Elster Q.Sonic PLUS Quick Start Manual

Elster NV/SA

Rijkmakerlaan 9

2910 Essen,

Belgium

T + 32 3 670 0700

www.elster-instromet.com

DOCUMENT TITLE

ULTRASONIC FLOWMETER SERIES 6, MODELS Q.SONIC

PLUS

SUBTITLE

QUICK START MANUAL

DOCUMENT NUMBER

22.100.200.000.02/2

REVISION

B

REVISION DATE

2013-02-22

This reproduction is sole property of Elster NV/SA and is subject to the conditions that it or any information contained therein will not be used in

any way detrimental to our interests and that all copies will be returned immediately on demand

PAGE:

1 OF 29

22.100.200.000.02_2_B ULTRASONIC FLOWMETER SERIES 6.DOC

Ultrasonic Flowmeter Series 6,

Q.Sonic

plus

Quick start manual

Elster NV/SA

Rijkmakerlaan 9

2910 Essen,

Belgium

T + 32 3 670 0700

www.elster-instromet.com

DOCUMENT TITLE

ULTRASONIC FLOWMETER SERIES 6, MODELS Q.SONIC

PLUS

SUBTITLE

QUICK START MANUAL

DOCUMENT NUMBER

22.100.200.000.02/2

REVISION

B

REVISION DATE

2013-02-22

This reproduction is sole property of Elster NV/SA and is subject to the conditions that it or any information contained therein will not be used in any way

detrimental to our interests and that all copies will be returned immediately on demand

PAGE

2 OF 29

22.100.200.000.02_2_B ULTRASONIC FLOWMETER SERIES 6.DOC

Table of contents

1

About this technical documentation .......................................................................................... 4

1.1 Introduction ........................................................................................................................ 4

1.2 Warranty ............................................................................................................................. 4

1.3 Typographical Conventions ............................................................................................. 5

1.4 Abbreviations ..................................................................................................................... 5

2

Ultrasonic Flowmeter Series 6 gas flow meter ......................................................................... 6

2.1 General ............................................................................................................................... 6

2.2 Applicable standards ........................................................................................................ 6

2.3 Configuration ..................................................................................................................... 6

2.4 Calibration .......................................................................................................................... 7

3

Theory of operation ..................................................................................................................... 8

3.1 Flow velocity measurement .............................................................................................. 8

3.2 Correction after calibration .............................................................................................. 9

3.3 Volume flow at line conditions ......................................................................................... 9

4

System description .................................................................................................................... 10

4.1 Flow cell ............................................................................................................................ 10

4.2 Signal processing unit .................................................................................................... 10

4.3 Transducers ..................................................................................................................... 11

4.4 Flow cell optional pressure sensor ............................................................................... 11

4.5 Flow cell optional temperature sensor .......................................................................... 12

4.6 Labels and nameplates ................................................................................................... 12

4.6.1. ATEX certified .................................................................................................................................. 12

4.6.2. IECEx certified ................................................................................................................................. 13

4.6.3. FM certified ...................................................................................................................................... 13

4.7 Sealing .............................................................................................................................. 15

4.7.1. Main plate ........................................................................................................................................ 15

4.7.2. SPU ................................................................................................................................................. 15

5

Installation and commissioning ............................................................................................... 17

5.1 Introduction ...................................................................................................................... 17

5.2 Installation requirements flow cell................................................................................. 17

5.2.1. Installing meter in pipeline ............................................................................................................... 17

5.2.2. Testing installation ........................................................................................................................... 18

5.3 Wiring instructions .......................................................................................................... 18

5.4 SPU configuration ........................................................................................................... 18

5.5 Cold commissioning ....................................................................................................... 18

5.6 Hot commissioning ......................................................................................................... 19

6

Operation .................................................................................................................................... 20

6.1 LED at display .................................................................................................................. 20

6.2 Front panel ....................................................................................................................... 21

6.2.1. Verifying software versions .............................................................................................................. 21

6.2.2. Display test ...................................................................................................................................... 22

Elster NV/SA

Rijkmakerlaan 9

2910 Essen,

Belgium

T + 32 3 670 0700

www.elster-instromet.com

DOCUMENT TITLE

ULTRASONIC FLOWMETER SERIES 6, MODELS Q.SONIC

PLUS

SUBTITLE

QUICK START MANUAL

DOCUMENT NUMBER

22.100.200.000.02/2

REVISION

B

REVISION DATE

2013-02-22

This reproduction is sole property of Elster NV/SA and is subject to the conditions that it or any information contained therein will not be used in any way

detrimental to our interests and that all copies will be returned immediately on demand

PAGE

3 OF 29

22.100.200.000.02_2_B ULTRASONIC FLOWMETER SERIES 6.DOC

6.2.3. Checking errors and warnings ......................................................................................................... 23

6.3 Software package ............................................................................................................ 23

7

Maintenance, service and repair .............................................................................................. 24

7.1 Introduction ...................................................................................................................... 24

7.2 Exchanging components ................................................................................................ 24

7.2.1. Pressure sensors exchange ............................................................................................................ 24

7.2.2. Temperature sensors exchange ...................................................................................................... 25

7.2.3. Transducer exchange ...................................................................................................................... 25

7.2.4. SPU exchange ................................................................................................................................. 25

8

Storage and shipping ................................................................................................................ 27

9

MID requirements ....................................................................................................................... 28

9.1 General ............................................................................................................................. 28

9.2 EC declaration of conformity ......................................................................................... 28

9.3 Sealing .............................................................................................................................. 28

9.4 Calibration ........................................................................................................................ 28

9.5 Installation requirements ................................................................................................ 28

Appendix I. References ....................................................................................................................... 29

Figures

Figure 1: Path types ................................................................................................................................ 6

Figure 2: path layout Q.Sonic

plus

............................................................................................................. 7

Figure 3: Ultrasonic measuring line ........................................................................................................ 8

Figure 4: Example of an Elster-Instromet Ultrasonic gas flowmeter ..................................................... 10

Figure 5: SPU compartments ................................................................................................................ 11

Figure 6: SPU cover .............................................................................................................................. 11

Figure 7: NG transducer ........................................................................................................................ 11

Figure 8: NG transducer with the mounting bracket. ............................................................................ 11

Figure 9: example main plate ................................................................................................................ 12

Figure 10: example ATEX label ............................................................................................................ 13

Figure 11: example IECEx label ........................................................................................................... 13

Figure 12: example FM label................................................................................................................. 14

Figure 13: sealing main plate ................................................................................................................ 15

Figure 14: Example PCB sealing bracket ............................................................................................. 15

Figure 15: hardware protection on the main board ............................................................................... 16

Figure 17: LED at display ...................................................................................................................... 21

Figure 18: Front panel ........................................................................................................................... 21

Figure 19: checking software versions and checksum through the front panel .................................... 22

Figure 20: Display test .......................................................................................................................... 22

Figure 21: Errors / Warnings ................................................................................................................. 23

Tables

Table 1: Power LED .............................................................................................................................. 20

Table 2: Status LED .............................................................................................................................. 20

Elster NV/SA

Rijkmakerlaan 9

2910 Essen,

Belgium

T + 32 3 670 0700

www.elster-instromet.com

DOCUMENT TITLE

ULTRASONIC FLOWMETER SERIES 6, MODELS Q.SONIC

PLUS

SUBTITLE

QUICK START MANUAL

DOCUMENT NUMBER

22.100.200.000.02/2

REVISION

B

REVISION DATE

2013-02-22

This reproduction is sole property of Elster NV/SA and is subject to the conditions that it or any information contained therein will not be used in any way

detrimental to our interests and that all copies will be returned immediately on demand

PAGE

4 OF 29

22.100.200.000.02_2_B ULTRASONIC FLOWMETER SERIES 6.DOC

1 About this technical documentation

1.1 Introduction

This manual is a quick guide to the operation and maintenance of the Ultrasonic Flowmeter

Series 6 gas flow meter, models Q.Sonic

plus

. This manual together with

22.100.200.001.02/2, Ultrasonic Flowmeter Series 6 Safety Instructions and

03.302.101.003.07/2, Ultrasonic Flowmeter Series 6 wiring instructions describes essential

information for safe use in compliance with and insofar applicable:

- European Directives (e.g. ATEX, PED, EMC, MID).

- International IECEx standards.

- North American FM Approvals standards.

- Canadian CSA standards (pending).

In this manual is explained how to verify from the labelling on your ultrasonic flowmeter to

which certifications it complies.

The manual also contains important instructions to prevent accidents and serious damage

before start-up, during operation, and to ensure trouble-free operation in the safest possible

way. Before using the product read this manual carefully, familiarise yourself with the

operation of the product, and strictly follow the instructions.

If you have any questions, or need further details of specific matters concerning this

product, please do not hesitate to contact one of our staff members, email: sales@elster-

instromet.com (See the address information on header).

This manual is based on the latest information. It is provided subject to alterations. We

reserve the right to change the construction and/or configuration of our products at any time

without obligation to update previously shipped equipment.

1.2 Warranty

The warranty provisions stipulated in the manufacturer's Terms of Delivery are applicable

to the product. The manufacturer shall have no obligation in the event that:

Repair or replacement of equipment or parts has been required through normal wear

and tear, or by necessity in whole or part by catastrophe, or the fault or negligence of

the purchaser.

The equipment, or parts, have been maintained or repaired by other than an authorised

representative of the manufacturer, or have been modified in any manner without prior

express written permission of the manufacturer.

Non-original parts are used.

Equipment is used improperly, incorrectly, carelessly or not in line with its nature and/or

purpose.

The product is used with unauthorised equipment or peripherals, including, but not

necessarily limited to, cables, testing equipment, computers, voltage, etc.

Elster NV/SA

Rijkmakerlaan 9

2910 Essen,

Belgium

T + 32 3 670 0700

www.elster-instromet.com

DOCUMENT TITLE

ULTRASONIC FLOWMETER SERIES 6, MODELS Q.SONIC

PLUS

SUBTITLE

QUICK START MANUAL

DOCUMENT NUMBER

22.100.200.000.02/2

REVISION

B

REVISION DATE

2013-02-22

This reproduction is sole property of Elster NV/SA and is subject to the conditions that it or any information contained therein will not be used in any way

detrimental to our interests and that all copies will be returned immediately on demand

PAGE

5 OF 29

22.100.200.000.02_2_B ULTRASONIC FLOWMETER SERIES 6.DOC

The manufacturer is not responsible for the incidental or consequential damages resulting

from the breach of any express or implied warranties, including damage to property, and to

the extent permitted by law, damage for personal injury.

1.3 Typographical Conventions

This manual employs consistent visual cues and some standard text formats to help you

locate and interpret information easily.

Warning!

A warning indicates hazards or unsafe practices that could result

in severe personal injury or death.

Caution!

A caution indicates hazards or unsafe practices that could result

in minor personal injury or product or property damage.

A caution is also used to indicate operations or practices that

may cause the product to operate in an undefined or unexpected

way, or may produce non-specification results.

1.4 Abbreviations

ATEX Atmosphères Explosibles; European Directive 94/9/EC on equipment

and protective systems intended for use in potentially explosive

atmospheres

CSA Canadian Standards Association

DC Direct Current

EC European Community

EMC ElectroMagnetic Compatibility; European EMC Directive 2004/108/EC

IECEx International Electrotechnical Commission System for Certification to

Standards Relating to Equipment for use in Explosive Atmospheres

FM Factory Mutual Approvals

MID European Directive 2004/22/EC on measuring instruments

NMi Nederlands Meetinstituut

PED Pressure Equipment Directive; European Directive 97/23/EC concerning

pressure equipment

PC Personal Computer

PCB Printed Circuit Board

SPU Signal Processing Unit

UFM Ultrasonic FlowMeter

Elster NV/SA

Rijkmakerlaan 9

2910 Essen,

Belgium

T + 32 3 670 0700

www.elster-instromet.com

DOCUMENT TITLE

ULTRASONIC FLOWMETER SERIES 6, MODELS Q.SONIC

PLUS

SUBTITLE

QUICK START MANUAL

DOCUMENT NUMBER

22.100.200.000.02/2

REVISION

B

REVISION DATE

2013-02-22

This reproduction is sole property of Elster NV/SA and is subject to the conditions that it or any information contained therein will not be used in any way

detrimental to our interests and that all copies will be returned immediately on demand

PAGE

6 OF 29

22.100.200.000.02_2_B ULTRASONIC FLOWMETER SERIES 6.DOC

2 Ultrasonic Flowmeter Series 6 gas flow meter

2.1 General

The Ultrasonic Flowmeter Series 6 is a sophisticated, multi-path ultrasonic gas flow meter

manufactured by Elster NV/SA. It has been specifically designed for custody transfer

measuring applications that demand a high degree of accuracy and reliability.

2.2 Applicable standards

The Ultrasonic Flowmeter Series 6 is manufactured to be in accordance with European

Directives: ATEX, PED, EMC and optionally MID.

If the meter is ordered for use at a location where European Directives are NOT mandatory,

the meter can alternatively be manufactured with IECEx or FM approval for use in

hazardous area.

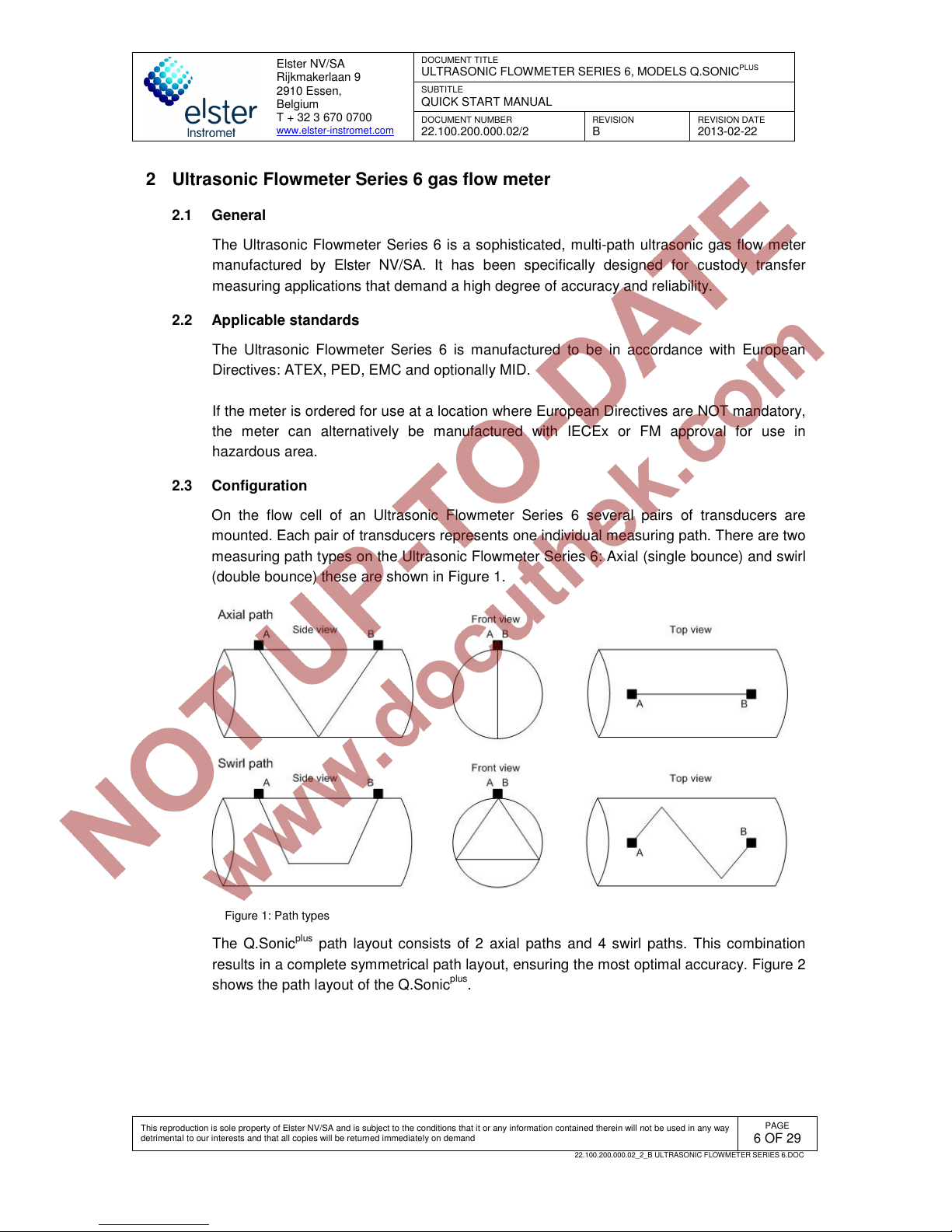

2.3 Configuration

On the flow cell of an Ultrasonic Flowmeter Series 6 several pairs of transducers are

mounted. Each pair of transducers represents one individual measuring path. There are two

measuring path types on the Ultrasonic Flowmeter Series 6: Axial (single bounce) and swirl

(double bounce) these are shown in Figure 1.

Figure 1: Path types

The Q.Sonic

plus

path layout consists of 2 axial paths and 4 swirl paths. This combination

results in a complete symmetrical path layout, ensuring the most optimal accuracy. Figure 2

shows the path layout of the Q.Sonic

plus

.

Elster NV/SA

Rijkmakerlaan 9

2910 Essen,

Belgium

T + 32 3 670 0700

www.elster-instromet.com

DOCUMENT TITLE

ULTRASONIC FLOWMETER SERIES 6, MODELS Q.SONIC

PLUS

SUBTITLE

QUICK START MANUAL

DOCUMENT NUMBER

22.100.200.000.02/2

REVISION

B

REVISION DATE

2013-02-22

This reproduction is sole property of Elster NV/SA and is subject to the conditions that it or any information contained therein will not be used in any way

detrimental to our interests and that all copies will be returned immediately on demand

PAGE

7 OF 29

22.100.200.000.02_2_B ULTRASONIC FLOWMETER SERIES 6.DOC

Figure 2: path layout Q.Sonic

plus

2.4 Calibration

When using the Ultrasonic Flowmeter Series 6, model Q.Sonic

plus

in custody transfer

applications, most countries demand (by law) a calibration from a certified calibration

institute, supervised by an inspector of weights and measures. Examples of facilities

generally used for calibrations are Euroloop in Rotterdam (NL), TransCanada Calibrations

in Canada and PIGSAR GH45 of E.ON Ruhrgas AG in Dorsten (D).

If the Q.Sonic Series 6 has to be in accordance with MID, extra restrictions should be taken

into account (see chapter 9.4).

Elster NV/SA

Rijkmakerlaan 9

2910 Essen,

Belgium

T + 32 3 670 0700

www.elster-instromet.com

DOCUMENT TITLE

ULTRASONIC FLOWMETER SERIES 6, MODELS Q.SONIC

PLUS

SUBTITLE

QUICK START MANUAL

DOCUMENT NUMBER

22.100.200.000.02/2

REVISION

B

REVISION DATE

2013-02-22

This reproduction is sole property of Elster NV/SA and is subject to the conditions that it or any information contained therein will not be used in any way

detrimental to our interests and that all copies will be returned immediately on demand

PAGE

8 OF 29

22.100.200.000.02_2_B ULTRASONIC FLOWMETER SERIES 6.DOC

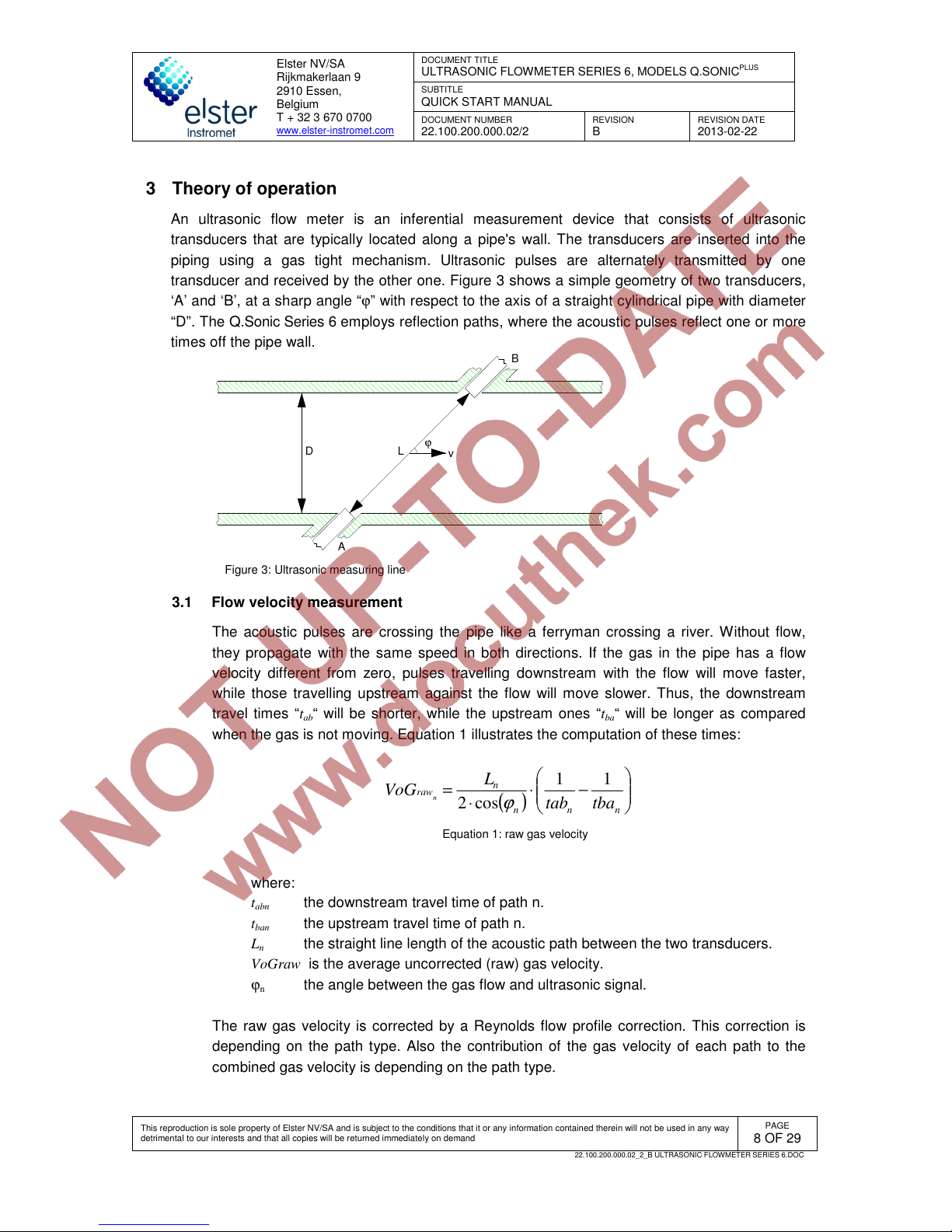

3 Theory of operation

An ultrasonic flow meter is an inferential measurement device that consists of ultrasonic

transducers that are typically located along a pipe's wall. The transducers are inserted into the

piping using a gas tight mechanism. Ultrasonic pulses are alternately transmitted by one

transducer and received by the other one. Figure 3 shows a simple geometry of two transducers,

‘A’ and ‘B’, at a sharp angle “ϕ” with respect to the axis of a straight cylindrical pipe with diameter

“D”. The Q.Sonic Series 6 employs reflection paths, where the acoustic pulses reflect one or more

times off the pipe wall.

v

B

A

L

D

ϕ

Figure 3: Ultrasonic measuring line

3.1 Flow velocity measurement

The acoustic pulses are crossing the pipe like a ferryman crossing a river. Without flow,

they propagate with the same speed in both directions. If the gas in the pipe has a flow

velocity different from zero, pulses travelling downstream with the flow will move faster,

while those travelling upstream against the flow will move slower. Thus, the downstream

travel times “tab“ will be shorter, while the upstream ones “tba“ will be longer as compared

when the gas is not moving. Equation 1 illustrates the computation of these times:

( )

−⋅

⋅

=

nnn

n

raw

tbatab

L

VoG

n

11

cos2

ϕ

Equation 1: raw gas velocity

where:

t

abn

the downstream travel time of path n.

t

ban

the upstream travel time of path n.

Ln the straight line length of the acoustic path between the two transducers.

VoGraw is the average uncorrected (raw) gas velocity.

ϕn the angle between the gas flow and ultrasonic signal.

The raw gas velocity is corrected by a Reynolds flow profile correction. This correction is

depending on the path type. Also the contribution of the gas velocity of each path to the

combined gas velocity is depending on the path type.

Elster NV/SA

Rijkmakerlaan 9

2910 Essen,

Belgium

T + 32 3 670 0700

www.elster-instromet.com

DOCUMENT TITLE

ULTRASONIC FLOWMETER SERIES 6, MODELS Q.SONIC

PLUS

SUBTITLE

QUICK START MANUAL

DOCUMENT NUMBER

22.100.200.000.02/2

REVISION

B

REVISION DATE

2013-02-22

This reproduction is sole property of Elster NV/SA and is subject to the conditions that it or any information contained therein will not be used in any way

detrimental to our interests and that all copies will be returned immediately on demand

PAGE

9 OF 29

22.100.200.000.02_2_B ULTRASONIC FLOWMETER SERIES 6.DOC

3.2 Correction after calibration

After flow calibration the meter can be adjusted either through an adjust factor or through

linearization. How the meter is adjusted can be visualized at the display (see chapter 6.1).

3.3 Volume flow at line conditions

The volume flow at line conditions Q

Line

is the (adjusted) profile-corrected gas velocity V

line

multiplied by the internal cross section A of the flow cell:

[

]

h

m

D

V

tAVQ

line

lineline

3

2

3600

4

⋅

⋅

⋅=

⋅⋅=

π

Equation 2: calculation of the line volume flowrate

where:

Q

Line

the volume flow at line conditions

V

line

the adjusted profile-corrected gas velocity

D the internal diameter of the meter

A the internal crosssection of the flow cell

t time coefficient to go from seconds to hours.

Loading...

Loading...