Operation Guide

Power Tower

351401.013

Issue 2

July 2003

Flatpack

Information in this document is subject to change without notice and does not represent a commitment

on the part of ELTEK Energy.

No part of this document may be reproduced or transmitted in any form or by any means — electronic

or mechanical, including photocopying and recording — for any purpose without the explicit written

permission of ELTEK Energy.

Copyright ©: ELTEK Energy, Norway 2006

NS-EN ISO 9001:1994 Certificate no: 900005Q NS-EN ISO 14001:1996 Certificate no: 900005E.

This product holds a CE mark and satisfies all requirements covering relevant standards and directives.

EMC

Generic Immunity Standard

▫ EN61000-6-1 Residential, Commercial and Light Industry

▫ EN61000-6-2 Industrial Environment

Generic Emission Standard

▫ EN61000-6-3 Residential, Commercial and Light Industry

▫ EN61000-6-4 Industrial Environment

ETS 300386 v1.3.1 Telecommunication Equipment

LVD

▫ EN 60950 Safety of Technology Equipment

Certificate no: 900005E

Head Office:

Eltek Energy

P.O. Box 2340 Strømsø

N-3003 DRAMMEN

Norway

Phone: (+47) 32 20 32 00

Fax: (+47) 32 20 32 10

E-Mail:

eltek@eltekenergy.com

Visit our Web site on Internet: http://www.eltekenergy.com

351470.013 Issue 2, July 2003

This document was produced using Microsoft Word

Certificate no: 900005Q

2(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

Table of Contents

1 Table of Contents

1 Table of Contents 3

2 Key Stakeholders/ Document History 5

3 Scope 7

4 Description of Flatpack Power Tower 9

4.1 General ..............................................................................................................9

5 Installation Procedures 11

5.1 Safety Precautions ...........................................................................................11

5.2 Mechanical Installation ................................................................................... 11

5.3 Earth connections ............................................................................................12

5.4 Mains Connections.......................................................................................... 13

5.5 General Arrangement ......................................................................................14

5.6 Installation of rectifiers ................................................................................... 18

6 System Monitoring 27

7 Specification Flatpack Power Tower 29

8 Figures 31

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

3(48)

Table of Contents

4(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

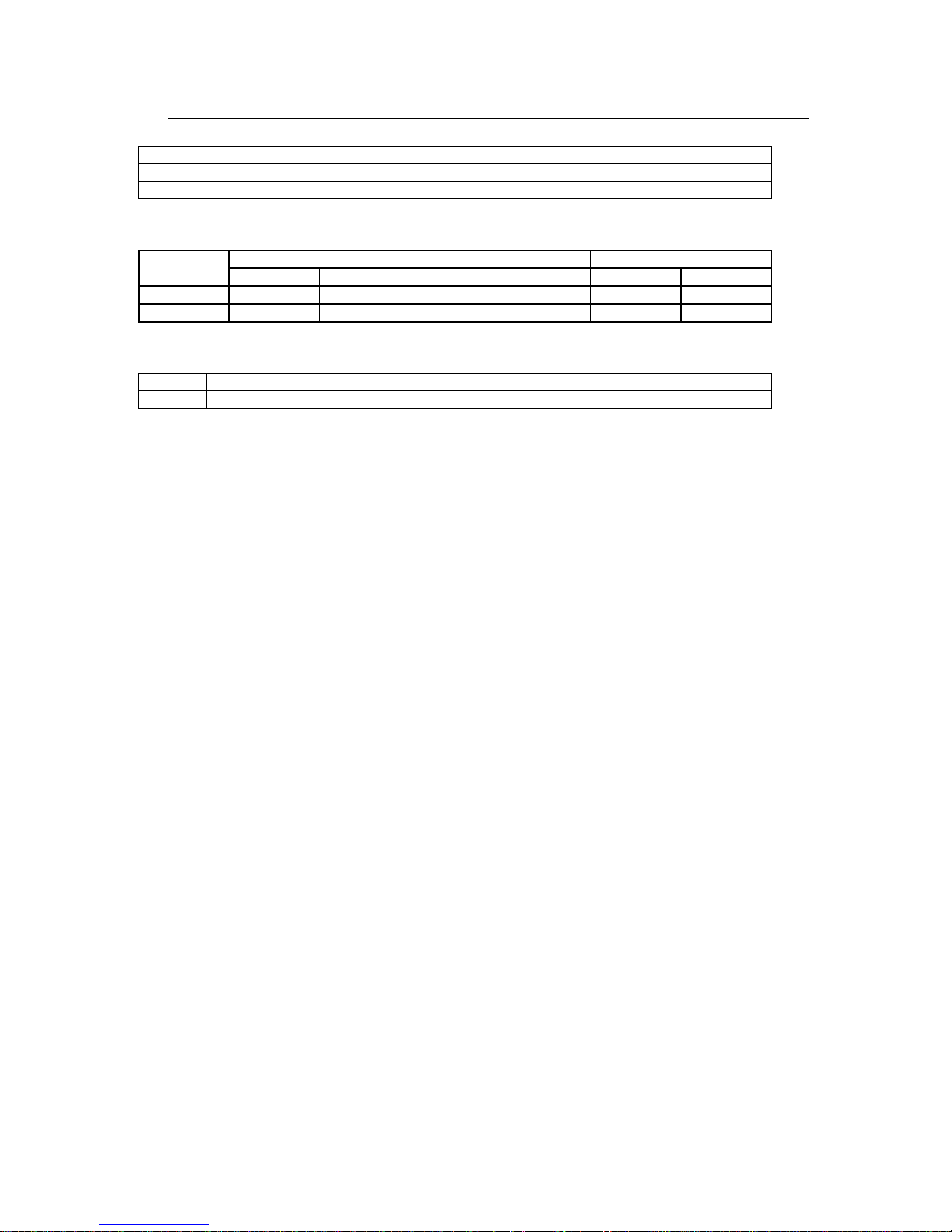

2 Key Stakeholders/ Document History

2 Key Stakeholders/ Document History

Name Title

Kjartan Albrigtsen Product Manager

Roar Linseth Technical Responsible

Written by Checked by Approved by

Rev Date Sign Date Sign Date Sign

V1 19.02.03 M.G.C. R.L.. K.A.

V2 18.07.03 M.G.C. 04.08.2003 J.K 04.08.2003 I.F

Rev.V1

Rev.V2

The original signatures are recorded on the company’s logistic data system

First issue

Updated to include Imperial measurements

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

5(48)

2 Key Stakeholders/ Document History

6(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

3 Scope

3 Scope

Flatpack Power Systems are made up of Power Shelves for plug-in rectifier modules, a DC distribution that

includes a monitoring and control unit and optional Batteries.

The power shelves include the necessary amount of rectifiers needed in the system. The DC distribution include

fuses, breakers (MCB`s), load and/or battery disconnect units as well as a Monitoring & Control Unit.

This Operation Guide contains information about the Flatpack Power Tower distribution. It includes information

about alarm connections, DC connections and optional equipment, together with a description on how to install

and commission the distribution.

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

7(48)

3 Scope

8(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

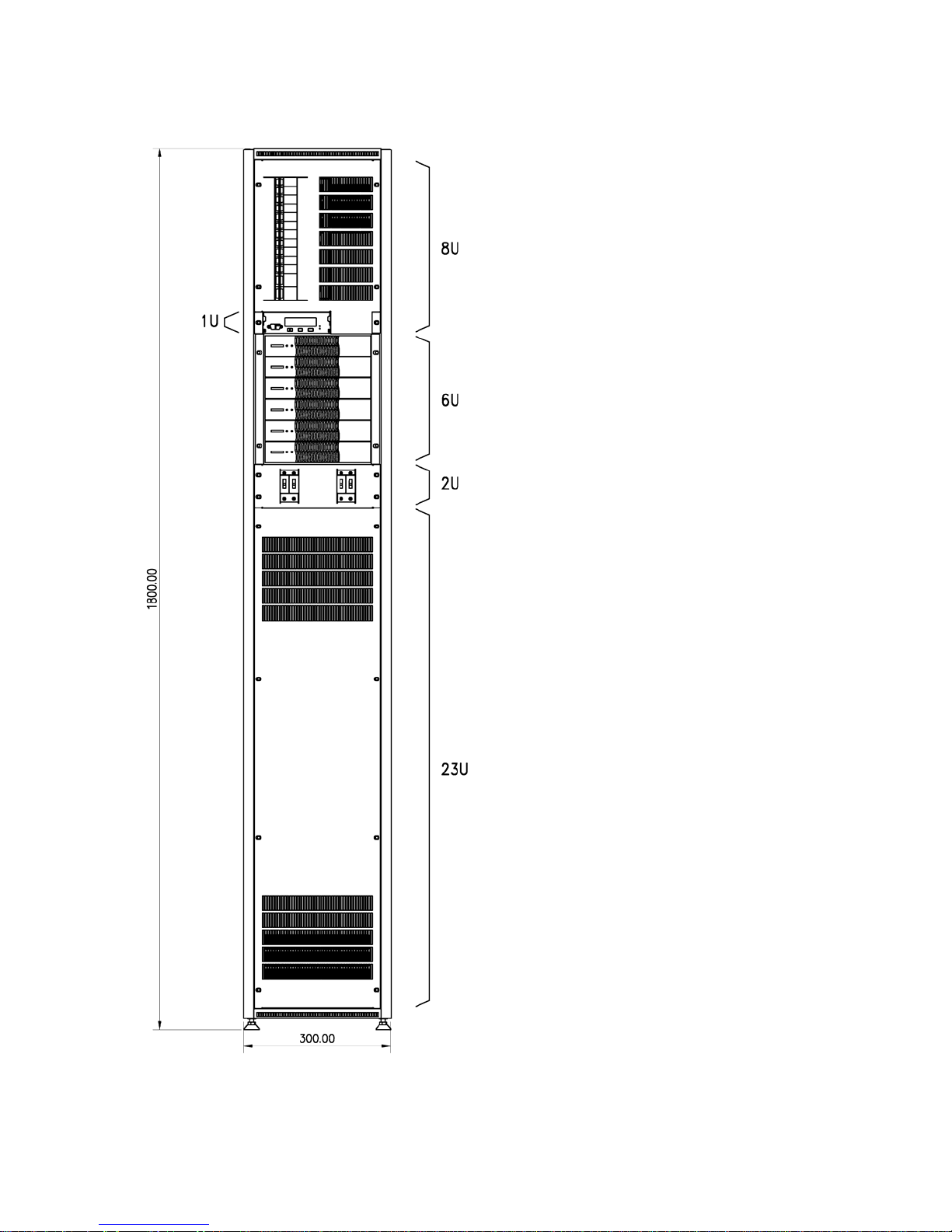

4 Description of Flatpack Power Tower

4.1 General

4 Description of Flatpack Power Tower

The Power Tower system is a power rack system based on the Flatpack 1500 W 48Vdc.

The systems contain a DC distr., until 6 Flatpack 1500 W 48Vdc. To provided monitoring and control Flatpack

Monitoring/Control Unit (MCU) are used. The distribution is rated for 200A, negative distribution.

The system is designed for cable entry from top. Prepared for 2 battery banks (2 x100Ah) and max. output

current of 200A.

DC output is made by connection between the positive rail and the different load/battery fuses. Negative

distribution is standard.

Cabinet size is 300x600x1800mm (11.8”x23.6”x70.9”).

The system is build up from a basic number and prepared for different armament (Valid option

3

).

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

9(48)

4 Description of Flatpack Power Tower

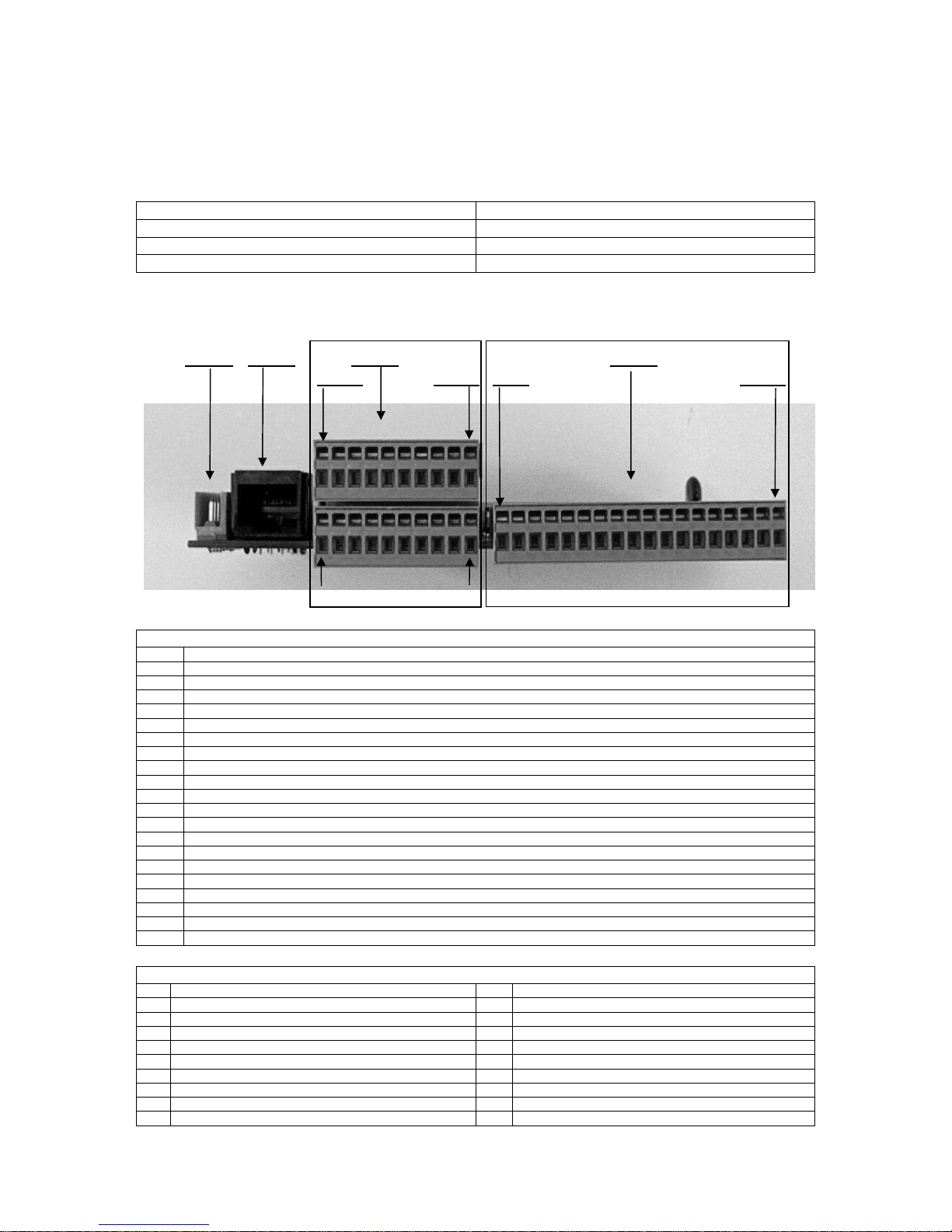

4.1.1 Basic or extended functionality for monitoring and control

The Flatpack Power Tower is available with either basic- or extended functionality for monitoring and control of

the system. The type of interface PCB mounted inside determines whether the distribution unit has basic or

extended functionality. The pictures below show that the interface PCB used distribution units with basic

functionality has less wire connectors than the PCB used in distribution units with extended functionality.

A distribution with extended functionality includes five more alarm relay outputs (totally 11) in addition to the

standard monitoring and control features.

4.1.1.1 Basic functionality

Interface PCB for distribution units with basic

functionality (part no. 100350). Includes all

standard monitoring and control features.

See chapter 5.6.2.2Basic version (PCB part no.

100350) for more details.

4.1.1.2 Extended functionality

4.1.1.3 Front access interface PCB

Interface PCB for distribution units with extended

functionality (part no. 100145). Includes all

standard monitoring and control features and five

additional alarm relay outputs.

See chapter 5.6.2.3 Extended version (PCB part

no 100145)for more details.

Interface PCB for distribution units with basic

functionality (part no. 1001714). Includes all

standard monitoring and control features.

See chapter 5.6.2.4 Front Access PCB (PCB Part

number 101714) for more details.

10(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

5 Installation Procedures

5 Installation Procedures

5.1 Safety Precautions

The equipment described in this manual must only be operated

by Eltek Energy personnel or by persons who have attended a

suitable Eltek Energy training course.

The equipment represents an energy hazard and failure to

observe this could cause terminal injury and invalidate our

warranty.

There are hazardous voltages inside the rectifier system. As

the rectifier units incorporate large charged capacitors, it is

dangerous to work inside the system even if the mains supply

is disconnected.

Products into which our components are incorporated have to

comply with a number of requirements. Installation is to be in

accordance with the recommendations herein.

Please read the manual carefully before using the equipment.

5.2 Mechanical Installation

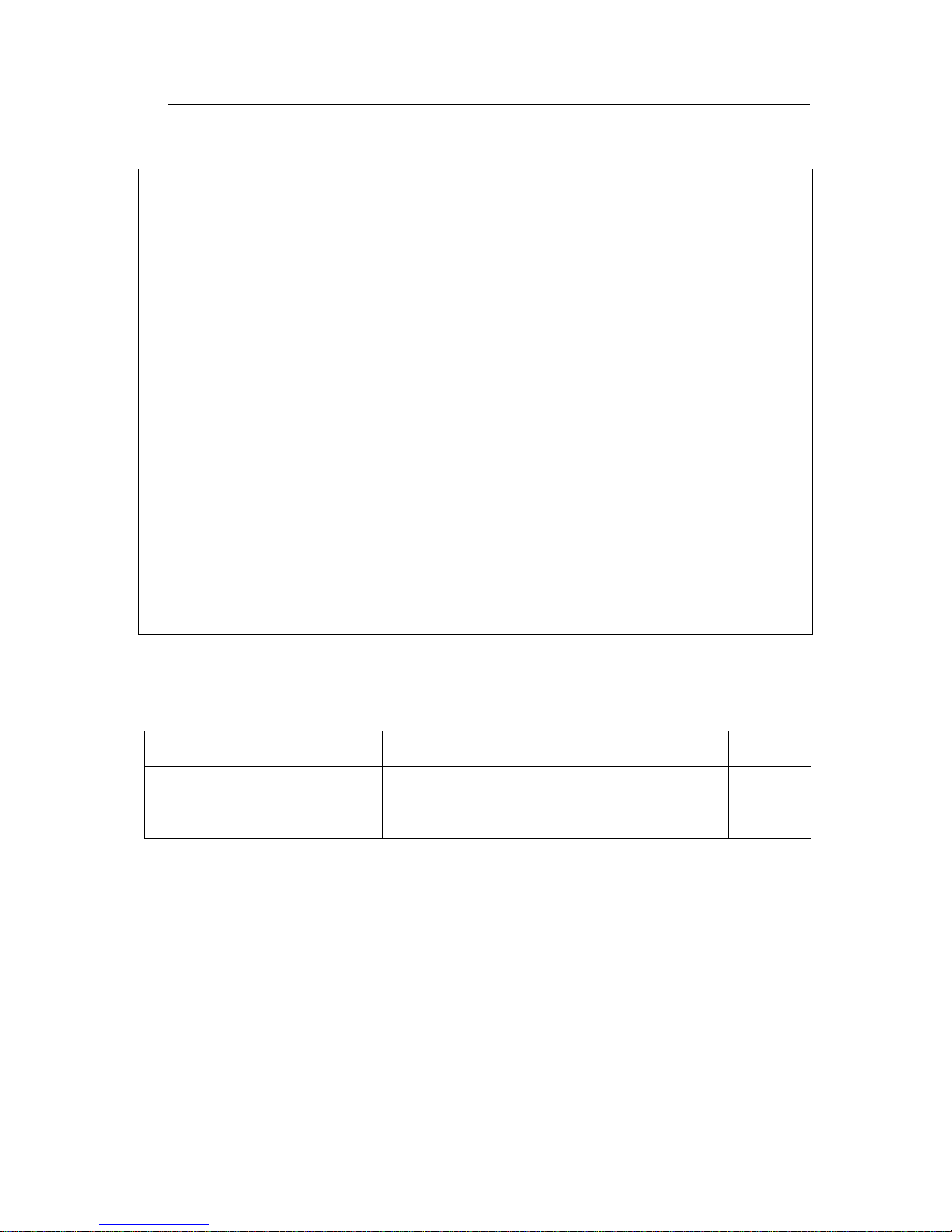

Installation Step Comments Okay

1 TAKE THE FLATPACK POWER TOWER

OUT OF THE PACKAGING

Procedure 1: Mechanical Installation Flatpack Power Tower

NSPECT THE DISTRIBHUTION UNIT FOR ANY PHYSICAL

I

DAMAGE

. DAMAGED EQUIPMENT SHOULD BE RETURNED TO

YOUR SUPPLIER

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

11(48)

5 Installa tion Proced ures

5.3 Earth connections

The ground point (M6 stud) is located

behind the AC terminals

The System Ground Cable must be connected to the Common Positive Busbar to ensure that the positive output

of the rectifiers will be connected to ground and the negative output will represent the – 48Vdc supply voltage.

The common positive busbar is connected to the chassis through an earth strap.

Earth connection between

chassis and common

positive bar (system ground)

12(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

5 Installation Procedures

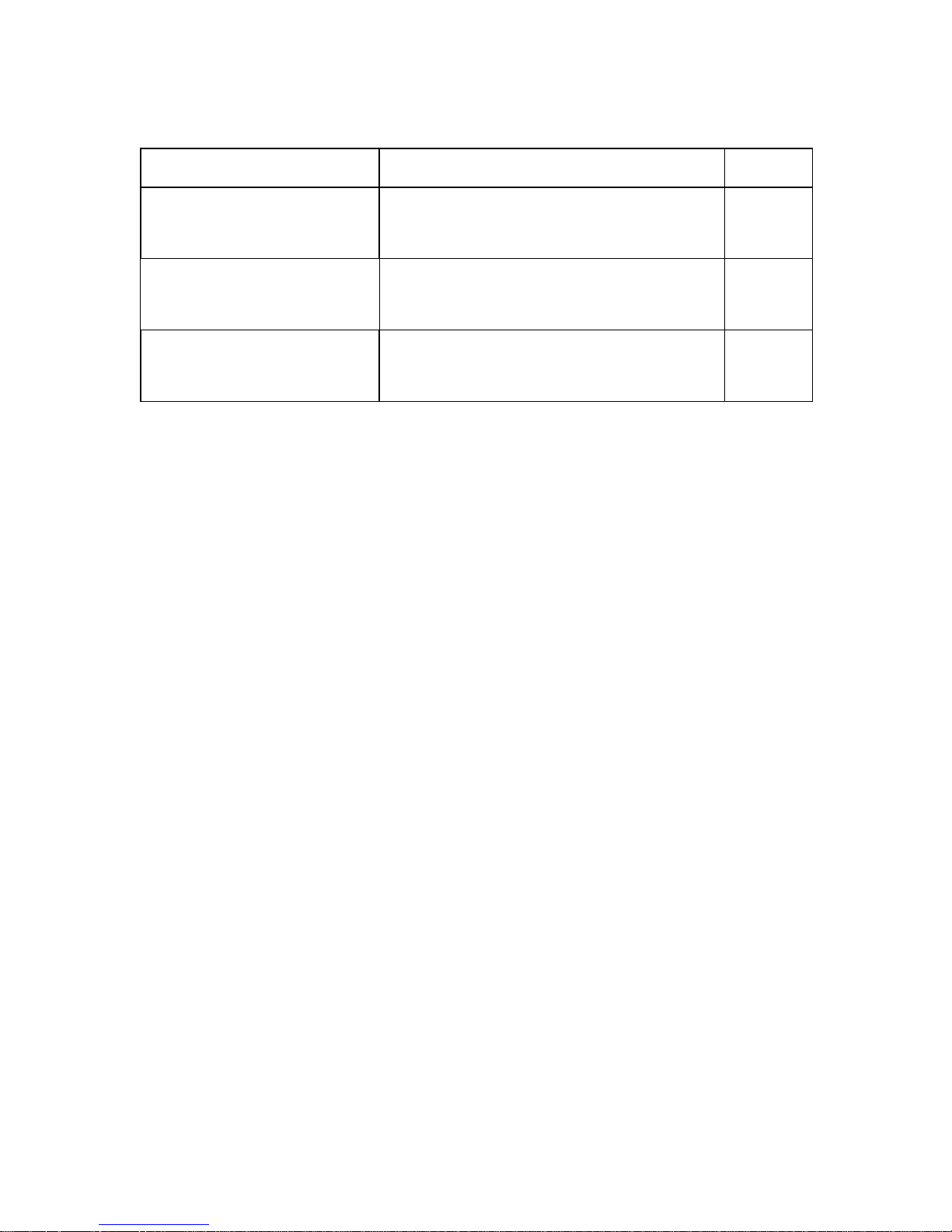

5.4 Mains Connections

Installation Step Comments OK

1. VERIFY WHICH MAINS

CONFIGURATION IS APPLICABLE

FOR YOUR SYSTEM

2. IF NECESSARY, RECONFIGURE THE

MAINS TERMINALS ACCORDING TO

THE SUPPLY AVAILABLE

3. CONNECT THE PROTECTIVE

EARTH BEFORE ANY OF THE LIVE

TERMINATIONS

Procedure 2: Mains Connections Flatpack Power S helf

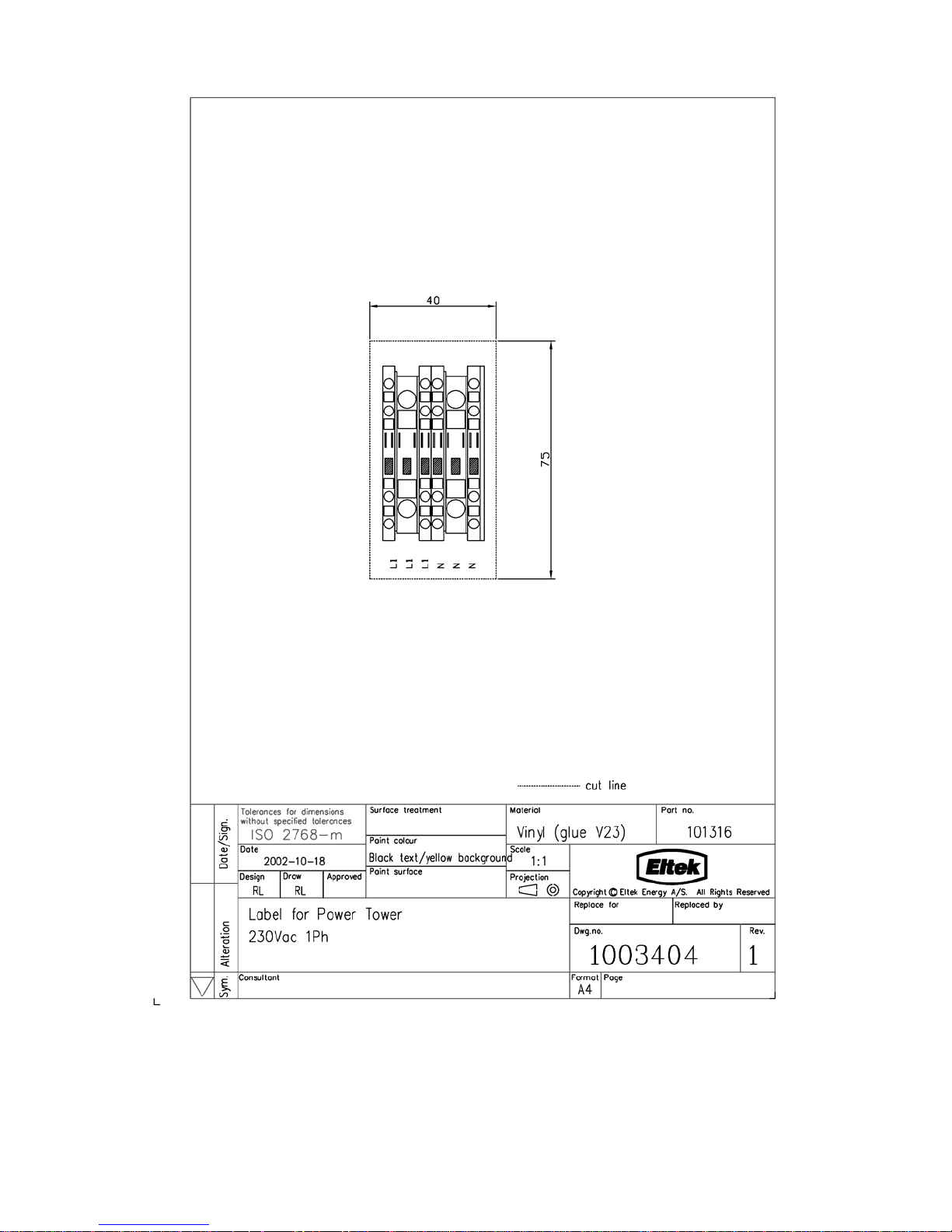

Refer to label for Power Tower AC connections

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

13(48)

5 Installa tion Proced ures

5.5 General Arrangement

14(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

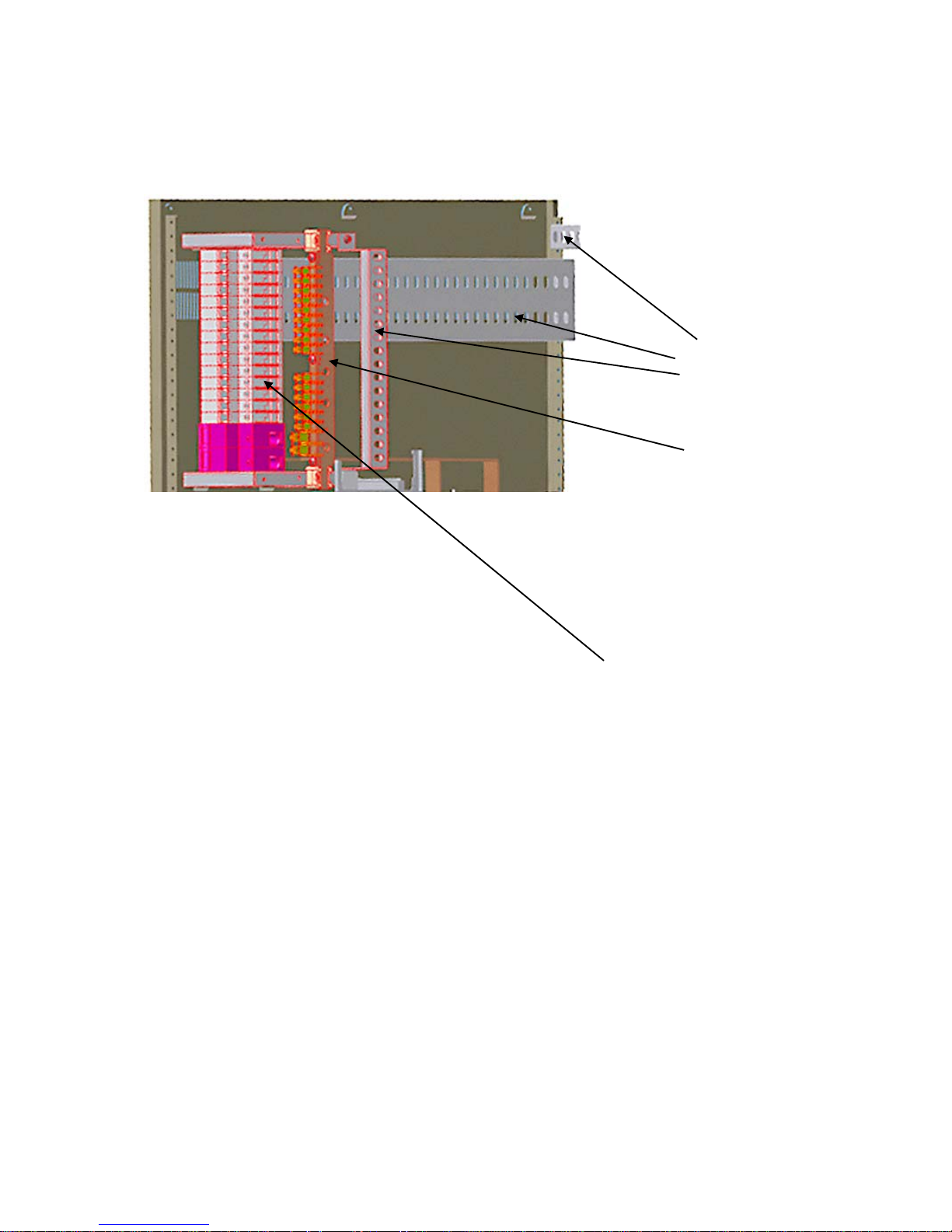

5.5.1 DC Connections/Terminations

5 Installation Procedures

Cord

anchorage

Common

positive busbar

DC load MCB’s with the

negative output on top of

each MCB.

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

15(48)

5 Installa tion Proced ures

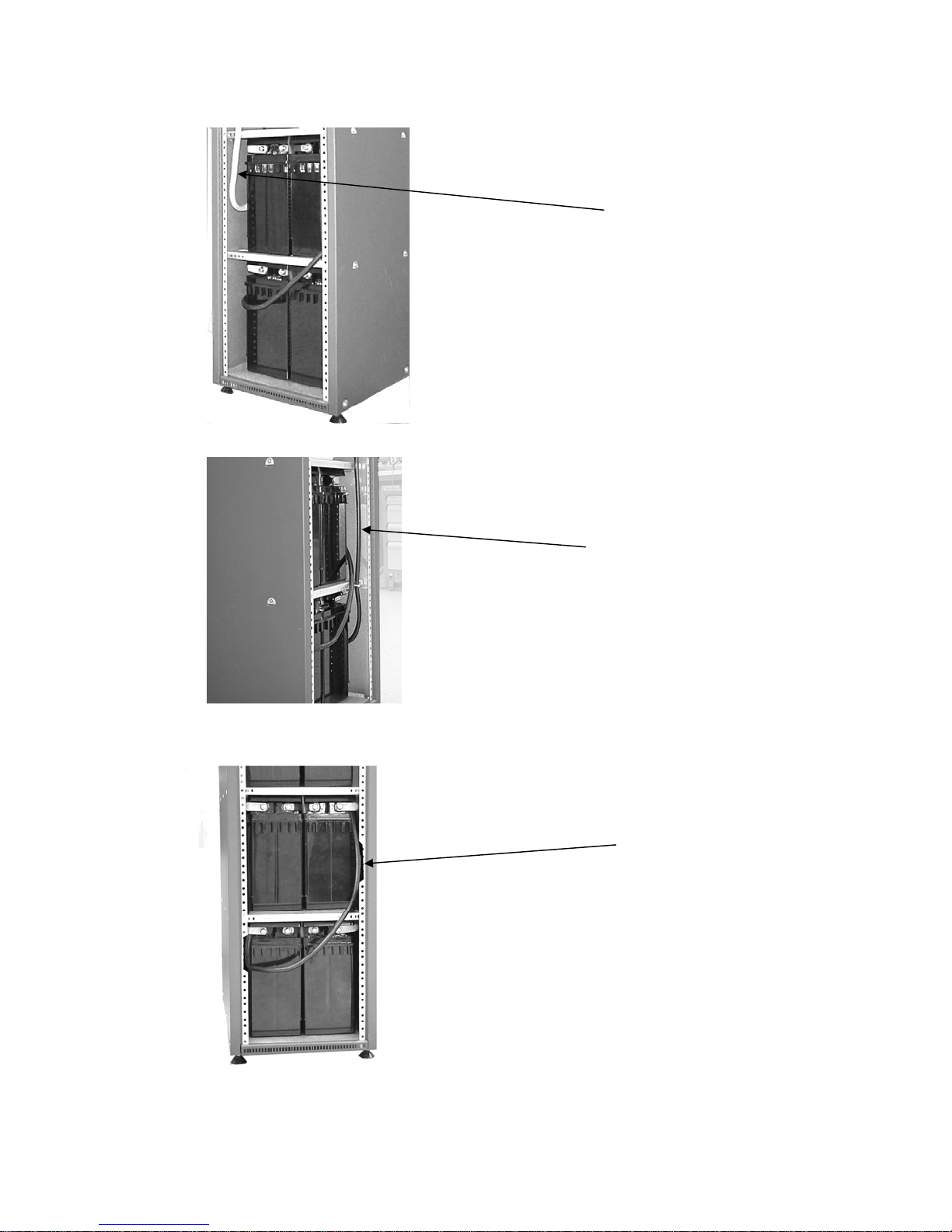

5.5.2 Description of battery connections

Connection of negative

pole from battery fuse

Connection of positive pole

(from common Positive Busbar)

Cutaway view showing

connection of a battery

bank in series

16(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

Batt. Bank No. 1

(Batt.fuse 1)

5 Installation Procedures

Batt. Bank No. 2

(Batt.fuse 2)

5.5.3 Procedure for connection of DC cables

Installation Step Comments OK

1 DECIDE CABLE ENTRY

2 DRESS THE CABLES INTO THE

CABINET

, CUT TO LENGTH AND FIT

CABLE LUGS OR FERRULES IF

APPLICABLE

3 FASTEN THE CABLES TO THE DC

TERMINALS

6 FASTEN ALL CABLES AWAY FROM

SHARP EDGES AND RELIEVE ANY

STRAIN FROM THE TERMINALS

.

The cables or copper bars can enter from top

Use cable cutter and cable lug crimper fitted with

appropriate sized die.

For cables/wires

The holes are dimensioned for M8 bolts, which are fitted

at delivery

See chapter “connections/terminal” for connection

details

Ensure that the cables do not impose any stress to the

terminal connections.

Ensure that the cables do not rest against any sharp edges

inside the cabinet

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

17(48)

5 Installa tion Proced ures

5.6 Installation of rectifiers

Installation of Flatpack 1500 Rectifiers

Installation Step Comments OK

1. PLUG IN THE NEW SMPS

MODULE(S)

2. FASTEN THE MODULE BY PUSHING

THE LEVERS BACK INTO POSITION

3. VERIFY THAT THE RECTIFIER IS ON

4. MOUNT BLIND PANELS ON EMPTY

RECTIFIER POSITIONS

Make sure that the levers on each side of the rectifier are

pulled forward (see section 5.6.1)

The green “Power” LED is lit and no alarm is activated

For safety reasons all vacant rectifier positions must be

covered by blind panels

Procedure 3: Installation of Rectifiers

5.6.1 Handles and locking me chanism

The Flatpack 1500 rectifier incorporates handles that serve two purposes:

1.TO LOCK THE RECTIFIER INTO POSITION

When the rectifier is plugged into its slot, it is then locked into position using the handles on either side of the

front panel. The handles must be rotated into their housings and firmly pushed home only after the rectifier is in

position, failure to do so will prevent the rectifier from making proper contact.

18(48) Operation Guide, Flatpack Power Tower

Handle in locked position

351401.013v2 July 2003

5 Installation Procedures

To unlock and release the handles, insert a small screw driver into the holes in the upper corners of the rectifier

front panel to release the spring mechanism. Do not use excessive force. The handle will release and pop out.

2. PULL-OUT HANDLES

When both handles are released use them to pull the rectifier loose.

o Do not hold or hand-carry the rectifier by its handles.

o Use gentle force, when releasing the handles from their locked position

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

19(48)

5 Installa tion Proced ures

5.6.2 Description of alarm and sign al connections

Three types of PCB`s are used for this purpose (Basic and Extended version). All PCB`s are described in this

chapter. Please verify which type of PCB is mounted in your system before any connections are made (see

chapter “Basic or extended functionality for monitoring and control” for details).

5.6.2.1 Alarm relay specification

Nominal switching capacity 2A/30V DC

Maximum switching power 60W (resistive load)

Maximum switching voltage 220V DC

Maximum switching current 2A DC

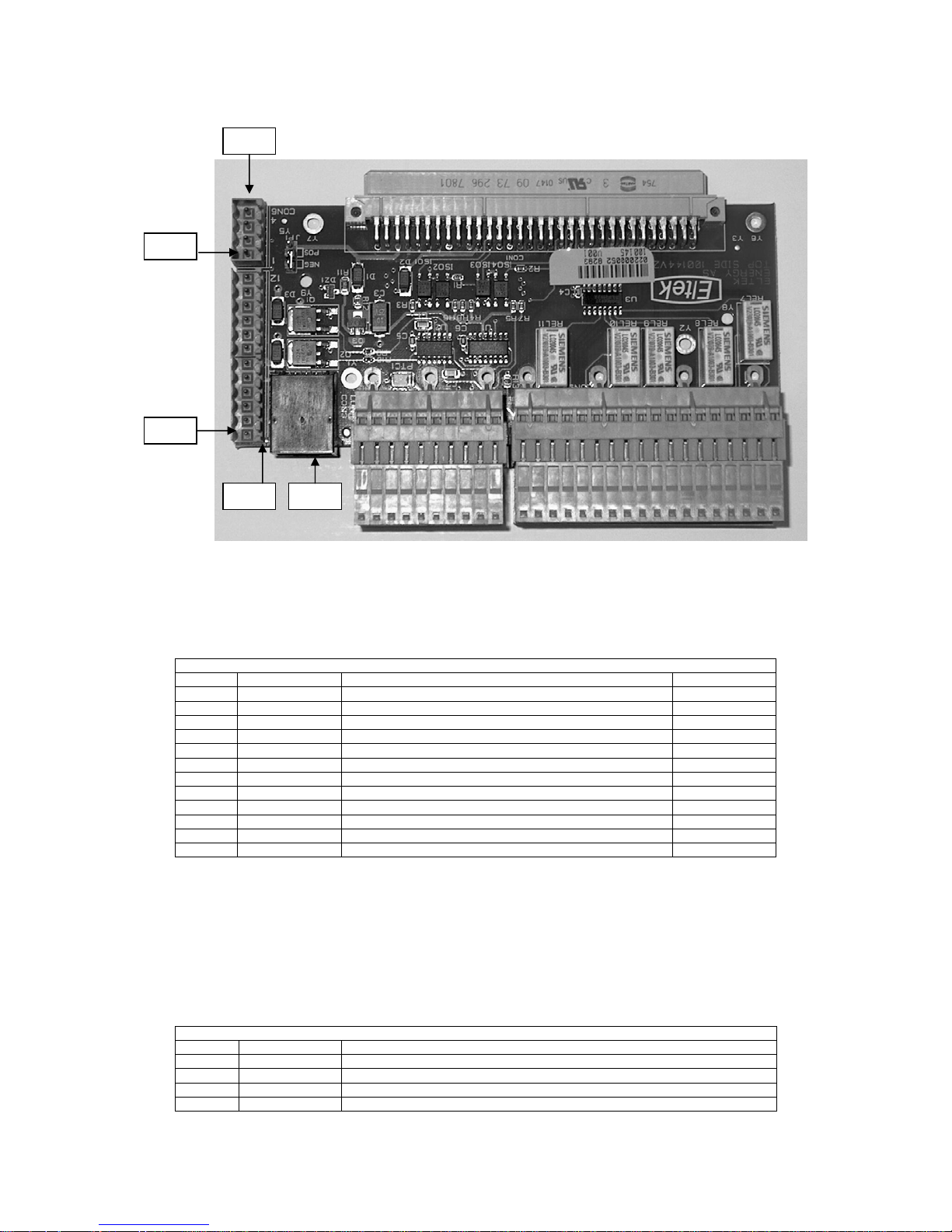

5.6.2.2 Basic version (PCB part no. 100350)

CON2 CON3 CON4 CON5

PIN11

PIN20 PIN1 PIN18

PIN1 PIN10

PIN DESCRIPTION

1 Digital Input 1 (When shorted to AGND (PIN2), the input will be de-activated)

2 AGND

3 Digital Input 2 (When shorted to AGND (PIN4), the input will be de-activated)

4 AGND

5 Digital Input 3 (When shorted to AGND (PIN6), the input will be de-activated)

6 AGND

7 Digital Input 4 (When shorted to AGND (PIN8), the input will be de-activated)

8 AGND

9 Symmetry Alarm 2 (Digital input referred to AGND (PIN9). For use together with external symmetry alarm PCB(`s).

10 AGND

11 Symmetry Alarm 1 (+) (Analog measurement between PIN11 and PIN12)

12 Symmetry Alarm 1 (-) (Analog measurement between PIN11 and PIN12)

13 Symmetry Alarm 3 (+) (Analog measurement between PIN13 and PIN14)

14 Symmetry Alarm 3 (-) (Analog measurement between PIN13 and PIN14)

15 AUX.power output (+) (20Vdc/ 200mA (21V ±5%) Intended for powering a modem)

16 AUX.power output (-) (20Vdc/ 200mA (21V ±5%) Intended for powering a modem)

17 Not in use

18 Temperature sensor (+) (For connection of temperature probe)

19 Temperature sensor (-) (For connection of temperature probe)

20 Temperature sensor (cable screen)

CON4 PIN ASSIGNMENT (for basic PCB version part no. 100350)

PIN DESCRIPTION PIN DESCRIPTION

1 Alarm relay 6 NC (Alarm relay output) 10 Alarm relay 3 NC (Alarm relay output)

2 Alarm relay 6 NO (Alarm relay output) 11 Alarm relay 3 NO (Alarm relay output)

3 Alarm relay 6 C (Alarm relay output) 12 Alarm relay 3 C (Alarm relay output)

4 Alarm relay 5 NC (Alarm relay output) 13 Alarm relay 2 NC (Alarm relay output)

5 Alarm relay 5 NO (Alarm relay output) 14 Alarm relay 2 NO (Alarm relay output)

6 Alarm relay 5 C (Alarm relay output) 15 Alarm relay 2 C (Alarm relay output)

7 Alarm relay 4 NC (Alarm relay output) 16 Alarm relay 1 NC (Alarm relay output)

8 Alarm relay 4 NO (Alarm relay output) 17 Alarm relay 1 NO (Alarm relay output)

9 Alarm relay 4 C (Alarm relay output) 18 Alarm relay 1 C (Alarm relay output)

CON5 PIN ASSIGNMENT (for basic PCB version part no. 100350)

20(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

5 Installation Procedures

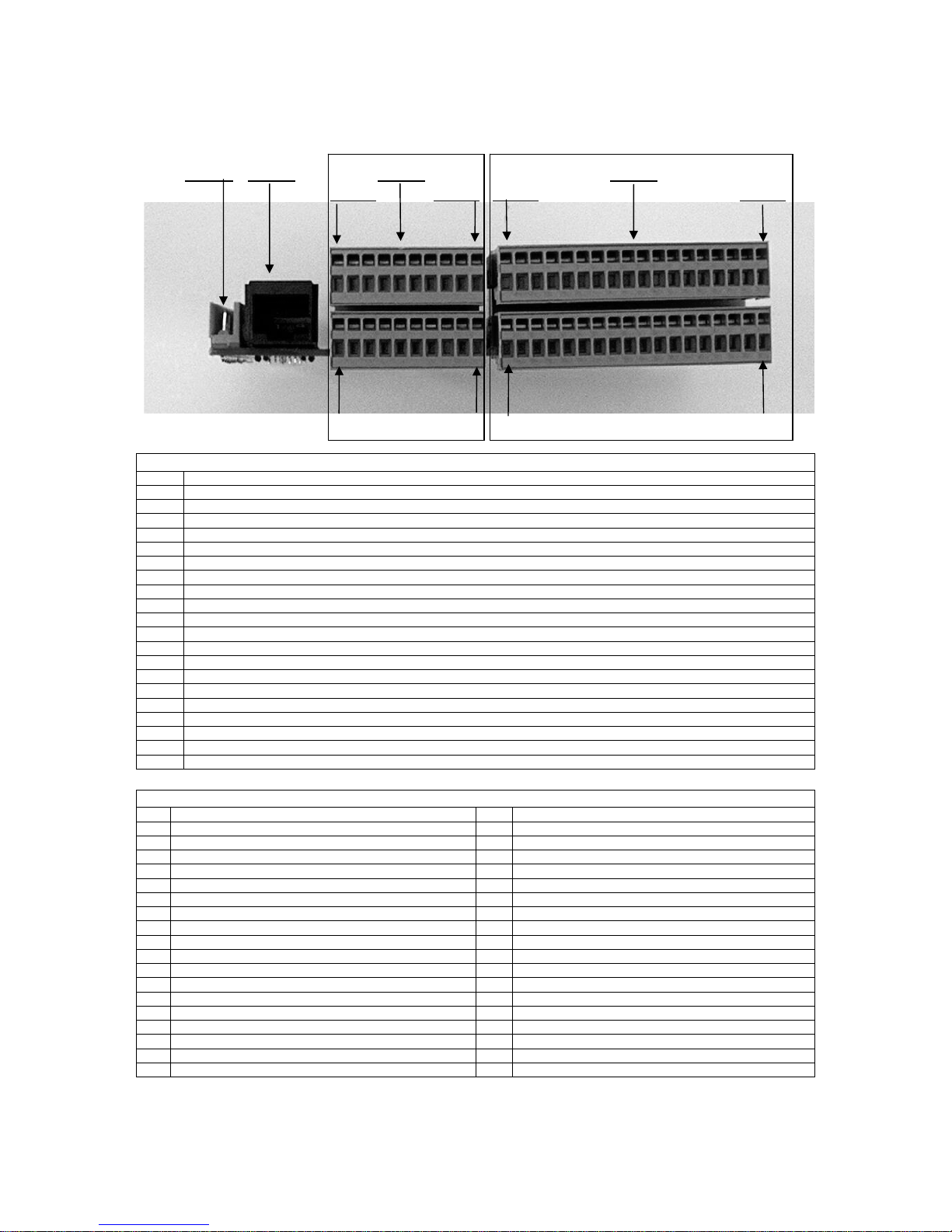

5.6.2.3 Extended version (PCB part no 100145)

CON2 CON3 CON4 CON5

PIN11

PIN20 PIN19 PIN36

PIN1 PIN10 PIN1 PIN18

PIN DESCRIPTION

1 Digital Input 1 (When shorted to AGND (PIN2), the input will be de-activated)

2 AGND

3 Digital Input 2 (When shorted to AGND (PIN4), the input will be de-activated)

4 AGND

5 Digital Input 3 (When shorted to AGND (PIN6), the input will be de-activated)

6 AGND

7 Digital Input 4 (When shorted to AGND (PIN8), the input will be de-activated)

8 AGND

9 Symmetry Alarm 2 (Digital input referred to AGND (PIN9). For use together with external symmetry alarm PCB(`s).

10 AGND

11 LVD1 status (For external verification of contactor state. An alarm switch mounted on the contactor must be hardwired to CON6)

12 LVD1 status (For external verification of contactor state. An alarm switch mounted on the contactor must be hardwired to CON6)

13 LVD2 status (For external verification of contactor state. An alarm switch mounted on the contactor must be hardwired to CON6)

14 LVD2 status (For external verification of contactor state. An alarm switch mounted on the contactor must be hardwired to CON6)

15 Symmetry Alarm 1 (+) (Analog measurement between PIN11 and PIN12)

16 Symmetry Alarm 1 (-) (Analog measurement between PIN11 and PIN12)

17 Symmetry Alarm 3 (+) (Analog measurement between PIN13 and PIN14). Not in use

18 Symmetry Alarm 3 (-) (Analog measurement between PIN13 and PIN14). Not in use

19 AUX.power output (+) (20Vdc/ 200mA (21V ±5%) Intended for powering a modem)

20 AUX.power output (-) (20Vdc/ 200mA (21V ±5%) Intended for powering a modem)

CON4 PIN ASSIGNMENT (for extended PCB version part no. 100145)

PIN DESCRIPTION PIN DESCRIPTION

1 Temperature sensor (+) (For connection of temp. probe) 19 Alarm relay 6 NC (Alarm relay output)

2 Temperature sensor (-) (For connection of temp. probe) 20 Alarm relay 6 NO (Alarm relay output)

3 Temperature sensor (cable screen) 21 Alarm relay 6 C (Alarm relay output)

4 Alarm relay 11 NC (Alarm relay output) 22 Alarm relay 5 NC (Alarm relay output)

5 Alarm relay 11 NO (Alarm relay output) 23 Alarm relay 5 NO (Alarm relay output)

6 Alarm relay 11 C (Alarm relay output) 24 Alarm relay 5 C (Alarm relay output)

7 Alarm relay 10 NC (Alarm relay output) 25 Alarm relay 4 NC (Alarm relay output)

8 Alarm relay 10 NO (Alarm relay output) 26 Alarm relay 4 NO (Alarm relay output)

9 Alarm relay 10 C (Alarm relay output) 27 Alarm relay 4 C (Alarm relay output)

10 Alarm relay 9 NC (Alarm relay output) 28 Alarm relay 3 NC (Alarm relay output)

11 Alarm relay 9 NO (Alarm relay output) 29 Alarm relay 3 NO (Alarm relay output)

12 Alarm relay 9 C (Alarm relay output) 30 Alarm relay 3 C (Alarm relay output)

13 Alarm relay 8 NC (Alarm relay output) 31 Alarm relay 2 NC (Alarm relay output)

14 Alarm relay 8 NO (Alarm relay output) 32 Alarm relay 2 NO (Alarm relay output)

15 Alarm relay 8 C (Alarm relay output) 33 Alarm relay 2 C (Alarm relay output)

16 Alarm relay 7 NC (Alarm relay output) 34 Alarm relay 1 NC (Alarm relay output)

17 Alarm relay 7 NO (Alarm relay output) 35 Alarm relay 1 NO (Alarm relay output)

18 Alarm relay 7 C (Alarm relay output) 36 Alarm relay 1 C (Alarm relay output)

CON5 PIN ASSIGNMENT (for extended PCB version part no. 100145)

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

21(48)

5 Installa tion Proced ures

CON 3

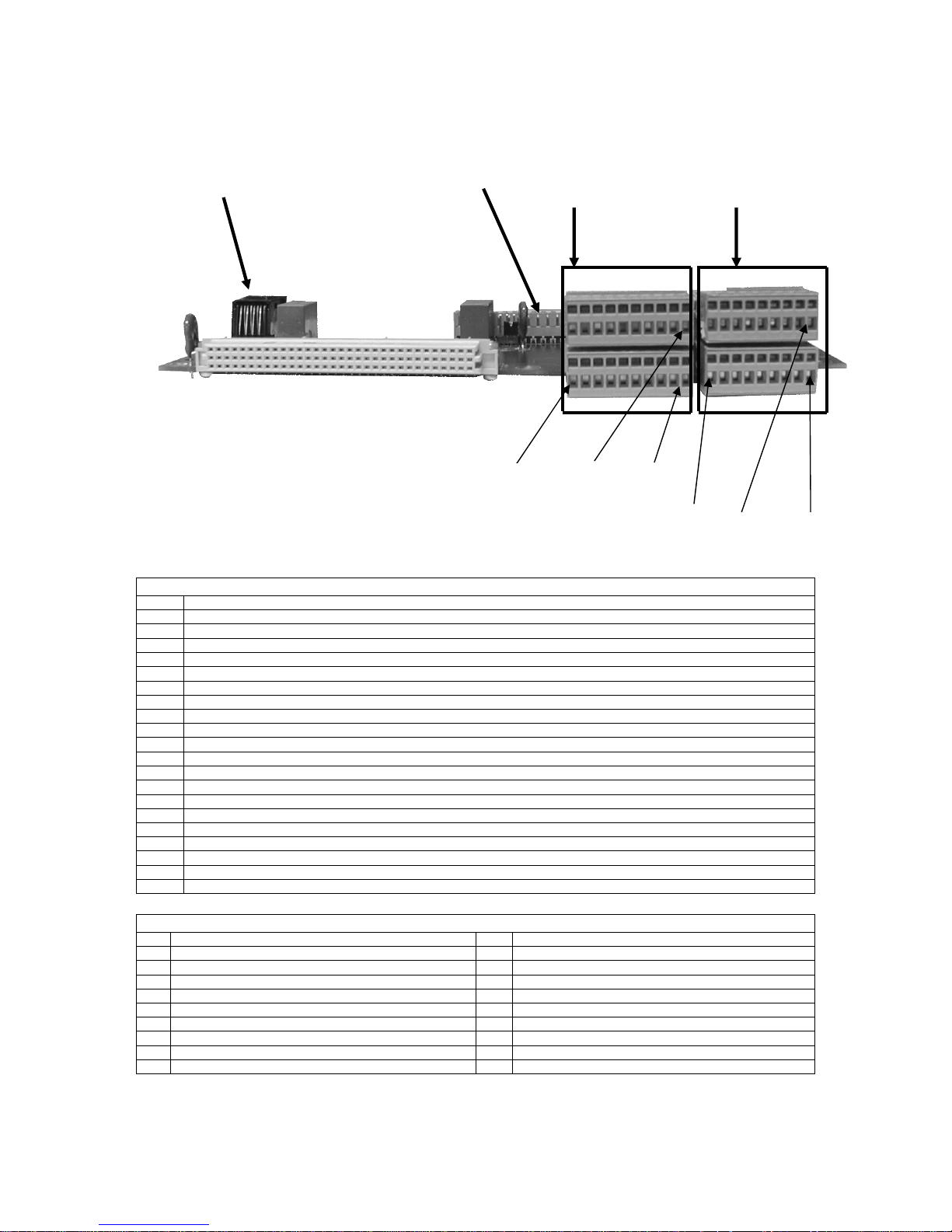

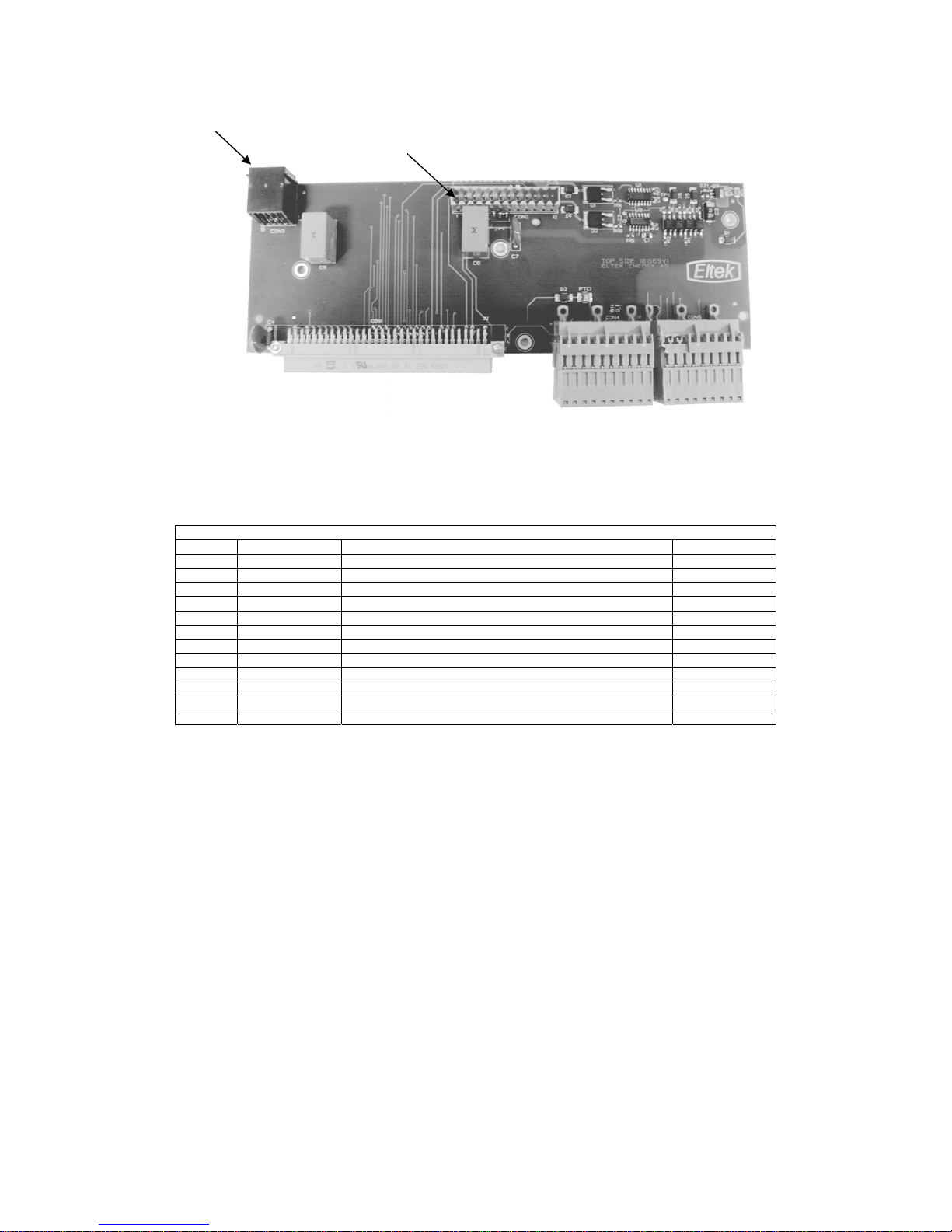

5.6.2.4 Front Access PCB (PCB Part number 101714)

CON 2

CON 4 CON 5

Pin 1

Pin 20

Pin 10

Pin 1

CON4 PIN ASSIGNMENT (for basic PCB version part no. 101714)

PIN DESCRIPTION

1 Digital Input 1 (When shorted to AGND (PIN2), the input will be de-activated)

2 AGND

3 Digital Input 2 (When shorted to AGND (PIN4), the input will be de-activated)

4 AGND

5 Digital Input 3 (When shorted to AGND (PIN6), the input will be de-activated)

6 AGND

7 Digital Input 4 (When shorted to AGND (PIN8), the input will be de-activated)

8 AGND

9 Symmetry Alarm 2 (Digital input referred to AGND (PIN9). For use together with external symmetry alarm PCB(`s).

10 AGND

11 Symmetry Alarm 1 (+) (Analog measurement between PIN11 and PIN12)

12 Symmetry Alarm 1 (-) (Analog measurement between PIN11 and PIN12)

13 Symmetry Alarm 3 (+) (Analog measurement between PIN13 and PIN14)

14 Symmetry Alarm 3 (-) (Analog measurement between PIN13 and PIN14)

15 AUX.power output (+) (20Vdc/ 200mA (21V ±5%) Intended for powering a modem)

16 AUX.power output (-) (20Vdc/ 200mA (21V ±5%) Intended for powering a modem)

17 Not in use

18 Temperature sensor (+) (For connection of temperature probe)

19 Temperature sensor (-) (For connection of temperature probe)

20 Temperature sensor (cable screen)

PIN DESCRIPTION PIN DESCRIPTION

1 Alarm relay 6 NC (Alarm relay output) 10 Alarm relay 3 NC (Alarm relay output)

2 Alarm relay 6 NO (Alarm relay output) 11 Alarm relay 3 NO (Alarm relay output)

3 Alarm relay 6 C (Alarm relay output) 12 Alarm relay 3 C (Alarm relay output)

4 Alarm relay 5 NC (Alarm relay output) 13 Alarm relay 2 NC (Alarm relay output)

5 Alarm relay 5 NO (Alarm relay output) 14 Alarm relay 2 NO (Alarm relay output)

6 Alarm relay 5 C (Alarm relay output) 15 Alarm relay 2 C (Alarm relay output)

7 Alarm relay 4 NC (Alarm relay output) 16 Alarm relay 1 NC (Alarm relay output)

8 Alarm relay 4 NO (Alarm relay output) 17 Alarm relay 1 NO (Alarm relay output)

9 Alarm relay 4 C (Alarm relay output) 18 Alarm relay 1 C (Alarm relay output)

CON5 PIN ASSIGNMENT (for basic PCB version part no. 101714)

Pin 18

Pin 9

22(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

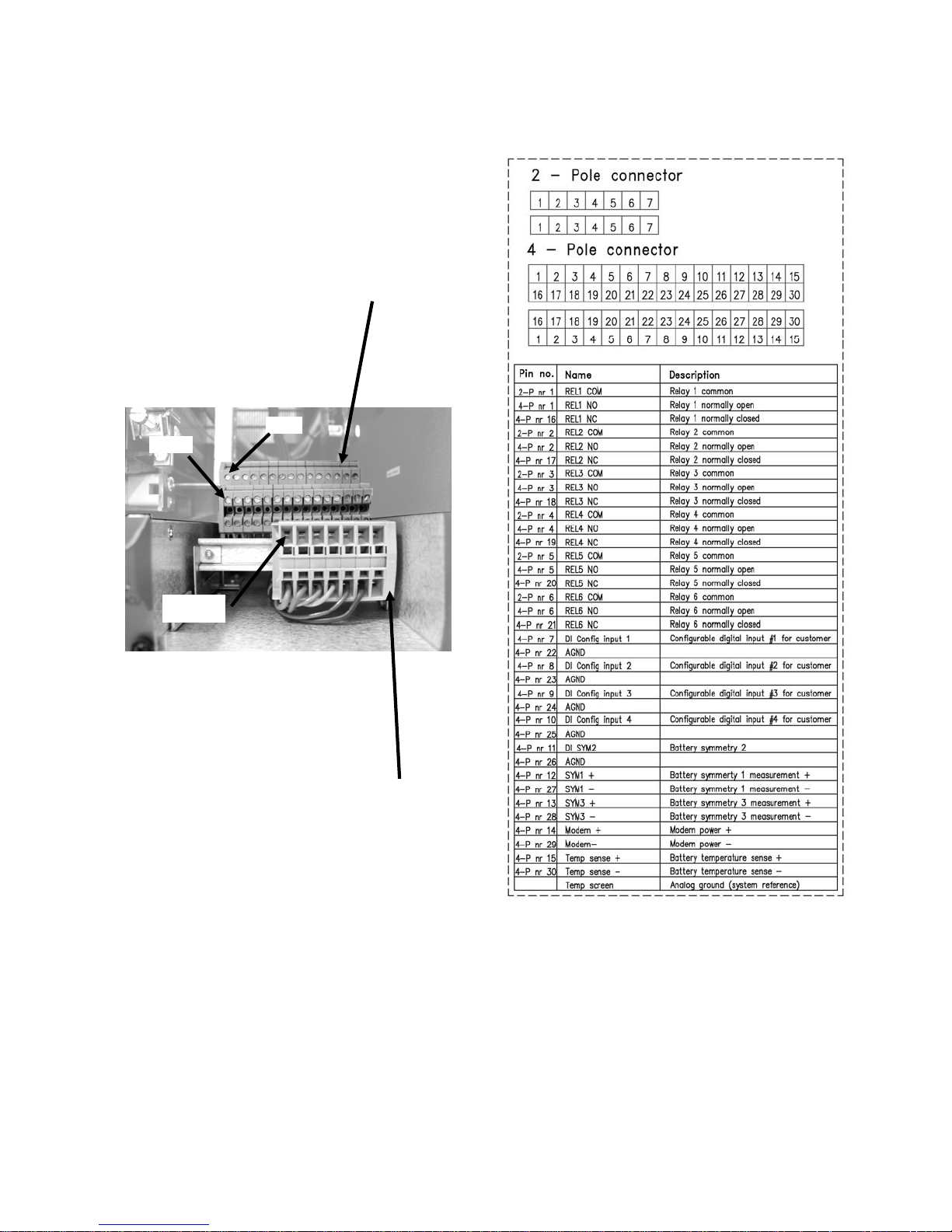

5.6.2.5 Front access from PCB 100350

Pin 16

Pin 1

4 - pole connector

Pin 1

2 – pole connector

5 Installation Procedures

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

23(48)

5 Installa tion Proced ures

5.6.2.6 Connectors for Internal system wiring

PIN1

PIN1

CON6

CON3 CON2

The connectors CON2 and CON3 have the same pin assignment on both the basic and the extended PCB

versions. CON6 is only mounted on the extended version PCB. CON3 is used for rectifier and power shelf

communication. All three connectors are only used for internal system wiring, which has been done at the

factory. These connectors are not involved in the system installation and commissioning process. The tables

below show the pin assignment for CON2 and CON6.

Pin no. Name Description Classification

Batt curr + Current measurement, battery A/I

1

Batt curr - Current measurement, battery A/I

2

Rect curr + Current measurement, rectifier A/I

3

Rect curr - Current measurement, rectifier A/I

4

Power + Power for Flatpack Monitoring/Control Unit O

5

Power - Power for Flatpack Monitoring/Control Unit O

6

Vdc+ Voltage measurement, dc bus voltage A/I

7

Signal ref/Vdc- Voltage measurement, dc bus voltage A/I

8

DI Batt fuse Battery fuse state D/I

9

Load fuse Load fuse detection D/I

10

LVD1 Contactor control O

11

LVD2 Contactor control O

12

CON2 PIN ASSIGNMENT

CON6 can be used to get an alarm via voltage free change over contacts, if the battery/load disconnect

contactor(s) fail to change state, or remains mechanically locked in any state. The contactors must be equipped

with alarm switch(s). CON6 is only used to improve the connectivity to external equipment. The alarm signal(s)

from the alarm switch(s) are connected to CON6 so they can be obtained on CON4 for easy connection to

external monitoring equipment.

The same alarm(s) can be transmitted to a remote/local management station via software in Flatpack MCU, if the

signal(s) are connected directly to any of the programmable digital input(s) on CON4. See “Flatpack MCU

Operation Guide” for detailed information about digital inputs and how they are programmed in software.

Pin no. Name Description

LVD1 status For internal wiring to alarm switch on LVD1. Obtained on CON4 for external connection

1

LVD1 status For internal wiring to alarm switch on LVD1. Obtained on CON4 for external connection

2

LVD2 status For internal wiring to alarm switch on LVD2. Obtained on CON4 for external connection

3

LVD2 status For internal wiring to alarm switch on LVD2. Obtained on CON4 for external connection

4

CON6 PIN ASSIGNMENT

24(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

5 Installation Procedures

5.6.2.7 Internal connections for front access Interface PCB

Con 3

The connectors CON2 and CON3 have the same pin assignment on both the basic and the extended PCB

versions. CON3 is used for rectifier and power shelf communication. All three connectors are only used for

internal system wiring, which has been done at the factory. These connectors are not involved in the system

installation and commissioning process. The table below shows the pin assignment for CON2.

Pin no. Name Description Classification

Batt curr + Current measurement, battery A/I

1

Batt curr - Current measurement, battery A/I

2

Rect curr + Current measurement, rectifier A/I

3

Rect curr - Current measurement, rectifier A/I

4

Power + Power for Flatpack Monitoring/Control Unit O

5

Power - Power for Flatpack Monitoring/Control Unit O

6

Vdc+ Voltage measurement, dc bus voltage A/I

7

Signal ref/Vdc- Voltage measurement, dc bus voltage A/I

8

DI Batt fuse Battery fuse state D/I

9

Load fuse Load fuse detection D/I

10

LVD1 Contactor control O

11

LVD2 Contactor control O

12

Con 2 Pin 1

CON2 PIN ASSIGNMENT

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

25(48)

5 Installa tion Proced ures

26(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

6 System Monitoring

6 System Monitoring

The Flatpack system can be monitored locally or from a remote location via the Flatpack MCU Monitoring &

Control Unit. The Flatpack MCU monitors and controls the entire rectifier system including distribution and

batteries, as well as other equipment on site.

Please refer to the Flatpack MCU Operation Guide, for detailed information about system monitoring

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

27(48)

6 System Moni toring

28(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

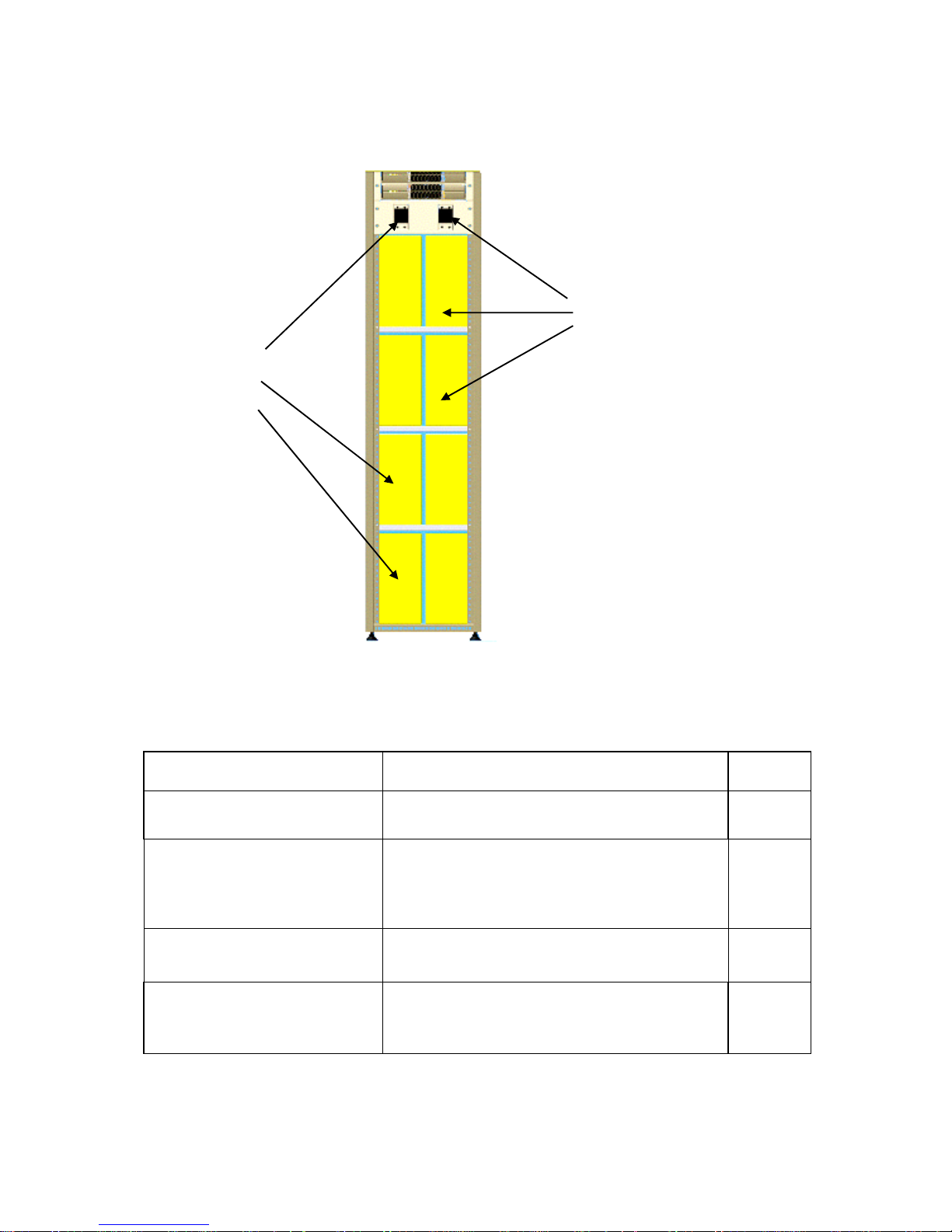

7 Specification Flatpack Power Tower

.

7 Specification Flatpack Power Tower

FlatPack Power Tower

SPECIFICATION

RATING

Voltage 0-60Vdc

Max. Current 200A

DISTRIBUTION OPTIONS

No. of Load breakers

(Note: Customer

distribution can be

made on request)

No. of Battery fuses 2 (max. 200A)

Low Voltage Battery

Disconnect

Low Voltage Load

Disconnect

MONITORING

Monitoring Unit1 Flatpack MCU

RS 232 serial port 1

Local operation Menu driven software via

Remote operation Winpower via modems

Alarm relays 6 relays are standard

Visual indications Green LED – Power ON

Digital inputs 4 (can be used to monitor

Current

measurements

Load fuse alarm Yes

Battery fuse alarm Yes

Low voltage battery

disconnect alarm

Low voltage load

disconnect alarm

Low output voltage

alarms

High output voltage

alarms

See Flatpack MCU datasheet for d et a i l ed i n f ormation regarding monitoring & control

2 x 125A Siemens

+11 x (Siemens 5SY4)

breakers

or

15 x (Cbi, Q-series)

breakers

1 (option)

1 (option)

Keypads and LCD

NMS via SNMP-agent

5 extra relays are optional

Red LED – Active alarm(s)

LCD – system status and

interrogation via keypads

external equipment)

- Battery current

- Rectifier current

- Load current

(calculated)

Yes

Yes

2 (individual alarm levels)

2 (individual alarm levels)

CONNECTIONS

Battery

connections

Load MCB

connections

Alarm

connections

OTHER SPECIFICATIONS

Complies to the

following

standards

Isolation 3.0 KVAC – input and output

Operating Temp -10 to +70°C / 14 to +158°F

Storage Temp -40 to +85°C / -40 to +185°F

Humidity Operating:

Dimensions W:300mm D:600mm H:1800mm

Weight Max. 65kg (143lbs) excl. MCU

Battery cable, M6

Negative, directly in the breakers

Positive, common positive buss

bars

Plug-in wire connectors located in

the rear of the MCU (front access

optional)

Electrical safety:

EN 60950

EMC:

EN 300 386 V.1.3.1 (Class B)

EN 61000-6-3

(emission, light industry)

EN 61000-6-2

(immunity, industry)

Environment:

ETS 300 019

1.5 KVAC – input earth

1.0 KVDC – output earth

5% to 95% RH non-condensing

Storage:

0% to 99% RH non-condensing

W:11.81” D:23.62” H:70.87”

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

29(48)

7 Specification Flatpack Power Tower

30(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

8 Figures

8 Figures

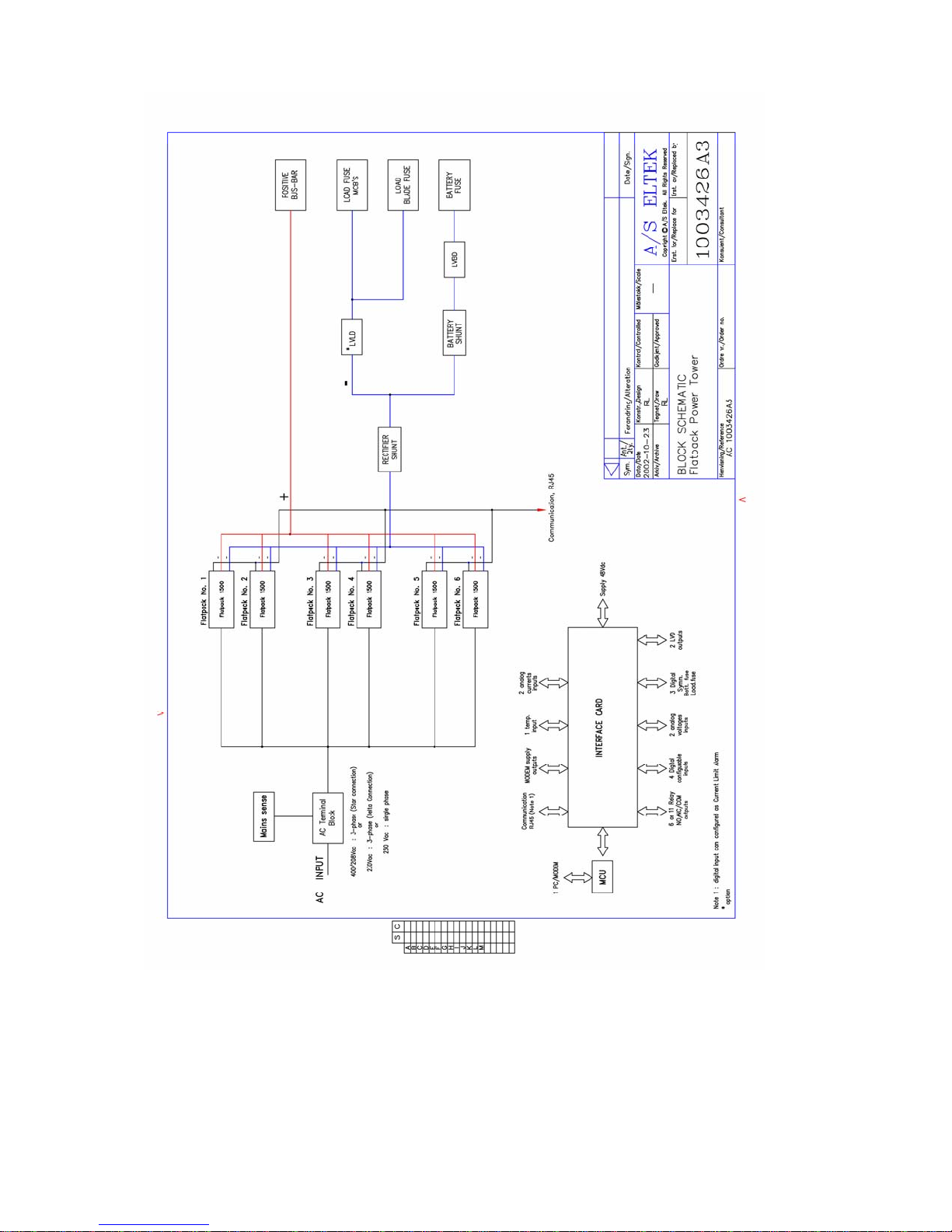

Figure 1 Block Schematic, Flatpack Power Tower ................................................................................................. 32

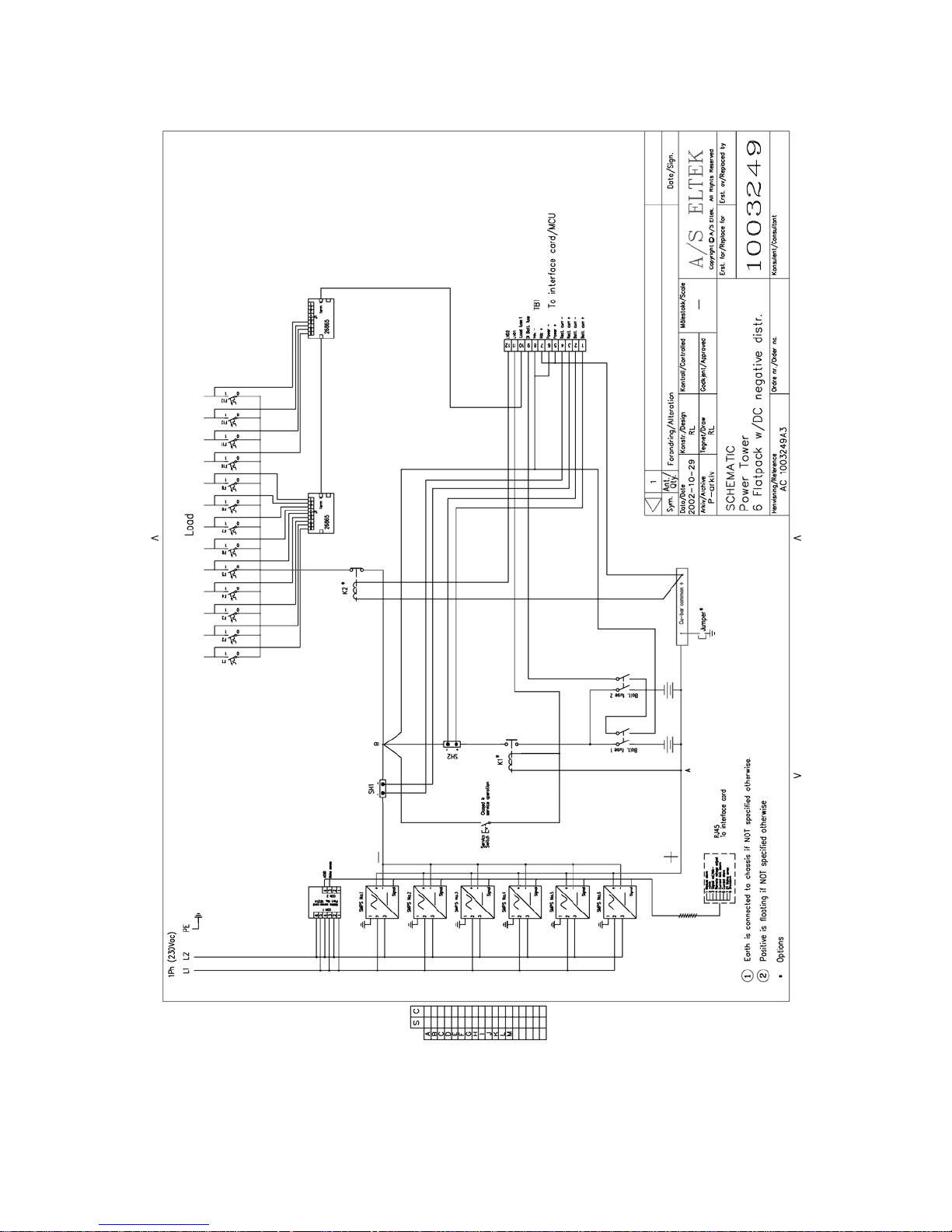

Figure 2 Schematic, 1Ph (230Vac) .......................................................................................................................... 34

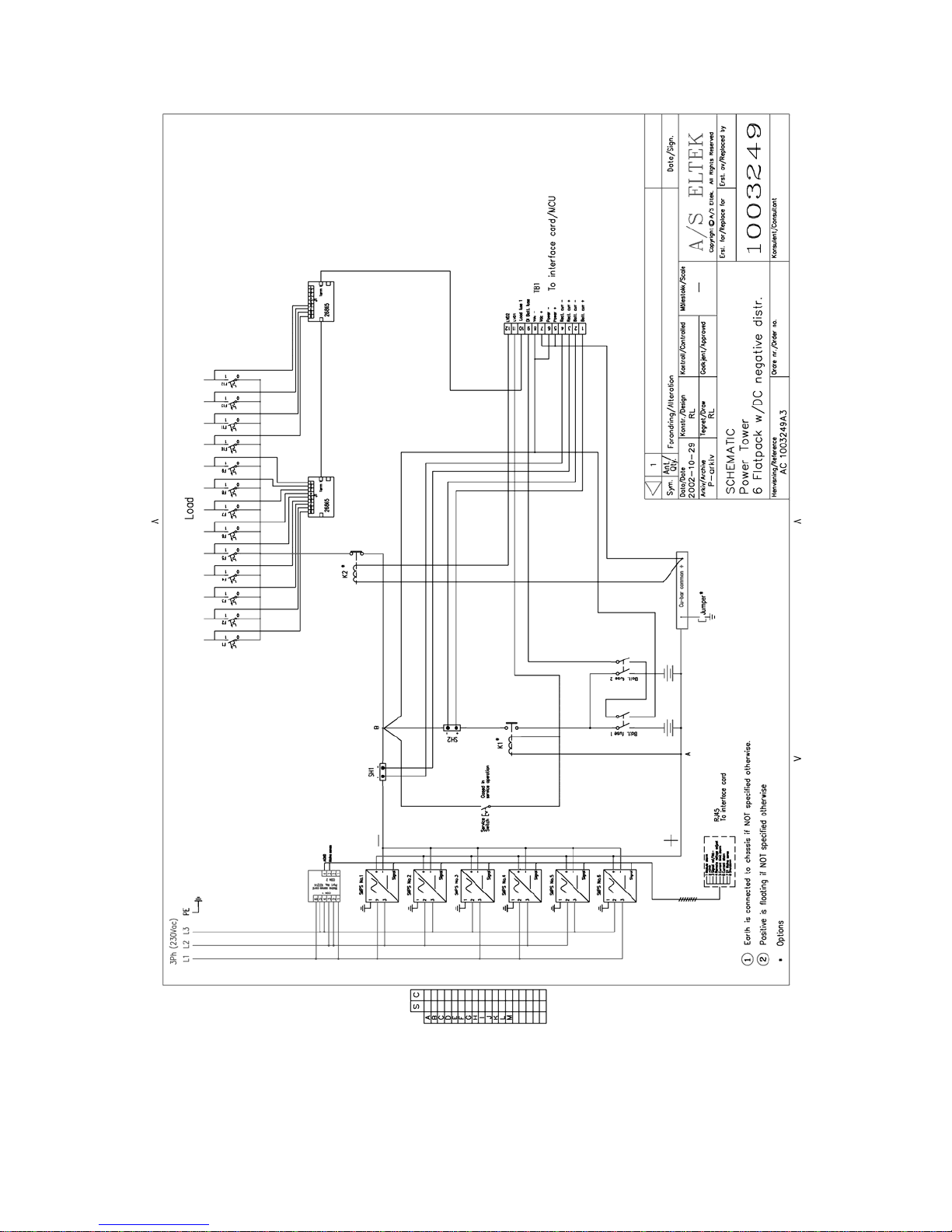

Figure 3 Schematic, 3Ph (230Vac) ......................................................................................................................... 36

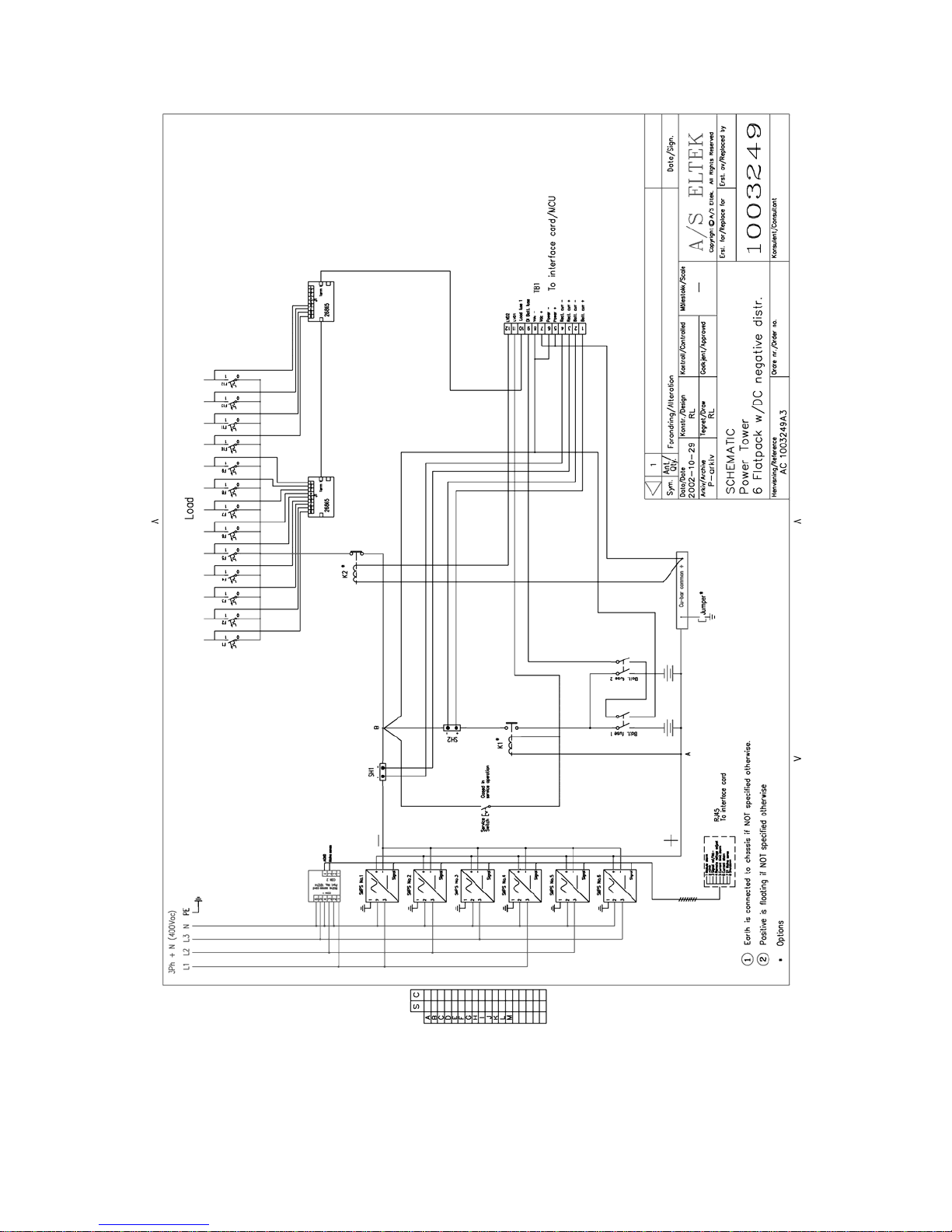

Figure 4 Schematic Power Tower, 3Ph +N (400Vac)............................................................................................. 38

Figure 5 Label for Power Tower 230Vac 1Ph......................................................................................................... 40

Figure 6 Label for Power Tower 230Vac 3Ph......................................................................................................... 42

Figure 7 Label for Power Tower 400Vac 3Ph+N.................................................................................................... 44

Figure 8 General Assembly Drawing....................................................................................................................... 46

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

31(48)

8 Figures

Figure 1 Block Schematic, Flatpack Power Tower

32(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

8 Figures

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

33(48)

8 Figures

Figure 2 Schematic, 1Ph (230Vac)

34(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

8 Figures

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

35(48)

8 Figures

Figure 3 Schematic, 3Ph (230Vac)

36(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

8 Figures

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

37(48)

8 Figures

Figure 4 Schematic Power Tower, 3Ph +N (400Vac)

38(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

8 Figures

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

39(48)

8 Figures

Figure 5 Label for Power Tower 230Vac 1Ph

40(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

8 Figures

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

41(48)

8 Figures

Figure 6 Label for Power Tower 230Vac 3Ph

42(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

8 Figures

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

43(48)

8 Figures

Figure 7 Label for Power Tower 400Vac 3Ph+N

44(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

8 Figures

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

45(48)

8 Figures

Figure 8 General Assembly Drawing

46(48) Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

8 Figures

Operation Guide, Flatpack Power Tower

351401.013v2 July 2003

47(48)

ELTEK Energy

P-O- BOX 2340 StØmsØ

N-3003 DRAMMEN

NORWAY

Phone: +4732203200

Telefax: +47 32203210

Internet: http://www.eltekenergy.com

e-mail: eltek@eltekenergy.com

Loading...

Loading...