Page 1

EA_Inspector

Release 3.6

User Guide

TM42-3013I

Page 2

Contents

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

New in release 3.6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Changes in release 3.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

About handheld devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

About This manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

New users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Existing users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

What is the EnergyAxis System? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

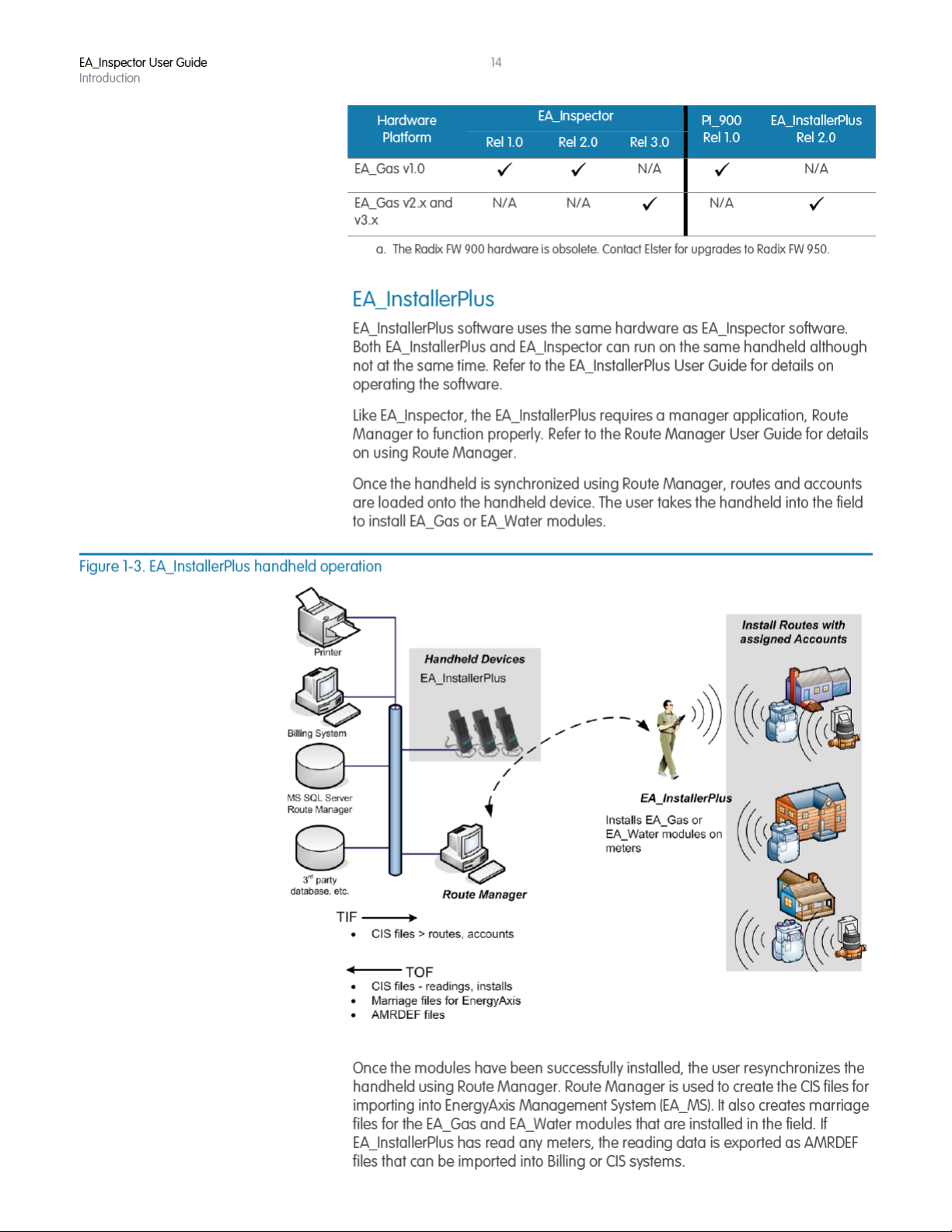

EnergyAxis tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EA_InstallerPlus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

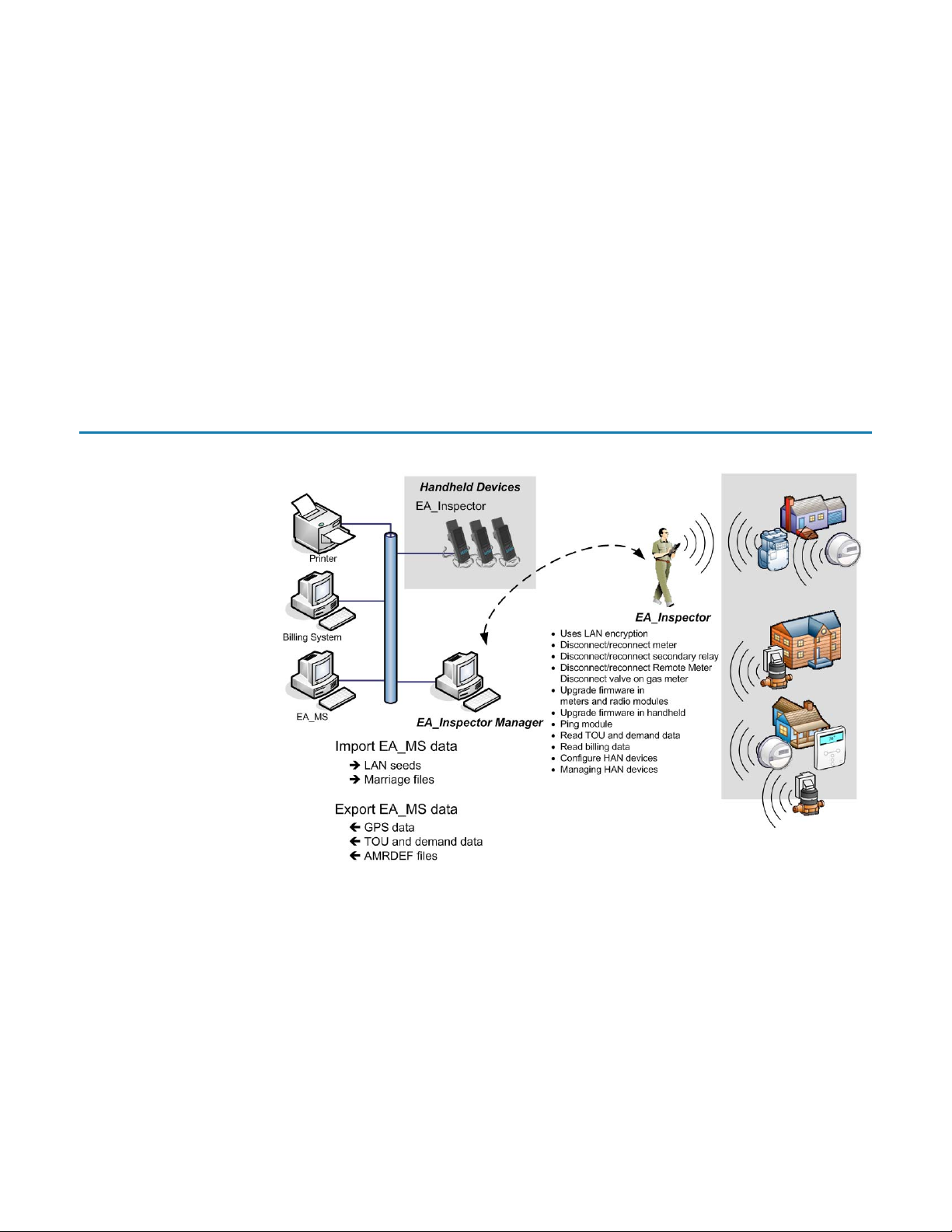

EA_Inspector and EA_Inspector Manager. . . . . . . . . . . . . . . . . . 15

2 About the handheld. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

About the handheld. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Radix specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Safe RF exposure using external antenna . . . . . . . . . . . 18

EA_Inspector Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

EA_Inspector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Transmission accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Navigating the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Database warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

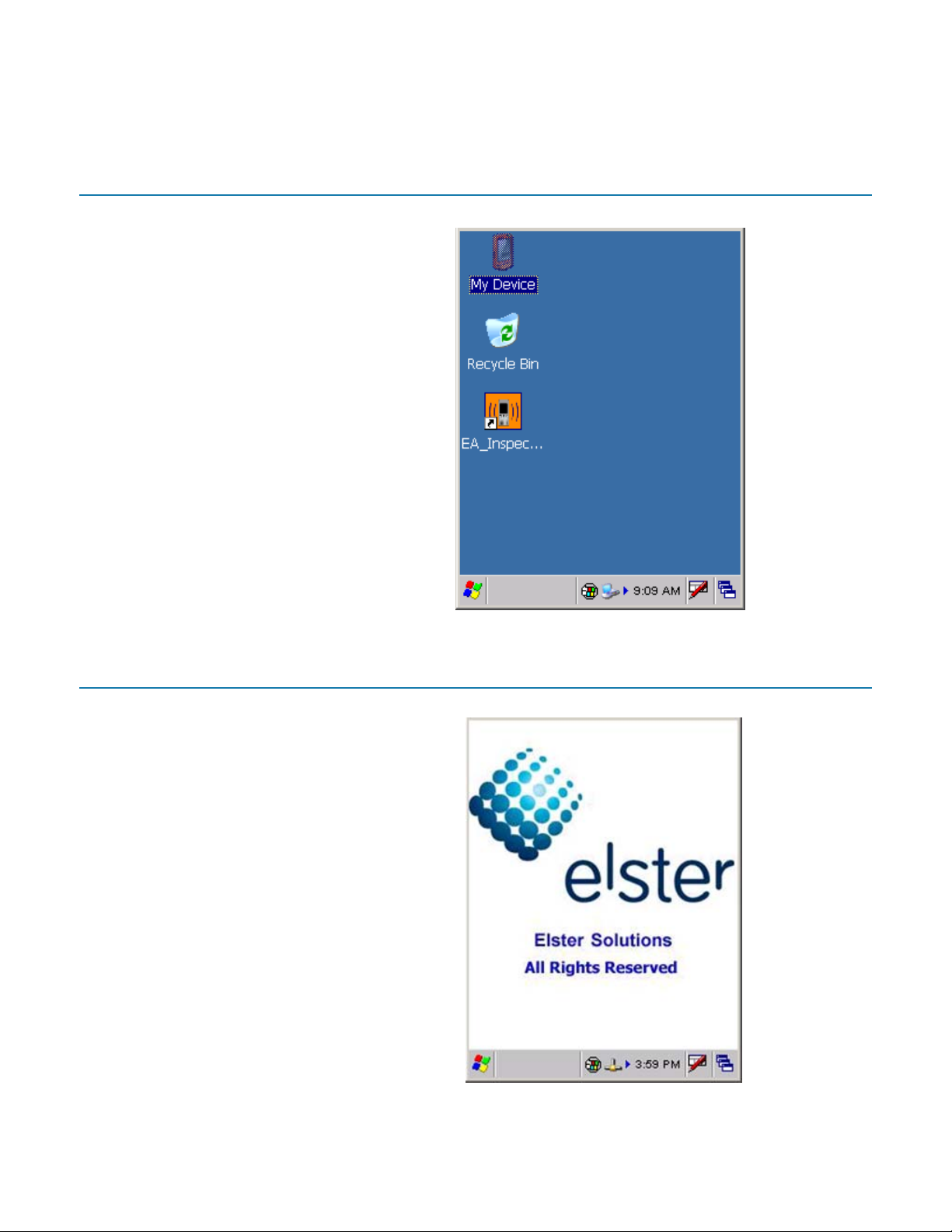

3 Operating the handheld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Commonly used keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

<Esc>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

<Enter> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Arrow keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

<Tab> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Entering responses (Yes/No). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Using the stylus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Turning the device on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Charging the device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Resetting the handheld device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Opening EA_Inspector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Logging in to the handheld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Holding the handheld for meter reading . . . . . . . . . . . . . . . . . . . . . . . . 28

Page 3

EA_Inspector User Guide

Contents

3

4 About EA_Inspector software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Navigating the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

User privileges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Saving notes and GPS data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Exiting EA_Inspector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Exiting from the login screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 Performing a ping test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

About ping tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Accessing ping test menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

One shot ping test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

One shot ping of electric meter. . . . . . . . . . . . . . . . . . . . . . . . . . . 39

One shot ping of a EA_Gatekeeper . . . . . . . . . . . . . . . . . 42

One shot ping of gas module or AC-250 RMD. . . . . . . . . . . . . . 44

One shot ping of a one-way water meter . . . . . . . . . . . . . . . . . . 49

One shot ping of two-way water meter. . . . . . . . . . . . . . . . . . . . 52

Continuous ping test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Continuous ping of electric meter. . . . . . . . . . . . . . . . . . . . . . . . . 56

Continuous ping of a gatekeeper . . . . . . . . . . . . . . . . . . 58

Continuous ping of gas or two-way water module . . . . . . . . . . 60

Node to node ping test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Editing continuous ping test settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6 Locating a node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

About locating nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Accessing node location menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Registered node locator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Find all IDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Finding an ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Unregistered node locator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7 Reading meter data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Accessing Read Meter Data menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Reading previous period data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Reading current period data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8 Gas/Water Comms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

About gas and water communication. . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Accessing Gas/Water Comms menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Reading gas/water comm info from an electric device. . . . . . . . . . . . . 80

Reading gas/water comm info from a gas/water device. . . . . . . . . . . 81

9 Disconnecting and reconnecting meters. . . . . . . . . . . . . . . . . . . . . . . . . 82

About disconnecting and reconnecting electricity meters. . . . . . . . . . . 82

REX meter service control switch status. . . . . . . . . . . . . . . . . . . . 82

REX2 meter service control switch status. . . . . . . . . . . . . . . . . . . 82

A3 ALPHA meter with internal polyphase service control . . . . . 83

About disconnecting and reconnecting gas meters . . . . . . . . . . . . . . . 83

Accessing Connect/Disconnect menu. . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Page 4

EA_Inspector User Guide

Contents

4

Reading status of the service control switch . . . . . . . . . . . . . . . . . . . . . . 85

Checking load side voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Connecting an electricity meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Disconnecting an electricity meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Reading the state of the secondary relay . . . . . . . . . . . . . . . . . . . . . . . . 91

Connecting a secondary relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Disconnecting a secondary relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Controlling a gas valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Gas valve privileges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Reading a gas valve’s modules . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Battery alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Hardware failure detected . . . . . . . . . . . . . . . . . . . . . . . . 99

Opening a gas valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Closing a gas valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Controlling a meter’s RF transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Reading the current state of an RF transmitter . . . . . . . . . . . . . 106

Disabling an RF transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Enabling an RF transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10 Upgrading firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

About upgrading firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

REX2 meter with EA_NIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

A3 ALPHA meter with EA_NIC. . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Upgrading the EA_NIC firmware in the handheld . . . . . . . . . . . . . . . . .110

Upgrading a gas or water module’s firmware. . . . . . . . . . . . . . . . . . . .112

Upgrading a gas meter’s RMD firmware . . . . . . . . . . . . . . . . . .116

Upgrading a meter’s EA_NIC radio firmware . . . . . . . . . . . . . . . . . . . . .119

Upgrading a REX2 meter’s firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Upgrading an A3 ALPHA meter’s firmware . . . . . . . . . . . . . . . . . . . . . 125

Upgrading 900 MHz HAN devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Upgrading a 900 MHz HAN device’s radio . . . . . . . . . . . . . . . 128

Upgrading a 900 MHz HAN device firmware. . . . . . . . . . . . . . .131

11 Configuring meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

About HAN broadcasts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Accessing HAN Broadcast menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Configuring HAN Broadcast settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Checking the status of the meter’s HAN broadcast . . . . . . . . . . . . . . . 139

Turning off the meter’s broadcast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Turning on the meter’s broadcast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Setting meter associations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Configuring water module leak settings . . . . . . . . . . . . . . . . . . . . . . . . 146

Performing a demand reset on an electricity meter. . . . . . . . . . . . . . . 148

12 Managing home area network devices . . . . . . . . . . . . . . . . . . . . . . . . 150

Accessing Home Area Network menu . . . . . . . . . . . . . . . . . . . . . . . . . .151

ZigBee HAN device commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

View devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Viewing HAN NIC information . . . . . . . . . . . . . . . . . . . . . . . . . . 154

900 MHz HAN devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Page 5

EA_Inspector User Guide

Contents

5

Commissioning a 900 MHz device . . . . . . . . . . . . . . . . . . . . . . 155

Reading a 900 MHz HAN device . . . . . . . . . . . . . . . . . . 156

Pinging a 900 MHz HAN device . . . . . . . . . . . . . . . . . . 157

Method 1 - from the Commission Device screen157

Method 2 - from the Ping Device screen158

Decommissioning a 900 MHz device . . . . . . . . . . . . . . . . . . . . 159

Reading a decommissioned device . . . . . . . . . . . . . . . .161

Configuring a 900 MHz device. . . . . . . . . . . . . . . . . . . . . . . . . . .161

Accessing the Config 900 MHz HAN menu . . . . . . . . . .161

Configuring general parameters . . . . . . . . . . . . . . . . . . 162

Configuring pricing parameters . . . . . . . . . . . . . . . . . . 164

Clearing pricing parameters . . . . . . . . . . . . . . . . . . . . . 166

Configuring messaging parameters . . . . . . . . . . . . . . . 167

13 Configuring the handheld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

About configuring the handheld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Accessing handheld configuration menu . . . . . . . . . . . . . . . . . . . . . . . 170

Configuring handheld settings and utility IDs . . . . . . . . . . . . . . . . . . . . .171

Configuring EA Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Viewing About EA_Inspector information . . . . . . . . . . . . . . . . . . . . . . . 176

A Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

General troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Trouble connecting to EA_Inspector Manager . . . . . . . . . . . . . . . . . . . 177

Communication mode errors and warning messages . . . . . . . . . . . . 177

Verifying encrypted communications. . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Elster contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Page 6

EA_Inspector User Guide 6

FCC and Industry Canada compliance

Compliance statement (Part 15.19)

Radix FW950 (equipped with the EnergyAxis network interface card) and Radix

FW950 (equipped with the EnergyAxis network interface card and an external

antenna) comply with Part 15 (Class B), Part 90 of the FCC rules and with RSS-210

of Industry Canada.

The FCC ID's are G8JHHI03 and G8JHHI04. The Industry Canada is 4557C-HHI03.

General information

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference

that may cause undesired operation.

Industry Canada statement

This device complies with Industry Canada license-exempt RSS-210 standard(s).

Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference

that may cause undesired operation.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux

conditions suivantes: (1) l'appareil ne doit pas produire de brouillage, et (2)

l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même

si le brouillage est susceptible d'en compromettre le fonctionnement.

Industry Canada antenna statement

Radix FW950 (equipped with the EnergyAxis network interface card and an

external antenna) incorporates an external antenna onto the handheld unit. For

the handheld units please note the following statements as they relate to the

external antenna on the handheld unit.

Under Industry Canada regulations, this radio transmitter may only operate using

an antenna of a type and maximum (or lesser) gain approved for the transmitter

by Industry Canada.

To reduce potential radio interference to other users, the antenna type and its

gain should be so chosen that the equivalent isotropically radiated power (e.i.r.p.)

is not more than that necessary for successful communication.

Conformément à la réglementation d'Industrie Canada, le présent émetteur

radio peut fonctionner avec une antenne d'un type et d'un gain maximal (ou

inférieur) approuvé pour l'émetteur par Industrie Canada.

Dans le but de réduire les risques de brouillage radioélectrique à l'intention des

autres utilisateurs, il faut choisir le type d'antenne et son gain de sorte que la

puissance isotrope rayonnée équivalente (p.i.r.e.) ne dépasse pas l'intensité

nécessaire à l'établissement d'une communication satisfaisante.

Page 7

EA_Inspector User Guide

7

This radio transmitter IC:4557C-HHI03 has been approved by Industry Canada to

operate with the antenna types listed below with the maximum permissible gain

and required antenna impedance for each antenna type indicated. Antenna

types not included in this list, having a gain greater than the maximum gain

indicated for that type, are strictly prohibited for use with this device.

Le présent émetteur radio IC:4557C-HHI03 a été approuvé par Industrie Canada

pour fonctionner avec les types d'antenne énumérés ci-dessous et ayant un gain

admissible maximal et l'impédance requise pour chaque type d'antenne. Les

types d'antenne non inclus dans cette liste, ou dont le gain est supérieur au gain

maximal indiqué, sont strictement interdits pour l'exploitation de l'émetteur.

• Antenna Part Number: 1B11922

Warning (Part 15.21)

Changes or modifications to the equipment not expressly approved by Elster

could void the user's authority to operate this equipment.

User information

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced radio/ TV technician for help.

RF exposure

A separation distance of at least 8 inches (20 cm) is to be maintained between

the antenna and the human body and must not be co-located or operated in

conjunction with any other transmitter or antenna.

Disclaimer of warranties and limitation of liability

There are no understandings, agreements, representations, or warranties either

expressed or implied, including warranties of merchantability or fitness for a

particular purpose, other than those specifically set out by any existing contract

between the parties. Any such contract states the entire obligation of the seller.

The contents of this technical manual shall not become part of or modify any prior

or existing agreement, commitment, or relationship.

The information, recommendations, descriptions, and safety notices in this

technical manual are based on Elster experience and judgment with respect to

the operation and maintenance of the described product. This information should

not be considered as all–inclusive or covering all contingencies. If further

information is required, Elster should be consulted.

Page 8

EA_Inspector User Guide 8

No warranties, either expressed or implied, including warranties of fitness for a

particular purpose or merchantability, or warranties arising from the course of

dealing or usage of trade, are made regarding the information,

recommendations, descriptions, warnings, and cautions contained herein.

In no event will Elster be held responsible to the user in contract, in tort (including

negligence), strict liability, or otherwise for any special, indirect, incidental, or

consequential damage or loss whatsoever, including but not limited to: damage

or loss of use of equipment, cost of capital, loss of profits or revenues, or claims

against the user by its customers from the use of the information,

recommendations, descriptions, and safety notices contained herein.

Safety information Installation, operation, and maintenance of this product can present potentially

hazardous conditions (for example, high voltages) if safety procedures are not

followed. To ensure that this product is used safely, it is important that you:

Review, understand, and observe all safety notices and recommendations within

this manual.

Do not remove or copy individual pages from this manual, as this manual is

intended for use in its entirety. If you were to remove or copy individual pages,

cross references and safety notices may be overlooked, possibly resulting in

damage to the equipment, personal injury, or even death.

Inform personnel involved in the installation, operation, and maintenance of the

product about the safety notices and recommendations contained in this manual.

Within this manual, safety notices appear preceding the text or step to which they

apply. Safety notices are divided into the following four classifications:

Notice is used to alert personnel to installation, operation, or maintenance

information that is important but not hazard related.

Caution is used to alert personnel to the presence of a hazard that will or can

cause minor personal injury, equipment damage, or property damage if the

notice is ignored.

Warning is used to alert personnel to the presence of a hazard that can cause

severe personal injury, death, equipment damage, or property damage if notice

is ignored.

Page 9

EA_Inspector User Guide

New in release 3.6 EA_Inspector Manager and EA_Inspector introduce the following new features:

9

Danger is used to alert personnel to the presence of a hazard that will cause

severe personal injury, death, equipment damage, or property damage if the

notice is ignored.

• support for 900 MHz HAN devices

• support for enabling/disabling an RF transmitter

• support for controlling the AC-250 RMD (Remote Meter Disconnect) for gas

meters

Note: The Radix FW950 handheld (Style No. 1C12455G01) should be

equipped with an external antenna to perform actions on the

AC-250 RMD. The external antenna allows the Radix handheld

to issue commands to gas valves up to 900 feet from the

handheld. Contact your Elster respresentative for more

information.

Note: To use the new features in EA_Inpsector 3.6, you must use

EA_Inspector Manager 3.6. While EA_Inspector will function

with prior releases of EA_Inspector Manager, to fully use the

software requires EA_Inspector Manager 3.6.

Changes in release 3.6 • To prevent over-writing valid encryption seeds, EA_Inspector Manager

checks for new seed data received from EA_MS.

Earlier releases would allow null key sets to overwrite valid keys in the

EA_Inspector.

Caution: Elster strongly recommends that encryption seeds only be

downloaded after seed changes are made.

Page 10

1 INTRODUCTION

This document provides comprehensive operating instructions for the use of the

EA_Inspector software.

About handheld devices Handheld devices are lightweight and easy to use handheld computers for

troubleshooting EnergyAxis meter communications using touch screen

technology.

About This manual This guide provides instructions for setup, operation and troubleshooting of the

handheld device. It is structured for use as an adjunct to Elster system training, as

well as a standalone instruction guide and reference. The screen shots shown in

various illustrations may vary slightly from your handheld's display.

Audience

This document is designed for utility industry meter readers and supervisory staff.

In order to establish appropriate levels of detail for the material, this document

assumes the following:

• The user is experienced in reading meters of the type currently compatible

with Elster meters and possesses all the skills necessary to conduct meter

reading by conventional means.

• The user has little or no prior expertise with automated metering

infrastructure (AMI) technology.

• The user is competent in the basic use of computers and software.

New users

If you are new to Elster AMI products, or are new to AMI products in general,

please take some time to go through all the sections of the user guide.

Existing users

If you are already familiar with Elster AMI products, you will still find it helpful to go

through the Introduction and detail sections to understand how the features of

the handheld device work together and what information is needed to perform

each feature.

Page 11

EA_Inspector User Guide

Introduction

11

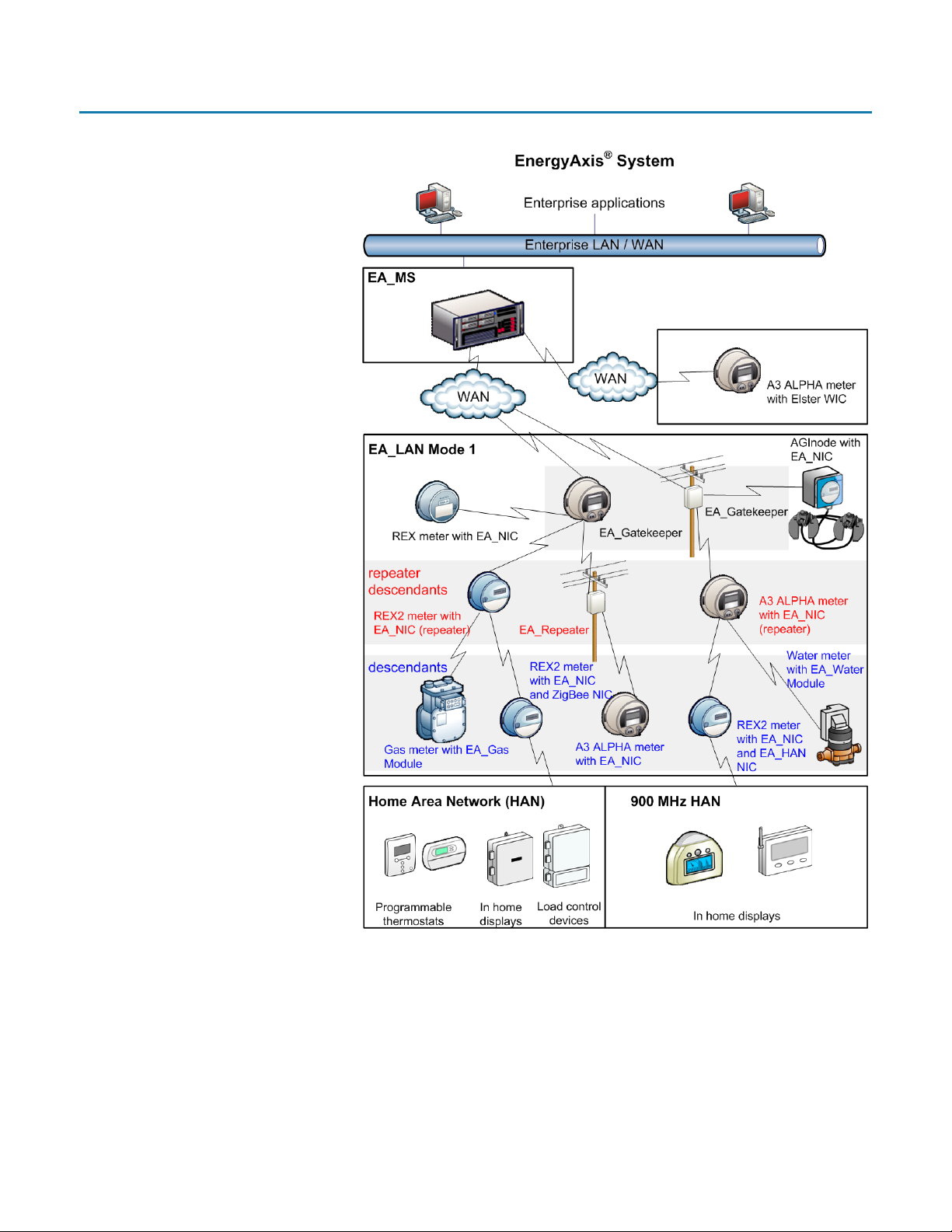

What is the EnergyAxis

System?

The EnergyAxis System (Figure 1-1) is designed for residential and commercial and

industrial (C&I) metering automation of electricity, gas and water. It is composed

of up to three parts:

1. EnergyAxis Management System (EA_MS) that reads gatekeepers to gather

meter data, analyzes RF LAN performance, and exports an XML file of all

read data for importing into various enterprise systems such as billing, work

order management, outage management, etc.

2. One or more 900 MHz radio frequency (RF) networks composed of an

EA_Gatekeeper and up to 1024 or 2048 of the following meters:

• REX, REX2, and gREX meters equipped with an EA_NIC

• optional service control switch for remote reconnection/disconnection

• optional ZigBee communications option board for home automation

(REX2 meters only)

• A3 ALPHA meters with the EA_NIC (EnergyAxis network interface card)

• water meters equipped with EA_Water Module (900 MHz RF radio)

• gas meters equipped with EA_Gas Module (900 MHz RF radio)

3. Optional – one or more home automation networks (HAN) composed of a

REX2 meter with ZigBee comm option and one or more ZigBee-enabled

home area devices (HAD) - for example, programmable thermostat, in

home display, or load control device.

Page 12

EA_Inspector User Guide

Introduction

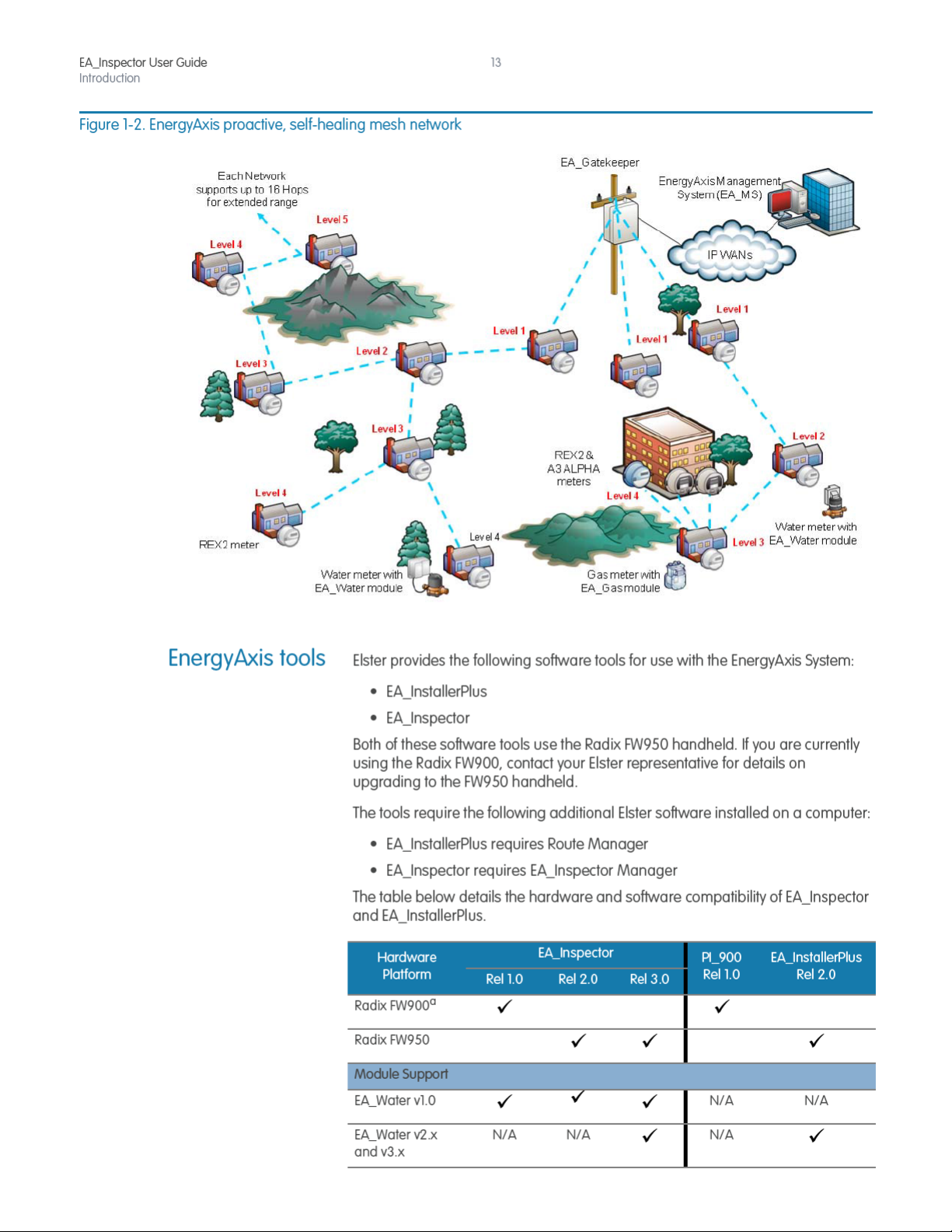

Figure 1-1. EnergyAxis System

12

Each gatekeeper gathers and stores meter data from its registered node meters

and associated water and gas modules and manages the EA_LAN. These

gatekeepers upload the data to the EnergyAxis Management System (EA_MS) via

a public or private WAN either on a scheduled or on-demand basis.

Each REX and REX2 meter, EA_Repeater and A3 ALPHA node can act as

repeaters that relay meter data from downstream, or descendent, meters up to

the gatekeeper. When a repeater’s RF transmission capability is blocked, the

gatekeeper determines that something is wrong and initiates a node scan. The

node scan re-builds the 900 MHz network bypassing the faulty node. In this

manner, the network is called proactive and self-healing.

Page 13

Page 14

Page 15

EA_Inspector User Guide

Introduction

Figure 1-4. EA_Inspector

15

EA_Inspector and EA_Inspector Manager

The EA_Inspector is a tool for use with EnergyAxis System. EnergyAxis devices are

equipped with RF modules that transmit meter data to gatekeepers through the

EA_LAN. The EA_LAN occasionally may need troubleshooting to locate issues and

EA_Inspector is the tool designed to locate these issues.

EA_Inspector also performs firmware upgrades for devices in the field.

EA_Inspector can also help locate unknown meters or determine the best

placement for an EA_Repeater.

Before going into the field, the user synchronizes the handheld with EA_Inspector

Manager. This loads and updates the user credentials (logon and permissions)

and any other necessary security features.

Note: A new EA_Inspector handheld must be synchronized with

EA_Inspector Manager prior to being used in the field to enable

user logon capability.

Once the functions have been performed in the field, resynchronize the handheld

using EA_Inspector Manager. EA_Inspector Manager is then used to export GPS

coordinates, TOU and demand data and AMRDEF files. Additionally, activity logs

(one encrypted and one unencrypted) are downloaded from the handheld.

Note: Encrypted logs are only accessible by the EA_Inspector

Manager security administrator.

Page 16

2 ABOUT THE HANDHELD

About the handheld The handheld is a Radix FW950 device that functions as the platform handheld

installation tool for Elster’s EA_Gas and EA_Water modules, as well as supporting

EA_Inspector.

The handheld is a rugged Radix handheld computer with the EnergyAxis network

interface (EA_NIC) card installed. This handheld allows field personnel to install

the EA_Gas and EA_Water modules onto gas meters. The handheld also

supports controlling the AC-250 gas meter with Remote Meter Disconnect (RMD).

The handheld also performs troubleshooting tasks for EnergyAxis meter RF

communications.

Figure 2-1. Radix FW950 handheld (Style No. 7S1501G002)

Radix specifications

• Windows CE 5.0

• .NET Framework 1.1 or 2.0

• Marvell PXA270, 520MHz processor

• 128 MB RAM 512 MB flash drive

• 3.5” (89mm) 240 x 320 TFT 65K Color industrial grade touch screen

• 48-key ergonomic keypad with separate numeric keys

• User replaceable lithium-ion battery pack, 3 hour charge, up to 8 hours use

• EnergyAxis network interface card (EA_NIC)

• Elster software

• RF Transmitter - 451 MHz (wake-up tone); 900 MHz

• RF Receiver - 900 MHz

Page 17

EA_Inspector User Guide

About the handheld

17

• FCC compliance: Part 90 and Part 15. The FCC ID is G8JHHI03.

• Operating temperature: -4 °F to +140 °F (-20 °C to + 60 °C)

• USB, Ethernet, serial, IPP, multiple communications ports

• IP-67 rated (1 meter submersion)

• Elster nose cone is IP-67 rated (1 meter submersion)

• MIL-STD-810F method - 1.5 meter drop onto concrete test

• Optional - the Radix handheld supports using an external antenna for use

with the AC 250 Remote Meter Disconnect (RMD) valve control module.

Figure 2-2. Radix FW950 with external antenna (Style No. 1C12455G01)

Page 18

EA_Inspector User Guide

About the handheld

18

Safe RF exposure using external antenna

The antenna used for the Radix transmitter must be installed to provide a

separation distance of at least 8 inches (20 cm) from all persons and must not be

co-located or operating in conjunction with any other antenna or transmitter.

EA_Inspector Manager EA_Inspector Manager synchronizes the handheld with a host computer.

Synchronizing the handheld copies files between the handheld and the host

computer.

Figure 2-3. Handheld-to-meter RF communication

Before EA_Inspector can be run, EA_Inspector Manager must load the following

files onto the handheld:

• user credentials (user names and passwords) file

• meter ID (marriage) file

• LAN seed file

3

• 900 MHz HAN parameter files

2

4

1

After the first synchronization, the EA_Inspector is ready to be used in the field.

1. Required to operate the handheld.

2. Only required if operating in meter ID mode; LAN ID mode works without marriage

files.

3. Not required to operate; only needs to update LAN seeds if changes were made.

4. Only needed if HAN operations are planned.

Page 19

EA_Inspector User Guide

About the handheld

19

EA_Inspector The EA_Inspector is a tool for the EnergyAxis System. EnergyAxis devices

(electricity, gas, and water meters and in-home devices are equipped with RF

modules that transmit meter data to EA_Gatekeepers through the EA_LAN. The

EA_LAN occasionally may need troubleshooting to locate issues and

EA_Inspector is the tool designed to locate these issues. EA_Inspector also

performs firmware upgrades for devices in the field. EA_Inspector can also help

locate unknown meters or determine the best placement for an EA_Repeater.

The software performs the following actions:

• ping test

• locate node

• read meter data

• gas/water comms

• disconnect and reconnect meters

• update firmware

• configure meters

• manage home area network devices

Note: The handheld may also be loaded with EA_Installer or

EA_InstallerPlus software. Both EA_InstallerPlus and

EA_Inspector may be installed on the same handheld; however,

only one application may be active at a time.

Transmission accuracy

The accuracy of transmitted data is insured in two ways:

• the meter only replies after detection of its unique ID (serial number or LAN

ID)

• the EA_NIC and module transmits an error-detection code with the meter

data that is used by the handheld to confirm that the data has been

received without errors.

Navigating the software

Simple menu commands allow access to the software functions. These

commands fall into the following categories:

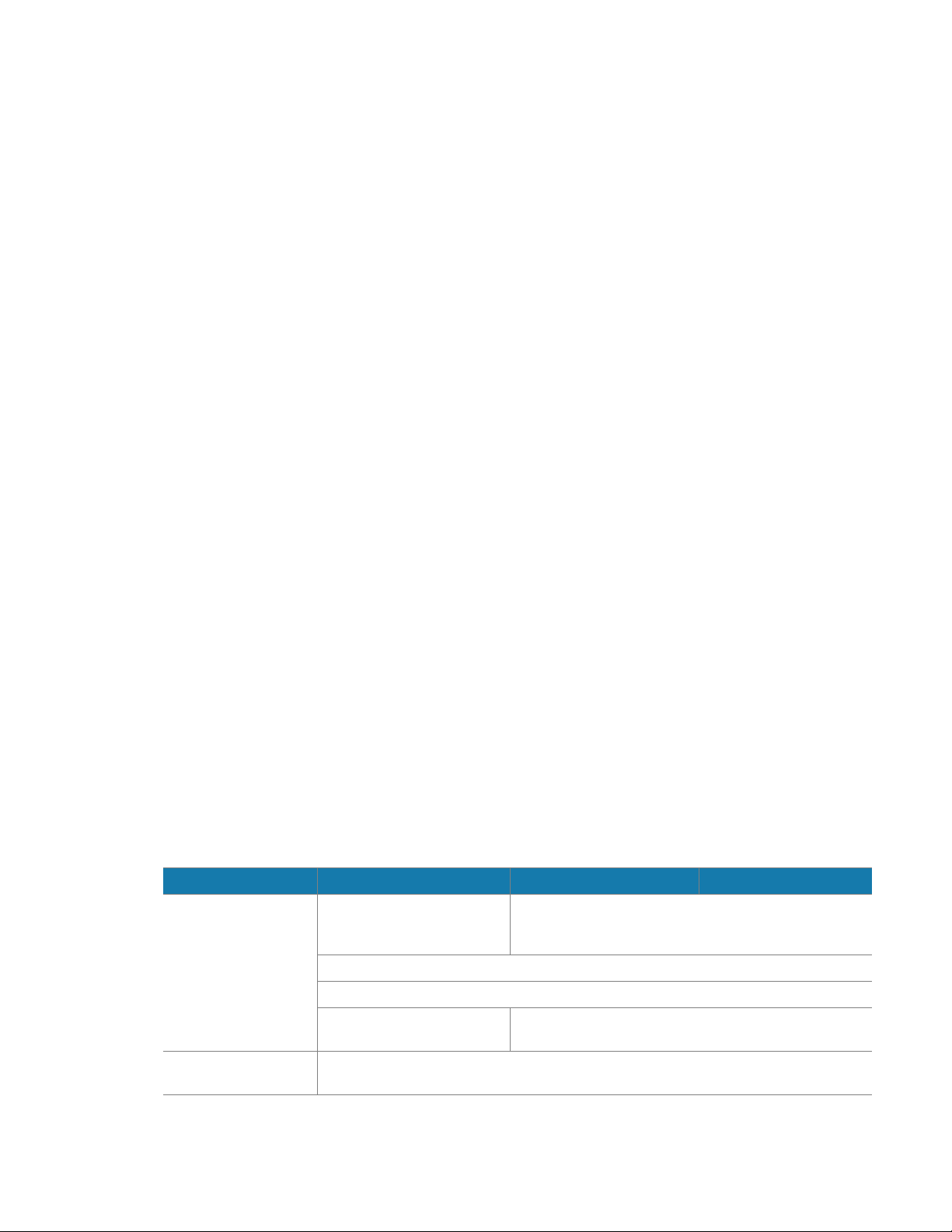

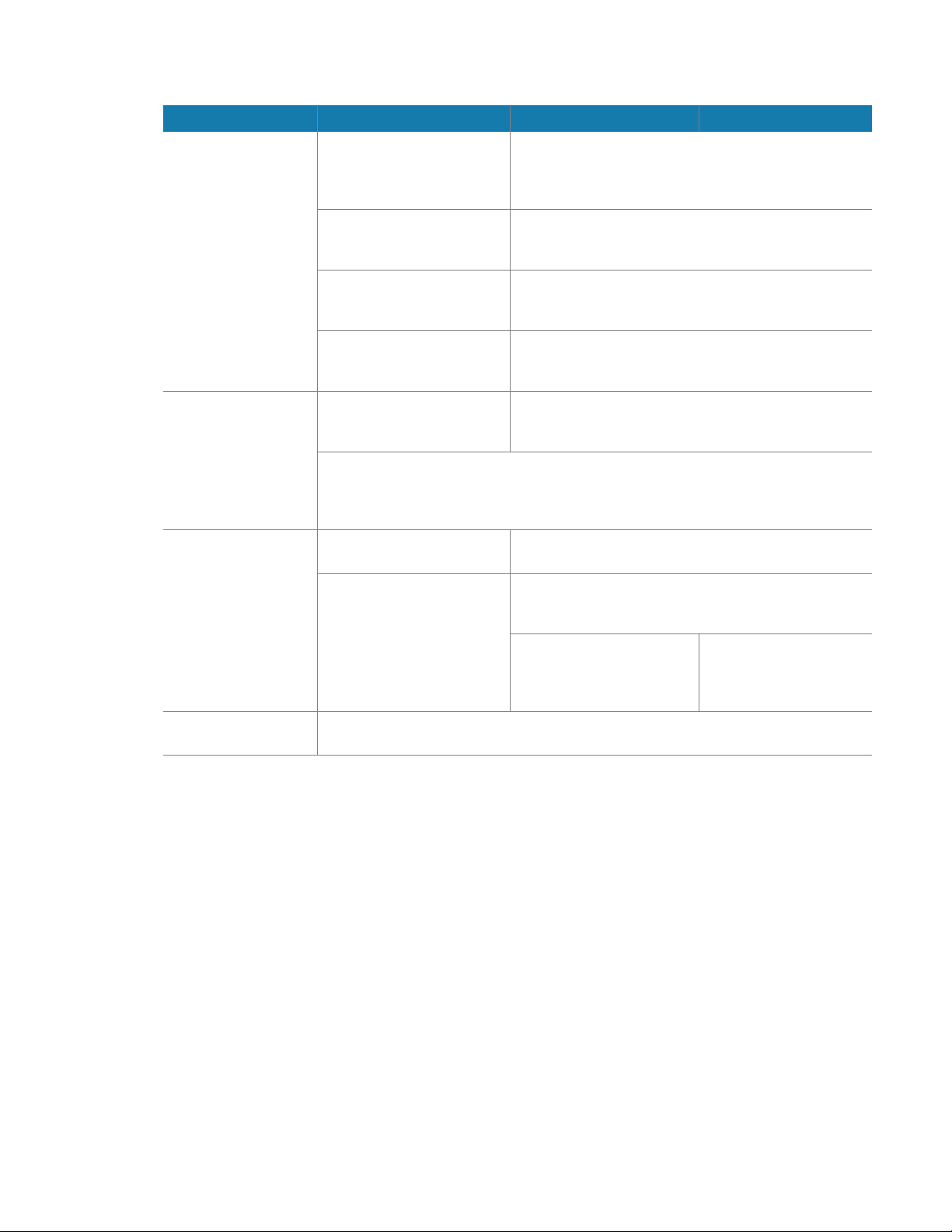

Main Menu Sub menu Sub menu

RF Troubleshooting Ping One shot ping test

Continuous ping test

Node to node ping test

Registered node locator

Unregistered node locator

Gas/Water Comms Read from Electric

Read from Gas/Water

Read Meter Data Read Current Data

Read Previous Data

Page 20

EA_Inspector User Guide

About the handheld

Main Menu Sub menu Sub menu

Connect/Disconnect Load Side Power Read Current State

Config Meter HAN Broadcast Read Current State

20

Load Side Voltage Check

Connect

Disconnect

Secondary Relay Read Current State

Open Relay

Close Relay

Gas Valve Control Read

Open

Close

RF Control Read Current State

Disable RF (Transmitter)

Enable RF (Transmitter)

Start - turn ON

End - turn OFF

Meter Association

EA_Water Module

Demand Reset

Firmware Upgrade

Home Area Network ZigBee HAN View Devices

HAN NIC Info

900 MHz HAN Commission

Ping

Decommission

Configure General

Pricing

Messaging

Firmware Upgrade

HH Config HH settings

EA Defaults

Database warning Do not attempt to modify or edit any of the database tables or files outside of the

Elster handheld / EA_Inspector Manager environment without prior authorization

by Elster technical support personnel. Unauthorized manipulation of these files

may void your software service agreements.

Page 21

Page 22

EA_Inspector User Guide

Operating the handheld

Using the stylus Use the stylus to tap a command button or to move focus to a data entry field. If

22

Arrow keys

These keys (<Up>, <Down>, <Left>, and <Right>) are used to navigate

directionally in the screen.

<Tab>

• Navigates between fields within the current screen (for example, messages

and search).

Entering responses (Yes/No)

You respond to questions using either of the following methods:

• Tap the button Yes or No with the stylus

• Press <Y> or <N> on the keyboard

• Moving to the desired button by using left/right arrow keys and pressing

<Enter> when the button is highlighted

you do not have a stylus, use the tip of your fingernail (not the soft pad of your

finger).

Turning the device on

and off

To turn the handheld on, press and hold any key until the handheld turns on.

The handheld turns off automatically after the handheld had been idle for more

than one minute off the charging cradle; the idle timeout is configurable.

Charging the device Place the handheld in its cradle to recharge the battery. The red Battery Status

Light on the top right corner of the handheld will flash on and off while the battery

is charging. Once that battery is fully charged, the status light will remain on.

Resetting the handheld

device

To reset the handheld:

1. Hold down the <R> + <X> + <> keys down simultaneously for several

seconds.

2. Release the keys when the screen goes blank.

3. Recalibrate the touch screen as directed.

Note: Resetting the handheld in the cradle will remove the

EA_Inspector application short-cut from the desktop.

Page 23

EA_Inspector User Guide

Operating the handheld

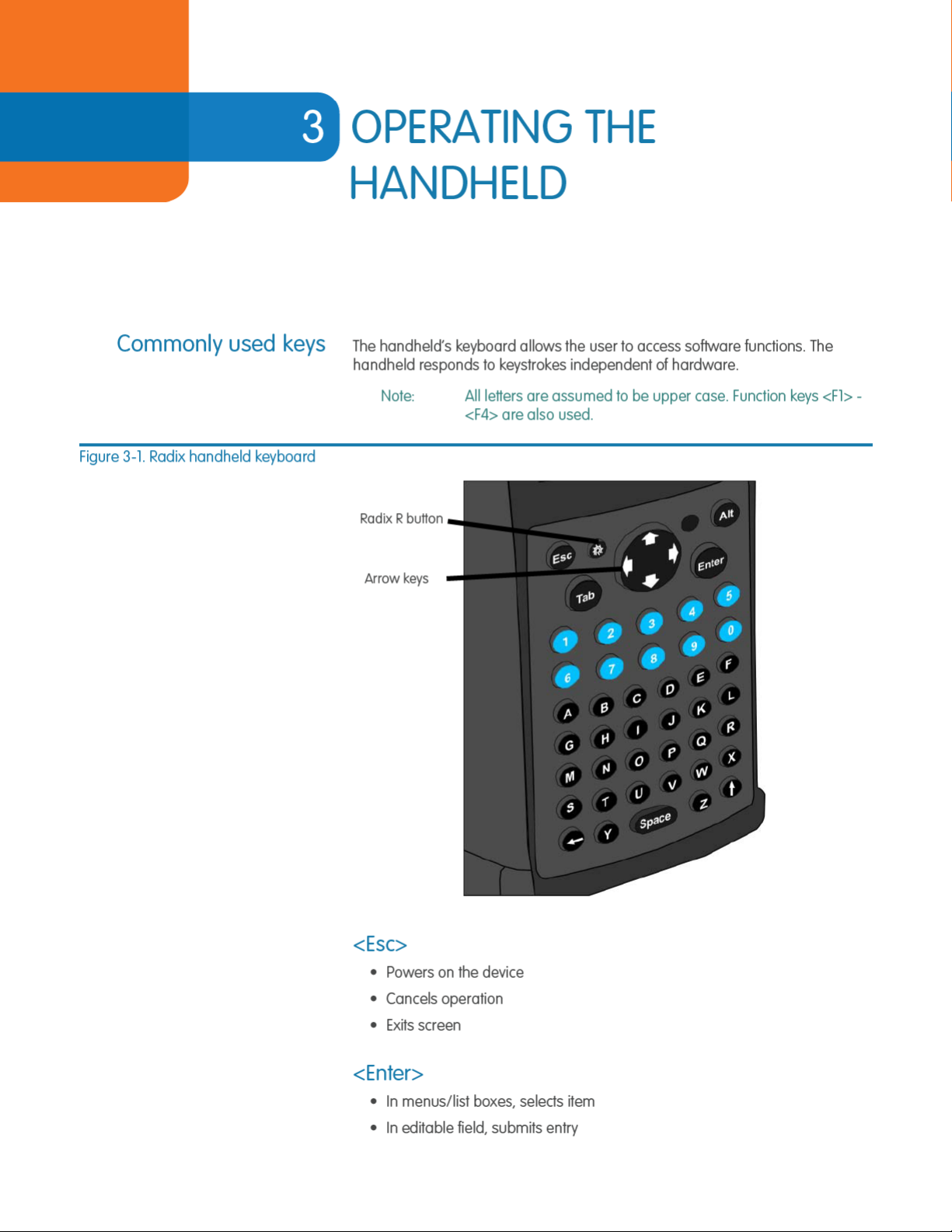

Opening EA_Inspector To access EA_Inspector:

1. From the handheld’s desktop, select the EA_Inspector icon and press

<Enter>.

Figure 3-2. Handheld desktop

23

Figure 3-3. EA_Inspector splash screen

The EA_Inspector splash screen displays.

The EA_NIC loads the EA_Inspector firmware.

Page 24

EA_Inspector User Guide

Operating the handheld

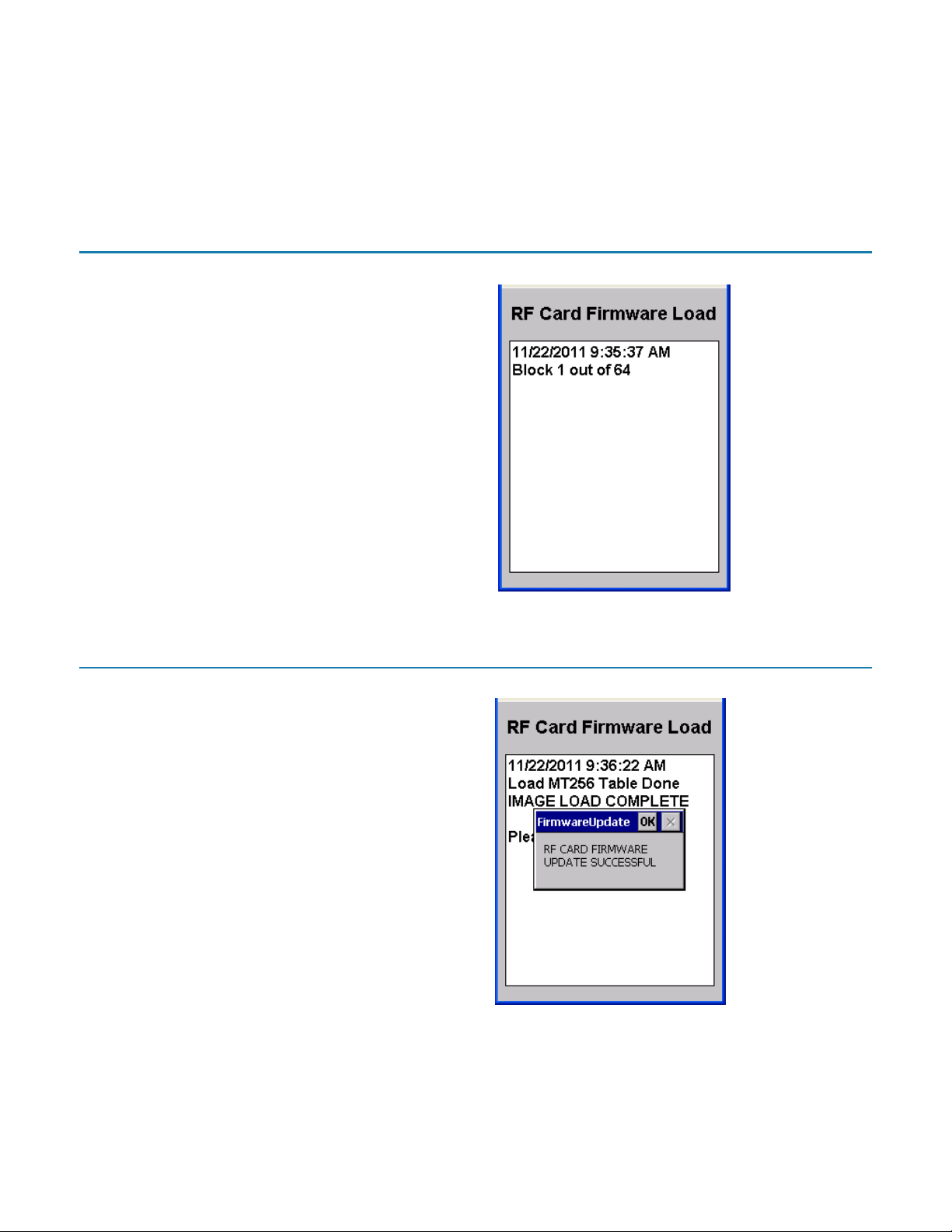

Figure 3-4. Loading firmware

24

Note: You will see the RF Firmware Load screen only if EA_Inspector

detects a firmware file with a different version in the handheld

than the existing EA_NIC firmware version. If the firmware file

version is higher than the current firmware version in EA_NIC,

EA_Inspector will upgrade the EA_NIC firmware. Otherwise,

EA_Inspector will ask the user "Are you sure you want to update

vm.m over vn.n?”

Figure 3-5. Firmware loaded

2. Click OK to acknowledge the firmware is loaded.

The login screen displays. See “Logging in to the handheld” on page 25 for

instructions on logging in to EA_Inspector.

Page 25

EA_Inspector User Guide

Operating the handheld

25

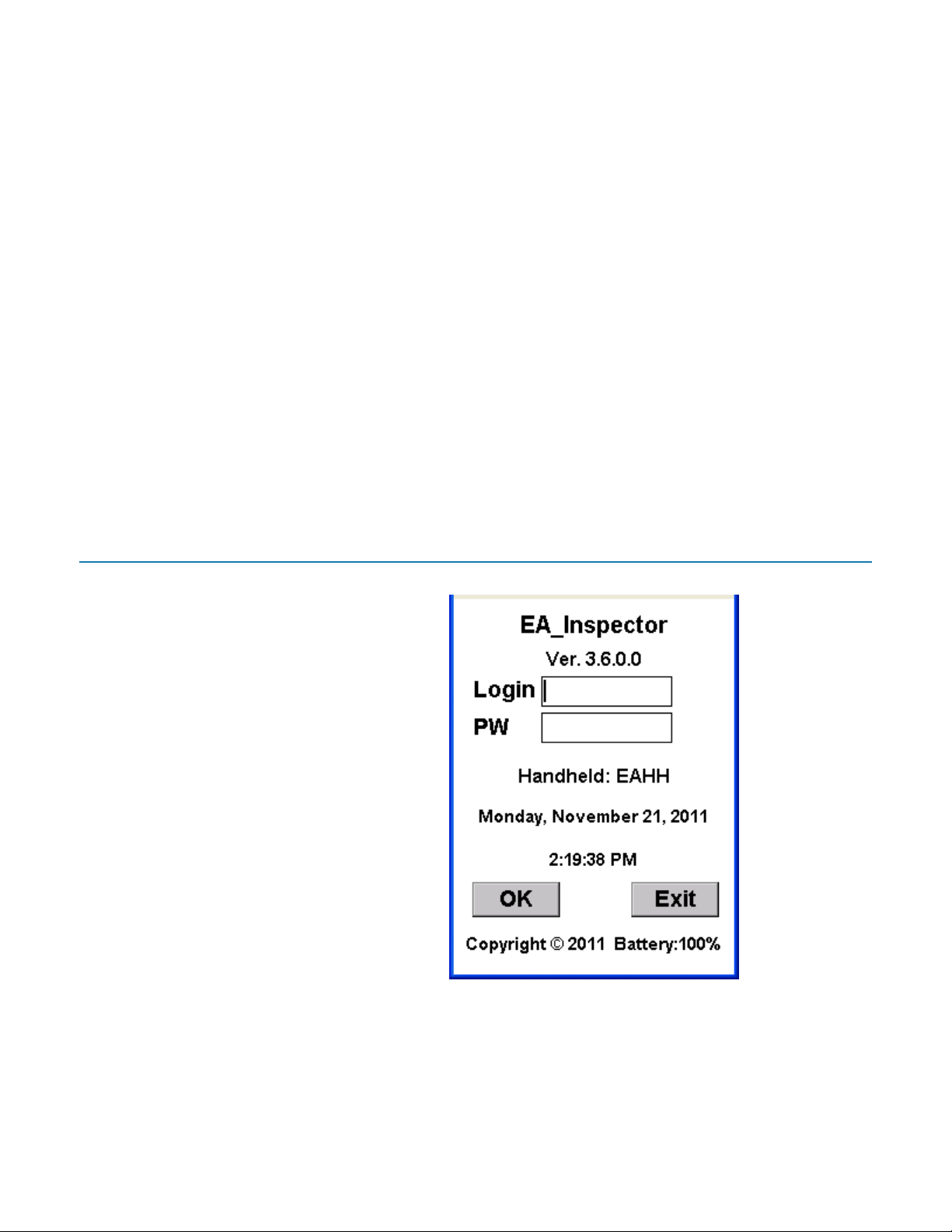

Logging in to the

handheld

Before you can operate the EA_Inspector on the handheld, you must first

synchronize the handheld with EA_Inspector Manager. This ensures that users’

credentials and other needed files are downloaded to the handheld.

See the EA_Inspector and EA_Inspector Manager Installation and Administration

Guide for details on synchronizing the handheld with EA_Inspector Manager.

Note: A new EA_Inspector handheld must be synchronized with

EA_Inspector Manager prior to being used in the field to ensure

user logon capability. Without an initial synchronization, a user

cannot log onto the EA_Inspector application on the handheld.

Note: If the expiration date is passed, you cannot log in to

EA_Inspector. You must have the Security Administrator

synchronize the handheld with EA_Inspector Manager to reset

the HH expiration date.

Note: The Login ID and password are not case sensitive. So you do

not need to be concerned about typing upper and lower case

letters.

To login to EA_Inspector:

1. Enter your Login ID.

Note: A Security Admin cannot log in to EA_Inspector. The Security

Admin privilege applies to EA_Inspector Manager only.

Figure 3-6. Login screen

2. Enter your Password.

3. Click OK.

EA_Inspector displays the Main Menu.

— OR —

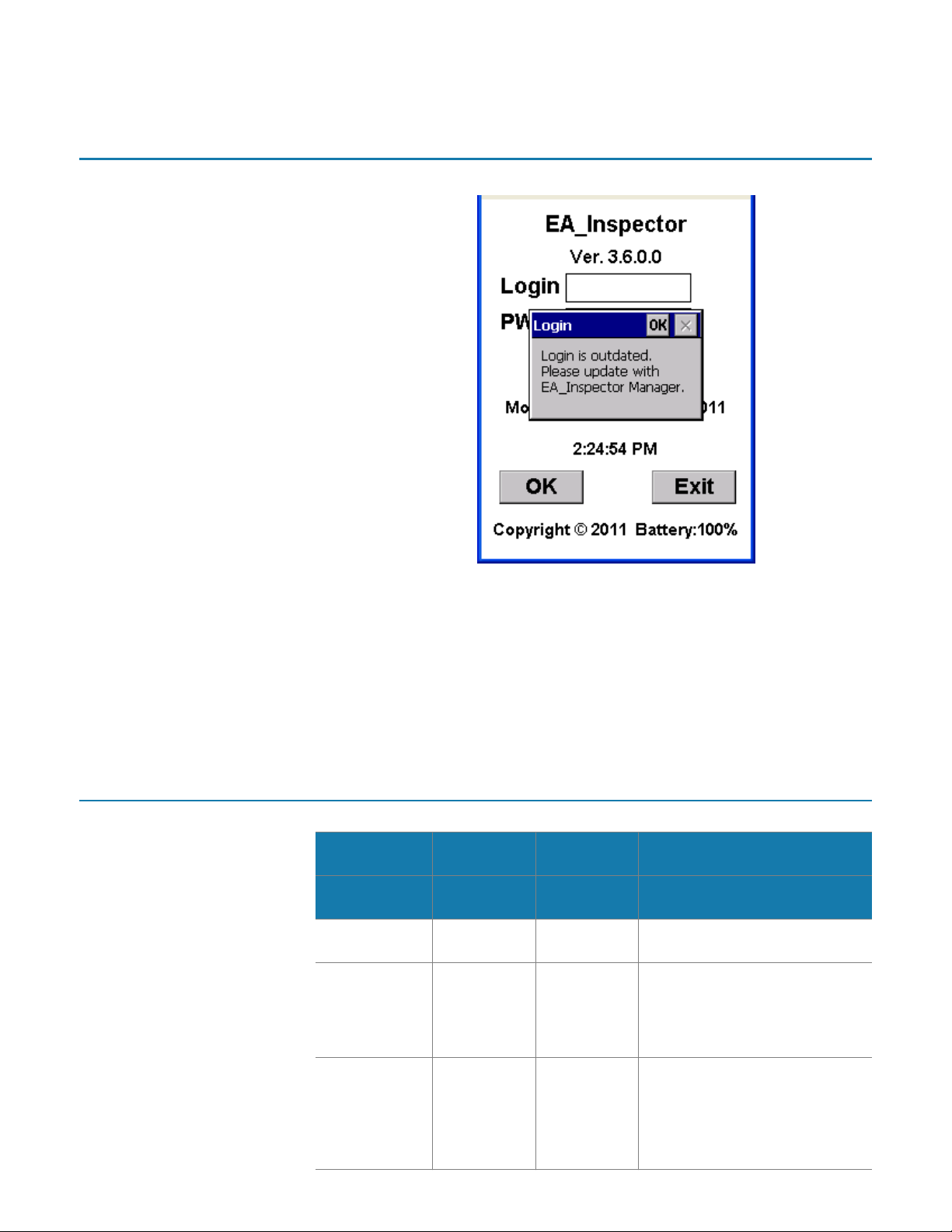

If the expiration date has passed or a new handheld was not synchronized,

a note displays. Your system administrator will need to synchronize the

Page 26

EA_Inspector User Guide

Operating the handheld

Figure 3-7. Handheld expiration

26

handheld with EA_Inspector Manager to load user logon information and

set the handheld’s expiration date.

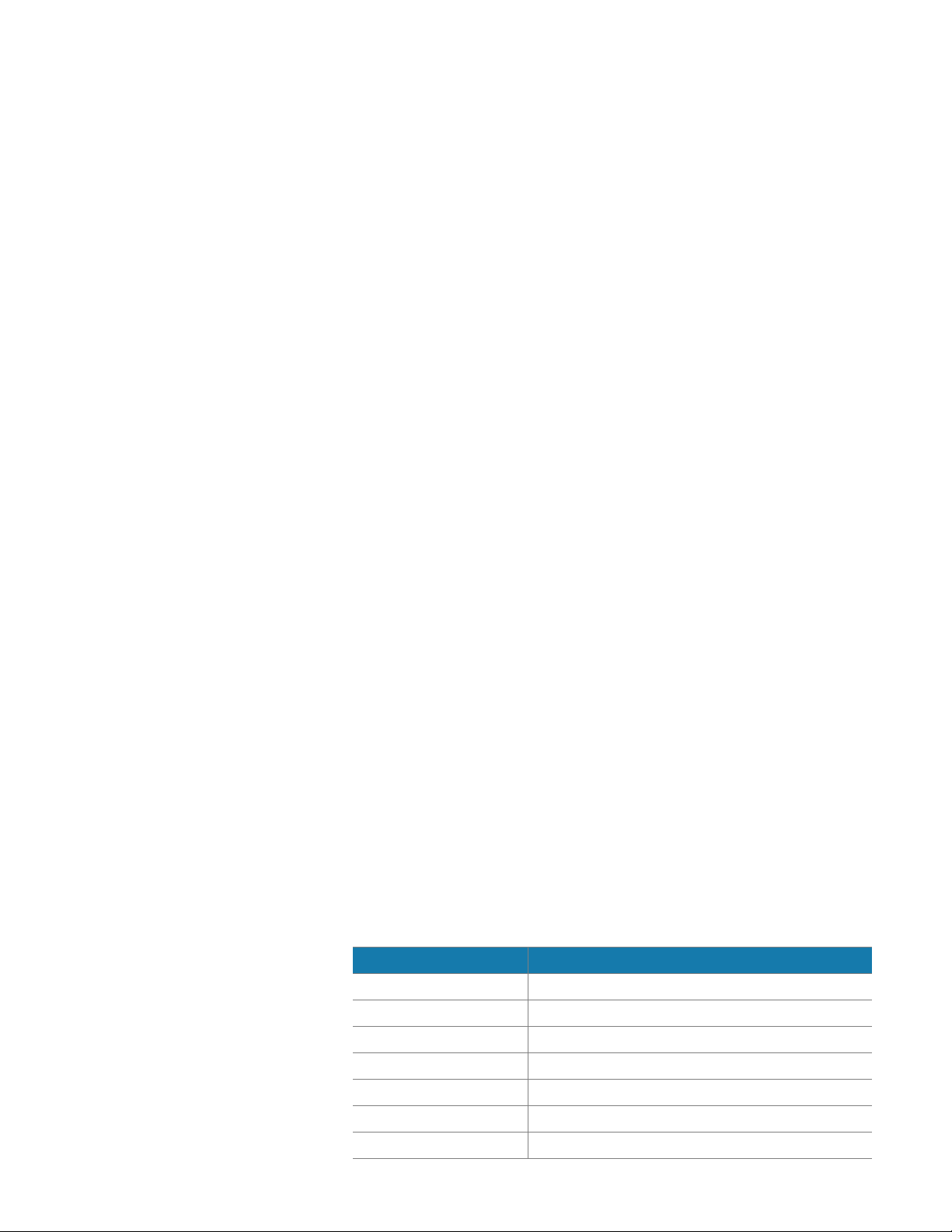

Table 3-1. Permissions and privileges

— OR —

To properly use EA_Inspector, the handheld must be synchronized with

EA_Inspector Manager.

Depending on the user’s permissions and privileges (see EA_Inspector

Installation and Administration Guide) the handheld may respond in

unexpected ways.

If the handheld has not been synchronized with EA_Inspector Manager, the

handheld displays a message “No meter SN/LAN ID file exists. Please

update with EA_Inspector Manager.”

EA_Inspector

Manager

Synchronized

Handheld files

Yes Yes Yes • Uses meter LAN ID to identify

Yes No No • Displays a message “No meter SN/

a

User ID Handheld EA_Inspector software

Allow LAN ID

privilege

UseLANID

setting enabled

Behavior

devices.

LAN ID file exists. Please update

with EA_Inspector Manager.”

• Uses meter Serial Number (SN) to

identify devices.

Yes Yes No • Displays message “No SN/LAN ID

file found: Use LAN ID mode

enabled.”

• Automatically enables UseLANID.

• Uses meter LAN ID to identify

devices.

Page 27

EA_Inspector User Guide

Operating the handheld

a. Refer to the EA_Inspector and EA_Inspector Manager Installation and Administration Guide for

details on synchronizing the handheld using EA_Inspector Manager.

Figure 3-8. EA_MS meter and Meter ID file not on handheld

27

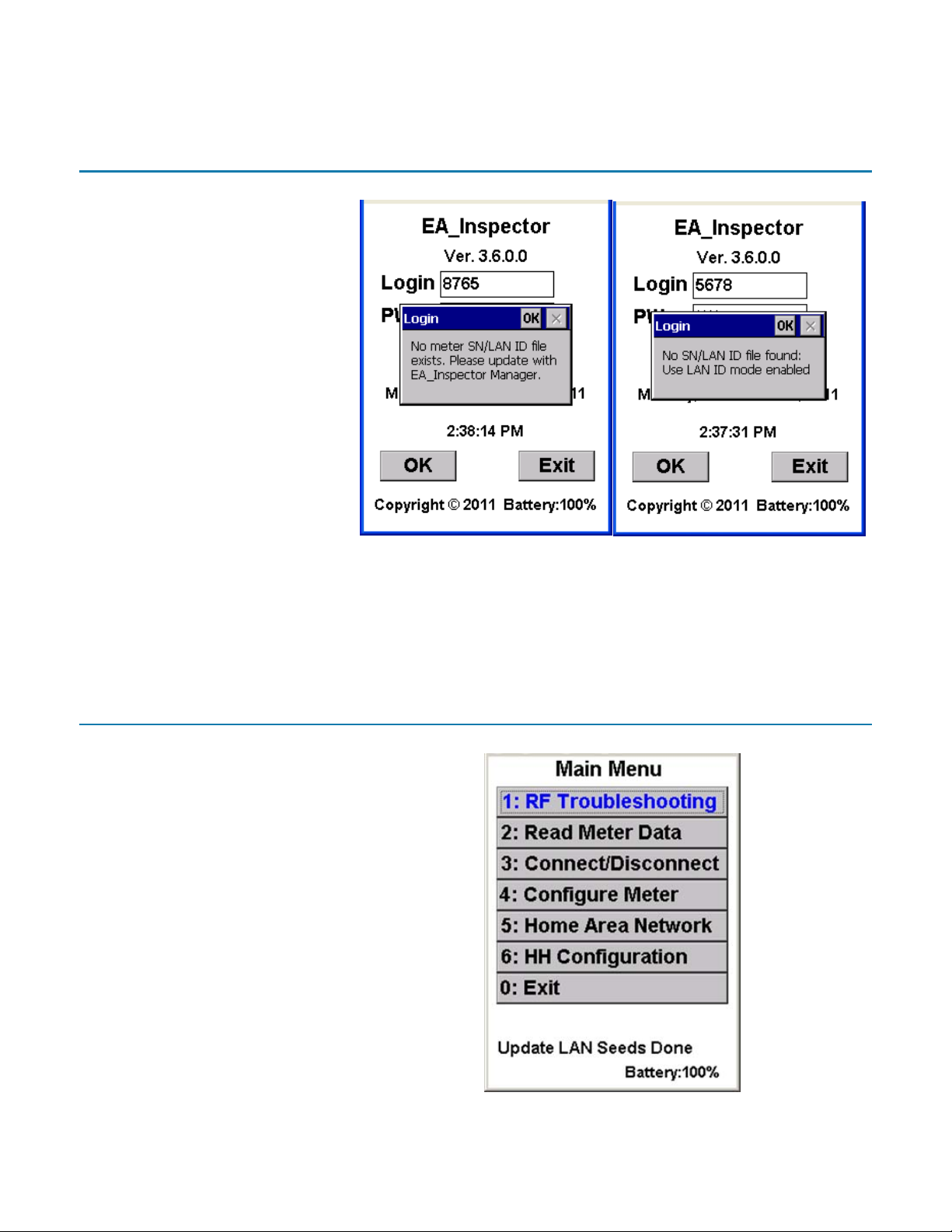

Figure 3-9. EA_Inspector Main Menu

No SN/LAN ID file but without

Allow LAN ID privilege

Logon disabled

No SN/LAN ID file but with

Allow LAN ID privilege

Logon enabled

Page 28

EA_Inspector User Guide

Operating the handheld

28

Holding the handheld for

meter reading

Figure 3-10. Handheld-to-meter RF communication

When using a handheld device to read a meter, hold the handheld device

upright.

Note: The stronger RF signals radiate out of the extended antenna

from the front and back of the cover.

Page 29

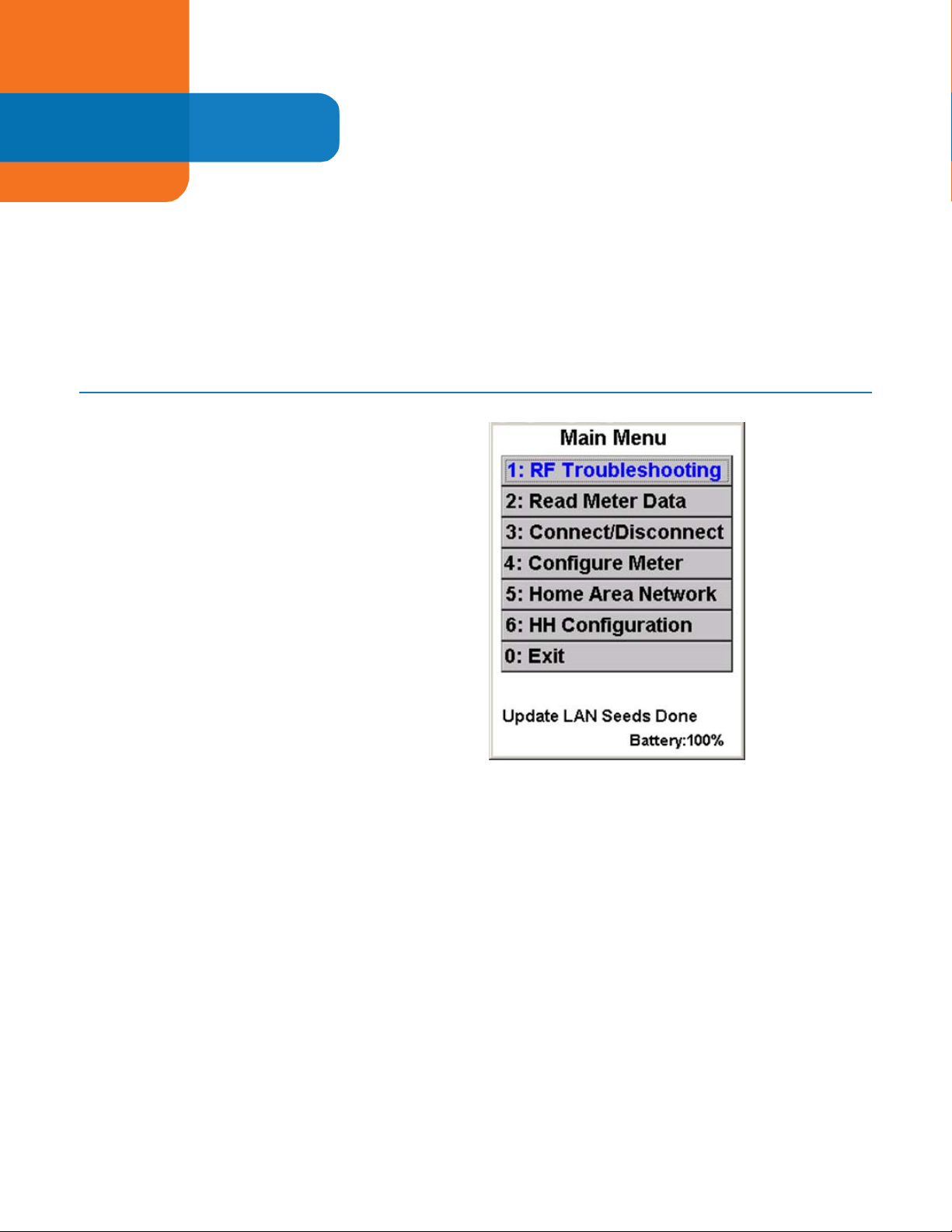

Figure 4-1. EA_Inspector Main Menu

4 ABOUT EA_INSPECTOR

SOFTWARE

After successfully logging into the handheld device, you will see the main menu

screen.

The main menu screen allows the selection of the following modes:

1. RF Troubleshooting

• Ping

• Locate node (registered and unregistered)

• Gas/Water Comms

2. Read Meter Data

• Read Current Data

• Read Previous Data

3. Connect/Disconnect

• Load Side Power:

• Read current state

• Load side voltage check

• Connect

• Disconnect

• Gas Valve Control

• Read

Page 30

EA_Inspector User Guide

About EA_Inspector software

30

• Open

• Close

• RF Control

• Read Current State

• Disable RF (Transmitter)

• Enable RF (Transmitter)

• Secondary Relay:

• Read Current State

• Open Relay

• Close Relay

4. Configure Meter

• EA HAN Broadcast

• Meter Associations

• EA_Water Module

• Demand Reset

• Firmware Upgrade

5. Home Area Network

• ZigBee HAN

• Ping

• Devices

• Channels

• HAN NIC Info

• 900 MHz HAN

• Commission

• Ping

• Configure

• Decommission

6. HH Configuration

• HH Settings

• EA Defaults

Navigating the software Instead of using the stylus to navigate the software, you can press the number

preceding the command. For example, from the main menu screen you can

press the keys to access the commands:

Key Command

<1> RF Troubleshooting

<2> Read Meter Data

<3> Connect/Disconnect

<4> Configure Meter

<5> Home Area Network

<6> HH Configuration

<0> Exit

Page 31

EA_Inspector User Guide

About EA_Inspector software

User privileges Depending on the privileges set by the system administrator when adding a user

31

You can also use the arrow keys to navigate up and down the list of commands

and then press <Enter> to execute the command.

Additionally, the first letter of each button label is an accelerator key for that

function. For example, <S> for Save, <P> for Ping, <C> for Cancel, etc. <ESC> can

be used for Cancel or for exiting any menu.

in EA_Inspector Manager, the user may use the LAN ID or the Serial Number to

identify a device. Refer to the EA_Inspector and EA_Inspector Manager

Installation and Administration Guide for details on user privileges.

If the user has the Allow LAN ID privilege, the user may use the device’s LAN ID on

data entry screens. If the user does not have the Allow LAN ID privilege, the user

must enter the device’s Serial Number (S/N) on data entry screens.

Note: To use MAS 6.2 or earlier, you must have Allow LAN ID

privileges.

Note: If Allow LAN ID is disabled and the EA_MS 7.0 meter name and

LAN ID data have not been downloaded to the handheld, the

user will not be able to use EA_Inspector. See “Downloading

meter and LAN ID information” on page 33 for details.

In addition to the user having the proper privileges to Allow LAN ID, the handheld

itself must be enabled to Use LAN ID. See Table 3-1 on page 26 and “Configuring

handheld settings and utility IDs” on page 171 for details on configuring the

handheld to use LAN IDs.

Saving notes and GPS

data

To enter any action notes or collect GPS data:

1. Click Save on any screen.

The Notes screen displays allowing you to enter any notes regarding the

activity.

Page 32

EA_Inspector User Guide

About EA_Inspector software

Figure 4-2. Notes screen

32

Figure 4-3. GPS Details screen

2. Additionally, you can click GPS to collect the GPS coordinates for the

handhelds current location at the time of the communication.

The GPS Details screen displays.

The GPS Details screen indicates the status of the attempt to get GPS

coordinates.

A successful read displays a status of GPS Info Completed.

3. If the GPS read fails, press Retry or <R> to retry the operation.

4. Click OK to exit the screen and save the coordinate values.

Click Cancel to return to the previous screen without GPS values.

Page 33

EA_Inspector User Guide

About EA_Inspector software

Exiting EA_Inspector 1. While the Main Menu screen is open, press <Esc> or press Exit to exit the

Figure 4-4. Exiting EA_Inspector

33

software.

A dialog displays asking you to confirm you wish to exit.

2. Use <Tab>, <Left> or <Right> arrow keys to select the response.

— OR —

Touch Yes or press <Y> or press <Enter> when the button is highlighted to

accept the selection.

Touch No or press <N> or press <Enter> when the button is highlighted to

cancel.

Exiting from the login screen

To exit without logging in:

1. From the Login screen, press Exit.

A dialog displays asking you to confirm you wish to exit.

Page 34

EA_Inspector User Guide

About EA_Inspector software

Figure 4-5. Exiting EA_Inspector

34

2. Use <Tab>, <Left> or <Right> arrow keys to select the response.

— OR —

Touch Yes or press <Y> or press <Enter> when the button is highlighted to

accept the selection.

Touch No or press <N> or press <Enter> when the button is highlighted to

cancel.

Page 35

5 PERFORMING A PING TEST

About ping tests A ping test sends an RF command to an EnergyAxis RF module (EA_NIC) or meter

and retrieves the devices ID and serial number. A ping test sends ten packets,

receives ten packets in response and reports the average received signal

strength indication (RSSI) from the ten attempts. RSSI is displayed in decibel

milliWatts (dBm) except for Node to node ping test which uses the range of 0 to 7

where 0 indicates no signal and 1 indicates the best (or maximum) RSSI and 7

indicates the worst RSSI:

RSSI Strength (in dBm)

0 no signal

1 > -40 best

2

3

4

5

6

7

-40 and > -50

-50 and > -60

-60 and > -70

-70 and > -80

-80 and > -90

-90 worst

The continuous ping test performs multiple ping tests in sequence.

Page 36

EA_Inspector User Guide

Performing a ping test

36

Accessing ping test

menu

Figure 5-1. EA_Inspector Main Menu

To access the Ping Test menu:

1. From the Main Menu, select RF Troubleshooting.

Figure 5-2. RF Troubleshooting menu

The RF Troubleshooting menu displays.

The RF Troubleshooting menu displays.

2. From the RF Troubleshooting menu, select Ping.

Page 37

EA_Inspector User Guide

Performing a ping test

Figure 5-3. Ping Test menu

37

3. The Ping Test menu allows you to select from the following list of ping tests:

• One shot ping test

• Continuous ping test

• Node to node ping test

One shot ping test To perform a one shot ping:

1. From the Ping Test menu, select One Shot.

The One Shot Ping Test menu displays.

Note: Depending on the type of utility, you may see the One Shot Ping

Test menu for an electric, gas and water utility or the One Shot

Ping Test menu for an electric and gas utility. However, if the

handheld is set up for electric only, you will not see the One Shot

Ping Test menu. Instead you will see the Ping Test input screen.

Page 38

EA_Inspector User Guide

Performing a ping test

Figure 5-4. Ping menu for electric, gas and water utility

38

Figure 5-5. Ping menu for electric and gas utility

2. The One Shot Ping Test menu allows you to select from the following ping

tests:

1) One shot ping of electric meter

2) One shot ping of gas module or AC-250 RMD

3) One shot ping of a one-way water meter

4) One shot ping of two-way water meter

Page 39

EA_Inspector User Guide

Performing a ping test

Figure 5-6. Ping test input screen

39

One shot ping of electric meter

To perform a one shot ping of an electric meter (REX, REX2, EA_Repeater,

EA_Gatekeeper or A3 ALPHA node):

1. From the One Shot Ping Test menu, select Electric.

See “One shot ping of a EA_Gatekeeper” on page 42 for details on pinging a

gatekeeper.

EA_Inspector displays the ping test input screen.

Use LAN ID unchecked

Use LAN ID checked

2. Enter the ID of the electric meter to be pinged.

Note: To use the LAN ID to ping devices, you must have Allow LAN ID

privilege (see EA_Inspector and EA_Inspector Manager

Installation and Administration Guide for details) as well as Use

LAN ID enabled on the handheld (see “Configuring handheld

settings and utility IDs” on page 171 for details. To use the

meter’s serial number to ping devices, your system

administrator must download EA_MS meter ID (marriage data)

file from EA_MS and synchronize the file to the handheld.

3. Check if the device Is a GK (gatekeeper).

4. Click Ping.

The ping test occurs and the input screen displays the results as they are

received.

Page 40

EA_Inspector User Guide

Performing a ping test

Figure 5-7. Successful ping test results - REX2 meter

40

Serial No. not in database

Note: If the entered ID is not in the downloaded EA_Inspector file, the

display lists the ID and a message that the specified ID is

unknown.

The ping test results displays the following information:

Item Description

GK (Gatekeeper) Indicates the pinged meter’s registered gatekeeper.

Parent Indicates the parent node (or repeater) of the pinged

meter.

Level/Desc Example, 2/1 - The 2 (

the registered gatekeeper of the pinged meter (for

example, a node level of 2 indicates that the pinged

meter communicates with its registered gatekeeper

through one repeater meter); the 1 (

number of repeater descendants below.

Total kWh Indicates the Total kWh in the pinged meter’s register.

Host/RadioFW Indicates the firmware version for the host and the radio

of the pinged meter.

Packets Indicates the

number the packets received/number

Level) indicates the node level from

Desc) indicates the

of sent. For example, 7/10 indicates that 7 out of 10

packets were received.

RSSI Indicates the EA_NIC’s received signal strength indicator

Meter RSSI

a

in dBm

For REX2 meters FW 3.0 or higher, indicates the meter’s

received signal strength indicator (in dBm).

.

a. Decibel milliwatts (also dBmW).

Page 41

EA_Inspector User Guide

Performing a ping test

Figure 5-8. Communication warnings

41

If you receive a communication error or warning message [Figure 5-8], see

“Communication mode errors and warning messages” on page 177 for

details on troubleshooting communication problems.

5. Click Save to save the results to a file for uploading into EA_Inspector

Manager.

EA_Inspector opens a Notes screen. See “Saving notes and GPS data” on

page 31 for details on collecting and saving GPS data.

Page 42

EA_Inspector User Guide

Performing a ping test

Figure 5-9. Entering notes for saving to log

42

6. Use the keyboard to enter any notes regarding the test.

7. Press <Enter> to save your notes to the activity log and exit the test.

— OR —

Press <Esc> to exit the test without saving your notes.

One shot ping of a EA_Gatekeeper

Note: If you are pinging a gatekeeper with FW v4.x or 5.x, you must

turn off encryption in the handheld. See “Configuring handheld

settings and utility IDs” on page 171 for details.

To perform a one shot ping of a EA_Gatekeeper (both enclosure-based and in an

A3 ALPHA meter):

1. From the One Shot Ping Test menu, select Electric.

EA_Inspector displays the ping test input screen.

2. Check Is GK (Gatekeeper).

3. Enter the ID of the gatekeeper to be pinged.

4. Click Ping.

Page 43

EA_Inspector User Guide

Performing a ping test

Figure 5-10. One shot ping of a gatekeeper

43

Figure 5-11. Successful ping of gatekeeper

The ping test occurs and the input screen displays the results as they are

received.

5. Click Save to save the results to a file for uploading into EA_Inspector

Manager.

EA_Inspector opens a Notes screen. See “Saving notes and GPS data” on

page 31 for details on collecting and saving GPS data.

Page 44

EA_Inspector User Guide

Performing a ping test

Figure 5-12. Ping test input screen

44

One shot ping of gas module or AC-250 RMD

To perform a one shot ping of a gas meter’s RF module or on an AC-250 RMD

(valve control module):

1. From the One Shot Ping Test menu, select Gas.

EA_Inspector displays the ping test input screen.

Figure 5-13. Hold magnet prompt

2. Click Ping.

EA_Inspector prompts you to hold a magnet on the gas module for 3

seconds.

Page 45

EA_Inspector User Guide

Performing a ping test

3. Hold the magnet on the bottom left of the gas module approximately 0.5

Figure 5-14. Holding magnet on gas module v1.0

45

inches in from the left edge (see Figure 5-14, Figure 5-15, and Figure 5-16).

Figure 5-15. Holding magnet on gas module v2.0

The EA_Gas v3.0 module requires a magnet swipe unless it is operating in

Mobile mode or in Hybrid (Fixed and Mobile) mode.

Page 46

EA_Inspector User Guide

Performing a ping test

Figure 5-16. Holding magnet on gas module v3.0

46

Figure 5-17. Successful ping test results

The ping test occurs and the input screen displays the results as they are

received.

The ping test results displays the following information:

Item Description

ID Indicates the serial number ID of the EA_Gas module.

Read Indicates the index reading (that is, gas usage).

Page 47

EA_Inspector User Guide

Performing a ping test

47

Item Description

Status drop list • EncReadErr - a problem has occurred when reading

an encoder-type water module; it means a bad digit

was read. If Tamper is also set, it means a complete

read failure.

• RESET_ERROR - the module has been reset since the

last clear data. This flag is always set at power up, but

will be cleared at final assembly, and at install.

• TiltTmpr - Indicates the meter has a tilt tamper

condition in effect.

• SwitchTmpr - for Water modules this indicates a Leak

condition has been detected; indicates the meter has

a switch tamper condition in effect as the result of

holding a magnet next to the gas module for more

than 5 minutes.

• LowBattery - indicates that the battery has fallen below

the set threshold after a transmit; this is a latched

status.

• BackFlow - for water modules with encoder-type

registers; indicates a back flow condition has been

detected

• OverLimit - for water modules with encoder-type

registers; indicates an over limit condition has been

detected

• ModuleErr- indicates a configuration error, CRC error,

or EEPROM write error has occurred; this is a latched

status.

PreDiv Indicates the Predivider; the number used to convert

meter pulses to index usage value. A predivider of 50

means that 50 pulses received from the meter converts to

one index read.

PCF Indicates the pressure compensation factor used to

adjust the meter reading for billing.

Time Indicates the date and time kept in the module.

Trans period Indicates the number of hours between gas module

transmissions of data to its associated gatekeeper. For

example, if Trans period is 4 hours, the gas module

transmits its data to the gatekeeper every 4 hours.

Trans var Indicates the window time for the gas module to transmit

its data. For example, if the Trans period is 4 hours and

the Trans variance is 4 hours, the gas module transmits

its data to the gatekeeper at a randomly selected time

between 4 AM and 8 AM.

Firmware Indicates the firmware version used by the EA_Gas

module.

4. If the display indicates one or more tamper statuses, click Clear Status to

clear the statuses from the module.

Note: If a tamper status is not in effect, the Clear Status button will

appear disabled.

Page 48

EA_Inspector User Guide

Performing a ping test

Figure 5-18. Clearing a status

48

Figure 5-19. View more information

5. Click More to view more information on the gas meter and module.

The More screen displays the following additional information about the gas

meter:

Item Description

SubCount Indicates the pulse count stored internally in the meter

before the predivider is applied to obtain the meter read.

IntDiv/Len Indicates the Interval Divisor and Length in minutes for

determining interval data.

Page 49

EA_Inspector User Guide

Performing a ping test

49

Item Description

DailySnapShot Indicates the time of the day at which the meter read is

recorded for the daily read.

Style Indicates the Elster style number for the gas module.

Assembly Indicates the Elster assembly serial number.

DST Indicates the time of the daylight saving time change

followed by the recurring day and month for the Spring

and Fall DST change dates. For example, 2nd Sun/3

indicates the second Sunday in March and 1st Sun/11

indicates the first Sunday in November.

OPMode Indicates the operating mode of the meter:

• 0 - EnergyAxis System - the default network mode set

after installation using the PI 900 handheld software

• 1 - Walk By/Drive By

• 2- EAHybrid - Future use

• 3- Legacy - Future use

• 4 - DeepSleep - factory shipped mode

• 5 - Burn-in - mode used during factory configuration

• To return to the previous screen, use a stylus or finger to press More on

the handheld’s display.

6. Click Save to save the results to a file for uploading into EA_Inspector

Manager.

EA_Inspector opens a Notes screen. See “Saving notes and GPS data” on

page 31 for details on collecting and saving GPS data.

One shot ping of a one-way water meter

To ping a one-way or two-way water module, you must perform a Find that

reports the data transmitted by the water module after a magnet triggers an RF

transmission. See “One shot ping of two-way water meter” on page 52 for details

on pinging a two-way water module.

To perform a one shot ping of a one-way water meter’s RF module:

1. From the One Shot Ping Test menu, select Water.

EA_Inspector displays the ping test input screen.

Page 50

EA_Inspector User Guide

Performing a ping test

Figure 5-20. Ping test input screen

50

2. For a one-way water module, click Find.

EA_Inspector prompts you to hold a magnet on the water module for 3

seconds.

Figure 5-21. Hold magnet prompt

3. Lift the cover over the water meter.

4. Hold the magnet on the bottom center of the water module (see

Figure 5-22).

Page 51

EA_Inspector User Guide

Performing a ping test

Figure 5-22. Holding magnet on water meter module 1.0

51

Figure 5-23. Successful ping test results

The ping test occurs, the water module transmits one packet of data that the

input screen displays.

Page 52

EA_Inspector User Guide

Performing a ping test

52

The ping test results displays the following information:

Item Description

ID Indicates the serial number ID of the EA_Water module.

LAN ID Indicates the LAN ID for the EA_Water module.

EncReg Indicates the encoder register number.

Mt Read Indicates the meter reading (that is, total water usage).

Status Indicates the status of the meter or module:

Bad Digit - indicates data received from the encoding

•

register was corrupted

•

Leak - alarm indicating the meter detected a possible

leak

•

No Read - indicates that module did not receive data

from the meter

•

Tamper - alarm indicating the meter detected a

possible tamper event

5. Click Save to save the results to a file for uploading into EA_Inspector

Manager.

EA_Inspector opens a Notes screen. See “Saving notes and GPS data” on

page 31 for details on collecting and saving GPS data.

Figure 5-24. Ping test input screen

One shot ping of two-way water meter

You can perform a standard ping test a two-way EA_Water 2.0 module. Two-way

water modules may be either encoder-based modules or pulse-based modules.

See “One shot ping of a one-way water meter” on page 49 for details on pinging

a one-way water meter.

To perform a one shot ping of a two-way water meter’s RF module:

1. From the One Shot Ping Test menu, select Water.

EA_Inspector displays the ping test input screen.

Encoder-based

Pulse-based

Page 53

EA_Inspector User Guide

Performing a ping test

EA_Inspector prompts you to hold a magnet on the water module for 3

seconds to waken the module.

The EA_Water v3.0 module requires a magnet swipe unless it is operating in

Mobile mode or in Hybrid (Fixed and Mobile) mode.

Figure 5-25. Holding magnet on water meter module 2.0/3.0

53

Figure 5-26. Holding magnet on pit mounted meter module

2. For a two-way water module, click Ping.

EA_Inspector pings for any two-way water modules within range. The water

module responds to the ping.

Page 54

EA_Inspector User Guide

Performing a ping test

Figure 5-27. Successful ping two-way water module

54

Encoder-based Pulse-based

Figure 5-28. Clear statuses

3. Click Clear Status to clear the statuses in the module.

The handheld displays the results after the statuses are cleared.

4. Click More to view additional information.

More screen

• To return to the previous screen, use a stylus or finger to press More on

the handheld’s display.

5. Click Save to save the results to a file for uploading into EA_Inspector

Manager.

Page 55

EA_Inspector User Guide

Performing a ping test

55

EA_Inspector opens a Notes screen. See “Saving notes and GPS data” on

page 31 for details on collecting and saving GPS data.

Continuous ping test A continuous ping test performs multiple ping tests lasting for the number of

minutes specified by the Test Time with a delay time of a specified number of

Seconds Between Pings. For example, by default, a continuous ping test would

perform a ping test lasting 2 minutes with a delay of 5 seconds between ping

tests on an electricity meter.

See “Editing continuous ping test settings” on page 64 for details on changing

settings.

Note: For a continuous ping on a gas module or a two-way water

module, the time between pings is 0.8 seconds and cannot be

configured.

Note: You cannot perform a continuous ping test on a one-way water

meter. You can perform a FInd on a one-way water meter. See

“One shot ping of a one-way water meter” on page 49 for

details.

The continuous ping test performs multiple ping tests of an EA_Gas module, REX,

REX2 and A3 ALPHA meters and EA_Gatekeeper and EA_Repeater.

To perform a continuous ping test:

1. From the Ping Test menu, select Continuous.

Figure 5-29. Continuous ping menu and settings

The Continuous Ping Test menu displays.

2. From the Continuous Ping Test menu, you can select to perform one of the

following:

1) Continuous ping of electric meter

2) Continuous ping of gas or two-way water module

3) Editing continuous ping test settings

Page 56

EA_Inspector User Guide

Performing a ping test

Figure 5-30. Ping test input screen

56

Continuous ping of electric meter

To perform a continuous ping of an electric meter (REX, REX2, EA_Repeater,

EA_Gatekeeper or A3 ALPHA node):

1. From the Continuous Ping Test menu, select Electric.

See “Continuous ping of a gatekeeper” on page 58 for details on pinging a

gatekeeper.

EA_Inspector displays the ping test input screen.

2. Enter the ID of the electric meter to be pinged.

3. Click Ping.

The ping test occurs and the input screen displays the results as they are

received.

Page 57

EA_Inspector User Guide

Performing a ping test

Figure 5-31. Result of continuous ping of electric meter

57

Figure 5-32. Continuous ping test complete

Note: Only REX2 meters with FW 3.0 or higher return Meter RSSI.

The continuous ping test continues displaying the results of each test until

the testing is complete.

The ping test results display the number the packets received/number of

sent, RSSI. For example, 9/10,-23, -19, indicates that nine packets were

received out of ten packets sent for an RSSI of -23 dBm and a meter RSSI of 19 dBm.

Page 58

EA_Inspector User Guide

Performing a ping test

Continuous ping of a gatekeeper

To perform a continuous ping of an A3 ALPHA gatekeeper:

Figure 5-33. Continuous ping test - gatekeeper

58

4. Click Save to save the results to a file for uploading into EA_Inspector

Manager.

EA_Inspector opens a Notes screen. See “Saving notes and GPS data” on

page 31 for details on collecting and saving GPS data.

Note: If you are pinging a gatekeeper with FW v4.x or 5.x, you must

turn off encryption in the handheld. See “Configuring handheld

settings and utility IDs” on page 171 for details.

1. From the Continuous Ping Test menu, select Electric.

EA_Inspector displays the ping test input screen.

2. Check Is GK (Gatekeeper).

3. Enter the ID for the gatekeeper.

Page 59

EA_Inspector User Guide

Performing a ping test

Figure 5-34. Continuous ping test - gatekeeper

59

Figure 5-35. Continuous ping test - gatekeeper

4. Click Ping.

5. Click Save to save the results to a file for uploading into EA_Inspector

Manager.

EA_Inspector opens a Notes screen. See “Saving notes and GPS data” on

page 31 for details on collecting and saving GPS data.

Page 60

EA_Inspector User Guide

Performing a ping test

Figure 5-36. Ping test input screen

60

Continuous ping of gas or two-way water module

To perform a continuous ping of a gas or two-way water meter’s RF module:

1. From the Continuous Ping Test menu, select Gas/Water.

EA_Inspector displays the ping test input screen.

2. Click Ping.

EA_Inspector prompts you to hold a magnet on the gas/water module for 3

seconds. See Figure 5-14 for an illustration on how to hold the magnet on a

gas module. See Figure 5-22 for an illustration on how to hold the magnet

on a water module.

Page 61

EA_Inspector User Guide

Performing a ping test

Figure 5-37. Hold magnet prompt

61

The ping test occurs and the input screen displays the results as they are

received.

Figure 5-38. Result of continuous ping of gas RF module

The continuous ping test continues displaying the results of each test until

the testing is complete.

The ping test results display the number the packets received/number of

sent, RSSI. For example, 9/10, -22 indicates that nine packets were received

out of ten packets sent for an RSSI of -22 dBm.

Page 62

EA_Inspector User Guide

Performing a ping test

62

3. Click Save to save the results to a file for uploading into EA_Inspector

Manager.

EA_Inspector opens a Notes screen. See “Saving notes and GPS data” on

page 31 for details on collecting and saving GPS data.

Node to node ping test A node-to-node ping test signals a meter to ping another meter (whether a REX,

REX2, EA_Repeater or A3 ALPHA meter). The node-to-node ping test requires the

initiator node is a meter registered to a gatekeeper.

Initiator Responder

REX meter

Note: REX meters FW 4.1 cannot initiate

node to node ping tests.

REX2 meter

gREX meter

EA_Repeater

A3 ALPHA meter/node

Note: An A3 ALPHA gatekeeper cannot initiate or respond to a node-

to-node ping test.

To perform a node-to-node ping test:

any meter

Note: REX meters FW 4.1 and higher can

respond to node to node ping tests.

Figure 5-39. Node to node ping input screen

1. From the Ping Test menu, select Node to Node Ping.

EA_Inspector displays the Node to Node Ping dialog.

2. Enter the ID of the Initiator (the meter initiating the ping).

3. Enter the ID of the Responder (the meter to be pinged).

4. Click Ping.

Page 63

EA_Inspector User Guide

Performing a ping test

Figure 5-40. Ping in process

63

Figure 5-41. Successful node-to-node ping

EA_Inspector displays the results of the node-to-node ping including the

number of packets sent and the RSSI as a range of 0 to 7 where 0 indicates

no signal and 1 indicates the best (or maximum) RSSI and 7 indicates the

worst RSSI. See “About ping tests” on page 35 for details on RSSI and dBm

range represented by the node-to-node ping results.

5. Click Save to save the results to a file for uploading into EA_Inspector

Manager.

Page 64

EA_Inspector User Guide

Performing a ping test

64

EA_Inspector opens a Notes screen. See “Saving notes and GPS data” on

page 31 for details on collecting and saving GPS data.

Editing continuous ping

EA_Inspector allows you to configure the following continuous ping test settings:

test settings

See “About ping tests” on page 35 for details about RSSI and signal strength.

To change ping test settings:

Figure 5-42. Edit continuous ping test settings

• Ping packet repeats

• Test time (in minutes)

• Seconds between Pings (applies to electricity meters only)

1. From the Continuous Ping Test menu, select Edit Ping Settings.

EA_Inspector displays the Ping Settings dialog.

2. Edit the settings as needed:

• Ping Packet Repeats - the number of additional packets transmitted at

different frequencies within the 900 MHz unlicensed band

For example, if packet repeats is set to the default of 2, a total of 3 packets

(1 packet plus an additional 2 packets) would be send over each of 3

different frequencies in the 900 MHz band.

• Test Time (in minutes) - the duration time (in minutes) of the ping test

• Seconds between Pings - the delay time (in seconds) between ping tests;

applies to electricity meters only

Note: For a continuous ping on a gas module, the time between pings

is 0.8 seconds and cannot be configured.

3. Click Save to save your changes.

You are ready to perform a continuous ping test using the changed settings.

Page 65

EA_Inspector User Guide

Performing a ping test

65

Page 66

6 LOCATING A NODE

About locating nodes EA_Inspector is capable of locating registered and unregistered REX, REX2 and

A3 ALPHA node electricity meters.

Note: Elster recommends disabling EA_Inspector encryption before

locating a registered or unregistered node, especially utilities

supporting both unencrypted and encrypted LAN

communications. See “Configuring handheld settings and utility

IDs” on page 171 for details on disabling LAN encryption.

Note: Gas and water modules are battery operated devices that

remain in a sleeping state until they are awakened (by magnet

swipe for one-way modules or by receiving a magnet swipe or

a wake up signal (v3.x modules) for two-way modules). They

cannot be located using the Registered Node or Unregistered

Node Locator functions.

Accessing node location

menu

Figure 6-1. EA_Inspector Main Menu

To access the Locate Node test menu:

1. From the Main Menu, select RF Troubleshooting.

The RF Troubleshooting menu displays.

Page 67

EA_Inspector User Guide

Locating a node

Figure 6-2. RF Troubleshooting menu

67

2. From the RF Troubleshooting menu, select from the following:

• Registered node locator

• Unregistered node locator

Registered node locator The Reg Node Locator command allows you to perform the following node locate

functions:

• Find all IDs

• Finding an ID

Note: The accelerator key for Find All is <A> and the key for Find ID is

<I>.

Find all IDs

To find all registered nodes:

1. From the RF Troubleshooting menu, select Reg Node Locator.

2. Select Find All.

EA_Inspector commands all registered nodes to respond.

Page 68

EA_Inspector User Guide

Locating a node

Figure 6-3. Find All nodes

68

Figure 6-4. Find all registered nodes results

EA_Inspector displays a listing of registered nodes including the following

information:

Item Description

ID Indicates the Serial Number or the LAN ID of the

registered node (depending on user privileges).

Page 69

EA_Inspector User Guide

Locating a node

69

Item Description