User's Guide

Rectifiers and Supervision

FlatpackS DC Power Supply Systems

Anatel Homolgation Numbers

Rectifier 0863-15-2298

Power System 0864-15-2298

FlatpackS Modules

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

2 User’s Guide Flatpack2 Rectifier & Supervision Modules,

DC Power Supply Systems

SAFETY and ENVIRONMENTAL PRECAUTIONS

The product warranty becomes invalid if the following safety precautions are not followed during handling,

installation, commissioning and general use/operation of Eltek DC power supply system.

General Precautions

CAUTION: Even though the product incorporates protection circuitry and other safeguards, it can be damaged, perform

poorly or have a reduced lifetime if it is exposed to incorrect treatment during transport, installation or service.

Always handle the equipment using proper lifting techniques, do not roll, climb or drill hole in the cabinets or enclosures.

WARNING: Opening the equipment may cause terminal injury — even if the mains AC supply is disconnected.

Hazardous voltages may be present inside, as large capacitors may still be charged.

Device

Hazard

!

Electric

Shock

G1

G2

Environmental Precautions

CAUTION: To avoid damage the equipment, keep objects clear of system ventilation inlets, outlets and system

fans, if any, ensuring the airflow through the units is not obstructed, and that the fans rotate freely. Use caution with

rectifiers, as they can reach extreme tempera tures under load and normal operation.

WARNING: The installer/user is responsible for ensuring that the DC power system is not damaged by current

surges, over-voltages, etc. caused by external transients, lightning, electrostatic discharge, etc. To avoid

damage and obtain the expected system re liability, it is mandatory to always install SPDs in Eltek’s power

supply systems. Follow the instructions given in “Guidelines for Lightning and Surge Protection”, doc. 2024623.

WARNING: The electronics in the power supply system are designed for indoor , clean environment. When

installed in outdoor enclosures, it is important to keep the door closed during operation, and replace the filters

on a regular basis. Indoor installations in dusty or humid areas require appropriate air filtering of the room, or

filtering of the air entering the DC power system. Follow the instructions given in “ Generic Guidelines

Environmental Protection.”, doc. 2038879.

Ventilated

Hot Surface

s

ss

Humidity & Dust

Protection

Current Surge

Protection

E2

E1

E3

CAUTION: This product is tested and verified according to international safety, environmental and EMC standards. Any

non-Eltek equipment installed into this product after delivery might influence the performance and could infringe the

original approvals. The installer is responsible for ensuring that the environmental properties of this product/ system

do not deteriorate during installation, and that it is performed in accordance with applying regulations.

Installations in USA and Canada must comply with NEC/CEC requirements.

Precautions during Installation

CAUTION: Read the user documentation carefully before installing and using the equipment, as installation and

operation is to be performed as described in it. Always tighten screws and bolts with the torque values recommended in

the documentation. For safety reasons, the commissioning and configuration of the equipment is only to be

performed by Eltek’s personnel or by authorized and qualified persons.

CAUTION: Before you start the electrical installation, you must alw ays disconnect all external AC supply fuses, as well as

internal battery and load fuses/ breakers, if any.

WARNING: For safety reasons (high leakage current / high touch current) you must always connect the AC

earth wire (PE) to the terminals, before you connect the AC input cable(s).

The batteries, if any, represent a major energy hazard. To avoid short-circuit of battery poles, you must always

remove metallic objects — uninsulated tools, rings, watches, etc. — from the vicinity of the batteries.

WARNING: 60V and higher DC power systems are only to be installed in Restricted Access Locations (RAL).

Access must be limited by use of tool, i.e. lock and key.

Device

Hazard

!

Qualified

Personnel

!

EMC, NEC/CEC

Regard

!

Electric

Shock

Electric

Shock

I1

I2

I3

I4

I5

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

User’s Guide FlatpackS Rectifier & Supervision Modules, 3

Information in this document is subject to change without notice and does not represent a commitment on the

part of Eltek.

No part of this document may be reproduced or transmitted in any form or by any means — electronic or

mechanical, including photocopying and recording — for any purpose without the explicit written permission of

Eltek.

Copyright ©: Eltek, 2015

Safety Precautions

The equipment described in this manual must only be operated by Eltek

personnel or by persons who have attended a suitable Eltek training course

The equipment represents an energy hazard and failure to observe this

could cause terminal injury and invalidate our warranty

There are hazardous voltages inside the power system. As the modules

incorporate large charged capacitors, it is dangerous to work inside the

system even if the mains supply is disconnected

Products into which our components are incorporated have to comply with a

number of requirements. Installation is to be in accordance with the

recommendations herein

Please read the manual carefully before using the equipment

Anatel Label

The folowing picture shows the Anatel label that is applied on bottom of the Rectifier.

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

4 User’s Guide Flatpack2 Rectifier & Supervision Modules,

Table of Contents

1. Introduction 5

About this Guide ............................................................................................................ 5

System Diagrams Flatpacks DC Power Systems ...................................................... 5

FlatpackS PS System ~ Telecom .............................................................................. 5

2. FlatpackS Rectifier & Supervision Modules 6

Key Features ................................................................................................................. 6

Typical Applications ....................................................................................................... 6

3. Installation of Flatpack2 Modules 7

Installing Rectifiers, Controller and Blind Panels .............................................. 7

Removing Flatpack S Rectifiers ........................................................................... 7

Mounting Flatpack S Rectifiers ...................................................................................... 7

Mounting or Removing Blind Panels .............................................................................. 8

Removing Smartpack S Controller ................................................................................ 8

Mounting Smartpack S Controller .................................................................................. 8

Accessing the Controller’s Ethernet Port ....................................................................... 9

Terminals and Pin-out Locations, Smartpack S Controller ............................. 10

Location of Connector, Communication Ports .............................................................. 10

Connection Drawing .................................................................................................... 11

4. Operation 13

Front Panel — Flatpack S Rectifier Module ...................................................... 13

Front Panel Operation – Smartpack S Controller ............................................. 13

Graphical Display ........................................................................................................ 14

Front Keys ................................................................................................................... 14

Software Menus .......................................................................................................... 15

Controller Access — Via Stand-alone PC ......................................................... 16

5. Technical Specifications 17

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

User’s Guide FlatpackS Rectifier & Supervision Modules, 5

1. Introduction

The FlatpackS rectifier module is a powerful and cost-effective power supply used in

Eltek’s FlatpackS DC power systems.

About this Guide

This booklet provides users of FlatpackS DC power systems with the required information

to install and operate the FlatpackS rectifier modules. The booklet also presents the

modules’ technical specifications, such as input voltage range, output power, operating

temperature range, etc.

Read also the generic and site specific documentation that was delivered with your

FlatpackS DC power system.

For detailed functionality description, browse and search through WebPower or

PowerSuite Online Help.

System Diagrams Flatpacks DC Power Systems

The FlatpackS modules are the building blocks of Flatpack2 PS systems, used for DC

power supply of telecom and industrial equipment, in grid-fed sites or hybrid solar sites.

FlatpackS PS System ~ Telecom

The example in Figure 1 represents a typical FlatpackS PS system for DC power supply of

telecom equipment. The system is fed from an external AC mains supply, and consists of

rectifiers in power shelves, a controller and DC distribution unit. Battery banks, LVD

contactors, etc. are typically also a part of the system. The system controller monitors

the whole system, and serves as the local user interface. You can configure the system

from a standard web browser, or installing the PowerSuite application in a computer.

Figure 1 Typical FlatpackS PS system for DC power supply of telecom equipment

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

6 User’s Guide Flatpack2 Rectifier & Supervision Modules,

2. FlatpackS Rectifier & Supervision Modules

The FlatpackS module is a hot-pluggable, digitally controlled switch mode power supply.

The module is designed for battery charging and supplying of high quality DC power to

telecom, industrial, solar hybrid equipment and similar applications.

The module works in stand-alone mode or in parallel with other modules, then

communicating via CAN bus with the system’s main controller and other connected

modules. FlatpackS DC power systems are implemented by mounting the rectifiers in 23”

or 19” power shelves (4 modules across).

A wide range of features are implemented in the FlatpackS module, as mentioned below.

Key Features

Highest efficiency in minimum space

Resonant topology makes the module efficiency industry leading, and

contributes to the module’s ultra-compact dimensions.

Specially, the Flatpack2 HE module stands out with 96.5% efficiency.

Digital controllers

Primary and secondary controls are digitalized, enabling excellent monitoring

and control characteristics. Also, the number of components has been reduced

by 40% compared to previous module generation - for highly reliable, long

life, trouble free DC power systems.

Heat management

Front-to-back and back-to-front air flow modules, with chassis-integrated

heat sinks, gives the module the most suitable working environment and no

limitations in the scalability of the desired system solution.

CAN bus networked

The Flatpacks module is connected in a CAN bus network for communication

with the controller and other modules.

Unique connection

A true plug-and-play connection system: reducing time-to-install related cost.

Global approvals

Flatpacks is CE marked, UL recognized and NEBS certified for worldwide

installation

Typical Applications

Wireless, fiber and fixed line communication

Today’s communications demand state-of-the-art, cost efficient and compact DC power

systems. FlatpackS modules deliver industry leading power density and superb reliability

at lowest lifetime cost.

Broadband and network access

Increasing network speed demands flexible and expandable DC power solutions. The

Flatpack2 module is your key building block for future needs.

Industrial and Solar Hybrid sites

Also appropriate for power supply facilities with or without battery in all areas of

industry, power generation and power distribution The solar charger option is suitable for

any telecom site with autonomous (solar only) or hybrid solar power.

Eltek

Label

Anatel

Label

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

User’s Guide FlatpackS Rectifier & Supervision Modules, 7

3. Installation of Flatpack2 Modules

Installing Rectifiers, Controller and Blind Panels

Removing Flatpack S Rectifiers

To remove the

Flatpack S

rectifiers, do following:

Unlock the rectifier

by

using a screwdriver to turn the locking screw ¼ of a turn

clockwise to the unlocked position (

)

Remove the rectifier

by

using the rectifier’s handle to pull the module loose. Support

from underneath before the unit is completely free

Mount blind panels

in

unused rectifier locations

Mounting Flatpack S Rectifiers

To mount the

Flatpack S

rectifiers, do following:

Unlock the rectifier

by

using a screwdriver to turn the locking screw ¼ of a turn clockwise to

the unlocked position ( )

Notice

: the rectifiers may be inserted in the power shelf with the

locking screw in both locked and unlocked positions

Insert the rectifier

by

sliding it fully into the power shelf, so that it makes proper contact.

Support from underneath

Lock the rectifier

by

using a screwdriver to turn the locking screw ¼ of a turn counter

clockwise to the locked position ( ). Then, the rectifier will be

securely locked in the shelf, or ready for transport

CAUTION:

The rectifiers may be warm, you may hand-carry them by their handle.

The rectifier incorporates a Mains fuse in each line. Double Pole / Neutral Fusing.Device

Hazard

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

8 User’s Guide Flatpack2 Rectifier & Supervision Modules,

Mounting or Removing Blind Panels

Always mount blind panels in unused

Flatpack S

rectifiers’ and

Smartpack S

controllers’ locations. Do following:

To mount a blind panel

insert the panel in an unused location until the panel

engages and locks into position

To remove a blind panel

push the panel’s handle downwards and pull out to

release the panel

Removing Smartpack S Controller

To remove the

Smartpack S

controller, do following:

Unlock the controller

by

using a screwdriver to turn the locking screw ¼ of a turn

clockwise to the unlocked position (pos 2).

Notice

: in this position, the display is locked (), see

“Accessing the Controller’s Ethernet Port” on page

<ET>

Remove the controller

by

using the controller’s handle to pull the module loose.

Support from underneath before the unit is completely free

Mount blind panels

in

unused module locations

Mounting Smartpack S Controller

To mount the

Smartpack S

controller, do following:

Unlock the controller

by

using a screwdriver to turn the locking screw ¼ of a turn

clockwise to the unlocked position (pos 2)

Notice

: the controllers may be mounted in the power

shelf with the locking screw in both locked and unlocked

positions

Insert the controller

by

sliding it fully into the power shelf, so that it makes proper

contact. Support from underneath

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

User’s Guide FlatpackS Rectifier & Supervision Modules, 9

Lock the controller

by

using a screwdriver to turn the locking screw ¼ of a turn counter clockwise to the

locked position (pos 1). Then, the rectifier will be securely locked in the shelf, or

ready for transport.

Notice

: in this position, the display is unlocked (), see

“Accessing the

Controller’s Ethernet Port” on page <ET>

Accessing the Controller’s Ethernet Port

The controller’s Ethernet port can be accessed from the front (temporary

connections) or from the rear (permanently connections.

To access the

Smartpack S

controller

Ethernet port from the front, do following:

1- Lock the controller

(pos 1)

2- Slide

the controller’s

display unit

slightly out

Pos 1= SP S and Display

Pos 2= SP S and Display

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

10 User’s Guide Flatpack2 Rectifier & Supervision Modules,

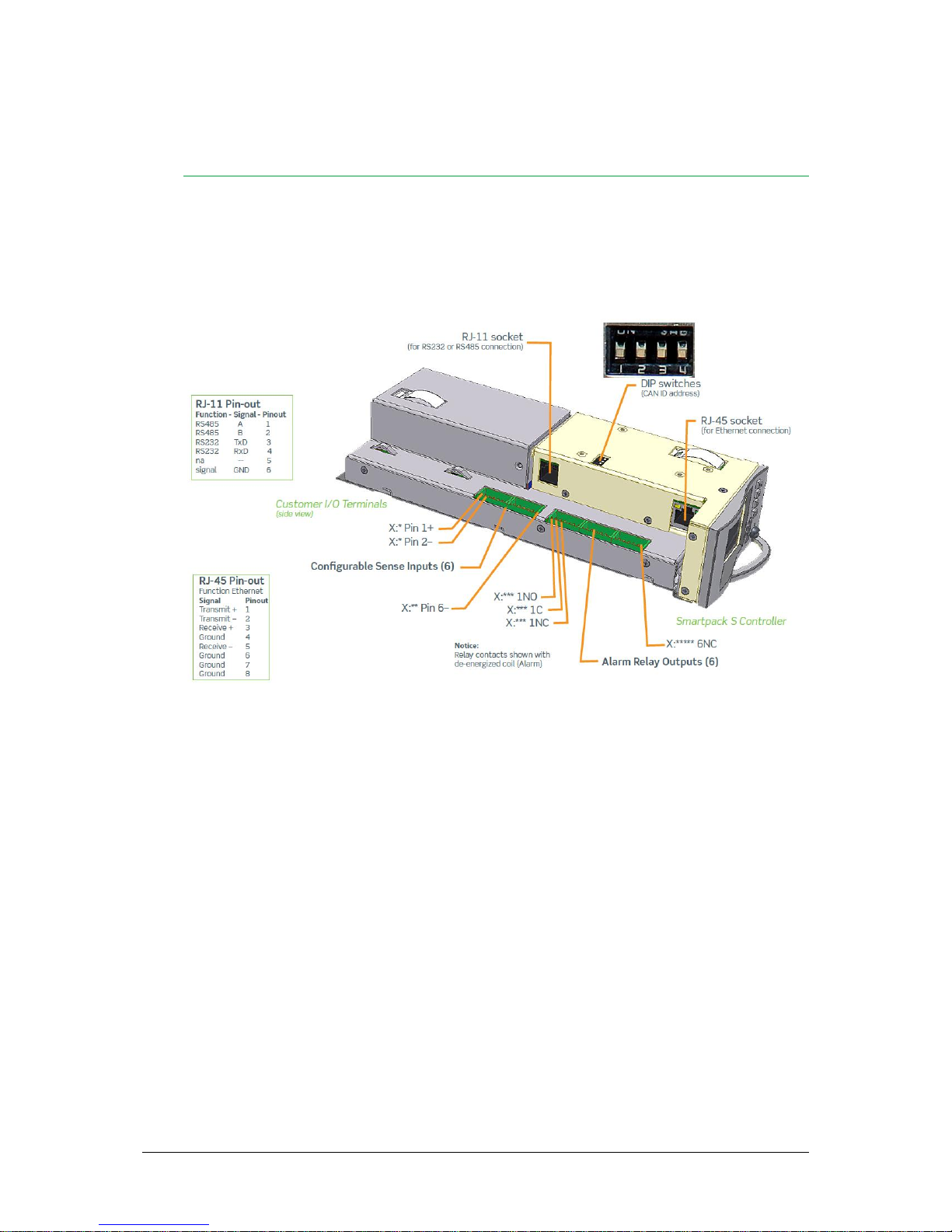

Terminals and Pin-out Locations, Smartpack S

Controller

Location of Connector, Communication Ports

For a complete list of signals, pin-out, etc, refer to chapter “Connection Drawing” on

page12

Location of pluggable terminal blocks, RS232/RS485 port and Ethernet connector in

the Smartpack S controller (the pluggable terminals may be black or green)

All the controller’s system connections to the system’s backplane are implemented via an

edge connector, when inserting the controller in the power system.

Notice that when using the RS232 / RS485 port, you must configure RS232 to COM1 and

RS485 to COM2, e.g. via PowerSuite.

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

User’s Guide FlatpackS Rectifier & Supervision Modules, 11

Connection Drawing

Use this drawing as a customer connection reference for all cabling. You find the exact

location of connection terminals, plugs, DIP switches, jumpers, etc. by referring to chapter

“Location of Connector, Communication Ports” on page 11.

Connection Drawing for Smartpack S controller

The configurable inputs 1 through 4 operate in the range of max. – 10 to +10VDC, and

are intended for great accurate measurements, e.g. for temperature sensing using an

external temperature NTC probe. Also, these inputs are suitable for monitoring other

sensors (of pressure, humidity, etc.) that output 4mA to 20mA. An external 470 ohms

resistor is then to be connected to the input’s terminals on the controller, in parallel with

the sensor’s cables.

The configurable inputs 5 and 6 operate in the range of 0 to 75VDC, and are intended

for e.g. system voltage and battery symmetry measurements.

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

12 User’s Guide Flatpack2 Rectifier & Supervision Modules,

All the 6 inputs may be configured as Auxiliary Switch (open/close, pull-up or pull-down),

as temperature sense inputs with external NTC sensors, or as Clock inputs.

The SmartpackS controller also have a panel mounted version, that is shown in the picture

below. Both controllers have the same hardware, but in different format.

SmartpackS in the panel version.

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

User’s Guide FlatpackS Rectifier & Supervision Modules, 13

4. Operation

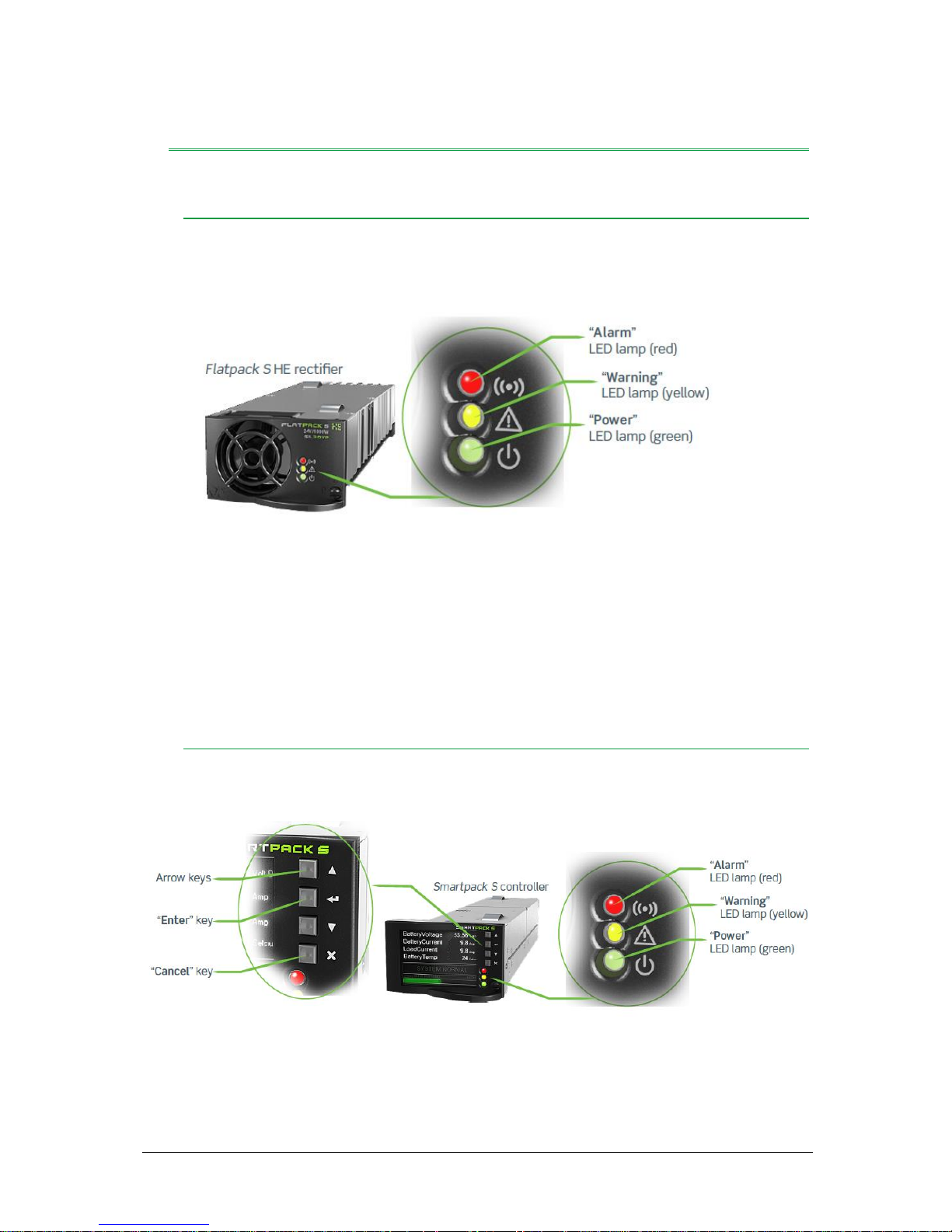

Front Panel — Flatpack S Rectifier Module

The Power LED is OFF (mains unavailable), Flashing (controller accessing information)

or ON (powered).

Flatpack S HE rectifier’s front lamps

The Warning LED is ON (derating or similar minor warning), Flashing (over-voltage

mode) or OFF (OK)

The Alarm LED is ON (shutdown or similar major alarm) or OFF (OK, no alarm)

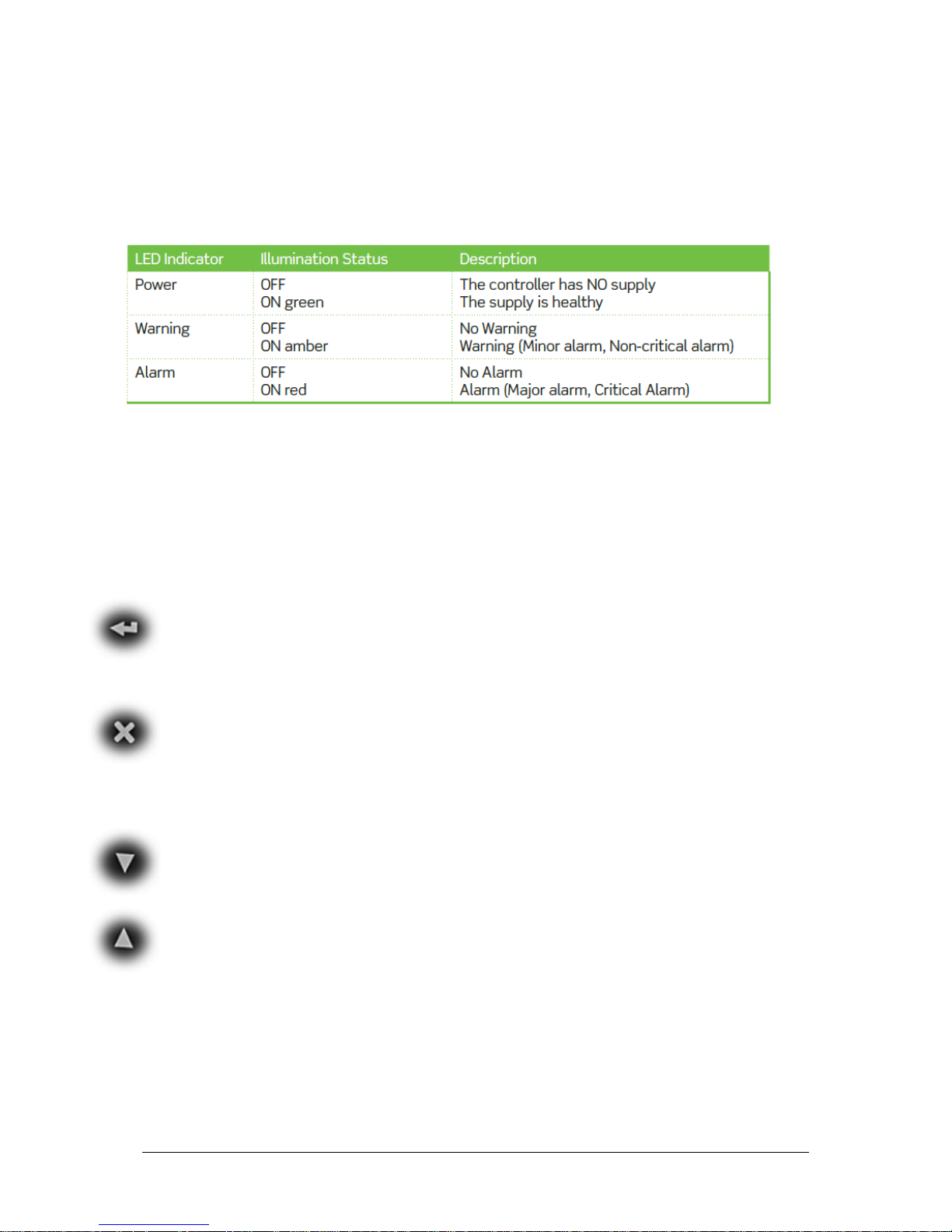

Front Panel Operation – Smartpack S Controller

This chapter describes the Smartpack S controller’s keys and indicators, and how to

operate the Smartpack S-based DC power system from the controller’s front panel.

Smartpack S controller’s front keys and indicators

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

14 User’s Guide Flatpack2 Rectifier & Supervision Modules,

Graphical Display

The Graphical Color Display — 2.2” TFT — is either in Status Mode (displays the system’s

status) or in Menu Mode (displays the menu structure).

The Smartpack S controller has the following LED indications:

Description of the Smartpack S controller’s LED illumination status

Front Keys

You can operate the power system navigating intuitively through the graphical menu

structure via the following 4 front keys. We recommend using a pen or similar tool to

press the keys, as they are small.

The

Enter

or

Left arrow

key

When entering numbers, a

short press

of this key navigates to the left.

A

long press

of this key to enter and save data

The

Cancel

or

Right arrow

key

When entering numbers, a

short press

of this key navigates to the right.

A

long press

of this key to cancel or abort data

The

Up

and

Down arrow

keys

to navigate up- or downwards the menu icons, point at options and increase

and decrease values

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

User’s Guide FlatpackS Rectifier & Supervision Modules, 15

Software Menus

The Smartpack S-based system’s functionality is accessed via a network of software

menus and submenus1, enabling you to configure and control the whole power system

from the controller’s front panel. When browsing the menus, the Menu Level Indicator

shows the menu level you are in. Editing parameters is password protected, (default pin

code <0003> should be changed). The display can be in Status Mode or in Menu Mode.

1

From a PC’s web browser, via WebPower, or running the PowerSuite program, you can also access the complete

system functionality, described in the programs’ Online Help

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

16 User’s Guide Flatpack2 Rectifier & Supervision Modules,

Controller Access — Via Stand-alone PC

You can access the Smartpack S controller directly from a stand-alone computer, or via a

Local Area Network (LAN) if available.

Each controller is shipped with a unique Eltek MAC address stored inside the controller

and marked on the controller’s label, and with the fixed IP address <192.168.10.20>.

Do following to access the controller:

Start the

“Eltek Network Utility”

(ENU) program

(or EVIPSetup.exe)

Connect the computer to the controller

(see

“Accessing the Controller’s

Ethernet Port” on page 5

). Check its MAC address is displayed

Find the computer NIC’s IP address

and subnet mask (network card)

Tip:

using DOS command IPCONFIG, in a Command Prompt window e.g.

computer’s IP address <169.254.52.132> Subnet mask <255.255.0.0>

Change the controller’s IP address

and Network Mask to be in the same range as the

computer’s

Tip:

Using the ENU program,

1. Select the controller,

2. Click in the “Configuration” button

3.

Change e.g. from default <192.168.10.20> <0.0.0.0>

to IP address <169.254.52.133> <255.255.0.0>,

4. Click on the “Enable Static IP” button

Notice: Check that the IP address <169.254.52.133> is

not used, e.g. issuing the DOS command: “Ping

169.254.52.133“

5. Access the controller

’s configuration pages in your Web browser,

e.g. clicking the “Web Interface” button in the ENU program

6. Log in

with the <admin> account

7. Change

the controller’s Device Name

After accessing the controller, you can configure and monitor the power system using a

standard web browser (via WebPower) or via the PowerSuite program. PowerSuite’s

newest version is always available on our FTP server. Contact your closest Eltek

representative.

For detailed functionality description, browse and search through the Functionality

Description Help file (or 350020.073) or WebPower Online Help file.

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

User’s Guide FlatpackS Rectifier & Supervision Modules, 17

5. Technical Specifications

Model

48/1000 HE

48/1800 HE

Part number

241122.105

241122.125

INPUT DATA

Voltage (nominal)

185 - 270 VAC / 185 - 250 VDC 1)

1952) - 277 VAC / 1952) - 250 VDC 1)

Voltage (operating range)

85 - 300 VAC / 85 - 250 VDC 1)

852) - 305 VAC / 852) - 250 VDC 1)

Current (maximum) @ nominal input, full load

5.9 A

RMS

9.9 A

RMS

Frequency

45 - 66 Hz / 0 Hz1)

Power Factor

> 0.99 at 50% load or more

Protection

Fuse in L & N

Varistor

Shutdown when input voltage is out of operating range

OUTPUT DATA

Voltage (default)

53.5 VDC

Voltage (adjustable range)

43.5 - 57.6 VDC

Power (maximum) @ nominal input

1000 W

1800 W

Power @ 85 VAC

420 W

700 W2)

Current (maximum) @ nominal input

20.9 A (@V

OUT

< 48VDC)

37.5 A (@V

OUT

< 48VDC)

Hold up time, maximum output power

>20ms; output voltage > 41 VDC

>10ms; output voltage > 42 VDC

Current sharing (10 - 100% load)

±5% of maximum current from 10 to 100% load

Static Voltage regulation (10 - 100% load)

±0.5%

Dynamic Voltage regulation

±5.0% for 10-90% or 90-10% load variation, regulation time < 50ms

Ripple

< 150 mV

PP

, 30 MHz bandwidth

Protection

ORing FET

Short circuit proof

High temperature protection

Over voltage Shutdown

OTHER SPECIFICATIONS

Efficiency

Up to 95.5 %

Up to 95.8 %

Isolation

3.0 kVAC - input to output

1.5 kVAC - input to earth

710 VDC - output to earth

Alarms: Red LED

Low and high input voltage shutdown, High and low temperature shutdown, Rectifier

Failure, Overvoltage shutdown on output, Fan failure, Low output voltage alarm, CAN

bus failure

Warnings: Yellow LED

Rectifier in power de-rate mode, Remote output current limit activated, Input voltage

out of range, flashing at overvoltage, Loss of CAN communication with controller

Normal operation: Green LED

MTBF (Telcordia SR-332 Issue I method III (a))

>315 000 (@ T

ambient

: 25 °C)

>300 000 (@ T

ambient

: 25 °C)

Operating temperature (5-95% RH n.cond.

hum.)

Maximum output power de-rates above temp /

to

-40 to + 85°C [-40 to +185°F]

45°C [113°F] / 600W @ 85°C[185°F]

-40 to + 85°C [-40 to +185°F]

45°C [113°F] / 1000W @ 85°C[185°F]

Storage temperature

-40 to +85°C (-40 to +185°F), humidity 0 - 99% RH non-condensing

Dimensions[WxHxD] / Weight

72 x 41.5 x 217mm (2.83 x 1.63 x 8.54”) / < 850 g (1.9 lbs)

DESIGN STANDARDS

Electrical safety

UL 60950-1, EN 60950-1

EMC

ETSI EN 300 386

EN 61000-6-1 / -2 / -3 / -4 TS 61000-6-5

FCC CFR 47 Part 15

Environment

ETSI EN 300 019: 2-1 (Class 1.2), 2-2 (Class 2.3) & 2-3 (Class 3.2)

RoHS (2011/65/EU) and WEEE (2002/96/EC) compliant

Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto que deverá

aparecer aqui. Erro! Use a guia Página Inicial para aplicar Heading 1 ao texto

que deverá aparecer aqui.

18 User’s Guide Flatpack2 Rectifier & Supervision Modules,

1) DC input only allowed when up-stream breaker is rated for the applicable DC input voltage and has a maximum current rating of 32A

2) For HW revisions 1 - 1.31, nominal range is 207 - 277 VAC / 207 - 250 VDC, maximum output power at 176 V

AC/DC

is 1180 W with further linear de-rating to 90W at 122 V

AC/DC

. Not to

be used in applications with 110/120 VAC mains.

www.eltek.com

Headquarters:

Eltek

Gråterudv. 8, Pb 2340 Strømsø, 3003 Drammen, Norway

Phone: +47 32 20 32 00 Fax: +47 32 20 32 10

Loading...

Loading...