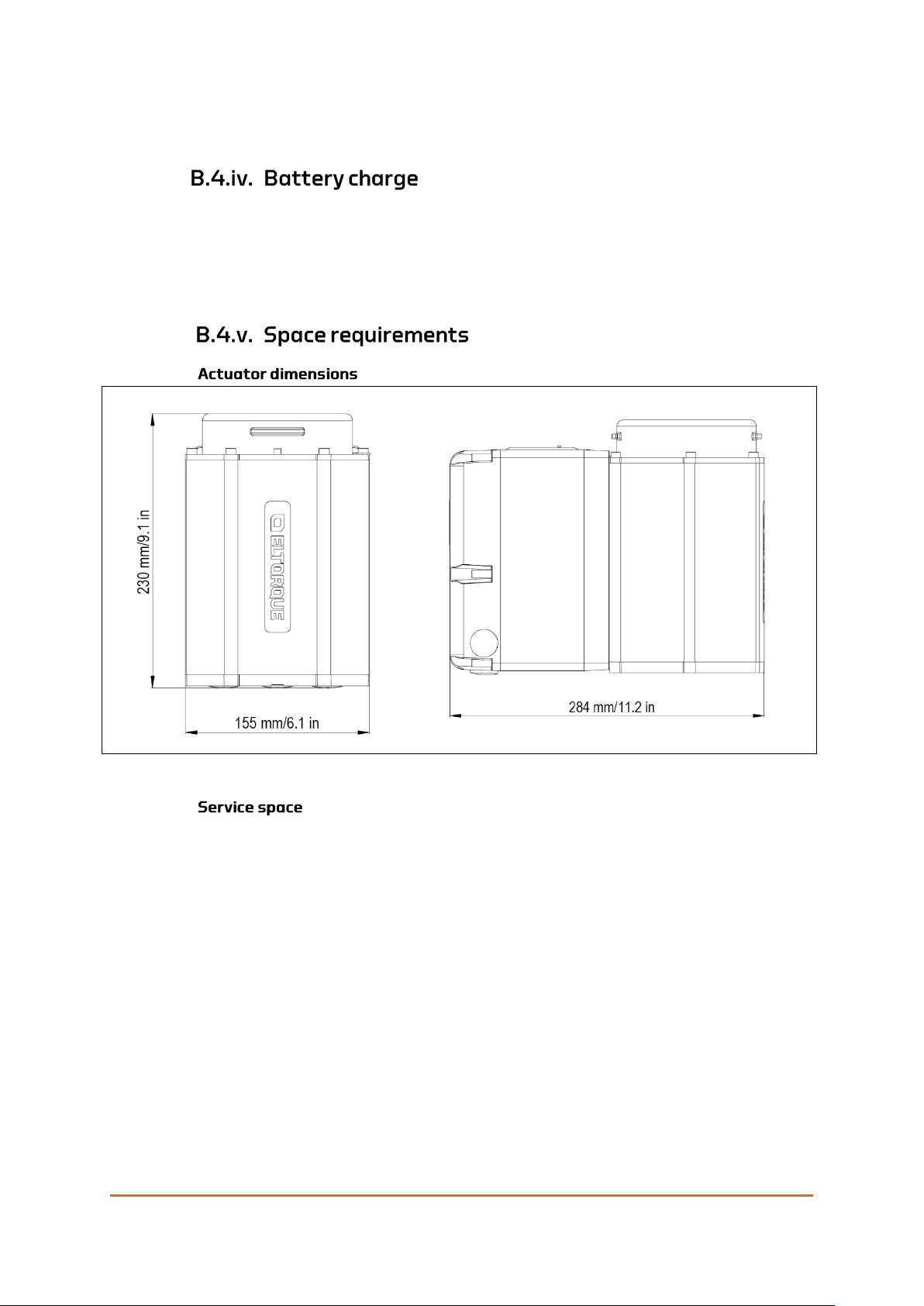

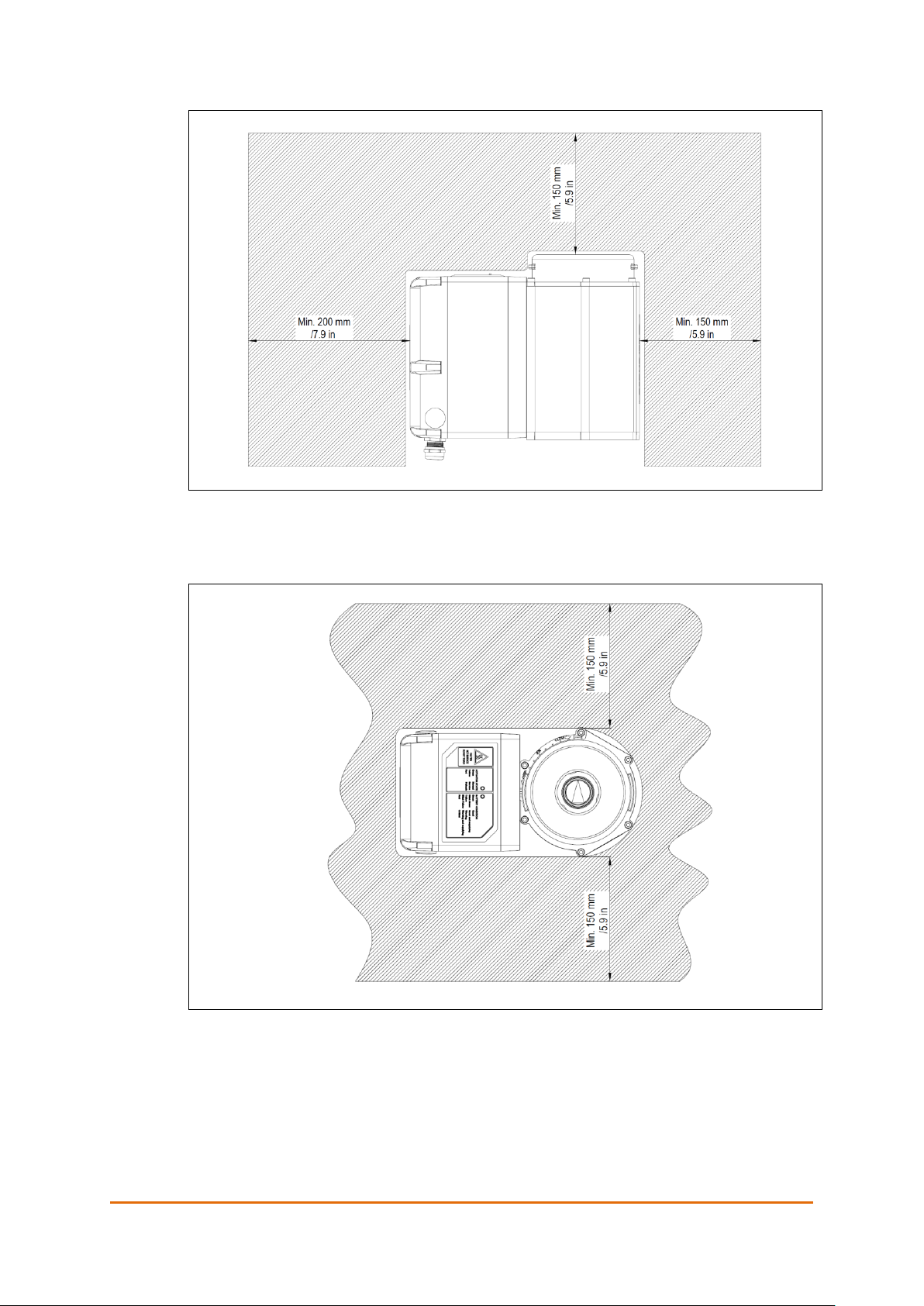

B.4.v. Space requirements ---------------------------------------------------------------- 69

B.5 System interface .......................................................................................... 71

B.6 Mounting and installation .......................................................................... 71

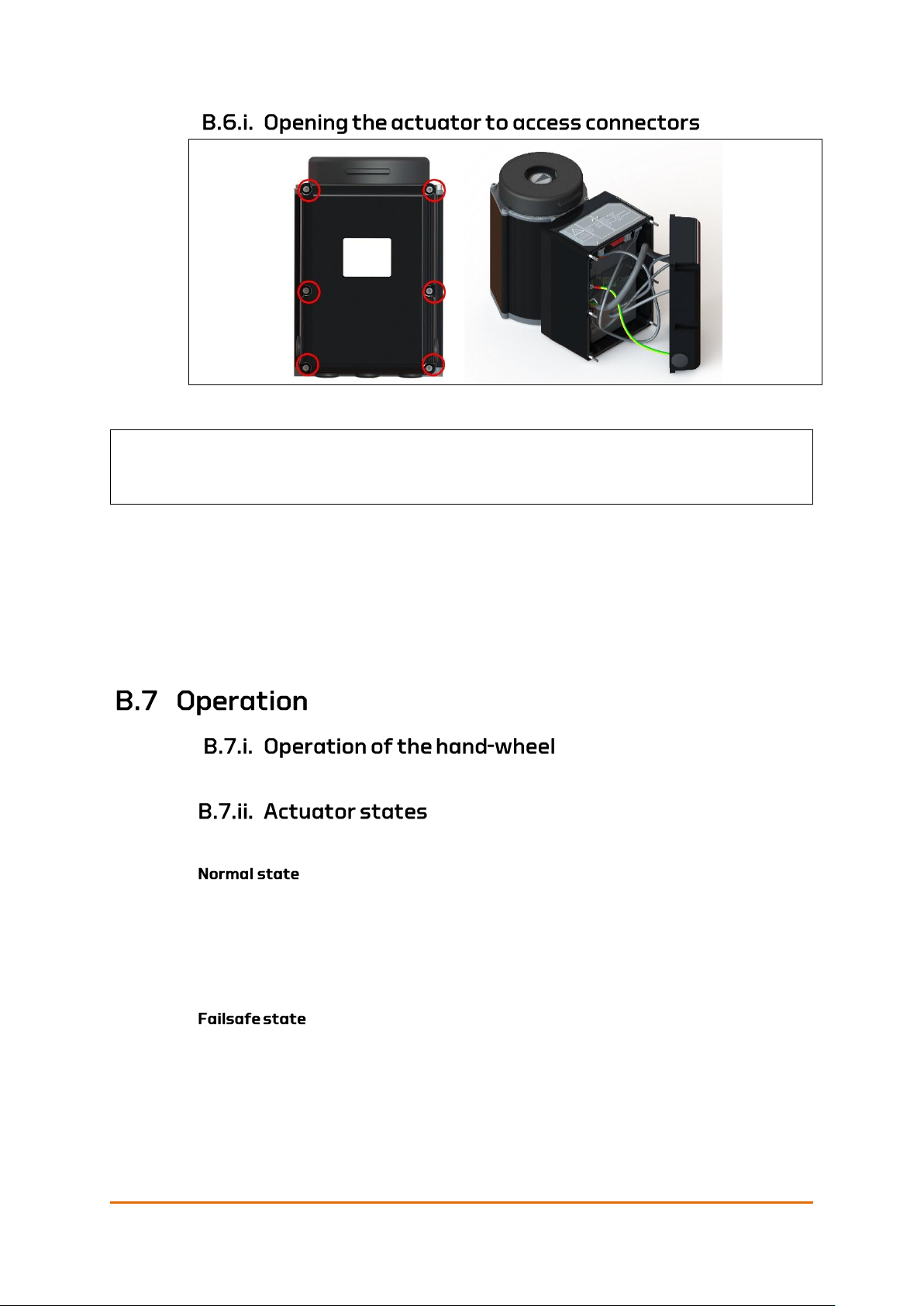

B.6.i. Opening the actuator to access connectors ---------------------------- 72

B.7 Operation ..................................................................................................... 72

B.7.i. Operation of the hand-wheel -------------------------------------------------- 72

B.7.ii. Actuator states ----------------------------------------------------------------------- 72

B.7.iii. LED indication ------------------------------------------------------------------------ 73

B.7.iv. Troubleshooting overview ------------------------------------------------------ 74

B.8 Maintenance ................................................................................................ 74

B.8.i. Battery discharge and charge ------------------------------------------------- 74

B.8.ii. Changing battery on the UPS unit ------------------------------------------- 75

B.9 Ordering information .................................................................................. 79

Torque and Screw Recommendations .................................................................................................... 81

C.1 Eltorque torque recommendations ............................................................ 81

C.2 Mounting screws and lubrication .............................................................. 81

C.3 M4 screws on communication interface box ............................................ 82

Earthing Methods in Maritime Installations ....................................................................................... 83

Table of Contents

Page 6 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

This page is left intentionally blank

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 7 of 86

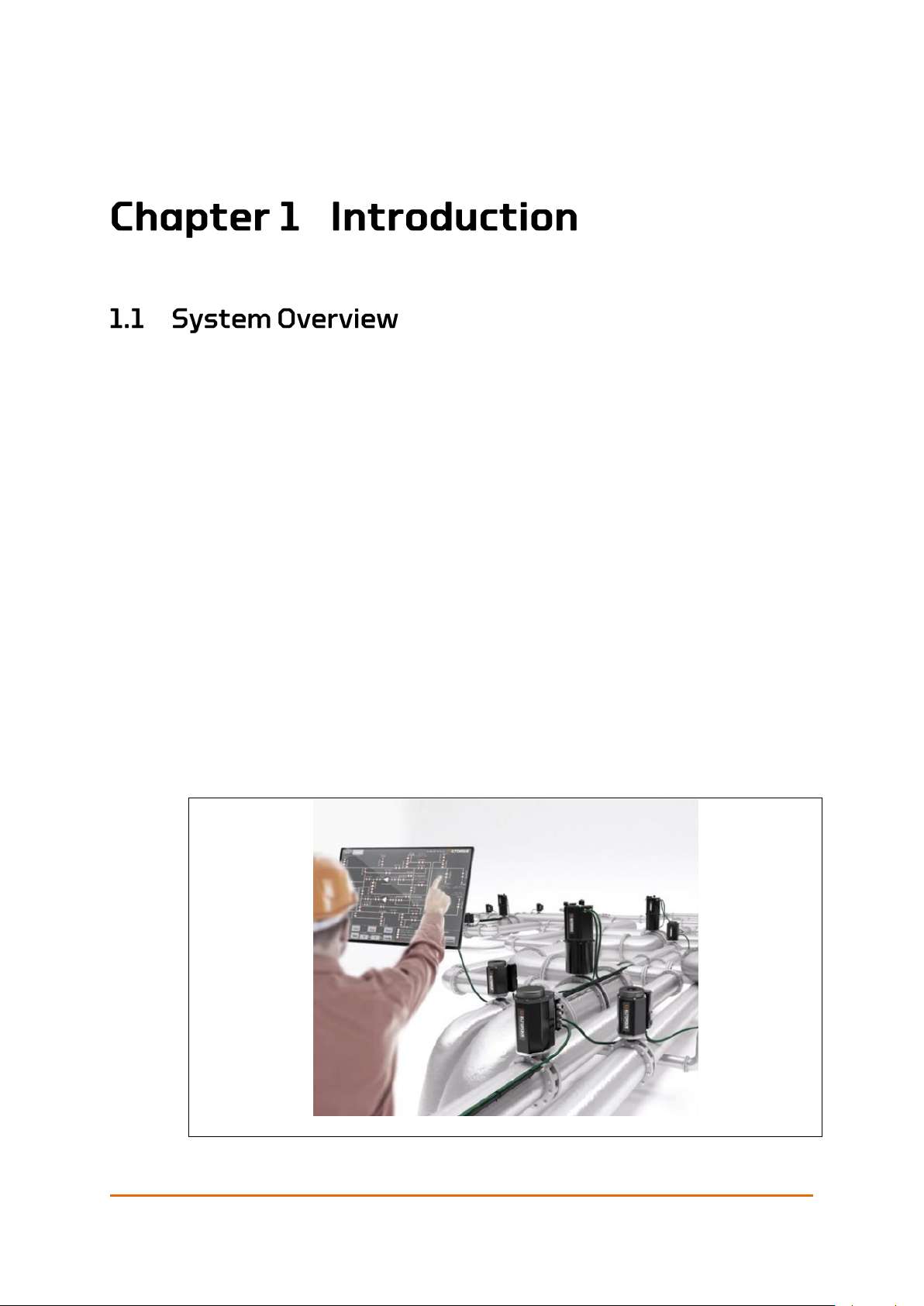

The Eltorque Lifelong Intelligent control concept provides maintenance-free,

configurable eco-friendly and fully electric actuators with real-time feedback.

The Eltorque actuators are divided in two main families:

• QT-series of actuators are ideal for quarter-turn valves such as butterfly and

ball-valves.

• MT-series of actuators are multi-turn actuators optimized for linear valves

such as globe valves, and with a form factor that make the MT-series ideal for

manifold actuation.

The Eltorque actuators are fully electric and can be connected in series. They

offer a plug and play solution with low installation costs and high level of

security. By combining the Eltorque actuators with the Eltorque Hybrid Marine

Cable, the cost of installation is even further reduced.

The Electric bus connected actuator installation eliminates the cable clutter,

transportation loss, air or oil leakage associated with conventional actuator

The use of permanent magnet-based motor technology and efficient electric,

mechanics and firmware design guarantee an eco-friendly and cost-efficient

ownership.

Eltorque actuators have a proven track record of lifelong maintenance-free

operation with 15 years of proven operation.

Figure 1: System overview example

Introduction

Page 8 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

The QT250 and QT800 described in this manual are part of the QT series. This

series is characterized by their quarter-turn movement and low energy

consumption along with their small footprint. They are suited for butterfly, ball

and other quarter-turn valves.

The QT250 and QT800 actuators are available in different versions with

corresponding User Manuals:

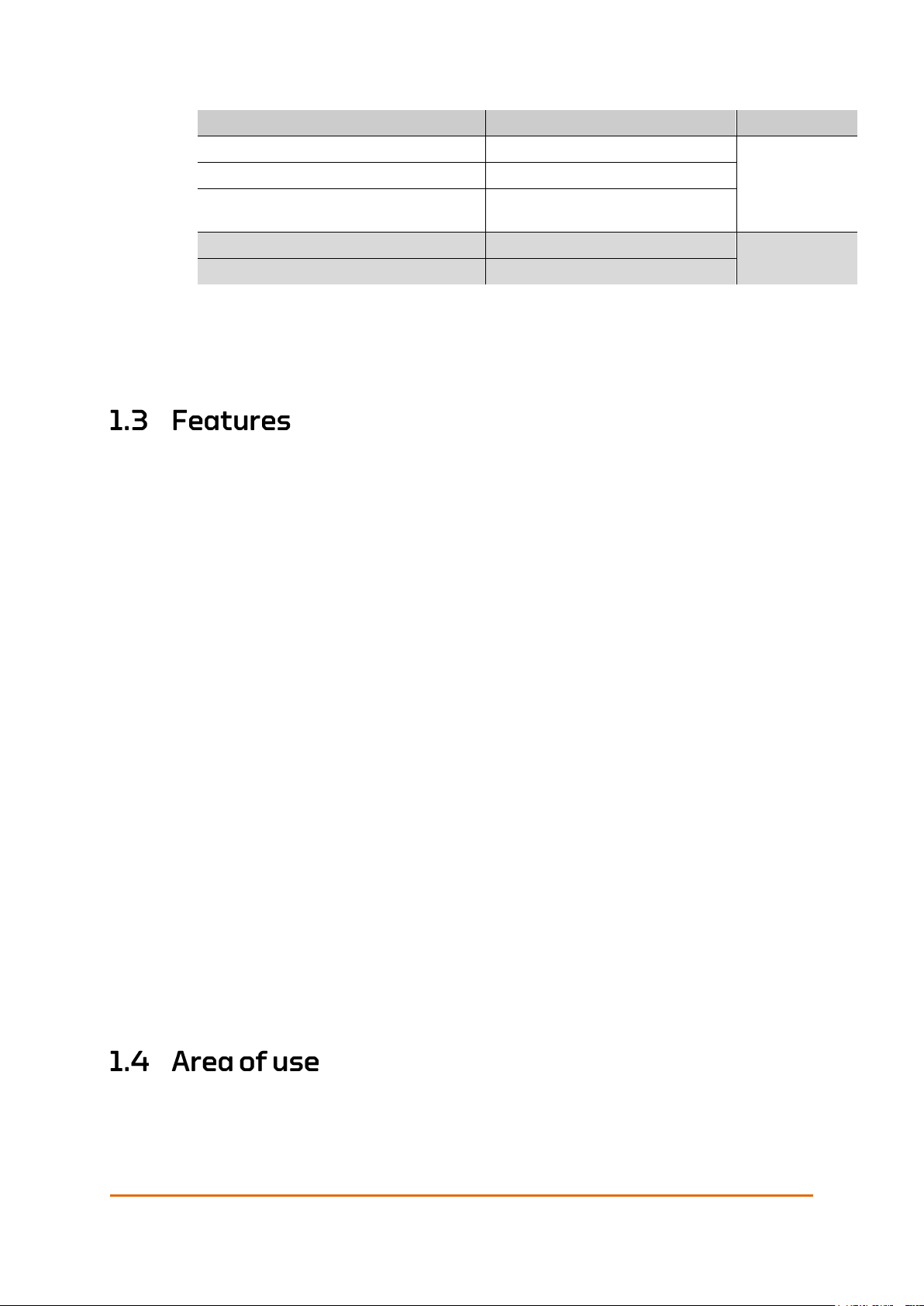

Table 2: Product overview

A= Plain actuator, B= with Failsafe option, R1= with Dual CAN, R2= with Failsafe

and Dual CAN, H= Actuator with cable glands for Eltorque Hybrid Marine Cable.

Product

Product id

User Manual

QT250 2.5 CANopen Actuator

250.120.5A and 250.120.5AH

Doc ID 2021

QT250 2.5 Digital/Analog Actuator

250.150.5A

QT800 2.5 CANopen Actuator

800.120.5A and 800.120.5AH

QT800 2.5 Digital/Analog Actuator

800.150.5A

QT250 2.5 CANopen Failsafe Actuator

250.120.5B and 250.120.5BH

QT800 2.5 CANopen Failsafe Actuator

800.120.5B and 800.120.5BH

QT250 2.5 Dual CAN Actuator

250.120.5R1 and 250.120.5R1H

QT800 2.5 Dual CAN Actuator

800.120.5R1 and 800.120.5R1H

QT250 2.5 Dual CAN and Failsafe

Actuator

250.120.5R2 and 250.120.5R2H

QT800 2.5 Dual CAN and Failsafe

Actuator

800.120.5R2 and 800.120.5R2H

QT250 1.0 CANopen Actuator

250.120.1and 250.120.1H

Doc ID 1372

QT250 1.0 Digital Actuator

250.110.1

QT250 1.0 Analog Actuator

250.130.1,

QT250 1.0 Modbus Actuator

250.140.1 and 250.140.1H

QT800 1.0 CANopen Actuator

800.120.1and 800.120.1H

QT8001.0 Digital Actuator

800.110.1

QT800 1.0 Analog Actuator

800.130.1

QT800 1.0 Modbus Actuator

800.140.1and 800.140.1H

QT250 1.0 CANopen Actuator - Open

Deck

250.121.1 and 250.121.1H

QT250 1.0 Digital Actuator- Open Deck

250.111.1

QT250 1.0 Analog Actuator- Open Deck

250.131.1

QT250 1.0 Modbus Actuator- Open

Deck

250.141.1 and 250.141.1H

QT800 1.0 CANopen Actuator- Open

Deck

800.121.1 and 800.121.1H

Introduction

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 9 of 86

Product

Product id

User Manual

QT800 1.0 Digital Actuator- Open Deck

800.111.1

QT800 1.0 Analog Actuator- Open Deck

800.131.1

QT800 1.0 Modbus Actuator- Open

Deck

800.141.1 and 800.141.1H

QT250 CANopen 2.4 EX Actuator

EX250.125.4 and EX250.125.4H

Doc id 1193

QT800 CANopen 2.4 EX Actuator

EX800.125.4 and EX800125.4H

This User Manual describes the standard 2.5 version with the options for Dual

CAN and Failsafe.

The Eltorque actuators provides a wide range of attractive features:

• Optimized single-axis architecture, ensuring a compact and low-weight

actuator.

• Accurate real-time magnetic position control with no mechanical limit

switches, ensuring maintenance-free operation.

• Few spare parts - low lifetime costs.

• Easy setup and commissioning – low installation cost.

• Specific alarms including over-torque and temperature – providing high

operation safety.

• Robust implementation of CANbus protocol ensuring a reliable bus

connection.

• Reduced power consumption that gives a greener profile.

• Self-lock feature which allows movements from the motor, but immediately

locks movements from the valve side.

• Fast and precise motor that reduces the closing time.

• Low start-up load which enables a high number of actuators per power fuse.

• Remote programming via the CAN bus protocol on the Hybrid Marine Cable.

• Specific alarms including over-torque and temperature – providing high

operation safety.

• Option for Dual CAN see Appendix A on page 59.

• Option for Failsafe operation see 0 on page 64

Eltorque actuators are an ideal choice in a wide range of Maritime and Onshore

systems such as:

• Cargo handling

• Bilge and ballast

Introduction

Page 10 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

• Tank gauging

• SPS system

• Anti-heeling systems

• RSW systems

• Bulk handling

• Fuel systems

• Hydro power and district heating

• Waste water treatment

• HVAC system

• Fire water system

• Oil Production system, oil transfer line

If you require technical support outside of this manual, we recommend that you

use the support functions available on the web-site or contact us via e-mail.

If you have feedback to this manual, that should also be routed through e-mail.

Eltorque AS

Julianus Holms veg 34

7071 Trondheim

Norway

Web: www.eltorque.no

e-mail: info@eltorque.no

Phone: +47 74 85 55 20

Fax: +47 74 85 55 12

The following reader groups have been defined for this User Manual:

• Project and engineering personnel

• Installation personnel

• Operators

• Supervisors

• Technical support personnel

• Technical management personnel

The following notations have been used in this manual:

Bold is used for commands and menu selection.

Italic is used to give emphasis to information. It is also used for names of

documents referred to in the manual.

Note! Note is used to draw attention to important or helpful information

Caution! A caution is used when there is a danger that the equipment is damaged

if you do not follow the instructions.

Introduction

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 11 of 86

Warning is used to draw attention to information of very high importance,

for example to avoid injuries to personnel.

This User Manual QT250 and QT8001 is related to the following documentation:

Table 3: Related documentation

Document

Document ID

Hybrid Marine Cable product datasheet

Eltorque document ID 1946

Eltorque E3C Manual

Eltorque document ID 1687

Guidelines for earthing in maritime

installations

Published by the Norwegian Electrical

Safety Directorate. Available on net or

supplied by Eltorque on request.

System Integrators Manual CANopen

Interface

Eltorque document ID 1691

User Manual

QT250 2.4 EX

QT800 2.4 EX

Eltorque document ID 1193

User Manual QT250 and QT800

1

Eltorque document ID 1372

Note! 1 See Table 2: Product overview on page 8 for specification of the relevant User

Manuals for the QT250/QT800 series.

The information contained in this document is subject to change without prior

notice. Eltorque AS shall not be liable for errors contained herein or for incidental

or consequential damages about the furnishing, performance, or use of this

document. It is the customer’s responsibility to verify that he has the latest

revision available by checking the document area of www.eltorque.no

Table 4: Terms and abbreviations

Term

Description

ABS

American Bureau of Shipping.

AFD

Asbestos Free Declaration.

Analog Control

Step-less control utilizing analog signals, e.g. 4-20 mA. Allows positioning of the

valve actuator between Open and Closed.

BTO

Break to open. The torque required to unseat the closed valve.

Introduction

Page 12 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Term

Description

CAN/CAN bus

Controller Area Network.

CAN bus is a fieldbus which allows communication between a maximum of 127

actuators connected to the same network. It is not a “master-slave” network (ref.

Modbus), hence all the nodes in the network can actively send messages at their

own initiative. Communication is prioritized meaning that urgent messages are

transmitted and received before information with lower priority. Compared to

Modbus, CAN bus has quite a few advantages:

− More reliable communication

− More nodes per network

− More control and configuration features are available

− Higher performance

CANopen

CANopen is a higher-level protocol and is running on top of the CAN protocol for

all Eltorque actuators.

The standard consists of an addressing scheme for the nodes on the CAN bus

and several small protocols for communicating with each node. In terms of the

OSI model, CANopen implements the levels above, including the network layer.

CCS

Central Control System.

Communication

Interface Box

Electronic device controlling the actuator according to signals from an overall

control system such as a PLC or other type of electronic controller.

Configuration

The set-up of parameters, which affects the actuator’s performance and

behavior.

Digital Control

Simple control utilizing relays, on/ off switches and indicators. Allows only Open

or Closed functionality for a valve actuator.

DNV GL

Det Norske Veritas Germanischer Lloyd.

E3C

Eltorque Common Configuration Controller.

E-VCI

Eltorque Valve Control Interface

E-VCS

Eltorque Valve Control System offers a dedicated control system

for operation of Eltorque actuators.

Eltorque Valve Control System is suitable for installations where the operator

requires full control of all valves and pumps, and in addition monitor level,

temperature, flow and pressure.

Hazardous area

Area in which the permanent or periodical presence of explosive substances

causes a risk of explosion.

Products described in this manual are not suitable for use in hazardous areas.

Eltorque can deliver actuators for use in such areas if required. Please contact

your local representative for further details.

HMI

Human Machine Interface.

HSE

Health, Safety and Environment.

HVAC

Heath, ventilation and air condition

IACS

International Association of Classification Societies

IAS

Integrated Automation System.

ICS

Integrated Control System.

IMO

International Maritime Organization

LR

Lloyd’s Register.

MAST

Maximum allowable stem torque/thrust.

MD

Material Declaration.

MEPC

The Marine Environment Protection Committee

Introduction

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 13 of 86

Term

Description

OSI model

Open Systems Interconnection model. The model is a conceptual model that

standardizes communication systems without regard to the underlying internal

structure. The model partitions a communication system into abstraction layers.

Out of range

Definition of position. The outgoing shaft is outside the defined position area.

PF

Power factor

PCB

Printed circuit board.

PLC

A Programmable Logic Controller is a digital computer used for automation of

industrial processes, such as control of machinery on factory assembly lines,

measurement and control of process plants etc.

RSW

Refridgerated sea water system

SDoC

Supplier Declaration of Conformity.

SOLAS

Safety Of Life At Sea – conversion under IMO concerning safety for personnel and ships at

sea.

SPC

Statistical process control

VA

Voltampere

UPS

Uninterruptable power supply.

Valve

A valve is a device that controls the flow of materials (gases, fluidized solids,

slurries, or liquids) by opening, closing, or partially obstructing various

passageways.

Actuator

A device for control of valves in various process control systems.

Valve top

flange

The flange on top of the valve which integrates the actuator. Key parameters to

be aware of are summarized in 3.3 Technical specification on page 19. As an

example, butterfly valves typically comprise four screw holes for the flange

integration and a square stem for valve operation.

Within range

Definition of position. The outgoing shaft is within the defined position area.

This user manual describes the guidelines for installation, setup and operation of

QT250 and QT800 in a valve control system. The valid products for this manual

are listed in Table 2: Product overview on page 8.

Chapter 1 introduces the product and this manual.

This chapter is intended for all reader groups.

Chapter 2 informs on health, safety and environment issues.

The reader group for this chapter is for supervisors, technical support and

technical management personnel.

Chapter 3 gives a product description including the mechanical construction of

the actuator, technical specifications and a functional description. There is also

an overview of technical issues that should be considered in the design and

planning phase for the installation.

The reader group for this chapter is supervisors, project and planning personnel.

Introduction

Page 14 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Chapter 4 covers the mechanical installation on valves and the electrical

installation of power and control signal.

The reader group for this chapter is installation personnel.

Chapter 5 covers the use of the actuator such as how to use the manual

emergency operation. There is also an overview of error messages and a

troubleshooting overview.

The reader group for this chapter is operators.

Chapter 6 covers maintenance, inspection and repair of the actuator.

The reader group for this chapter is operators, technical support and

management personnel.

Chapter 7 gives more in-depth technical information on the product.

The reader group for this chapter is technical support and management

personnel.

Chapter 8 gives ordering information.

The reader group for this chapter is technical support and management

personnel.

Appendix A describes the Dual CAN option, how to install and operate an

actuator with this option. The reader group for this chapter is installation

personnel, operators, support personnel and management personnel.

Appendix B describes the Failsafe option, how to install and operate an actuator

with this option. The reader group for this chapter is installation personnel,

operators, support personnel and management personnel.

Appendix C gives an overview of torque recommendations for actuator bolts.

The reader group for this chapter is installation personnel.

Appendix D includes the document “Earthing Methodology in Maritime

Installations” The reader group for this chapter is installation personnel,

technical support and technical management personnel.

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 15 of 86

This chapter includes safety information that the user needs to know to operate

the equipment without doing harm to personnel or the environment.

The operation of the equipment is safe provided that the recommended

operating procedures are followed. There are specific hazards however

that need to be addressed so that the user knows how to deal with them.

Electrical installations shall be designed and installed by personnel with

certifications according to applicable laws and regulations. Ensure that all

such work is done according to applicable laws and regulations.

Service must always be performed by trained personnel.

All batteries and electronic equipment may contain substances harmful to the

environment. After removing used equipment, return them for disposal

according to local governmental guidelines.

Caution! Do not use ammonia, alkaline cleaners, lye or strong acid for cleaning as

this can damage the protective anodized layer of the product surface.

Caution! Do not use high pressure power washer directly on the actuators as the

product is not IP69K rated.

HSE Information

Page 16 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

This page is left intentionally blank

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 17 of 86

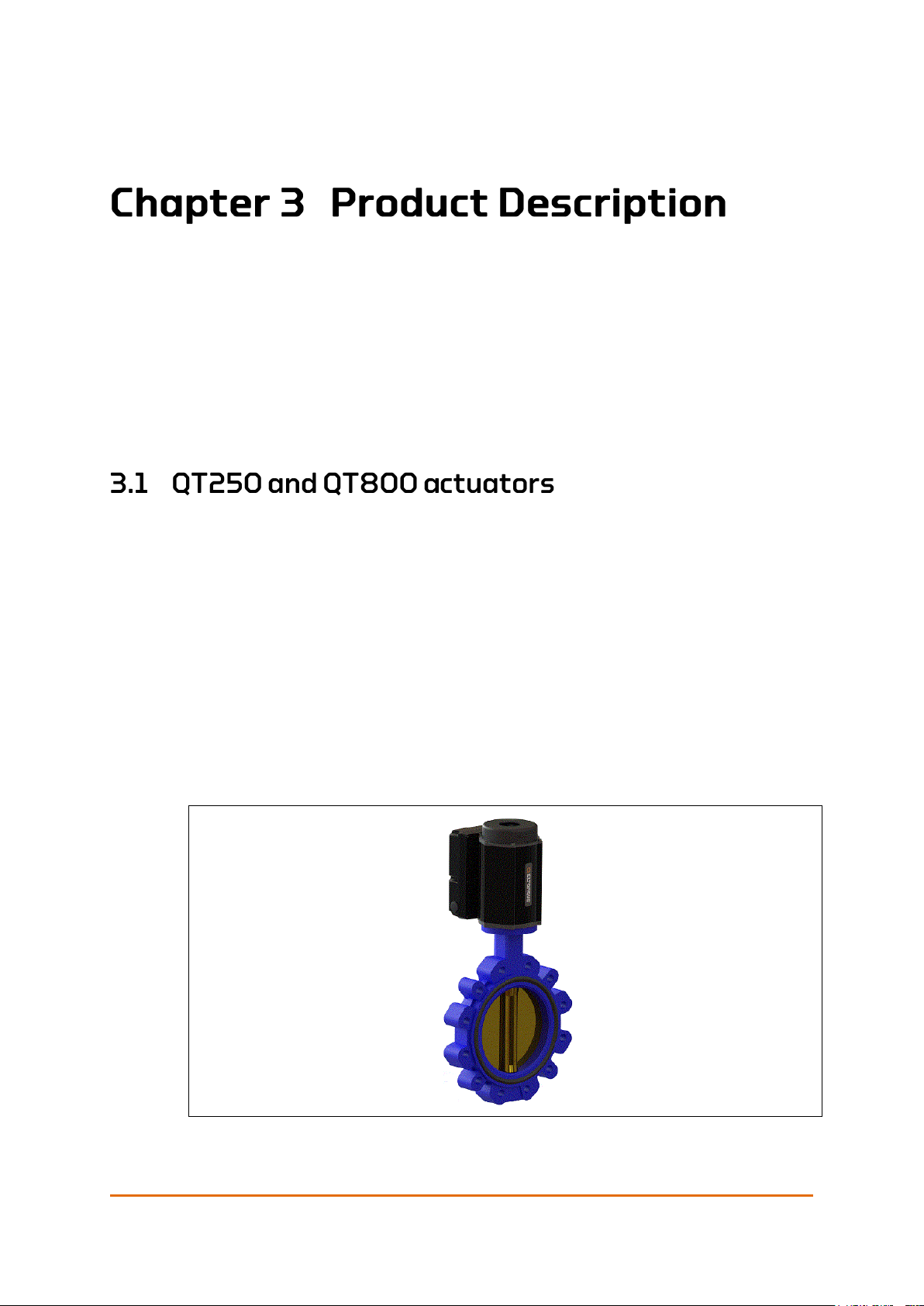

The QT250 and QT800 are the most sold products in the Eltorque portfolio. They

have been used on a various of vessel types on butterfly and ball valves. The

QT800 is based on the QT250, with an additional gearbox to further increase the

output torque. They are equipped with a magnetic position sensor that gives a

correct position feedback, even after a power outage. Both can be manually

operated by the means of a fixed hand wheel located under the cover on top of

the actuator without the need for external tools. Both QT250 and QT800 can be

delivered with the Failsafe option described in 0 on page 64 and the CAN Dual

option described in Appendix A on page 59.

The QT250 actuator is suitable for valves with torque requirements between 100250 Nm, while the QT800 is suitable for 320-800 Nm. Both can be delivered with

CANopen, Analog and Digital communication.

Note! For actuators equipped with Failsafe and/or Dual CAN options, these are only

available with the CANopen communication interface.

The actuators are designed to be operational during a temporary submerged

situation, see details for housing in Table 5: System performance parameters for

QT250 and QT800 actuators on page 19.

Figure 2: Actuator mounted on a valve

Caution! Remember to have the actuator checked by Eltorque after all submerged

situations to keep the warranty.

Product Description

Page 18 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

The actuator must be integrated with the main control system in one of two

ways:

• Directly to the main control system. In this case it is important to consider

the communication protocol.

• Through a stand-alone sub-system delivered by Eltorque. This is a

standardized hardware and software platform tailored for Eltorque actuators.

The solutions illustrated below show a bus connection with the Eltorque Hybrid

Marine Cable. This cable can be used with the CANopen and Dual CAN

communication interface. In addition, Eltorque actuators support Digital and

Analog connections.

Figure 3 below shows Eltorque actuators that are connected to a cabinet with

Eltorque valve control system (E-VCS). In this example, pump starters are also

connected to the E-VCS. Other equipment, such as sensors can also be connected

to the E-VCS. The E-VCS includes an HMI interface on the cabinet and can also

support an HMI interface on main control level.

Figure 3: Eltorque Valve Control System (E-VCS) with valve and pump control

Figure 4 below shows Eltorque actuators that are connected directly to a

customer specific PLC, PC or other control unit. In addition, Eltorque actuators

support digital and analog connections. On system level, the PLC, PC or

Controller must be compliant with Eltorque communication protocol according to

Eltorque System Integrators Manual.

Product Description

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 19 of 86

Figure 4: Eltorque actuator loop connected to Integrated Automation Control System (IAS

or ICS)

Table 5: System performance parameters for QT250 and QT800 actuators

QT250

QT800

Valve flange and max

allowed rated torque

options

100, 150 or 250 Nm

320, 480 or 800 Nm

Closing time options

0-90 movement:

12, 15, or 20 seconds

0-90 movement:

42, 52.5 or 70 seconds

Valve spindle adaptor

SQ17

depth 38 mm/1.50 in

SQ27

depth 45 mm/1.77 in

Max. allowed valve

flange and related

torque

(Ref. ISO5211) 2001E

F05

F07

F10

F10

F12

125

250

500

500

1000

Valve applications

Quarter-turn

Examples:

Butterfly DN50-DN200 PN16

Floating Ball DN65-DN100 CL150

Quarter-turn

Example:

Butterfly DN150-DN200 CL150

Weight

11 kg/24.3 lb

20 kg/44.1 lb

Dimensions (HxWxD)

229 x 156 x 209 mm

9.02 x 6.14 x 8.23 in

333 x 200 x 239 mm

13.11 x 7.87 x 9.41 in

Manual operation –

number of turns

21 turns on hand wheel =

90 movement on valve

73 turns on hand wheel =

90 movement on valve

Color

Black

Housing

IP66 and IP x8 (10 m – 100 hours/32 ft 9.7 in – 100 hours).

Corrosion protected aluminum and steel enclosure.

Should not be exposed to corrosive chemicals.

Storage temperature

5 – 35C/41 – 95F

Product Description

Page 20 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

QT250

QT800

Operating temperature

With Failsafe option

-25 to 55C/-13 to 131F

0 to 45C/32 to 113F

Temperature protection

Motor current is switched off in case of over-heating.

Power supply

1-phase,110 – 240V AC, 50/60 Hz, Max 240 VA

Power consumption

Opening and closing

with max torque1

100 VA, PF 0.79

Power consumption

Standby1

9 VA, PF 0.37

Duty performance

According to AN 15714-

1 / IEC 60034-1

Class A – 10 cycles per hour/52 – 15 min.

Endurance

According to EN 157122

Classes A and B – 10 000 cycles per lifetime.

Cable glands

Up to five M20 glands allows bus connection of power supply and

signal wiring. Use IP68 (10 m 72 hours) cable glands for all wires.

Communication

Interfaces options

CANopen allows positioning and other extended control of the

actuator. The absolute maximum theoretical number of devices allowed

on the bus is 127, but the actual number of nodes is limited by the

baud-rate and the cable quality. Eltorque recommends a maximum of

80 nodes on 500 m/1660ft cable.

Digital 2 DI (Open-Close) and 3 D0 (Open-Close-Alarm.)

Analog Al (Set position) A0 (Feedback position) and D0 (Alarm) (4-20

mA) AI/A0 signal.

Position sensor

Resolution: 360°/12bit = 0.35156°/bit

Integral Non-Linearity (INL): typ. ± 0.8°

Differential Non-Linearity (DNL): ± 0.176°

Output shaft accuracy: 1%

Position feedback not corrupted by power outage.

Configuration

USB connection to PC with Eltorque E3C. Special configuration cable is

needed, see E3C User Manual.

Configurable parameters

Open and Closed positions. Actuator speed, torque and valve position

regions. Inverted IO or bus parameters depending on the applied

communication interface.

Manual operation

Standard feature using fixed hand-wheel. Mechanical valve position

indicator. No need for external tools.

Cover of handwheel

Can be removed and refitted without tools. Protects mechanism against

mechanical damage and foreign objects. The actuator must not be

lifted by the top cover.

Self-lock

The QT250 and QT800 are equipped with a mechanical self-locking

device that locks the valve to the target position when the actuator

movement command is completed.

Certification/type

approval

All valid certificates are listed on www.eltorque.no – support – technical

support – certificates.

1 Earlier versions of the QT250 and QT800 have other values for power consumption, see Table 2:

Product overview on page 8 for information on the correct documentation to consult.

Product Description

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 21 of 86

Bottom view

Bottom view Top view

Figure 5: QT250 external construction

Bottom view Top view

Figure 6: QT800 external construction

Product Description

Page 22 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

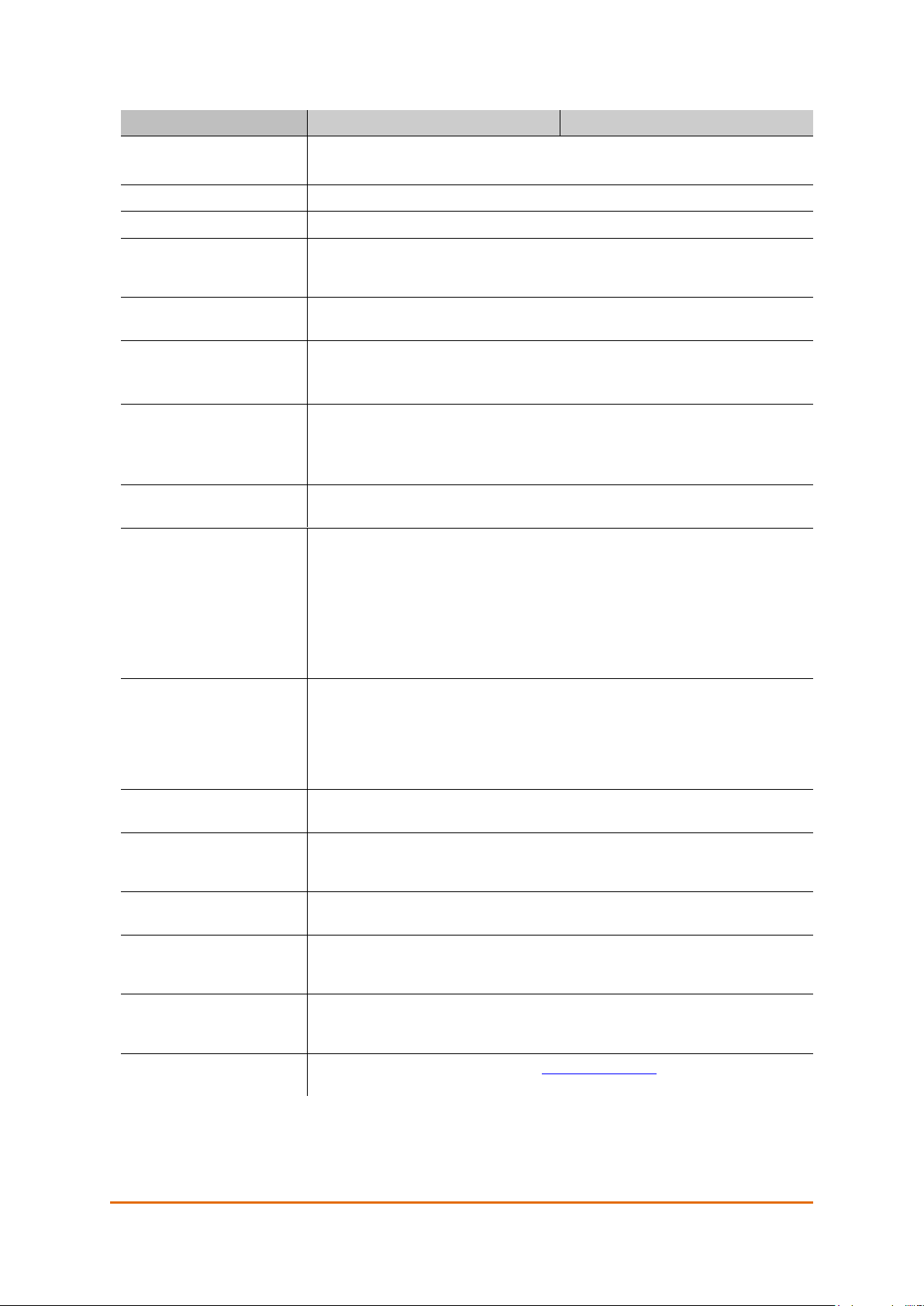

Figure 7: Communication interface box – CANopen

The communication interface box provides connectors for power, control signals

and configuration media.

The interface box is by default delivered in three versions:

• CANopen – interface using the CAN (Controller Area Network)

communications standard. Eltorque recommends a maximum of 80 nodes

on 500 m/1660 ft. cable.

The actuator can also be delivered with Dual CAN. Standard CANopen is

described in the main parts of this User Manual while Dual CAN is described

in Appendix A on page 59 and onwards.

• Digital – interface allowing simple Open and Close operation of valves.

Actuators with Digital Interface can be controlled directly from a

conventional panel with buttons/switches and indicator lamps. Alternatively,

it can be controlled from a PLC with digital inputs and outputs.

• Analog – interface allowing regulating valves where positioning of the valve

is needed. The actuator provides continuous feedback of its actual position,

for comparison between desired and actual position. Both positioning and

feedback signals are analog 4-20 mA. The Analog Interface also has a digital

Alarm output, which is trigged by failures in both actuator and valve.

If a Modbus interface is required, please contact your Eltorque representative.

More technical details on the different communication interfaces is given in

Chapter 7 Technical Details on page 51.

The label on the actuator housing states the type of communication interface

used in the unit as well as the specifications for torque, temperature, power

supply and IP rating.

The production serial number and the production date are also included.

When the communication interface box has been removed you can see labels

with interface details.

Product Description

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 23 of 86

Figure 8: Actuator labels

The cabling specifications depend on the type of communication interface to be

used.

The QT250 and QT800 control box has five threaded M20 holes for cable glands.

When ordering it is important to consider factors like cable type and size, as the

cable glands have a limited cable entry range. Eltorque standard cable glands can

accommodate a cable between 8-14 mm/0.32 – 0.55 in.

To maintain the Eltorque actuator’s IP encapsulation, it is important to use the

correct rated cable glands, see Table 5 on page 19 and chapter 4.5 on page 36.

The actuators have an EMC class A approval according to DNVGL– CG-0339

without the use of EMC glands. They are therefore by default delivered with nonEMC glands. If you require EMC glands, please notify your sales contact when

ordering.

The default glands for the different communication interface boxes and ordering

information is given in Chapter 8.

If your actuator cannot be installed immediately, it must be stored it in a dry

place until you are ready to install and connect cables. The actuator does not

come prepared for long time outdoors storage when arriving from Eltorque.

Details on storage temperature is found in Table 5: System performance

parameters for QT250 and QT800 actuators on page 19.

If the actuator can be mechanically installed, but not cabled, please ensure that

all glands and gland holes are thoroughly tightened to avoid ingress of moist.

The actuator’s IP rating is not valid until correctly installed.

Eltorque cannot accept responsibility for deterioration caused on site if the

actuator has been opened in ways not described as required in this manual. In

principle, the product should be powered within three years after production to

prevent components from derating. All actuators are thoroughly tested before

shipping to give trouble-free operation, if installed and commissioned properly.

Product Description

Page 24 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Electrical installations shall be designed and installed by personnel with

certifications according to applicable laws and regulations. Ensure that all

such work is done according to applicable laws and regulations.

It important to consider the number of actuators in both the power loop and the

signal loop when using bus-based communication. The loop list should be

finalized and approved before installation of the cable is started.

In case of power loss, none of the actuators in that power loop can be remotely

operated. In case of a signal loss, none of the actuators on that signal loop can

be remotely operated. Manual operation is however possible in both scenarios.

With the Dual CAN and the Failsafe options the system security in case of a

power or signal loss is largely enhanced. More details are found in Appendix A

Dual CAN Option on page 59 and in Appendix B Failsafe Option on page 65.

The power consumption varies depending on whether the actuator is in standby

mode or is running, see Table 5: System performance parameters for QT250 and

QT800 actuators on page 19.

Eltorque actuators may be used according to IEC 60034-1 duty type S2

Industrial Valves – Actuators, chapter 4.7:

For class A - ON/OFF operation, duty performance is defined as the minimum

number of cycles per hour, where "one cycle consists of nominal 90° angular

travel in both directions (i.e. 90° to open + 90° to close), based on an average

load of at least 30 % of the rated torque with the ability to transmit 100 % of the

rated torque for at least 5 % at each end of travel, with a cumulative operating

time not exceeding 15 minutes in one hour." (EN 15714-2, chapter 4.7.2.2, a.).

For class B - inching/positioning, duty performance is defined as the minimum

number of starts per hour, where "one start consists of a movement of at least 1°

in either direction, with a load of at least 30 % of the rated torque. The cyclic

duration factor (i.e. the ratio between the running period and total period)

shall be not less than 25 % (e.g. 1 s. running and 3 s. resting)" (EN 15714-2,

chapter 4.7.2.2, b.)

For classes C and D - modulating and continuous modulating, duty performance

is defined as the minimum number of starts per hour, where "one start consists

of a movement of at least 1°. in either direction, with a load of at least 30 % of

the rated torque" (EN 15714-2, chapter 4.7.2.2, c.).

Rotating electrical machines, chapter 4.2:

Duty type S2: "Operation at constant load for a given time, less than that

required to reach thermal equilibrium, followed by a time de-energized and at

Product Description

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 25 of 86

rest of sufficient duration to re-establish machine temperatures within 2 K of the

coolant temperature." (IEC 60034-1, chapter 4.2.2)

Eltorque actuators may be used classes A and B – 10 000 cycles per lifetime.

Endurance is defined according to EN 15714-2, chapter 4.1 and Annex A.

For classes A and B - ON/OFF operation and inching/positioning, endurance

defines the minimum number of cycles to be endured per life time, where "one

cycle consists of nominal 90°. angular travel in both directions (i.e. 90° to open +

90° to close), based on an average load of at least 30 % of the rated torque with

the ability to transmit 100 % of the rated torque for at least 5 % at each end of

travel, with a cumulative operating time not exceeding 15 minutes in one hour."

(EN 15714-2, chapter 4.1.2, b.)

For class B - inching/positioning, duty performance is defined as the minimum

number of starts per hour, where "one start consists of a movement of at least 1°

in either direction, with a load of at least 30 % of the rated torque.

The cyclic duration factor (i.e. the ratio between the running period and total

period) shall be not less than 25 % (e.g. 1 sec running and 3 sec resting)" (EN

15714-2, chapter 4.7.2.2, b.)

Shielded cables and appropriate cable glands should be used if the actuator is

installed near to or connected in the same network as equipment emitting high

levels of disturbances.

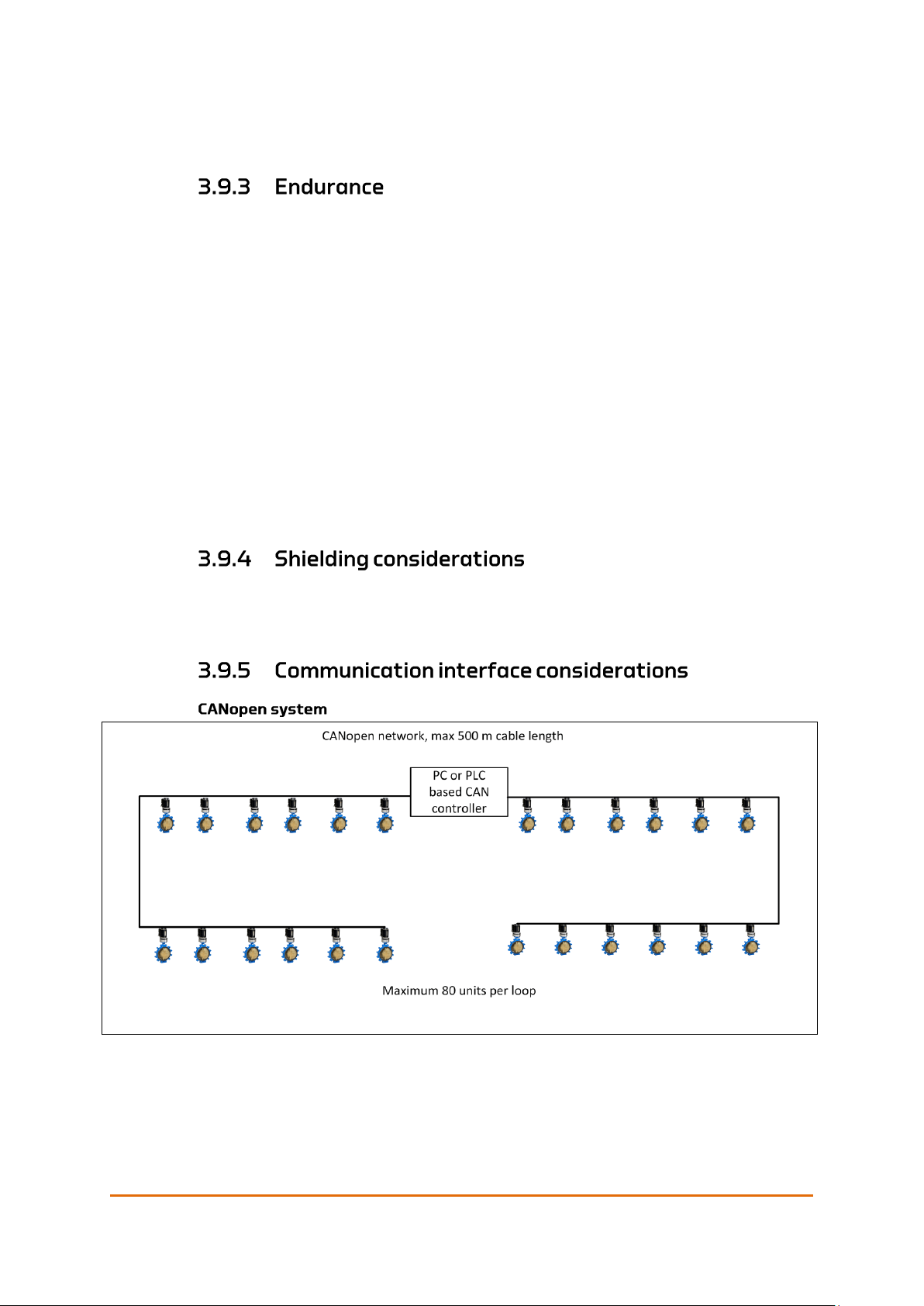

Figure 9: CANopen bus network

Note! Eltorque recommends a maximum of 80 nodes on 500 m/1660 ft cable.

Note! The cable between the nodes can be maximum 500m with bus speed with the

Eltorque Hybrid Marine Cable. For other data rates and cable lengths check with

Eltorque service department.

Product Description

Page 26 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Table 6: Cable requirements and recommendations for CANopen system

Cable parameter

Cable requirements and recommendations

Number of conductors

1 (GND) + twisted pair for CAN_H and CAN_L signals

Length related

resistance / Cross

section

Length related resistance;

typical 70 mΩ/m Max 100 m/m

70 mΩ/ 3ft 3.37 in Max 100 m/3ft 3.37 in

Normally equivalent to 0.5–1.5 mm2/0.02 – 0.06 in2

Cable length (affects

communication speed)

Maximum 500 m/1650 ft.

Shield

EMC glands are not mandatory but is recommended in case

the actuator is placed in conjunction with equipment

emitting high levels of disturbances.

Termination resistor

Nominal 120 Ω Both ends of the signal loop must have the

correct impedance. Use the internal resistor by setting the

terminal jumper in position ON, see Figure 26: CANopen

connection interface terminals on page 40.

For the analog interface, both the input and the outputs are passive. Analog has

two outputs. One Alarm output and one Position output (4 to 20 mA) (see Table

7 for details).

Table 7: Relay outputs – analog interfaces

Function

Value

Rated voltage

24 VAC/VDC

Max. switching voltage

24 VAC/VDC

Rated current

1A

Limiting continuous current

1A

Breaking capacity

Max. 48 VA (1A)

For the digital interface, the digital outputs are passive, and the digital inputs are

active with a 5 V/20 mA rating. The digital output must be powered (see Table 8

for details).

Table 8: Relay outputs – digital interfaces

Function

Value

Rated voltage

48V AC/VDC

Max. switching voltage

48V AC/VDC

Rated current

1A

Limiting continuous current

1A

Breaking capacity

Max. 48 VA (1A)

Product Description

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 27 of 86

Table 9: Cable requirements and recommendations digital and analog systems

Cable parameter

Required/ Recommended

Number of conductors

6 recommended twisted pair.

Cross section

0.5 - 1.5 mm2/0.0197 – 0.0591 in2.

Shield

Not mandatory but is recommended in case the

actuator is placed in conjunction with equipment

emitting high levels of disturbances.

Bus connection of actuators is undoubtedly the most cost-effective installation

methodology. Eltorque has developed a ground-breaking Hybrid CANbus/Power

cable especially designed for maritime applications.

Figure 10: Bus connection of actuators

The Eltorque Hybrid Marine Cable combines signal and power cable in a hybrid

cable with maritime type approval. The cable can only be used for installations

with CANopen communication interface box. When this cable is used, only two

cable glands are required, see Chapter 8 Ordering Information and

Recommended Spare Parts.

Figure 11: Hybrid Marine Cable

Further description of the Hybrid Marine Cable is found in the Hybrid Marine

Cable datasheet, Eltorque document ID 1982. The datasheet is available on

www.eltorque.no – Products – System components.

With traditional cabling, four cable glands are required to accommodate both

power and signal cables. When ordering please inform if you intend to use the

Hybrid Marine cable or a standard cable.

Product Description

Page 28 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

The actuator can freely be mounted both vertically standing or horizontally lying

to the side. An upside-down hanging position should be avoided.

Figure 12: QT250 dimensions

Figure 13: QT800 dimensions

During planning, please ensure sufficient space above and around the actuator

for installation, service and manual operation.

Product Description

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 29 of 86

There must be a minimum of 150 mm/5.9 in space above and to the sides of the

actuator to accommodate room for installation, operation and service. In front of

the communication interface box there should be at least 200 mm/7.9 in.

Figure 14: QT250 Space requirements for installation, service and manual operation -

side view

Figure 15: QT250 Space requirements for installation, service and manual operation – top

view

Product Description

Page 30 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Figure 16: QT800 Space requirements for installation, service and manual operation –

side view

Figure 17: QT800 Space requirements for installation, service and manual operation – top

view

Product Description

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 31 of 86

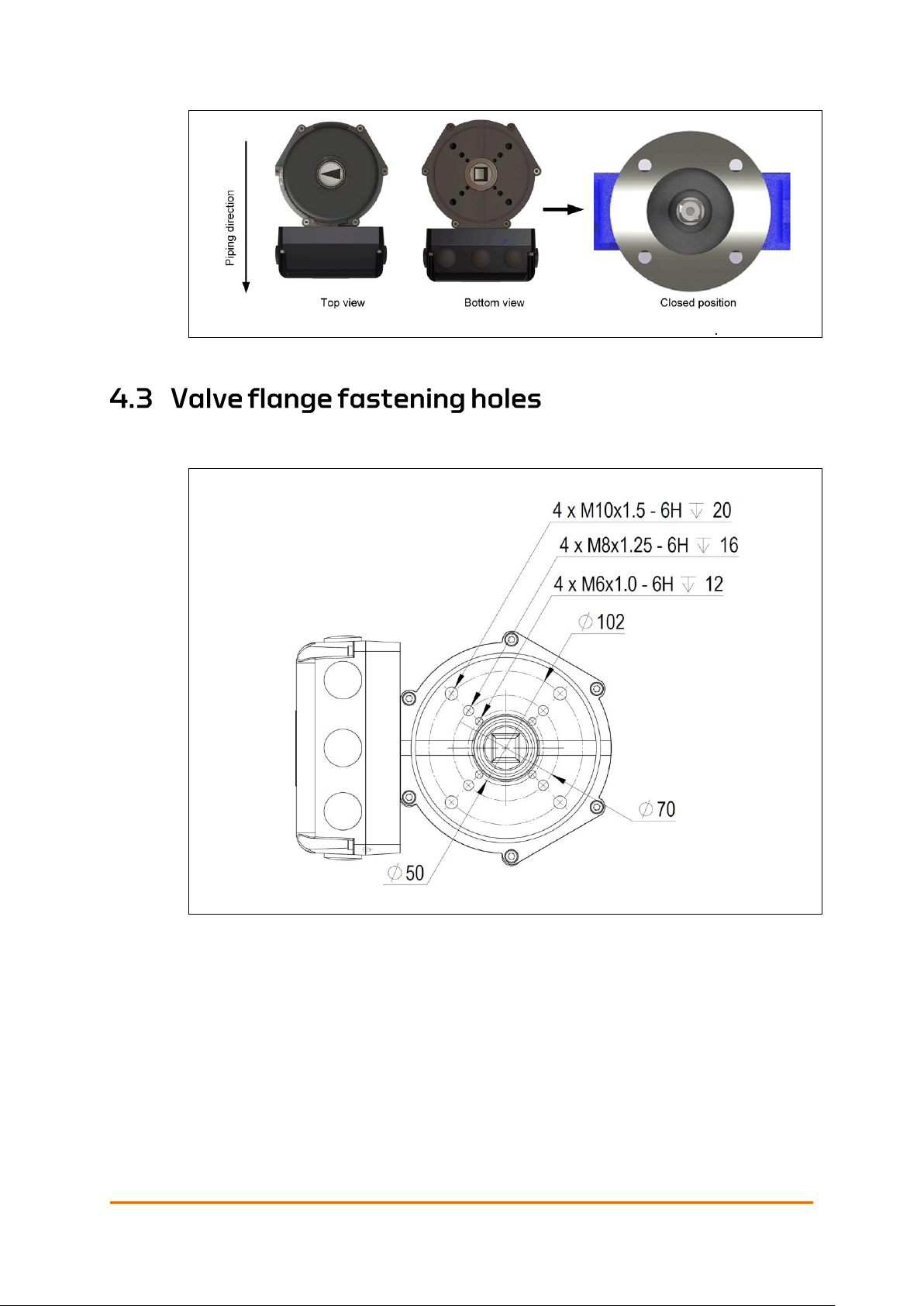

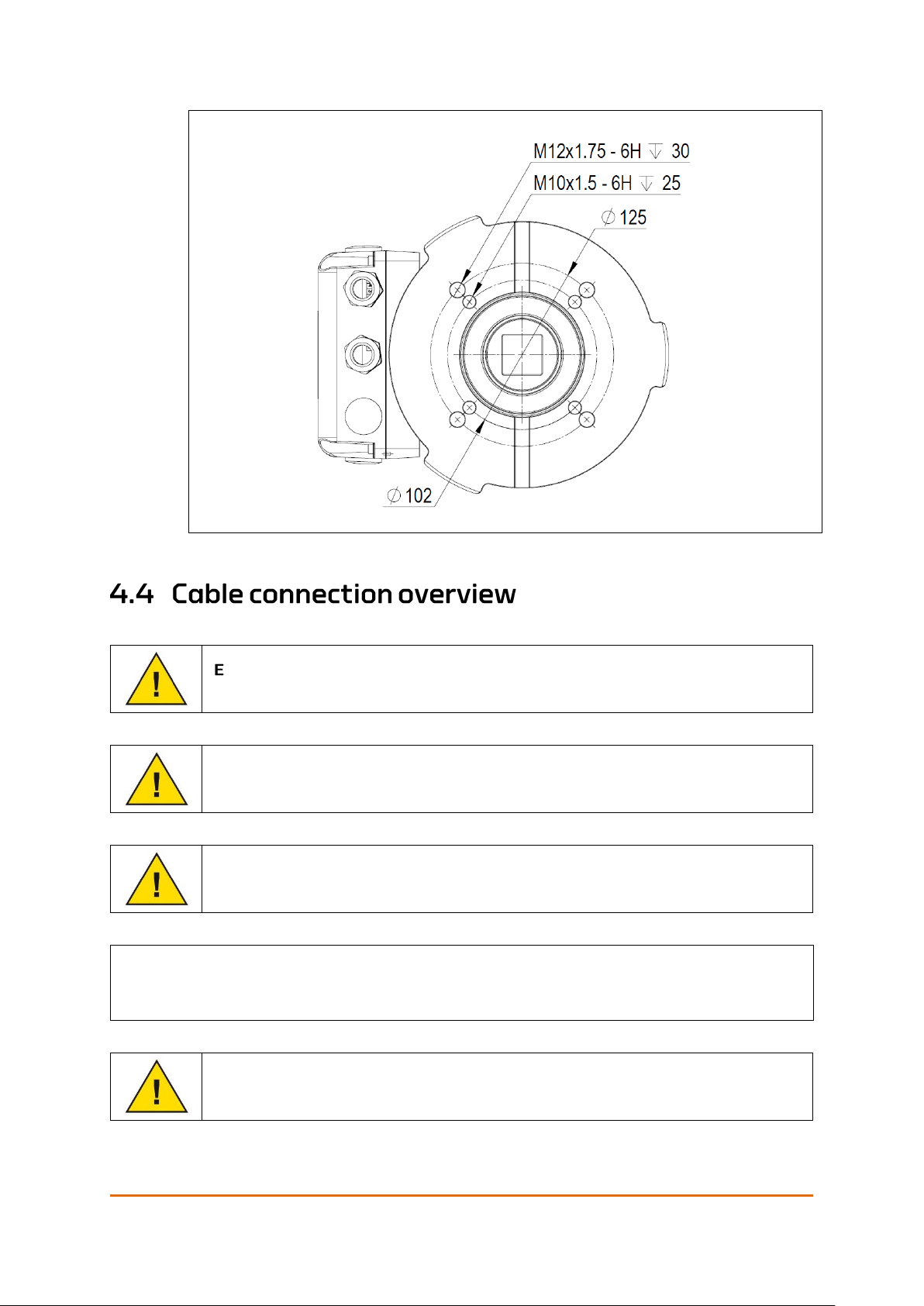

The actuators provide fastening holes of different dimension to facilitate

mounting on different types of valves, see details in Figure 20 on page 34 and

Figure 21 on page 35.

When the actuator and the valve do not have a natural match, it is necessary to

use an adaptor. There are various adaptors available, but the two most common

ones are the square reducer and the flange + stem adapter. When buying

actuator and valves together from Eltorque, this is handled by our project

personnel. If you order just the actuator take care to verify the critical

dimensions and whether the valve has parallel or standard configuration. Square

reducers might be necessary. Always use two pieces with QT250. The QT800

only has room for one. The type of reducer to be used depends on the valve type,

please contact your Eltorque representative or Eltorque support for further

details.

Figure 18: QT250 and QT800 Settings for closed position.

The setting for closed position can be changed by using E3C, see Eltorque E3C

Manual.

The actuator must have sufficient torque to operate the valve in all situations

with an acceptable safety margin. Valve type, temperature, operating pressure,

medium density and viscosity and the medium’s effect on the valve friction are

among the variables that need to be evaluated. A change in any of these

variables may change the required operating torque. Preferable a torque table

with all parameters should be used, but for an electrical actuator, the output

torque is constant, reducing the considerations to be made. Using the break to

open (BTO) value usually gives a correctly sized actuator. The break to open

torque is defined as the torque required to move the valve out of the seat.

Be aware that the MAST of the valve needs to be verified to prevent damage to

the stem. Eltorque can assist with the necessary experience in selecting the

correct actuator size for the valve.

For the QT250 and QT800, the closing time is configurable within a predesigned

interval. The opening and closing profiles are shown in Table 5: System

performance parameters for QT250 and QT800 actuators on page 19.

Product Description

Page 32 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

The actuator is configured from a computer and it is delivered with the

configuration specified by the customer. Eltorque provides the E3C

configuration software which runs on a standard PC and the corresponding User

Manual E3C Software.

The software can be downloaded from the Eltorque website www.eltorque.no –

Technical Support – Software.

The Eltorque Configuration Cable is needed to connect the actuator to the

configuration PC/PLC. It must be ordered separately, see Chapter 8 Ordering

Information and Recommended Spare Parts on page 55.

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 33 of 86

Keep hands away from the valve flanges

1. Apply multi-purpose corrosion protection grease on the valve spindle to ease

mounting and avoid corrosion.

2. Make sure that the valve and actuator are placed in the same position (closed).

3. Lift the actuator onto the valve; align its valve adapter with the valve spindle

and lower the actuator onto the valve flange.

4. Ensure that the spindle and valve mounting holes fit directly to the actuator.

5. In cases where square reducers are needed always insert two pieces with

QT250. The QT800 only has room for one.

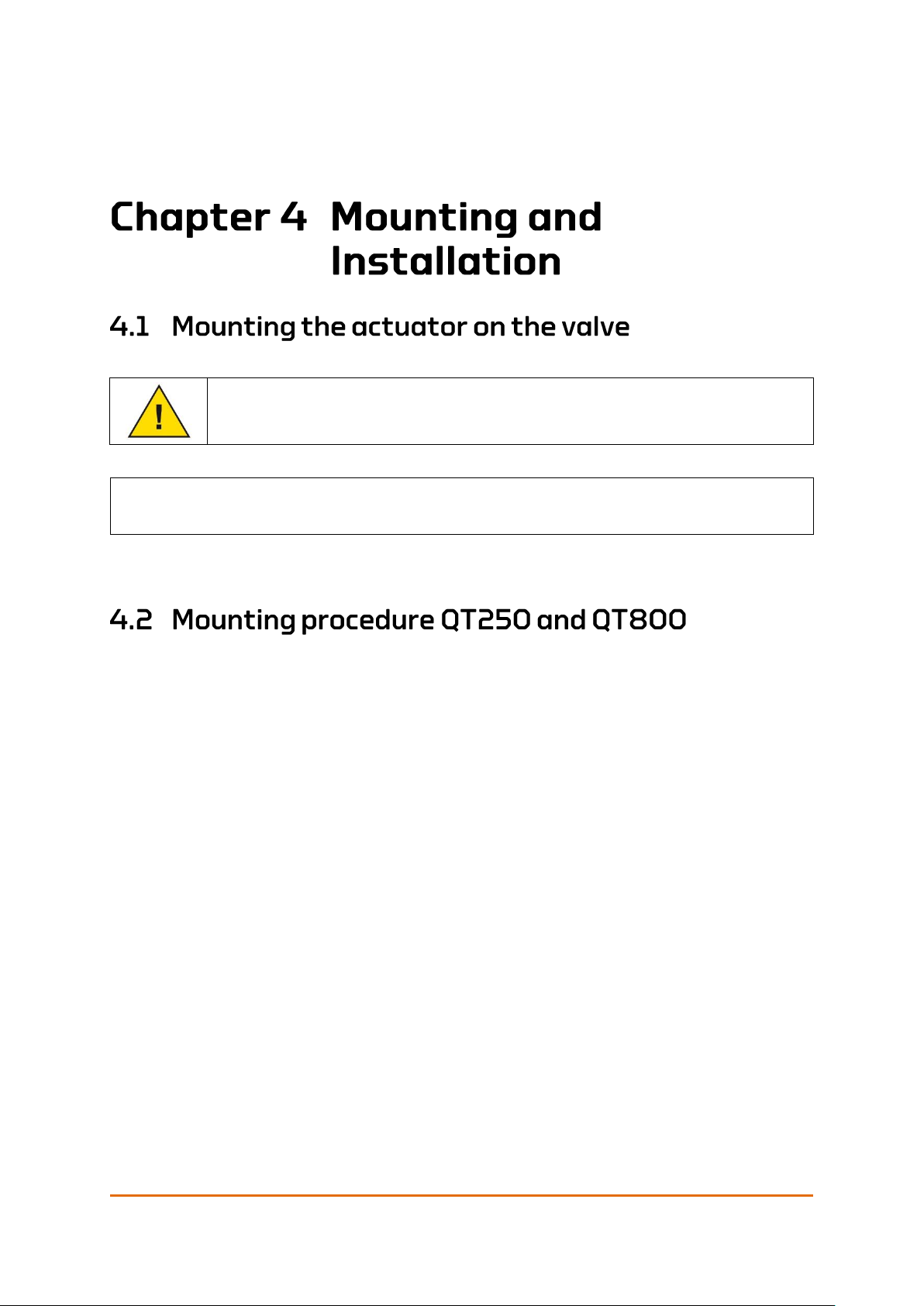

6. Check that the actuator is correctly positioned on the valve. The actuator’s

interface box should be placed in the same direction as the piping direction,

see Figure 19.

If square reducers are needed, se chapter 3.9.10 Additional information

adaption actuator/valve on page 31.

7. Remove the top cover and use the hand wheel to turn the actuator and align

the fastening holes of the valve flanges, see chapter 5.1Manual operation.

8. Insert the fastening screws and use washers according to specifications. For

screw dimensions see Figure 20 and Figure 21.

Tighten fastening screws to the specified torque, see Table 22: Screw torque on

page 81.

Caution! Do not lift the actuator by the top cover.

Mounting and Installation

Page 34 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Figure 19: Piping direction

The actuator provides fastening holes of different dimension to facilitate

mounting on different types of valves.

Figure 20: QT250 Valve flange fastening holes

Mounting and Installation

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 35 of 86

Figure 21: QT800 Valve flange fastening holes

nsure that electricians have certifications according to applicable laws

and regulations before being allowed to do any work on installations.

The supply voltage must be 1-phase, 110 – 240V AC, 50/60 Hz,

Max 240 VA.

Make sure the fuses are disconnected before you open the

Communication Interface Box.

If ferrules are used the sole responsibility for a correct installation lies on

the installing party.

Caution! When using stranded wires, make sure that all wire strands are properly

fastened in the spring connector. Using ferrules is not recommended.

Mounting and Installation

Page 36 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

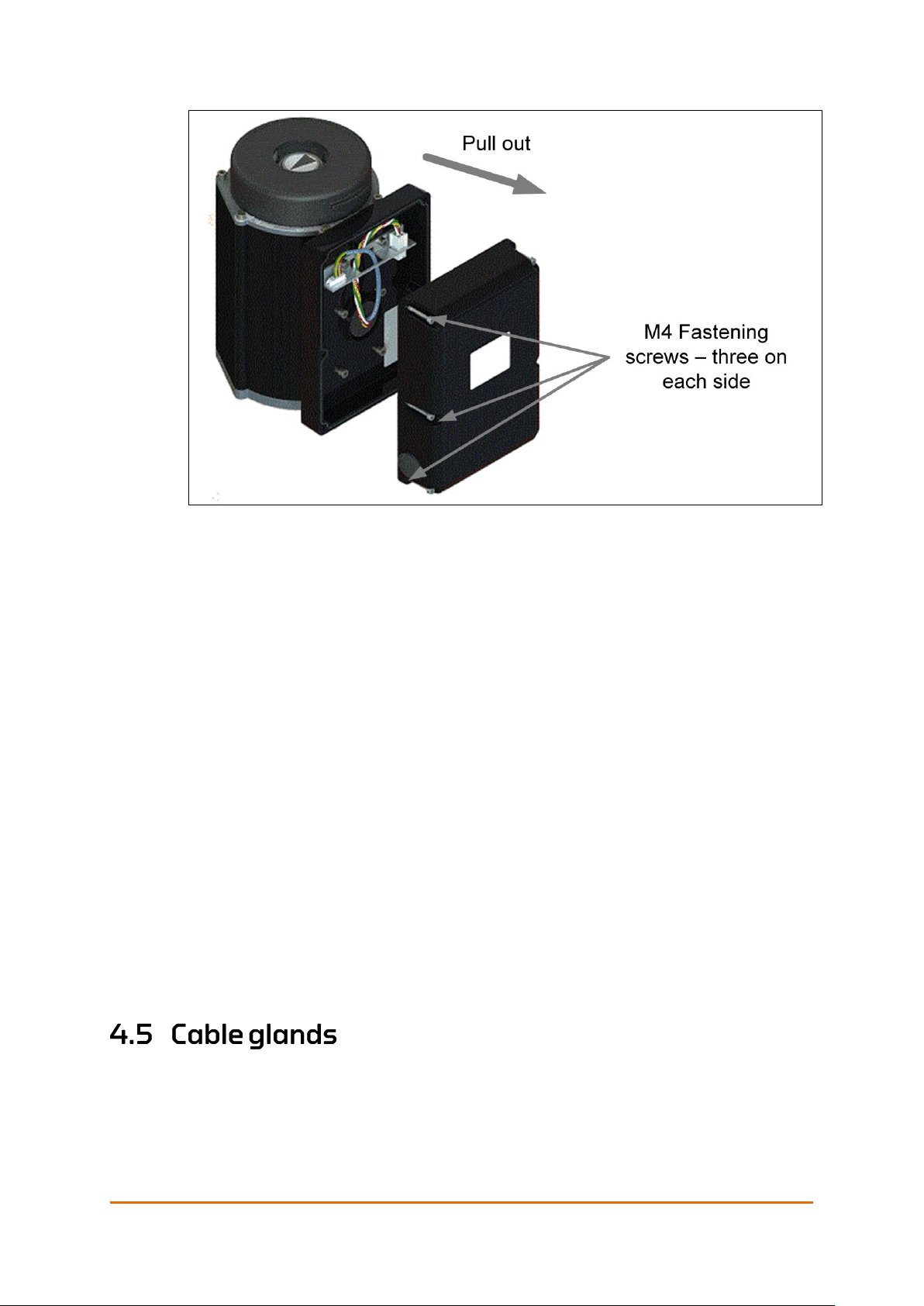

Figure 22: Removing the communication interface box

1. Loosen the six fastening screws (three on each side) on the

communication interface box, see Figure 22 above.

2. Remove the box by pulling it straight out.

3. Install the required cable glands, see section 4.5.

4. Strip all wire-ends to 8 – 9 mm/0.31 – 0.35 in.

5. Install the power supply cables through the cable glands on the right side

and connect them to the L, N and G/ PE terminals, see section 4.6.

6. Install the control signal cables through the cable glands on the left and

connect them according to the type of communication interface box used

in the installation. See section 4.8.

7. Connect the configuration medium to X2 configuration connector if

applicable.

Note! When re-assembling the communication interface box with the actuator, make

sure that no wires are jammed between the surfaces and that the screws are

cross-tightened. It is also recommended to apply some seal lubrication on the

gasket to ensure that the actuator remains water proof.

8. Replace the box and tighten the fastening screws to the specified torque.

See Table 22: Screw torque on page 81. Also see the note above.

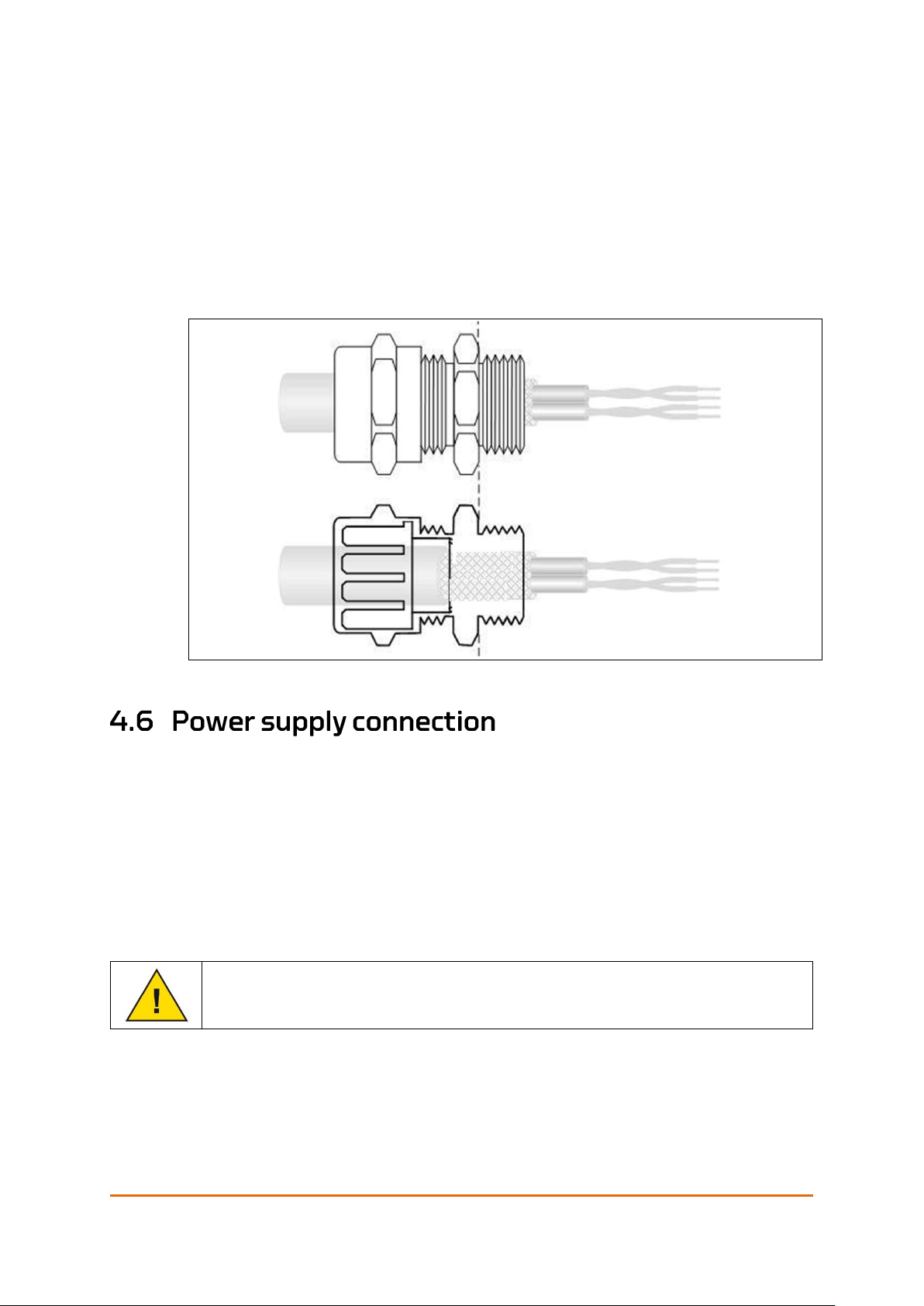

For trouble-free operation, it is important to install the glands and cable

correctly. Eltorque’s IP certification may be voided if the instructions of the

glands are not followed.

Note! Support the cable to prevent it from twisting

• Ensure that the correct cable and gland are at hand.

Mounting and Installation

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 37 of 86

• Be sure to allow sufficient length striped cable.

• Pass the cable through the cable gland and ensure that the cable is correctly

positioned in the gland. Eltorque recommends having a 5mm cable edge

over the end of the gland.

• Hold the body of the gland in position with a spanner (24mm / 0.94 in.) or

wrench to prevent rotation and tighten the back-nut to min 5Nm, maximum

15Nm.

• Finalize the gland installation with a visual verification to ensure correct

positioning of all parts.

• For other glands follow the instructions from the supplier.

Figure 23: Mounting of cable gland

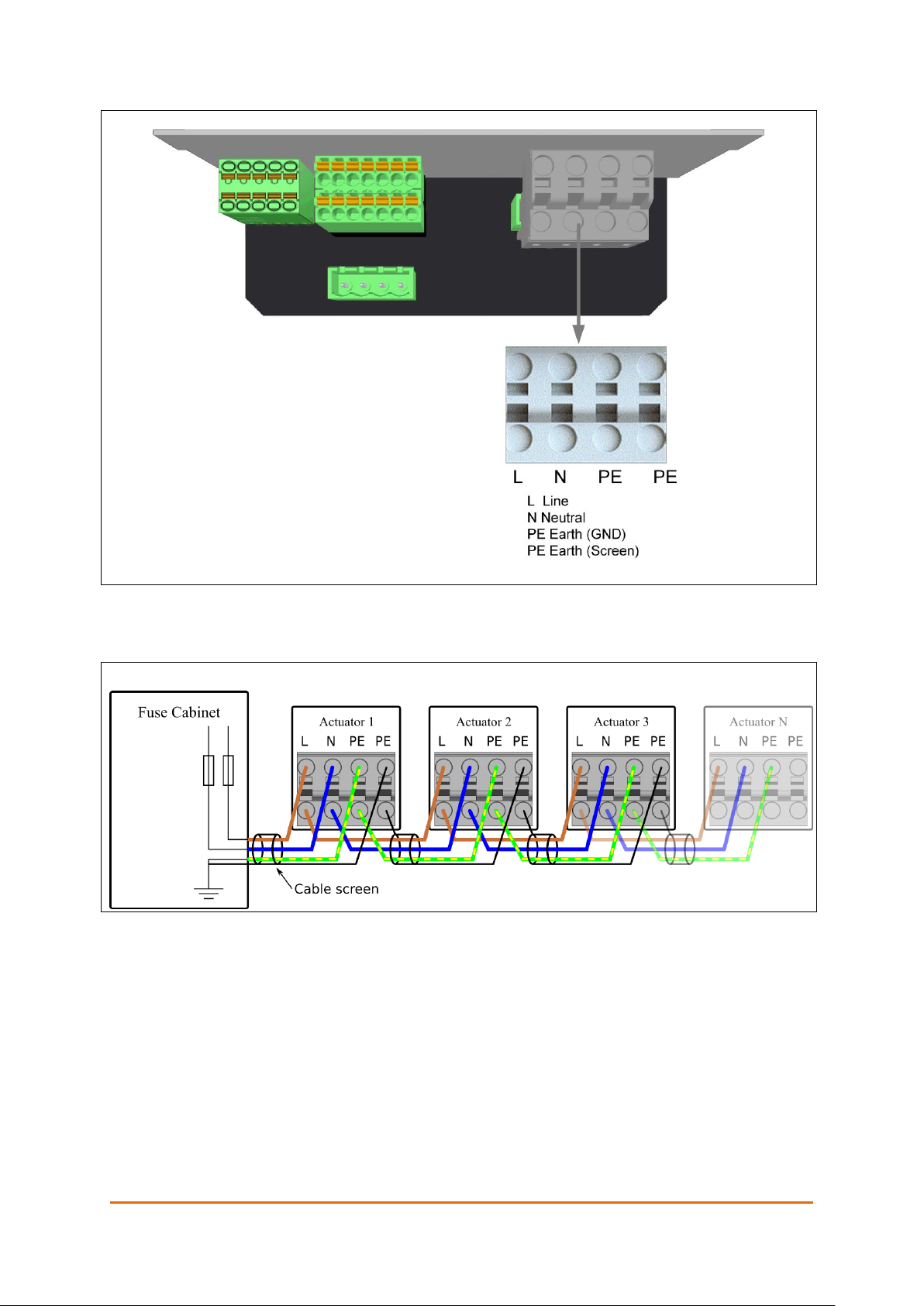

Note! Connection of the power supply is identical for all types of communication

interface box for QT250 and QT800 actuators.

Each actuator has a double power supply connector enabling bus power

connection of multiple actuators. Verify that the voltage levels are in accordance

to the products requirements.

All terminals can accommodate:

• Fine-stranded conductor

0.25 … 2.5 mm²/0.0098 - 0.0984 in2.

If ferrules are used the sole responsibility for a correct installation lies on

the installing party.

Mounting and Installation

Page 38 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Figure 24: Power supply connection QT250 and QT800

Figure 25: Multiple actuators with bus power connection

Refer to Appendix D Earthing Methods in Maritime Installations on page 83 for

information on connection of screen for the last actuator in the loop (actuator N).

Mounting and Installation

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 39 of 86

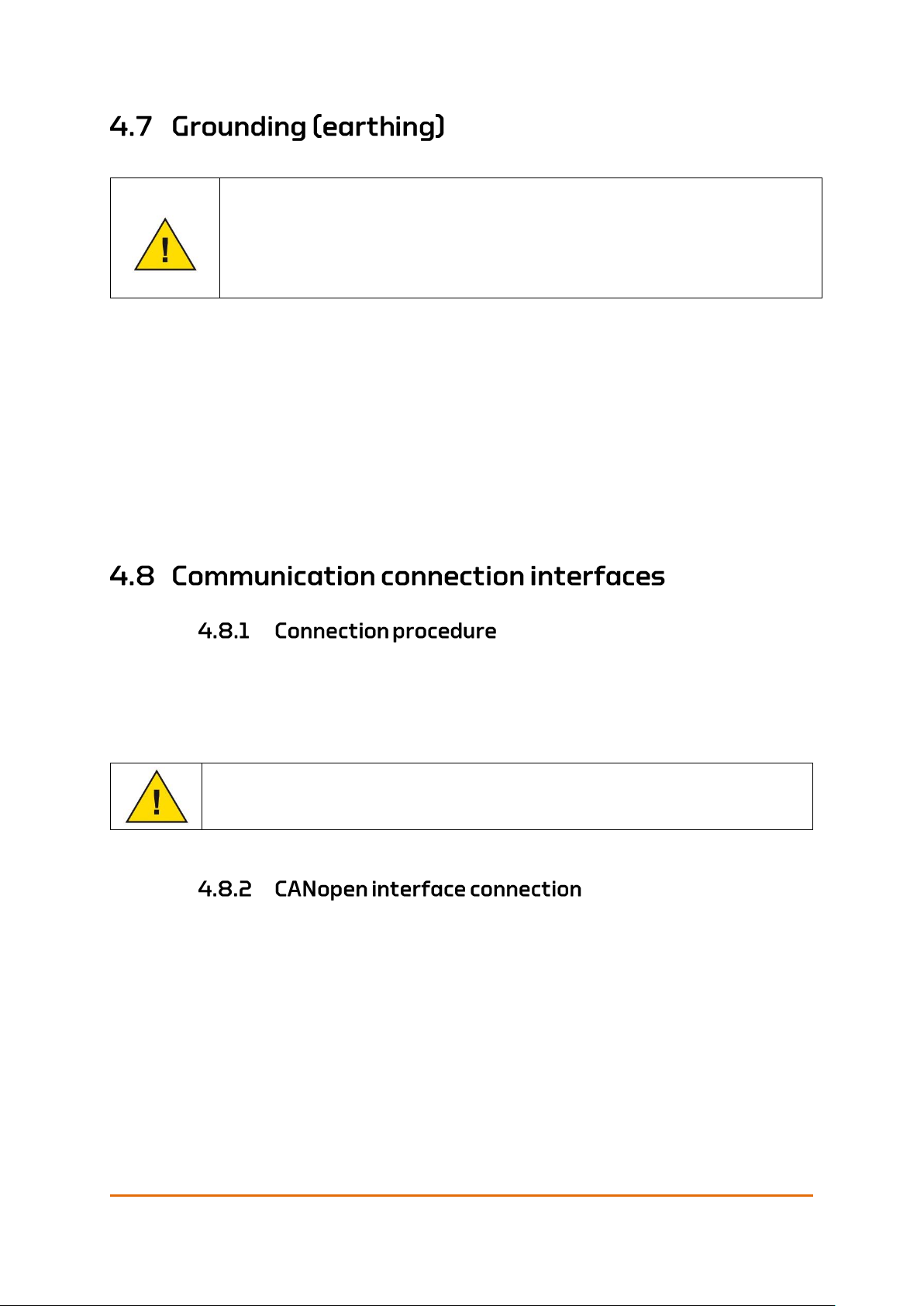

For maximum personnel and equipment protection, the installation shall

comply with “Guidelines for earthing in maritime installations” published

by The Norwegian Electrical Safety Directorate. Failing to do so may void

the warranty.

Exception: Field equipment shall be grounded through the supply cable.

All bare metal wires, screens or others not covered by the terminal shall be

thoroughly covered in a shrink tube to avoid unintended contact between wires,

housing or similar.

Only one conductor is allowed in each terminal of a terminal block/row for

external connections. This is not related to terminals that are integrated parts of

internal components of the equipment (such as relays and contactors).

Also see Appendix D Earthing Methods in Maritime Installations on page 83.

Note! Not following the recommended earthing guidelines may result in unwanted

system behavior.

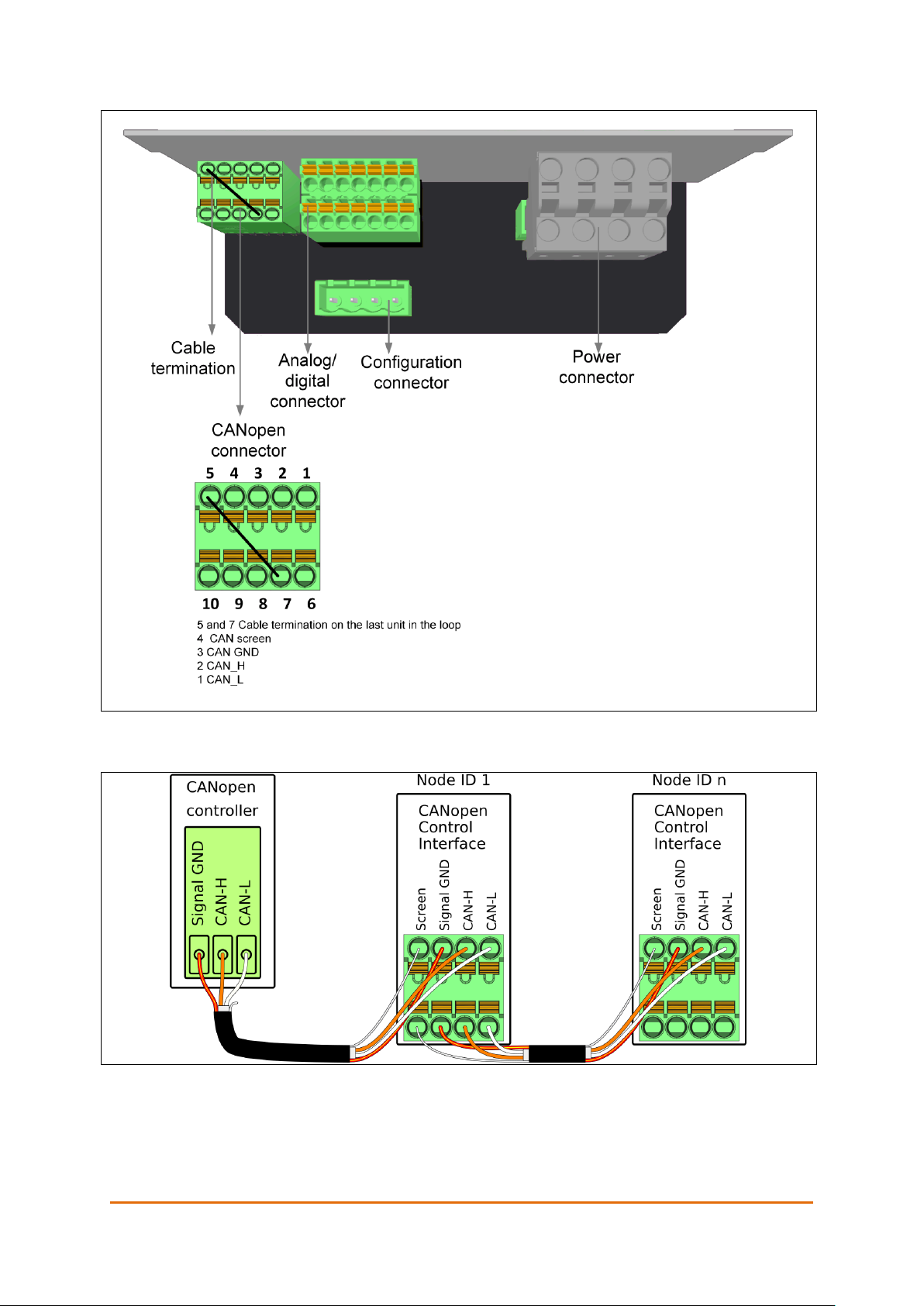

• Strip the wire-end to 8 –9 mm (0.31in – 0.35in).

• Insert the wires according to the labelling.

All terminals can accommodate wires of cross section

0.5 – 2.5 mm2/0.02 - 0.10 in2. The cable must follow the ISO 11898-2 standard.

If ferrules are used the sole responsibility for a correct installation lies on

the installing party.

Note! The cable termination is set on the last unit in the loop by using a 0.75mm

2

wire

and connect pin 5 with pin 7 on the CANopen connector, see Figure 26.

For information on how to set the node ID, please consult the Eltorque E3C

Manual.

Mounting and Installation

Page 40 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Figure 26: CANopen connection interface terminals

Figure 27: Example of CANopen network connections

Mounting and Installation

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 41 of 86

Specifications for IOs are given in chapter 7.2.2 Digital interface on page 51.

Figure 28: Digital connection interface terminals

The digital interface can be used in various control circuits as shown below:

Figure 29: Digital interface options

Caution! The Common input terminal (#1 on X1) is active and has an internal power

supply of 15 V/ 50 mA. Do not attempt to connect an external supply to this

terminal as it can damage the communication interface box. Digital outputs

are passive and need external power supply for operation of equipment.

Mounting and Installation

Page 42 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Specifications for IOs are given in chapter 3.7.1

Figure 30: Analog connection interface terminals

Figure 31: Example of 4-20 mA analog control circuit.

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 43 of 86

Eltorque actuators can be operated in several ways:

• As part of a system directly via IAS.

• Via an Eltorque E-VCS which controls the unit.

• Using the E3C tool, which is described in the EC3 Manual.

• Emergency operation where you can operate the actuator manually.

• Failsafe operation is described in Appendix A on page 59.

The control commands and procedures depend on the type of control system

that is used. In this chapter the manual emergency operation is described.

In case of power failure, control system error or another fault preventing normal

operation of the actuator, it is possible to manually operate the actuator without

the need of additional tools.

Table 10: Input and output torque for handwheel

Input torque on handwheel

Output torque on actuator

QT250

QT800

1 Nm

75 Nm

225 Nm

2 Nm

150 Nm

450 Nm

3 Nm

225 Nm

675 Nm

4 Nm

300 Nm

900 Nm

Note! A manual operation will most likely result in an error message in the system.

1. Remove the hand-wheel cover by grabbing the tabs and pulling it straight

up.

2. Turn the hand-wheel clockwise to close or counter-clockwise to open the

valve. The valve position can be seen on the visual indicator in the center of

the hand-wheel and reference is made to the scale, see Figure 33: Position

scale.

Caution! Do not subject the hand wheel to more than the valve MAST or maximum

4Nm on the handwheel, as you may damage the actuator or valve. Below is

a table showing approximate output torque on input torque.

Operation

Page 44 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

3. When the manual operation is completed, refit the hand-wheel cover by

pressing it down until it stops against the actuator’s top cover.

Figure 32: Manual operation of the actuator

Figure 33: Position scale

The following subsections describe what triggers an alarm, reactions from the

actuator and how the alarm is reset.

• Trigger conditions: One or more of the alarms POSITION UNDEFINED,

TEMPERATURE or TORQUE is active.

• Reaction from actuator: None for the GENERAL alarm itself, but the other

alarms that are active have reactions.

• Reset conditions: The alarms POSITION UNDEFINED, TEMPERATURE and

TORQUE must be inactive.

• Trigger conditions: The outgoing shaft of the actuator is out of range.

• Reaction from actuator: None besides an active alarm.

• Reset conditions: The outgoing shaft must be run back within range.

Operation

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 45 of 86

Valve percent position is a [0%, 100%] value. A value of 0% corresponds to

CLOSED position, while a value of 100% corresponds to an OPEN position. Seen

from the top of the actuator, the outgoing shaft moves in a counter-clock-wise

(CCW) direction from CLOSED position to OPEN position (see Figure 33: Position

scale on page 44.

A position encoder is connected to the outgoing shaft of the actuator and maps

positions from 0° to 359° on the outgoing shaft. For each unit, correct CLOSED

and OPEN positions for the valve must be configured in the firmware of the

actuator for proper functionality.

The position encoder reads out the absolute positional information. This means

that if the outgoing shaft is moved while the actuator is powered off, the correct

position is still shown when the actuator is powered on again.

• Trigger conditions: The alarm is activated when the temperature of the

actuator is near the max operating temperature of the internal electronics.

This may happen if the environmental temperature is higher than the max

rated temperature for the actuator or if the actuator has been run with a

higher duty cycle than specified in section 3.3.

• Reaction from actuator: The voltage to the motor is cut off if the

temperature increases above the max operating temperature of the internal

electronics. The motor can run again when the temperature alarm is inactive.

• Reset conditions: The temperature must decrease well below the max

operating temperature of the internal electronics.

• Trigger conditions: The actuator has been running but has stopped

unexpectedly. This may be caused by too high braking torque on the

outgoing shaft or failure in the motor control and feedback system.

• Reaction from actuator: The actuator stops running.

• Reset conditions: A new position command (OPEN, CLOSE, GOTO, STOP).

The motor can then run again, given that the trigger conditions for the alarm

has disappeared.

Operation

Page 46 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

The Eltorque actuator is a robust maintenance-free product, but you might

encounter some issues with the unit. Below is a list of the most common issues

that may occur and how to solve them. If you still have problems, please contact

Eltorque support for further help.

Table 11: Troubleshooting overview

Problem description

Cause and solution

No response from the actuator either on the

control system or if you connect with E3C.

No change in resistance on the hand wheel if

you cycle the power supply.

No power supply, check fuses and wiring.

Supply voltage can be checked using a voltage

meter.

L-N voltage should be 1-phase,110 – 240V AC,

50/60 Hz, Max 240 VA.

The actuator’s alarm output is active, on a bus

system it gives torque alarm.

The actuator attempts to move valve when a

control signal is given.

The valve operation torque is too high, please

check the torque by manual operation.

Be aware that foreign objects in the pipe can

block the valve and that valve torque changes

over time.

OR

The actuator torque has been set too low,

increase it by using the E3C configuration

software as described in the Eltorque E3C

Manual.

On bus control systems, torque can be adjusted

via the bus communication.

The actuator can operate the valve, but the

operation time is longer or shorter than desired.

Change the actuator’s speed by using the E3C

configuration software as described in the

Eltorque E3C Manual.

On bus control systems, speed can be adjusted

via the bus communication.

The actuator’s alarm output is active, on a bus

system it gives temperature alarm.

The actuator responds normally to control

signals.

The actuator’s internal temperature is

10 C/50 F or less from the motor current shut-

down limit.

If possible, allow the actuator to cool down by

leaving it in standby mode for 15 minutes or

more.

The actuator’s alarm output is active, on a bus

system it gives torque alarm.

The actuator responds only with a small position

change

The encoder cable is not properly connected or

could be damaged. Check the cable and

connector for corrosion or damage.

The actuator’s alarm output is active, on a bus

system it gives temperature alarm.

The actuator does not respond to control

signals.

The actuator has over-heated and the motor

current is shut down to prevent damage.

Make sure the surrounding temperature is within

limits and that the duty type requirements are

followed. See section 3.3Technical specification

on page 19 for more details.

The actuator with bus interface does not

respond to control signals.

The actuator responds normally when tested

with E3C.

Incorrect bus settings, please check the

configuration described in the Eltorque E3C

Manual.

OR

Bus control system is not wired or configured

correctly.

Operation

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 47 of 86

Problem description

Cause and solution

The actuator with digital or analog interface

does not respond normally to control signals.

The actuator responds normally when tested

with E3C.

Incorrect digital or analog inversion settings,

please check the configuration described in the

Eltorque E3C Manual.

OR

The digital or analog control system is not wired

or configured correctly.

The actuator does not respond neither to control

signals nor when tested with E3C.

Restart the actuator (power on/off).

Verify the power supply with a voltage meter. If

the power is OK, the communication interface

box is defect and must be replaced.

After replacement of interface, the actuator does

not operate correctly.

The interface has not been configured correctly,

please refer to chapter 3.8 Configuration.

Contact the local Eltorque agent for support if

required.

Operation

Page 48 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

This page is left intentionally blank

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 49 of 86

The QT250 and QT800 actuators are in principle maintenance-free. All bearings

and gears are lifetime lubricated and components are designed to last

throughout the actuator’s lifetime. It is however recommended that the actuator

is inspected regularly to reveal any damages caused by for example mechanical

impact or corrosion.

• Inspection

• Lubrication

• Care and cleaning of anodizing

• Maintenance of battery in a Failsafe system, see chapter B.8 Maintenance on

page 74.

• The actuators should be regularly inspected once a year:

- Check that the bolts connecting the actuator and valve together are

fastened according to required torque.

- Check that the top cover gasket and operation shaft are lubricated. If they

seem to be dry, follow the procedure in 6.4.

- Check for corrosion or other physical damage.

- Perform a test run for each actuator from the control unit.

• If the actuator has been submerged to sea water, Eltorque recommends that

the unit is inspected for damage by Eltorque qualified personnel.

See Appendix C Torque and Screw Recommendations on page 81.

The top cover gasket and manual operation shaft seal should be lubricated if

they appear to be dry. Use suitable silicone lubricants for O-rings such as

MOLYKOTE 55 O-RING grease or Super Lube silicone lubricating compound.

For cleaning purposes use organic solvents such as mild soap or detergent,

alcohol, acetone or MEK (methyl ethyl ketone).

Caution! Do not use ammonia, alkaline cleaners, lye or strong acid for cleaning

Caution! Do not use high pressure power washer directly on the actuators as the

product is not IP69K rated.

Maintenance

Page 50 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

This page is left intentionally blank

User Manual QT250 and QT800, ID 2021 2.0 July 2018

Page 51 of 86

Eltorque actuators have been designed to withstand harsh environments. All

products have undergone and passed severe 700 hrs. salt mist tests according to

DNVGL-CG-0339. Different types of surface treatment have been used.

Aluminum parts are typically anodized or CED coated, and steel parts are treated

with Dacromet and painted.

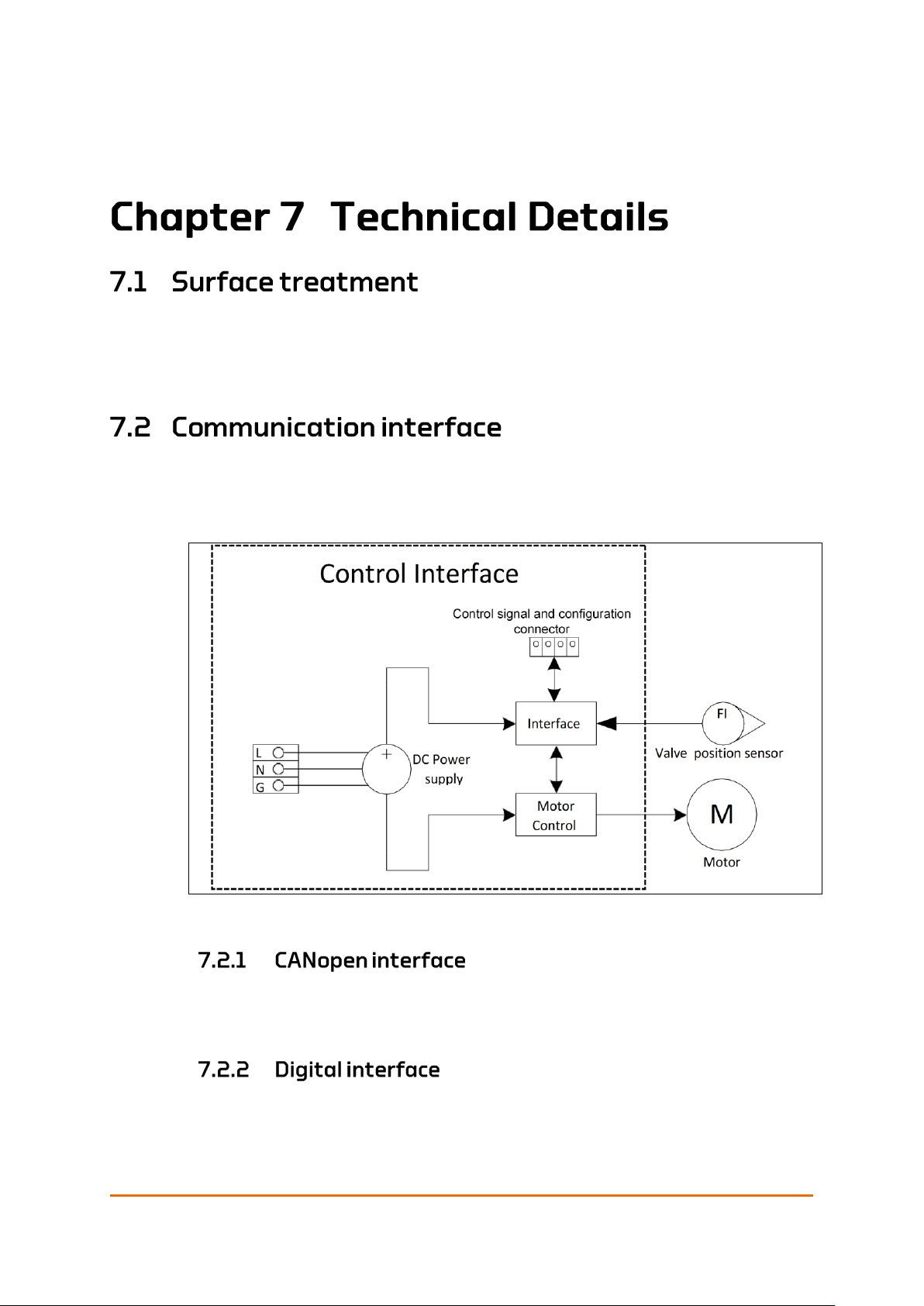

The Eltorque communication interface consists of three main modules:

1. Power supply

2. Motor control

3. Interface

Figure 34: Communication interface schematics

For more technical information about the Eltorque CANopen communication,

refer to the “System Integrators Manual CANopen interface” ID 1691.

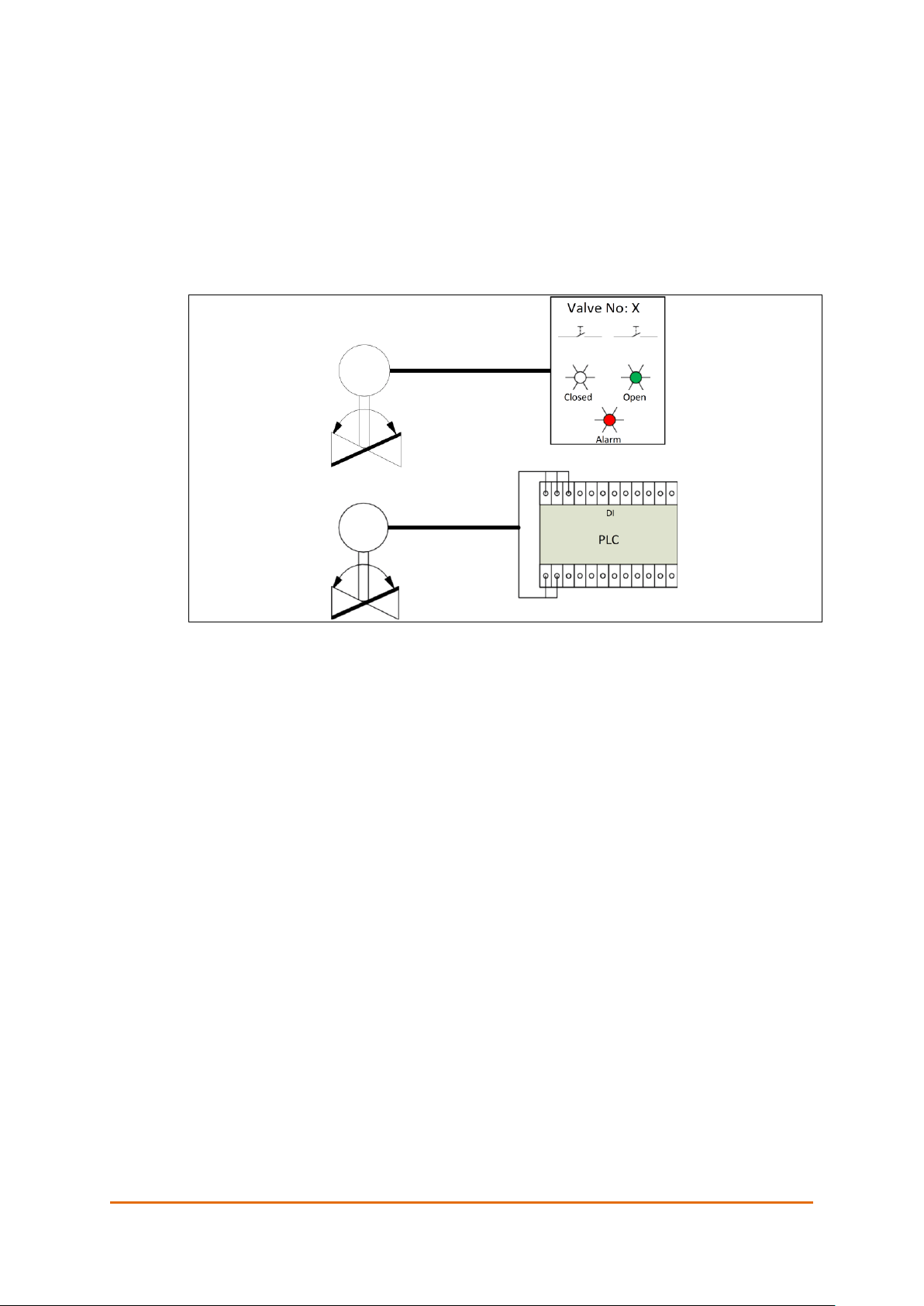

The following functions are available:

• CLOSE and OPEN command (inputs):

Technical Details

Page 52 of 86

User Manual QT250 and QT800, ID 2021 2.0 July 2018

- Is trigged by a positive edge followed by an active signal for at least 100

Ms.

- The actuator stops and sets ALARM status if OPEN signal is activated

during a CLOSE command, or CLOSE signal is activated during an OPEN

command.

• CLOSED signal and OPEN signal (outputs)

• ALARM signal (output)

- Activated if GENERAL ALARM is triggered.

Figure 35: Digital control using buttons and lamps or PLC