Page 1

INSTALLATION INSTRUCTIONS

The Kent Range of Domestic Meters

V100, V110 & V200

Volumetric in-line cold water meters

All Elster water meters are manufactured and tested in

accordance with either BS5728 or BSEN14154 according to

the appropriate type approval and comply with the relevant

UK Weights and Measures regulations. The meters are

suitable for cold potable water up to a temperature of 30ºC

and working pressure of 16 bar (10 bar only for V110).

If the meter has been provided with an encoded register,

please refer to the appropriate additional instructions:

1. Electronic Meter Reading (EMR) Installation Instructions

ref. 8593D9791.

2. Electronic Meter Reading (InVISION EMR) Installation Instructions

ref. 8505A2750.

The meter must be fully flooded with clean cold water at all times.

No air or water/air mixtures should be allowed

to flow through the meter, otherwise errors

and damage may result.

20724 V100, V110, V200 Inst Instr EN Master AW.indd 1

28/02/2013 13:02

Page 2

Handling

Water meters are accurate measuring devices and although of robust

construction should be treated with due care. The meters should

remain within their protective packaging until the point of installation.

Storage

Storage temperatures should remain within a range of 5 to 10ºC,

avoiding direct sunlight and heat.

Installation

The meter may be connected to horizontal, vertical or inclined pipes.

The installation should comply with BS5728 or BSEN14154, according to

the appropriate meter type approval and respect all relevant local byelaws. Only approved sealing materials should be used for making pipe

connections. The meter should be installed in a position to ensure it is

fully flooded with clean cold water at all times, in a frost protected area.

The meter should be accessible for ease of reading and should not be

subjected to installation induced stresses or vibration. Failure to do so

may result in meter damage and leakage occurring.

Earthing caution:

National legislation and local rules in force concerning the use of water

pipes for earthing shall always be consulted and adhered to. Where

the meter installation forms part of the electrical earthing, in order to

minimise the risk to operational staff, there shall be a permanent shunt

for the water meter and its associated fittings.

To enable the meter to be removed it is recommended valves be fitted

upstream and downstream of the meter, together with a drain cock

between the meter and downstream valve.

20724 V100, V110, V200 Inst Instr EN Master AW.indd 2

28/02/2013 13:02

Page 3

Meter Installation Instructions

1. Prior to installation of the meter, new or existing inlet and outlet

pipework must be thoroughly flushed free of foreign material,

using a make-up piece of pipe where the meter is to be fitted.

2. Install the meter with the flow direction arrow pointing in the

direction of flow.

3. Tighten all meter couplings.

Start-up procedure

Commissioning:

The meter’s measuring device may be damaged if subjected to full flow

conditions prior to expelling air from the pipeline.

4. With the downstream valve open, slowly open upstream valve,

until all air is expelled from the meter. Fully open the upstream

valve once all the air has been expelled.

5. Observe that the register is responding to water throughput.

6. Close downstream outlet, (meter register should stop).

7. Check all connections for leaks.

Installation Leakage

If the connections and fittings show signs of leakage, carry out start-up

procedure again.

How to read your meter

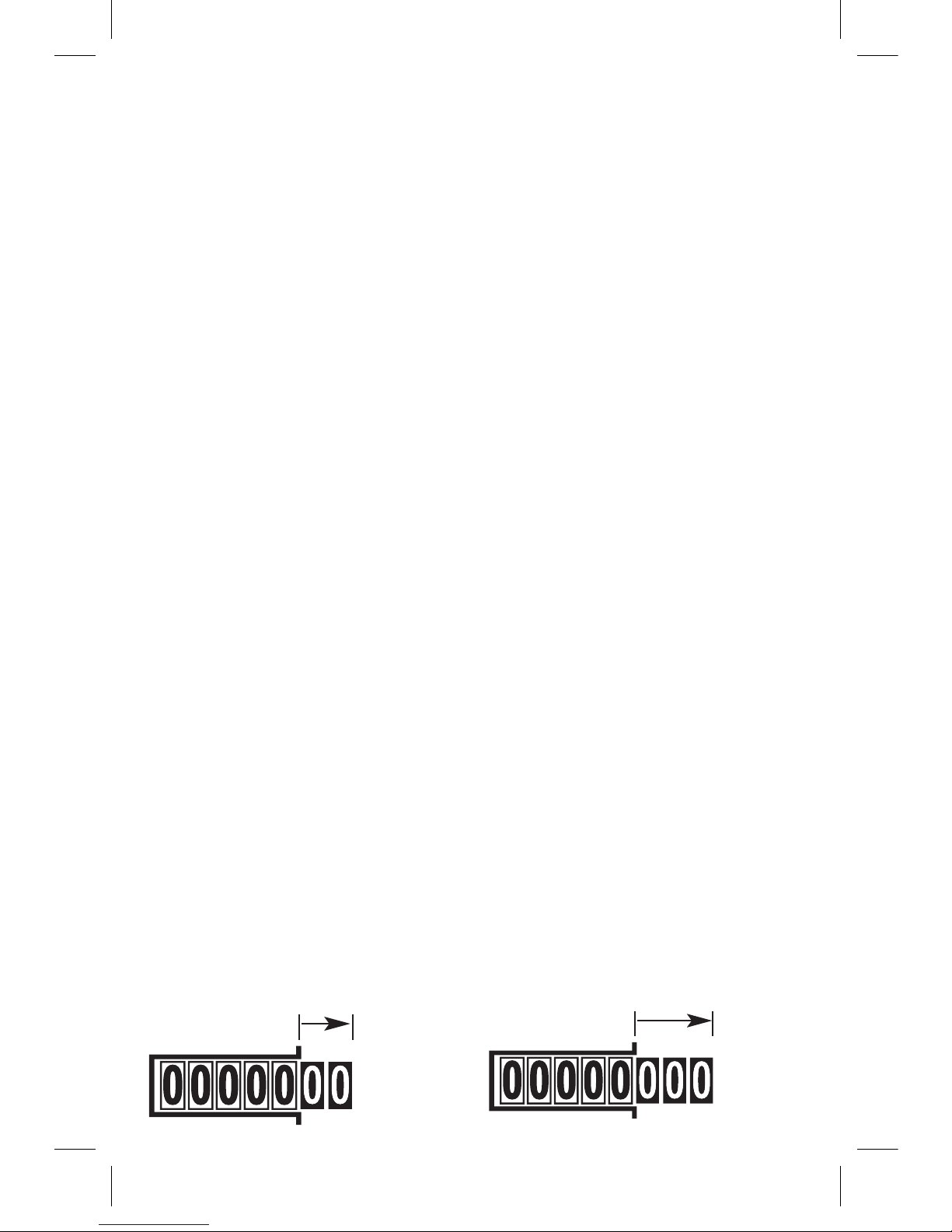

Mechanical register:

The reading is from left to right.

Black numbers on white rollers denote cubic metres. White numbers

on red rollers (or white numbers on black rollers, as is the case with

InVISION) denote litres. (1000 Litres = 1 Cubic Metre).

litres

litresAlternative

20724 V100, V110, V200 Inst Instr EN Master AW.indd 3

28/02/2013 13:02

Page 4

Electronic register:

The reading is from left to right.

The main display of large digits indicates billable units in cubic metres.

The smaller digits, in the red frame, indicate sub-units.

(1000 Litres = 1 Cubic Metre)

012356

02653

Billable units

Sub units

(red frame)

Tell-tale

Main Display

Display: Self-checking mode Display: Alert status mode

888888

88888

E

All of the display segments

are temporarily activated

for self-checking.

An alert is signalled by an “E” in the alert flag

field. The type of alert can be identified by the

alert code. Refer to the operating instructions.

In the absence of an alert, the five dashes will

be seen in the alert code field, as shown.

012356

-----

Alert code Alert flag

The Tell-tale signals that the meter is in measurement mode and can

be activated by manual rotation of the register without water flowing.

The Tell-tale will continue to display for a short period after activation.

During normal operation, the display will periodically show a selfchecking and alert status mode.

20724 V100, V110, V200 Inst Instr EN Master AW.indd 4

28/02/2013 13:02

Page 5

Special installation and maintenance

instructions for polymer bodied meters

In addition to the instructions given in this document, special

consideration is required when installing and maintaining polymer

bodied meters.

1. The meter installation site should be protected from frost, direct sunlight

and away from heat sources.

2. The installation type and position should minimise the risk of chemical

contamination through flooding or soil contact, or by run-off from

adjacent surfaces or fittings.

3. Care must be taken to ensure that any chemicals used during the

installation process, such as cleaning fluids or jointing fluxes, are not

permitted to come into contact with the meter.

4. It is essential that stresses due to poor installation methods should not

act across the meter body. Ensure the correct gap is provided in the

pipework to fit the meter length. Ensure the upstream and downstream

pipe connectors are aligned and sealing faces are parallel. Ensure

upstream and downstream pipework is firmly anchored.

5. Polymer pipe connection pieces should be used. If brass connection

pieces have to be used, they should be of a dezincification resistant

(DZR) grade.

6. Only the provided connector seals should be used. The use of PTFE tape

or sealing fluids may damage the meter.

7. For V110 and V200 polymer meters it is important that the foam

washers, provided at the end of both connection threads, remain in

place after installation.

8. The pipe connectors should be carefully threaded onto the meter by

hand to avoid cross threading. The final tightening with a spanner

should not exceed 20Nm, avoiding damage to, or loading across the

meter body.

20724 V100, V110, V200 Inst Instr EN Master AW.indd 5

28/02/2013 13:02

Page 6

9. The meter connections must be completely water tight when

the system is pressurised.

10. Once installed, the meter should not be painted or come into contact

with chemicals such as household cleaning fluids.

11. When making repairs to pipework near to the meter installation,

care should be taken to prevent damage to the meter, especially when

using a heat source.

Health and Safety at Work Act 1974

1. We wish to inform you that in accordance with Section 6 of the

above Act, we take every care, as far as is reasonably practicable

to ensure that our products are safe without risk to health when

properly handled, transported, installed, used, maintained and

disposed. However, as manufacturers and suppliers of a wide

range of products, we would advise you that related information

for these products will be found in the following literature.

• Regulations(suchastheCOSHHRegulations,ManualLifting

Regulations, Personal Protective Equipment Regulations),

British Standards and other applicable ISO and European

Specifications and Codes of Practice, as applicable to the

intended application of the products.

• Regulationsforelectricalequipmentofbuildings(publishedby

the Institution of Electrical Engineers).

• CataloguesandproductleaetsofthisCompanyorliterature

which may be obtained by specific request to the Company.

20724 V100, V110, V200 Inst Instr EN Master AW.indd 6

28/02/2013 13:02

Page 7

2. It is important that the products concerned should be installed,

handled, transported, commissioned and maintained by, or under

the supervision of, competent persons in accordance with good

engineering practice and:

• IEERegulationsfortheelectricalequipmentofbuildings.

• Regulations,British,European,ISOandotherstandards,

specifications and Codes of Practice, as applicable to the

intended application of products, i.e. Water Supply Bye-Laws.

• StatutoryRequirements.

• AnyinstructionsspecicallyadvisedbytheCompanyand,

where appropriate, with particular reference to information

marked on the product. The product must only be used in

the condition supplied or specified by the Company, without

modification, and for the purpose for which it was designed.

3. In accordance with your statutory duties to employees and other

persons, you are therefore requested to take such steps as are

necessary to ensure that any appropriate information relevant to

our products is made available by you to everyone concerned.

The Company takes no responsibility for any failure to comply with

the above guidelines.

Pressure equipment directive 97/23/EC

This product is applicable in networks for the supply, distribution and

discharge of water and associated equipment and is therefore exempt.

20724 V100, V110, V200 Inst Instr EN Master AW.indd 7

28/02/2013 13:02

Page 8

Leaflet ref. 8593C9780 Issue 9

The Company’s policy is one of

continuous improvement and the right

is reserved to modify the

specifications without notice.

DECLARATION OF CONFORMITY

We, Elster Water Metering Limited, 130 Camford Way, Sundon Park,

Luton, Bedfordshire, LU3 3AN hereby declare that the meter type:

V100, V110 & V200

conforms, where applicable, to the following directives:-

Measuring Instrument Directive 2004/22/EC

Electromagnetic Compatibility (EMC) Directive 2004/108/EC

RoHS2 DIRECTIVE 2011/65/EU

Signature:…………………………………………

Full Name: Nigel Maynard

Position: Quality Manager

Date: August 2014

Measuring instruments directive 2004/22/EC

This Declaration of Conformity applies to meters verified according to

the directive and bearing the relevant CE verification mark.

Elster Water Metering Limited

130 Camford Way

Sundon Park

Luton

Bedfordshire

LU3 3AN

United Kingdom

T: +44 (0) 1582 846400

F: +44 (0) 1582 564728

water.metering@elster.com

www.elstermetering.com

Loading...

Loading...