Page 1

Table of Contents

1. Overview ____________________________________________________________ 0

1.1 System Components ______________________________________________________ 1

2. Setup _______________________________________________________________ 2

3. Controls & Indicators__________________________________________________ 3

3.1 Power Supply____________________________________________________________ 3

3.2 Power/Status Panel _______________________________________________________ 4

3.3 Transmitter/Receiver _____________________________________________________5

4. Operation ___________________________________________________________ 6

4.1 Reading Mode ___________________________________________________________ 6

4.1.1 GPS Operation &Alarms________________________________________________________9

4.2 Performance Enhancement Features _______________________________________ 10

4.2.1 GEO Mode _________________________________________________________________ 10

4.2.2 Dynamic Window____________________________________________________________11

4.2.3 Frequency Scan______________________________________________________________ 11

4.3 Command Mode ________________________________________________________ 12

4.3.1 Summary Command __________________________________________________________12

4.3.2 Tools Command _____________________________________________________________ 17

4.3.3 Quit Command ______________________________________________________________ 27

4.3.4. Help Command _____________________________________________________________ 29

5. Troubleshooting _____________________________________________________ 32

Appendix A: File Formats _______________________________________________ 33

A.1 GUIDE File____________________________________________________________33

A.2 READING.RTE File ____________________________________________________34

A.3 .VAN File______________________________________________________________ 36

Appendix B: Specifications ______________________________________________ 37

Page 2

List of Figures

Figure 1. Mini-MI ______________________________________________________ 1

Figure 2. MMI Status Indicators __________________________________________ 3

Figure 3. Transmitter/Receiver Status Indicators _____________________________ 5

Figure 4. Reading Mode Display___________________________________________ 8

Figure 5. Summary Command Menus _____________________________________ 12

Figure 6. Summayr Display Data Format __________________________________ 13

Figure 7. Tools Command Menus_________________________________________ 17

Figure 8. Trouble Shoot Display __________________________________________ 18

Figure 9. System Setup Menu ____________________________________________ 20

Figure 10. Route Scan Menu_____________________________________________ 22

Figure 11. Backup Memory Menus________________________________________ 23

Figure 12. Frequency Control Menu ______________________________________ 24

Figure 13. Set Perm Menu_______________________________________________ 26

Figure 14. Quit Command Menus_________________________________________ 27

Figure 15. Help Command Menus ________________________________________ 29

Figure 16. Location & Time Menu ________________________________________ 30

Figure 17. Set Time & Date Menu ________________________________________ 31

Figure 18. READING.RTE Header Format_________________________________ 34

Figure 19. READING.RTE Record Format_________________________________ 34

Figure 20. READING.RTE Example File __________________________________ 35

Figure 21. VAN File Header Format______________________________________ 36

Figure 22. VAN File Record Format ______________________________________ 36

Figure 23. VAN File Example____________________________________________ 36

Page 3

Chapter 1 Overview

Chapter 1: Trace MMI Overview

The Trace ® Mini-Mobile Interrogator (MMI) is a portable data retrieval and storage

system designed to provide remote meter reading in conjunction with the Trace meter

transponders. The Trace system is designed to convert the mechanical index reading of a

utility meter to a duplicate electronic register reading. This electronic register reading is

transmitted via radio frequency (RF) signals to the MMI. The Trace MMI reads each

transponder by use of an RF interrogation that consists of a unique serial number along

with a command requesting the contents of the electronic register. Each transponder is

selected for reading on either a first-in-first-out (FIFO) basis, a latitude/longitude (L/L)

basis, or a combination of the two GEO mode. The MMI obtains route data from a

customer supplied floppy disk containing the street address, latitude/longitude , and serial

number of each transponder that is to be read.

The MMI uses a GPS-based navigation system that tracks the vehicle position. If the

Lat/Lon mode of interrogation has been selected, whenever the MMI comes into the

range of a particular transponder it begins to send an interrogation for that unit. When

the transponder receives a signal with the correct serial number it transmits its electronic

register reading, tamper status, and an error detection code.

The MMI listens for each transponder reply using an 8-channel receiver. Reply data

integrity is confirmed by monitoring receiver data tracking signals and by an error

detection code known as a BCH code. A transponder reply is only accepted if the BCH

code analysis is valid. This ensures that the data was received without error. The meter

reading along with transponder status, receiver channel activity, time of the read, and

vehicle position at the time of the read is stored in an output file contained on a floppy

disk. Once the MMI has been initialized with the appropriate route data, the system will

collect readings automatically, allowing the operator to drive the route in a safe and

efficient manner.

Page 4

Chapter 1 Overview

MMI System Components

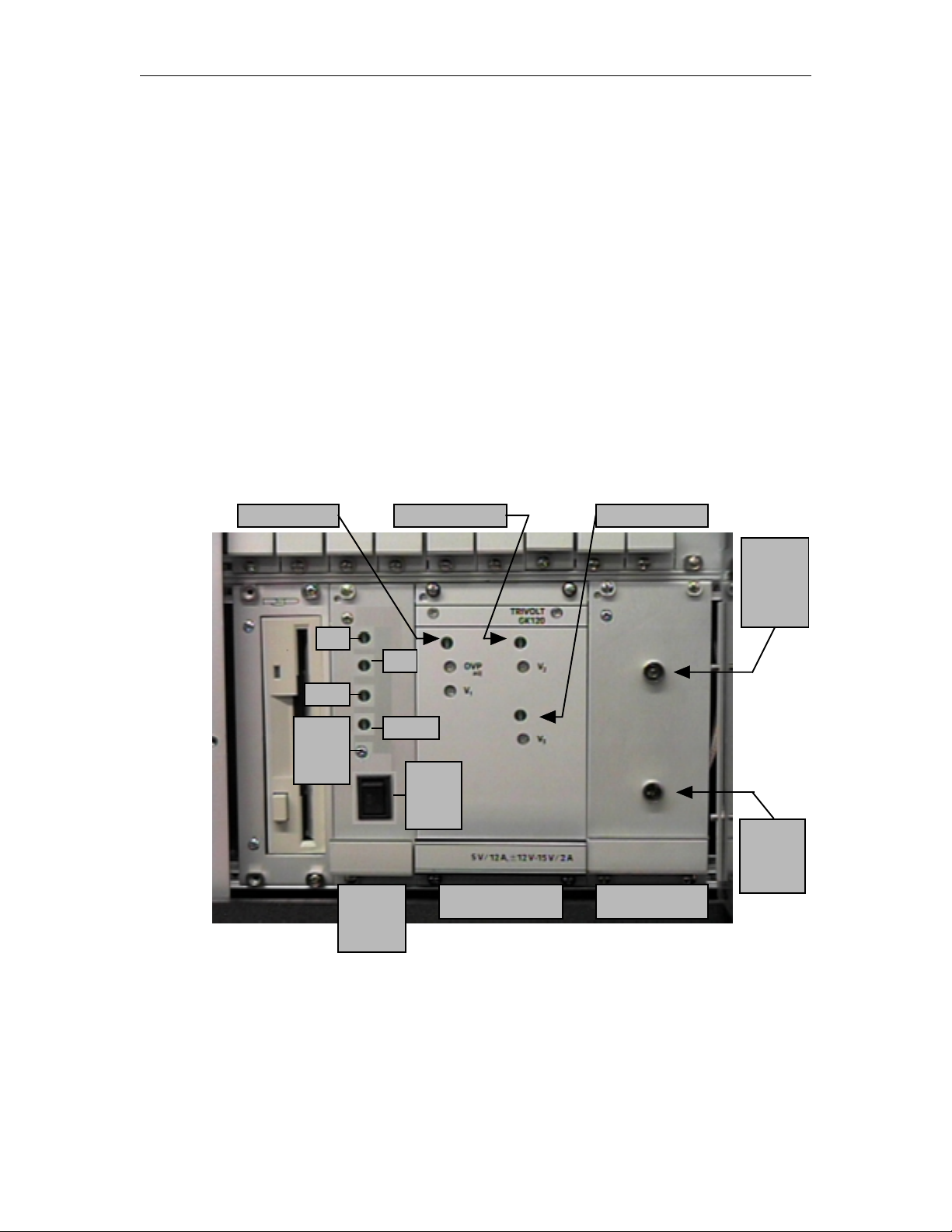

Figure 1. Mini-MI

The MMI system consists of several main components, as displayed in figure 1. All

components are stored in the end covers during transportation. The entire system

consists of a handheld terminal, GPS receiver, transmitter antenna, receiver antenna,

power cord, and a main computer. The connection and usage of these components is

covered in chapter 2.

Page 5

Chapter 2 Setup

Chapter 2: MMI Setup

The MMI is transported with all components contained in the carrying case. Before use,

these components must be unpacked and connected. Setup is simple and fast, and the

entire setup operation should take no more than five minutes. Use the following

instructions for a fast and trouble free setup:

• Unlatch the two latches on the rear cover door. Open the door slightly and then slide

the door off the two hinge pins. Now remove the GPS receiver, power cable, and

both antennas from their storage pouches. Store this door in a safe place.

• Next, unlatch the two latches on the front cover door. As above, remove the door,

then remove the handheld terminal and connecting cable, and the desired route disk

from their storage pouches. Store this door in a safe place.

• Now connect the transmit antenna to the appropriate connector and finger tighten

until snug. Next connect the receive antenna by pushing in on the connector and

twisting ¼ turn until it locks. Both antennas use unique connectors which are keyed,

so they cannot be connected backwards.

• Place both antennas on the top of the vehicle, and make sure that they are separated by

approximately 3 feet. A separation distance of two arms length apart is sufficient.

Typically the transmit antenna is placed at the front of the vehicle, and the receive

antenna at the rear. The coaxial cable may be routed over the top of the door on some

vehicles, or it may be necessary to route the cable through a slightly opened window.

Caution: If routing the cable over the top of the door, be certain to inspect the

distance between the top of the door and the vehicle frame to ensure there is adequate

clearance for the cable to avoid crushing it.

• Next connect the GPS receiver to the appropriate connector and finger tighten until

snug. Next moisten the suction cups on the GPS mount, and attach the unit to the

outside top of the vehicle windshield. As with the transmit and receive antennas, the

signal cable may routed over the top of the door, or through a window.

• The handheld terminal may now be connected using the supplied cable. Either end of

the cable may be connected to the terminal.

• Finally, connect the power cable to the appropriate MMI rear connector and finger

tighten until snug. Continue by inserting the opposite connector into the vehicle

cigarette lighter port.

Now the MMI is properly setup and ready to receive a route disk. Please take time to

read the following section to become familiar with the various controls and indicators

found on the MMI.

Page 6

Chapter 3 Controls & Indicators

K

K

K

K

l

p

Controls & Indicators

The MMI uses a combination of LED’s (light emitting diodes), audible alarms, and the

handheld terminal to provide both status and a means of control to the operator. These

indicators are used to convey the status of the power supply unit, external voltages,

temperature, and transmitter/receiver operation. This section should be well understood

before operating the MMI. Failure to become familiar with the various status and control

features built into the MMI could lead to poor performance, or even system damage.

Power Supply Indicators:

The power supply unit is equipped with 3 status LED’s. Each of these are illuminated

when the MMI is powered, and each respective supply voltage is operation normally. As

shown in figure 2, the LED’s denote whether the +5, +12, and -12 volt power supplies are

working properly. Also, the RF amplifier is equipped with an LED to indicate the

condition of the +12 volts used to power it. Under normal circumstances, all four of

these LED’s should be illuminated at all times while the MMI is powered.

+5 volts O

Silence

Switch

+12

Tem

Status

Pane

+12 volts O

Batt

AlarmAlarm

Main

Power

Switch

-12 volts O

RF

AMP

Power

O

RF

AMP

Enabled

RF A mplifie rPower SupplyPower /

Figure 2. MMI Status Indicators

Page 7

Chapter 3 Controls & Indicators

Power/Status Panel Indicators & Control:

The power/status panel shown in Figure 2 contains 2 switches and 4 LED’s used to

monitor and control the main power provided to the MMI as well as to monitor the

internal temperature. All four of the status LED’s should be off under normal conditions.

The bottom switch is the main power switch and is used to power the MMI on and off.

The alarm silence switch is a push-button used to silence the audible alarm which is

activated any time a new alarm condition is detected. Once an alarm condition is

detected, an audible alarm will beginning sounding on and off at about 2 beeps per

second. Also, the alarm LED will begin flashing at the same rate as the audible alarm.

The audible alarm is used to alert the operator that a major status problem has been

detected, and requires immediate attention. If the alarm is chosen to be ignored, then the

alarm silence push-button may be pressed, which will shut off the audible alarm. The

alarm LED will continue to flash, however, until the actual alarm condition ceases. The

audible alarm will not sound again until all alarm conditions are eliminated and then one

or more conditions recur, or until the MMI is powered off then back on again. The

following three items are monitored by the power/status module for proper operation:

• +12 LED: This will be illuminated any time the external 12 volt supply

connected to the cigarette lighter drops to an unusable voltage.

This alarm may occur due to the power cable becoming

disconnected, or if the vehicle alternator is unable to produce

adequate operating current.

• Batt LED: This will be illuminated any time the internal battery voltage drops

to an unusable voltage. Once this alarm occurs, the MMI should

be

immediately shut down. Ignoring this alarm could cause

unpredictable behavior. The MMI is able to operate approximately

10 minutes from the internal battery before the voltage becomes

unusable.

• Temp LED: This will be illuminated any time the internal MMI temperature

exceeds approximately 160° F. This condition may be caused

by several factors, including cooling fan failure, blocked fan

intakes, or excessive ambient temperature.

• Alarm LED: This will flash on and off approximately 2 times per second

whenever any or all of the +12, Batt, and Temp LED’s are

illuminated. This LED will continue to flash until all of the

+12, Batt, and Temp alarms are discontinued.

Page 8

Chapter 3 Controls & Indicators

N

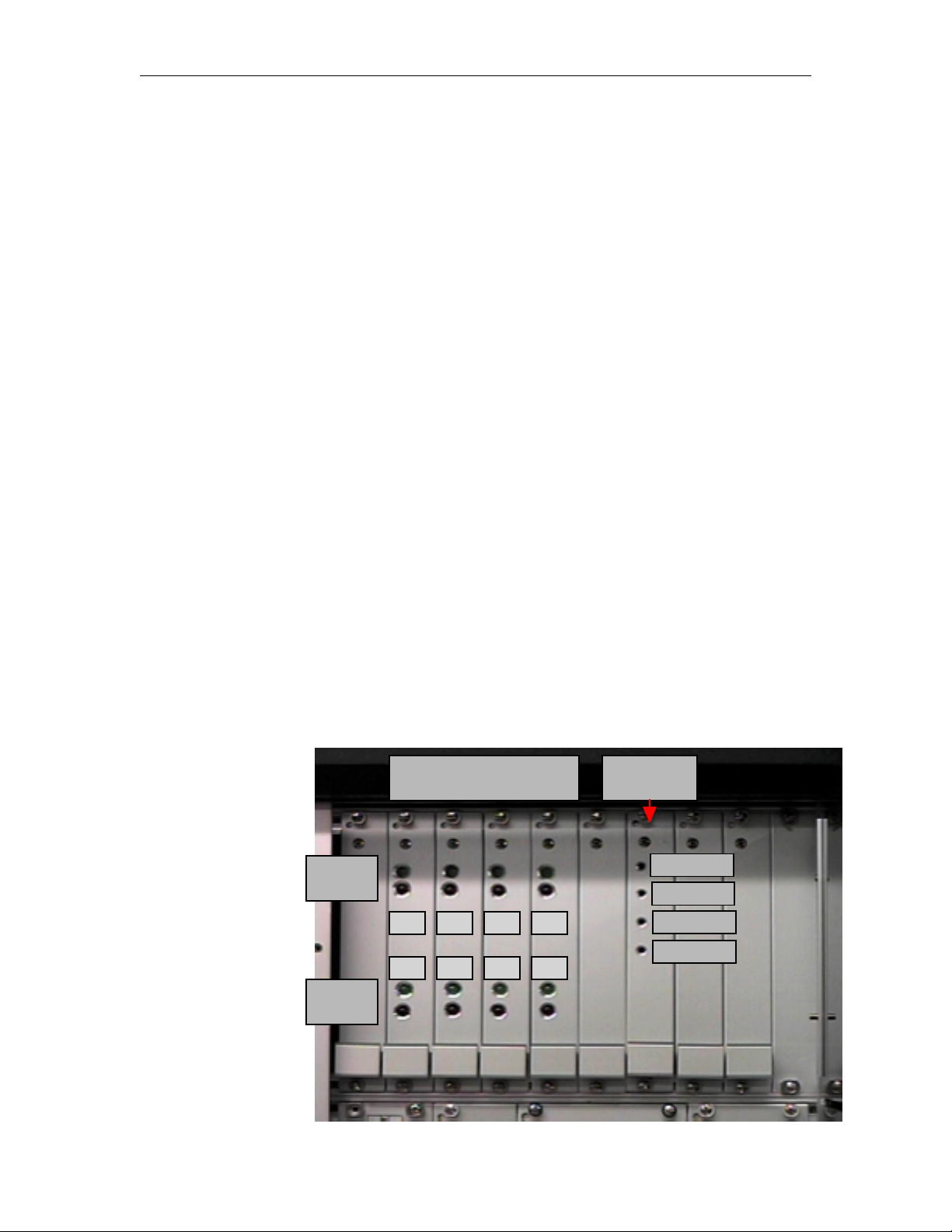

Transmitter/Receiver Status Indicators:

The MMI is equipped with eight receivers and one transmitter. All of these devices use

phase-locked-loops (PLL’s) to control each frequency with a high degree of accuracy.

The PLL’s also allow both transmitter and receiver frequencies to be easily changed with

software in real time. Many of the status LED’s to be described below display PLL

programming status. Since each PLL is software programmable, it is important to be able

to instantly verify if a particular one has been programmed correctly. It is possible to

improperly, either intentionally or accidentally, program a PLL to a frequency where the

transmitter or receiver is not able to operate correctly. In this case, the PLL OK LED

would be turned off.

There are four receiver boards with two receivers on each board. These cards and their

locations are displayed in figure 3. Each receiver channel has two LED’s to display

programming and data status. Each green LED on the receiver boards is used to verify

that particular channel has been programmed to a valid frequency. The green LED’s

should be illuminated at all times during operation except for approximately 7 seconds

after MMI power is initially applied. During this time, the LED’s may be either on or off

randomly. During normal operation, all green LED’s should be illuminated. The red

LED’s will flash any time a particular channel is receiving valid data, visually verifying

that the receiver is working properly.

There is one transmitter board in the MMI and its location is shown in figure 3. The

transmitter has three LED’s used to display its status. The Power OK LED should be

illuminated any time the MMI is powered. As with the receiver PLL OK LED, the

transmitter PLL OK LED should be illuminated at all times. The TX On LED displays

whether the transmitter has been enabled by the software. Referring to figure 2, anytime

the TX On LED is illuminated, the RF Amp Enabled LED should be illuminated as well.

This verifies that the RF amplifier is operating.

Receiver C a r ds

#1&2 #3&4 #5& 6 # 7&8

Tra n smitter

Card

Figure 3.

Transmitter/

Receiver Status

Indicators

PLL OK

Data

CH1 CH3 CH5 CH7

CH2 CH4 CH6 CH8

PLL OK

Data

Power OK

PLL OK

ot used

TX On

Page 9

Chapter 4 Operation

Chapter 4 Operation

Once the MMI is unpacked and the external components are properly connected, the route

disk may be inserted. Once the MMI is powered on, it performs several internal selfchecks. The indication and results of these tests are displayed on the hand-held terminal.

Some self-check problems will require the operator to press a key to acknowledge the

error before continuing. Please consult the trouble-shooting section of this manual if

errors occur during testing which prevent normal usage of the MMI. Once the self-check

has been completed, the MMI will read in a new route from the floppy disk (if the MMI is

not resuming a interrupted route). From here, the reading mode is automatically entered,

and meter reading may begin. Initially, MMI operating parameters are determined by the

settings contained in the Guide file. Many of these parameters may be overridden using

the system setup menu contained within the tools menu, discussed in the command mode

operating section.

All MMI operations fall into one of two basic modes, the Reading mode, and the

Command mode. The Reading mode is entered as soon as the MMI has been initialized.

The Command mode is used to analyze system data and parameters, alter operational

parameters, and perform miscellaneous tasks. The Command mode exists as a group of

five main commands. Each main command has various sub-menus that are supported.

The Reading mode does not require any operator input, and therefore has no menu

structure. There are two operations available in the Reading mode, the mode of reading

may be changed with the back space key, or the Reading mode may be exited by pressing

any other key. Pressing any of the yellow keys on the handheld terminal will invoke the

particular menu associated with that key.

Reading Mode

During normal operation of the MMI, the Latitude/Longitude (Lat/Lon or L/L) or GEO

mode of interrogation is used, and only transponders in the interrogation window are

interrogated. The interrogation window is an imaginary area surrounding the MMI that is

used to determine which transponders should be interrogated. This is simply a means in

which only certain transponders are selected for interrogation. Correspondingly, the

route may be driven in any order, since the MMI is constantly computing which

transponders are available for interrogation. A transponder will typically respond within

distances less than 2000 feet. The window size typically never needs to be changed, but it

may be necessary to reduce it, for example, when there are many transponders in a small

area. The smaller window size will allow for a smaller group of transponders to be

placed in the interrogation window, allowing them to be polled more quickly. The

window size may also be increased if there is some inaccuracies in the stored position of

a transponder, and you want to be sure that it is interrogated. If the window size is too

small, the MMI may never interrogate a particular transponder, which if interrogated,

would probably respond. Likewise, if the window size is set too large, then too many

transponders may be located in the window, which will slow down the interrogation for

each one.

Page 10

Chapter 4 Operation

If the transponder Lat/Lon database is known to be good, then the performance

enhancement feature known as Dynamic Windowing may be enabled. This feature

examines the route transponder density in real time, and adjusts the interrogation window

automatically to allow only the optimum number of transponders into the window at a

given time.

The MMI should typically be used in the GEO mode of interrogation, although there may

be some instances where the FIFO mode may be necessary. In the FIFO mode, the MMI

scans the entire list of transponders in memory, and will attempt to read each unread

transponder one-by-one. If there is a large number of unread transponders in the database,

then this method can become very slow, even becoming ineffective. The FIFO mode

should only be used with a small number of transponders, and with the MMI either

stationary, or moving slowly. The FIFO mode may be used in the unlikely event that

there are problems with the navigation system. In FIFO mode, the vehicle location is not

used, therefore the data from the GPS system is not needed.

While in the Reading mode, various display items are used to provide feedback to the

operator. Using the parameters in the Guide file, or through the System Setup sub-menu,

the option may be selected to display information for each transponder with a good status

as it is processed by the MMI. Along with this option, the MMI can be directed to beep

with each good read. If desired, all display options may be turned off, or any combination

of options may be turned on.

The MMI may be placed in the Command mode at any time during operation. While in

the Command mode, the polling of transponders in the route is suspended. During the

execution of a particular route, the operator may change any of the System Setup

parameters as needed. The altering of the various parameters will not affect any of the

data in the route, but improper settings may adversely affect the performance of the MMI.

In the event that the System Setup parameters have been altered, and the original settings

are unknown, the operator may use the Break option, to halt the MMI. The MMI may

then be re-powered, and the default Guide file settings will be restored, and the prior

progress of the route will resume from the point where the Break option was used.

If the MMI is inadvertently turned off before a proper exit is accomplished, the current

route data will still be saved in backup memory. When the MMI is turned on again, the

route will continue from the point where it was at before it was turned off. The MMI may

be anywhere along the route when power is restored.

The vehicle position is constantly calculated and updated by the GPS navigation system.

The current vehicle position is used with the Lat/Lon or GEO mode of interrogation to

determine which transponders are within range of the vehicle, and may therefore be

interrogated. The current vehicle position is also used with either interrogation mode to

mark the Lat/Lon coordinates at the moment a good read takes place. The resulting

position data is stored with the other data for the transponder that responded. The mode

of interrogation may be changed at any time during the reading mode by pressing the

Page 11

Chapter 4 Operation

backspace key. This will change the current interrogation mode from FIFO to GEO to

L/L. The mode of interrogation may also be changed using the System Setup command

within the Tools sub-menu.

As shown in figure 4, several pieces of information are displayed for a good transponder

reply during the reading mode (if the option to do so has been enabled). The first item

displayed is the serial number. Next, the meter reading is displayed. The next item is the

tamper status. A '.' is displayed for a non-tampered transponder. A 'T' is displayed for a

tampered transponder, ‘R’ for a tamper reset, and a 'F' is displayed if the tamper reset

command failed. The last field displayed is the street address of the meter.

10:22 | MOD E : FIFO | G ood : 200 | GPS : A | IW : A LL

2539216 1235 T 123 South Main St.

2558131 10144 . 96 Valley View Drive

0078067 9411 T 5995 Hagley Drive

0078067 . . . . . . . . R 5995 Hagley Drive

2121411 104551 T 4545 W. Brown Deer Rd.

2121411 . . . . . . . . F 4545 W. Brown Deer Rd.

Figure 4. Typical Reading Mode Display

A status line, shown above, is displayed at the top of the screen during the reading mode.

The time, mode of reading, number of good reads, GPS status, and number of

transponders inside the interrogation window are displayed. The GPS status area may be

at one of three statuses; ‘A’ indicates the GPS receiver is communicating with the MMI

and is producing valid position data, ‘S’ indicates that the GPS receiver is

communicating, but is not producing valid position data, and the self-navigation option is

active and functioning. The status ‘N’ indicates the GPS receiver is communicat ing, but

is not currently producing valid position data, and finally ‘-‘ indicates that the GPS

receiver is not communicating with the MMI properly.

Page 12

Chapter 4 Operation

GPS Self Navigation & Lost Coverage Alarms

While in the Reading mode using either L/L or GEO modes, the MMI depends on the

continual position updates provided by the GPS receiver. Since the GPS receiver is

listening to satellites at various positions in the sky, objects such as tall buildings, trees

and high-growing foliage may block the view of some of the necessary satellites. When

such a blockage occurs, the GPS receiver is temporarily unable to provide Lat/Lon

coordinates. This naturally presents a serious problem while in L/L or GEO modes.

An option known as self-navigation is available that can continue producing Lat/Lon

position updates during brief GPS blockages. While in self-navigation mode, each time

the MMI receives a reply from a transponder, it takes the stored Lat/Lon coordinate for

that transponder and updates the vehicle position. While in self-navigation mode, the

Dynamic Window (see the performance enhancement section for a description) feature is

disabled, since the vehicle position may have a greater amount of error than normal. As

long as the MMI is continually receiving transponder replies, and the time between

successive reads is brief, then the self-navigation mode will continue. If however, a

period of no read activity occurs, then the self-navigation mode will be terminated, and

the FIFO mode will become active. Once self-navigation mode is terminated, it will not

resume again until the GPS status transitions from active to inactive. At the time valid

GPS position data becomes available again, the previous reading mode will become

active, and features such as Dynamic Window will be resumed, if enabled.

The MMI will alert the operator whenever the GPS becomes unable to produce position

data for any reason while in either L/L or GEO modes. Any time the GPS data becomes

unavailable, both an audible and message alert will be presented on the handheld

terminal. When the GPS position becomes unavailable, and self-navigation mode has not

been enabled, then a message will be displayed indicating that the GPS is blocked, and

FIFO mode is being initiated. If self-navigation mode was enabled at the time of GPS

blockage, then another message will be displayed indicating that GPS data is unavailable,

and the self-navigation mode is now active. If self-navigation mode is unable to continue

to produce position data, and GPS data is still unavailable, then an alert will be given

indicating that no position data is available, and FIFO mode is being initiated. Finally,

when GPS position data is restored, then another alert will be issued indicating this status.

Upon the resumption of GPS data, the reading mode which was active prior to the loss of

position data, as well as any performance enhancement features will be restored.

Page 13

Chapter 4 Operation

Reading Mode Performance Enhancement Features

This section describes three MMI performance enhancement features that are often

employed to achieve a greater read success in certain situations. These features are the

GEO mode of interrogation, Dynamic Interrogation Window, and Frequency Scan. The

interrogation mode and the Dynamic Interrogation option may be enabled or disabled at

any time through the System Setup menu contained within the Tools command. The

interrogation mode may also be changed by pressing the backspace key while in Reading

mode. The Frequency Scan option is controlled from the Frequency Control menu within

the Tools command.

GEO Mode

As described in the Reading mode section, the GEO mode is similar to L/L mode in that

it uses the Lat/Lon locations of transponders to determine whether or not they should be

interrogated. However, it differs by also including in the interrogation window any

transponder that does not have a Lat/Lon coordinate. This most often occurs as new

transponders are added to an existing route. Most utilities do not have a means of

assigning a Lat/Lon coordinate at the time the transponder data is added to the route. As

a result, any new and uninitialized transponder would never be read while in L/L mode,

which is the primary mode of interrogation. Ordinarily, such transponders would have to

be read using FIFO mode, which would require the operator to be aware of where each

uninitialized transponder was located, and then switch interrogation modes until the

desired uninitialized transponder reading was obtained. On all but the smallest routes,

this need to constantly change interrogation modes would prove too unproductive to be

practical.

It is when a small number of uninitialized transponders are mixed into the route, that

GEO mode is used. GEO gets its name since transponders without coordinates are

geocoded as they are read. Geocoding is simply an action that assigns a Lat/Lon

coordinate to an object. Since the MMI records Lat/Lon information for each transponder

as it is read, once a read occurs there now exists an approximate Lat/Lon coordinate for

that transponder that may be used the next time that transponder is uploaded to the MMI.

Because the recorded Lat/Lon coordinate is the position where the MMI obtained the

reading, and not where the transponder is actually located, an additional restriction is

placed on the transponder before its reading is accepted. Each time a transponder reply is

received, a measure of its signal strength is recorded. The signal strength is proportional

to the distance to the transponder. As the MMI moves closer to the transponder, the

received signal strength increases. Therefore, the goal is to ensure that an uninitialized

transponder is read in GEO mode at a shorter range than normal. This ensures that the

recorded Lat/Lon coordinate will be effective the next time the transponder is read using

its new coordinates. To force this range restriction, a minimum signal strength

requirement is set in the System Setup menu that will be applied only to uninitialized

transponders being read in GEO mode. Other transponders with Lat/Lon coordinates, as

well as any transponder in FIFO mode will not face this restriction. Any transponder

reply

Page 14

Chapter 4 Operation

that does not meet the signal strength requirement will result in a NO_RD status. This is

the same status which occurs any time the MMI does not receive a reply from a

transponder. The default minimum signal strength setting will most not likely never need

to be altered.

Dynamic Interrogation Window

Another performance enhancement feature implemented in the MMI is the Dynamic

Interrogation Window. Ordinarily, the interrogation window is set to a particular fixed

radius, and is not altered. This is normally acceptable for routes that have a consistent

installation density. However, on routes where there are widely varying installation

densities, a fixed interrogation window size can actually cause performance degradation.

If an excessive non-adjustable window size is used on a dense route, then the MMI will

not have as much time to re-interrogate transponders that are close, but have not yet been

read. This would result in either missed transponder readings, or would require the

operator to slow the vehicle to an unacceptable speed. Likewise, if the non-adjustable

window size becomes too small, then some transponders may never be interrogated at all

due to the vehicle speed and errors in the Lat/Lon coordinate information. To overcome

these limitations, the dynamic interrogation feature may be enabled by the System Setup

menu within the Tools command. When enabled, this feature will automatically adjust

the interrogation window size once per second to try to maintain a fixed number of

transponders in the window. This ensures that in situations where there are a large

number of transponders in a small area, the interrogation window size will be kept

smaller, so time is not wasted on interrogating transponders that are farther away. Also, it

ensures that in situations where there is a small number of transponders in a large area,

the interrogation window size will be allowed to grow, which prevents transponders from

never being interrogated at all.

Frequency Scan

To accommodate older transponders whose reply frequency has drifted down beyond

normal limits, the frequency scan feature may be enabled. This feature is enabled in the

Frequency Control menu contained in the Tools command. This feature will tune

receiver channel 1 between two frequency limits defined in the Frequency Control menu.

This allows transponder replies at abnormally low frequencies to be received, without any

special or additional effort. However, one caution should be noted when using this

feature. Since a receiver channel 1 is changing frequencies quite often, a transponder

reply may not be received since the receiver was at one frequency, while the transponder

was at another. This results in a potentially increased read time for transponders that

have abnormally low reply frequencies. The amount of speed degradation is related to

how wide the frequency scan is. The wider the frequency scan range, the potentially

slower the response time will be for low frequency transponders. By default the upper

frequency limit for the scan is one channel below the lowest channel currently

programmed in channels 2-8. Both limits may be arbitrarily changed within the

Frequency Control menu.

Page 15

Chapter 4 Operation

Command Mode

The operator may stop reading at any time by pressing any key other than the backspace

key on the hand-held terminal. Doing so will place the MMI in the Command mode,

where various operations are available. Stopping the reading process in this manner will

not affect any previously read transponders, and the Reading mode may be entered or

exited as often as necessary. All transponder data is stored in non-volatile memory which

protects valuable data from being lost in the event of main power loss. This also allows

the operator to quickly and easily pause the MMI while in the process of reading a route,

and resume reading the remainder of the route at a later time. While in command mode,

transponder interrogation is suspended.

The Command mode consists of the following main commands: Summary, Reading,

Tools, Quit, and Help. Each of these main commands have various sub-menus from

which to choose. On all Command mode menus the location of the menu squares on the

display roughly match their respective location on the keypad. Using the Summary menu

display in figure 5 as an example, the ALL menu selection would be chosen by pressing

the ‘0’ key on the handheld terminal. Each command is discussed in more detail in the

remainder of this section.

Summary Command

The Summary command menu is the invoked by pressing the ‘S’ key while in Reading

mode, or while the main Command mode menu is displayed. The six Summary command

menu selections display the total number of transponders having a particular status. As

an example, this information can be used to identify how many transponders have been

tampered with, then display each address so that a visual inspection of the transponder

may be performed.

SUMMARY READING TOOLS QUIT HELP

ALL

100

GOOD

90

UNRD

1

TMPD

5

UNINT

4

InWIN

3

Figure 5. Summary Command Sub-menus

Page 16

Chapter 4 Operation

The Summary command menus display information in the format shown in Figure 6.

When the operator selects a particular Summary command menu, the MMI searches the

route for only those transponders that have responded accordingly.

Summary Entry # Address SN # Status Reading

1 2804 Weber St. 2789321 G_NT 3749

2 12806 Weber St. 2930587 G_NT 9712

3 1474 Main St. 2002189 G_NT 7834

4 1795 North Main St. 2501987 G_NT 0328

4

UP DOWN QUIT HELP

Figure 6. Summary Display Data Format

The six menus of the Summary command detail the various possible states for the

transponders in the route. This serves to give a quick, detailed look at the progress being

made in the reading of the route. The definition of each Summary command menu and

associated transponder states are discussed below:

All All transponders in the route will be displayed.

Unrd Any unread transponders in the route will be displayed.

Unint Any transponders that have never been polled will be displayed.

Reminder: The MMI will not poll a transponder until it is in the

interrogation window while in the Lat/Lon or GEO mode of reading,

or unless it has not Lat/Lon coordinate, and GEO mode is active.

Good Those transponders that have been successfully read, including tampered units,

will be displayed. Refer to Table 1 for a summary of transponder status

definitions.

Tmpr Any transponders which have returned a tamper status will be displayed.

Inwin In the Lat/Lon mode of reading, all transponders which are in range of the MMI

read window and are displayed. In the FIFO mode of reading, all unread

transponders will be displayed as being in the window.

Page 17

Chapter 4 Operation

Particular entries may be searched for in any of the summary displays by using the S

(search) key. This will allow the operator to input a street number, street name, serial

number, or just a part of an entry that corresponds to a transponder of interest. The

summary display will then display only those transponders that match the search string

and are in the main summary category initially selected.

The operator may also jump to a particular entry in the summary display, by typing in the

desired entry number and pressing the Enter key. The display will then start at that entry

a scroll down from there. The number displayed in the box above the S key is the total

number of entries contained in this summary. This number will change if the operator

inputs a search string and narrows the summary, and will then display only the number of

entries that match the search string. Help is available at any time in the summary screen

by pressing the H key.

Within some of the Summary sub-menus there are various status labels placed on each

transponder entry. These statuses reflect the success of a transponder read or show why a

read failure was detected. The Code field shown in Table 1 corresponds to the code field

in the MMI output data file.

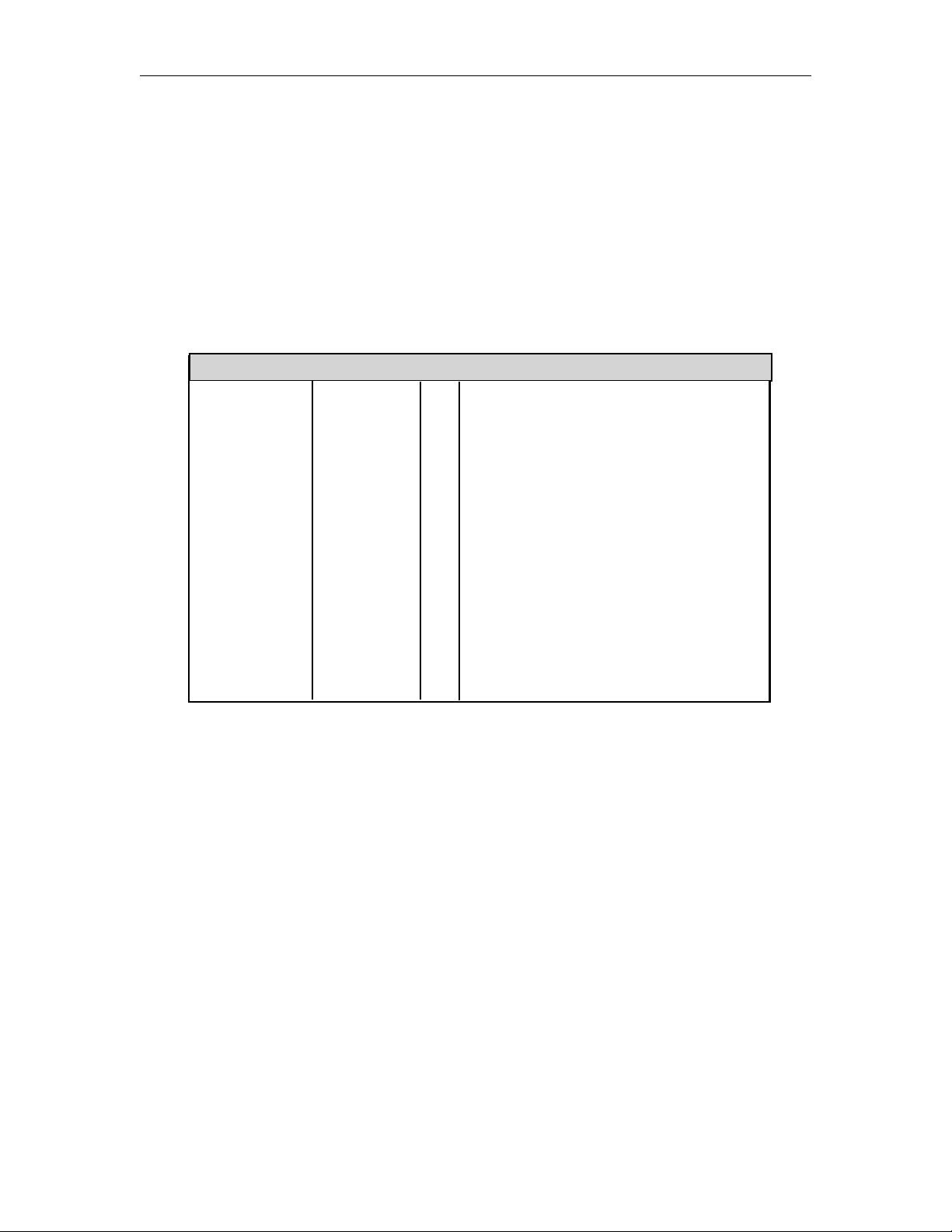

Status Description Code Tamper Good Read Good Status

UNINT Uninterrogated 10 N/A No No

G_NT Good;Not Tampered 01 No Yes Yes

G_NR Good;Not Reset 03 Yes Yes Yes

G_TR Good;Tamper Reset 07 Yes Yes Yes

G_T_RF Good;Tamper Reset Failed 0B Yes Yes Yes

G_T_RP Good;Tamper Reset Pending 0F Yes Yes No

NO_RD No Read 20 N/A No No

BAD_RD Bad Read 40 N/A No No

* BAD_MR Bad Meter Reading Checksum 41 N/A No No

* BAD_ID Bad Serial Number Checksum 42 N/A No No

* BAD_B2 Both Checksums Bad 43 N/A No No

N_T_RP No Read; Tamper Reset Pending 2F Yes Yes No

B_T_RP Bad Read;Tamper Reset Pending 4F Yes Yes No

PENDNG Pending;Was UNINT prior 90 N/A No No

PENDNG Pending;Was G_T_RP prior 8F Yes Yes No

PENDNG Pending;Was NO_ RD prior A0 N/A No No

PENDNG Pending;Was BAD_RD prior C0 N/A No No

* Status Pertains To 3rd Generation Transponders Only

Table 1. Transponder Status Definitions

The transponder status definitions shown in Table 1 are described below:

UNINT The transponder has never been polled because it has never been within

the

interrogation window. The Tamper field in Table 1 does not apply with

this status since the transponder has never been read.

Page 18

Chapter 4 Operation

G_NT The transponder has replied with a good read, no tamper condition.

G_NR The transponder has replied with a good reading and is showing a tamper

status, but the MMI is not going to reset the tamper condition as controlled

by the system configuration. The system configuration may be changed in

the System Setup menu, or by changing the values in the Guide file.

G_TR The transponder has replied with a good reading and was showing a

tamper status, and the MMI successfully reset the prior tamper condition.

G_T_RF The transponder has replied with a good reading and is showing a tamper

status, but the MMI cannot reset the tamper condition, possibly because

the transponder is still in a position that is causing the tamper status.

G_T_RP The transponder has replied with a good reading and is showing a tamper

status, but the MMI was not able to verify if the tampered condition was

reset. This may occur if the MMI goes out of range of the transponder

while still trying to interrogate it to verify the tamper status. The reading

for the transponder is good, but the tamper condition may or may not still

exist.

NO_RD The transponder has been polled, but the minimum number of receiver

channels did not received enough good data to pass the channel matching.

This usually occurs when a transponder is still too far away from the MMI.

BAD_RD The transponder has been polled and the receiver was able to lock on to

the

incoming data, but the BCH error detection has failed. This may occur if

the MMI is in an area of strong interference, and is usually corrected when

the MMI gets closer to a transponder.

BAD_MR The 3rd generation transponder has replied with an indication that the

meter reading checksum has failed. This could be due to a new battery

being inserted in the transponder, or due to a malfunction. The transponder

should be checked and reprogrammed. The meter reading should not be

trusted.

BAD_ID The 3rd generation transponder has replied with an indication that the

serial

number checksum has failed. This could be due to a new battery being

inserted in the transponder, or due to a malfunction. The transponder

should be checked and reprogrammed. The meter reading should not be

trusted.

Page 19

Chapter 4 Operation

BAD_B2 The 3rd generation transponder has replied with an indication that both the

meter reading and serial number checksums have failed. This could be due

to a new battery being inserted in the transponder, or due to a malfunction.

The transponder should be checked and reprogrammed. The meter reading

should not be trusted.

N_T_RP The transponder has replied with a good reading and is showing a tamper

status, but during the tamper reset verification, the transponder reply

resulted in a NO_RD status. The reading for the transponder is good, but

the tamper condition may or may not still exist.

B_T_RP The transponder has replied with a good reading and is showing a tamper

status, but during the tamper reset verification, the transponder reply

resulted in a BAD_RD status. The reading for the transponder is good,

but the tamper condition may or may not still exist.

PENDNG The transponder has replied with a particular non-good status, and is now

in a transition between the prior status, and a new status.

Page 20

Chapter 4 Operation

Tools Command

The Tools command consists of seven sub-menu options. These options are used for

trouble shooting a problem with one of the Trace system components, changing the

system configuration, turning the transmitter on and off, searching and displaying

expanded data for a particular transponder, accessing stored data in the non-volatile

backup memory, or changing the default frequency control values. The Tools collection

of menus is by far the most involved and user-driven set of commands. Figure 7 shows

the location of the Tools command menu choices. Additionally, the ENTER key will

toggle the backlight on and off while in the Tools command.

SUMMARY READING TOOLS QUIT HELP

TRBLE

SHOOT

ROUTE

SCAN

SYSTM

SETUP

BKUP

MEMORY

XMIT

<ON>

FREQ

CTRL

Figure 7. Tools Command Sub-menus

SET

PERM

Page 21

Chapter 4 Operation

Trouble Shoot Menu (key 4)

The Trouble Shoot menu is used to interrogate 4 user-definable transponders, and display

useful statistics for each one. The display used for this menu may be broken down into

two parts; the bottom half is used for user entry of transponder serial numbers and basic

commands, while the top half is used for transponder response information. An example

of the troubleshoot menu is shown in figure 8.

Rx Chans Reading Tries % Good Status

- - - - - - - - 0 41 0.00 -

- - - + + * * 1234 41 95.97 *

- - * + - - - - 999 41 85.22 T

- - * * * - - - 38 41 88.65 M

#1 - 0000000

#2 - 2120045

#3 - 0078067

#4 - 2581191

0 : Reset Counts

1-4 : Change Serial Number

‘Q’ : Exit Trou ble Shoot

Figure 8. Trouble Shoot Display Format

Troubleshoot User Entry

The keys 1-4 are used to enter a new transponder serial number. After choosing an entry

between 1-4, the new transponder serial number is entered most significant digit (MSD)

first, and will begin to be interrogated. As each active transponder entry is interrogated,

the appropriate top-half display fields update accordingly. To reset the current display

data, the ‘0’ key is used. The Troubleshooting sub-menu may be exited at any time by

pressing the ‘Q’ key.

Page 22

Chapter 4 Operation

The top half of the display contains five columns. The channel activity displays which of

the 8 receiver channels are receiving valid data using a + or * symbol. Channel 1 appears

at the left of the channel display, and channel 8 appears at the right. The next field i s the

meter reading. This data is not checked for any errors, and will be displayed with or

without errors. Next is the interrogation count field. This is the number of times an

interrogation has been sent for a particular transponder. This field starts at 0 upon

entering a new id, whenever the count rolls over from 99 , or whenever the ‘0’ key is

pressed.

The percentage of successful replies field is a running percentage of good replies which

the MMI has received. As in the count field, this percentage is set to 0 by entering a new

id or pressing the 0 key. The final field is the BCH/Tamper indication. A ‘*’ symbol

indicates that a reply with a good BCH code and no tamper indication is being received.

A ‘T’ symbol indicates that a good BCH code and a tamper indication is being received.

The ‘+‘ symbol indicates that the received data does not pass BCH error code detection,

but the receiver channel is locked on to the incomin g data. This most often occurs if the

receiver delay is invalid, and does not match the transponders delay. An ‘M’ symbol

indicates that a good BCH code and a meter reading checksum error is being received,

most likely indicating that a transponder has undergone a software reset. The ‘M’ status

can only be reset in the transponder by reprogramming it.

Page 23

Chapter 4 Operation

System Setup Menu (key 6)

The System Setup sub-menu allows the operator to display and modify various system

operation parameters. The default system parameters that the MMI uses after turn-on is

stored in the floppy disk file Guide. A 6-digit password (which is also stored in the

Guide file) must be entered correctly before access to the System Setup screen is all owed.

The password digits are not echoed as they are entered, and no Enter key is required. If

the user fails to enter the correct password after the fourth attempt, all access to the

System Setup menu is barred until the MMI is restarted. Figure 9 shows the layout of

the System Setup screen.

S Y S T E M S E T U P

0) Read Mode? (L/L, FIFO, GEO).………….…L/L

1) Display good reads?………………………….Yes

2) Beep with good reads?……………………….Yes

3) Reset tampers?…………………………….…Yes

4) Window size (x100 feet)..…………………….. 8

5) Sort unread summary display?…………….….Yes

6) Dynamic window on?…………………………Yes

7) Reject reads with checksum errors?…………..Yes

8) Self-navigation on?……………………………Yes

9) Minimum GEO mode signal st r ength……….…215

Press ENTER t o accept, Q to abandon.

Figure 9. System Setup Menu Display

Any of the System Setup options may be changed as many times as desired during

operation. The following is a summary of each option:

Option 0: This option is used to toggle the reading method between the Lat/Lon,

GEO, and FIFO mode.

Option 1: This selects whether the MMI will display the total number of good

readings, the transponder serial number, meter reading, and street address

of a transponder after a good read. The options are YES and NO.

Page 24

Chapter 4 Operation

Option 2: This selects whether the MMI will beep after each good reading. The

options are YES and NO.

Option 3: This selects whether the MMI will attempt to reset a tamper indication

after it performs a reading. The options are YES and NO.

Option 4: This option allows the user to set the interrogation window size. When

selected, the user must key in a new value, followed by the Enter key. The

value entered must be the desired window size divided by 100. Valid

ranges are 1-99.

Example: If a window size of 1500 feet is desired, enter 1 5.

Option 5: Enabling this option allows the user to sort the unread display

in order of increasing distance from the MMI.

Option 6: This option allows the Dynamic Window to be turned on and off. The

options are YES and NO.

Option 7: This option determines whether or not transponder replies containing

a meter reading checksum error will be allowed. Caution! Any meter

reading information from a transponder with such a status should not

be trusted! The options are YES and NO.

Option 8: This option allows the Self-navigation mode to be turned on and off.

The options are YES and NO.

Option 9: This option is used to set the minimum signal level that is required

to accept a reply from an uninitialized transponder in GEO mode.

Valid ranges are 0-255.

Enter: Press this key to exit, and use any new settings.

‘Q’ key: Press this key to exit, and abandon all changes.

Page 25

Chapter 4 Operation

Route Scan Sub-menu (key 5)

To view detailed transponder information not available with other menus, the Route Scan

menu may be used. Information such as read status, meter reading, street address, and

location are displayed. If the transponder has not yet been read, then the Lat/Lon

coordinates that are displayed are those which were read from the floppy disk. If the

transponder has a good read status, then the location of the MMI where the read was

obtained will be displayed as that transponders Lat/Lon. Upon entering the Route Scan

menu, the user is prompted for an ID number. At this point, the user must enter the serial

number of the desired transponder followed by the Enter key. Leading zeros in the entry

are not required. Once the current display is complete, the user may either choose a new

transponder to search for, or return to the main menu. Figure 10 shows a sample Route

Scan menu display.

BACK

MAIN

Id .................... 2789324

Status .............. ( 10 ) Unint

Reading ........... 0

Address ........... 1305 Philmont Ave.

Latitude ........... 72.49987

Longitude ........ 38.20110

The distance to the MMI is : 407.23 feet

SEARCH

ANOTHR

Figure 10. Route Scan Sub-menu Display

Backup Memory Menu (key 7)

The Backup Memory menu allows the user to view and retrieve all the data stored in the

battery backed-up memory. This data may either be the data for the current route, or the

data for previously used routes. Figure 11 shows the menus available within the Backup

Memory menu. The backup memory can store a maximum of 30,000 transponders or 30

routes, and each route may contain up to 10,000 transponders. A discussion of each

Backup Memory menu is described below:

Page 26

Chapter 4 Operation

BRIEF

TOTAL

DETAIL

ONE

QUITLD_TO

DISK

Figure 11. Backup Memory Sub-menus

Brief Total

The Brief Total sub-menu displays a description of all routes stored in memory. This

display shows the internal route number used by the MMI, the route name and date, and

the number of transponders (records) in the route. The route number is used by the MMI

in other Backup Memory menus to select a particular route.

Detail One

For detailed route information, the route number should first be obtained using the Brief

Total option. Once the desired route has been identified, and the route number for that

route has been obtained, the Detail One option may be used. At the Enter the route

number prompt, the range of stored routes is displayed within the parenthesis. The user

should now enter the desired route number followed by the Enter key. Once the display

has finished scrolling, pressing any key will return the user to the Backup Memory menu.

LD_TO Disk

The LD_TO Disk option is used to save a selected route to floppy disk. This is useful if a

previously executed route was lost, or a copy of the route needs to be made. Upon

selection of this option, the user is prompted for the number of the route to be saved.

When the route is located, the disk is checked for available space, and the save operation

proceeds, and a bargraph shows the completion status.

Quit

As in other menus, the ‘Q’ key returns the user to the previous menu level, which in this

case is the Tools command main menu.

Page 27

Chapter 4 Operation

Frequency Control Menu (key 9)

The Frequency Control menu, shown in figure 12 below, enables complete control of

each receiver channel frequency. It also allows control of the transmitter frequency with

the use of a factory password which is obtained by a special request to American Meter

Company. This menu is also used to setup and enable/disable the frequency scan option

on channel 1. The frequency for each channel is displayed in the frequency grid at the top

of the display. The top line of the grid box displays the receiver channel number, and the

bottom line of the grid box displays the frequency applied to that channel. The frequency

display is in the format ?.? which is an abbreviation of 41?.?. For example, if the

frequency display for channel 1 is displaying 3.1, then the frequency programmed into

channel 1 is 413.1. If the frequency display is flashing for any channel, then that

indicates that the channel has not accepted the programmed frequency. The

corresponding green LED on the receiver channel will also be turned off (for additional

information on receiver status indicators, refer to the Transmitter/Receiver Status

Indicator section of the manual). The flashing display is usually a result of an out of

range frequency being programmed into the channel, or because the channel is defective.

The functions available through the frequency control menu are described below:

Receiver / Trans mitter Frequency Setup

12345678

3.0 3.3 3.6 3.9 4.2 4.5 4.8 5.1

Chan 1 Scan: On

Enter Lower Scan Limit: 41?.? MHz

Enter Upper Scan Limit: 41?.? MHz

Enter Base Frequency : 41?.? MHz

Enter Chan Spacing: ?.? MHz

FULL REDO XM IT QUIT SCAN

Figure 12. Sample Frequency Control Menu Screen

FULL (key S): This option allows all receiver frequencies to be setup at

one time by entering a base frequency for channel 1, and then

entering an offset frequency that will be applied to each successive

channel. Once the ‘S’ key is pressed, a flashing cursor block will

appear over the digit to be changed. Simply press a key 0-9 or

press the ‘Q’ key to abandon any changes.

Page 28

Chapter 4 Operation

REDO (key R): This option simply re-initializes each receiver channel with

the frequencies displayed in the frequency grid.

XMIT (key T): This allows the factory-set transmitter frequency to be adjusted.

This command requires a special password acquired from

American Meter Company to enable operation.

QUIT (key Q): As with most menus, this exits out of the current menu.

SCAN (key H): This option is used to enable or disable the frequency scan

option for channel #1, and allows the range of the frequency

scan to be set. Upon pressing the ‘H’ key, The ON/OFF field of

the scan control line contains a flashing cursor. Pressing the ‘0’

key disables the scan feature, and pressing the ‘1’ key enables it.

If the scan control is enabled, then two additional lines will appear

below the scan control status line. Pressing the ENTER key will

move the cursor to the lower scan limit line. Enter the frequency

here as with other frequency control entries. Pressing ENTER

again will move the cursor to the upper scan limit line, which by

default is set to the first channel below the lowest frequency

enabled on channels 2-8. Pressing the ENTER key a final time

will

finish the scan control data entry. Any time the frequency scan

option is enabled, a flashing ‘S.S’ will appear in the frequency

grid for channel 1 to indicate that the frequency for channel 1

is constantly changing.

Keys 1-8: Pressing any of these keys will invoke the individual frequency

control entry. This allows for a single receiver channel to be

programmed to an arbitrary frequency, without disturbing the

frequencies of any other channel.

Page 29

Chapter 4 Operation

K

Set Perm Menu (backspace key)

This menu displays and allows control of all permanent settings stored in special nonvolatile memory. Settings found in this menu never need to be loaded from the floppy

disk, and typically never need changed. Special items such as the MMI electronic serial

number, usage statistics, receiver delay parameters, licensed transmitter frequency, and

service history are shown in this menu, an example of which is shown in Figure 13.

Non-authorized users may display this page, but may not modify any of the parameters.

To change any of the settings, the menu must be unlocked by pressing the ‘T’ key and

entering the factory unlock password.

Permanent Settings *LOCKED*

1) S/N: 000000122

2) Usage: 000006041

3) Update: 100197:142358

4) Last svc: 000000

5) 2ndG_dly: 9230

6) 3rdG_dly: 9530

7) 4thG_dly: D000

8) Transm it: 4??.???

9) Encrypt: F23A99C6

0) S_PWD: 12345678

0123456789ABCDEF

<-- -->

Figure 13. Set Perm Menu Display

UNLC

QUIT

P:001

Page 30

Chapter 4 Operation

Quit Command

The Quit command consists of three menus which are used to conclude or pause the

execution of a route. Figure 14 is an example of the Quit command. An explanation of

each sub-menu is given in the remainder of this section.

SUMMARY

READING TOOLS QUIT HELP

SAVE

& EXIT

EXIT

BREA

K

Figure 14. Quit Command Sub-menus

Save & Exit

The Save & Exit option is used to save the results of the current route to floppy disk, and

then exit the menu system. Before the route is saved, the floppy is checked for available

disk space, and then either the route is saved, or the user is prompted to insert a di sk wit h

adequate storage space. Once the save is complete, the next time the MMI is used, it will

attempt to load in a new route from disk. This option may be used at any time during a

route, even if no or few readings have been collected.

Note: After saving a given route, the route data is still stored in backup memory until it

is overwritten by subsequent route data.

Break

The Break option is used to pause the execution of the current route. This allo ws the user

to completely shut down the MMI, then restart it at a later time, continuing the active

route. The route information that was initially loaded from floppy disk is stored in the

backup memory, and this is the data that the MMI uses while executing a route. Even if a

different floppy disk is inserted into the MMI during the break, the current route will still

be resumed. If the user wishes to abort the reading of a route after returning from a break,

the MMI must be powered on and then an Exit or Save&Exit command may be issued.

Page 31

Chapter 4 Operation

Exit

The Exit option is used to exit out of the current route without saving it to floppy disk.

After this option is used, the MMI will load a new route from disk the next time it is

powered up. This option may be used at any time during a route, even if no or few

readings have been collected.

Note: Even though the Exited route was not saved to disk, the entire route is still saved

in the backup memory, and will remain there until it is overwritten by subsequent route

data.

Page 32

Chapter 4 Operation

Help Command

The Help command is used to display a brief on-line operation guide (Quick Manual),

current vehicle position, to view or set the time/date (Loc & Time), and to execute and

view self-check results, as well as display the firmware revision currently executing

(About MMI). Figure 15 shows the Help sub-menus. Both sub-menus are described in

more detail below:

SUMMARY

READING TOOLS QUIT HELP

ABOUT

MI

QUICK

Manual

LOC &

TIME

Figure 15. Help Command Sub-menus

Quick Manual

The Quick Manual option will display several pages of brief descriptions of various MMI

commands and transponder statuses. The user may scroll up or down through the

manual, and exit from any page. The quick manual menu is intended to be used as a

quick reference, not a complete guide. For detailed operating instructions and

explanations, please consult the appropriate section of this manual.

Page 33

Chapter 4 Operation

Location & Time

The Location & Time menu displays GPS navigation information as well as the current

system time and date. This menu also allows the GPS, time, and date information to be

changed. An example of the Location & Time menu is displayed in figure 16.

Location & Time

GPS: No Response

GPS Sats: 0

GPS DOP: 0.0

System Time: 08:24:47

System Date: 10-29-97

GPS UTC Time: 13:25:16

GPS Latitude: 38.1345

GPS Longitude: 81.5516

Time GPS QUIT

Figure 16. Location & Time Menu Display

As shown in figure 16, Both GPS and system time are displayed. The top of the display

details current GPS navigation system status. The GPS status indicator may one of three

statuses:

No Response: This indicates that there is no data being received from the GPS

receiver by the MMI.

No Position: This indicates that the MMI is receiving data from the GPS receiver,

but there are not enough satellites in view to navigate with.

Active: This is the normal status indication that the MMI is receiving data from

the GPS receiver, and the receiver is producing good Lat/Lon position

data.

The next lines on the display show the current system date as well as both system and

GPS time. The GPS UTC time is in a format known as universal time coordinated (UTC)

which is a world-wide time. Depending on the location in the U.S., UTC time is a few

hours ahead of local time. UTC time is extremely accurate, as it is derived from atomic

clocks abord the GPS satellites.

Page 34

Chapter 4 Operation

The current system date and time may also be adjusted from with the Loc & Time display

using the Time option by pressing the ‘S’ key. This will invoke the display shown in

figure 17. New time or date digits are simply pressed on the handheld terminal, and the

two arrow keys moves the flashing cursor over top of the digit to be changed. Also, the

system time and date may be synchronized to the GPS UTC time and date by using the

UTC option (key ‘T’). It should be noted, that in the U.S., UTC time will not match local

time. Pressing the ‘Q’ key exits back to the Loc & Time menu.

Set System Time & Date

08:24:47 10-29-1997

Use the S & H keys to select the digit

you wish to change . Press the E NTER key

to set the time, or press the Q key to

abandon changes.

<--

Figure 17. Set Time & Date Menu Screen

QUIT

-->UTC

Page 35

Chapter 5 Troubleshooting

Troubleshooting

This section offers brief suggestions to try in the event that the MMI is not functioning

properly. The only items covered in this section are those which are user serviceable, or

those which the operator is responsible for properly setting up or checking during

operation.

••••

••••

Tools

is

each

Handheld terminal does not turn on, or does not respond.

First verify that there are no illuminated and non-flashing red LED’s on any of the

main computer boards at the upper left of the MMI. If nothing seen, then

inspect that the main power cable is correctly connected. If there no obvious

cabling problems, then the two internal fuses should be checked.

These may be found just inside the rear cover door of the MMI which is opened

by removing three small screws. There is a separate fuse holder for the external

power connection as well as for the internal battery. These fuses are standard

automotive types. Replace with a 20-amp fuse.

Poor reading performance or range.

This should be verified by using the Troubleshoot menu contained within the

command. Using a known good transponder, if it is verified that the transponder

difficult to communicate with, then check both antennas. The whip section of

antenna should be screwed down tightly to the base, and the transmit antenna

must be screwed on the MMI connector until tight. Also verify that all the

green PLL OK LED’s are illuminated on the transmitter and receiver boards.

Also verify that both RF amplifier LED’s are illuminated.

••••

••••

Uninitialized transponders are not read in GEO mode.

Using the System Setup menu contained within the Tools command, verify that

the minimum GEO mode signal strength requirement is not set too high. As a

check, this value may be set to 0 to disable the requirement.

Transponders are able to be read in FIFO mode, but not in L/L mode.

Verify that the GPS has an active status. If so, then turn off the dynamic window

feature, then check the interrogation window size using the System Setup menu in

the Tools command. As a check, this value may be set to 20 to use a 2000-foot

window radius. If this still fails to produce readings in L/L mode, then verify that

the MMI considers the transpoders in question to be within range by using the

UNRD summary menu. This will display the distance between each unread

transponder and the MMI. If the displayed distance is not what is expected, then

the Lat/Lon coordinates for the transponders in question may be unitialized, or

invalid.

Page 36

Appendix A File Formats

File Formats

The MI requires three important disk files for operation. These files consist of operating

parameters and transponder data which is usually generated with a PC, but may be

created with any system capable of accessing a 1.44Meg PC-formatted floppy disk.

Normally the first two files, the Start and Guide files are not altered or re-created. They

may be simply copied from a master source each time they are needed. The Reading.rte

file contains the transponder information, which is usually created from a larger database

of transponder data, and only the transponders for a particular route are extracted and

placed in the file. The MMI also creates an output file ending with the extension .VAN

which contains transponder output data. This data in this file is typically read back into

the master database, and then erased off the floppy.

The Start File

The start. file is used by the operating system, and contains directions used only during

power-up.

The GUIDE File

The GUIDE file contains system operation parameters that control how the MMI

operates. Each of these parameters may be displayed and changed while the MMI is

operating by using the System Setup option from the Tools command. A typical GUIDE

file configuration might look like this :

0 1 1 1 15 0 000 123456 1 1 1 1 2.0 3.0

where:

1st entry: The mode of interrogation. 0 = Lat/Lon, 1 = FIFO, 2 = GEO.

2nd entry: The option to display good reads. 0 = No, 1 = Yes.

3rd entry: The option to send a beep with each good read. 0 = No, 1 = Yes.

4th entry: The option to reset any tamper indications. 0 = No, 1 = Yes.

5th entry: The interrogation window size in hundreds of feet (15 = 1500 feet).

Range: 1-99

6th entry: This entry is not used in the MMI but remains as a place holder.

th

entry: This entry is not used in the MMI but remains as a place holder.

7

8th entry: The 6-digit password used to access the System Setup and the Set Time

options.

th

9

entry: The option to sort summary unread display. 0 = No, 1 = Yes.

th

entry: The dynamic window option enable. 0 = No, 1 = Yes.

10

th

11

entry: Option to reject reads with checksum errors. 0 = No, 1 = Yes.

12th entry: Frequency scan option enable. 0 = No, 1 = Yes.

th

entry: Lower scan limit frequency in the format 41?.?.

13

14th entry: Upper scan limit frequency in the format 41?.?.

Page 37

Appendix A File Formats

The READING.RTE File

The data in the Reading.rte file specifies what transponders are to be read. This data

contains the transponder serial number, latitude, longitude, and street address. The

latitude and longitude are used when the MI is in the Lat/Lon or GEO modes of

interrogation. The list of transponders loaded from disk may be examined at any time by

using the options under the Summary command. This file is usually created from a

larger, more centralized database using TICS, however it may be created using any means

available. The Reading.rte file consists of an input header, followed by up to 10000

transponder entries. The format of the input file must be strictly adhered to, as even a

single character out of place will corrupt the file. The file format is shown below, and

Figure 20 is a sample Reading.rte file listing.

route name latitude longitude file creation

date

columns 1-3 5-10 12-17 19-24 26-30

width 3 6 6 6 5

type characters hexadecimal hexadecimal decimal decimal

Figure 18. READING.RTE input file header format

serial

number

columns 1-7 9-14 16-21 23-41 43-45

width 7 6 6 19 3

type decimal hexadecimalhexadecimalcharacters characters

Figure 19. READING.RTE input file record format:

Notes: 1. The latitude and longitude in the file header may be the Lat/Lon of the

place where the file was created. This is for reference only.

latitude longitude street

address

total record

count

place

identifier

2. The latitude and longitude are stored as 24-bit binary quantities known

as BAMS which stands for Binary Angular Measurements. This is a

format

which allows a number consisting of degrees, minutes, and seconds to be

stored as a binary equivalent number. The binary format is faster and

easier

for the MI to work with. A BAMS number is created as follows:

BAMS = ( Total degrees ÷ 360 ) × 16777216

Total degrees = Degrees + ( Minutes ÷ 60 ) + ( Seconds ÷ 3600 )

Page 38

Appendix A File Formats

Example: Degrees/Minutes/Seconds value: 38° 27' 06"

Total degrees = 38 + ( 27 ÷ 60 ) + ( 06 ÷ 3600 )

Total degrees = 38.4517 (round result to 4 places right of the decimal)

BAMS = ( 38.4517 ÷ 360 ) × 16777216

BAMS = 1791979 decimal -or- 1B57EB hexadecimal

AMR,1C5852,358B16,100292,00006

0011758,1B57EB,3A42A0,84 ERSKINE LANE ,WVA

0011486,1B57EB,3A42A0,86 ERSKINE LANE ,WVA

0012061,1B57EF,3A42A2,101 E. MAIN STREET,WVA

0010783.1B57F0,3A42A2,123 E. MAIN STREET,WVA

0011578,1B5921,3A43B3,96 VALLEY VIEW DR,WVA

0011499,1B5A04,3A43C1,140 CASCADE DR ,WVA

Figure 20. READING.RTE Example File Format

Page 39

Appendix A File Formats

The .VAN Output File

Each time the MMI Save & Exit command is used, an output file is created on the floppy

disk. This file contains transponder information such as the meter reading, the receiver

channel activity, and the status code. This file, like the Reading.rte file, has a header

followed by a variable number of transponder records. The actual filename used for this

file is built from a combination of the route name stored in the Reading.rte file, the

system month and day, and if needed, a single letter suffix. This method of filename

creation allows for the same route to be read multiple times using the same disk, without

overwriting data from the previous route file. If the floppy disk is full when a .van file is

to be written, the MMI will prompt for a disk change. The format of the .van file is

shown below, and Figure 23 is a sample .van output file listing.

route name record

count

columns 1-3 5-9 11-16 18-23 25-30 32-37 39-44

width3 5 66666

type characters decimal decimal decimal decimal decimal decimal

file date load date load time quit date quit time

Figure 21. VAN Output File Header Format

serial number status code reading latitude longitude channel activity time

columns 1-7 9-10 12-19 21-26 28-33 35-40 42-48

width 7 2 8 6 6 6 6

type decimal hex decimal hex hex hex decimal

Figure 22. VAN Output File Record Format

Notes: 1. See Table 1 for the definition of the status codes.

2. The Channel activity has a bit for each receiver channel that passed the BCH

check.

AMR,00006,100292,100392,133504,100392,150143

0011758,01,00000127,1B57EB,3A42A0,03FC0C,134003

0011486,01,00000035,1B57EB,3A42A0,0FFF0C,134514

0012061,07,00000089,1B57EF,3A42A2,01B80C,135055

0010783.01,00000039,1B57F0,3A42A2,00FF0C,135632

0011578,0B,00000008,1B5921,3A4300,01FFCC,140224

0011499,01,00000104,1B5A04,3A43C1,03EB0C,144312

Figure 23. VAN Output File Sample Listing

Page 40

Appendix B Specifications

Specifications

Power Source: 12 VDC Vehicle Power / Sealed Internal Gel-Cell Battery

Power Consumption: 120 Watts (10 Amps maximum current) fully loaded

RF Transmitter: 5 Watts Nominal Power, Software Tunable

RF Receiver: 8 Independent Channels, Software Tunable,

-106 dBm sensitivity

FCC Compliance: Part 90:63 / FCC ID: G8JVAN01

Operating Temperature: -5ºF to +160ºF Package Temperature

-4ºF to +140ºF Handheld Terminal

Storage Temperature: -40ºF to +185ºF Package Temperature

-4ºF to +140ºF Handheld Terminal

Humidity: 5% to 95% Non condensing

Size: ???????????????

Weight: (Approximate) 60 lbs.

Loading...

Loading...