Page 1

September 2010 IL42-5015A

EA_Gas Module

Installation Instructions

Introduction

The EA_Gas Module is designed for use with most residential diaphragm meters. Modules for residential meters are available in three

distinct types:

• Type A = American Meter Company® products

• Type R & R415 = Rockwell / Equimeter / Invensys

• Type S = Sprague / Schlumberger / Actaris / Metris

®

®

Tools, equipment and materials

All or some of the following items may be needed in order to install the module, depending upon the type of meter/index and the

condition of the old index cover and gaskets:

•EA_Gas Module

• Elster’s EA_Installer handheld with software

• Index screws (2 each)

• Meter mounting bolts (3 or 4 each, depending upon the meter type)1

• Index cover (if old one is not reusable)

• Index cover gasket

• Putty knife or scraper (to remove old gaskets)

• #2 Phillips screwdriver

• Awl (to remove existing tamper seals)

• Tamper seals (2 each)

• Pressure compensation factor value, if needed (obtain from Elster)

1

1

1

Preparation and installation

Preparing

Prior to removing the existing index and index cover, verify that the module style is compatible with the meter style.

1

Supplied with the module.

Elster

Raleigh, North Carolina United States

+1 800 786 2215 (US toll free)

+1 905 634 4895 (Canada)

support@us.elster.com

www.elster.com

Page 2

IL42-5015A September 2010

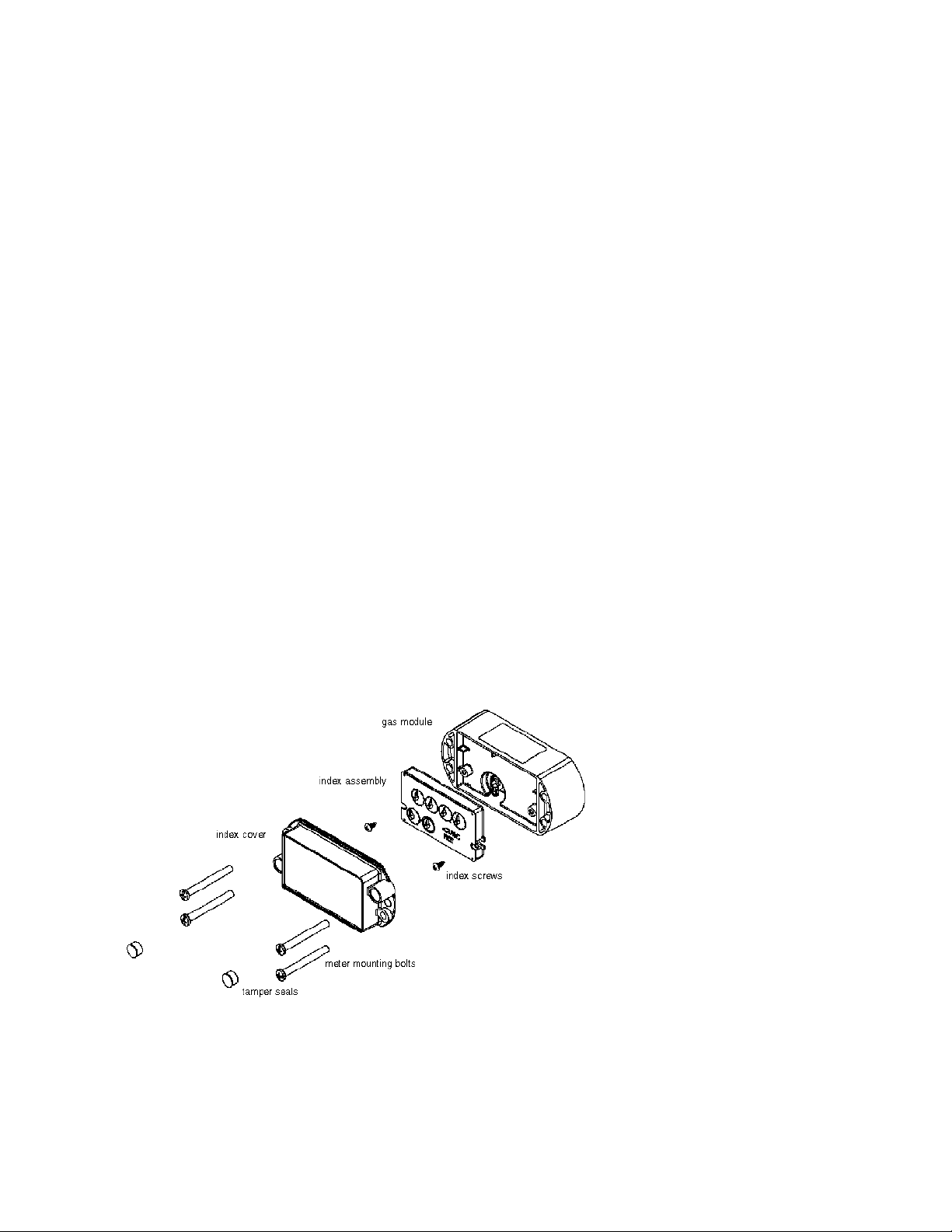

EA_Gas module (front side)

EA_Gas module (battery side)

Figure 1. EA_Gas module for Type A meter index

Installing index onto module

1. Remove the existing index cover and index (or module) from the meter.

Use an awl to remove the existing tamper seals.

2. Clean any debris from index and cover.

3. Using a scraper or putty knife, remove the gasket and any adhesive material from the meter.

4. Align index wriggler with module wriggler (battery side), as shown below.

2

Page 3

September 2010 IL42-5015A

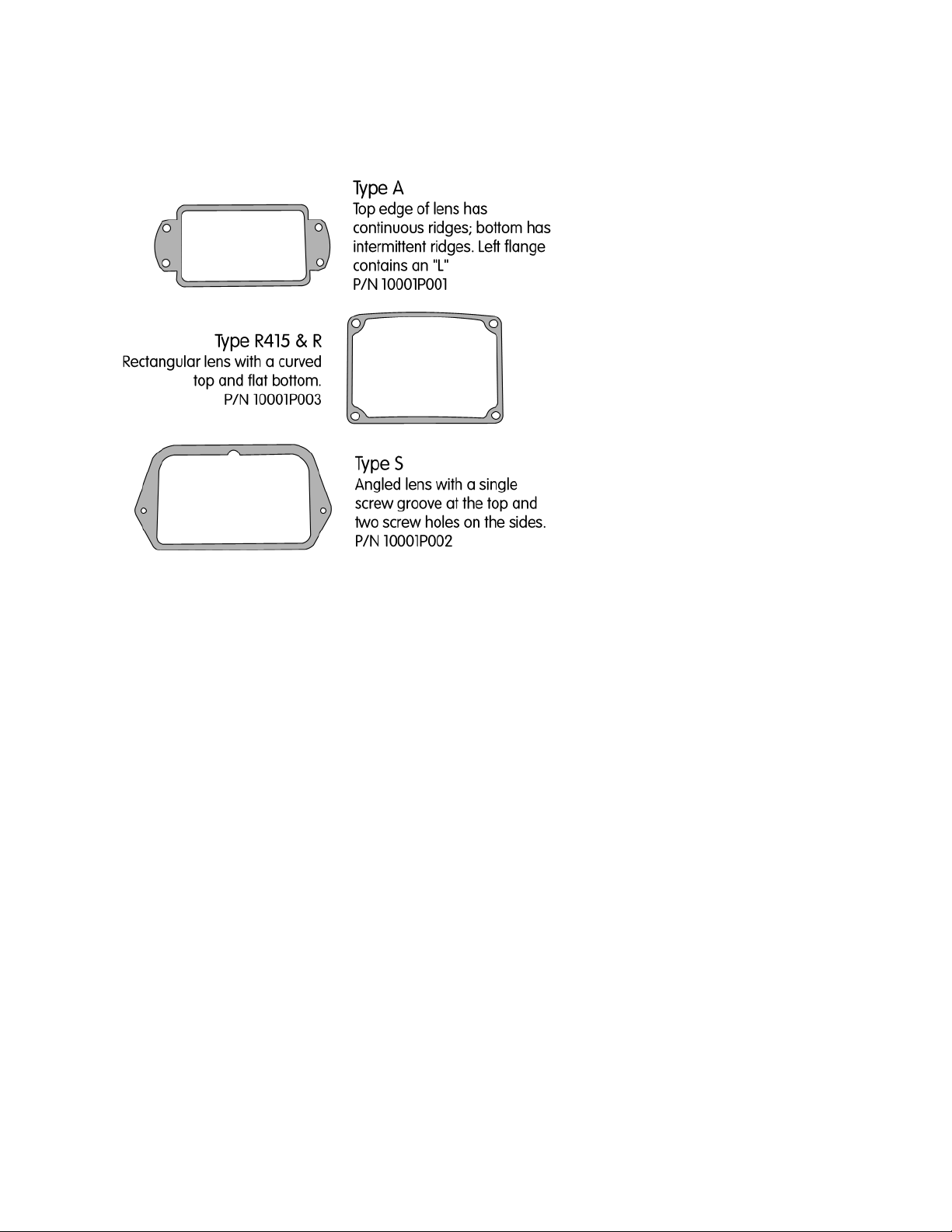

Type A

Type R 4 15

Type R

Type S

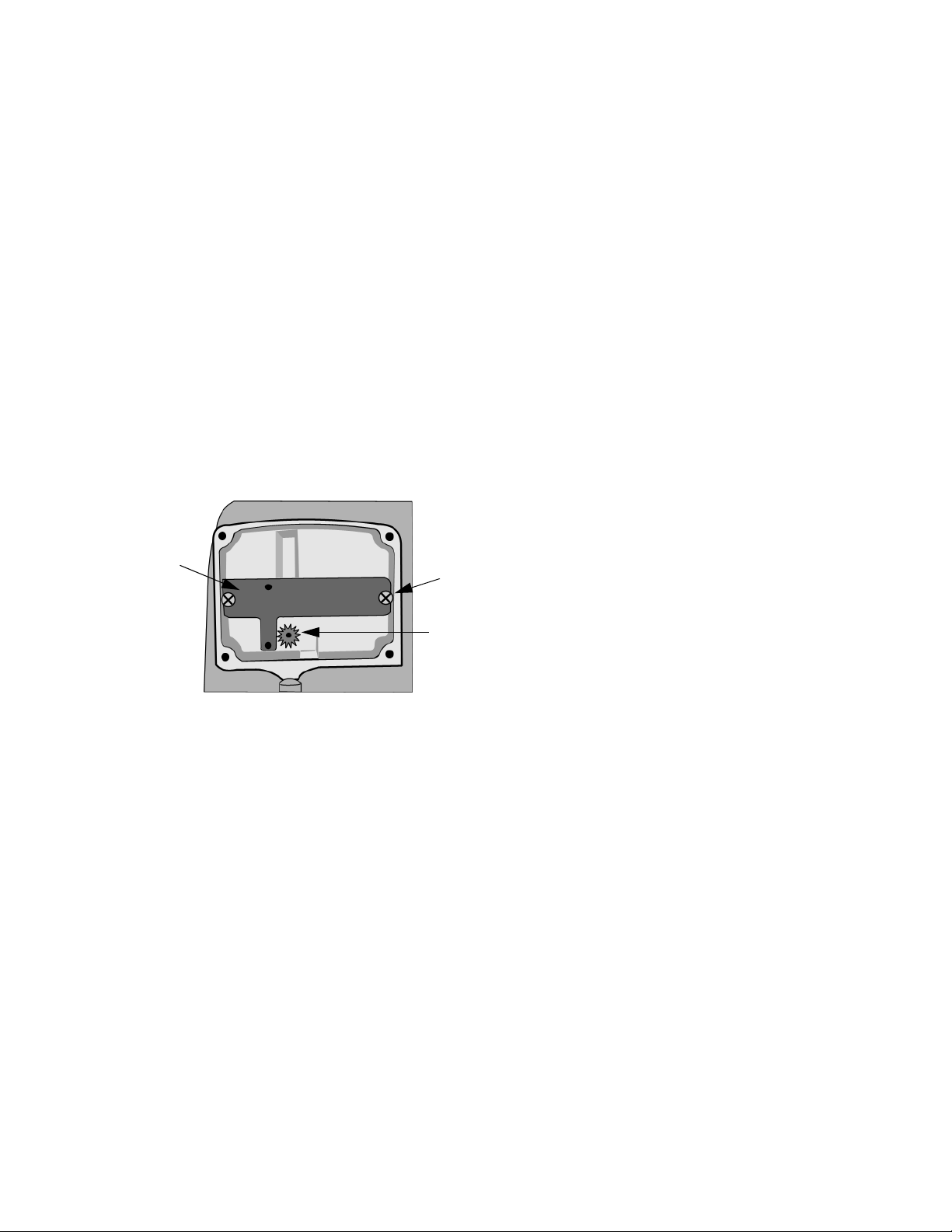

Figure 2. Gas module battery compartment and wriggler

Figure 3. Alignment of wrigglers

5. Attach the index to module using the appropriate two (2) index screws.

Figure 4. Exploded installation view of the gas meter index with gas module

Caution: Do not over tighten index screws.

3

Page 4

IL42-5015A September 2010

6/32” screw

meter adapter

gears meshed

correctly

Checking mechanical operation

This procedure will verify the attached index rotates freely and without resistance.

1. Rotate the index drive dial 3 times clockwise.

2. If it turns easily, rotate the drive dial 3 times counterclockwise to remove counts or subcounts from the mechanical index.

If it does not turn easily:

a. Rotate the drive dial 3 times counterclockwise to remove subcounts from the mechanical index.

b. Unscrew the index/module assembly and repeat from step 4 of “Installing index onto module” on page 2.

Note: Subcounts added to the electronic index during this procedure will be cleared when the index reading is programmed into the

module.

3. Verify that the gasket material on the index cover is free of rips or tears.

4. If the gasket cover is ripped or torn, removed the damaged gasket from the index cover and replace with a new gasket.

Mounting the module-index assembly

Note: Be sure to have your module/index assembly, screwdriver, index cover and index cover gasket within easy reach before starting

this procedure.

1. For Rockwell 415 modules Only: Install the meter adapter to the meter using the two 6/32” screws supplied in the assembly.

Note: Make sure the gears on the adapter and meter are properly meshed.

Figure 5. Rockwell gas meter with meter adapter (P/N 52870G031) and index wriggler

2. Visually align module wriggler with meter wriggler or meter adapter (drive dog).

• If wriggler cannot be put in a fixed position, position it correctly by rotating the drive dial with your finger.

3. Mate the module wriggler with the meter wriggler or meter adapter (drive dog) and hold the mated assembly against the

meter.

4. While holding the assembly against the meter, gently try to turn the drive wheel clockwise, then counterclockwise.

• If the drive wheel meets resistance in both directions, it is properly mated. Proceed to step 5.

• If it meets no resistance in either direction, and can rotate freely through an angle of 360 degrees and beyond, then make

sure the meter is completely free of old gasket material and forcefully press the module into the meter. Repeat this step

(step 4). If the unit still does not correctly engage with the meter, return it to Elster Integrated Solutions.

• For American Meter modules Only: If the American Meter module meets resistance in one direction then turns 360

degrees the other way before again meeting resistance, it is not properly mated. Repeat from step 1.

Caution:

It is very important that the wriggler on the module is correctly

engaged onto the meter. If it is not, it could produce an

erroneous indication during utility leak test procedures that

monitor drive dial (proving dial) movement. Incorrectly

engaged wrigglers could also cause meter damage. CORRECT

EXECUTION OF STEPS 1, 2 and 3 IS CRITICAL.

5. While holding the module firmly in place so as to not lose the wriggler alignment, place the index cover and index cover gasket

onto the module/ index assembly.

4

Page 5

September 2010 IL42-5015A

• Verify the index cover is properly oriented with its vent holes at the bottom.

• See figure below for orientation cues.

Figure 6. Gaskets by meter type

6. Using the appropriate mounting bolts provides, screw the module/index/cover assembly to the meter and tighten bolts using a

torque driver set to 20 in-lbs (with +/- 4 in-lbs tolerance) to secure assembly to meter.

7. Install the tamper seals into the index cover receptacles.

Figure 7. Meter index assembly with tamper seals

Programming the module using the EA_Installer

Although modules may contain default or utility-specified values that are programmed during manufacturing, it is important to program

certain data only after the module has been installed in the field:

• Modules can accumulate subcounts during shipping, handling and installation due to the movement of its wriggler.

• The module’s tamper sensing switch must be told which orientation should be considered its normal (not tampered) condition.

• During a field module retrofit the meter’s existing index is reused and that index reading must be programmed into the module.

Therefore, all modules (even those mated with indexes set at 0000) should be programmed after installation on the meter.

Note: If required, be sure to have the module’s pressure compensation factor. Contact Elster Support at (919) 250-5700.

For specific instructions for installing and programming modules using Elster’s EA_Installer handheld please refer to the

User Guide, Chapter 7, “Installing RTMs

.”

Elster Handhelds

5

Page 6

IL42-5015A September 2010

To use the EA_Installer handheld to install EA_Gas Modules, a route must first be set up in Route Manager with a Route Type = Install. This

route will contain the meter number, customer name, service address and other account information. Typically this route is imported from

a CIS system where the route is being used as a manual read route.

Appointments can be assigned to accounts in the Install route from Route Manager.

After the route is downloaded to the handheld device you can select the route from the handheld device Route Select screen. The

selected route should have a type of Install.

Installing EA_Gas Modules using EA_Installer

To install EA_Gas Modules:

1. On the EA_Installer, from the Account installation screen, click Find or press <F>.

The screen prompts you to hold a magnet on the RTM nearest to the wriggler for 3 seconds.

6

Page 7

September 2010 IL42-5015A

2. Hold a magnet on the side of the RTM for 3 seconds (see Figure 8).

Figure 8. Holding magnet on the gas module

3. Click Cancel to return to the installation screen.

7

Page 8

IL42-5015A September 2010

Note: Verify that the LAN ID on the display matches the LAN ID on the module. The LAN ID follows the hyphen after the Utility ID. For

example, 242-0000000016, has the Utility ID of 242 and a LAN ID of 0000000016.

After the 3 seconds, the module broadcasts the module’s RTM number and is recognized by the handheld.

Note: The EA_Installer handheld is programmed with the utility ID at the factory. This prevents the handheld from communicating with

modules or RTMs with different utility IDs.

The handheld displays the following information for the module:

• RTM number

•PreDiv

8

Page 9

September 2010 IL42-5015A

• Sub-counts

•PCF

• Status message

The handheld prompts you to read the subcounts.

4. To check subcounts:

a. Press Cnt or <C>.

The current module subcount will be returned.

When you have verified the subcounts are recording correctly, proceed to the

next step.

5. To program the RTM:

a. Click Def or press <D>.

9

Page 10

IL42-5015A September 2010

The screen displays the Ins Def Codes (Installation Definition Codes).

b. Select the appropriate Installation Definition Code from the list.

Note: Code 99 is reserved for upgrading the module firmware using a file obtained from Elster Customer Support. Use this code only if

directed to by Elster.

Refer to the

Definition Codes.

Route Manager User Guide

for details on configuring Installation

Note: The Installation Supervisor must insure the attributes such as predivider are correctly established for each of the Installation

Definition Codes and that installers are trained to determine which code is to be used for a particular meter.

c. Enter the visual read index value in the Mt Rd.

10

Page 11

September 2010 IL42-5015A

d. If you wish to use the default values, select the Installation Definition Code = 0.

e. If the displayed predivider, PreD, is incorrect, enter the correct value.

f. If a meter has a pressure compensated index (that is, red face index) enter the PCF ratio that is appropriate for that index.

Note: If required, be sure to have the module’s pressure compensation factor. Contact Elster Support at (919) 250-5700.

g. Click Set or press <S>.

The interrogator will read, check and set the parameter values.

The final status will be displayed as either

Set Pass

or

Set Fail

.

11

Page 12

IL42-5015A September 2010

After a successful installation:

• The RTM subcount value will be set to zero.

• The status will be displayed as Installed.

• The date and time will be set.

6. Press OK to move to the next account.

12

Page 13

September 2010 IL42-5015A

Notes

13

Page 14

IL42-5015A September 2010

Notes

14

Page 15

September 2010 IL42-5015A

Notes

15

Page 16

IL42-5015A September 2010

FCC and Industry Canada Compliance

User Information (Part 15.105): This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, the user is encouraged to try to correct the interference by one or more of the following measures:

• reorient or relocate the receiving antenna

• increase the separation between the equipment and the receiver

• connect the equipment into an outlet on a circuit different from that to which the receiver is connected

• consult the dealer or an experienced radio/TV technician for help

If you experience trouble with this equipment, please use the Return Material Request (RMR) feature available at the Online Customer Services at

www.elstersolutions.com. Do not attempt to repair this equipment itself unless you are replacing the entire module.

Compliance Statement (Part 15.19): This device complies with Part 15 of the FCC Rules and with RSS-210 of Industry Canada. Operation is subject to the

following two conditions: 1) This device may not cause harmful interference, and 2) This device must accept any interference received, including

interference that may cause undesired operation.

Warning (Part 15.21): Changes or modifications not expressly approved by Elster could void the user's authority to operate the equipment.

RF Radiation Safety Guidelines per Part 2 of FCC Rules and Regulations: The meter should be installed in a location where there will be a separation

greater than 20 cm from locations occupied by humans.

Industry Canada Statement: The term "IC" before the certification/registration number only signifies that the Industry Canada technical specifications were

met.

Collocation Statement: Collocation of simultaneously-transmitting (co-transmitting) antennas within 20 cm of each other in a final product is not allowed.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY

There are no understandings, agreements, representations, or warranties either express or implied, including warranties of merchantability or fitness

for a particular purpose, other than those specifically set out by any existing contract between the parties. Any such contract states the entire obligation of the seller. The contents of this document shall not become part of or modify any prior existing agreement, commitment, or relationship.

The information, recommendations, descriptions, and safety notices in this document are based on Elster experience and judgment with respect to

operation and maintenance of the described product. This information should not be considered as all-inclusive or covering all contingencies. If further information is required, Elster should be consulted.

No warranties, either expressed or implied, including warranties of fitness for a particular purpose or merchantability, or warranties arising from the

course of dealing or usage of trade, are made regarding the information, recommendations, descriptions, warnings, and cautions contained herein.

In no event will Elster be responsible to the user in contract, in tort (including negligence), strict liability or otherwise for any special, indirect, incidental,

or consequential damage or loss whatsoever, including but not limited to: damage or loss of use of equipment, cost of capital, loss of profits or revenues, or claims against the user by its customers resulting from the use of the information, recommendations, descriptions, and safety notices contained herein.

Elster

Raleigh, North Carolina USA

© 2010 by Elster

All rights reserved.

Printed in the United States.

*IL42-5015A*

Loading...

Loading...