Eltek Smartpack2 User Manual

350020.013

Monitoring and Control Units

Powerpack, Flatpack2 & Minipack

DC Power Supply Systems

User's Guide

Smartpack2 Master Controller

1 Introduction

2 User's Guide Smartpack2 Master Controller 350020.013, Issue 2.0, 2014 Jan

DC Power Supply Systems

SAFETY and ENVIRONMENTAL PRECAUTIONS

The product warranty becomes invalid if the following safety precautions are not followed during handling,

installation, commissioning and general use/operation of Eltek DC power supply system.

General Precautions

CAUTION: Even though the product incorporates protection circuitry and other safeguards, it can be damaged, perform

poorly or have a reduced lifetime if it is exposed to incorrect treatment during transport, installation or service.

Always handle the equipment using proper lifting techniques, do not roll, climb or drill hole in the cabinets or enclosures.

WARNING: Opening the equipment may cause terminal injury — even if the mains AC supply is disconnected.

Hazardous voltages may be present inside, as large capacitors may still be charged.

Device

Hazard

!

Electric

Shock

G1

G2

Environmental Precautions

CAUTION: To avoid damage the equipment, keep objects clear of system ventilation inlets, outlets and system fans,

if any, ensuring the airflow through the units is not obstructed, and that the fans rotate freely. Use caution with rectifiers,

as they can reach extreme temperatures under load and normal operation.

WARNING: The installer/user is responsible for ensuring that the DC power system is not damaged by current

surges, over-voltages, etc. caused by external transients, lightning, electrostatic discharge, etc. To avoid damage

and obtain the expected system reliability, it is mandatory to always install SPDs in Eltek’s power supply systems.

Follow the instructions given in “Guidelines for Lightning and Surge Protection”, doc. 2024623.

WARNING: The electronics in the power supply system are designed for indoor, clean environment. When

installed in outdoor enclosures, it is important to keep the door closed during operation, and replace the filters on a

regular basis. Indoor installations in dusty or humid areas require appropriate air filtering of the room, or

filtering of the air entering the DC power system. Follow the instructions given in “Generic Guidelines

Environmental Protection.”, doc. 2038879.

Ventilated

Hot Surface

Humidity & Dust

Protection

Current Surge

Protection

E2

E1

E3

CAUTION: This product is tested and verified according to international safety, environmental and EMC standards. Any

non-Eltek equipment installed into this product after delivery might influence the performance and could infringe the

original approvals. The installer is responsible for ensuring that the environmental properties of this product/ system do

not deteriorate during installation, and that it is performed in accordance with applying regulations.

Installations in USA and Canada must comply with NEC/CEC requirements.

Precautions during Installation

CAUTION: Read the user documentation carefully before installing and using the equipment, as installation and

operation is to be performed as described in it. Always tighten screws and bolts with the torque values recommended in

the documentation. For safety reasons, the commissioning and configuration of the equipment is only to be performed

by Eltek’s personnel or by authorized and qualified persons.

CAUTION: Before you start the electrical installation, you must always disconnect all external AC supply fuses, as well

as internal battery and load fuses/ breakers, if any.

WARNING: For safety reasons (high leakage current / high touch current) you must always connect the AC earth

wire (PE) to the terminals, before you connect the AC input cable(s).

The batteries, if any, represent a major energy hazard. To avoid short-circuit of battery poles, you must always

remove metallic objects — uninsulated tools, rings, watches, etc. — from the vicinity of the batteries.

WARNING: 60V and higher DC power systems are only to be installed in Restricted Access Locations (RAL).

Access must be limited by use of tool, i.e. lock and key.

Device

Hazard

!

Qualified

Personnel

!

EMC, NEC/CEC

Regard

!

Electric

Shock

Electric

Shock

I1

I2

I3

I4

I5

356800.183, 3v3

1 Introduction

User's Guide Smartpack2 Master Controller 350020.013, Issue 2.0, 2014 Jan 3

Part number for Smartpack2 Master Controller: 242100.500

350020.013 Issue 2.0, 2014 Jan

Published 2014-03-06

mafeno

1 Introduction

4 User's Guide Smartpack2 Master Controller 350020.013, Issue 2.0, 2014 Jan

Table of Contents

1. Introduction ................................................................................. 5

About this Guide ............................................................................................... 5

System Diagram — Flatpack2 Power System w/SP2....................................... 5

2. The Smartpack2 Master Controller ............................................ 6

Key Features .................................................................................................... 6

Location of Connector, Communication Ports .......................................... 7

Opening and Closing Smartpack2 Master Controller ............................................... 7

CAN Bus Termination ....................................................................................... 8

CAN Bus Cabling ...................................................................................................... 8

Front Panel Operation ................................................................................. 9

Graphical Display .............................................................................................. 9

Front Keys ........................................................................................................ 9

Software Menus .............................................................................................. 10

Controller Access — Via Stand-alone PC ................................................ 11

Technical Specifications ........................................................................... 12

..................................................................................... 12

Firmware Upgrade Controller .................................................................... 13

Firmware Upgrade from the SD Card ..................................................................... 13

Firmware Upgrade from a Computer ...................................................................... 14

Overview LAN Devices and Firmware Files (PC - S19 Format)........................ 14

3. About Power System Configuration ........................................ 15

Logical Groups or Menu Options .................................................................... 15

1 - System Status options ....................................................................................... 16

2 - System Configuration options ............................................................................ 16

3 - Alarm Configuration options .............................................................................. 16

4 - Commands options ............................................................................................ 17

5 - Logs and Reports options .................................................................................. 18

6 - Statistics options ................................................................................................ 19

7 - Commissioning options ..................................................................................... 20

8 - Up/Download options (Data Storage Device) .................................................... 20

SD Card Storage - Overview Firmware Files (Binary Format) .......................... 21

Flash Memory Storage ...................................................................................... 22

Alarm Monitors ................................................................................................ 23

Types of Alarm Monitors ......................................................................................... 25

Typical Parameters for Alarm Monitors .................................................................. 26

Alarm Output Groups ...................................................................................... 28

Output Test Commands .................................................................................. 31

Alarm Outputs Isolation (Output Blocked) ...................................................... 31

1 Introduction

User's Guide Smartpack2 Master Controller 350020.013, Issue 2.0, 2014 Jan 5

1. Introduction

The advanced Smartpack2 Master controllers are developed for Eltek’s Flatpack2 DC

power systems that implement the Smartpack2-based distributed control system.

About this Guide

This booklet provides users of Smartpack2-based DC power systems with the required

information for operating the system using the Smartpack2 Master’s front panel. The

booklet also describes the Smartpack2 Master controller’s building blocks, external

connections and technical specifications.

Read also the generic and site specific documentation for your DC power system.

For detailed functionality description, browse and search through the Functionality

Description topic in PowerSuite Online Help or CWUI Online Help. Notice that you must

log in to access Online Help (contact your Eltek representative)

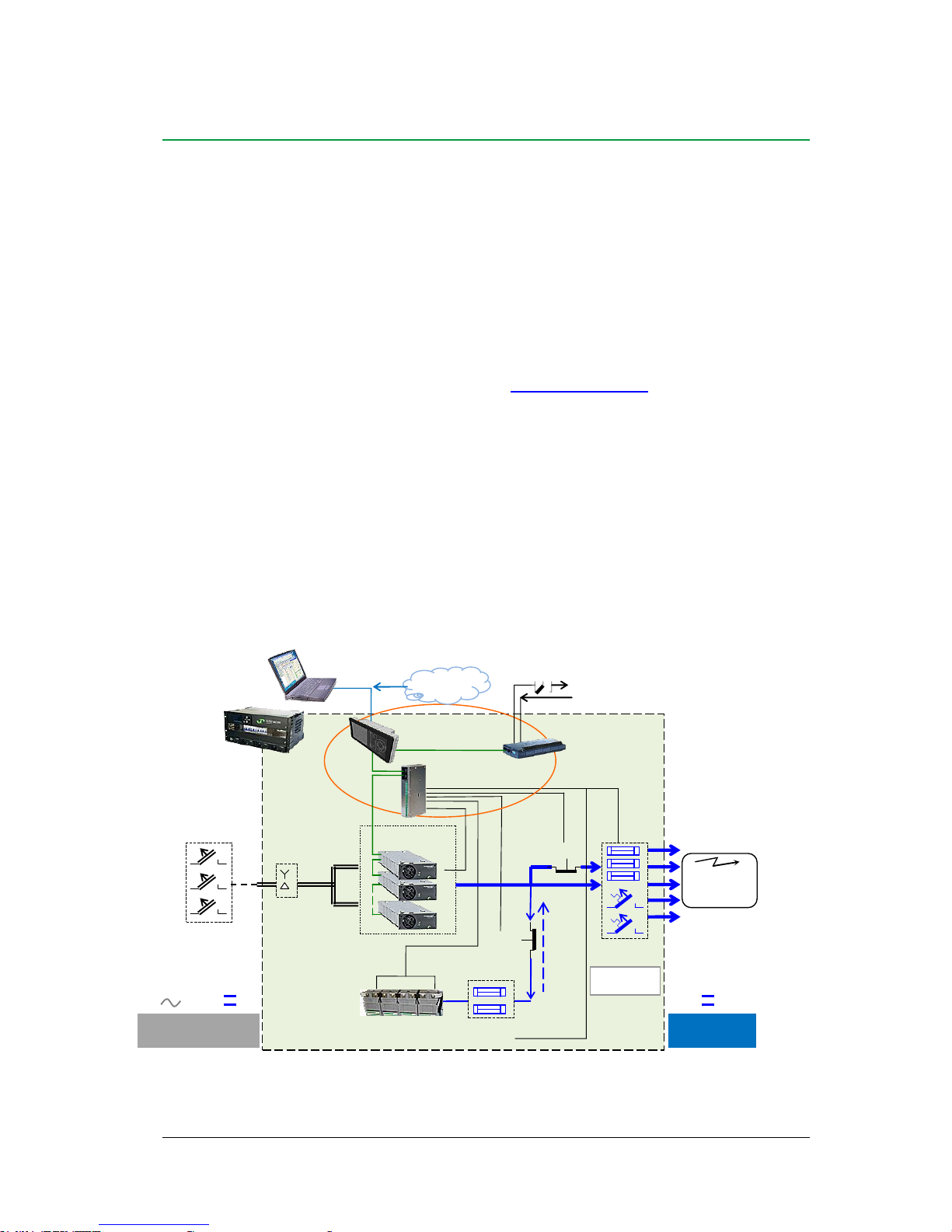

System Diagram — Flatpack2 Power System w/SP2

The generic Smartpack2 (SP2) distributed control system — used in Flatpack2 PS systems

— monitors and controls the whole system, and consists of the Smartpack2 Master (SP2M)

controller, the Smartpack2 Basic (SP2B) controller and the I/O Monitor2 CAN node.

The Smartpack2 Master serves as the local user interface between you and the system. The

system may also be configured via the Controller’s Web-based User Interface (CWUI) on

a standard web browser, and via the PowerSuite PC application. The Smartpack2 Basic

monitors and controls the power system’s internal wiring and supplies the CAN bus with

power. The I/O Monitor2 CAN node implements input and output signals.

Figure 1 Typical Flatpack2 DC power system for telecom and industrial equipment, fed from external AC mains or

DC supply. It consists of rectifiers in power shelves, master and basic controllers, DC distribution, etc.

Battery string #1

AC mains

supply

selector

Temp.

Sensors

LVLD

LVBD

Fuse Alarm

AC Fuses, external

(230VAC or 400VAC

or 85-300VDC)

Battery

Fuses

Load Fuses

& MCBs

Flatpack2 HE

rectifiers

CAN Bus

DC

Distribution

DC Output

(24V, 48V

or 60V)

Flatpack2

System

Ethernet

cable

Internet

Telecom and

Industrial

equipment

Smartpack2

Master Controller

Smartpack2

Basic Controller

Alarm Outputs NC-C-NO

Config. Inputs

CWUI

(Controller’s web-

based user interface)

I/O Monitor2

CAN node

AC Input

(Single- or 3-phase

or DC Input)

OR

2 The Smartpack2 Master Controller

6 User's Guide Smartpack2 Master Controller 350020.013, Issue 2.0, 2014 Jan

2. The Smartpack2 Master Controller

The Smartpack2 Master controllers are powerful modules used as master controllers in the

distributed control system of Smartpack2-based power supply systems. They serve as the

local user interface between you and the power system.

The Smartpack2 Master controller is 2U high and 160mm wide, and it is mounted in the

power system’s front panel or door. The CAN bus is the only connection between the

Smartpack2 Master and the Smartpack2 Basic controller, which provides great installation

flexibility.

Key Features

A wide range of features are implemented in the Smartpack2 Master controller, as

mentioned below:

Graphical TFT high contrast, high resolution color display for easy navigation

LEDs for local visual alarming (Major, Minor, Power ON)

Ethernet for remote or local monitoring and control via WEB Browser

Ethernet port for straight-through and crossover cables

SNMP protocol with TRAP, SET and GET on Ethernet. Email of TRAP alarms

Comprehensive logging

Automatic battery monitoring and test

Battery lifetime indication

Battery used and remaining capacity (Ah or %) monitoring

User defined alarm grouping (Boolean logic for grouped alarms)

Uploading and downloading of firmware and configuration files with SD card

SD card slot for downloading/uploading of logs and setup

Comprehensive generator/hybrid/DC solar system control and monitoring features

Read also chapter “Technical Specifications”, page 12, for more details.

2 The Smartpack2 Master Controller

User's Guide Smartpack2 Master Controller 350020.013, Issue 2.0, 2014 Jan 7

Location of Connector, Communication Ports

Figure 2 Location of CAN ports and Ethernet connector in the Smartpack2 Master controller

CAN port 1 and 2 are electrically identical, and are used to enable connection of the CAN

bus incoming and outgoing CAT5 cables, or the RJ45 CAN bus termination plug.

Opening and Closing Smartpack2 Master Controller

Opening the controller’s right side enables inserting an SD card and temporarily

connecting an Ethernet cable.

1. To open it,

pull the handle’s knob slightly outwards

(use your fingers or a pen) and

2. then slide the handle to the left

(the controller’s right side opens)

3. To close it,

slide the handle to the right (the controller's

right hand side closes, almost), then push the

controller's front inwards, to close it

completely

Ethernet

cable

Smartpack2

Master Controller

CWUI

(Controller’s webbased user interface)

(Ethernet cable

Standard straight through cable

OR crossover cable)

Smartpack2 Master

controller (open)

Handle in open

position

SD card

RJ-45 socket

for Ethernet connection

CAN port 1&2

Electrically identical

(CAN bus

(twisted-pair CAT5 cable)

RJ-45 socket

for Ethernet connection

Smartpack2 Master

controller (locked)

Handle in locked position

Smartpack2 Master

controller (open)

Handle in open

position

SD card

2 The Smartpack2 Master Controller

8 User's Guide Smartpack2 Master Controller 350020.013, Issue 2.0, 2014 Jan

CAN Bus Termination

To ensure a correct bus communication and avoid data reflection, you must always

terminate the CAN bus with two 120 resistors, one at each end of the line (60 bus

impedance).

Smartpack2-based DC power systems are shipped from factory with the CAN bus already

terminated with 120 resistors. The CAN bus termination is implemented with a special

RJ45 plug with built-in 120 end-of-line resistor.

Figure 3 Example of CAN bus addressing and termination in a Flatpack2 power system with

Smartpack2-based control system and several monitors connected the CAN bus

When connecting more CAN nodes to the bus, you have to remove the CAN bus

termination plug from one of the CAN bus ends, and plug it in one of the CAN ports on the

last connected CAN node.

CAN Bus Cabling

In addition to the two dedicated wires for communication, the CAN bus multi-wire cable

must integrate wires for the CAN power supply and other signals. In standard industrial

environments, the CAN bus can use standard cabling without shielding or twisted pair

wiring. If very low interference (EMI) is required, a CAT-5 twisted-pair cable is

recommended.

Flatpack2

DC Power System

CAN bus

(twisted-pair

CAT5 cable)

33

Battery string #1

Battery Monitor

ID Number

I/O Monitor2

81

Load Monitor

49

End-of-Line

Resistor

120

Fuses

Fuse Monitoring

Configurable Inputs

Current Monitoring

Sense Inputs

Shunts

Alarm Outputs NC-C-NO

Config. Inputs

End-of-Line

Resistor

120

Smartpack2

Basic Controller

Flatpack2 HE

Rectifiers

01

02 n 1

Internal System Monitoring

Smartpack2

Master Controller

Ethernet cable (LAN)

CWUI

(Controller’s web-based user interface)

I/O Monitor

82

Alarm Outputs NC-C-NO

Config. Inputs

Temp, Fan Speed Mon & Ctrl

2 The Smartpack2 Master Controller

User's Guide Smartpack2 Master Controller 350020.013, Issue 2.0, 2014 Jan 9

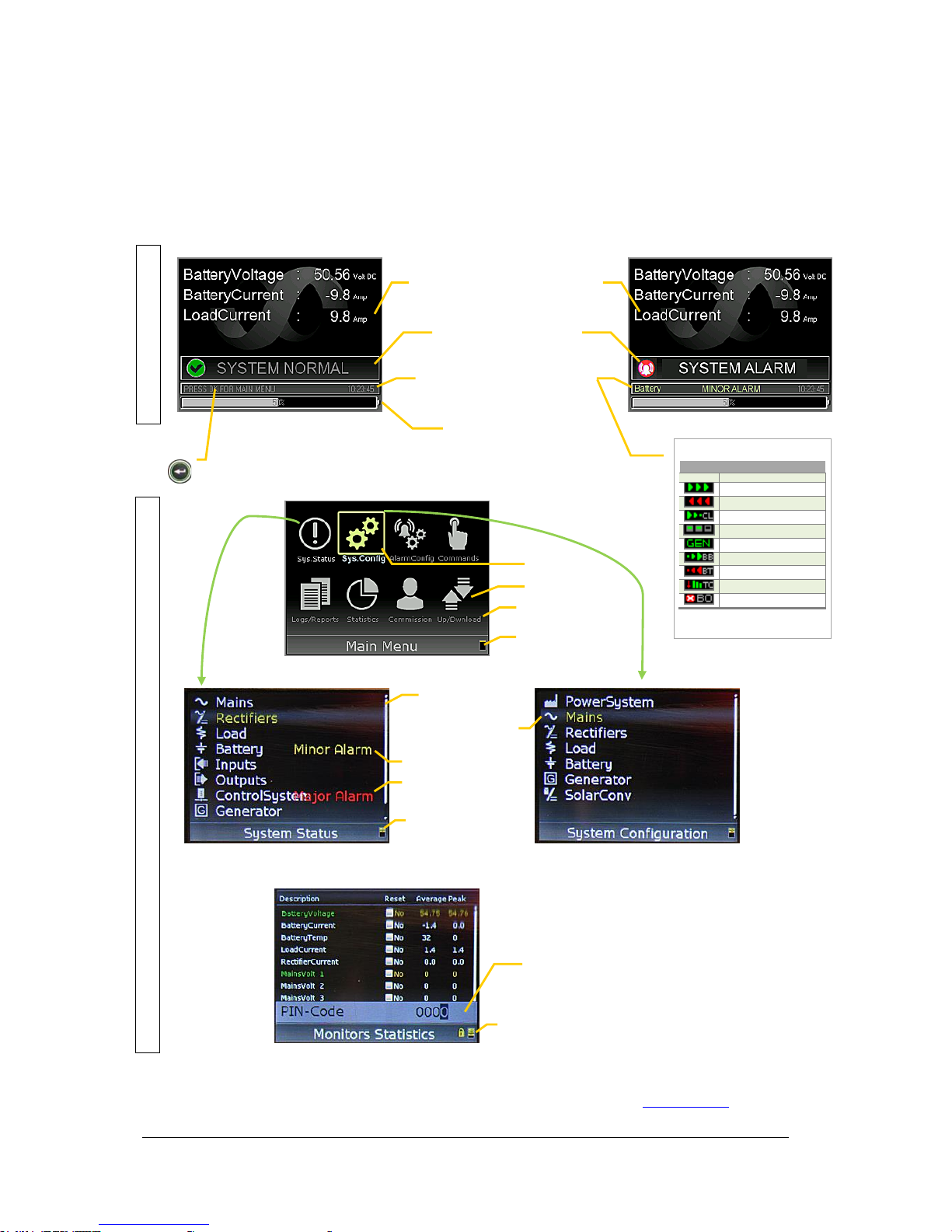

Front Panel Operation

This chapter describes the Smartpack2 Master controller’s keys and indicators, and how to

operate the Smartpack2-based DC power system from the controller’s front panel.

Figure 4 Smartpack2 Master controller’s front keys and indicators

Graphical Display

The Graphical Color Display — 3.2” TFT 32k, QVGA 320x240 — is either in Status

Mode (displays the system’s status) or in Menu Mode (displays the menu structure).

The Smartpack2 Master controller has the following LED indications:

Table 1 Description of the Smartpack2 Master controller’s LED illumination status

Front Keys

You can operate the power system navigating intuitively through the graphical menu

structure via the following 6 front keys.

Press on the key

to change from Status Mode to Menu Mode and to select options, enter values

Press the key

to navigate to previous level and cancel options and values

Press the

or

keys

to navigate up- or downwards, point at options and increase and decrease values

Press the

or

keys

to navigate one page up- or downwards and point at options

Smartpack2 Master controller

Handle in locked position

”Enter” key

“Cancel” key

Arrow keys

”Alarm” LED lamp (red)

“Warning” LED lamp (yellow)

“Power” LED lamp (green)

Graphical Color

Display

3.2” TFT 32k, QGVA

320x240

LED

Indicator

Illumination

Status

Description

Power

OFF

ON green

Flashing Green

The controller has NO supply

Supply healthy

Distributed Power Fault

Warning

OFF

ON amber

Flashing amber

No Warning

Warning (Minor alarm, non-critical alarm)

Communications Fault

Alarm

OFF

ON red

Flashing red

No Alarm

Alarm (Major Alarm, critical alarm)

SW Fault / Boot Loader Mode

2 The Smartpack2 Master Controller

10 User's Guide Smartpack2 Master Controller 350020.013, Issue 2.0, 2014 Jan

Software Menus

The Smartpack2-based system’s functionality is accessed via a network of software menus

and submenus, enabling you to configure and control the whole power system from the

controller’s front panel. When browsing the menus, the Menu Level Indicator shows the

menu level you are in. Editing parameters is password protected, (default pin code <0003>

may be changed for security reasons). The display can be in Status Mode or in Menu Mode.

From a PC’s web browser, or running the PowerSuite program, you can also access the

complete system functionality, described in the programs’ Help and in Online Help.

Status Mode

System in Normal Mode

System Parameters

Display more with the → and ← arrow keys.

(Display area P)

System in Alarm Mode

System Status

Normal mode, Alarm mode, etc.

(Display area S)

System Messages

Animated icons, keys to press, alarms,

system time, etc

(Multi-Info field, Display area M)

Status Battery Bank

Displayed in % or in Ah

(Display area B)

Menu Mode

Main Menu Options (Level 1)

Menu Icons

Menu Names

Menu Level Indicator

hierarchical menus (Level 1)

Submenu “System Status” (Level 2)

Submenu “System Configuration” (Level 2)

Scrollbar

Menu Level Indicator

hierarchical menus (Level 2)

Chosen option (yellow text)

Press “Enter” to display the

Mains submenu

Warning (minor alarm)

Alarm (major alarm)

Example Submenu “Monitors Statistics” (Level 3)

Menu Level Indicator

hierarchical menus (Level 3)

Pin Code required for changing configured parameters

(use the ↑ or ↓ arrow keys to enter code).

Default pin code <0003> (should be changed for security reasons)

Chosen option

To change from Status Mode

to Menu Mode press on this

key:

Animated System Messages (M)

in Normal Mode

Icon

Enabled Function

none

Float Batt. Charging

Battery Charging

Battery Discharging

Current Limitation

Efficiency Management

Generator running

Batt. Boost Charging

Battery Test

Temp. Compensated Ch.

Outputs Blocked

When no battery bank installed, the

icons are shown in Display area B

Loading...

Loading...