Page 1

G

Installation manual

MORI dMEV II - dMEV unit

Read this manual carefully before using the product and keep

it in a safe place for reference.

This product was constructed up to standard and in compliance

with regulations relating to electrical equipment and must be

installed by technically qualified personnel.

The manufacturer assumes no responsibility for damage to

persons or property resulting from failure to observe the

regulations contained in this booklet.

PRECAUTIONS FOR INSTALLATION, USE AND MAINTENANCE

• The device should not be used for applications other than those specified in this manual.

• After removing the product from its packaging, verify its condition. In case of doubt,

contact a qualified technician. Do not leave packaging within the reach of small children

or people with disabilities.

• Do not touch the appliance with wet or damp hands/feet.

• This appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge

if they have been given supervision or instruction concerning use of the appliance

in a safe way and understand the hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall not be made by children without

supervision.

• Do not use the product in the presence of flammable vapours, such as alcohol,

insecticides, gasoline, etc.

• If any abnormalities in operation are detected, disconnect the device from the mains

supply and contact a qualified technician immediately. Use original spare parts only for

repairs.

• The electrical system to which the device is connected must comply with regulations.

• Before connecting the product to the power supply or the power outlet, ensure that:

- the data plate (voltage and frequency) correspond to those of the electrical mains

- the electrical power supply/socket is adequate for maximum device power. If not,

contact a qualified technician.

• The device should not be used as an activator for water heaters, stoves, etc., nor

should it discharge into hot air/fume vent ducts deriving from any type of combustion

unit. It must expel air outside via its own special duct.

• Operating temperature: 0°C up to +50°C.

• The device is designed to extract typical household air only, i.e. without excessive

grease, soot, chemical or corrosive agents, or flammable or explosive mixtures.

• Do not leave the device exposed to atmospheric agents (rain, sun, snow, etc.).

• Do not immerse the device or its parts in water or other liquids.

• Turn off the main switch whenever a malfunction is detected or when cleaning.

• For installation an omnipolar switch should be incorporated in the fixed wiring, in

accordance with the wiring regulations, to provide a full disconnection under overvoltage

category III conditions (contact opening distance equal to or greater than 3mm).

• If the supply cord is damaged, it must be replaced by the manufacturer, its service

Fig. 1

1

Page 2

agent or similarly qualified persons in order to avoid a hazard.

• Do not obstruct the fan or exhaust grille to ensure optimum air passage.

• Ensure adequate air return into the room in compliance with existing regulations in

order to ensure proper device operation.

• If the environment in which the product is installed also houses a fuel-operating device

(water heater, methane stove etc., that is not a “sealed chamber” type), it is essential

to ensure adequate air intake, to ensure good combustion and proper equipment

operation.

• Install the product so that the impeller is not accessible from the air outlet side as

verified by contact with the Test Finger (test probe “B” of the norm EN61032) in

compliance with the current safety regulations.

• Ceiling installation

In order to guarantee the IPX4 degree of protection against moisture in case of ceiling

installation, use the appropriate ceiling mount kit, which is included in the box. Use

only the rear entry hole for supply cables. If there is a possibility of condensation

along the air discharge duct, provide a drainage system to prevent condensation from

discharging into the environment through the fan.

Attention: do not mount the product on the ceiling without this kit.

• Window installation

In case of window installation it is necessary to use the appropriate window kit, which

is not included.

Attention: do not mount the product on the window without this kit.

INTRODUCTION

MORI dMEV (fig. 1) is a decentralised mechanical ventilation unit designed to ensure air

extraction in small/medium-sized rooms such as bathrooms, toilets and kitchens.

Suitable for air discharge directly to the outside or in the presence of short ducted system.

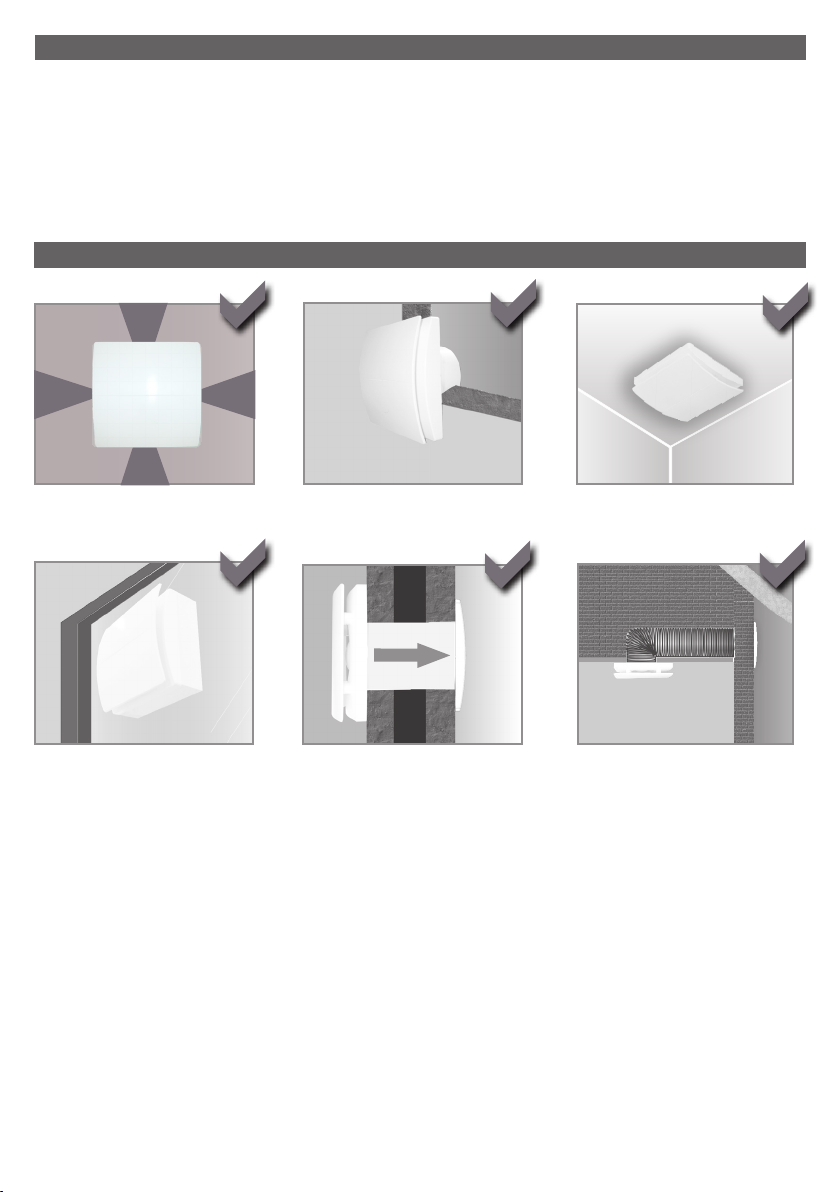

Wall, ceiling or window installation (fig. 2).

TECHNICAL SPECIFICATIONS

• Material: high quality, impact and UV-resistant ABS colour RAL 9010.

• Design front cover removable for cleaning without the use of tools.

• Rear reinforcement ring to prevent spigot deformation during installation.

• High efficiency aerodynamic fan with “winglet” blades to optimise quietness and

efficiency.

• Single phase EC Brushless motor with integral thermal protection.

• Motor mounted on high quality ball bearings.

• The fan is double insulated: no earth connection is required.

• Trickle speed selectable during installation.

• Option to boost from trickle (or from off) through LS connection or pull cord.

• Installation type selection available (through wall or ducted).

• Timer and Integral Humidistat versions available.

• IPX4 degree of protection.

•Power supply 220V to 240V~ 50Hz.

Model

MORI dMEV II T 83/47/29/21 23,1/13/8/6 27 2,5 26/23/13/11

MORI dMEV II HT 83/47/29/21 23,1/13/8/6 27 2,5 26/23/13/11

2

Airflow

m3/h l/s

Static pressure

Pa max

Power

W max

Sound pressure

dB(A) @3m

Page 3

VERSIONS

MORI dMEV II T (Timer version)

The fan is provided with over-run timer, adjustable from 0-30 minutes via a trimmer (fig.

17A). The fan works at the selected trickle speed (or off) and can be boosted using the

integrated pull cord switch or light switch. Once the boost switch is turned off the fan

will continue to run at the boost speed for the set period of time before reverting back

to the trickle speed.

The over-run timer function is activated only if the switch has been on for at least 60

seconds.

Pull Cord Operation: The pull cord works as the boost switch. Wire up as per diagram

(fig. 16A).

External Switch Operation: To boost the unit with an external switch such as a light

switch the pull cord should be disabled. To do this make sure the pull cord switch is

not on and simply cut the cord. The plastic caps on the wiring terminals will need to be

removed to allow the switch wires to be secured. Wire up as per diagram (fig. 16B).

External Switch and Pull Cord Operation: If the fan needs to be boosted via a pull cord

and external switch the switch used must be a double pole switch. This removes any

interference between the fan and the light. Wire up as per diagram (fig. 16B).

MORI dMEV II HT (Humidity control version)

The fan comes complete with an adjustable humidity sensor and adjustable timer. The

humidity threshold is adjustable from 50% to 95% Relative Humidity via a dedicated

trimmer, and the timer is adjustable from 0 - 30 minutes via a dedicated trimmer (fig. 17B).

The fan works at the selected trickle speed (or off) and can be boosted using the

integrated pull cord switch or light switch. Once the boost switch is turned off the fan will

continue to run at the boost speed for the set period of time before reverting back to the

trickle speed. There is also a comfort boost triggered by a humidity level above the set

threshold. The Comfort Boost flow rate is approximately half way between the pre-set

Background and Boost flow rate. Once the humidity level is below the set point the fan

will continue for a factory set period of time before returning to trickle speed.

To deactivate the humidistat function, turn the trimmer HY completely clockwise.

Pull Cord Operation: The pull cord works as the boost switch. Wire up as per diagram

(fig. 16D).

External Switch Operation: To boost the unit with an external switch such as a light

switch the pull cord should be disabled. To do this make sure the pull cord switch is

not on and simply cut the cord. The plastic caps on the wiring terminals will need to be

removed to allow the switch wires to be secured. Wire up as per diagram (fig. 16E).

External Switch and Pull Cord Operation: If the fan needs to be boosted via a pull cord

and external switch the switch used must be a double pole switch. This removes any

interference between the fan and the light. Wire up as per diagram (fig. 16E).

INSTALLATION TYPE SETTING

Installation type can be selected using the JUMPERS among different options. See fig. 18.

TRICKLE SPEED SETTING

Trickle speed can be selected using the JUMPERS among different options. See fig. 18.

Trickle speed can be also set to off.

3

Page 4

STANDARD CONFORMITY

2014/35/EU Low Voltage Directive (LVD)

2014/30/EU Electromagnetic Compatibility (EMC), in conformity with the following

standards:

Electrical Safety

EN60335-1(2012)+A11+A13; EN 60335-2-80(2003)+A1+A2.

Electromagnetic Compatibility

EN 55014-1(2017); EN 55014-2(2015); EN 61000-3-2(2014); EN 61000-3-3(2013).

INSTALLATION (Fig.2)

perimetrical exhausting

window (kit on demand)

wall

direct exhausting

ceiling (accessory included in the box)

short ducting

4

Page 5

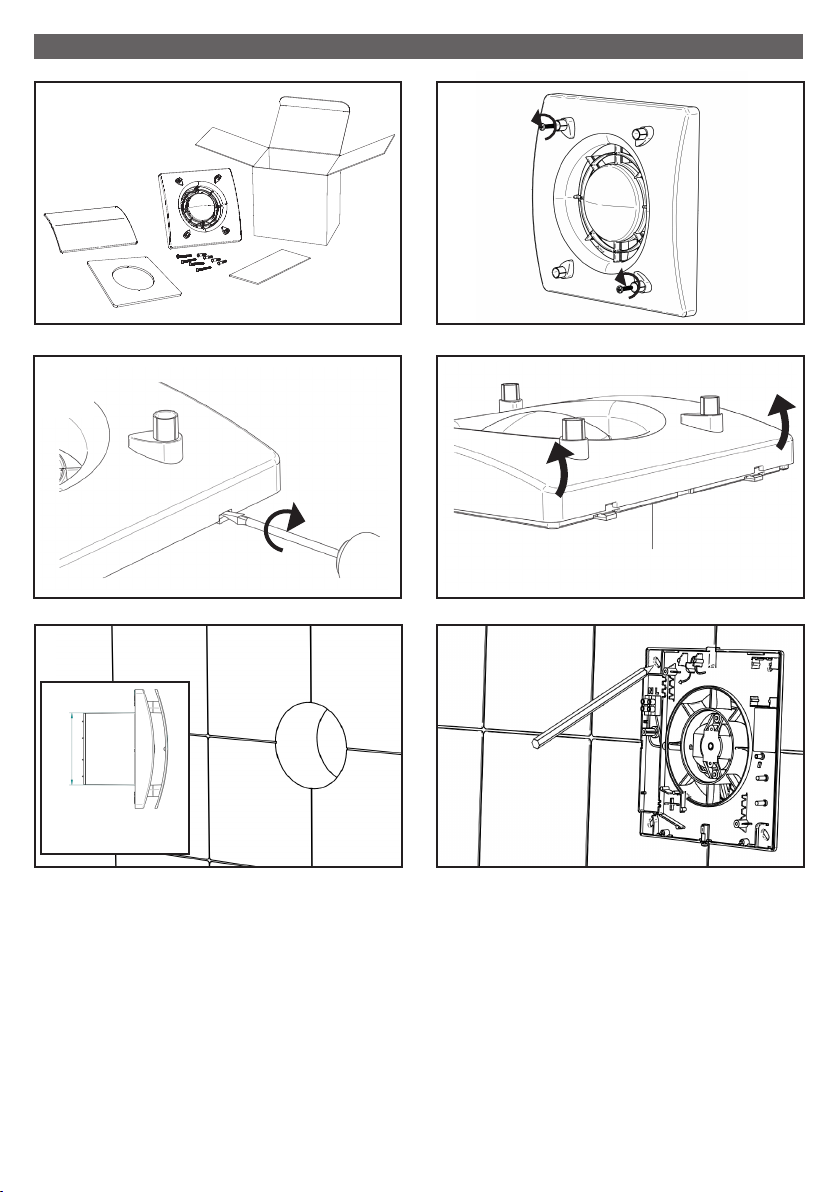

MOUNTING AND ELECTRICAL WIRING

3

5

7

4

6

6

8

Ø

MORI dMEV II = ø99 mm

5

Page 6

SURFACE CABLE

2 X 0,5 ÷ 1,5 mm2

BASE/STD

H03VV-F ; H05VV-F

{

3 X 0,5 ÷ 1,5 mm2

3 X 0,5 ÷ 1,5 mm

T-HT

{

4 X 0,5 ÷ 1 mm2

9A

2

4 x ø 5 mm

10A

12A

11A

d

Ø

Ø10mm

d

Ø

6

13A

Page 7

RECESSED CABLE ENTRY

H03VV-F ; H05VV-F

2 X 0,5 ÷ 1,5 mm2

BASE/STD

{

3 X 0,5 ÷ 1,5 mm2

3 X 0,5 ÷ 1,5 mm

T-HT

{

4 X 0,5 ÷ 1 mm2

9B

2

4 x ø 5 mm

10B

11B

12B 13B

14 15

The ceiling mounting gasket should be sandwiched between the fan and

the ceiling ensuring that it is flat against the ceiling. Included in the box.

For window mounting instruction please see the individual installation

manual.

7

Page 8

16A

N

L

PULL CORD

N

L

PULL CORD

16B

16C

16E

MORI dMEV II T

MORI dMEV II T

MORI dMEV II HT

MORI dMEV II T

16D

Double Pole Switch

MORI dMEV II HT

17A

+

-

TIMER

17B

TIMER

HY

+ higher humidity set point

8

JUMPER

+

-

+

-

18

1 2 3

MORI dMEV II M (ISSUE A & B)

MORI dMEV II T - MORI dMEV II HT

INSTALLATION AIRFLOW

through wall OFF

through wall 6L/s

through wall 8L/s

through wall 13L/s

in room OFF

in room 6L/s

in room 8L/s

in room 13L/s

= Jumper present

Page 9

19

20

CLICK

21

22 23

ON

OFF

9

Page 10

MAINTENANCE / CLEANING

The unit should be cleaned regularly as explained in this leaflet to maintain performance

and warranty cover. Cleaning should be carried out as and when required but please note

intervals between cleaning should not exceed 6 months. The installer should explain this

cleaning regime to the homeowner/occupier and ask the homeowner/occupier to keep a

record of the cleaning done on this leaflet as this will be required to be provided by the

homeowner/occupier to claim against any product failure under warranty.

24

25

26 27

28

10

Page 11

DISPOSAL AND RECYCLING

Information on disposal of units at the end of life.

This product complies with EU Directive 2002/96/EC.

The symbol of the crossed-out dustbin indicates that this product must be

collected separately from other waste at the end of its life. The user must,

therefore, dispose of the product in question at suitable electronic and

electro-technical waste disposal collection centres, or else send the

product back to the retailer when purchasing a new, equivalent type device.

Separate collection of decommissioned equipment for recycling, treatment

and environmentally compatible disposal helps to prevent negative effects

on the environment and on health and promotes the recycling of the

materials that make up the equipment. Improper disposal of the product

by the user may result in administrative sanctions as provided by law.

GUARANTEE

The product is offered with a five year warranty.

First year of warranty covers parts and labour, following this period the warranty covers

replacement parts only based on maintenance having being carried out in accordance

with our literature and terms and conditions of sale.

Proof of purchase, periodic inspection and maintenance will be required in the event of

any warranty claim.

11

Page 12

ErP Directive - Regulations 1253/2014 1254/2014

a) Mark - ELTA FANS ELTA FANS

b) Model -

c) SEC class - E C

c1) SEC warm climates kWh/m2.a -5,4 -11,3

c2) SEC average climates kWh/m2.a -13 -25,7

c3) SEC cold climates kWh/m2.a -26,4 -50,7

Energy label

d) Unit typology - Residenal - unidireconal Residenal - unidireconal

e) Type of drive - mul speed drive mul speed drive

f) Type of Heat Recovery System - absent absent

g) Thermal eciency of heat recovery % N/A N/A

h) Maximum ow rate m3/h 83 83

i) Electric power input at maximum ow rate W 2,6 2,6

j) Sound power level (LWA) dBA 44 44

k) Reference ow rate m3/h 61 61

l) Reference pressure dierence Pa 10 10

m) Specic Power Input (SPI) W/m3/h 0,028 0,028

n1) Control factor - 1 0,65

n2) Control typology - Manual control (no DCV) Local demand control

o1) Maximum internal leakage rate % N/A N/A

o2) Maximum external leakage rate % N/A N/A

p1) Internal mixing rate % N/A N/A

p2) External mixing rate % N/A N/A

q) Visual lter warning - N/A N/A

r) Instrucons to install regulated grilles - check the instrucon booklet check the instrucon booklet

s) Internet address for preassembly/disassembly instrucons - www.eltafans.com www.eltafans.com

t) Airow sensivity to pressure variaons % N/A N/A

u) Indoor/outdoor air ghtness m3/h 52 52

v1) AEC - Annual electricity consumpon - warm climates kWh 0,4 0,2

v2) AEC - Annual electricity consumpon - average climates kWh 0,4 0,2

v3) AEC - Annual electricity consumpon - cold climates kWh 0,4 0,2

w1) AHS - Annual heang saved - warm climates kWh 6,3 11,9

w2) AHS - Annual heang saved - average climates kWh 14 26,2

w3) AHS - Annual heang saved - cold climates kWh 27,3 51,3

- No No

MORI dMEV II T MORI dMEV II HT

12

Page 13

NOTES

13

Page 14

NOTES

14

Page 15

NOTES

15

Page 16

Elta Fans Limited

Building Services

46 Third Avenue

Pensnett Trading Estate

Kingswinford

West Midlands

DY6 7US

United Kingdom

T: +44 (0) 1384 275800

F: +44 (0) 1384 275810

E: bs@eltafans.co.uk

001435 - 05 - 0518

Loading...

Loading...