Flow Computer

enCore FC1

Manual

Part 2: Operating Instructions

FC1-BA2-EN a 2013-06-26

Page 2 of 78 Operating Instructions enCore FC1

Elster GmbH

Schloßstraße 95a

D - 44357 Dortmund / Germany

Tel.: +49 - 2 31 - 93 71 10 0

Fax: +49 - 2 31 - 93 71 10 99

E-mail: Support-DO@elster.com

enCore FC1 Operating Instructions Page 3 of 78

Contents

1 Introduction 6

1.1 Scope of Delivery 6

1.2 About these Instructions 6

1.3 Explanation of Symbols 8

1.3.1 Presentation of Hazard Warnings 8

1.3.2 Presentation of Safety Instructions 9

1.3.3 Presentation of Tips and Recommendations 9

1.4 Target Group Definition 9

1.5 Limitation of Liability 10

1.6 Applicable Standards and Guidelines 11

2 Safety 13

2.1 General Safety Instructions 13

2.2 Intended Use 15

2.3 Unauthorized Users 16

2.4 Operator Liability 16

3 Design and Function 18

3.1 enCore and enSuite 18

3.2 FC1 Functional Description 18

3.3 Device Description 20

3.4 Control Panel 21

3.4.1 Device Keys 22

3.4.2 Touch Screen 22

3.4.3 Operation and Navigation within the Display 22

3.4.4 Security Switch 22

3.4.5 LEDs 23

3.5 Interfaces (Rear Side of Device) 25

3.6 Available Process Boards 26

3.6.1 ExMFE5 Process Board 26

3.6.2 MFE7 Process Board 27

3.6.3 MSER4 Process Board 28

3.6.4 MFA8 Process Board 28

Page 4 of 78 Operating Instructions enCore FC1

4 Assembly and Installation 29

4.1 Line Connection 29

4.2 Power Supply and Grounding 31

4.3 Mounting of Process Boards 31

4.4 Connection Diagrams 37

4.4.1 Pt100 (EEx i) via ExMFE5 Board 37

4.4.2 Pt100 (EEx d) via MFE7 Board 38

4.4.3 Analog Pressure Transmitter (EEx i) via ExMFE5 Board 38

4.4.4 Analog Pressure Transmitter (EEx d) via MFE7 Board 39

4.4.5 Analog Pressure Transmitter (EEx i) via MFE7 Board 39

4.4.6 HART Transmitter (EEx i) via ExMFE5 Board 40

4.4.7 HART Transmitter (EEx d) via MFE7 Board (Internal Power Supply) 41

4.4.8 HART Transmitter (EEx d) via MFE7 Board (External Power Supply) 42

4.4.9 HART Transmitter (EEx i) via MFE7 Board 43

4.4.10 HART Transmitter (EEx d) via MFE7 Board (redundant) 44

4.4.11 HART Transmitter (EEx i) via MFE7 Board (redundant) 45

4.4.12 Gas Meter (Turbine): Encoder Index, 2 LF/HF Sensors (EEx i) via

ExMFE5 Board 46

4.4.13 Gas Meter (Turbine): Encoder Index, 2 LF/HF Sensors (EEx i) via

MFE7 Board 46

4.4.14 Gas Meter (Turbine): SMRI2 Bi-directional: 2 HF Sensors, Flow

Direction Detection (EEx i) via MFE7 Board 47

4.4.15 Q.Sonic Ultrasonic Gas Meter: Serial RS485 (EEx d) via MFE7 Board 48

4.4.16 FLOWSIC600 Ultrasonic Gas Meter: Serial RS485 (EEx d) via MFE7

Board 49

4.4.17 Serial Interface through COM Port (CPU or MSER4 Board) 50

4.4.18 Analog Output (0/4...20mA) via MFA8 Board 51

4.4.19 Message Output via MFA8 Board 52

4.4.20 Pulse Output via MFA8 Board 53

5 Device Configuration and Commissioning 54

5.1 enSuite Software 54

5.1.1 System Requirements 54

5.1.2 enSuite Installation 54

5.1.3 Installation of the USB driver 59

5.2 Device Parameterization 62

enCore FC1 Operating Instructions Page 5 of 78

5.3 Commissioning the Measurement System 63

5.3.1 Checking Device Settings 63

5.3.2 Checking Measurement Input Values 63

5.3.3 Checking Output Signals 64

5.3.4 Checking Digital Communication (Modbus, etc.) 64

5.3.5 Checking Measurements and Calculations 64

5.3.6 Sealing (if necessary) 64

6 Maintenance 65

6.1 Battery Replacement 65

6.2 Cleaning 68

6.3 Customer Service 69

6.4 Replacement Parts and Accessories 69

6.5 Warranty Conditions 70

7 Decommissioning / Disposal 71

7.1 Storage 71

7.2 Disposal 72

8 Technical Data 73

8.1 General 73

8.2 Inputs 74

8.3 Outputs 75

8.4 Interfaces for Digital Communication 75

9 Index 76

10 Appendix 78

1 Introduction

Page 6 of 78 Operating Instructions enCore FC1

1 Introduction

1.1 Scope of Delivery

The enCore FC1's scope of delivery includes:

enCore FC1 electronic flow computer

Confirmation of conformity or factory test protocol

Dispatch list / delivery note

FC1 manual - Part 1 (Brief instruction) and Part 2 (Operating

instructions)

enSuite installation CD

USB cable (A/B type)

Accessories (plugs incl. housing)

1.2 About these Instructions

The documentation on hand is Part 2 (Operating instructions) of the overall

documentation, and describes the assembly, installation, commissioning and

maintenance of the enCore FC1 flow computer (called FC1 below).

A hard copy of this portion of the documentation is included in the delivery

scope of the FC1.

These instructions make it possible to work with the FC1 in a safe and

efficient manner.

Compliance with all the safety and handling instructions specified in these

operating instructions is a prerequisite to working with the FC1 in a safe

manner and using it properly, and for obtaining accurate measurement and

calculation results.

In addition, compliance is also necessary with the guidelines, standards,

local accident prevention regulations and general safety regulations that

apply for the FC1's area of application.

Introduction 1

enCore FC1 Operating Instructions Page 7 of 78

The entire FC1 documentation consists of three parts:

Part 1 Brief instruction

Part 1 of the documentation briefly describes the legally relevant

properties of the FC1 flow computer. Apart from topics such as General

device information and Technical data, Display and Operation, Basic

functionalities and Description of compulsory AFBs (Application

Function Blocks), there is an Appendix including approval certificates

and other legally relevant documents (if applicable). A hard copy of this

portion of the documentation is included in the scope of delivery.

Part 2 Operating instructions

Part 2 is the document on hand. A hard copy of this portion of the

documentation is included in the scope of delivery.

Part 3 Configuration of the Device Software

Description of the Basic System including SFBs

(System Function Blocks, basic functionalities)

Descriptions of available AFBs (Application

Function Blocks)

Part 3 is a composition of several documents and is delivered in

electronic form only.

This part of the manual is intended for all specialized readers who are

interested in AFB functionality details. In particular, these

documentations explain how to configure the device parameterization

according to requirements. The information provided is completed by

the parameter descriptions included in the enSuite online help (enSuite

= PC software supporting enCore devices).

These instructions are a component of the product and must be kept in the

immediate vicinity of the FC1, so installation, operational, maintenance and

cleaning personnel may access them at any time.

The graphical illustrations in these instructions serve to depict the facts that

are being explained, and are therefore not necessarily true to scale and may

differ from the actual design of the FC1.

1 Introduction

Page 8 of 78 Operating Instructions enCore FC1

The data and material properties that are presented below are

guidelines. They must be reviewed for each individual case and

corrected if necessary.

1.3 Explanation of Symbols

1.3.1 Presentation of Hazard Warnings

Hazard warnings indicate hazardous situations that may result in material

damage and bodily harm up to death if disregarded.

Hazardous warnings are presented as described below:

DANGER WORD!

Type of danger

Consequences in case of non-compliance

- Avoiding danger

The danger word signals the hazard level:

DANGER!

…indicates an immediately hazardous situation that leads to death or

severe injury.

WARNING!

…indicates a possibly hazardous situation that may lead to death or

severe injury.

CAUTION!

…indicates a possibly hazardous situation that may lead to slight or

minor injuries.

ATTENTION!

…indicates a possibly hazardous situation that may lead to material

damage.

Introduction 1

enCore FC1 Operating Instructions Page 9 of 78

1.3.2 Presentation of Safety Instructions

Safety instructions include notes and information that can lead to FC1

functions not working correctly or not working at all if disregarded.

Safety instructions are presented as described below:

Safety instruction text

1.3.3 Presentation of Tips and Recommendations

Tips include notes and information that make it easier for the user to operate

the FC1.

Tips are presented as described below:

Tip text

1.4 Target Group Definition

The present documentation is directed to qualified electricians in the fields of

switch cabinet construction and maintenance, as well as qualified personnel

with specialized knowledge in device assembly, installation and

commissioning.

The qualifications for different areas of activity are listed below:

Trained individual

was instructed by the plant operator in an informational session on the

tasks assigned to him or her, and on possible hazards in case of

improper behavior.

Specialist

has the ability, because of his or her technical training, knowledge and

experience, as well as his or her knowledge of the relevant regulations,

to carry out the work to the FC1 assigned to him or her, and to

recognize and avoid possible hazards on his or her own.

1 Introduction

Page 10 of 78 Operating Instructions enCore FC1

Gas specialist

has the ability, because of his or her technical training, knowledge and

experience, as well as his or her knowledge of the relevant standards

and regulations, to carry out work to gas systems, and to recognize

possible hazards on his or her own. A gas specialist receives training for

the specific location in which he or she works, and is acquainted with

the relevant standards and regulations.

Metrology expert

has the ability and is authorized, because of his or her technical training,

knowledge and experience, to carry out fiscally protected work to gas

systems within the scope of legal metrology. A metrology expert is

trained to work with fiscally protected devices and systems, and is

acquainted with the relevant standards and regulations that apply in

specific countries.

Qualified electrician

has the ability, because of his or her technical training, knowledge and

experience, as well as his or her knowledge of the relevant standards

and regulations, to carry out work to electrical systems, and to recognize

and avoid possible hazards on his or her own. A qualified electrician

receives training for the specific location in which he/she works, and is

acquainted with the relevant standards and regulations.

1.5 Limitation of Liability

All specifications and instructions in these operating instructions were

compiled under consideration of applicable standards and regulations, the

current state of the art and the knowledge and experience we gained over

the years.

The manufacturer assumes no liability for loss due to:

Non-compliance with these operating instructions

Use of the device not in accordance with its intended use

Use of the device by non-instructed personnel

Unauthorized device modifications

Introduction 1

enCore FC1 Operating Instructions Page 11 of 78

Technical changes

Use of non-authorized replacement parts

The actual scope of delivery may differ from the explanations and

descriptions included here in case of special device designs, the use of

additional ordering options or because of the latest technical changes.

The obligations arranged in the delivery contract apply, as do the General

Terms and Conditions, manufacturer delivery conditions and current legal

regulations that apply at the time the contract was concluded.

Read through these operating instructions carefully before

beginning any work to and with the FC1, especially before

commissioning the device!

The manufacturer assumes no liability for loss and malfunctions that

result from non-compliance with these instructions.

We reserve the right to make technical changes within the scope of

improving performance characteristics and continuous development of the

device.

1.6 Applicable Standards and Guidelines

The construction, production and operation of the FC1 are based on the

following standards and guidelines:

EN 12405-1

(Gas meters - Conversion devices - Part 1: Volume conversion)

EN 61000-6-2

(Electromagnetic compatibility - Immunity for industrial environments)

EN 61000-6-3

(Electromagnetic compatibility - Emission standard for residential,

commercial and light-industrial environments)

EN 60079-0

(Explosive atmospheres - Equipment - General requirements)

1 Introduction

Page 12 of 78 Operating Instructions enCore FC1

EN 60079-11

(Explosive atmospheres - Equipment protection by intrinsic safety "i")

EN 60079-17

(Explosive atmospheres - Electrical installations inspection and

maintenance)

EN 60079-25

(Explosive atmospheres - Intrinsically safe systems)

ISO 12213

Parts 1-3 (Natural gas – Calculation of compression factor)

ISO 6976

(Natural gas – Calculation of calorific values, density, relative density,

and Wobbe index from composition)

Safety 2

enCore FC1 Operating Instructions Page 13 of 78

2 Safety

2.1 General Safety Instructions

WARNING

Risk of explosion

A risk of explosion exists if the FC1 is improperly installed

and connected!

The FC1 must be installed outside of ex-zones 0, 1 and 2.

The FC1 can be equipped with hardware modules that are

approved as associated electrical apparatus of category ib

with intrinsically safe electrical circuits according to

EN 60079-11 (i.e. input boards with the designation ExMFE5).

The FC1 is therefore suitable for being connected to

transmitters, pulse and signal generators that are located in

hazardous areas (e.g. zone 1). A mixed connection of

intrinsically safe and non-intrinsically safe circuits to these

hardware modules is not permitted.

Only intrinsically safe protection class [EEx ib] II C

temperature and pressure transmitters must be connected to

the respective ExMFE5 connection terminals.

Only pulse transmitters of protection class [EEx ib] II C must

be connected to the respective ExMFE5 connection terminals.

All signals from the potentially explosive area (zone 0, zone 1,

zone 2) that are connected to hardware modules other than

ExMFE5 must be blocked off by means of appropriate ex-

isolators.

The regulations in the relevant standards, especially

EN 60079-0, EN 60079-11, EN 60079-17 and EN 60079-25,

must be obeyed unconditionally.

2 Safety

Page 14 of 78 Operating Instructions enCore FC1

The following safety and warning instructions must be observed

unconditionally:

Any individual appointed to perform work to or with the FC1

must read and understand these operating instructions before

beginning work. This also applies if the individual concerned

has already worked with such a device or a similar one, or was

instructed by the manufacturer.

In order to avoid risks and to ensure that the FC1 performs in

an optimal manner, no changes or modifications that were not

expressly authorized by the manufacturer may be performed to

the device.

The FC1 must not be exposed to temperatures below -25°C or

above +60°C during storage.

A temperature that is between -10°C and +55°C must be

ensured while the FC1 is being operated.

The FC1 is supplied with power by means of 24V DC, and this

power supply must be protected externally using a 1A time-

delay fuse.

The grounding is connected to PE of the power supply socket

for equipotential bonding.

The range limits stated in the certificates of conformity for the

boards to be connected (e.g. EC type examination certificate

ATEX) must be observed.

If the device is used within the scope of legal metrology, the

range limits that are stated in the respective approval

certificate (e.g. EC type examination certificate MID) must be

observed.

Section 3.6: Available Process Boards contains a description of

process boards.

Safety 2

enCore FC1 Operating Instructions Page 15 of 78

2.2 Intended Use

The FC1 is designed and constructed solely for its intended use as

described here.

The FC1 is a process computer that handles the information of external

measurement devices and signal transmitters being connected to the FC1

device.

The FC1 is primarily used for gas measurement. In this case, the main task

of the device is to convert the gas volume measured at operating conditions

to base conditions (volume conversion). Additionally, the related thermal

energy and mass can be calculated. The measured and/or calculated data

can be logged and monitored.

The FC1 device may also carry out other functions and calculations (e.g. a

mass or volume conversion for liquids). Please refer to Part 3 of the FC1

Manual for a description of available functions (AFBs).

In addition, the FC1 can be used to measure, record and monitor other

process signals.

Compliance with all the specifications in these operating instructions also

falls under the device's intended use.

Any use of the FC1 that goes beyond or deviates from its intended use is

considered a misuse of the device, and may lead to hazardous situations.

Claims of any kind due to loss resulting from non-intended use of the device

are excluded.

2 Safety

Page 16 of 78 Operating Instructions enCore FC1

2.3 Unauthorized Users

Individuals whose ability to react is impaired, e.g. because of drugs, alcohol

or medication as well as physical or health restrictions are not permitted to

operate, assemble or configure the device.

2.4 Operator Liability

The FC1 is used in industrial applications. The FC1 operator is therefore

subject to legal obligations of occupational health and safety.

In addition to the safety instructions in these operating instructions, current

regulations of safety, accident prevention and environmental protection must

be observed for the FC1 area of application.

The following items especially apply:

The operator must ensure compliance with the current regulations of

safety, accident prevention and environmental protection that apply for

the overall system in which the FC1 is integrated.

The operator must keep himself/herself informed of the applicable

occupational health and safety regulations, and determine, over the

course of a risk assessment, the additional risks that arise from the

specific working conditions when the FC1 is being used. The operator

must include these items in the form of operating instructions for the

FC1.

The operator must review, over the entire operational life of the FC1,

whether the operating instructions prepared by him or her correspond to

the current status of the bodies of regulations, and revise the

instructions if necessary.

When selecting personnel to operate the device, make sure you

comply with the specific regulations of the overall technical plant

that concern age and occupation.

Safety 2

enCore FC1 Operating Instructions Page 17 of 78

The operator must definitively regulate and establish the responsibilities

for FC1 assembly, connection, commissioning, operation and

maintenance.

The operator must ensure that all employees who work with the FC1

have read and understood these operating instructions. In addition, the

operator must train these personnel at regular intervals and inform them

of the risks involved with the device.

The operator of the overall system in which the FC1 is integrated must

provide personnel with the required protective equipment.

In addition, the operator is responsible for ensuring the FC1 is always in

technically perfect condition. The following items therefore apply:

The operator must ensure that the installation and maintenance work

described in these operating instructions are performed properly.

The operator must have all safety installations checked regularly to

ensure they function correctly and are complete.

3 Design and Function

Page 18 of 78 Operating Instructions enCore FC1

3 Design and Function

3.1 enCore and enSuite

enCore is the name of an Elster product platform for sophisticated

measuring instruments. All enCore devices are based on the same hardware

components and software concepts.

enSuite is the name of the PC software that supports enCore devices along

with a number of other Elster devices. The enSuite software provides tools

for configuration, parameterization, diagnosis, software download and other

services.

The enCore FC1 device is a process computer based on the enCore

platform.

3.2 FC1 Flow Computer: Functional Description

The FC1 is a process computer that is primarily used as flow computer for

natural gas, i.e. for measuring and calculating the gas flow (flow conversion).

Please refer to Part 3 of the FC1 manual for information about further fields

of application.

If the FC1 is used for flow conversion, various measuring instruments have

to be connected to the device (gas meters, pressure transmitters,

temperature transmitters and optional gas quality measurement devices).

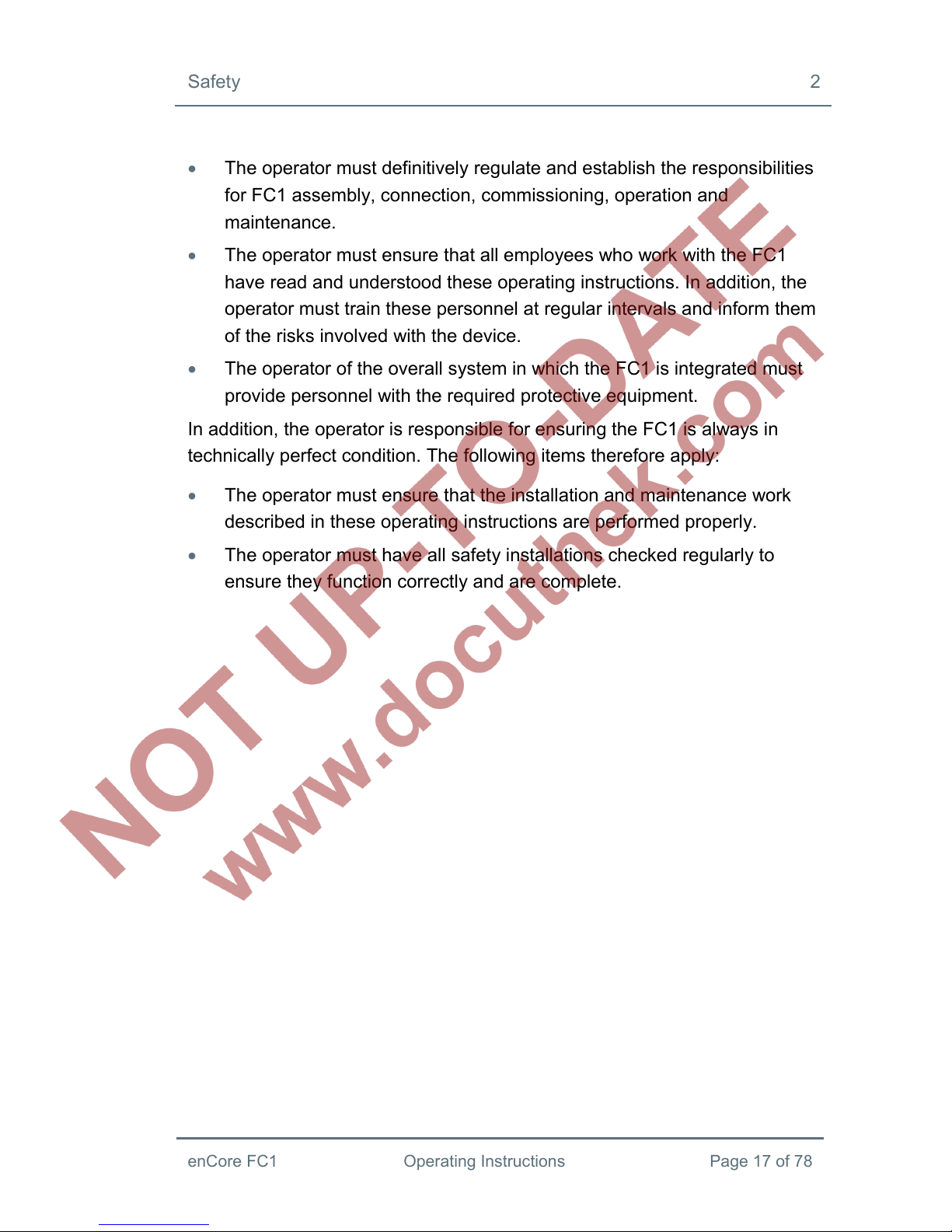

The FC1 has different interface options available for each of these

measuring instrument types:

Device Type Connection Option

Gas meter Pulse interface for turbine, rotary piston or

other pulse-generating gas meters.

Serial interface for ultrasonic gas meters via a

manufacturer-specific digital protocol

Interface for gas meters with an Encoder index

Design and Function 3

enCore FC1 Operating Instructions Page 19 of 78

Pressure transmitter 4…20 mA analog input

HART protocol interface

Temperature

transmitter

Resistance input for Pt100 with 4-wire

technology

HART protocol interface

Gas quality

measurement devices

Serial interface

TCP/IP interface

Table 1

Number of streams and their flow directions

The number of streams and their flow directions is variable since device

hardware and software can be extended. This number depends upon the

number of board slots available, individual hardware settings and the

software configuration.

European standards

The FC1 supports the following European standards for the calculation of

gas characteristics being used for flow conversion:

Value Selectable Calculation Standard

Compressibility AGA8-92 DC (ISO 12213-2)

SGERG-88 (ISO 12213-3)

AGA-NX19 mod

AGA-NX19 mod BR.KOR.3H

AGA-NX19 GOST

Density,

Relative density

AGA8-92 DC

ISO 6976

Heating values,

Wobbe index

ISO 6976

Table 2

3 Design and Function

Page 20 of 78 Operating Instructions enCore FC1

Dependent on the field of application, other European or International

standards are supported as well.

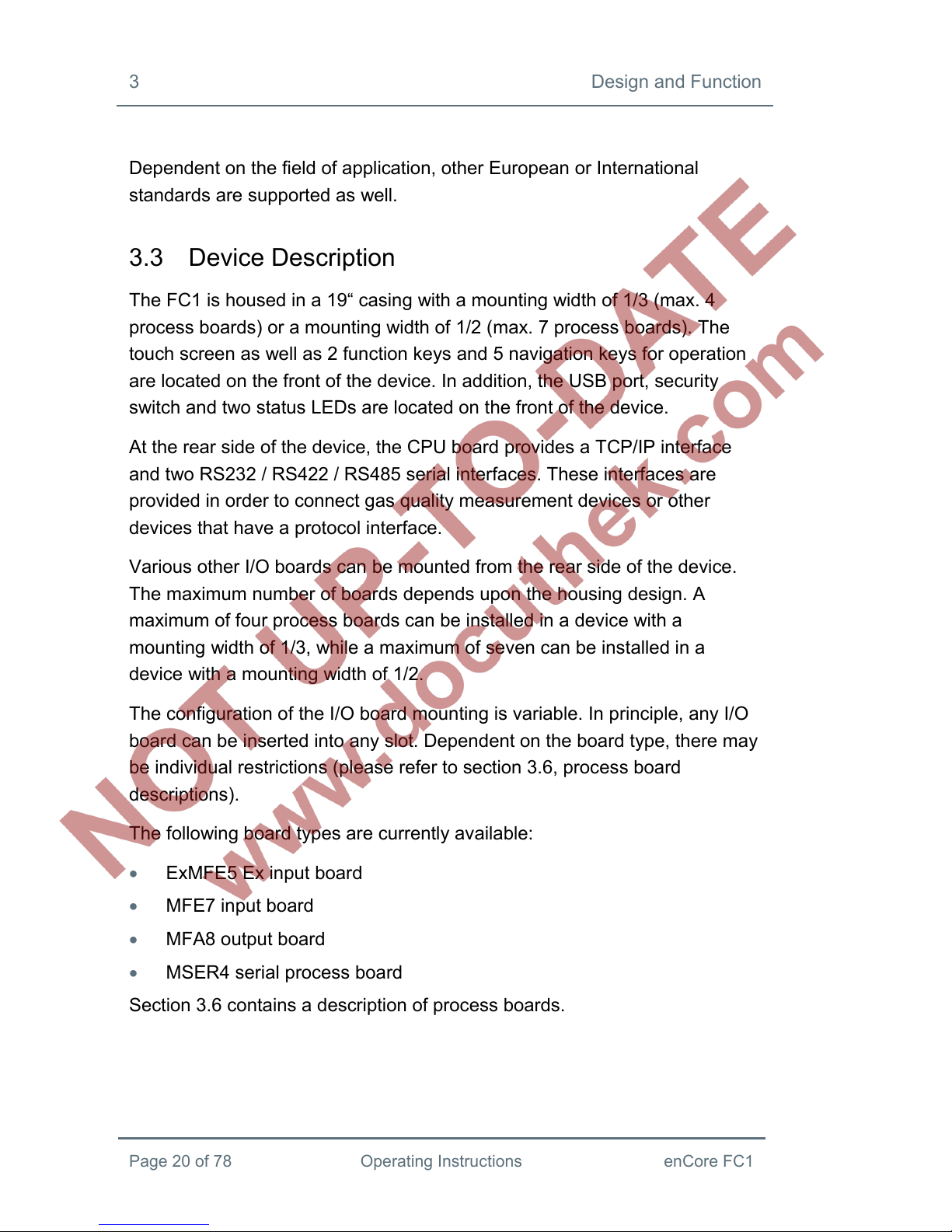

3.3 Device Description

The FC1 is housed in a 19“ casing with a mounting width of 1/3 (max. 4

process boards) or a mounting width of 1/2 (max. 7 process boards). The

touch screen as well as 2 function keys and 5 navigation keys for operation

are located on the front of the device. In addition, the USB port, security

switch and two status LEDs are located on the front of the device.

At the rear side of the device, the CPU board provides a TCP/IP interface

and two RS232 / RS422 / RS485 serial interfaces. These interfaces are

provided in order to connect gas quality measurement devices or other

devices that have a protocol interface.

Various other I/O boards can be mounted from the rear side of the device.

The maximum number of boards depends upon the housing design. A

maximum of four process boards can be installed in a device with a

mounting width of 1/3, while a maximum of seven can be installed in a

device with a mounting width of 1/2.

The configuration of the I/O board mounting is variable. In principle, any I/O

board can be inserted into any slot. Dependent on the board type, there may

be individual restrictions (please refer to section 3.6, process board

descriptions).

The following board types are currently available:

ExMFE5 Ex input board

MFE7 input board

MFA8 output board

MSER4 serial process board

Section 3.6 contains a description of process boards.

Design and Function 3

enCore FC1 Operating Instructions Page 21 of 78

3.4 Control Panel

Figure 3-1: FC1 control panel

- Navigation keys

- Function keys

- Touch screen

- Security switch

- Power LED

- Status LED

- USB port for PC connection

1

2

3

4

5

6

2

4

5

6

7

2

1

3

7

3 Design and Function

Page 22 of 78 Operating Instructions enCore FC1

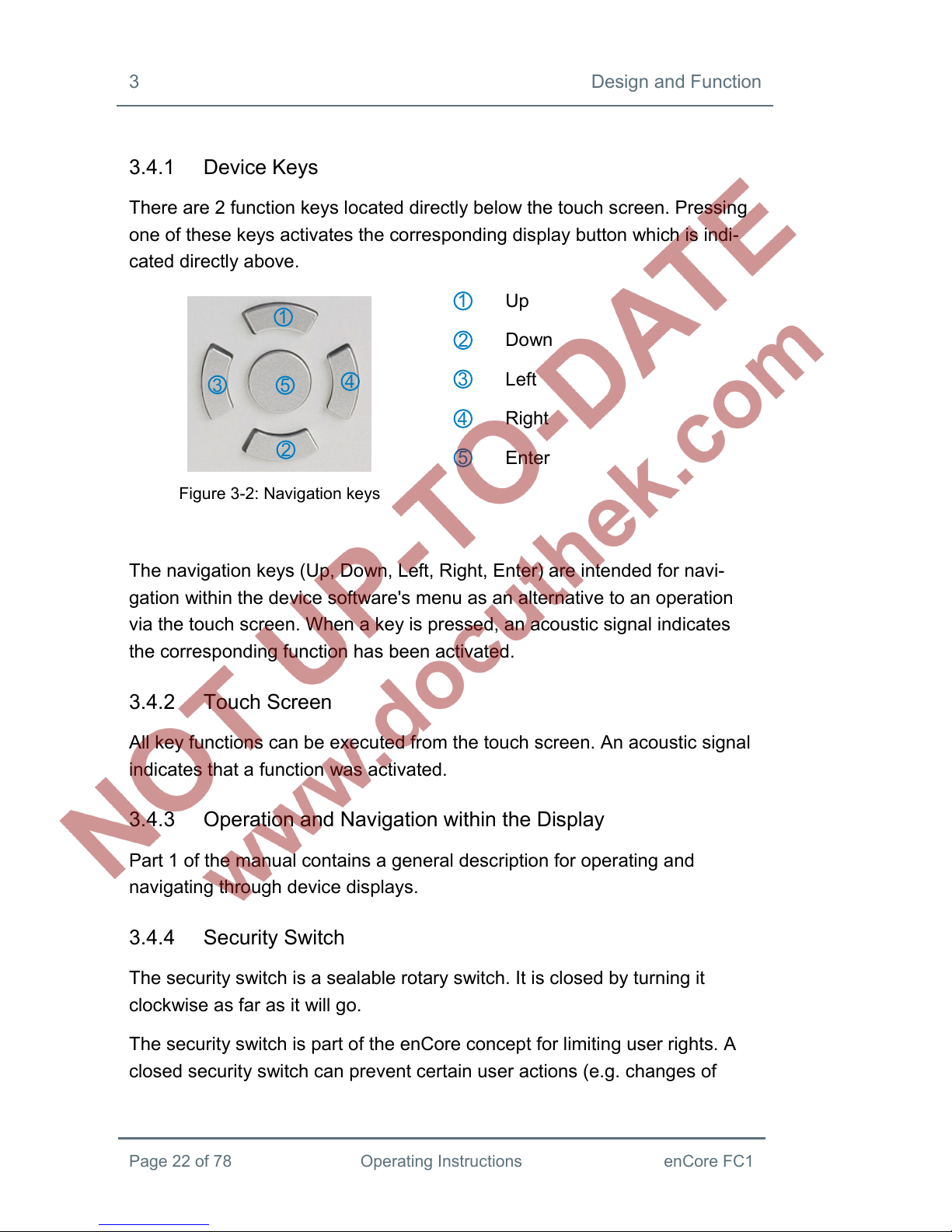

3.4.1 Device Keys

There are 2 function keys located directly below the touch screen. Pressing

one of these keys activates the corresponding display button which is indi-

cated directly above.

Figure 3-2: Navigation keys

Up

Down

Left

Right

Enter

The navigation keys (Up, Down, Left, Right, Enter) are intended for navi-

gation within the device software's menu as an alternative to an operation

via the touch screen. When a key is pressed, an acoustic signal indicates

the corresponding function has been activated.

3.4.2 Touch Screen

All key functions can be executed from the touch screen. An acoustic signal

indicates that a function was activated.

3.4.3 Operation and Navigation within the Display

Part 1 of the manual contains a general description for operating and

navigating through device displays.

3.4.4 Security Switch

The security switch is a sealable rotary switch. It is closed by turning it

clockwise as far as it will go.

The security switch is part of the enCore concept for limiting user rights. A

closed security switch can prevent certain user actions (e.g. changes of

5

4

3

2

1

1

2

3

4

5

Design and Function 3

enCore FC1 Operating Instructions Page 23 of 78

certain parameters or software download of fiscal or non-fiscal firmware

modules).

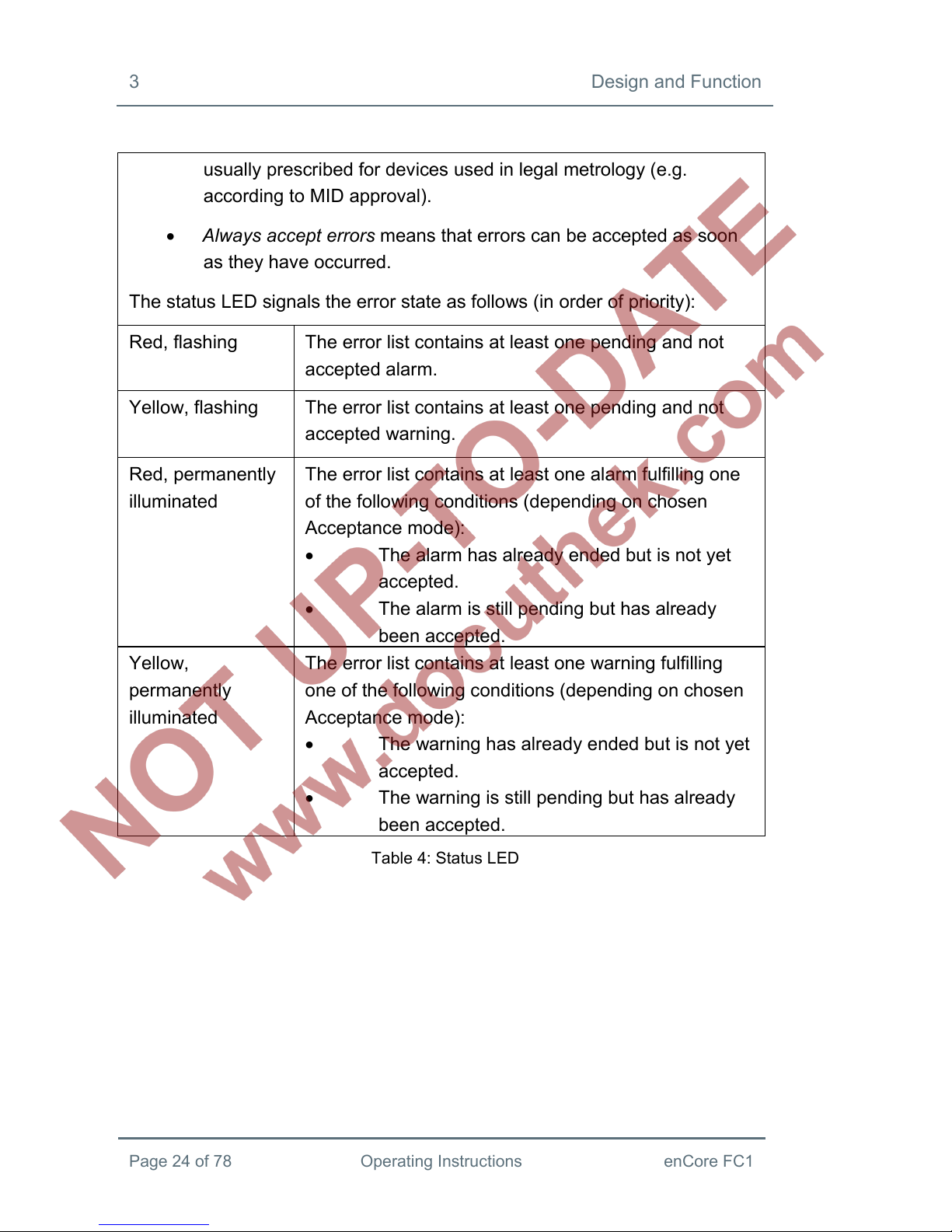

3.4.5 LEDs

There are two multicolor LEDs on the front panel, the Power LED and the

Status LED.

Power LED

LED status Meaning

Off Power off; no USB connection

Red Power off; USB connection detected

Green Power on; no USB connection

Orange Power on; USB connection active

Table 3: Power LED

Status LED

LED Status Meaning

Off Power off.

Green, flashing

A green flashing light appears during the start-up

phase after a power failure.

Green, perma-

nently illuminated

The device is working error-free, i.e. there are no

pending or not accepted alarms or warnings in the

error list. Please refer to the corresponding chapter in

Part 1 of the enCore FC1 Manual for detailed

information about alarms and warnings.

A red or yellow colored status LED indicates a currently pending or not

accepted error of alarm or warning type.

The setting of the Acceptance mode parameter determines under which

circumstances errors can be accepted:

Only accept inactive errors means that the acceptance of errors is

not possible as long as they are still pending. This setting is

3 Design and Function

Page 24 of 78 Operating Instructions enCore FC1

usually prescribed for devices used in legal metrology (e.g.

according to MID approval).

Always accept errors means that errors can be accepted as soon

as they have occurred.

The status LED signals the error state as follows (in order of priority):

Red, flashing

The error list contains at least one pending and not

accepted alarm.

Yellow, flashing

The error list contains at least one pending and not

accepted warning.

Red, permanently

illuminated

The error list contains at least one alarm fulfilling one

of the following conditions (depending on chosen

Acceptance mode):

The alarm has already ended but is not yet

accepted.

The alarm is still pending but has already

been accepted.

Yellow,

permanently

illuminated

The error list contains at least one warning fulfilling

one of the following conditions (depending on chosen

Acceptance mode):

The warning has already ended but is not yet

accepted.

The warning is still pending but has already

been accepted.

Table 4: Status LED

Design and Function 3

enCore FC1 Operating Instructions Page 25 of 78

3.5 Interfaces (Rear Side of Device)

Figure 3-3: Rear side of device (example 1/3 mounting width)

- TCP/IP interface (computer network)

- Serial interfaces

- 24V DC power supply

- Optional process boards

1

2

3

4

1

2

3

4

3 Design and Function

Page 26 of 78 Operating Instructions enCore FC1

3.6 Available Process Boards

The configuration of the I/O board mounting is variable. In principle, any I/O

board can be inserted into any slot. If there are any restrictions, they are

mentioned in the following paragraphs describing the individual boards.

Please refer to section 4.3 for a description of how the I/O board

configuration can be modified. Section 4.4 contains connection diagrams for

typical applications.

3.6.1 ExMFE5 Process Board

All ExMFE5 inputs are intrinsically safe ([EEx ib] IIC).

Three NAMUR inputs (Z1+/Z1-, Z2+/Z2-, Z3+/Z3-) for

messages, LF pulses or HF pulses. Pulse inputs are

typically used to connect gas meters that have a pulse

interface.

As an alternative, the first channel is suitable for

connecting a gas meter via an Encoder index.

A resistance input with 4-wire technology (I+/U+/U-/I-),

provided for connecting a Pt100 temperature sensor.

An analog current input 4…20mA (P+ / P-), alternatively

usable as a HART interface. Provided for connecting

measuring instruments that have a current output (e.g.

pressure transmitters) or HART interface (e.g. pressure

transmitters or temperature transmitters).

Two different modes are possible when using the current

input as a HART interface:

Fig. 3-4

- Multi-drop mode for a maximum of 4 HART devices

- Burst mode: 1 HART device

Design and Function 3

enCore FC1 Operating Instructions Page 27 of 78

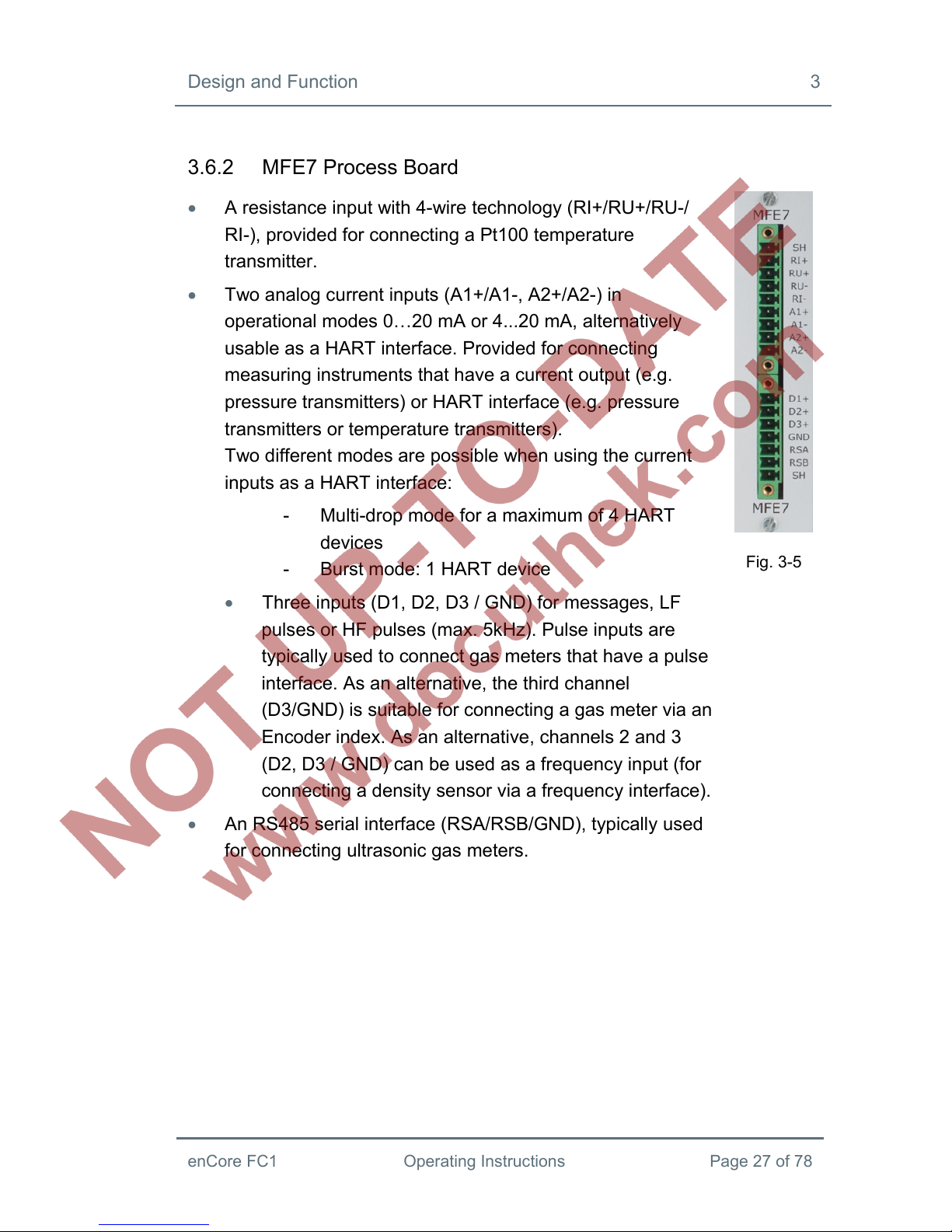

3.6.2 MFE7 Process Board

A resistance input with 4-wire technology (RI+/RU+/RU-/

RI-), provided for connecting a Pt100 temperature

transmitter.

Two analog current inputs (A1+/A1-, A2+/A2-) in

operational modes 0…20 mA or 4...20 mA, alternatively

usable as a HART interface. Provided for connecting

measuring instruments that have a current output (e.g.

pressure transmitters) or HART interface (e.g. pressure

transmitters or temperature transmitters).

Two different modes are possible when using the current

inputs as a HART interface:

- Multi-drop mode for a maximum of 4 HART

devices

- Burst mode: 1 HART device

Three inputs (D1, D2, D3 / GND) for messages, LF

pulses or HF pulses (max. 5kHz). Pulse inputs are

typically used to connect gas meters that have a pulse

interface. As an alternative, the third channel

(D3/GND) is suitable for connecting a gas meter via an

Encoder index. As an alternative, channels 2 and 3

(D2, D3 / GND) can be used as a frequency input (for

connecting a density sensor via a frequency interface).

An RS485 serial interface (RSA/RSB/GND), typically used

for connecting ultrasonic gas meters.

Fig. 3-5

3 Design and Function

Page 28 of 78 Operating Instructions enCore FC1

3.6.3 MSER4 Process Board

Four serial interfaces, each for one protocol channel (CH1,

CH2, CH3, CH4), supporting RS485 / RS422 / RS232. For

example used for connecting gas quality measurement

devices via digital protocol.

For devices with a mounting width of 1/3, a

maximum of one MSER4 board can be mounted in

slot 4 only. For devices with a mounting width of 1/2,

up to two MSER4 boards can be mounted in slots 6

and 7 only.

Fig. 3-6

3.6.4 MFA8 Process Board

One digital message output (D1a/D1b)

Three digital outputs (D2+/D2-, D3+/D3-) for messages or

LF pulses (max. 25 Hz).

Four analog outputs (I1, I2, I3 / I-) 0...20 mA or 4…20 mA

for measurements.

Fig. 3-7

Assembly and Installation 4

enCore FC1 Operating Instructions Page 29 of 78

4 Assembly and Installation

The FC1 is provided for assembly within a 19" cabinet, and is available in

either a mounting width of 1/3 or a mounting width of 1/2 model. Compliance

with the device's installation depth of 170 mm (with plugs approx. 220 mm) is

necessary so the connection terminals located on the rear of the device

remain accessible.

The FC1 must be installed in an Ex-free installation area (electrical

operating area) outside of ex-zones 0, 1 and 2, in accordance with

protection class IP 20.

It is recommended that the FC1 be installed in a swivel frame.

4.1 Line Connection

WARNING!

Risk of explosion

A risk of explosion exists when connecting any lines to the

ExMFE5 board while the FC1 is powered on!

- Only connect transmitter, pulse generator or signal lines

to the ExMFE5 board when the power supply of the FC1

is disconnected completely.

4 Assembly and Installation

Page 30 of 78 Operating Instructions enCore FC1

ATTENTION!

Risk of short circuit

The FC1 device may be damaged when connecting any lines

while the FC1 is powered on.

- Always make sure the power supply of the FC1 is

disconnected completely before making any change to

device wiring or before connecting transmitter, pulse

generator, signal or data lines.

The transmitter, pulse generator, signal and data lines are connected to the

FC1 by using plug-in screw terminals, each of which is located in a cable

terminal box. Fixed screw terminals are used for the power supply

connection.

Special attention must be paid to the intrinsically safe electrical circuits.

Before switching on the power supply, make sure that the plug connections

for the gas meter, pressure and temperature inputs of the ExMFE5 input

board are inserted, since this is the only way the straight line-gap of 50 mm

required in the relevant guidelines can be maintained.

The relevant installation guidelines must be observed when arranging the

wiring.

The lines must be free of tensile stress and must be provided with a kink

protection if the FC1 is mounted in a swivel frame.

Dimension the cable length in such a way that there is no tensile stress on

the cables when the swivel frame is opened up.

It is recommended that all incoming lines be placed on transfer terminals in a

switch cabinet, and then be connected with the FC1 from that point.

However, these terminals have to comply in part with the Ex-regulations, and

must possibly also be sealable, for example in order to fulfill the

requirements of an applicable approval.

Assembly and Installation 4

enCore FC1 Operating Instructions Page 31 of 78

4.2 Power Supply and Grounding

Hazardous Are

a

Safe Are

a

FC1 device

fuse 1A

slow

0V 24V

CPU board

PE

0V

24V

Figure 4-1

The FC1 must be operated with a nominal voltage of 24V DC.

The 24V power supply is connected via the + and – terminals at the rear of

the device, and must be protected externally using a 1A time-delay fuse.

The device is protected internally by means of a self-resetting overcurrent

protection component.

The grounding is connected to PE of the power supply socket for

equipotential bonding.

4.3 Mounting of Process Boards

In delivery condition, the device’s process board equipment is configured as

ordered. Due to the modular hardware concept, it is possible to mount

additional process boards in free slots or to modify the board configuration

even later on.

4 Assembly and Installation

Page 32 of 78 Operating Instructions enCore FC1

For safety reasons, any modifications of the process board

configuration should be carried out only by the manufacturer's

service department or by an appropriately trained specialist

working for the plant operator.

The housing of the device must be opened in order to add or

change process boards. The presence of a metrology expert may

be required for this purpose when the device is being used within

the scope of legal metrology.

ATTENTION!

Risk of short circuit

The FC1 device may be damaged when opening the device

while the FC1 is powered on.

- Always make sure the power supply of the FC1 is

disconnected completely before opening the device.

ATTENTION!

The integrated circuits of process boards may be destroyed

by electrostatic discharge.

- While working on the device for changing the I/O board

configuration, an ESD protected workplace according to

EN 61340-5-1 (ESD pad and ESD wrist strap) must be

used.

Assembly and Installation 4

enCore FC1 Operating Instructions Page 33 of 78

ATTENTION!

Incorrect replacement parts and accessories are a safety risk!

Incorrect or defective replacement parts and accessories may

detract from safety and lead to damage, malfunction, or total

device failure.

- Use only original replacement parts and accessories from

the manufacturer.

- Always contact the manufacturer if you are in doubt.

Procedure for mounting a process board into a free slot

(The procedure for changing or removing boards is similar.)

1. Ensure that all necessary accessories are available: Process board,

fitting labeling plate, and jumpers.

2. Use enSuite to read-out the parameterization of the FC1. (If necessary,

the enSuite installation on the computer has to be executed or updated

before, please refer to section 5.1.2).

3. Disconnect the power supply.

4. Remove all external cable connections to the device.

5. Remove the 4 mounting screws (positions A) from the rear side wall of

the device.

4 Assembly and Installation

Page 34 of 78 Operating Instructions enCore FC1

Figure 4-2: Rear side of device (example), mounting screws removed

6. Pull the board cage carefully straight out of the housing.

Figure 4-3: Pulling out the board cage

A

A

Assembly and Installation 4

enCore FC1 Operating Instructions Page 35 of 78

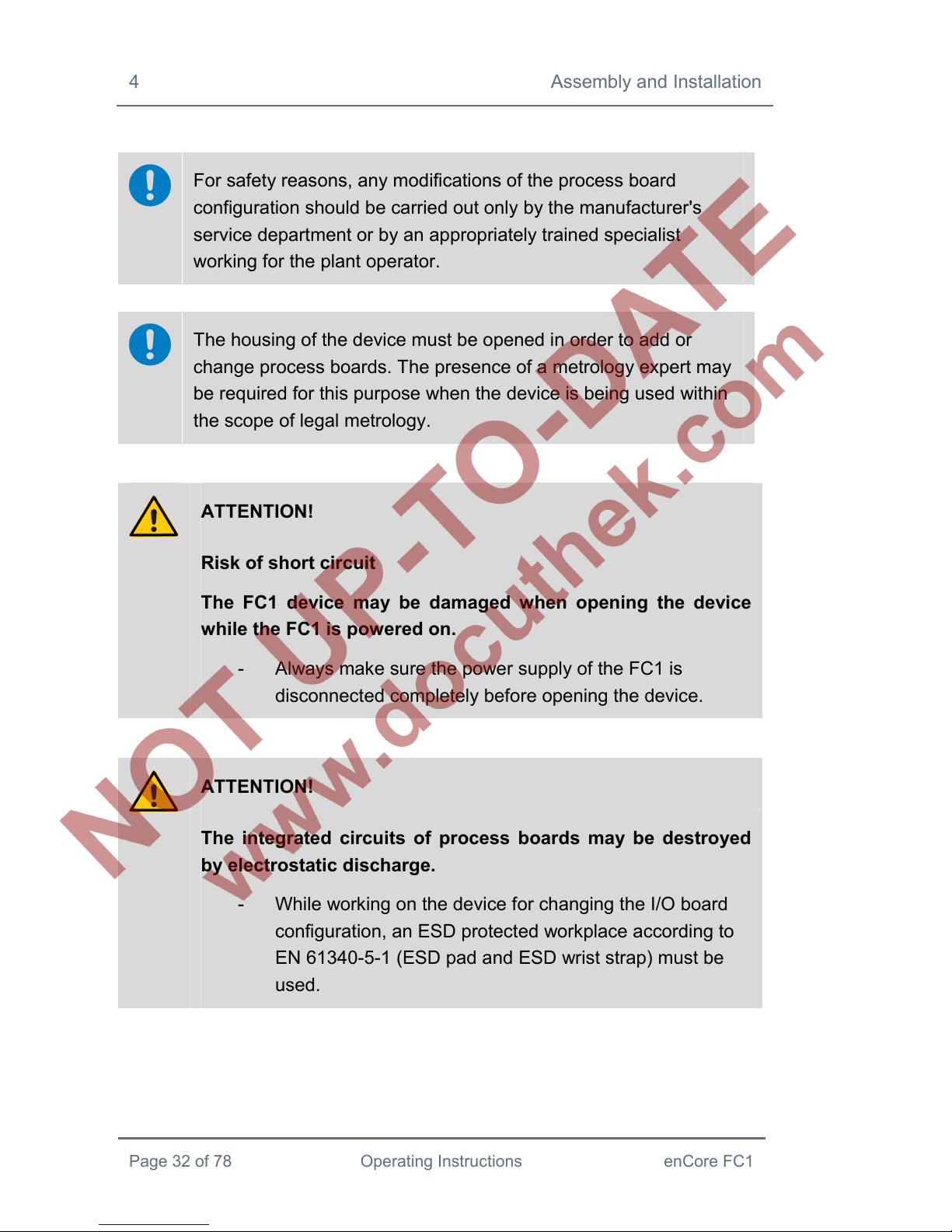

Figure 4-4: Dismounted board cage

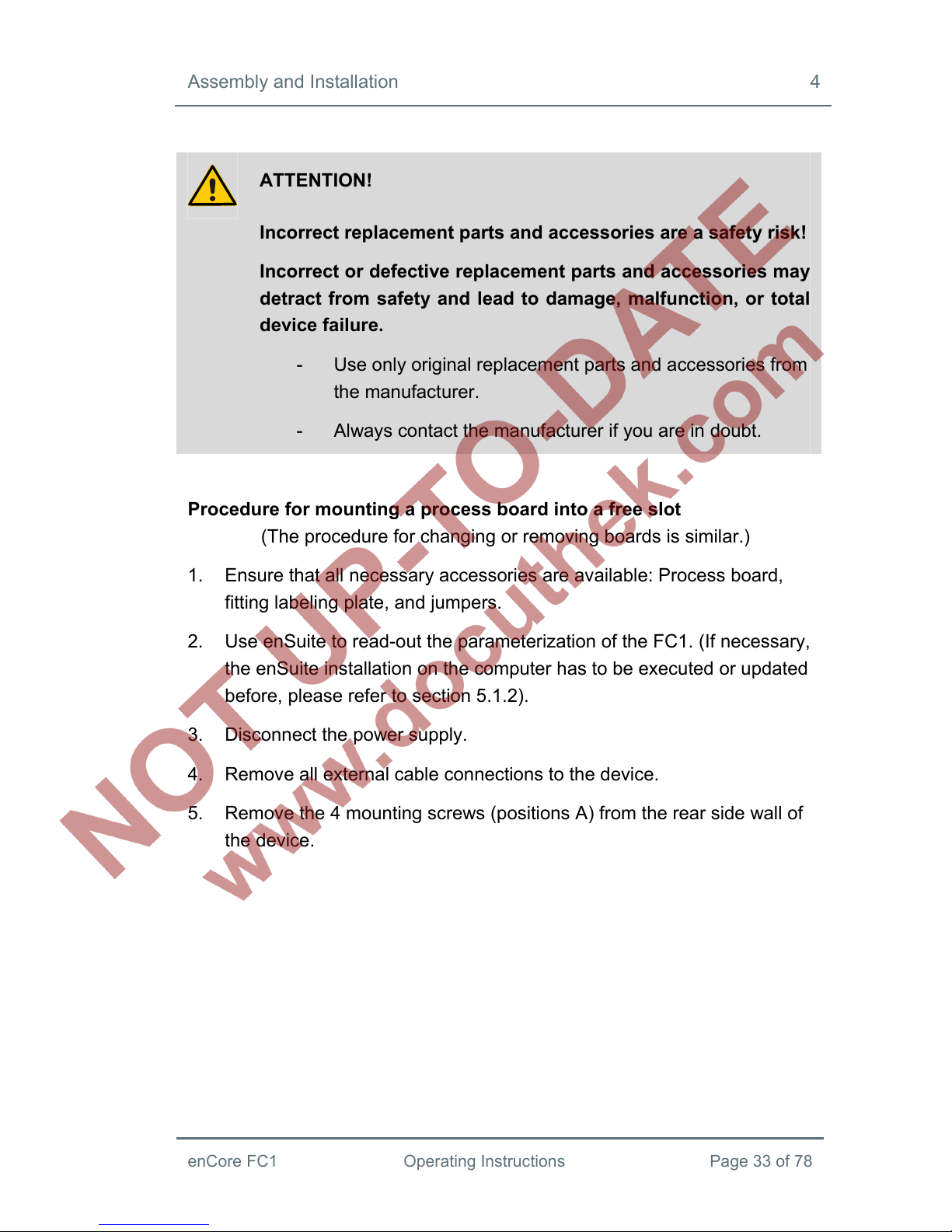

7. Check the position for the additional board (number of the slot). This

number has also to be configured as the board’s number, which is

essential for the functioning of the internal I/O bus communication later

on.

To set the number on the board, place jumpers on the respective pin

connector accordingly (please refer to Figures 4-5 and 4-6).

=

jumper

Board position

(slot no.)

1 2 3 4 5 6 7

Figure 4-5: Pin connector with jumper positions

8. Remove the covering plate of the respective slot (2 screws).

9. Insert the board in the slot of the rear side wall (the side for process

connection, blue connector for Ex boards, green connector else, cf.

Figure 4-2).

Make sure that the orientation of the board (top/bottom) is correct:

On the opposite side, the pin connector for the I/O bus connection (with

4 Assembly and Installation

Page 36 of 78 Operating Instructions enCore FC1

retaining clip) has to face downwards, to the bottom of the device (cf.

Figure 4-6, position B). The pin connector for determining the board

number has to face upwards (cf. Figure 4-6, position C).

Pin connector for I/O bus connection (with retaining clip)

Pin connector for determining the board number (here: 4)

Figure 4-6: Interior view of the board cage

10. Place the board’s labeling plate at the rear side of the device and fix

labeling plate and board using the screws.

11. Plug-in the connector for the internal I/O bus at the other side of the

board. The retaining clip closes automatically. Check that all other bus

connectors are still plugged in correctly.

12. Re-insert the board cage carefully into the housing. Press gently to

reinstall the plug-in connection between CPU and display board.

C

B

B

C

Assembly and Installation 4

enCore FC1 Operating Instructions Page 37 of 78

13. Close the device by means of the 4 mounting screws (positions A in

Figure 4-2).

14. Restore all external cable connections to the FC1.

15. Reconnect the power supply.

16. Use enSuite to edit the read-out parameterization by taking the new

board configuration into consideration. Add the new board to the

parameterization (parameter branch Basic System - I/O – I/O boards)

and adjust all settings for its process connection.

Transfer the edited parameterization to the device.

Please refer to FC1 Manual Part 3a for further information on the

parameterization process.

Section 4.4 contains connection diagrams for typical applications.

4.4 Connection Diagrams

This section shows connection diagrams for measuring instruments that are

typically connected to an FC1 flow computer (e.g. temperature and pressure

transmitters, gas meter and gas quality measurement devices).

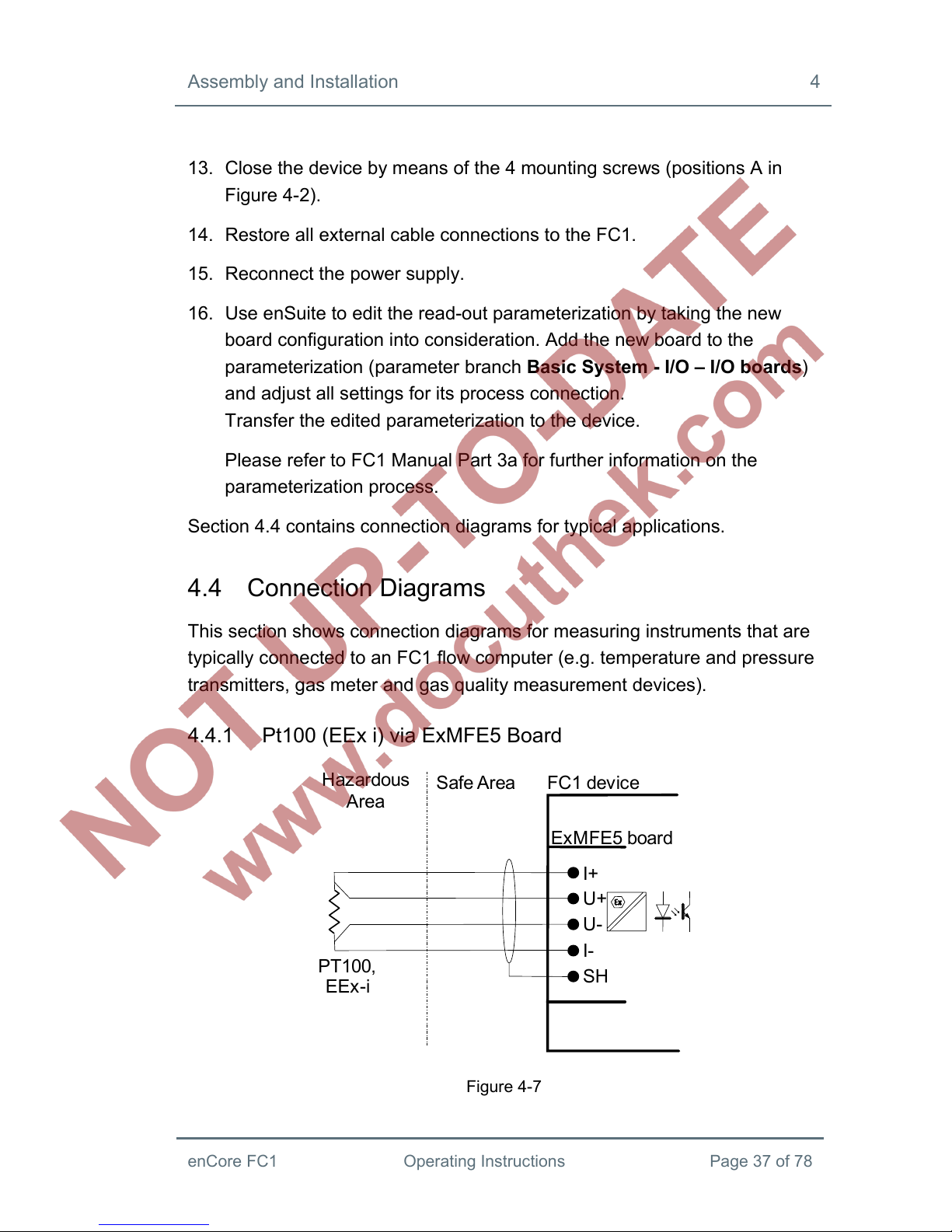

4.4.1 Pt100 (EEx i) via ExMFE5 Board

Hazardous

Area

Safe Area FC1 device

ExMFE5 board

I+

U+

U-

I-

SH

PT100,

EEx-i

Figure 4-7

4 Assembly and Installation

Page 38 of 78 Operating Instructions enCore FC1

4.4.2 Pt100 (EEx d) via MFE7 Board

Hazardous

Area

Safe Area FC1 device

MFE7 board

RI+

RU+

RU-

RI-

SH

PT100,

EEx-d

Figure 4-8

4.4.3 Analog Pressure Transmitter (EEx i) via ExMFE5 Board

Hazardou

s

Area

Safe Area FC1 device

ExMFE5 board

P+

P-

SH

analog pressure

transmitter

4...20 mA EEx-i

Figure 4-9

Parameterization note: Select Current input.

Assembly and Installation 4

enCore FC1 Operating Instructions Page 39 of 78

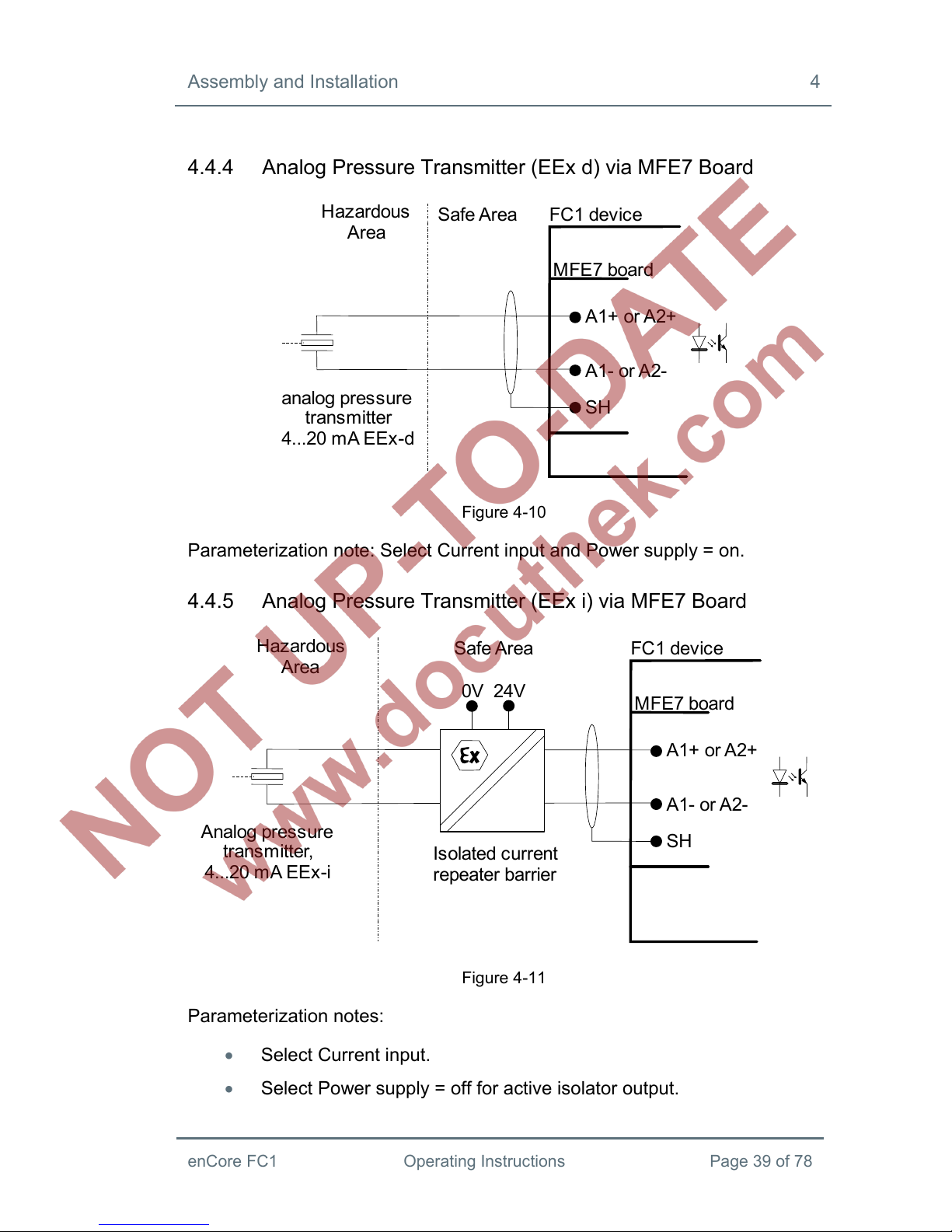

4.4.4 Analog Pressure Transmitter (EEx d) via MFE7 Board

Hazardous

Area

Safe Area FC1 device

MFE7 board

A1+ or A2+

A1- or A2-

SH

analog pressure

transmitter

4...20 mA EEx-d

Figure 4-10

Parameterization note: Select Current input and Power supply = on.

4.4.5 Analog Pressure Transmitter (EEx i) via MFE7 Board

Hazardous

Area

Safe Area FC1 device

MFE7 board

A1+ or A2+

A1- or A2-

SH

A

nalog pressure

transmitter,

4...20 mA EEx-i

0V 24V

Isolated current

repeater barrier

Figure 4-11

Parameterization notes:

Select Current input.

Select Power supply = off for active isolator output.

4 Assembly and Installation

Page 40 of 78 Operating Instructions enCore FC1

Select Power supply = on for passive isolator output.

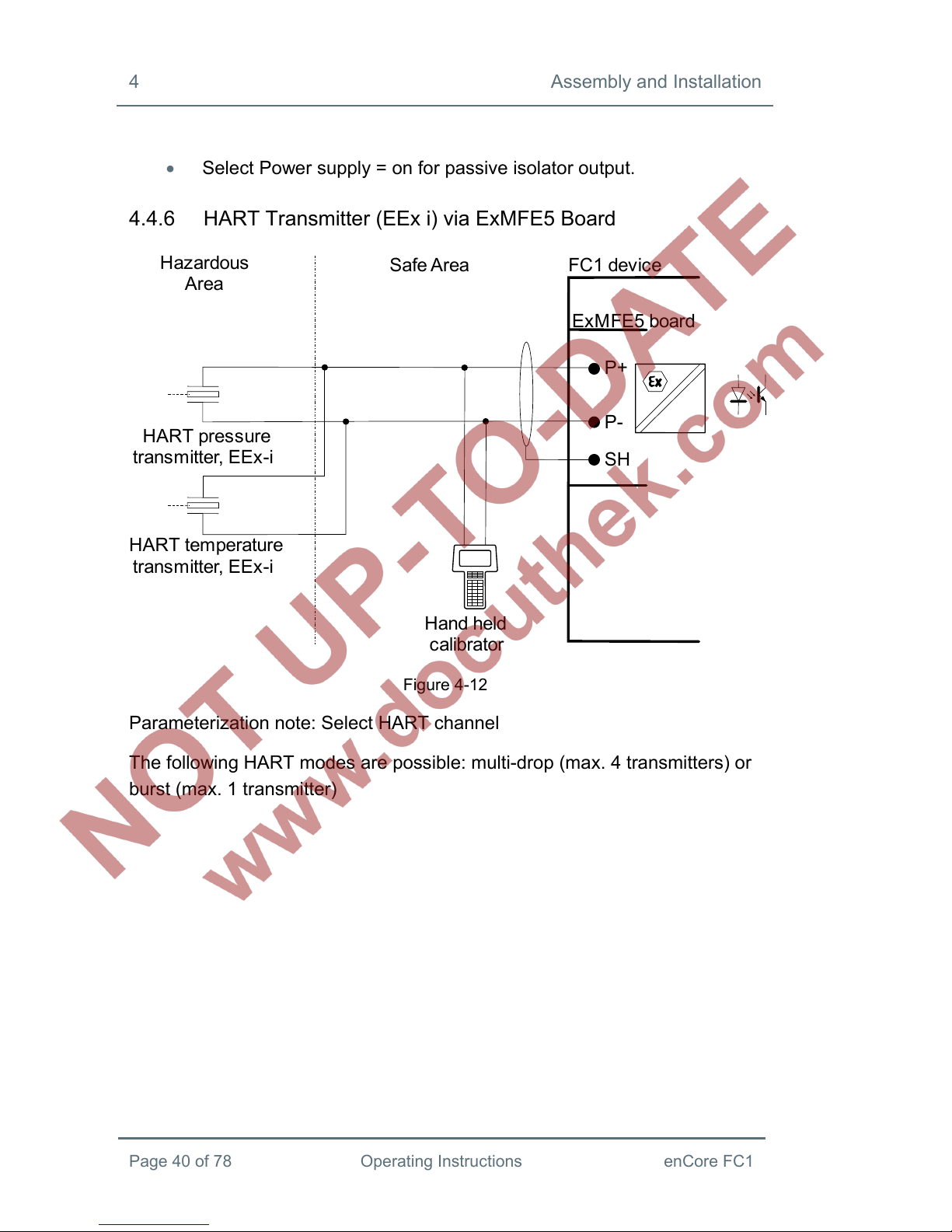

4.4.6 HART Transmitter (EEx i) via ExMFE5 Board

Hazardou

s

Area

Safe Are

a

FC1 devic

e

ExMFE5 board

P-

P+

SH

HART pressure

transmitter, EEx-i

HART temperatur

e

transmitter, EEx-i

Hand held

Figure 4-12

Parameterization note: Select HART channel

The following HART modes are possible: multi-drop (max. 4 transmitters) or

burst (max. 1 transmitter)

Assembly and Installation 4

enCore FC1 Operating Instructions Page 41 of 78

4.4.7 HART Transmitter (EEx d) via MFE7 Board (Internal Power

Supply)

Figure 4-13

Parameterization note:

Select HART channel and

Power supply = on

The following HART modes are possible: Multi-drop mode (max. 4

transmitters) or burst mode (max. 1 transmitter)

4 Assembly and Installation

Page 42 of 78 Operating Instructions enCore FC1

4.4.8 HART Transmitter (EEx d) via MFE7 Board (External Power

Supply)

Figure 4-14

Parameterization note:

Select HART channel and

Power supply = off

The following HART modes are possible: Multi-drop mode (max. 4

transmitters) or burst mode (max. 1 transmitter)

Assembly and Installation 4

enCore FC1 Operating Instructions Page 43 of 78

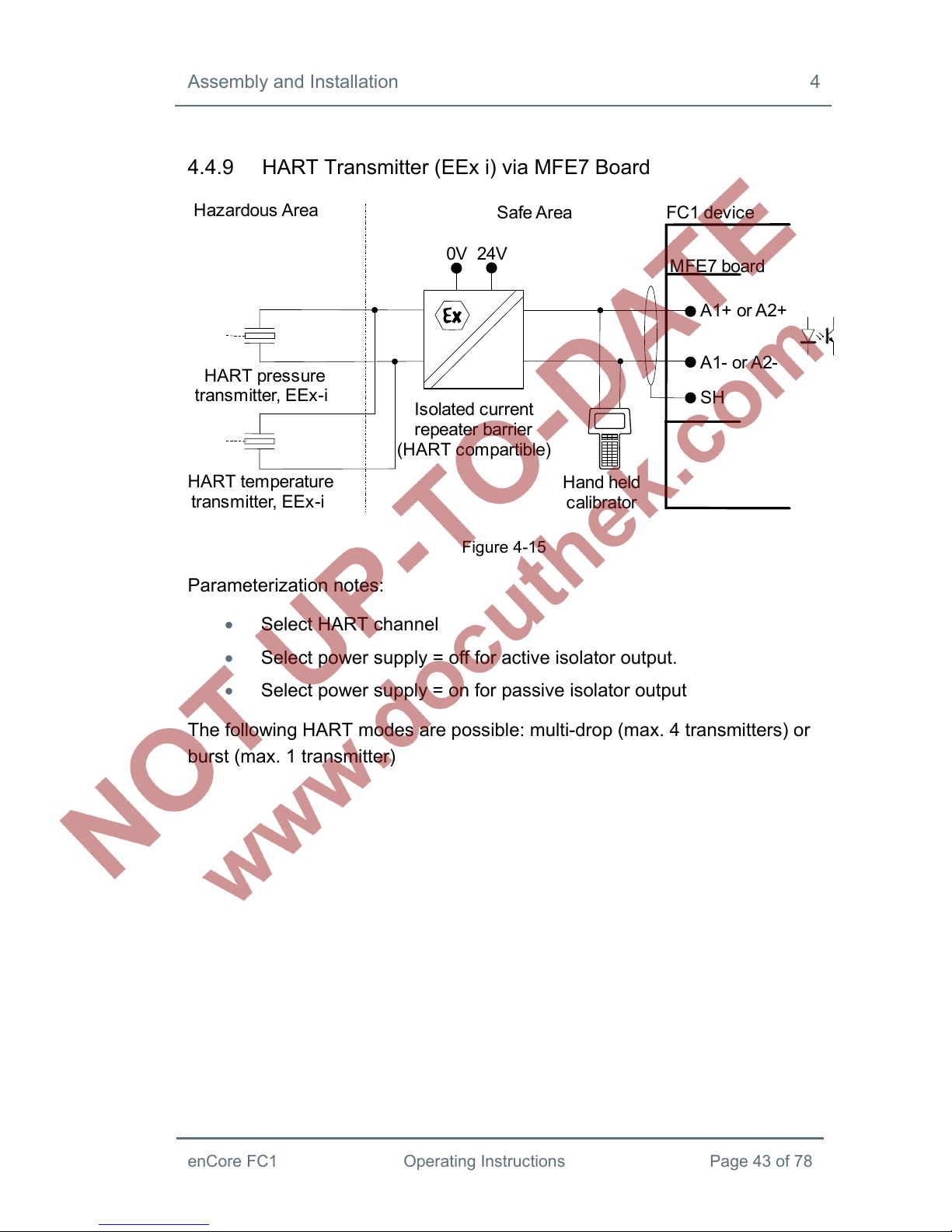

4.4.9 HART Transmitter (EEx i) via MFE7 Board

Hazardous Are

a

Safe Are

a

FC1 device

MFE7 board

A1+ or A2+

A1- or A2-

SH

HART pressure

transmitter, EEx-i

0V 24V

Isolated current

repeater barrier

(HART compartible)

HART temperatur

e

transmitter, EEx-i

Hand held

calibrator

Figure 4-15

Parameterization notes:

Select HART channel

Select power supply = off for active isolator output.

Select power supply = on for passive isolator output

The following HART modes are possible: multi-drop (max. 4 transmitters) or

burst (max. 1 transmitter)

4 Assembly and Installation

Page 44 of 78 Operating Instructions enCore FC1

4.4.10 HART Transmitter (EEx d) via MFE7 Board

(redundant)

Hazardous

Area

Safe Area

FC1 device 2

FC1 device 1

MFE7 board

MFE7 board

A1- or A2-

A1+ or A2+

SH

HART transmitter

EEx-d

A1- or A2-

A1+ or A2+

SH

Hand held

calibrator

Figure 4-16

Parameterization note:

Select HART channel and

Power supply = on (device 1)

Power supply = off (device 2)

Burst HART mode only (max. 1 transmitter).

Assembly and Installation 4

enCore FC1 Operating Instructions Page 45 of 78

4.4.11 HART Transmitter (EEx i) via MFE7 Board

(redundant)

Hazardous

Area

Safe Area

FC1 device 2

FC1 device

1

MFE7 board

MFE7 board

A1- or A2-

SH

A1+ or A2+

HART transmitter

EEx-i

Hand held

calibrator

0V 24V

Isolated current

repeater barrier

(HART compartible,

active output)

A1+ or A2+

A1- or A2-

SH

Figure 4-17

Parameterization note:

Select HART channel and

Power supply = off (device 1)

Power supply = off (device 2)

Burst HART mode only (max. 1 transmitter).

4 Assembly and Installation

Page 46 of 78 Operating Instructions enCore FC1

4.4.12 Gas Meter (Turbine):

Encoder Index, 2 LF/HF Sensors (EEx i) via ExMFE5 Board

Hazardous

Area

Safe Area FC1 device

Turbine:

Encoder and 2

LF / HF sensor

SH

Z3-

Z3+

Z2-

Z2+

Z1-

Z1+

ExMFE5 board

Figure 4-18

4.4.13 Gas Meter (Turbine):

Encoder Index, 2 LF/HF Sensors (EEx i) via MFE7 Board

Hazardous

Area

Safe Are

a

FC1 device

Isolated Pulse

Amplifier

(active output)

Turbine:

Encoder and 2

LF / HF sensor

SH

GND

D3+

D2+

D1+

MFE7 board

24V0V

Figure 4-19

Assembly and Installation 4

enCore FC1 Operating Instructions Page 47 of 78

4.4.14 Gas Meter (Turbine):

SMRI2 Bi-directional: 2 HF Sensors, Flow Direction

Detection (EEx i) via MFE7 Board

Hazardous

Area

Safe Area FC1 device

(1):

Isolated Pulse Amplifier

(active output)

Turbine SMRI bi:

2 HF and 2 MF

sensors

SH

GND

D3+

D2+

D1+

MFE7 board

24V0V

(2):

Flow dir Monitor, e.g.

KFU8-Ex2.D

(

active output

)

(1)

(2)

(1)

MF1

MF2

HF1

HF2

Figure 4-20

4 Assembly and Installation

Page 48 of 78 Operating Instructions enCore FC1

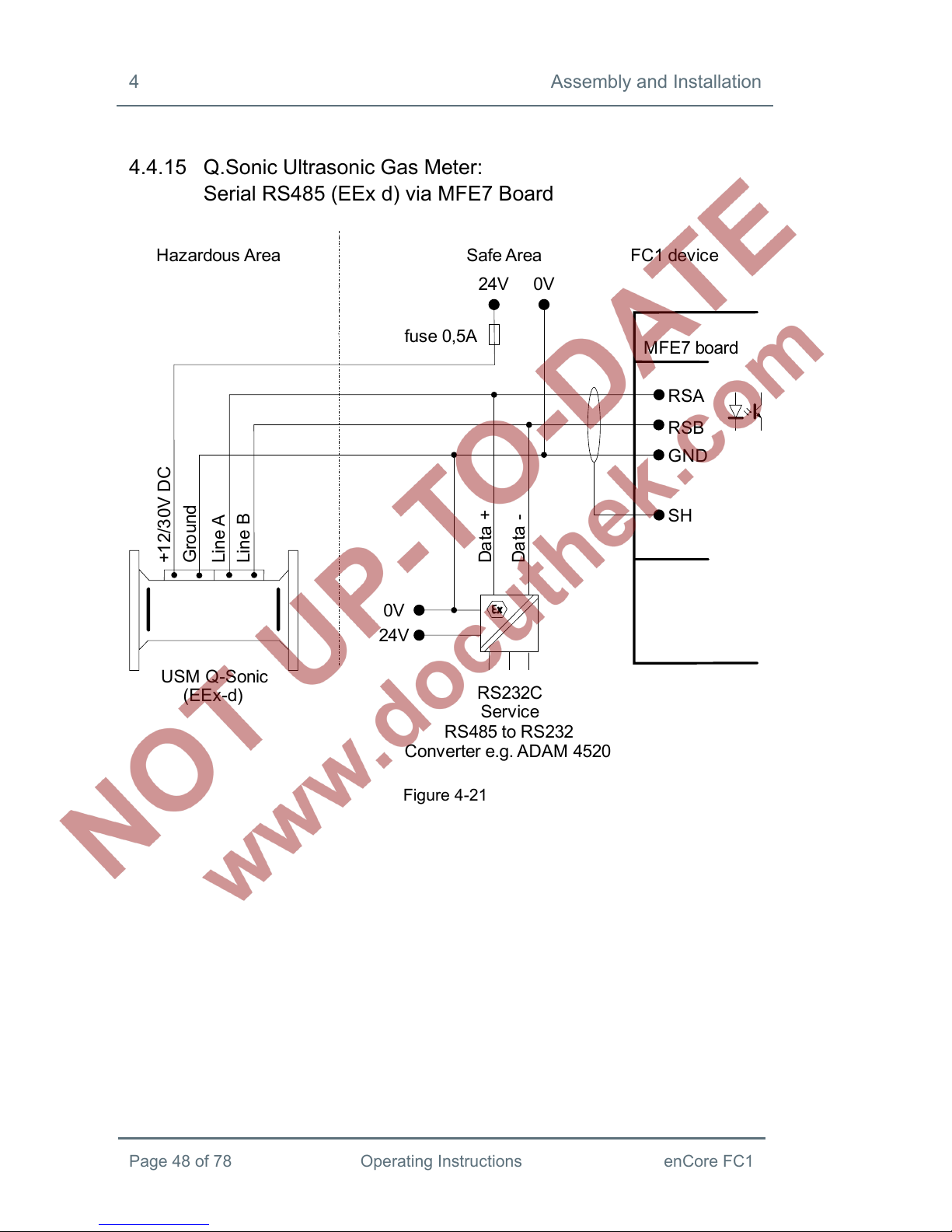

4.4.15 Q.Sonic Ultrasonic Gas Meter:

Serial RS485 (EEx d) via MFE7 Board

Hazardous Area Safe Area FC1 device

RS232C

Service

RS485 to RS232

Converter e.

g

. ADAM 4520

USM Q-Sonic

(EEx-d)

SH

GND

RSB

RSA

MFE7 board

24V 0V

24V

0V

fuse 0,5A

+12/3 0V DC

Ground

Line A

Line B

Data +

Data -

Figure 4-21

Assembly and Installation 4

enCore FC1 Operating Instructions Page 49 of 78

4.4.16 FLOWSIC600 Ultrasonic Gas Meter:

Serial RS485 (EEx d) via MFE7 Board

Hazardous Area Safe Area FC1 device

RS232C

Service

RS485 to RS232

Converter e.g. ADAM 4520

USM

FOWSIC600

(EEx-d)

SH

RSB

RSA

MFE7 board

24V 0V

24V

0V

fuse 0,5A

1+

2-

33

34

Data +

Data -

81

82

Figure 4-22

4 Assembly and Installation

Page 50 of 78 Operating Instructions enCore FC1

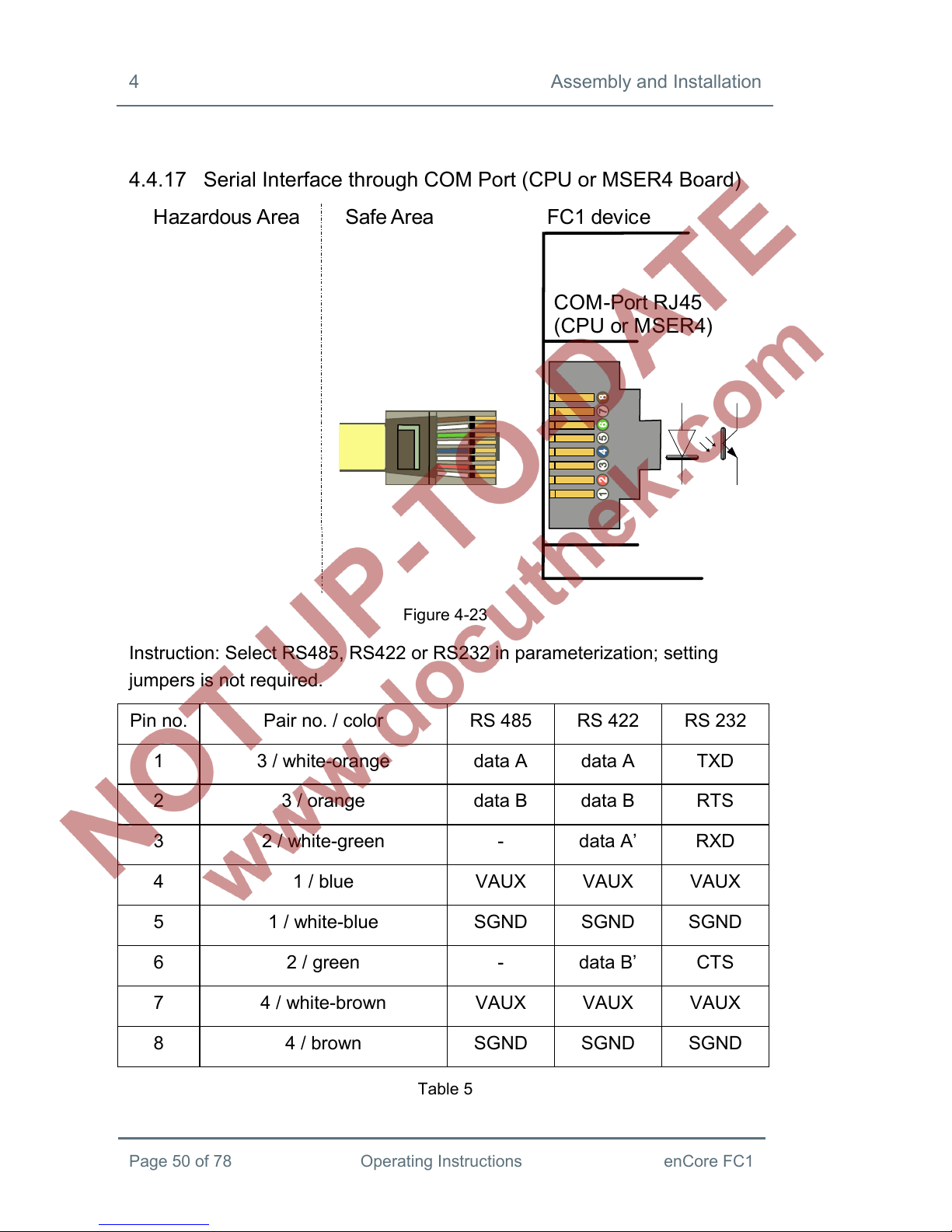

4.4.17 Serial Interface through COM Port (CPU or MSER4 Board)

FC1 device Safe AreaHazardous Area

COM-Port RJ45

(CPU or MSER4)

Figure 4-23

Instruction: Select RS485, RS422 or RS232 in parameterization; setting

jumpers is not required.

Pin no. Pair no. / color RS 485 RS 422 RS 232

1 3 / white-orange data A data A TXD

2 3 / orange data B data B RTS

3 2 / white-green - data A’ RXD

4 1 / blue VAUX VAUX VAUX

5 1 / white-blue SGND SGND SGND

6 2 / green - data B’ CTS

7 4 / white-brown VAUX VAUX VAUX

8 4 / brown SGND SGND SGND

Table 5

Assembly and Installation 4

enCore FC1 Operating Instructions Page 51 of 78

4.4.18 Analog Output (0/4...20mA) via MFA8 Board

Figure 4-24

Parameterization note:

The output current range is selectable (0 to 20 mA or 4 to 20 mA).

4 Assembly and Installation

Page 52 of 78 Operating Instructions enCore FC1

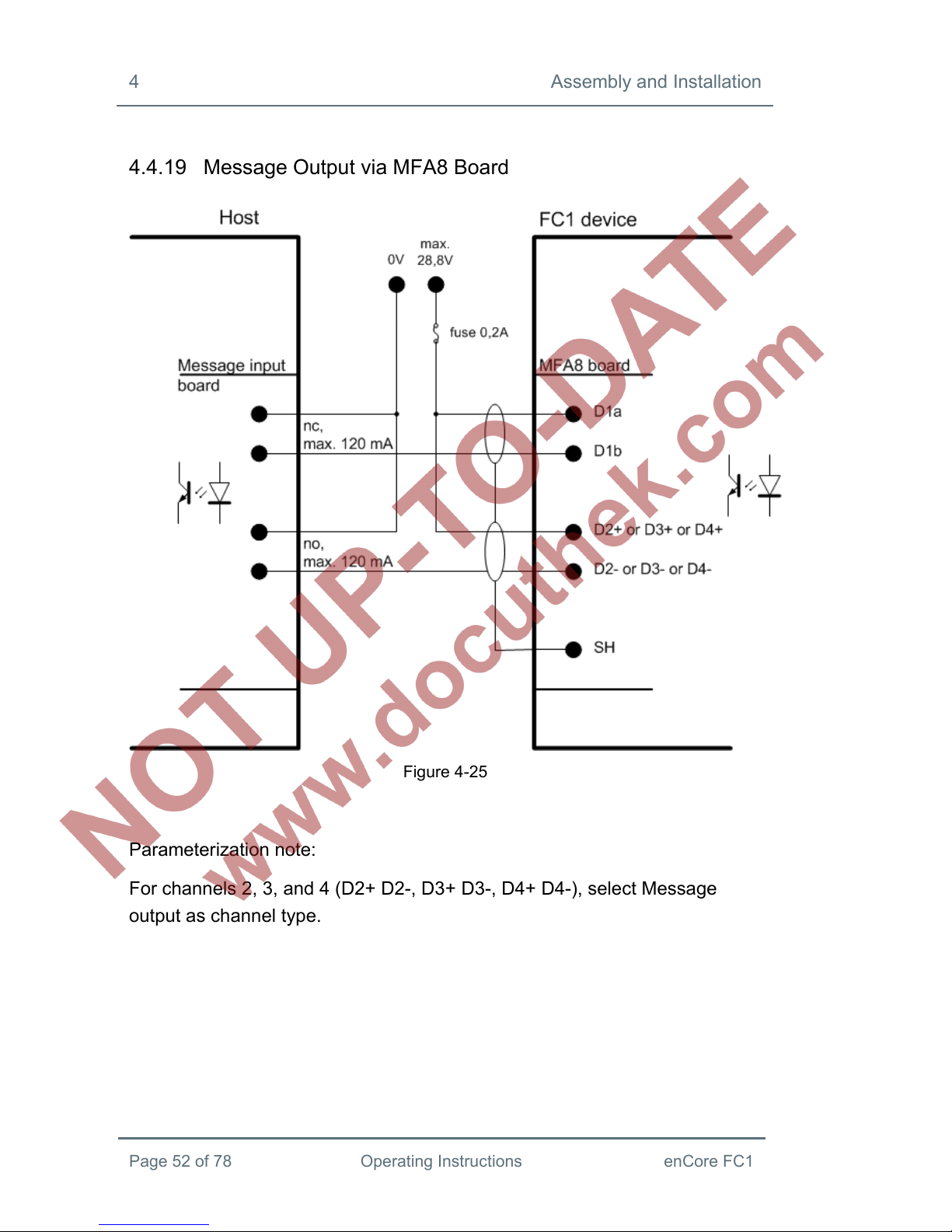

4.4.19 Message Output via MFA8 Board

Figure 4-25

Parameterization note:

For channels 2, 3, and 4 (D2+ D2-, D3+ D3-, D4+ D4-), select Message

output as channel type.

Assembly and Installation 4

enCore FC1 Operating Instructions Page 53 of 78

4.4.20 Pulse Output via MFA8 Board

Figure 4-26

Parameterization note:

For channels 2, 3, and 4 (D2+ D2-, D3+ D3-, D4+ D4-), select Pulse output

as channel type.

5 Device Configuration and Commissioning

Page 54 of 78 Operating Instructions enCore FC1

5 Device Configuration and Commissioning

All newly delivered devices are factory-configured so as to support all

available interfaces.

Setting FC1 parameters, i.e. configuring device functions and adjusting the

device to the actual measuring point, is done on site using enSuite software.

A gas specialist must be consulted for this work step. The presence of a

metrology expert is also required when the device is being used within the

scope of legal metrology.

The online help function in enSuite software contains instructions

for operating enSuite as well as a detailed description of its

parameters.

5.1 enSuite Software

5.1.1 System Requirements

enSuite is a PC software system running on Java. The following minimum

system requirements exist for an enSuite installation:

Microsoft® Windows™ XP or Windows™ 7

A graphics board with a resolution of at least 1024 x 768 pixel

10 GB free space on hard disk

1 GB RAM

Java SE 6 update 19 or higher (32bit)

5.1.2 enSuite Installation

The enclosed CD contains the installation program for enSuite software.

Alternatively, the installation program can be downloaded as compressed

ZIP-file from the software download area on the Elster-Instromet website.

The installation requires administrator rights.

Device Configuration and Commissioning 5

enCore FC1 Operating Instructions Page 55 of 78

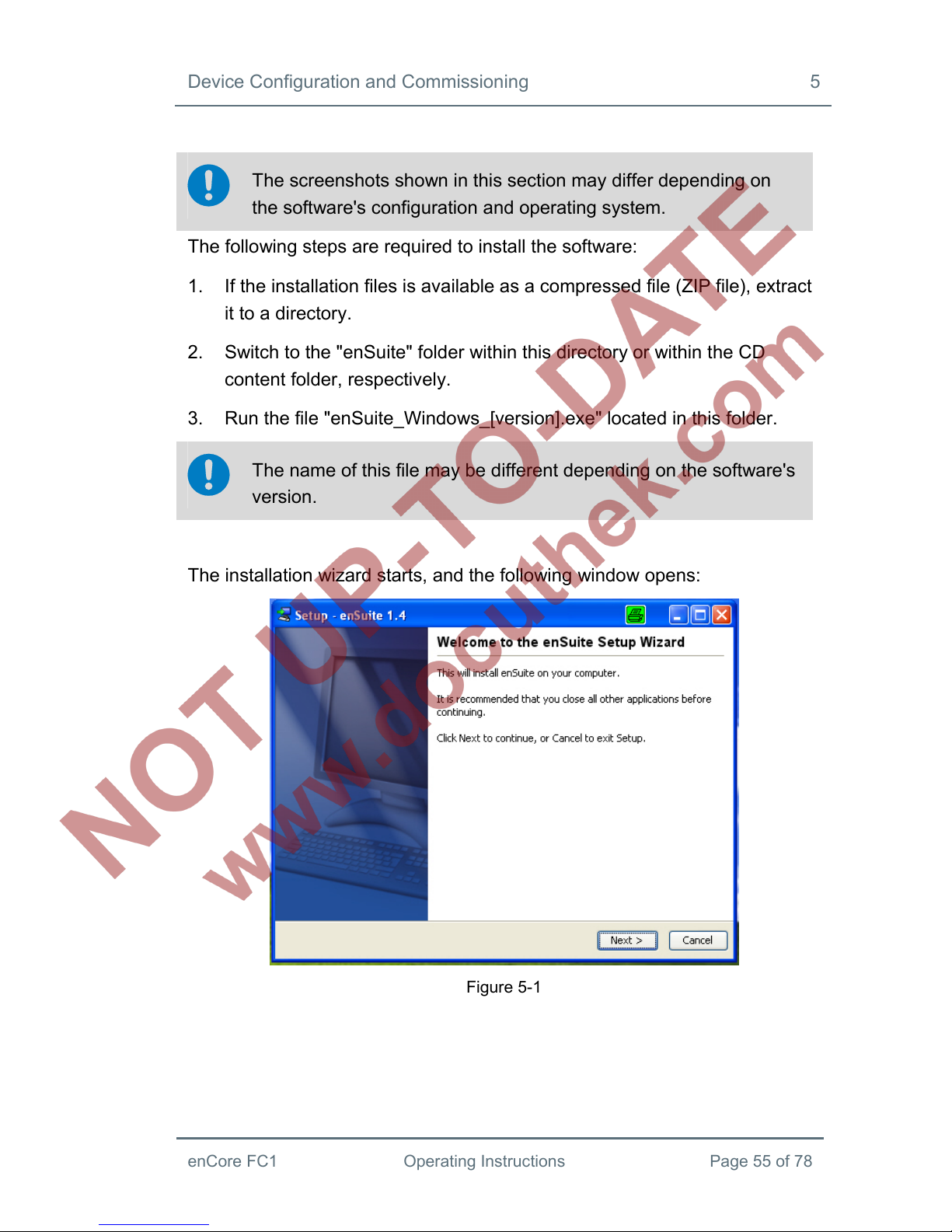

The screenshots shown in this section may differ depending on

the software's configuration and operating system.

The following steps are required to install the software:

1. If the installation files is available as a compressed file (ZIP file), extract

it to a directory.

2. Switch to the "enSuite" folder within this directory or within the CD

content folder, respectively.

3. Run the file "enSuite_Windows_[version].exe" located in this folder.

The name of this file may be different depending on the software's

version.

The installation wizard starts, and the following window opens:

Figure 5-1

5 Device Configuration and Commissioning

Page 56 of 78 Operating Instructions enCore FC1

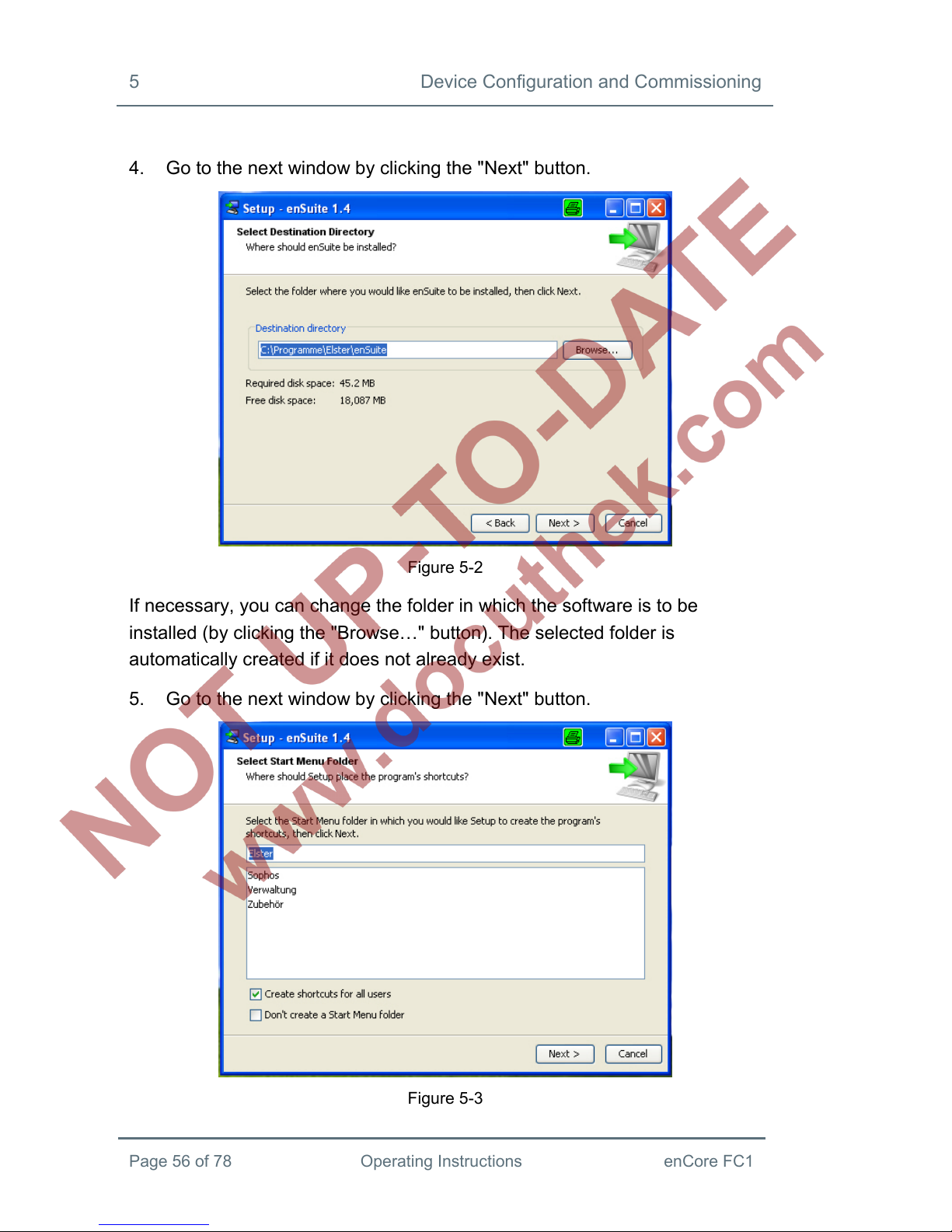

4. Go to the next window by clicking the "Next" button.

Figure 5-2

If necessary, you can change the folder in which the software is to be

installed (by clicking the "Browse…" button). The selected folder is

automatically created if it does not already exist.

5. Go to the next window by clicking the "Next" button.

Figure 5-3

Device Configuration and Commissioning 5

enCore FC1 Operating Instructions Page 57 of 78

This window allows you to specify the program groups in which the program

shortcut should be installed. By default, the shortcut is created in the

program group "Elster".

6. Go to the next window by clicking the "Next" button.

Figure 5-4

This window allows you to choose whether a shortcut to the program should

also be installed on your desktop, in addition to the shortcut in the start

menu.

5 Device Configuration and Commissioning

Page 58 of 78 Operating Instructions enCore FC1

7. Go to the next window by clicking the "Next" button.

Figure 5-5

Installation progress is displayed in this window. The next window opens

automatically after the installation is completed.

Figure 5-6

The end of installation progress is displayed in this window.

Device Configuration and Commissioning 5

enCore FC1 Operating Instructions Page 59 of 78

8. Click on the "Finish" button to confirm installation is complete.

The installation wizard is completed and the enSuite can be started.

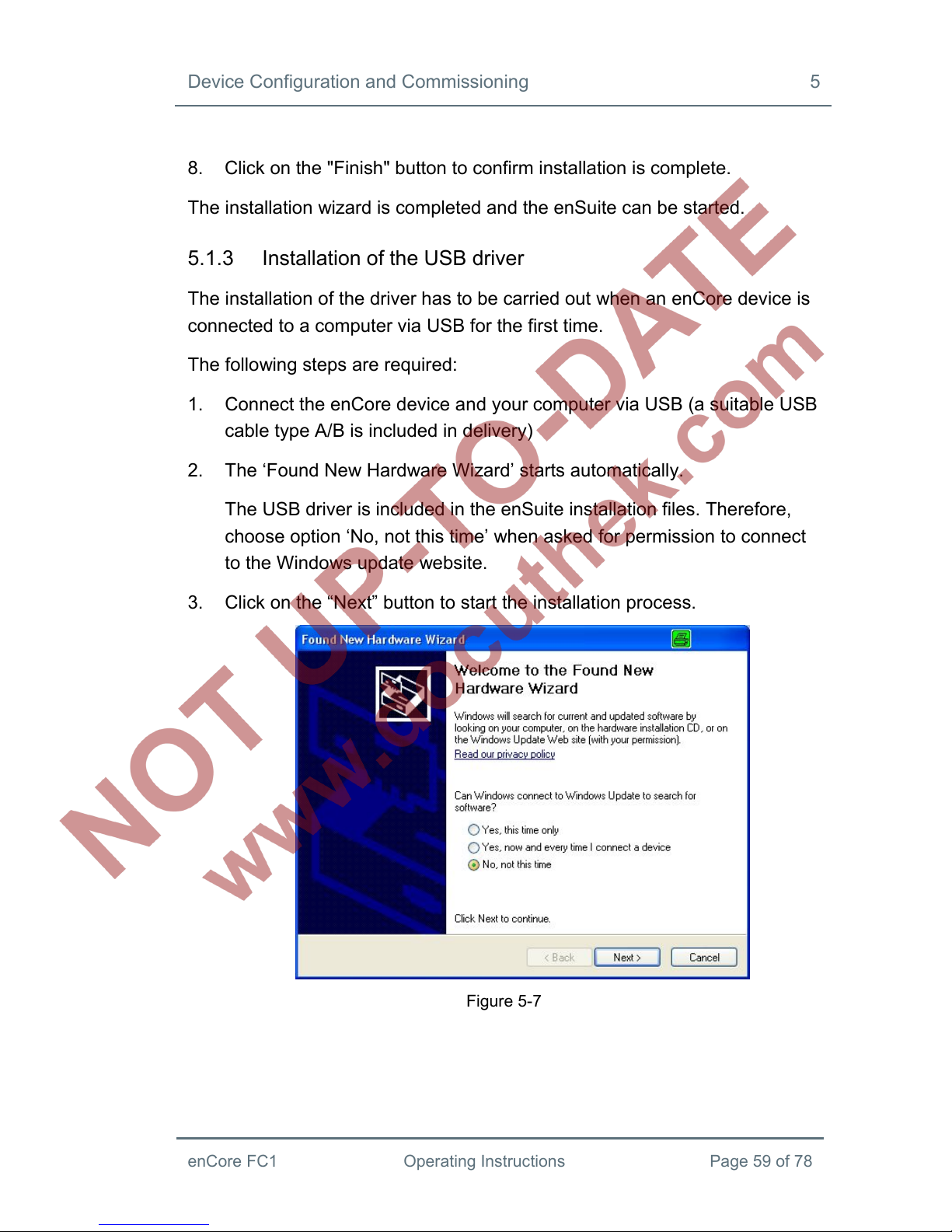

5.1.3 Installation of the USB driver

The installation of the driver has to be carried out when an enCore device is

connected to a computer via USB for the first time.

The following steps are required:

1. Connect the enCore device and your computer via USB (a suitable USB

cable type A/B is included in delivery)

2. The ‘Found New Hardware Wizard’ starts automatically.

The USB driver is included in the enSuite installation files. Therefore,

choose option ‘No, not this time’ when asked for permission to connect

to the Windows update website.

3. Click on the “Next” button to start the installation process.

Figure 5-7

5 Device Configuration and Commissioning

Page 60 of 78 Operating Instructions enCore FC1

4. Within the next window, you have two options.

Figure 5-8

Option 1 (recommended):

Insert the enSuite CD. Choose ‘Install the software automatically’

and click on the “Next” button. The driver is found automatically.

Option 2:

If the enSuite installation has been downloaded from the internet,

the driver cannot be found automatically.

Proceed as follows:

Choose ‘Install from a specific location’.

Click “Next” and select the directory containing the

extracted files of the downloaded installation, then the

subdirectory \drivers.

Click “Next”.

Device Configuration and Commissioning 5

enCore FC1 Operating Instructions Page 61 of 78

5. The software is installed.

Figure 5-9

6. Click “Finish” to close the wizard.

Figure 5-10

5 Device Configuration and Commissioning

Page 62 of 78 Operating Instructions enCore FC1

5.2 Device Parameterization

This section gives brief instructions on how to create a complete

parameterization for enCore devices and how to transfer it into the device

on-site via USB. Please refer to FC1 Manual Part 3a for details on this

process.

The following steps are required:

1. Start enSuite on your computer.

2. Create the USB connection to your enCore device.

3. Use enSuite to create an appropriate parameterization for the device.

4. Transfer the parameterization into the device.

As soon as the transfer of the parameterization starts, a user login

dialog appears on your computer screen. If the initial settings for the

user administration have not been changed, the default administrator

login (user name admin1 and empty password) will work. Otherwise,

you have to regard the individual user configuration of the device.

There are probably parameters that are not allowed to be changed

when the security switch is closed - especially if the device is within the

scope of legal metrology. If a new parameterization affects such

parameters, it is therefore necessary to open the security switch, so that

the presence of an authorized metrology expert may be required.

Device Configuration and Commissioning 5

enCore FC1 Operating Instructions Page 63 of 78

In very rare cases after parameterization and restart, it may happen

that the device shows a ‘No entry’ sign in the home display (see

figure below).

Figure 5-11

The ‘No entry’ sign indicates that the device has started in emergency

mode because of a system error that has been detected during

restart. All functions apart from basic functions for error handling are

deactivated. Typically, this error results from a wrong configuration

and can be solved by transferring a correct parameterization. Please

contact Elster if any further assistance or error diagnosis is required.

5.3 Commissioning the Measurement System

Note: The presence of a metrology expert is required for final commissioning

of the device when it is used within the scope of legal metrology. In this

case, the conditions of the applicable approval must be observed as well.

5.3.1 Checking Device Settings

The legally relevant parameters can be checked in special device displays

(cf. Part 1 of the FC1 Manual). The enSuite software will allow you to carry

out a complete check of the current device parameterization when the

software has an online connection with the device.

5.3.2 Checking Measurement Input Values

Measurement input values, in particular input values for flow computing

(measurement data from gas meters, pressure transmitters, temperature

5 Device Configuration and Commissioning

Page 64 of 78 Operating Instructions enCore FC1

transmitters and, if applicable, gas quality measurement devices) can be

checked on the device display (please refer to part 1 of the Manual).

5.3.3 Checking Output Signals

Parameterized output signals can be measured using appropriate measuring

instruments and checked in that way.

5.3.4 Checking Digital Communication (Modbus, etc.)

Appropriate tools (e.g. a protocol analyzer) can be used to check digital

communication.

5.3.5 Checking Measurements and Calculations

A final check of the accuracy of measurement results and calculations must

be carried out if the device is used within the scope of legal metrology. A

metrology expert is required for this process, and the applicable legal

regulations must be observed.

5.3.6 Sealing (if necessary)

It may be necessary for the device as well as for transmitter, pulse generator

and data lines to be sealed by a metrology expert when it is used within the

scope of legal metrology. The requirements of the applicable approval must

be observed in this case.

Maintenance 6

enCore FC1 Operating Instructions Page 65 of 78

6 Maintenance

The FC1 is practically maintenance-free. Only the battery, which is required

for purposes of data retention when the power supply is switched off, must

be replaced at certain intervals.

This section contains instructions for replacing the battery and cleaning the

device, as well as contact data for customer service and the service hotline.

6.1 Battery Replacement

The FC1 battery mainly comes into use when the FC1 is switched off

permanently, or it is being switched off then switched back on at frequent

intervals. The battery consumption can be neglected while the device is

powered on.

In addition, the battery loses energy as it ages.

The battery must be replaced with a new one at least every 10 years.

Special case: When the device is being stored and therefore permanently

disconnected from power supply, the battery loses approx. 3% of its charge

every month. The battery is therefore completely discharged after 3 years. It

is therefore recommended that the battery be replaced by a new one when

the FC1 has been without power supply for longer than 1 year.

Special case: The battery also loses additional charge when the power

supply is frequently disconnected and reconnected during operation. It is

therefore recommended that the battery be replaced by a new one when the

power supply has been disconnected and reconnected for 1,000 times.

The FC1 automatically signals as soon as battery capacity has dropped to

20% of that of a new battery.

A dead battery may sometimes lead to a loss of the measurement

data that was calculated and saved.

6 Maintenance

Page 66 of 78 Operating Instructions enCore FC1

For safety reasons, the battery should be replaced only by the

manufacturer's service department or by an appropriately trained

specialist working for the plant operator.

The housing of the device must be opened in order to replace the

battery. The presence of a metrology expert may be required for

this purpose when the device is being used within the scope of

legal metrology.

ATTENTION!

Risk of short circuit

The FC1 device may be damaged when opening the device

while the FC1 is powered on.

- Always make sure the power supply of the FC1 is

disconnected completely before replacing the device’s

battery.

Procedure for battery replacement:

A battery of the following type is required: Lithium 3V CR ½ AA.

1. For reasons of security, use enSuite to read-out the parameterization of

the FC1.

2. Disconnect the power supply.

3. Remove all cable connections to the FC1.

4. Remove the FC1 from the switch cabinet.

Maintenance 6

enCore FC1 Operating Instructions Page 67 of 78

Figure 6-1

5. Remove the 4 mounting screws (A) from the left side wall

6. Remove the left side wall.

Figure 6-2

Figure 6-3 Figure 6-4

7. Carefully remove the battery cover tabs (B) using a small screwdriver.

8. Remove the battery cover.

9. Take out the old battery.

A

B

A

6 Maintenance

Page 68 of 78 Operating Instructions enCore FC1

A capacitor ensures that device data will be retained for 15

minutes.

10. Insert the new battery.

Make sure the polarity is correct when inserting the battery (see

Fig. 6-2 to 6-4)! An incorrect polarity will make itself known through

a loss of data, only after a power failure of greater than 15 minutes.

11. Put the battery cover back on and carefully press on it until it snaps into

place with a soft click.

12. Reassemble the FC1.

13. Restore the cable connections to the FC1.

14. Reconnect the power supply.

The used battery must be disposed of properly, in accordance with the

instructions from the battery manufacturer.

6.2 Cleaning

ATTENTION!

Water penetrating the device will damage it!

Water may penetrate into the device and damage it when it is

cleaned with a cloth that is too wet.

Only use a damp cloth to clean the device.

Normally a dry, soft microfiber cloth is sufficient for cleaning the FC1. A mild

dishwashing liquid solution or a mild glass cleaner can be used for stubborn

stains.

Maintenance 6

enCore FC1 Operating Instructions Page 69 of 78

Cleaners that are recommended for cleaning navigation devices and similar

devices with a touch screen are also suitable for the FC1 screen.

Alternatively, a mixture of 50% isopropyl alcohol and distilled water can be

used to clean the screen.

6.3 Customer Service

Our customer service department is available for technical advice as well as

repairs.

Furthermore, our employees are always interested in new information and

experiences that arise through use of the device and that may be valuable

for improving our products.

You may contact our service hotline with any technical questions.

Tel.: +49 (0) 231 / 93711088

E-mail: support-do@elster.com

6.4 Replacement Parts and Accessories

ATTENTION!

Incorrect replacement parts and accessories are a safety risk!

Incorrect or defective replacement parts and accessories may

detract from safety and lead to damage, malfunction, or total

device failure.

- Use only original replacement parts and accessories from

the manufacturer.

- Always contact the manufacturer if you are in doubt.

6 Maintenance

Page 70 of 78 Operating Instructions enCore FC1

You must contact the responsible customer service department for

replacement parts and accessories (see section 6.3).

6.5 Warranty Conditions

You will find our current warranty conditions in the General Terms and

Conditions, e.g. on the Internet at:

http://www.elster-instromet.com/de/AGB.html

Decommissioning / Disposal 7

enCore FC1 Operating Instructions Page 71 of 78

7 Decommissioning / Disposal

7.1 Storage

ATTENTION!

Material damage from formation of condensation!

Storing the device can lead to the formation of condensation

resulting from variations in temperature. This may result in the

device malfunctioning at a later time.

- After the device was stored or transported in cold weather

or if it was subject to extreme variations in temperature, it

must be slowly brought to room temperature before it is

commissioned.

- The device must undergo a waiting period of at least 12

hours before it is put into operation if condensation formed

during storage.

The device's time may no longer be exactly correct after it is stored

for longer periods; i.e. its clock must be checked and set if

necessary.

It is also possible counters and archive files may have been

deleted.

Counters and archive files as well as time and date settings are

deleted if the device's power supply was interrupted during storage

because the battery was disconnected.

The battery (operational life of 3 years) must be replaced in case of

longer device storage times (cf. section 6.1).

7 Decommissioning / Disposal

Page 72 of 78 Operating Instructions enCore FC1

The following regulations apply for storage:

Relative humidity may not exceed 93%.

Packaging must only be stored in closed areas.

Storage temperature must be between -25° C and +60° C.

Mechanical vibrations must be avoided during storage.

7.2 Disposal

The manufacturer will take care of proper disposal of the FC1 after the

operational life of the device expires.

Address for returning the FC1:

Elster GmbH

Steinern Straße 19 – 21

D - 55252 Mainz-Kastel

Germany

Technical Data 8

enCore FC1 Operating Instructions Page 73 of 78

8 Technical Data

8.1 General

Dimensions / housing Plug-in unit in 19” design, 3 height units (3HU), 1/2

or 1/3 width.

Overall depth without plugs approximately 170 mm,

with plugs approximately 220 mm. Process

interfacing at the rear, control panel at the front.

Ambient conditions Ambient temperature range -10 °C to +55 °C.

Humidity < 90 %, non-condensing.

Installation outside Ex zones 0, 1, 2 only.

IP protection class IP20

Storage temperature -25°C to +60°C

Weight Approx. 1.2 kg (fully equipped).

Power supply 24 V DC +/- 20 %, power consumption up to 12 W

(typically 5 W).

Optionally: 230 V AC via external power supply.

Display / control panel 4.3“TFT color display with touch screen,

480x272x3 pixels, LED background illumination.

4 navigation and 2 function keys.

2 multi-color LEDs for power and status indication.

Sealable security switch.

Table 6: General technical data

8 Technical Data

Page 74 of 78 Operating Instructions enCore FC1

8.2 Inputs

ExMFE5 input board 3 NAMUR inputs [EEx ib] IIC for LF or HF

pulses (max. 5 kHz) or messages. One of

these inputs can be used alternatively for

connecting an encoder index.

Analog input for transmitters with 4 - 20mA

interface [EEx ib] IIC, alternatively suitable for

a connection of transmitters with HART

interface (one transmitter in burst mode or up

to four transmitters in multi-drop mode).

Pt-100 temperature sensor input (4-wire

technology), [EEx ib] IIC.

MFE7 input board 3 inputs (24 V DC) for LF or HF pulses (max. 5

kHz) or messages. One of these inputs can be

used alternatively for connecting an encoder

index or as frequency input.

2 analog inputs for transmitters with 4 - 20mA

interface, alternatively suitable for a connection

of up to four transmitters with HART interface

(one transmitter in burst mode or up to four

transmitters in multi-drop mode).

Pt-100 temperature sensor input in 4-wire

technology.

Table 7: Inputs: Technical data

Technical Data 8

enCore FC1 Operating Instructions Page 75 of 78

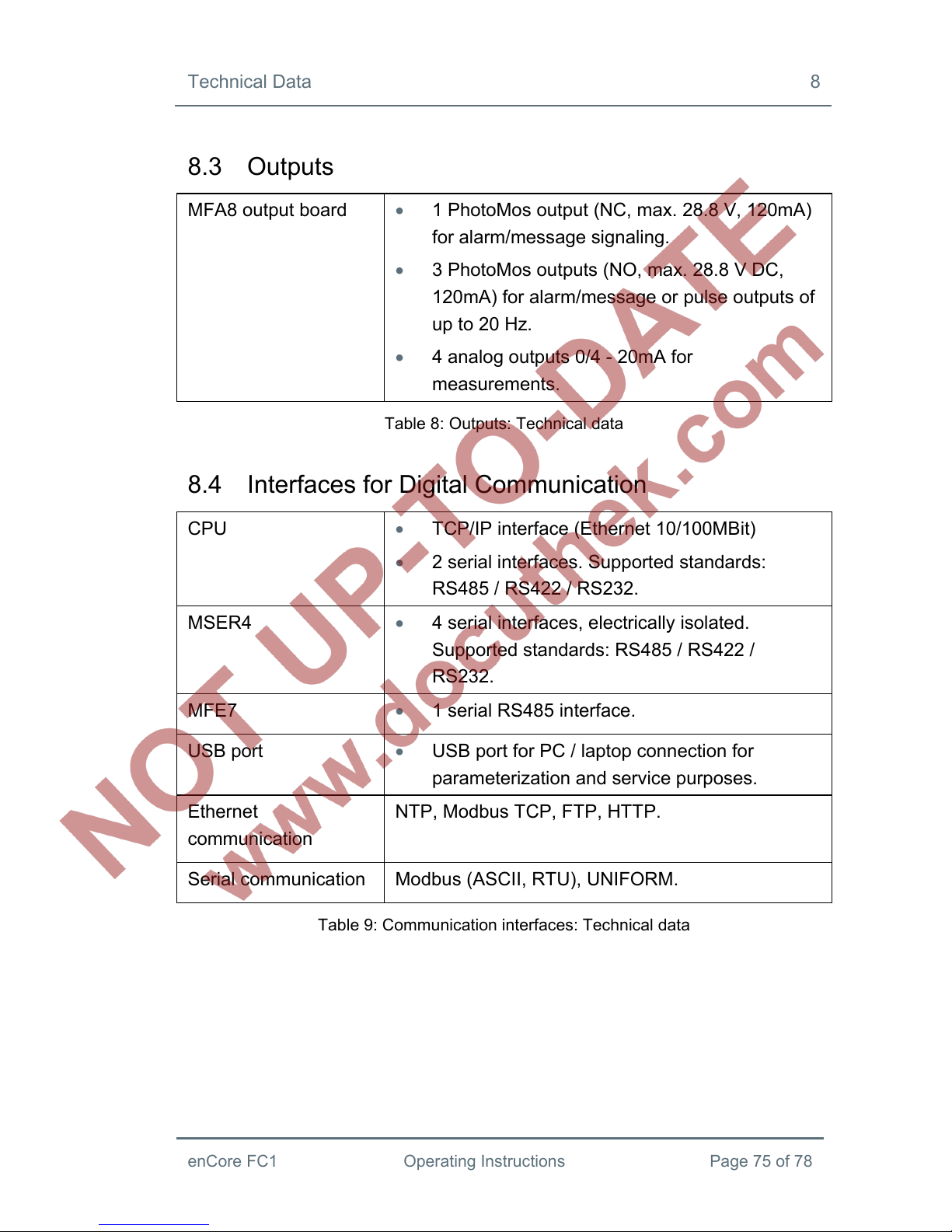

8.3 Outputs

MFA8 output board 1 PhotoMos output (NC, max. 28.8 V, 120mA)

for alarm/message signaling.

3 PhotoMos outputs (NO, max. 28.8 V DC,

120mA) for alarm/message or pulse outputs of

up to 20 Hz.

4 analog outputs 0/4 - 20mA for

measurements.

Table 8: Outputs: Technical data

8.4 Interfaces for Digital Communication

CPU TCP/IP interface (Ethernet 10/100MBit)

2 serial interfaces. Supported standards:

RS485 / RS422 / RS232.

MSER4 4 serial interfaces, electrically isolated.

Supported standards: RS485 / RS422 /

RS232.

MFE7 1 serial RS485 interface.

USB port USB port for PC / laptop connection for

parameterization and service purposes.

Ethernet

communication

NTP, Modbus TCP, FTP, HTTP.

Serial communication Modbus (ASCII, RTU), UNIFORM.

Table 9: Communication interfaces: Technical data

9 Index

Page 76 of 78 Operating Instructions enCore FC1

9 Index

A

Accessories 69

Assembly instructions 29

B

Battery cover 67

Battery replacement 65

C

Cleaner 69

Cleaning 68

Commissioning 63

Condensation 71

Control panel 21

Customer service 69

D

Danger word 8

Decommissioning 71

Device parameterization 62

Disposal 71, 72

E

enCore 18

enSuite 18

installation 54

ExMFE5 board 26

F

FC1 device description 20

Flow computer 18

G

Gas specialist 10

H

Hazard level 8

Hazard warnings 8

I

I/O boards 26

Board number 35

Mounting 33

Intended use 15

Interfaces 25

K

Keys 22

L

LEDs 23

Limitation of liability 10

Line connection 29

M

Maintenance 65

Index 9

enCore FC1 Operating Instructions Page 77 of 78

Metrology expert 10

MFA8 board 28

MFE7 board 27

MSER4 board 28

O

Operator liability 16

Overcurrent protection

component 31

P

Polarity 68

Process boards 20

Q

Qualified electrician 10

R

Relative humidity 72

Repairs 69

Replacement parts 69

S

Safety installations 17

Safety instructions 9, 13

Scope of delivery 6

Security switch 22

Specialist 9

Standards 11

Storage 71

Straight-line gap 30

T

Target group definition 9

Technical data 73

Trained individual 9

Transport 71

U

USB driver

installation 59

User login 62

Users 16

V

Vibrations 72

W

Warranty conditions 70

Wiring 30

10 Appendix

Page 78 of 78 Operating Instructions enCore FC1

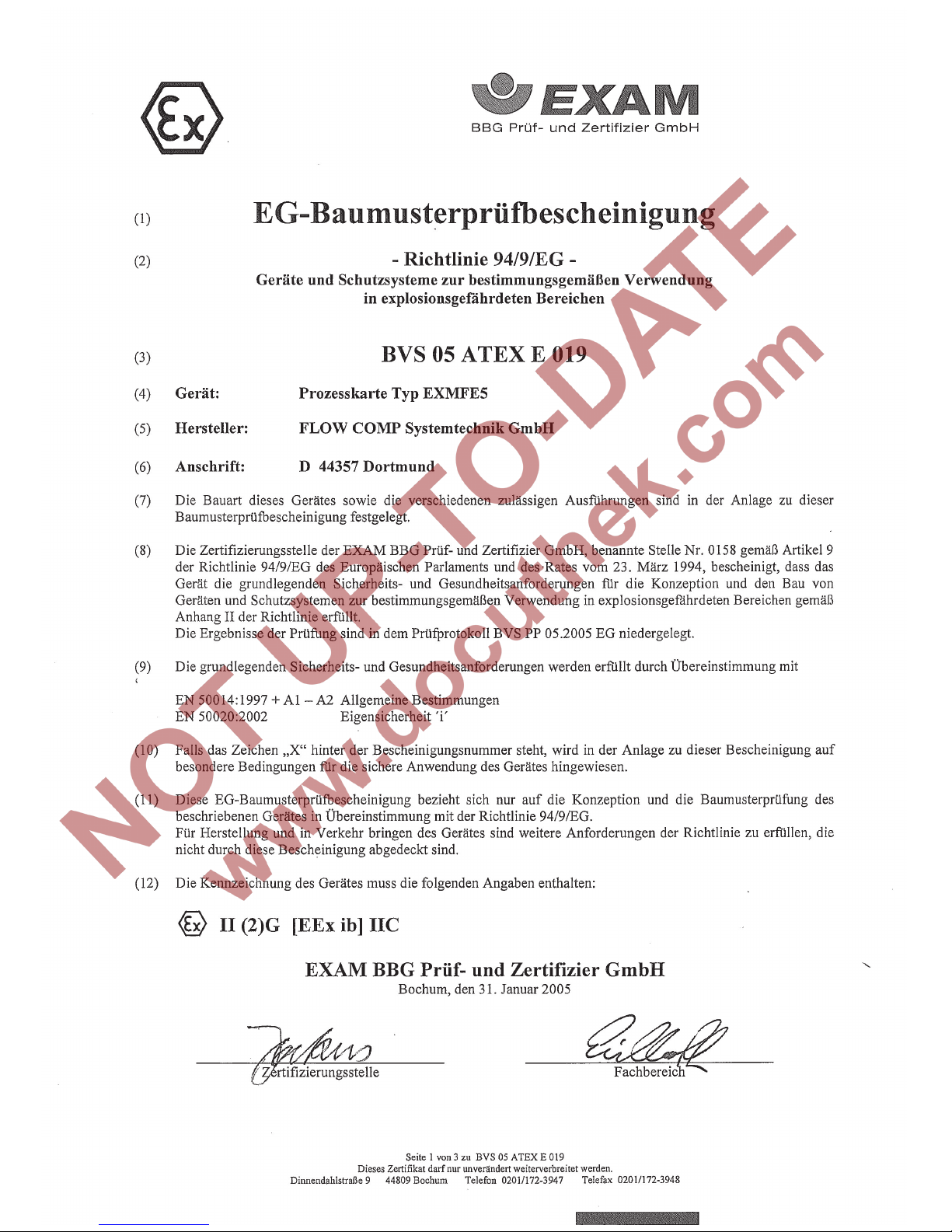

10 Appendix

enCore FC1: Declaration of Conformity

ExMFE5 board: EC Type Examination Certificate (ATEX)

- English translation of the German original certificate –

EX EXAM

BBG Prüf- und Zertifizier GmbH

(1)

EC Type Examination Certificate

(2)

- Council Directive 94/9/EC -

Protective devices and systems intended for use

in potentially explosive atmospheres

(3)

BVS 05 ATEX E 019

(4)

Device: Process Board Type EXMFE5

(5)

Manufacturer: FLOW COMP Systemtechnik GmbH

(6)

Address: D – 44357 Dortmund

(7) This device type and its various permissible versions are specified in the appendix to this Type

Examination Certificate.

(8) The EXAM BBG Prüf- und Zertifizier GmbH certification body, notified body no. 0158 in

accordance with Article 9 of the European Parliament and Council Directive 94/9/EC of 23 March

1994, certifies that this device has been found to comply with the Essential Health and Safety

Requirements relating to the design and construction of protective devices and systems intended for

use in potentially explosive atmospheres according to Annex II to the Directive.

The test results are recorded in the test report BVS PP 05.2005 EC.

(9) The compliance of the device with the Essential Health and Safety Requirements has been assured

by compliance with

EN 50014:1997 + A1 – A2 General Requirements

EN 50020:2002 Intrinsic Safety ‘i’

(10) If the character “X” is placed after the certificate number, it indicates that the device is subject to

special requirements for safe use as referenced in the appendix to this certificate.

(11) This EC type examination certificate refers only to the design and construction of the specified

device in accordance with Council Directive 94/9/EC.

Further requirements of this Directive, which are not covered by this certificate, apply to the

manufacture and supply of this device.

(12) The marking of the device shall include the following details:

Ex II (2)G [EEx ib] IIC

EXAM BBG Prüf- und Zertifizier GmbH