Elterm goldline asd-w, goldline asdc-w, goldline aszn-w, goldline asbii, redline ashn Operating And Assembly Manual

...

1

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

Operating and assembly manual:

electric tankless water heater for central heating systems

(Electric heating boiler)

GoldLine series:

RedLine series:

AsZN-W (Pułkownik/Uranus/Urano)

AsD-W (Generał/Neptune/Nettune)

AsDC-W (Marszałek/Pluto/Plutone)

AsBII (Bateria/Sun/Sole)

AsHN (Hetman/Moon/Luna)

AsBIV (Dywizja/Galaxy/Galassia)

Please see video prior installation

2

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

DIMENSIONS AND COMPONENTS OF ELECTRIC HEATING BOILERS

(for more detailed pictures please see www.elterm.pl)

Dimensions and components of AsD-W boiler

Dimensions and components of AsZN-W boiler

Dimensions and components of AsBII boiler

Dimensions and components of AsDC-W boiler

Dimensions and components of AsDC-W boiler

3

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

APPLICATION

All GoldLine and RedLine heating boilers are designed to provide heating to small and medium sized

locations equipped with either open or closed low-temperature (T<100°C) central heating water systems.

AsZN-W and AsHN boilers in closed central heating system – those models are designed for autonomous

operation in both open and closed central heating systems – safety unit, expansion vessel and circulation

pump are included.

AsD-W boiler in closed central heating system – this model is designed for autonomous operation in both

open and closed central heating systems – safety unit, expansion vessel and circulation pumps are

included. Additional hot utility water tank with coil (at least 12kW) is needed for proper boiler operation.

AsDC-W boiler in closed central heating system – this model is designed for autonomous operation in both

open and closed central heating systems – safety unit, expansion vessel and circulation pumps are

included. Boiler is build-in on top of 100l hot utility water tank equipped with 29kW coil.

AsBII and AsBIV boilers in closed central heating system - in closed type layout, the central system needs to

be equipped with an expansion vessel, which is not supplied with above models.

1. External metal cast

2. Mounting plate

3. Automatics mounting bracket

4. LED display

5. Control panel

6. Room thermostat connection strip

7. Boiler body

8. Boiler insulation

9. Heating unit

10. Automatic air vent ⅜’’

11. Terminal strip

12. Relays

13. Feed pipe ¾’’ (1’’ in AsBII and AsBIV)

14. Return pipe ¾’’ (1’’ in AsBII and AsBIV)

15. Electronic pump for C.H.

16. Safety valve 3 bar

17. Manometer 4 bar

18. Expansion vessel 8l

19. Return pipe ¾’’ for D.H.W. (in AsD-W only)

20. Electronic pump for D.H.W. (in AsD-W and

.AsDC-W only)

21. Switch ignition

22. Solar air vent

23. Industrial SSR relays

24. Metal manometer 4 bar

Dimensions and components of AsHN boiler

Dimensions and components of AsBIV boiler

4

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

HYDRAULIC ASSEMBLY

All GoldLine and RedLine boilers are hanging (except AsDC-W), vertical devices and

after taking down external metal cast, should be hung on the wall using attached

mounting screws.

Electric heating boiler has to be connected to the central heating system using

couplings (¾”, 1” or 1¼” – depending on model) according to the direction of water

flow (see glued arrows on boiler). Connection to be made in accordance with PN91/B-02413 (open systems), PN-91/B-02414 (closed systems) or applicable

regulations valid in the country of installation. Central heating system has to be

thoroughly flushed prior installation. Non-return valves (see upper picture on the

right) are mandatory for proper AsD-W boiler operation (not supplied with boiler).

For AsDC-W (see bottom picture on the right) one-way valves for C.H. and D.H.W.

are factory assembled. Legend: 1 – C.H. feed, 2 – D.H.W. feed, 3 – circulation, 4 –

cold water inflow, 5 – C.H. return.

ELECTRICAL ASSEMBLY

Connection to the electrical system needs to be done in accordance with regulations applicable in the

country where the given boiler is installed and therefore must be done by a qualified electrician only.

Boilers are designed for alternating current, 3-phase power supply (400V 3N~50Hz). Models with 4, 6, 9, 12

and 15kW powers are also available without any processing in 1-phase version (230V 1N~50Hz), greater

powers can also be prepared in 1-phase version upon request. Boiler’s power supply is connected to

terminal strip labeled as L1L2L3N or to switch ignition (for AsBII, AsHN and AsBIV). PE wire needs to be

connected to screw on mounting plate. Technical data table (below) provides information on the crosssection connecting power cord, the applicable parameters of the main fuse protecting boiler, as well as

estimated heated areas for main and alternative heating source. Boiler should be connected to permanent

electrical system via device enabling boiler’s disconnection from heating source at all ends, with the

distance between contactors not less than 3mm.

BASIC DATA

Connection strip (sensors)

A – CH measurement (CH)

B – connection to hydraulic balancer (BAL)

C – CH measurement (CH) - option

D – D.H.W. measurement (HUW)

E – inside/room temp. measurement (ROOM)

F – outside temp. measurement/weather compensation (WEAT)

G – outside thermostat/room temp. measurement

H – outside thermostat – D.H.W. temperature measurement

Please familiarise yourself with the electrical and hydraulic diagram and technical

data prior to assembly.

5

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

Connecting inside (room) and outside (weather compensation) temperature sensors

Inside temperature sensor is connected to boiler by 2-strand wire using terminal E, outside temperature

sensor using terminal F, wire is not included.

LED display, signaling system and control

Technical data table

Boiler

power

Manual power

distribution (%)

Power

modulation

Power supply

230/400V

Safety

fuses (A)

Power cord

(mm²)

Heated area A

(m²)*

Heated area B

(m²)**

4 kW

100 – 67 – 33

by 1/3

1 phase

1 x 20

3 x 2,5

~ 50

~ 70

4 kW

100 – 67 – 33

by 1/3

3 phases

3 x 6

5 x 1,5

~ 50

~ 70

6 kW

100 – 67 – 33

by 1/3

1 phase

1 x 32

3 x 4,0

~ 70

~ 100

6 kW

100 – 67 – 33

by 1/3

3 phases

3 x 10

5 x 2,5

~ 70

~ 100

9 kW

100 – 67 – 33

by 1/3

1 phase

1 x 40

3 x 10,0

~ 110

~ 150

9 kW

100 – 67 – 33

by 1/3

3 phases

3 x 16

5 x 2,5

~ 110

~ 150

12 kW

100 – 67 – 33

by 1/3

1 phase

1 x 63

3 x 10,0

~ 150

~ 210

12 kW

100 – 67 – 33

by 1/3

3 phases

3 x 20

5 x 4,0

~ 150

~ 210

15 kW

100 – 67 – 33

by 1/6

1 phase

1 x 80

3 x 10,0

~ 180

~ 250

15 kW

100 – 67 – 33

by 1/6

3 phases

3 x 25

5 x 4,0

~ 180

~ 250

18 kW

100 – 67 – 33

by 1/6

3 phases

3 x 32

5 x 6,0

~ 220

~ 310

21 kW

100 – 67 – 33

by 1/6

3 phases

3 x 40

5 x 6,0

~ 260

~ 360

24 kW

100 – 67 – 33

by 1/6

3 phases

3 x 40

5 x 10,0

~ 300

~ 400

27 kW

100 – 67 – 33

by 1/6

3 phases

3 x 50

5 x 16,0

~ 220 - 380

30 kW

100 – 67 – 33

by 1/6

3 phases

3 x 50

5 x 16,0

~ 240 - 400

33 kW

100 – 67 – 33

by 1/6

3 phases

3 x 50

5 x 16,0

~ 260 - 450

36 kW

100 – 67 – 33

by 1/6

3 phases

3 x 63

5 x 16,0

~ 280 - 480

39 kW

100 – 67 – 33

by 1/6

3 phases

3 x 80

5 x 25,0

~ 290 - 500

42 kW

100 – 67 – 33

by 1/6

3 phases

3 x 80

5 x 25,0

~ 300 - 520

45 kW

100 – 67 – 33

by 1/6

3 phases

3 x 80

5 x 25,0

~ 320 - 570

48 kW

100 – 67 – 33

by 1/6

3 phases

3 x 80

5 x 25,0

~ 340 - 600

* A – Heated area A – boiler as main source of heat ** B – Heated area B – boiler as alternative source of heat

Exact cable cross section must be matched by qualified electrician based on local conditions analysis.

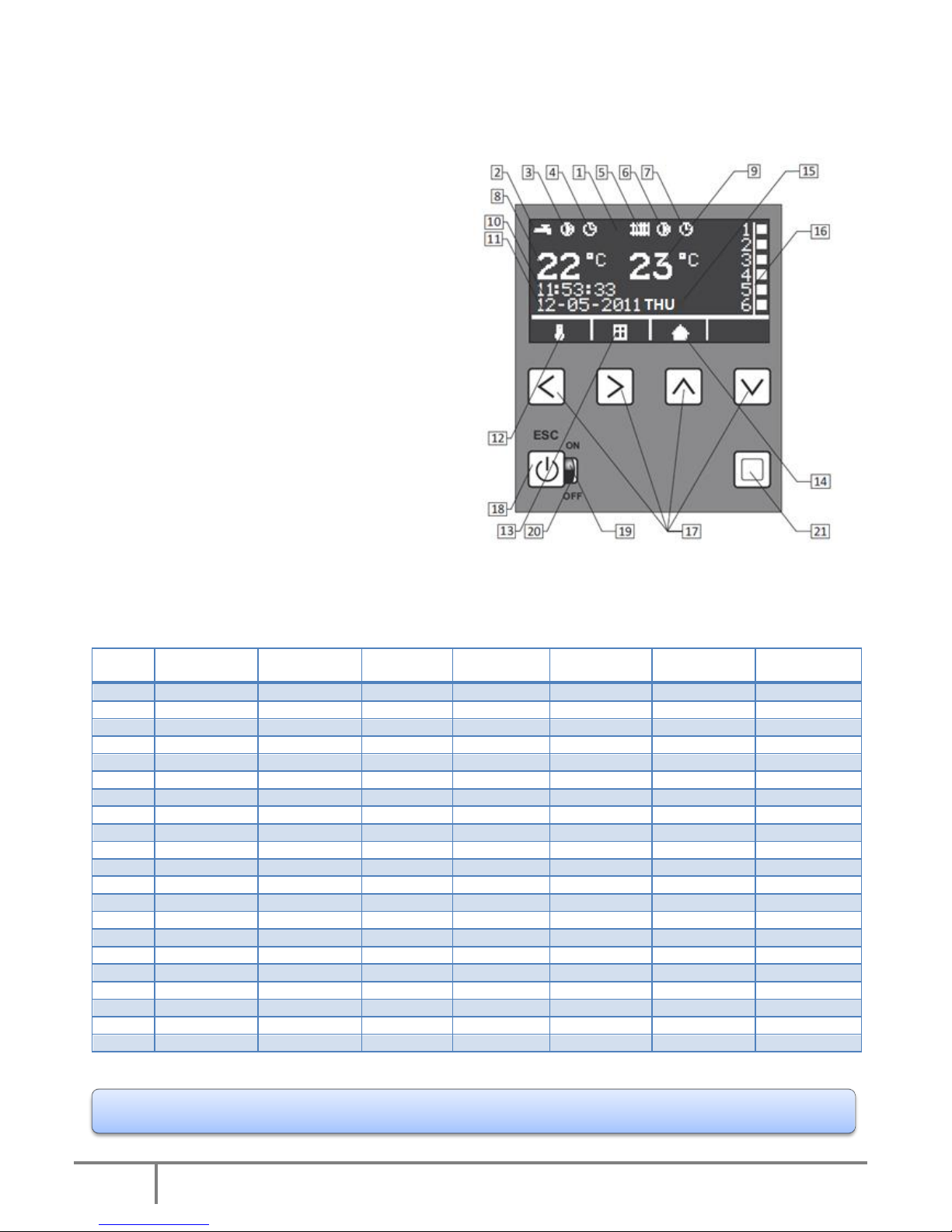

1. LCD screen

2. D.H.W. signal icon

3. D.H.W. pump active icon

4. D.H.W. program active icon

5. C.H. signal icon

6. C.H. pump active icon

7. C.H. program active icon

8. Current D.H.W. temperature

9. Current C.H. temperature

10. Time

11. Date

12. C.H. and D.H.W. temperature setting icon

13. Weather compensation icon

14. Room temperature icon

15. Weekday

16. Relays status

17. Function buttons (symbols ←→↑↓)

18. ON/OFF + return button

19. Green diode – boiler turned on

20. Red diode – boiler turned off

21. Choose button

6

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

PROGRAMMING

Basic settings (multiple pressing of causes return to main menu)

Boiler is on, in stand-by mode – red diode is visible (no 20 on display) – recommended mode in summer

season. For 5 seconds press , what should cause green diode to light (no 19). Using ↑↓ please choose

available language (A)(Polish, English, German, French – depending on program version), confirm with ←.

Display now shows „Venting” and progress bar (B), which counts down 5 minutes needed for all essential

activities to vent boiler, pump and whole installation. This function cannot be skipped. In the meantime

C.H. pump is activated (additionally D.H.W. pump for AsDC-W, optionally for AsD-W), and there is no

possibility do turn heaters on. Pre-set venting time should be sufficient to carry out the process, if however

it is not enough – whole procedure needs to be repeated by turning boiler off and on again.

The display switches to the home screen (C).

C.H. and D.H.W. (for AsD-W i AsDC-W) temperature setting – enter function from home screen (C) by

pressing ←, using ↑↓ choose either C.H. or D.H.W. (D). Press to enter temperature setting (E)(F), then

using ↑↓ increase or decrease parameter value. The choice is set by pressing .

Weather compensation curve (G) – enter function from home screen (C) by pressing →, using ↑↓ choose

weather compensation curve from 0 to 10. Curves operate for outside temperatures lower than 15°C, with

Make sure the boiler is connected to electrical system in accordance with hydraulic and electrical

assembly section, all valves on radiators shall stay completely open.

7

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

zero meaning no compensation. In standard operation mode, boiler maintains preset temperature

increased by adjustment parameter in accordance with below table.

For every outside temperature degree below 15°C, adjustment parameters are as follow:

K=1

0,1°C

K=3

0,3°C

K=5

0,5°C

K=7

0,7°C

K=9

0,9°C

K=2

0,2°C

K=4

0,4°C

K=6

0,6°C

K=8

0,8°C

K=10

1,0°C

Example (H): Curve is set on K=5 with boiler preset temperature 30°C. For outside temperature over 15°C,

boiler maintains 30°C. When it cools down to 5°C, adjustment will estimate: 10 x 0,5 = 5°C (degrees below

15°C x value for K=5), so the boiler will maintain 35°C; when it’s -5°C, adjustment will estimate 20 x 0,5 =

10°C, so the boiler will maintain 40°C, etc.

Room temperature setting on boiler (I) - enter function from home screen (C) by pressing ↓, using ↑↓

change preset room temperature in range 5-30°C.

Detailed settings (multiple pressing of causes return to main menu)

Menu structure (J, K, L):

1. Settings

1.1. Power

1.2. Sections

1.3. Date & time

1.4. PID-P

1.5. Hysteresis CO

1.6. Hysteresis CWU

1.7. Default settings

1.8. Room programs

1.9. DHW programs

1.10. Circulation pump

1.11. Circulation time

2. Energy consumption

3. Venting

1.1. Settings/Power – press on home screen (C) and enter SETTINGS (J), then choose Power (K) and

press once more. Using ↑↓ change boiler power in range 33/66/100% (M). The choice is set by pressing

.

1.2. Settings/Sections – press on home screen (C) and enter SETTINGS (J), then choose Sections (K) and

press once more. Using ↑↓ switch between C.H. and D.H.W. (N). Press to enter chosen section and

using ↑↓ switch between active (ON)(O) and inactive (OFF)(P) status. The choice is set by pressing .

8

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

1.3. Settings/Date & time – press on home screen (C) and enter SETTINGS (J), then choose Date & time

(K) and press once more. Using ←→ (R) switch between hour, date, weekday, and then using ↑↓

change parameters values, which are set by pressing .

1.4. Settings/PID-P – press on home screen (C) and enter SETTINGS (J), then choose PID-P (K) and press

once more. Using ↑↓ (S) change parameter value, which is then set by pressing . Attention: In case

boiler needs long time to reach set temperature – correct parameter value is 4 or 5, for too quick operation choose 1 or 2.

1.5. Settings/CH Hysteresis – press on home screen (C) and enter SETTINGS (J), then choose CH

Hysteresis (K) and press once more. Using ↑↓ (T) change parameter value (range 1-2-3-4-5-6), which is

then set by pressing .

1.6. Settings/DHW Hysteresis – press on home screen (C) and enter SETTINGS (J), then choose DHW

Hysteresis (L) and press once more. Using ↑↓ (U) change parameter value (range 1-2-3-4-5-6), which is

then set by pressing .

1.7. Settings/Default settings – press on home screen (C) and enter SETTINGS (J), then choose Def.

settings (L) and press once more. Using ← (W/Y) resign from default settings (NO), → agree on those

settings (YES), ↑ activate settings. - confirm choice.

Default settings

DHW temperature.......................................... 50°C

CH temperature................................................ 50°C

Power....................................................................... 100%

DHW sections..................................................... ON

CH sections............................................................ ON

PID-P........................................................................... 3

CH hysteresis........................................................ 6

DHW hysteresis.............................................. 7

9

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

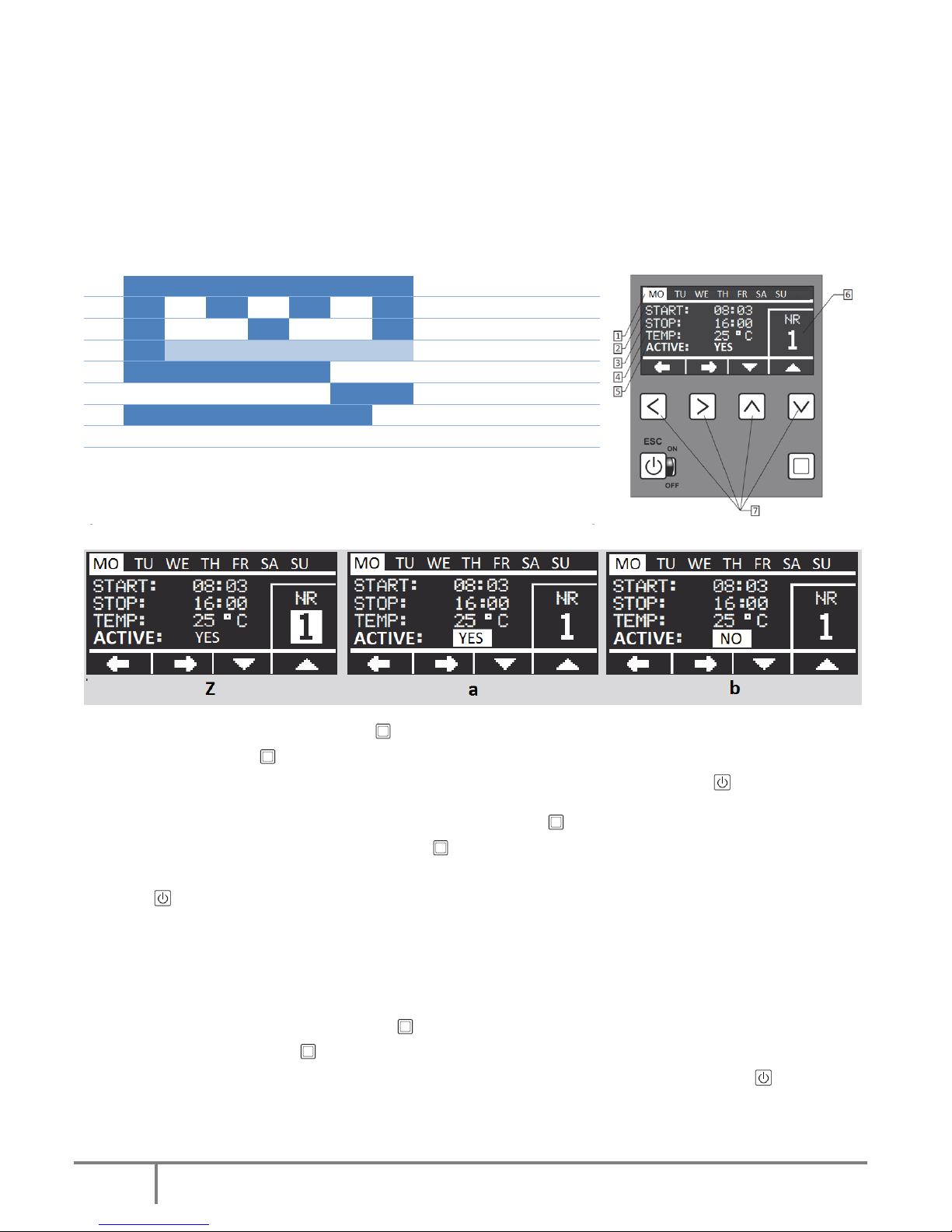

Room and DHW programs - settings

Room and DHW programs enable setting and maintaining requested temperature at any defined time

periods with one minute accuracy. Intuitive menu and illuminated display make the programming process

easy. All settings are stored in non-volatile memory and are not deleted even in case of a power off.

Electronic processor enables setting 9 independent programs, each can define requested temperature

within any given time span.

When two different temperatures from different programs overlap, higher one is prioritized.

I

MO

TU

WE

TH

FR

SA

SU

Active days: all

II

MO WE FR SU

Active days: 4

III

Mo

TH

SU

Active days: 3

IV

MO

TU

WE

TH

FR

SA

SU

Active day: 1 (to choose)

V

MO

TU

WE

TH

FR

Active days: working days

VI SA

SU

Active days: weekend

VII

MO

TU

WE

TH

FR

SA Active days: 6

VIII Active days: any

IX Active days: any

1. Weekdays, 2. Program start, 3. Program stop, 4. Temp. setting: 20-70°C,

5. Active: yes/no, 6. Program number: from 1 to 9, 7. Function buttons

1.8. Settings/ROOM programs – press on home screen (C) and enter SETTINGS (J), then choose Room

programs (L) and press once more. Using ←→ (Z) switch between parameters (weekdays, working time,

temperature, status), using ↑↓ change parameter value, which is then set by pressing .

1.9. Settings/DHW programs (for AsD-W and AsDC-W) – press on home screen (C) and enter SETTINGS

(J), then choose DHW programs (L) and press once more. Using ←→ (Z) switch between parameters

(weekdays, working time, temperature, status), using ↑↓ change parameter value, which is then set by

pressing .

Active/Inactive status – each program can be temporarily turned off. In order to do that, change status

within selected program (either Room or DHW one) for: no (b). To activate previously turned off program –

set status for: yes (a).

1.10. Settings/Circulation pump – press on home screen (C) and enter SETTINGS (J), then choose

Circulation pump and press once more. Using ←→ switch between parameters (weekdays, working

time, temperature, status), using ↑↓ change parameter value, which is then set by pressing .

10

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

1.11. Settings/Circulation time – press on home screen (C) and enter SETTINGS (J), then choose

Circulation time and press once more. Using ↑↓ change parameter value, which is then set by pressing

.

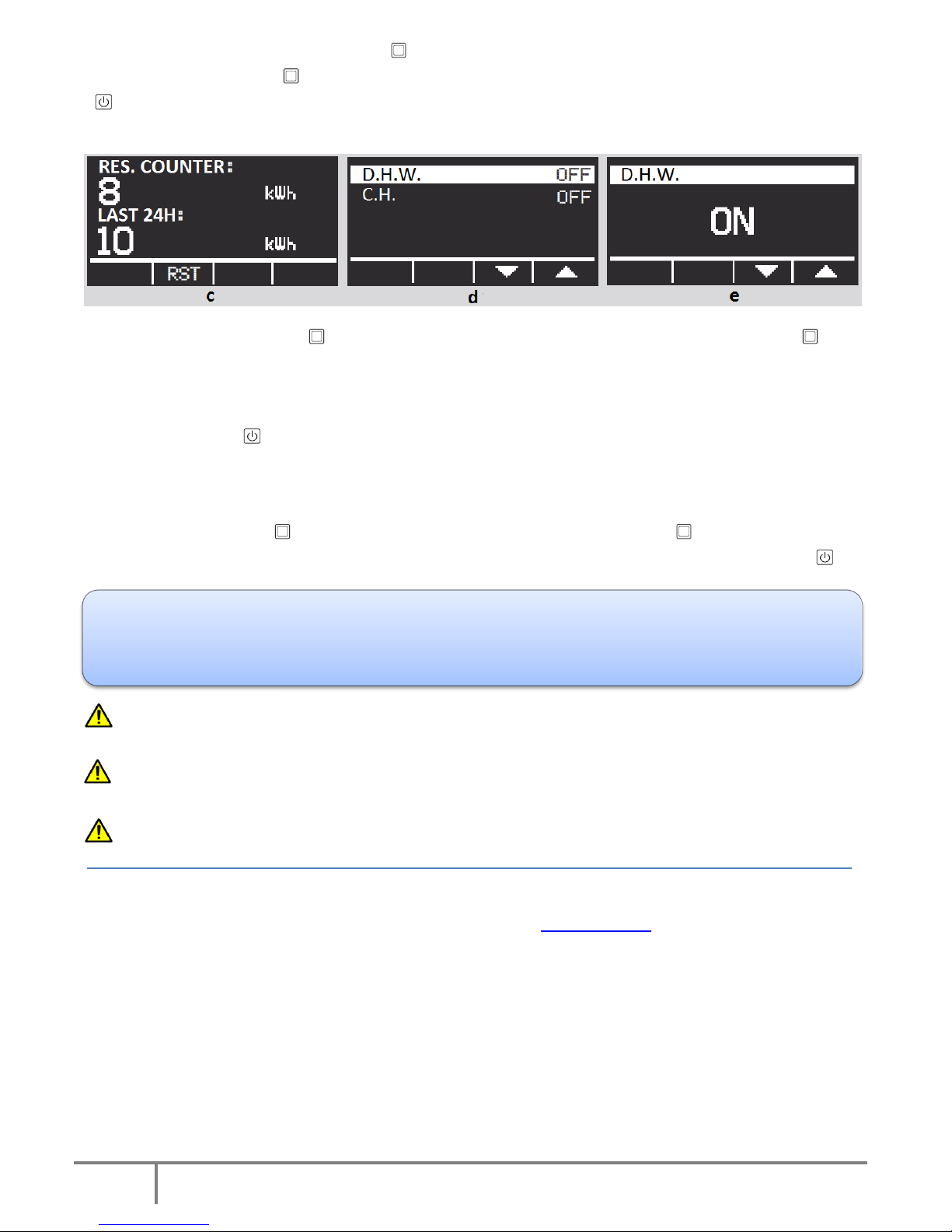

2. Energy consumption - press on home screen (C) and enter ENERGY CONSUMPTION (J). Press once

more to display energy consumption counters (c). Using → reset erasable counter (RES. COUNTER) – which

shows consumed energy in kWh since measurement start till any given moment within 24h time span. After

24 hours, counter stops automatically. LAST 24H – calculates energy consumption over the last 24 hours

with 20 min. updates. - return.

3. Venting – function enables additional system venting without turning boiler off. Proper system venting

guarantees its correct and prolonged, faultless operation. Function also enables to check proper

pump/pumps work. Press on home screen (C) and enter VENTING (J). Press once more to display

D.H.W./C.H. options (d). Using ↑↓ change parameter value- ON/OFF (e), which is then set by pressing .

Do not remove boiler external metal casing once device remains turned on.

In case boiler is activated by mistake with no water inside, wait until heaters cool down, fill device with

water and switch it on again. Under no circumstances fill device with cold water with heaters still hot!

Once water in central heating system is heated, system should be bled once again (special attention

must be paid to the bleeding of the central heating pump and boiler air vent).

For more information please visit www.elterm.pl

Elterm boilers are equipped in AntiStop function. Automatics turns the pump on for one minute once

every 14 days, what prevents it's rotor from seizing. AntiStop operates independently from on/off mode. It

is therefore highly recommended to keep boiler in off mode (red diode visible) in off-heating season - in

this mode device uses just 0,5W!

11

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

Declaration of conformity CE - EN3/2016

Elterm M.M.Kaszuba Sp.j., ul Przemysłowa 5, 86-200, Chełmno, Polska

We herewith declare, under our sole responsibility, that the following products: Tankless water heater for central heating

systems (electric central heating boiler) type EKW As:

Variants:

~ 230V,50Hz, max.power 4kW, 6kW, 9kW,12kW, 15kW, 18kW, 21kW and 24kW

3N~400V,50Hz, max.power 4kW, 6kW, 9kW,12kW, 15kW, 18kW, 21kW, 24kW, 27kW, 30kW, 33kW, 36kW, 39kW,

42kW, 45kW, 48kW and boiler cascades 1,5MW (each boiler up to 48kW)

Models: AsPC, AsP, AsBN, AsZN, AsD, AsBI, AsZN-W, AsD-W, AsDC-W, AsBII, AsHZ, AsHN, AsBIII, AsBIV, AsMB, manufactured at

the Elterm production plant, are in conformity with the applicable provisions of the following EC Directives:

Number

Title

2006/95/WE as amended

Low Voltage Directive (LVD)

2004/108/WE as amended

Electromagnetic Compatibility Directive (EMC)

2002/95/WE as amended

Directive on the restriction of the use of certain hazardous substances in

electrical and electronic equipment (RoHS)

2002/96/WE as amended

Directive on waste electrical and electronic equipment (WEEE), GIOŚ

register number E0001767

ErP 2009/125/WE

General rules for setting requirements concerning Ecodesign for energy

related products (Attachment 13)

EU Commission regulation nr 622/2012

With regard to Ecodesign requirements for glandless standalone

circulators and glandless circulators integrated in products

and that the standards hereinafter referred to have been duly applied and observed. The harmonized standards applicable to

the product to which this declaration of conformity pertains:

Number

Issue

Title

PN-EN 60335-1

2006 (U) as amended

Safety of household and similar devices

PN-EN 60335-2-35

2007 (U) as amended

Particular requirements for tankless water heaters

PN-EN 55014-1

2002 as amended

Interference emission for domestic appliances

PN-EN 55014-2

2004 as amended

Interference immunity

PN-EN 61000-3-2

2004 as amended

Harmonic current emissions

PN-EN 61000-3-11

2000 as amended

Limitation of voltage fluctuations and flicker in low-voltage

supply systems

PN-EN 50366

2006 (U) as amended

Electromagnetic fields- methods for evaluation and

measurement

Other documents or information required by the EC Directives:

Report number:

Laboratory:

B-47/03

KEWA – ECO, Bydgoszcz

CLBT/ZR/67/2003

GP – CLBT, Warszawa

456/BS/EMC/04

PREDOM – OBR, Warszawa

BE/39/2006

Laboratorium Elektrotechniczne PCBC S.A.

BEM-66/07

Laboratorium Badawcze Maszyn i Urządzeń J.N.B. EUROVITA Sp. z o.o.

B-71/07

Laboratorium Badawcze Maszyn i Urządzeń J.N.B. EUROVITA Sp. z o.o.

Chełmno, July 19th 2016

12

Elterm M.M.Kaszuba Sp.J., ul. Przemysłowa 5, 86-200 Chełmno

Boiler’s type, serial number, production date

Date of sales

Legible stamp of a retail outlet and signature

Unless the above stamps are present the guarantee is invalid

GUARANTEE

1. Guarantee for trouble-free operation is valid for a period of 24 months (12 months for AsMB).

2. Guarantee expires if any alterations are made to the product without the manufacturer’s consent, or if assembly or use are

not in accordance with the enclosed operation manual and terms and conditions of guarantee.

3. Guarantee repairs are made by the manufacturer or persons/companies authorized by the same.

4. If filled out incompletely, the guarantee is invalid.

5. If the serviceperson discovers machine failure resulting from the user’s fault (e.g. improperly made wiring system, air-locked

central heating system, use or assembly that is not in compliance with the user manual etc.), or in the event the guarantee is

invalid, the costs of repair and travelling are borne by the claimant.

6. Failure on the part of the user to follow the serviceperson’s recommendations provided in the guarantee repair protocol

results in the guarantee being suspended until such recommendations are implemented.

Do not call servicemen without becoming fully familiarized with the boiler user manual, as well as conditions of guarantee

and assembly. Before you call service, read the section „TROUBLESHOOTING.

Stamp of serviceman, short description of repair and recommendations for the user

Following guarantee repair by the serviceman, one of the below guarantee coupons to be cut off, filled out and handed to the serviceman

Guarantee coupon I

…………………………….……………………………………………………………………………………………………………………………

Full name and address of the boiler owner

…………………………….……………………………………………………………………………………………………………………………

Postal code, town /Boiler owner tel. no.

…………………………….………………………………………… …………………………………………………………

Production date Boiler serial no.

Guarantee coupon II

…………………………….……………………………………………………………………………………………………………

Full name and address of the boiler owner

…………………………….……………………………………………………………………………………………………………………………

Postal code, town /Boiler owner tel. no.

…………………………….………………………………………… …………………………………………………………

Production date Boiler serial no

Loading...

Loading...